Investment casting mold shell and splicing method thereof

A technology of investment casting and mold shell, which is applied in the field of investment casting mold shell and its splicing, which can solve the problems of welding stress and dimensional deformation, poor dimensional accuracy of large castings, long product manufacturing cycle, etc., and achieve residual stress and dimensional The effect of eliminating deformation, improving the dimensional accuracy of castings, and shortening the product manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

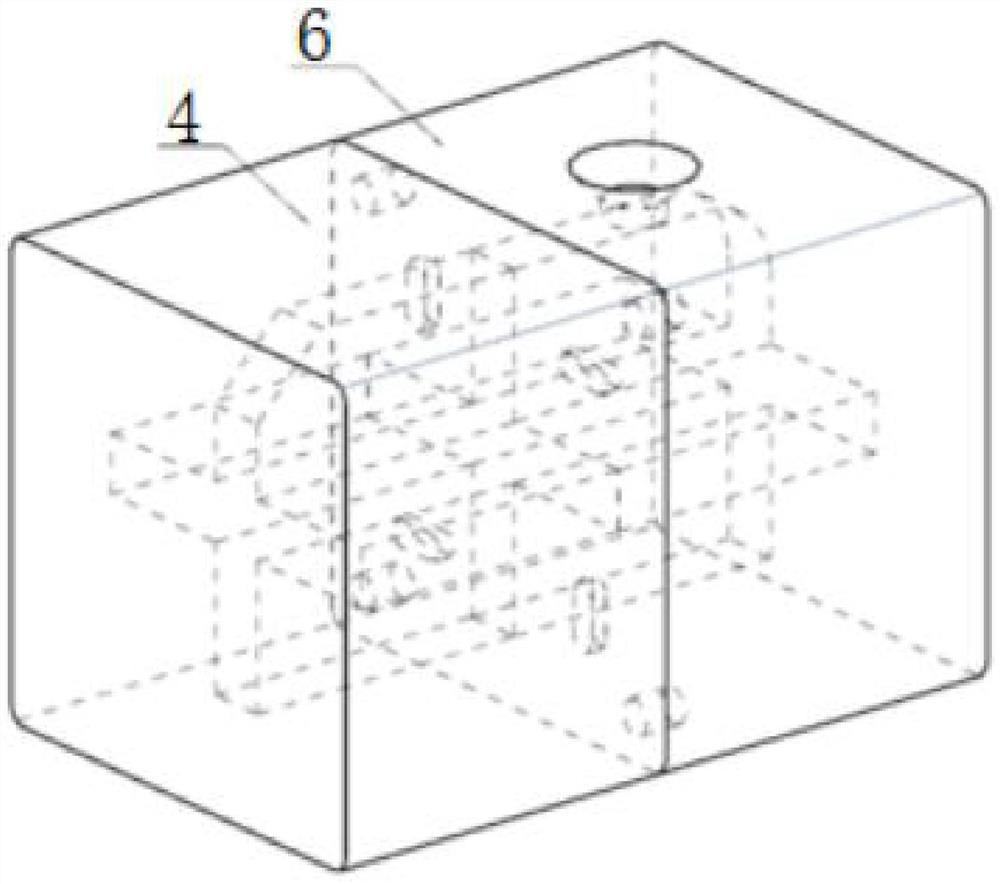

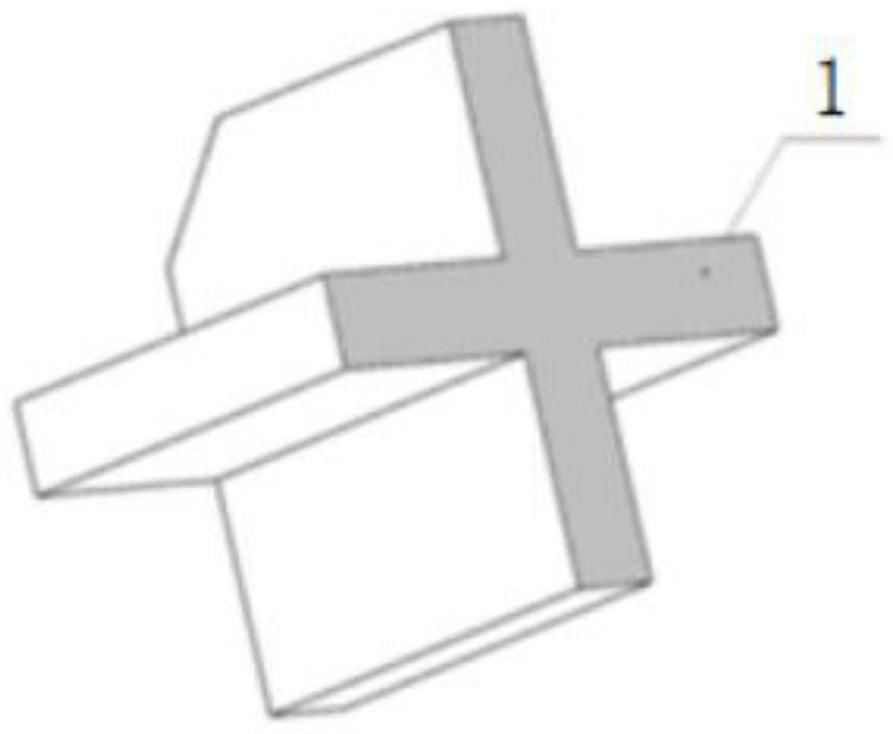

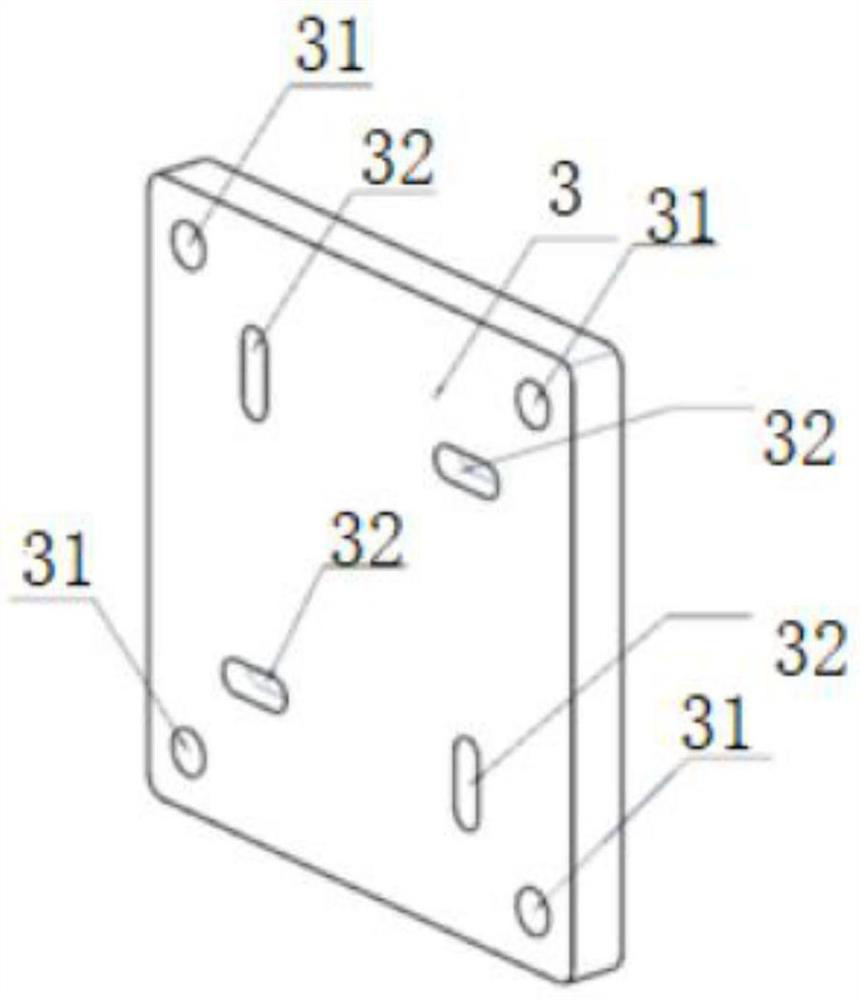

[0040] The invention provides an investment casting shell, such as Figure 1-11 As shown, including concave splicing piece 1, convex splicing piece 2, concave positioning template 3, male mold shell 4, convex positioning template 5 and female mold shell 6, the concave positioning template 3 is connected to the splicing surface of the concave splicing piece 1 to manufacture The male mold shell 4 connects the male positioning template 5 to the support female mold shell 6 on the splicing surface of the male splicing piece 2, and the male mold shell 4 and the female mold shell 6 are positioned and connected. The female positioning template 3 is respectively provided with four connecting holes 31 and four positioning grooves 32, and the positioning grooves 32 and the connecting holes 31 are not parallel to each other; the female mold shell 6 has the same four connecting holes as the female positioning template 3 31 and four positioning grooves 32. The male positioning template 5 i...

Embodiment 2

[0044] The invention also provides a method for splicing investment casting shells, such as Figure 1-11 shown, including the following steps:

[0045] S1, fix the concave positioning template 3 on the splicing surface of the concave splicing piece 1, prepare the wax mold model used for the investment casting casting, and then manufacture the male mold shell 4 through the sticking sand pouring process;

[0046] S2, fix the convex positioning template 5 on the splicing surface of the convex splicing piece 2, prepare the wax mold model used for the investment casting casting, and then manufacture the concave mold shell 6 through the process of sticking sand and pouring slurry, and the concave mold shell 6 is provided with Mould pouring port 61;

[0047] S3, the male mold shell 4 and the female mold shell 6 are positioned by the positioning bosses 52 and the positioning grooves 32, and connected by the connecting tenon 51 and the connecting hole 31, and assembled into an integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com