Water jacket of cylinder body of diesel engine

A technology of cylinder block and diesel engine, applied in the direction of cylinder, cylinder head, mechanical equipment, etc., can solve the problems of long production cycle, oil sintering, unqualified emission, etc., to reduce the difficulty of processing technology, reduce working temperature, and simple casting method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

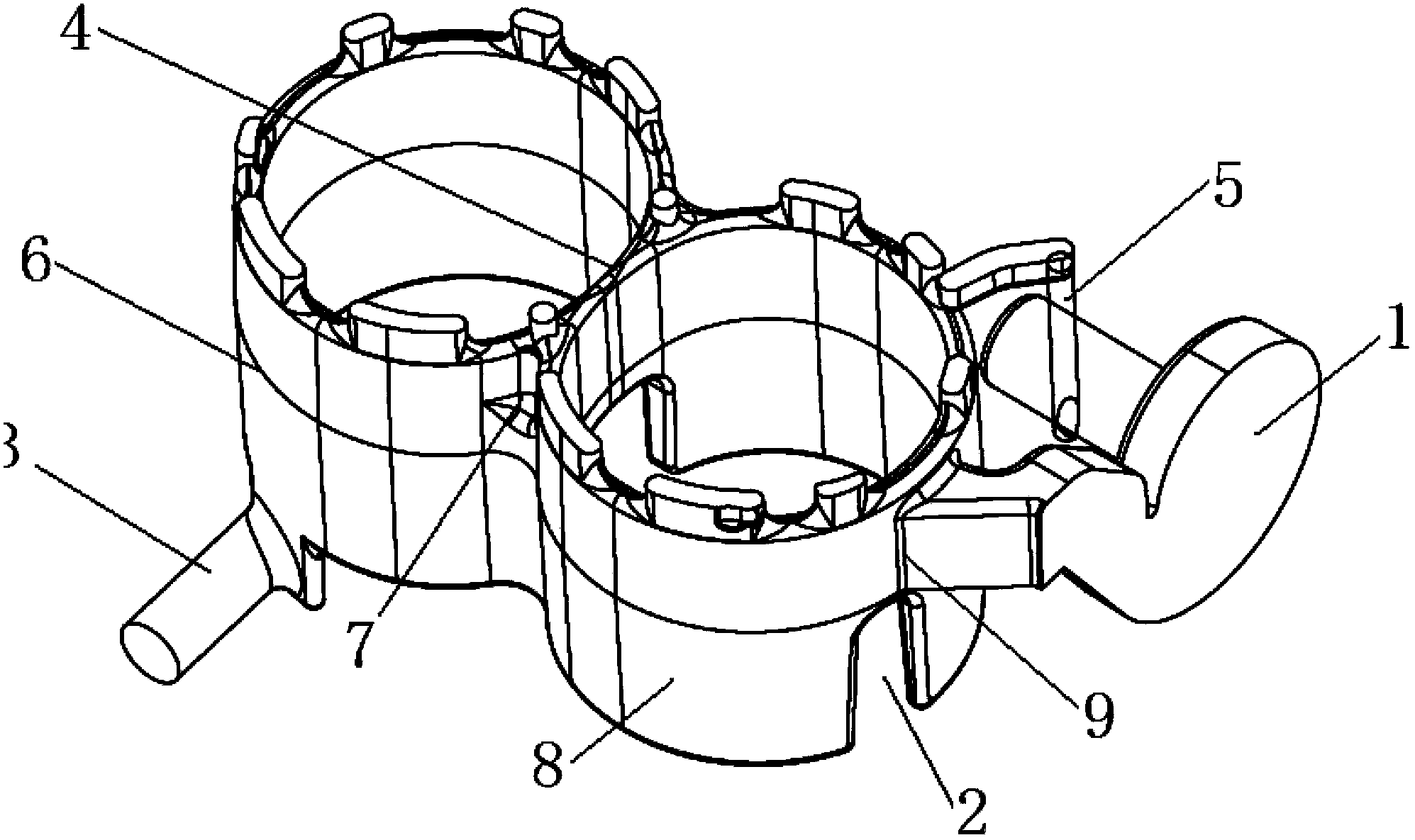

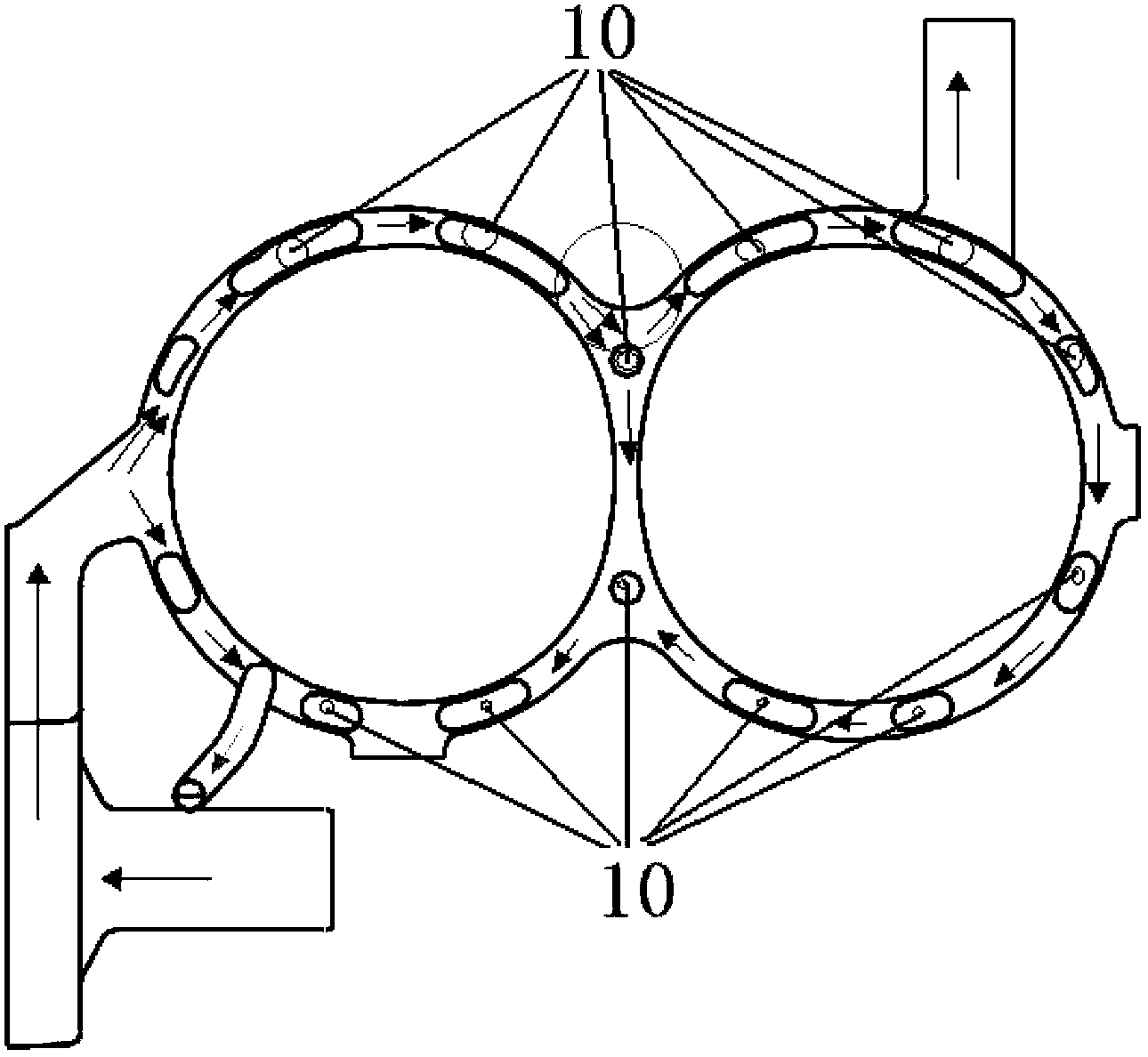

[0016] Such as figure 1 Shown is a diesel engine cylinder block water jacket 8 of the present invention, which is mainly composed of an annular cavity around the cylinder block, and a water hole is provided in the nose bridge area 4 between two adjacent cylinder holes, and the outlet of the water pump volute 1 The water port is communicated with the water jacket water inlet 9 on the cylinder block water jacket 8, and the water hole in the bridge of the nose area 4 is connected with the cylinder block water jacket 8. In order to solve the problems existing in the prior art, the water hole in the nose bridge area 4 of the present invention and the cylinder block water jacket 8 are integrally cast and formed, and after the coolant enters the cylinder block water jacket 8 from the water outlet of the water pump volute 1, Located at the intersection of two adjacent cylinder holes, it is divided into two paths, one path flows through the water hole in the nose bridge area 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com