Patents

Literature

124results about How to "Less machining process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

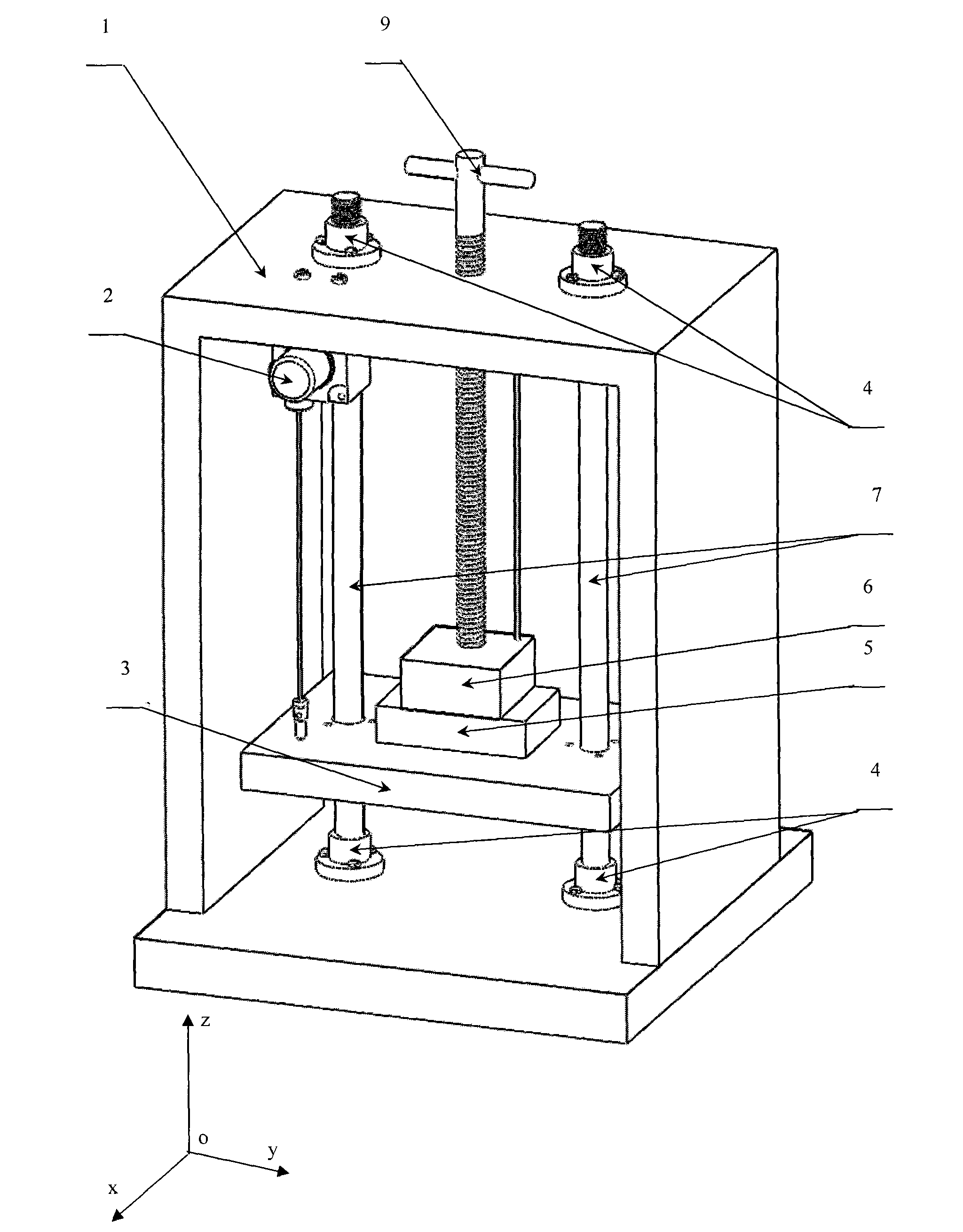

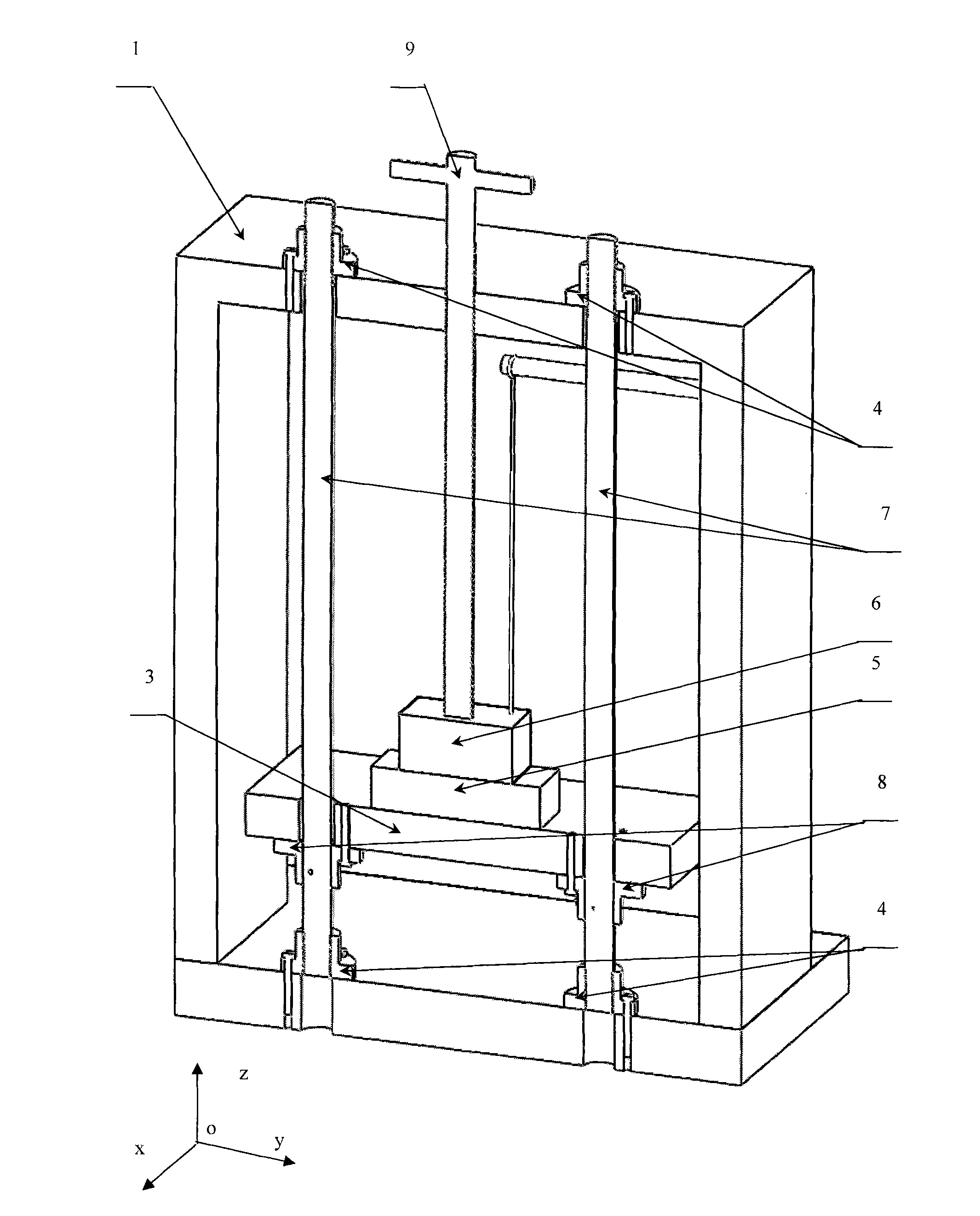

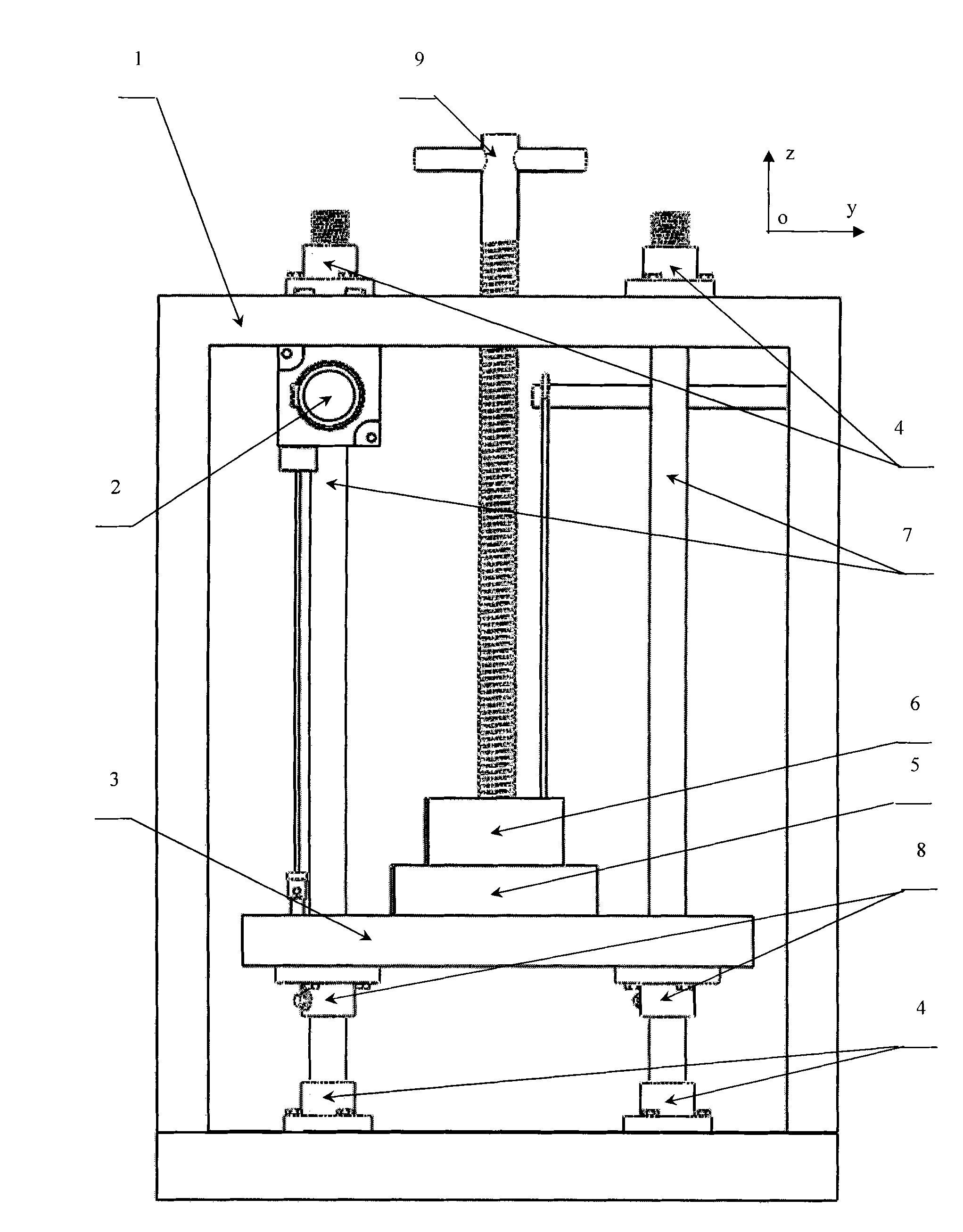

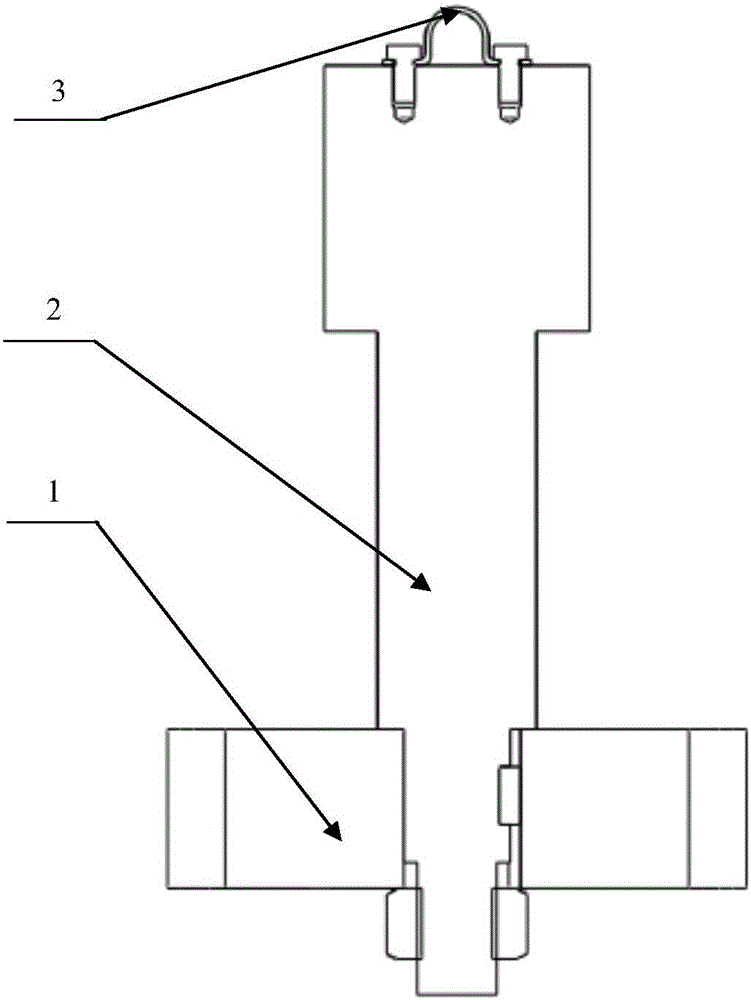

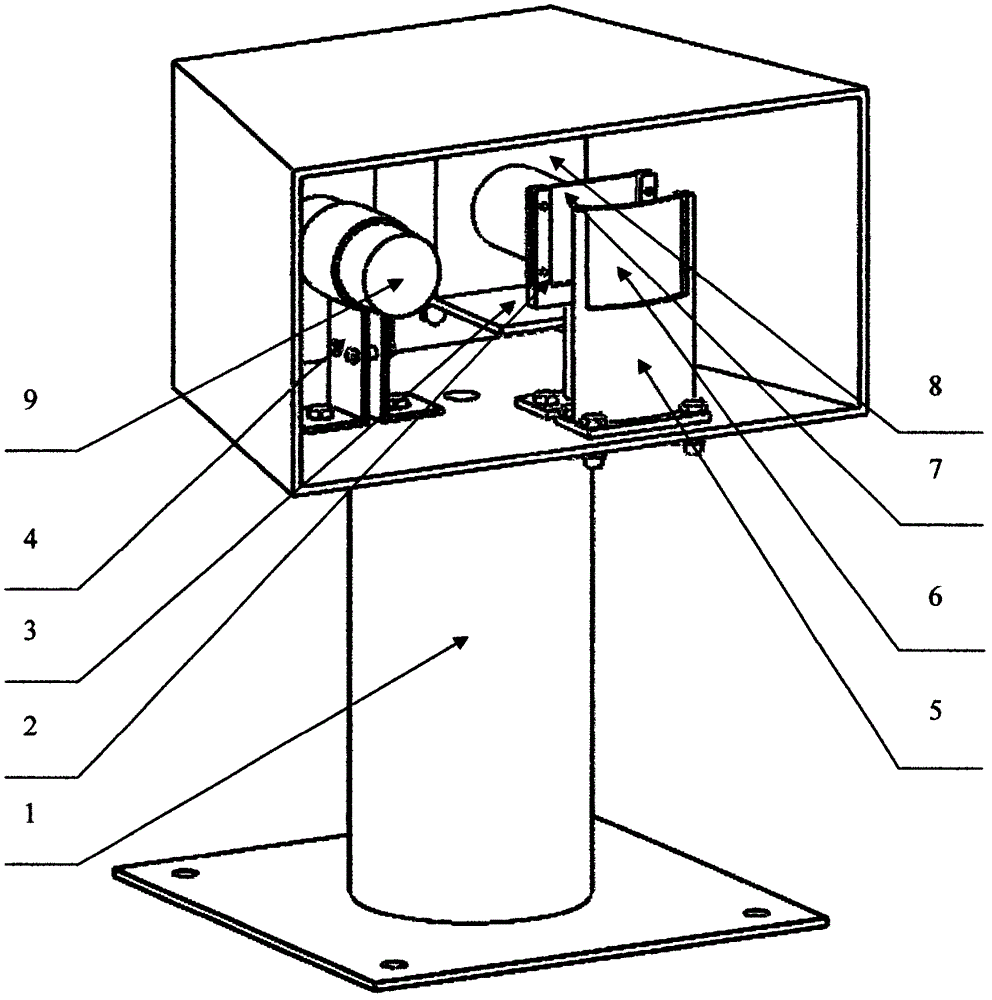

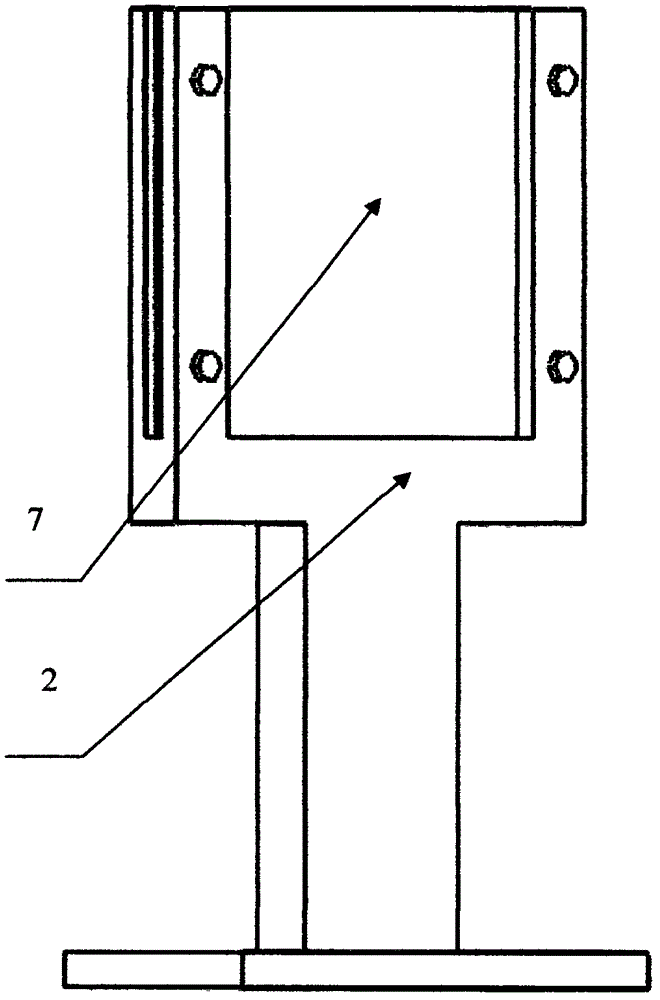

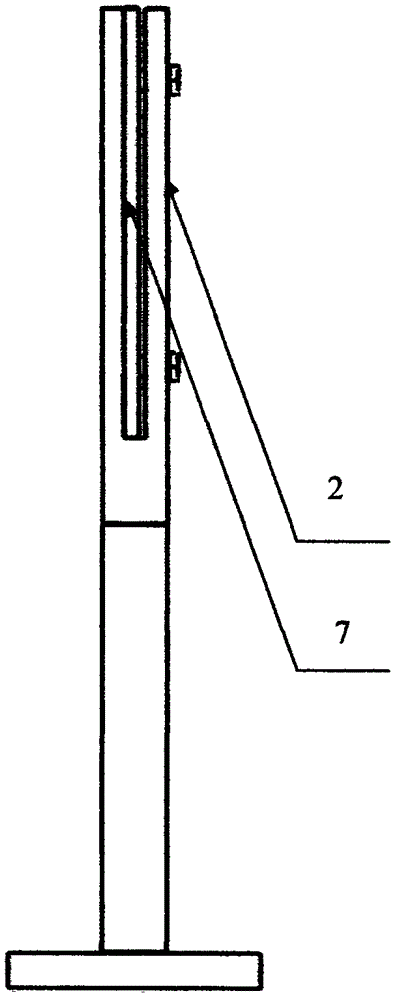

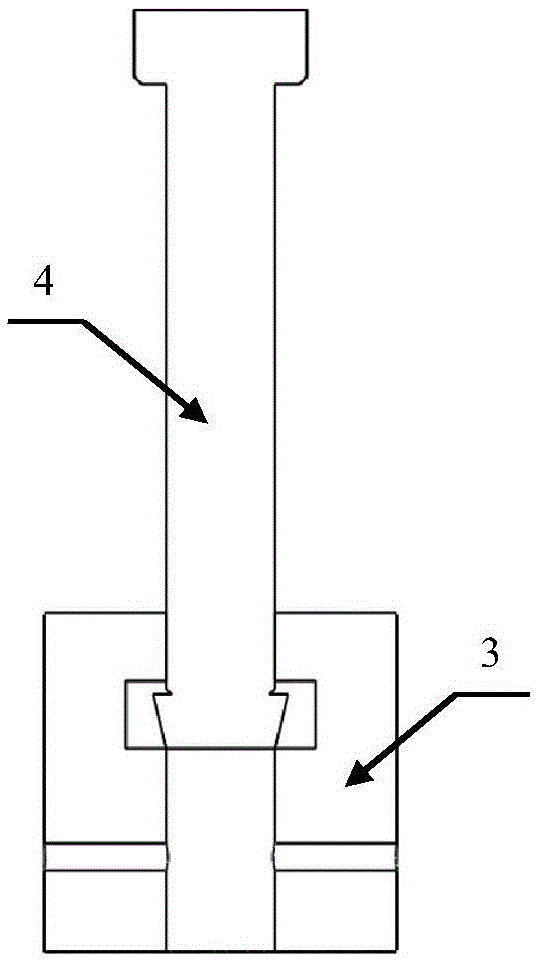

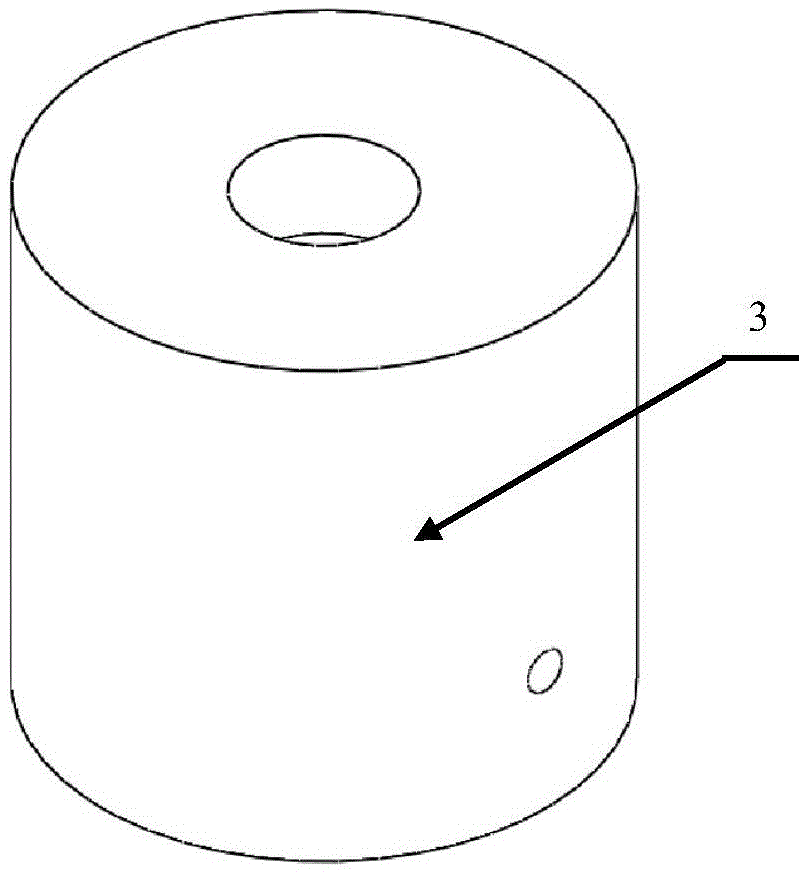

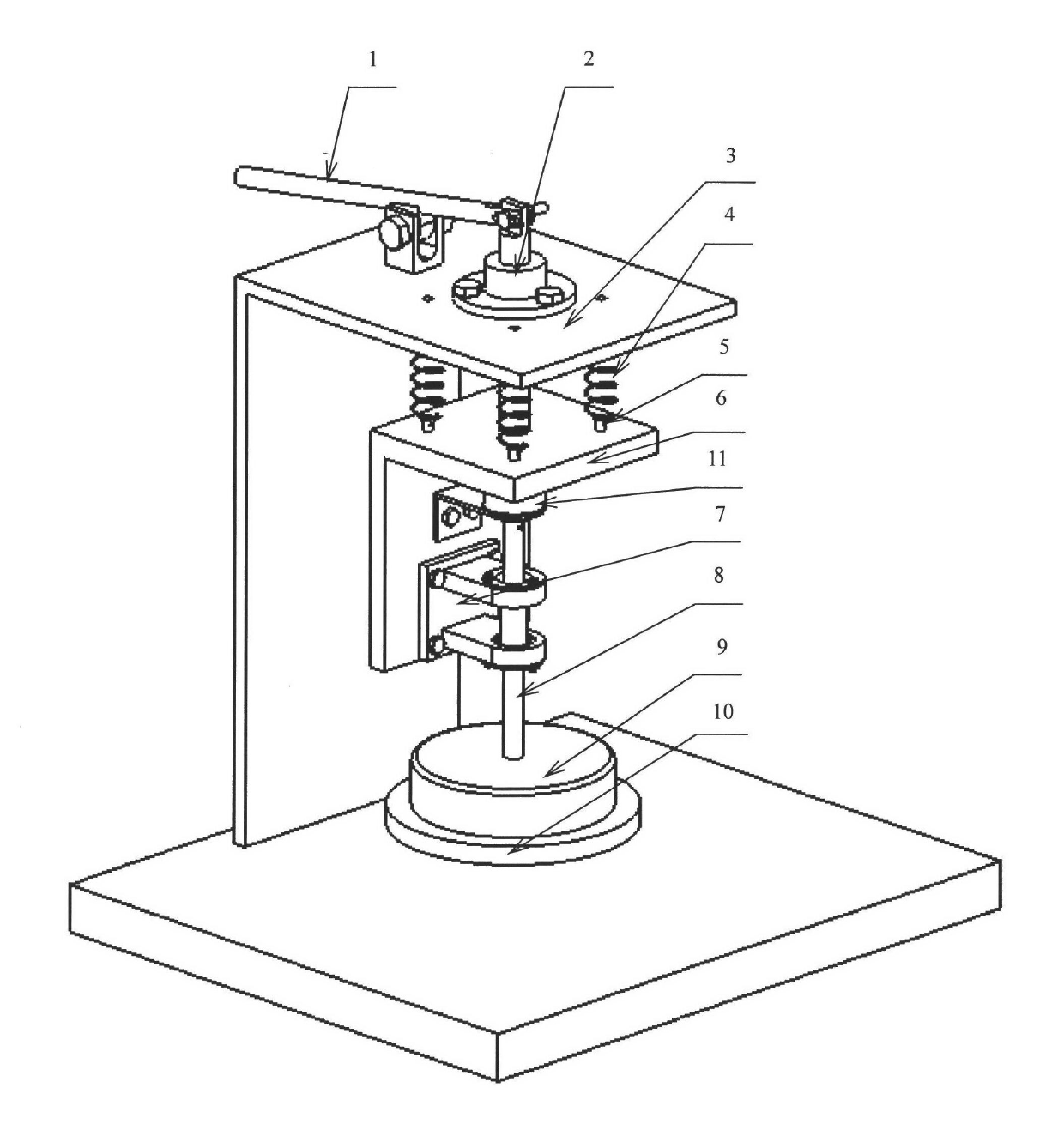

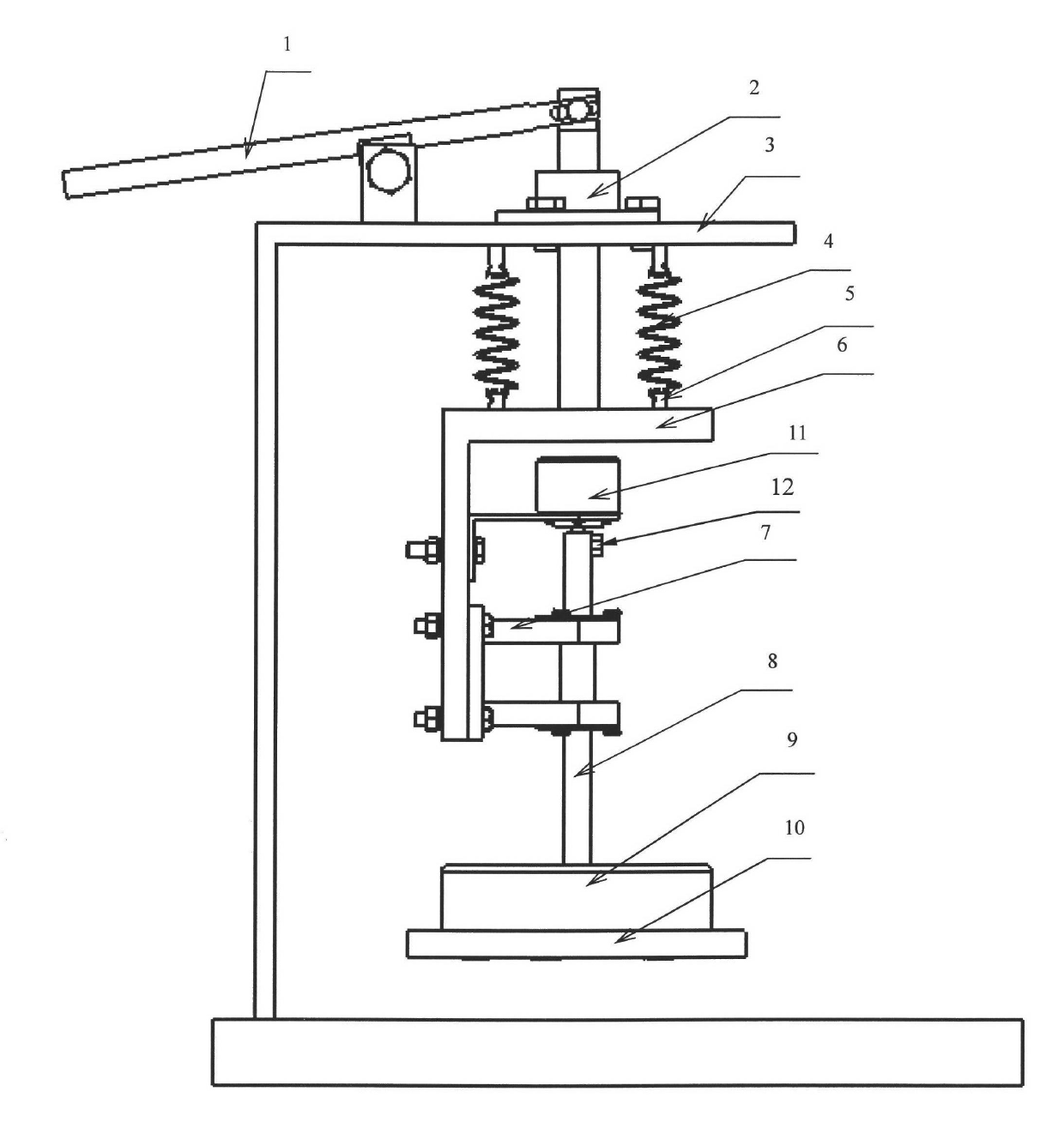

Calibrating device of automobile pedal force and travel detector

InactiveCN102116696ARealize integrated rapid verificationSimple and fast operationForce/torque/work measurement apparatus calibration/testingForce sensorAutomotive engineering

The invention discloses a calibrating device of an automobile pedal force and travel detector in the field of automobile industry, and aims to solve the problem that the automobile pedal force and travel detector cannot be calibrated. A system comprises a pedestal (1), a stayguy sensor (2), a supporting platform (3), a fixed sleeve (4), a force sensor (5), a guide post (7), a sliding sleeve (8) and a lead screw (9). The calibrating system can calibrate numerical values of pedal force and pedal travel of an automobile measured by the automobile pedal force and travel detector.

Owner:JILIN UNIV

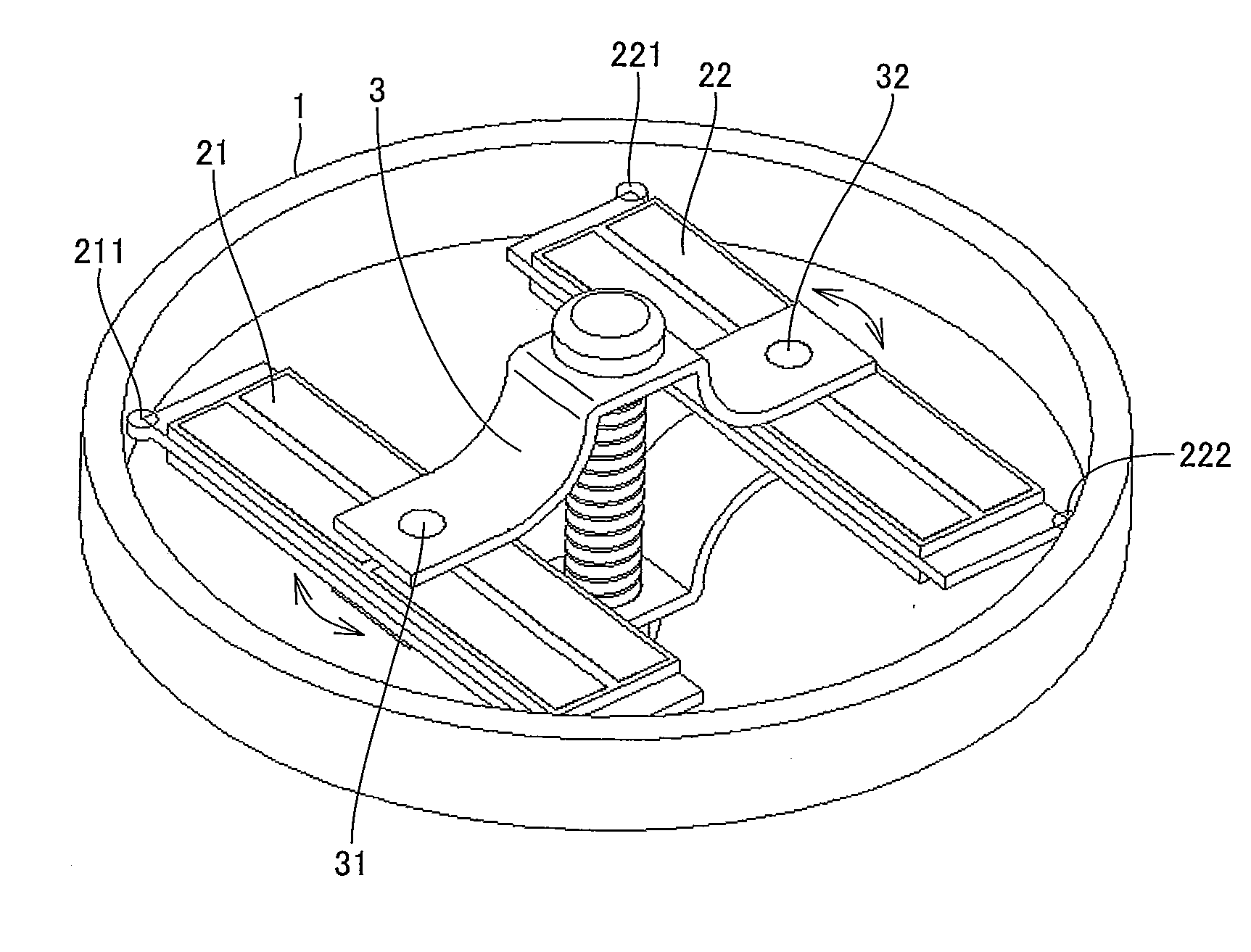

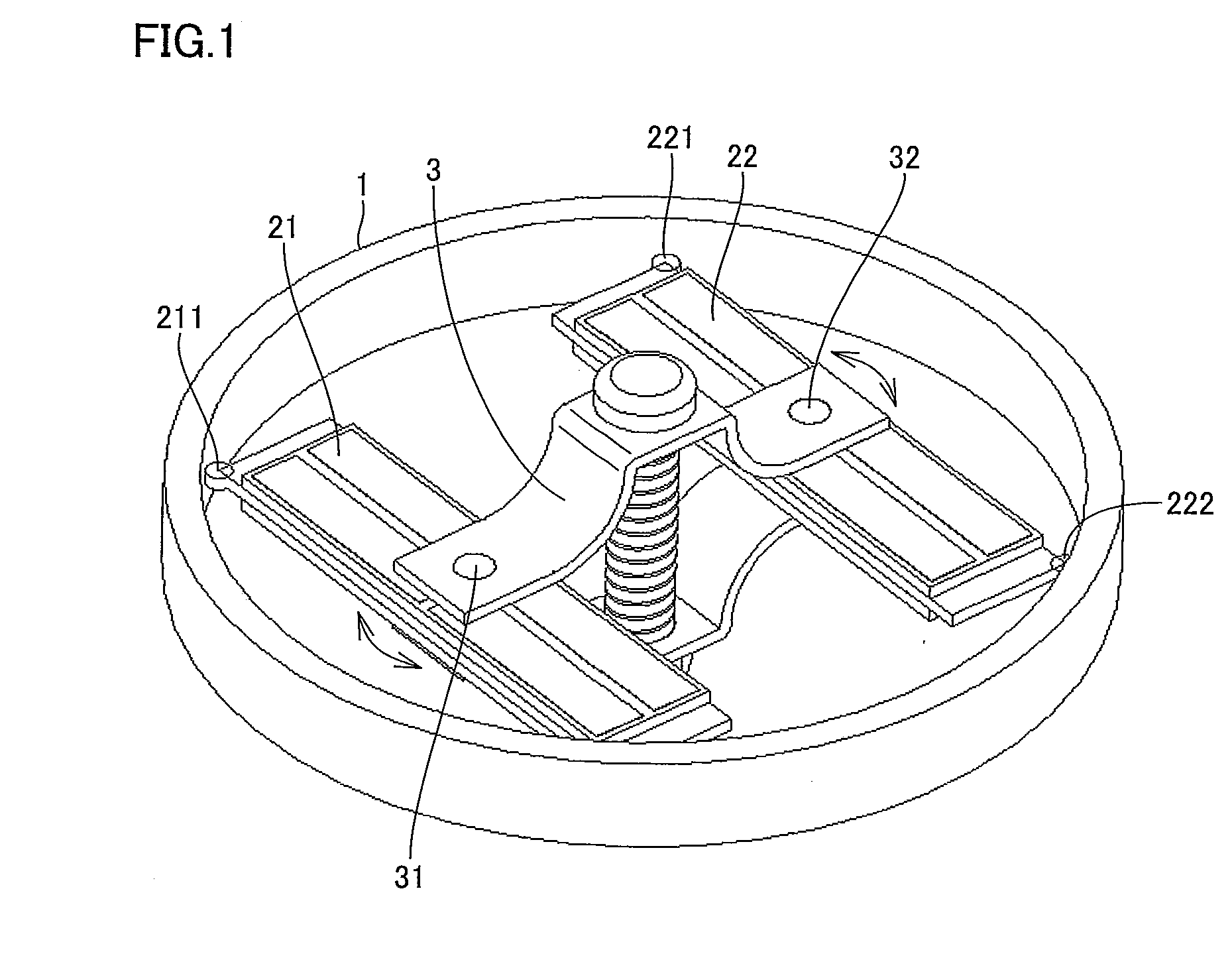

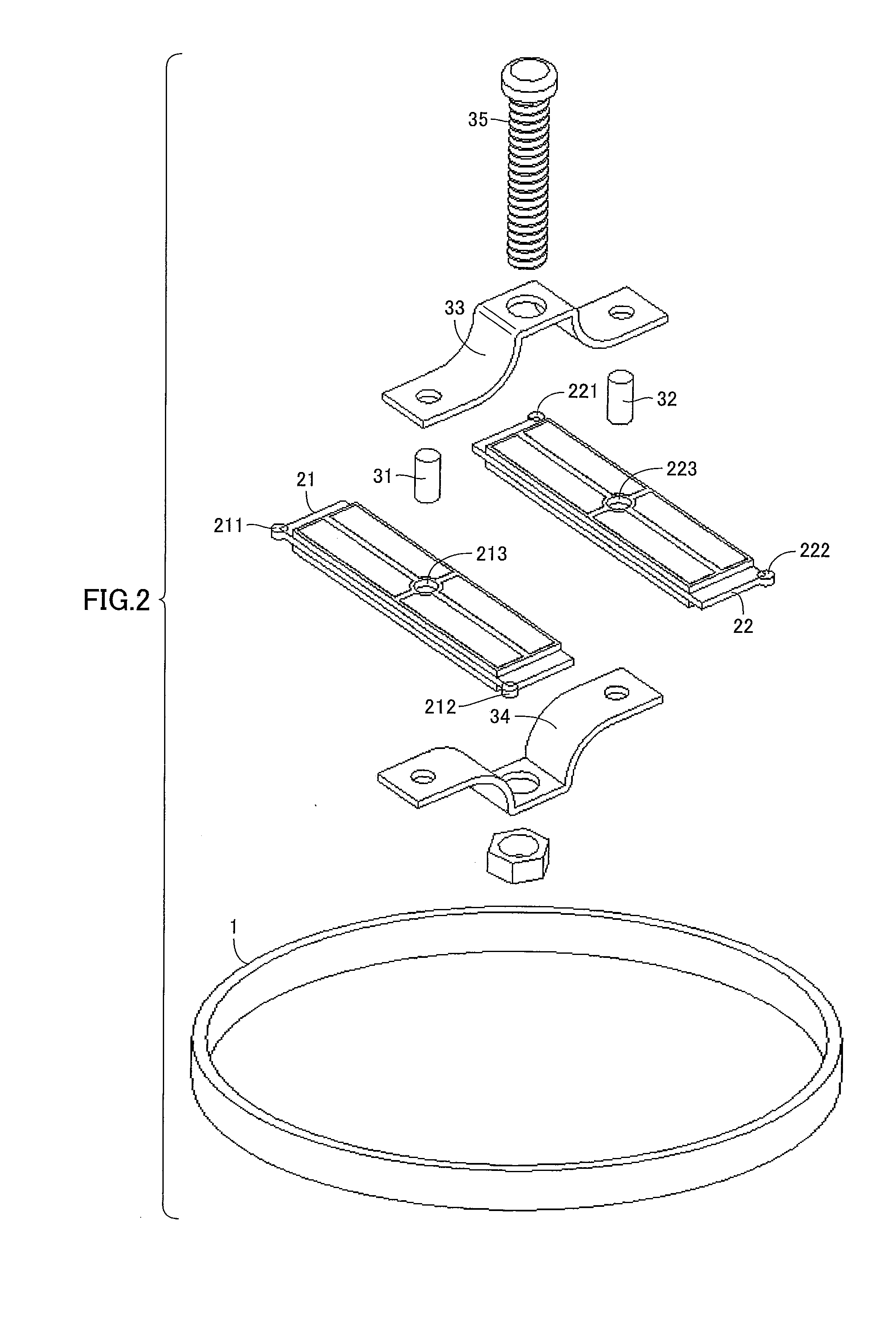

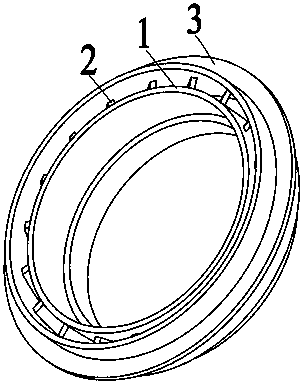

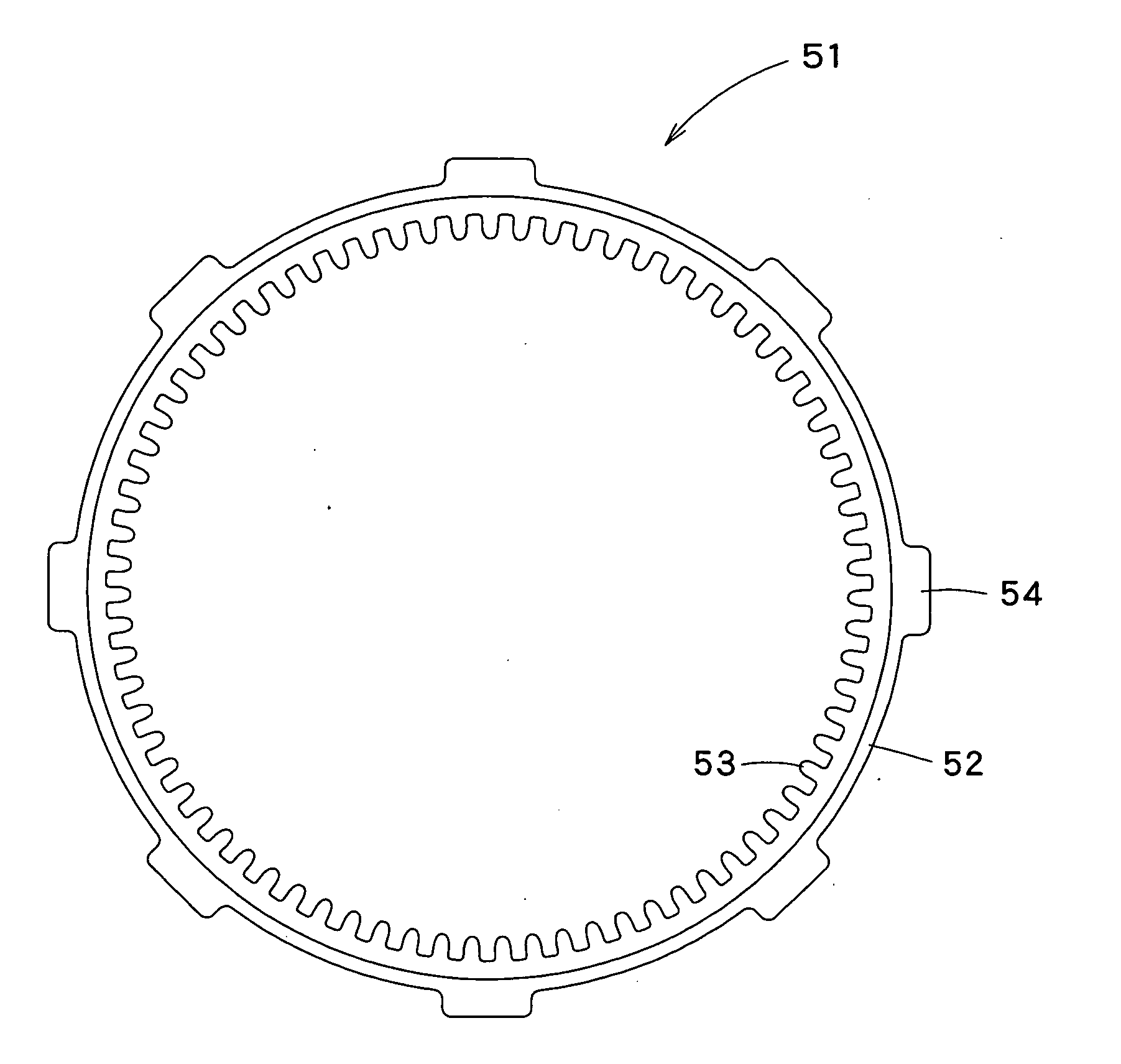

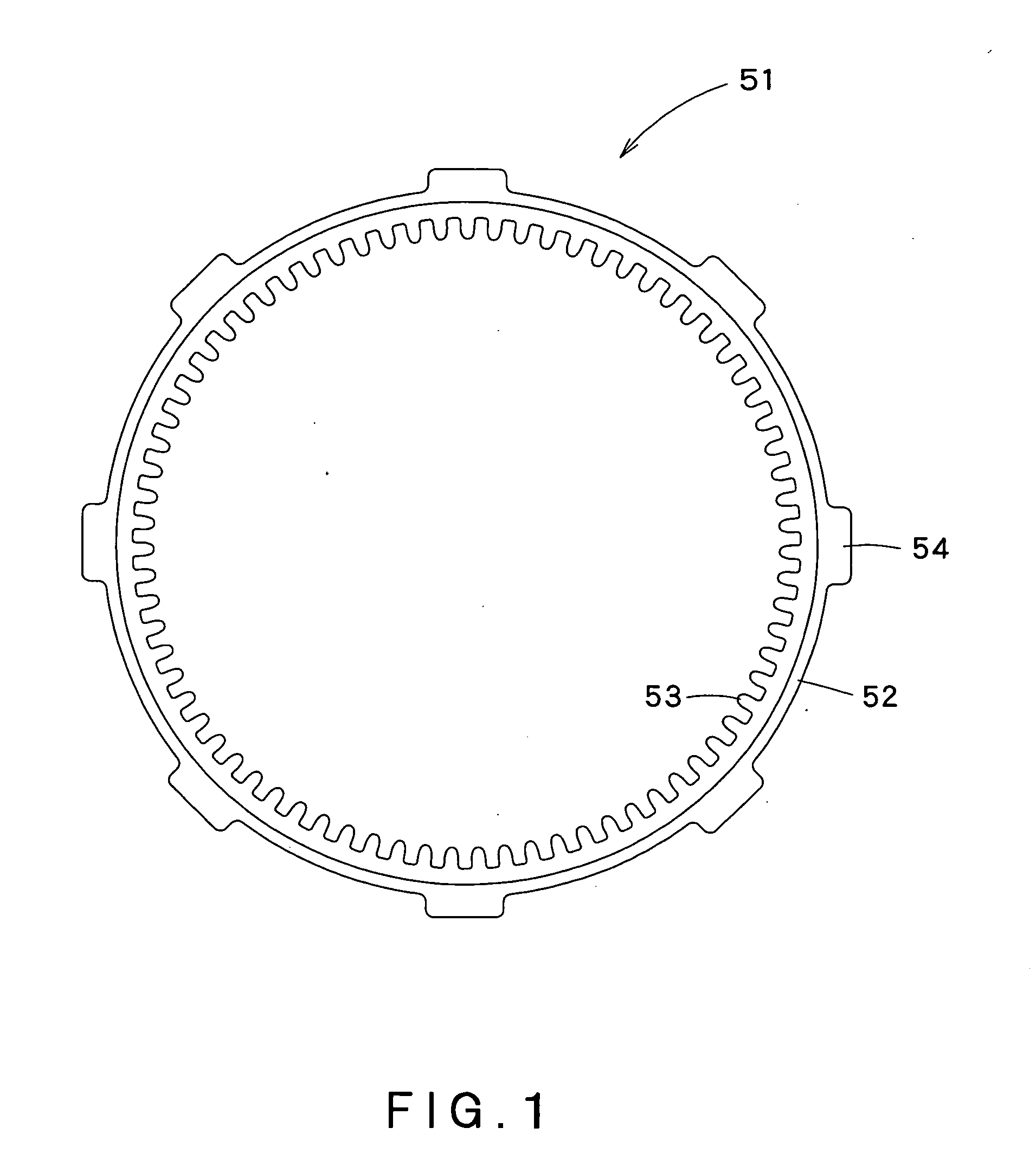

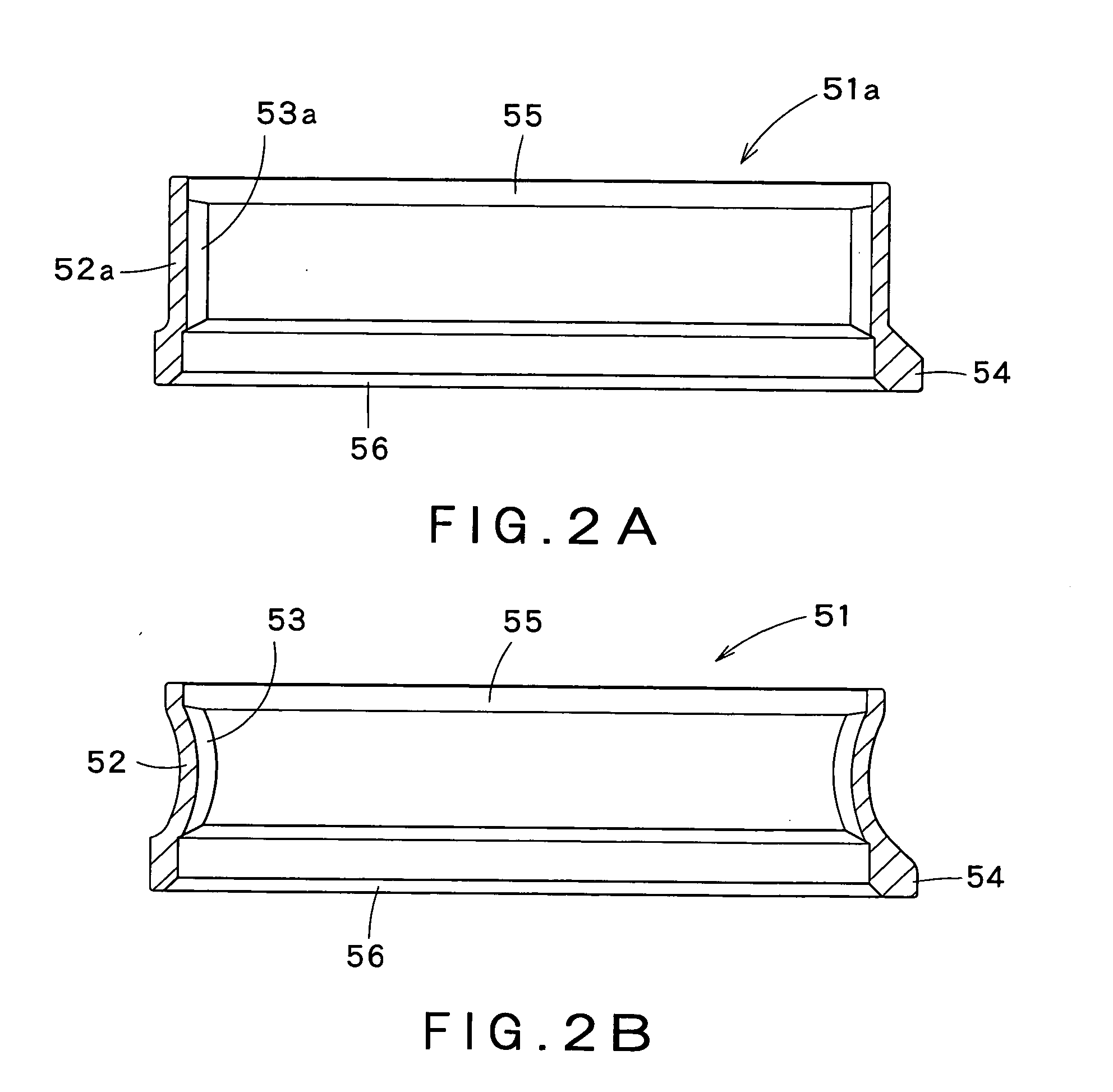

Ultrasonic motor

InactiveUS20090278421A1Less machining processAvoid excess performancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesContact typeEngineering

An ultrasonic motor has a cylindrical rotor for performing a mechanical output, a plurality of ultrasonic vibrators each having two points in internal contact with the rotor, and a preload mechanism for pressing the ultrasonic vibrators from an inside toward an outside of the rotor, and the ultrasonic vibrators are provided to be rotatable relative to the preload mechanism. With this configuration, an internal contact type ultrasonic motor capable of performing efficient drive by using a plurality of ultrasonic vibrators each in contact with a cylindrical rotor at two points and allowing contact at all contact points without requiring a high machining accuracy can be provided.

Owner:SHARP KK

Method for preparing reinforced tungsten carbide abrasion-resistant composite plate

InactiveCN102212821AIncrease productivityReduce manufacturing costMetallic material coating processesMetal layered productsSlagComposite plate

The invention discloses a method for preparing a reinforced tungsten carbide abrasion-resistant composite plate. The method comprises the following steps of: selecting a low-carbon steel plate or a low-alloy steel plate adapted with the size of a hearth of a heating furnace as a substrate, uniformly spreading film removing agent, alloy powder, tungsten carbide powder and slag forming agent powder on a cleared surface, horizontally putting the substrate into the heating furnace, and heating the substrate to obtain the reinforced tungsten carbide abrasion-resistant composite plate. The abrasion-resistant alloy surface of the working layer of the reinforced tungsten carbide abrasion-resistant composite plate produced by using the method is flat and attractive; the composite plate can be directly used for the working conditions (such as a baffle plate and the like) requiring flat surfaces, so a machining process and corresponding production cost are saved; and the composite plate can be widely applied to the working condition of high abrasive abrasion, and has longer service life.

Owner:SHANDONG UNIV

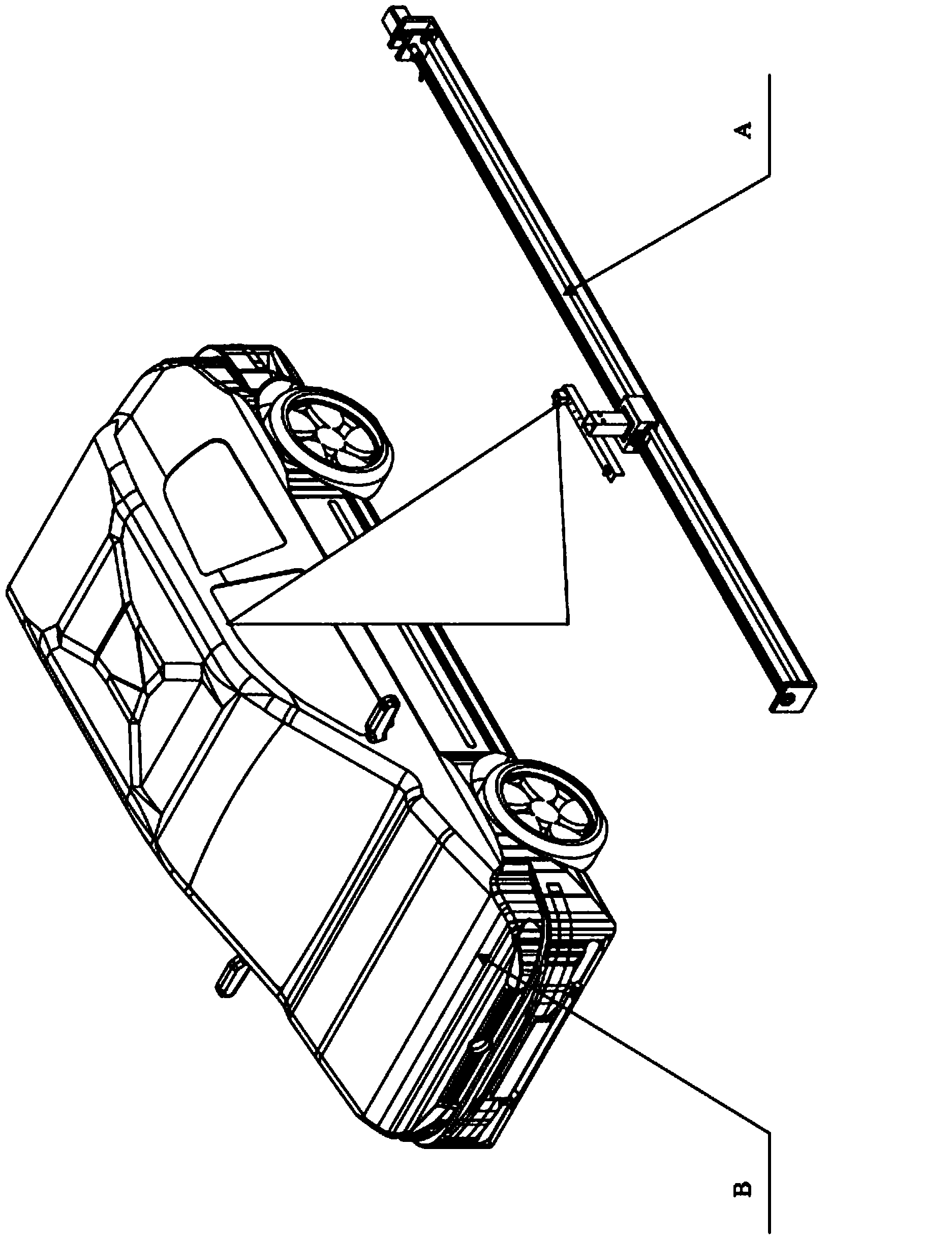

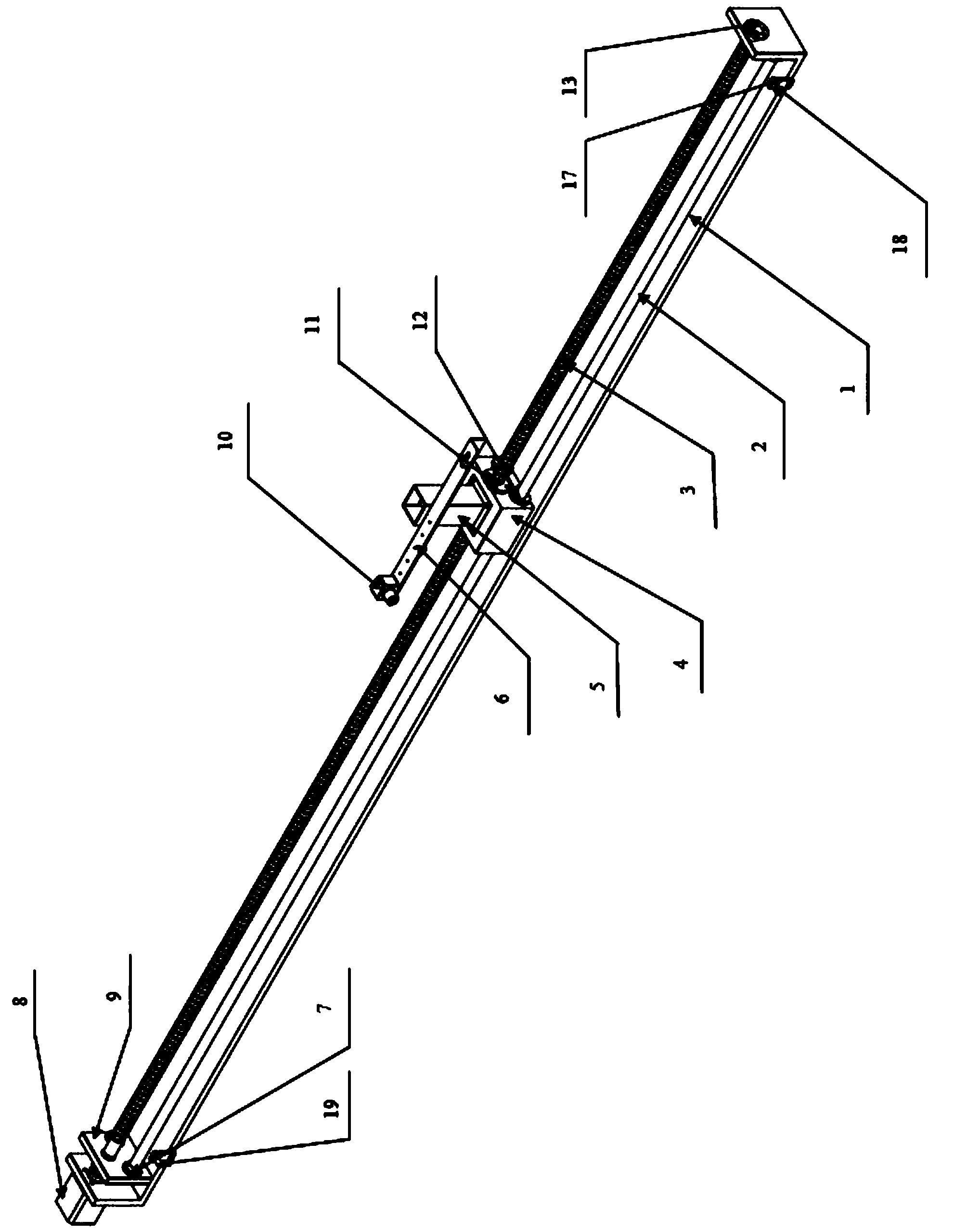

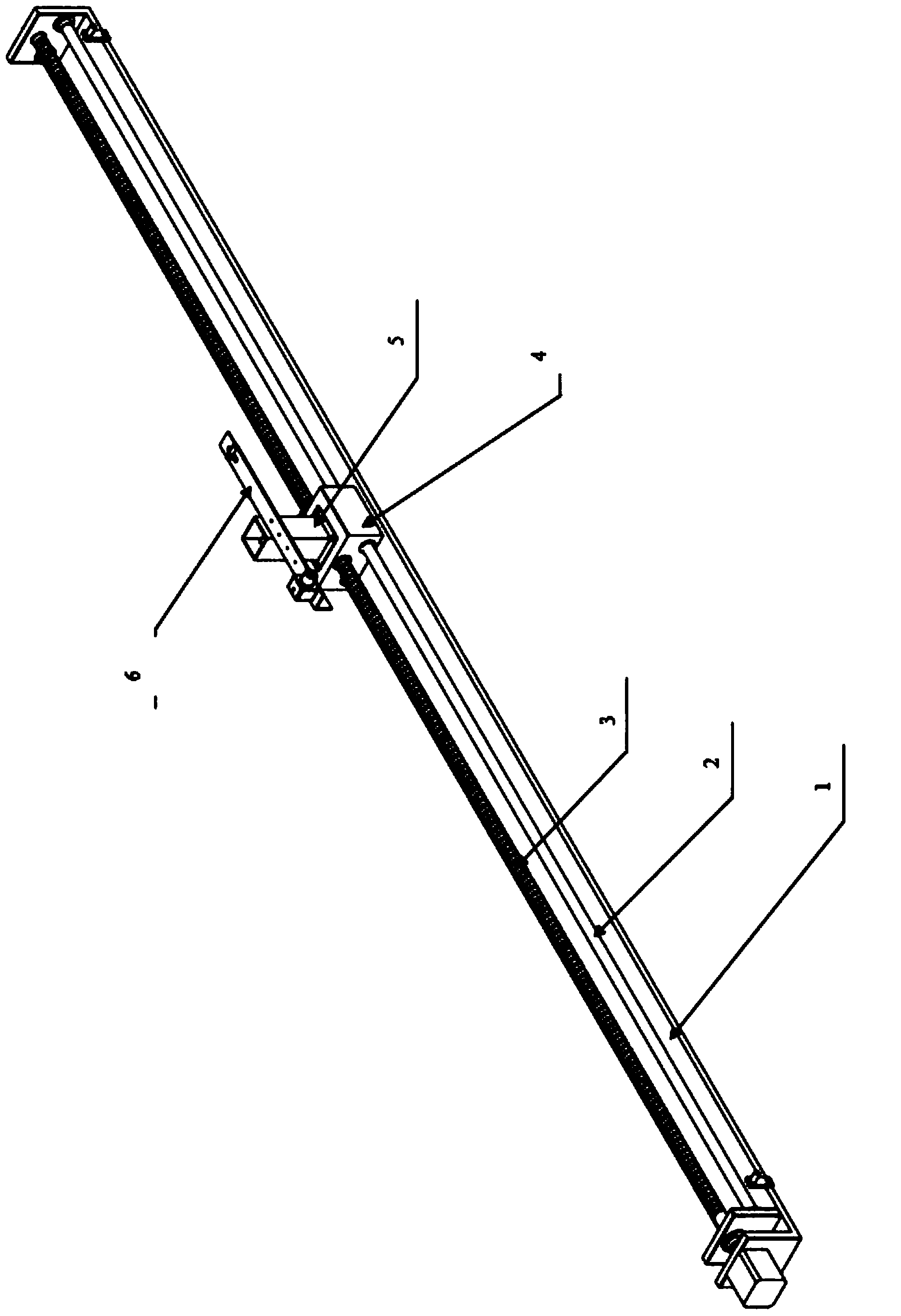

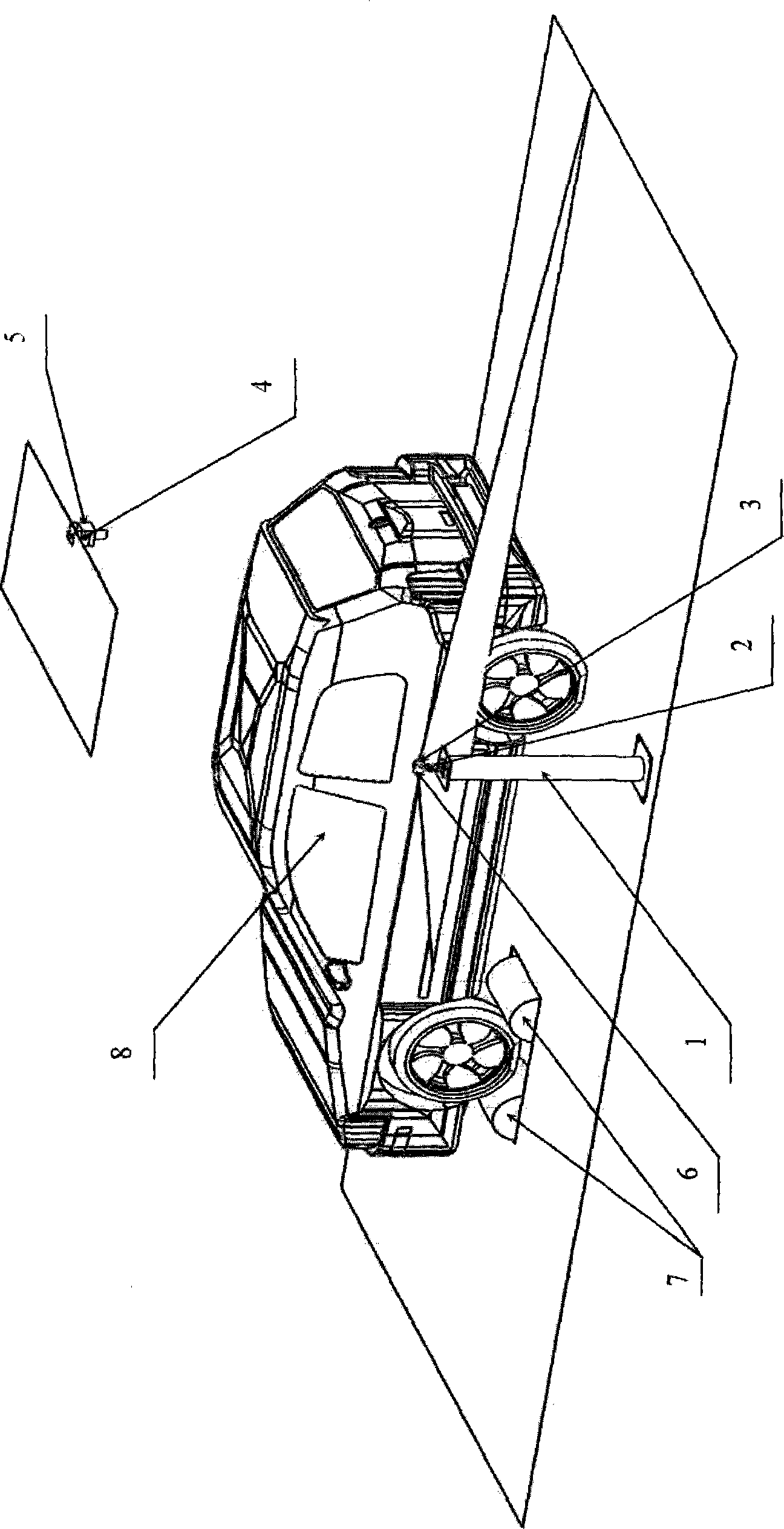

Surface structured light active vision based dynamic automobile body morphology reconstruction system

InactiveCN104101309ASmooth and Controlled MovementAvoid vibrationUsing optical meansEngineeringStationary state

The invention discloses a surface structured light active vision based dynamic automobile body morphology reconstruction system which aims at solving the problem that the automobile morphology active vision measurement on automobiles cannot be achieved through the surface structured light in the stationary state. The surface structured light active vision based dynamic automobile body morphology reconstruction system is mainly formed by a base (1), a lead screw (3), a stepper motor (8), a camera (10), a line projection instrument (15), a right proximity switch (18), a left proximity switch (19), a computer (20), an IO card (21), a switch power supply (22), a stepper motor driver (23), a left relay (24), a right relay (25) and the like. The surface structured light active vision based dynamic automobile body morphology reconstruction system is smooth in scanning, simple in structure, high in detection accuracy, convenient to operate, easy to install, low in cost and reliable in performance.

Owner:JILIN UNIV

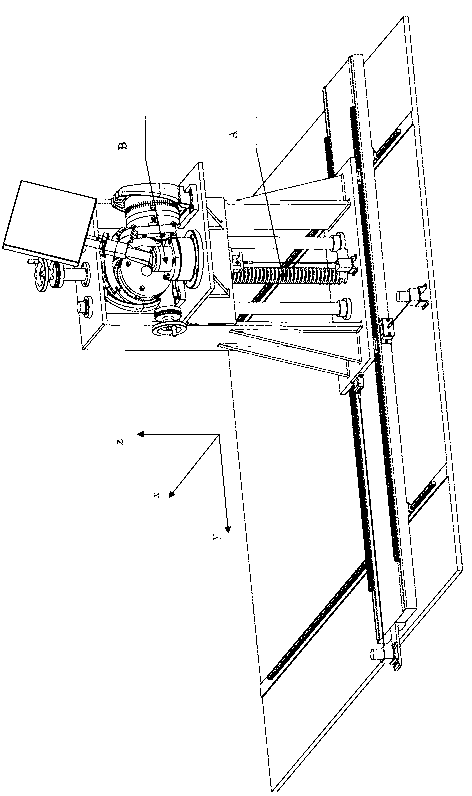

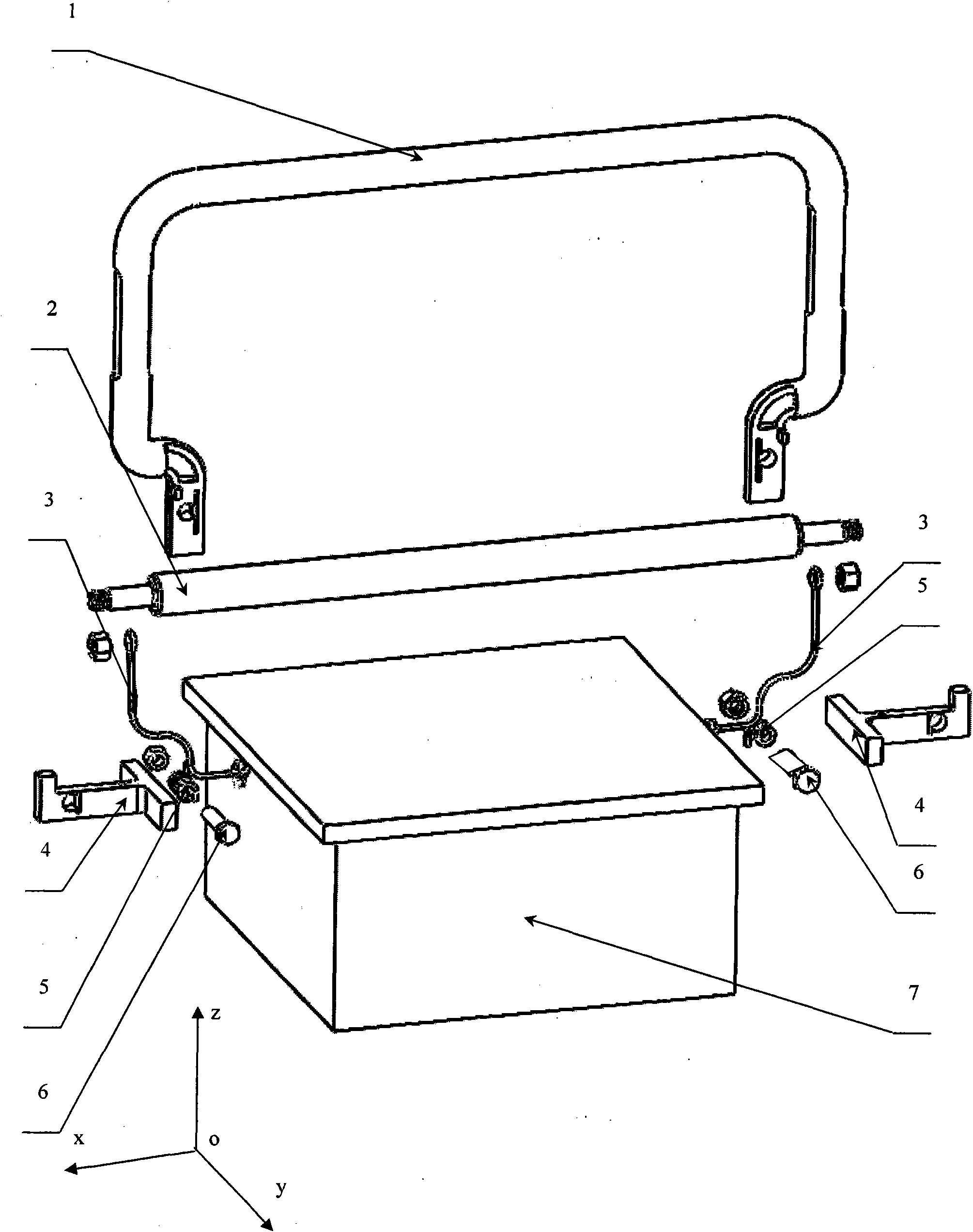

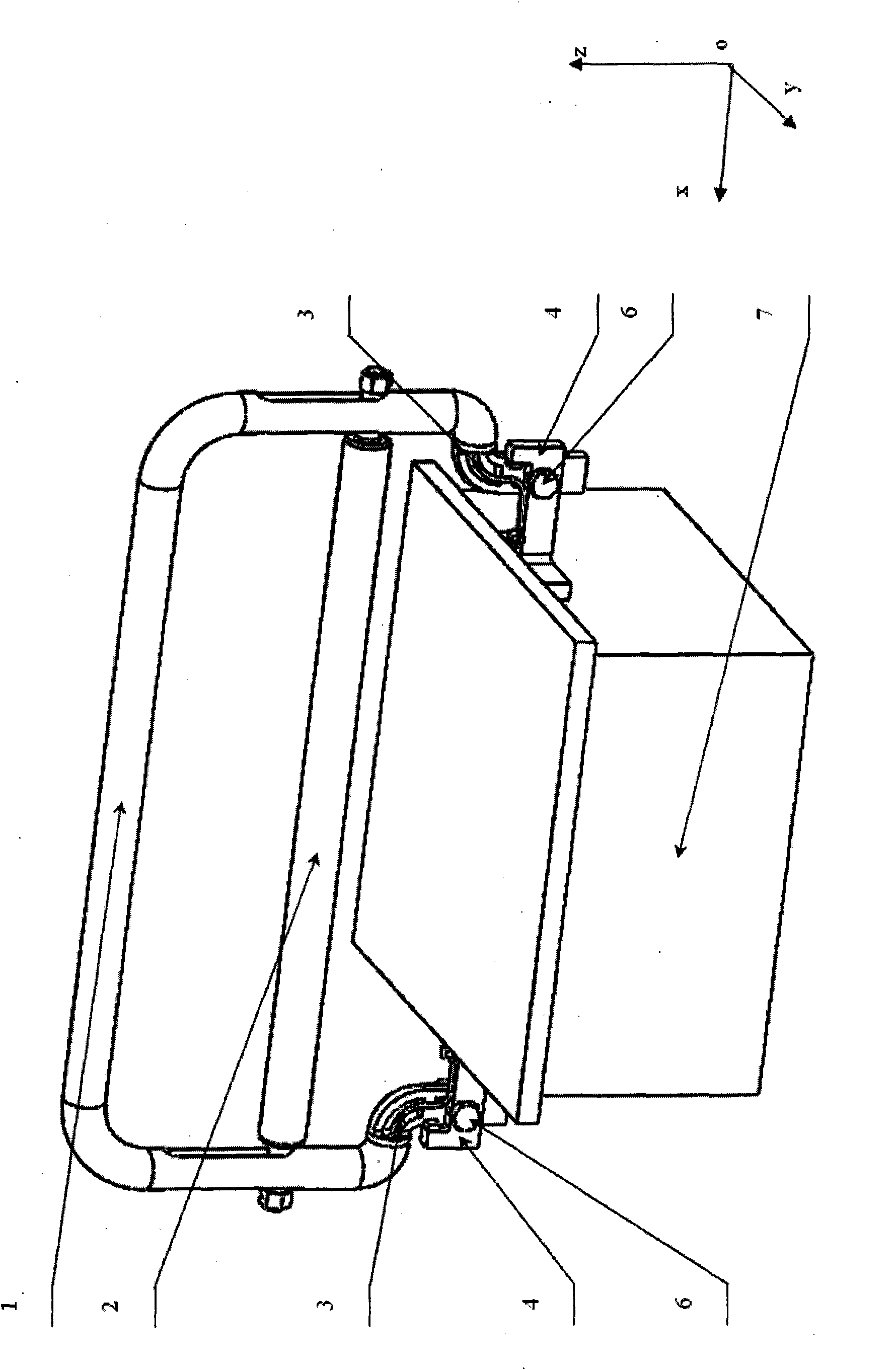

Space general position and orientation measurement standard of machine vision measurement system

InactiveCN103292700AAchieve testIncrease productionUsing optical meansFeature completeMachine vision

The invention discloses a space general position and orientation measurement standard of a machine vision measurement system, and aims to solve the problem that verification on measuring results of objects in general positions and orientations in space of the machine vision measurement system cannot be realized. A three-way linear guide rail and a two-way curved guide rail are utilized to enable a standard target to reach optional position angles in the space. The system has the advantages of simple structure, high accuracy in measurement, small accumulative errors, completeness in functions, convenience in operating and the like. The system comprises a position adjusting part (A) and an orientation adjusting part (B). By the aid of the space general position and orientation measurement standard, the verification on space general position and orientation measuring results of the machine vision measurement system is realized.

Owner:JILIN UNIV

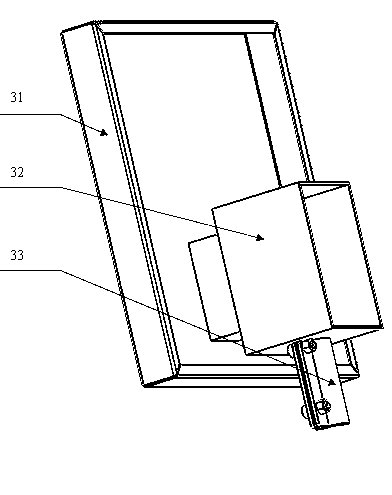

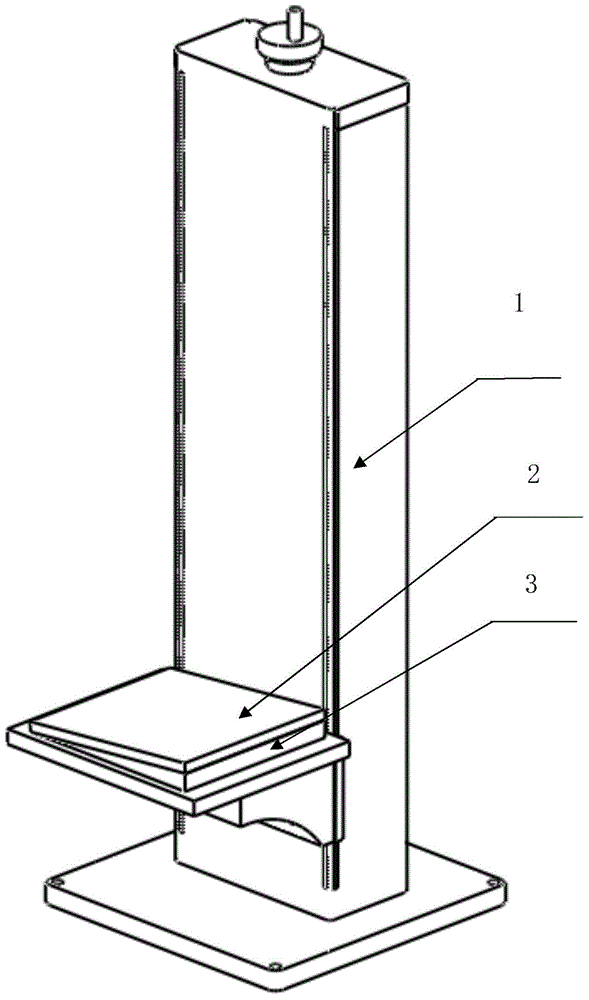

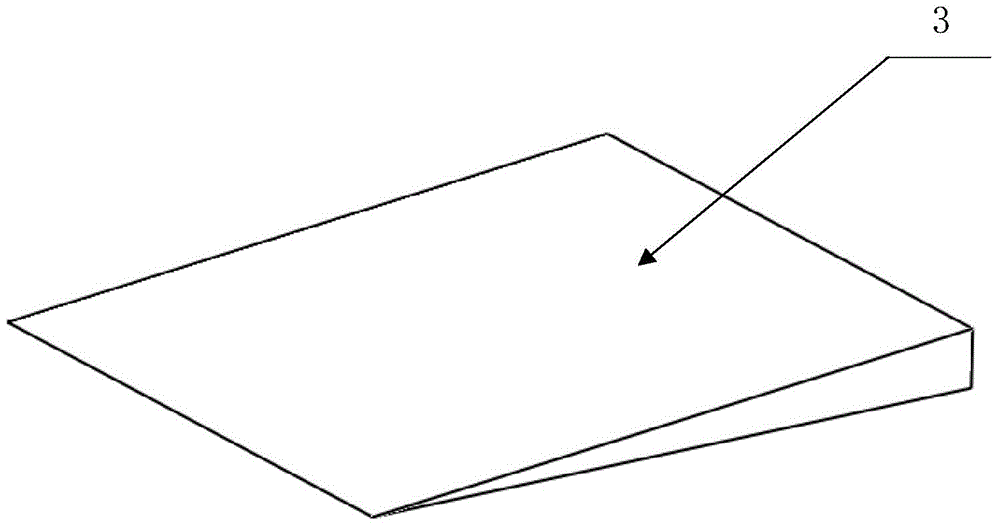

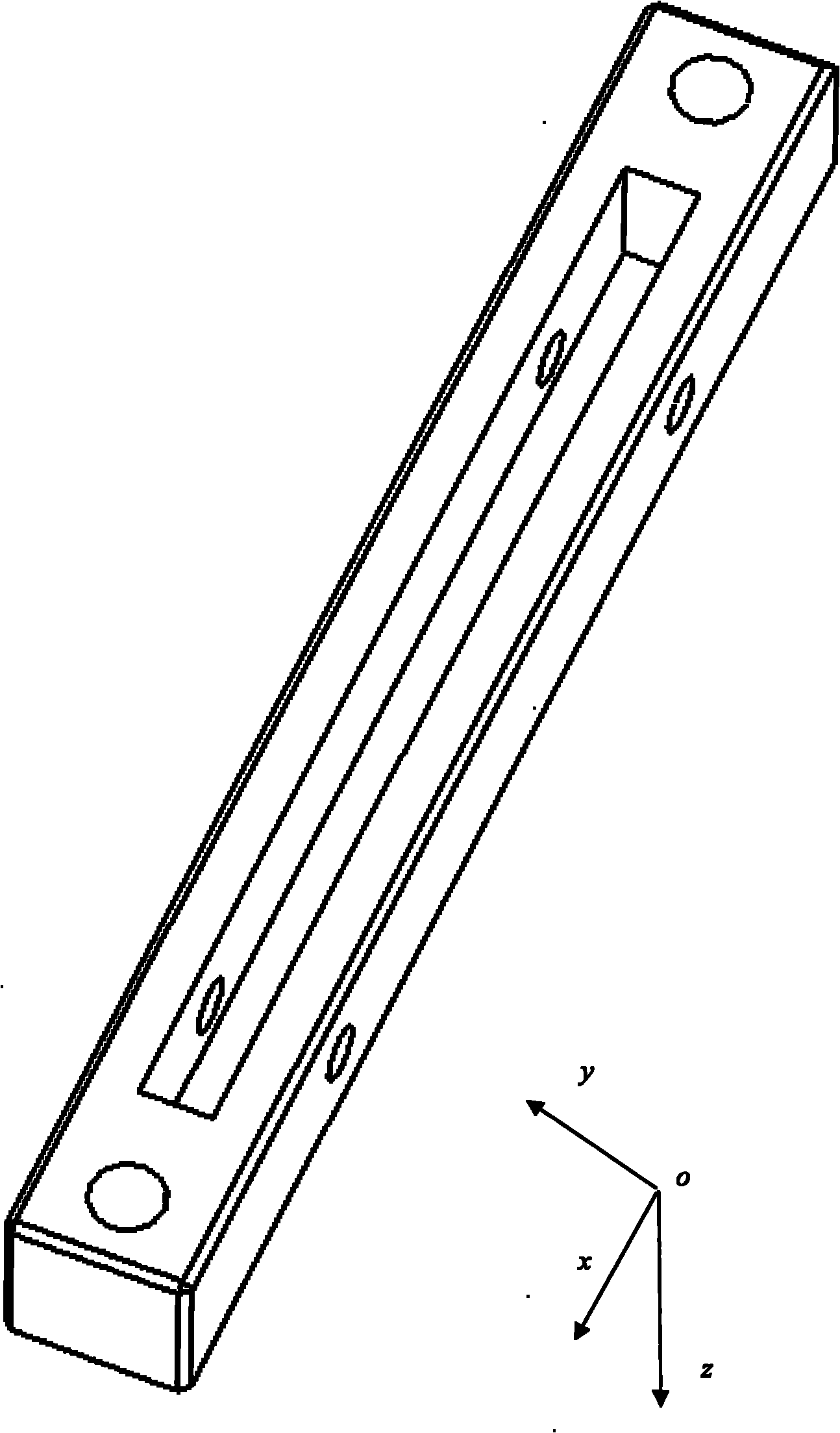

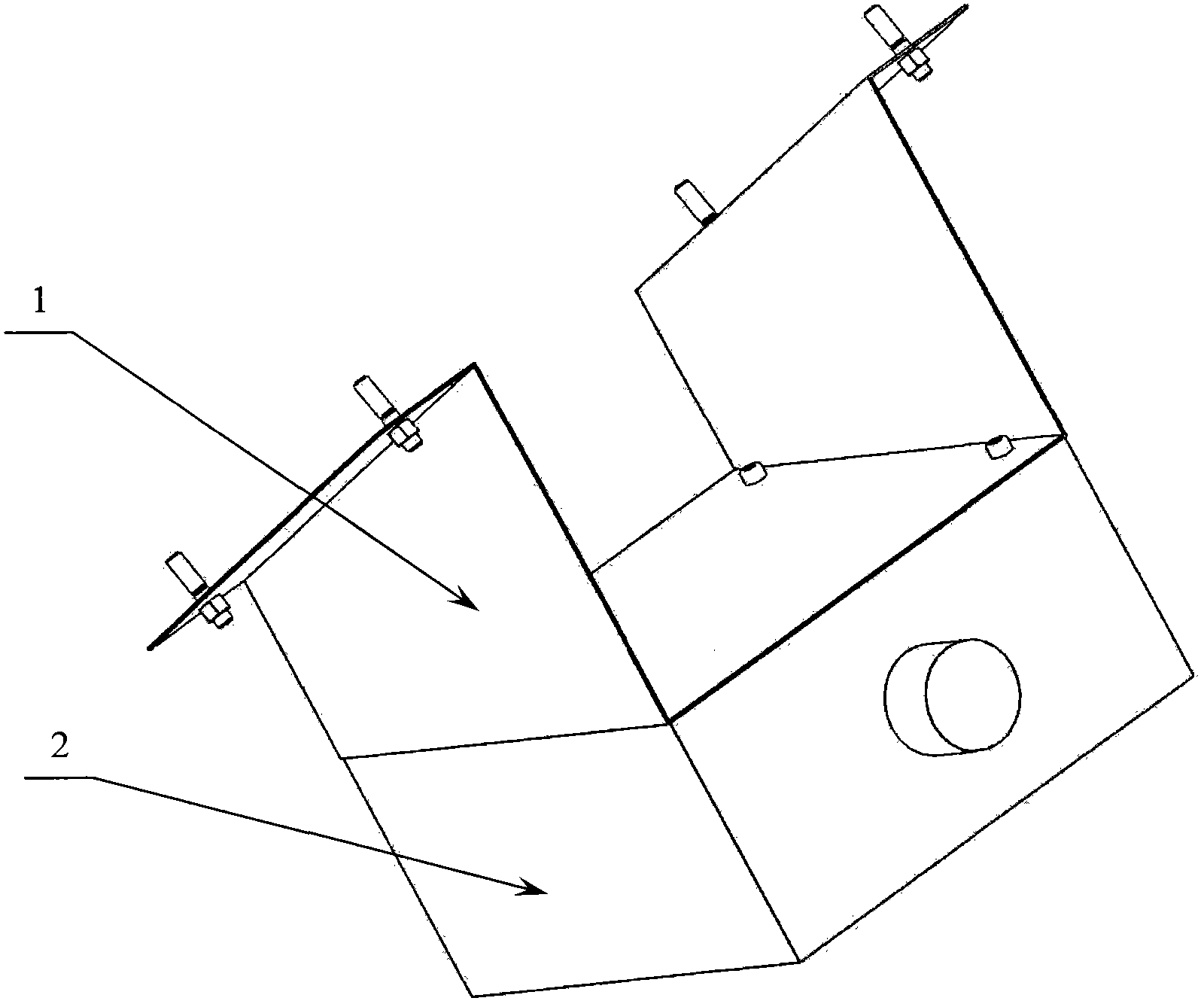

Verification system for vehicle-mounted pavement primary crack acquisition system based on line structured light reference

InactiveCN104452556AAchieve full verificationIncrease productionRoads maintainenceStructure of Management InformationRoad surface

The invention discloses a verification system for a vehicle-mounted pavement primary crack acquisition system based on line structured light reference, which aims at solving the problem that verification of the vehicle-mounted pavement primary crack acquisition system based on line structured light reference cannot be realized. The system comprises a height lifting adjusting platform (1), a target plate (2) and a wedge-shaped pad (3). According to the system provided by the design, the height and the angle can be respectively adjusted by virtue of the height lifting adjusting platform (1) and the wedge-shaped pad (3), and the vehicle-mounted pavement primary crack acquisition system based on line structured light reference is further verified.

Owner:JILIN UNIV

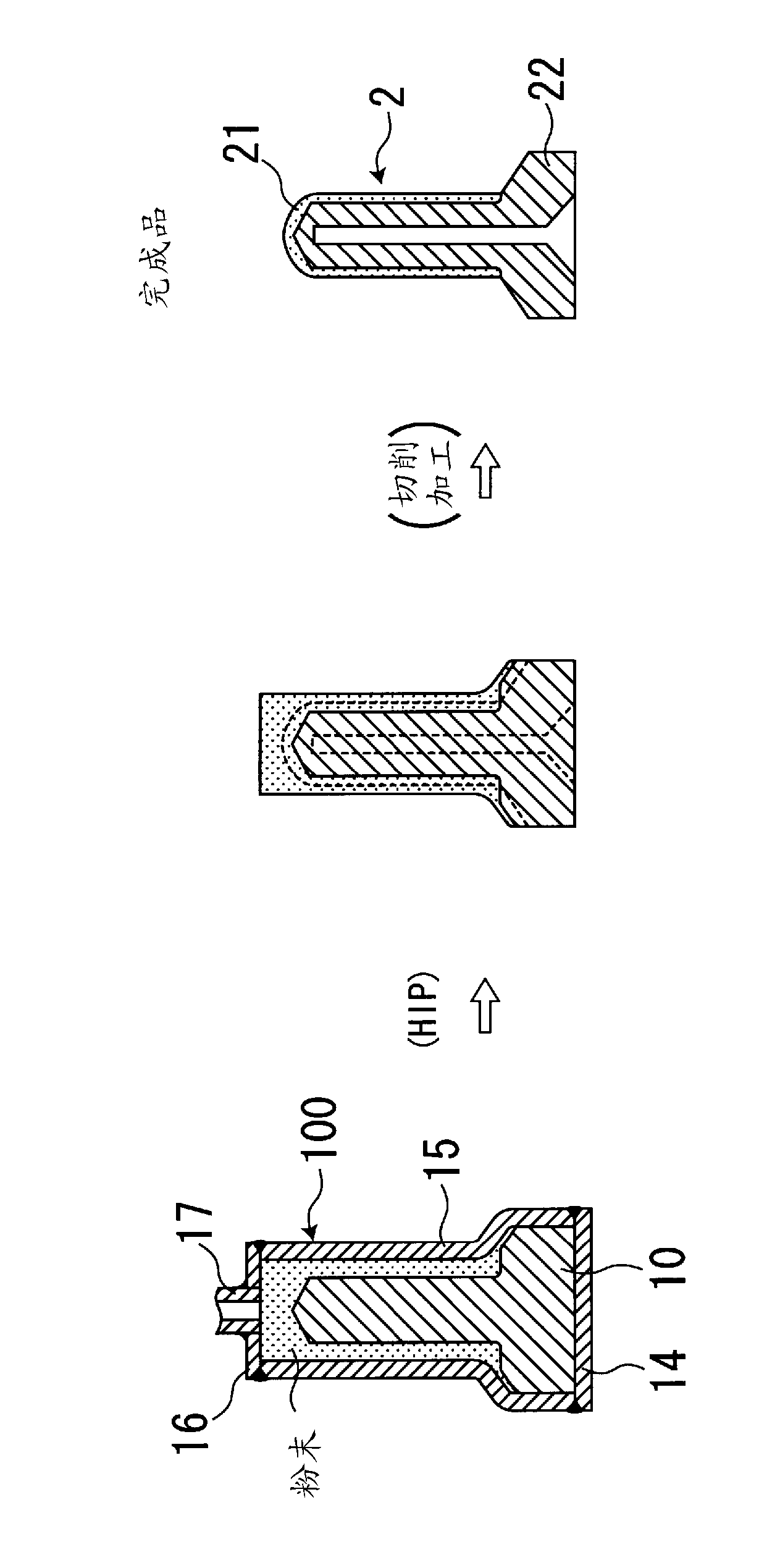

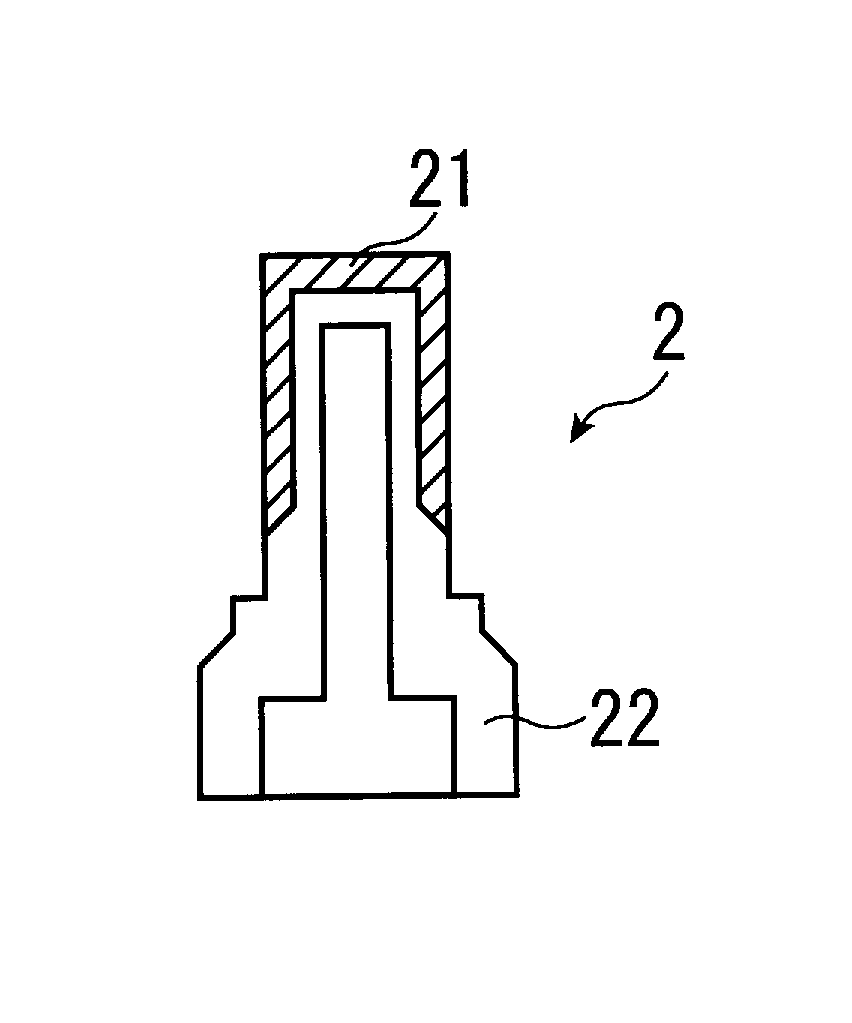

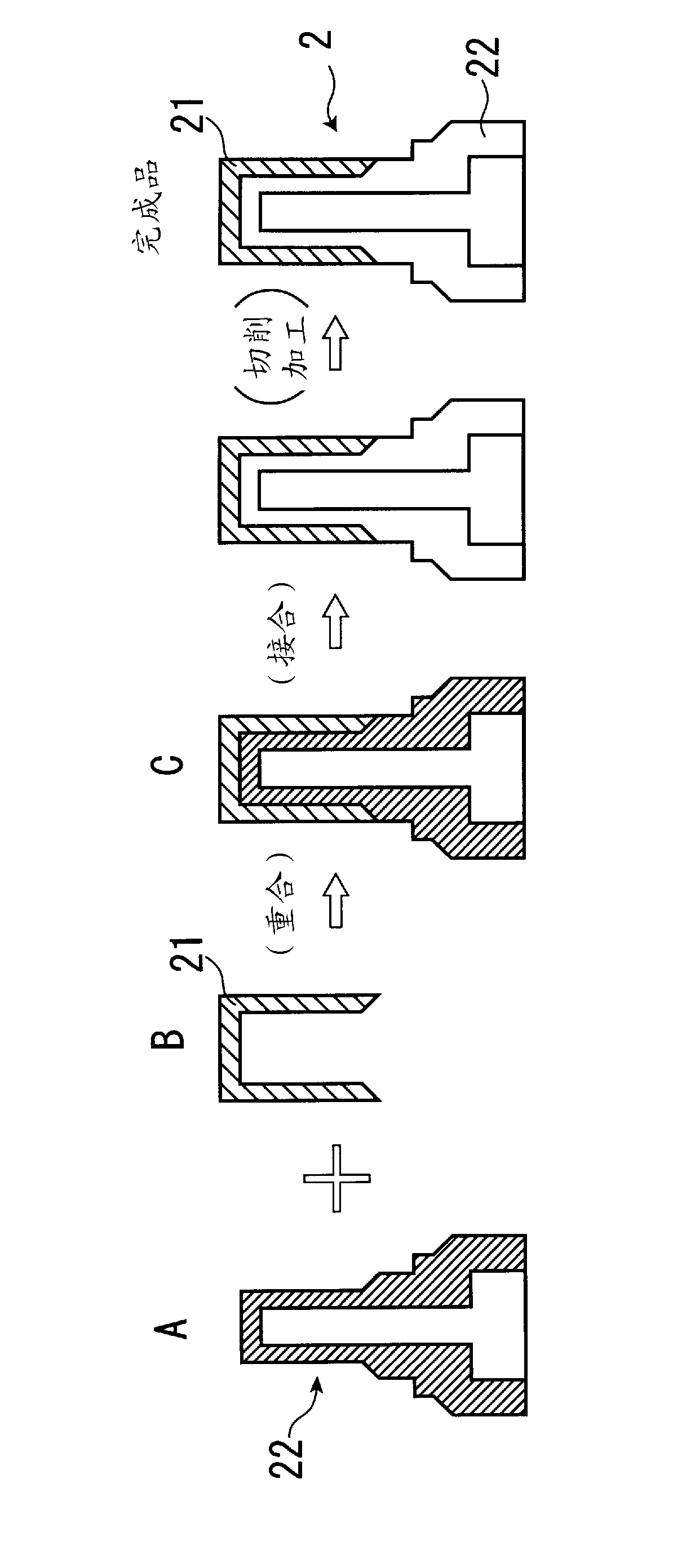

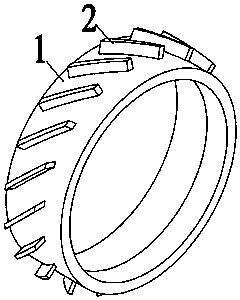

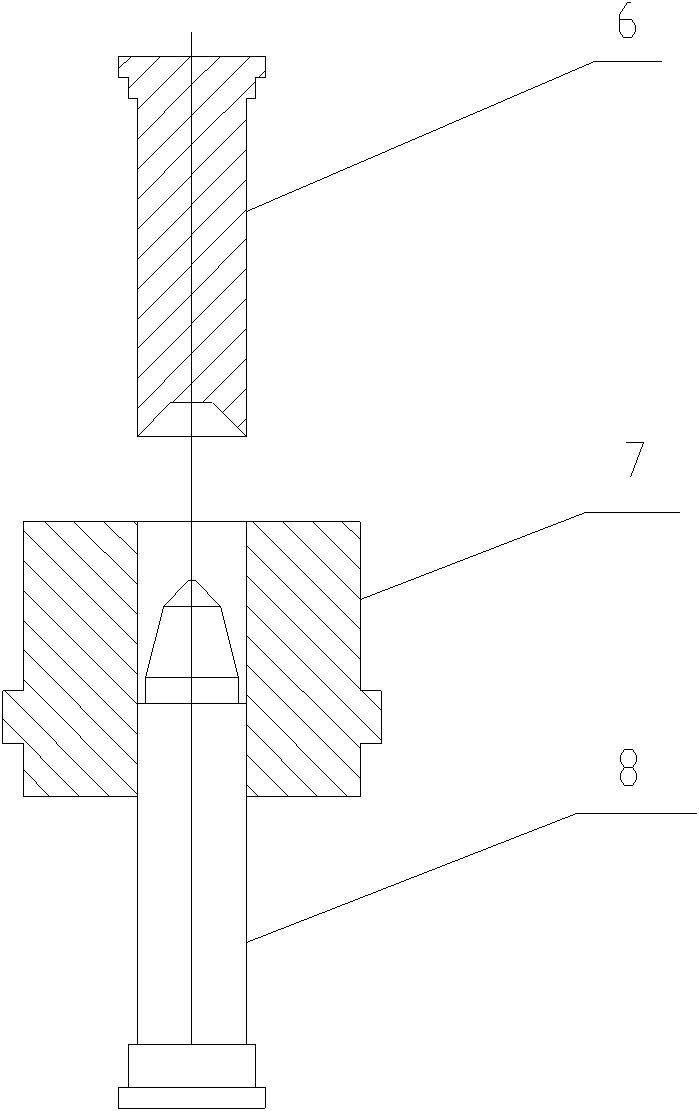

Fuel injection nozzle for internal combustion engine, nozzle blank and manufacturing method thereof

ActiveCN102472224ALess machining processImprove productivityMachines/enginesSpecial fuel injection apparatusHot isostatic pressingInternal combustion engine

Provided are a fuel injection nozzle for an internal combustion engine, a nozzle blank, and a manufacturing method for the nozzle blank, wherein the production processes are simple, the productivity is high, and the production can be performed at a low cost and with a high precision. A fuel injection nozzle for an internal combustion engine has a two layer structure of different materials, comprised of a nozzle body and a nozzle tip outer surface member which is arranged to cover a tip outer surface side of the nozzle body. The nozzle body is formed of a mold which has been molded into a predetermined shape by a metal powder injection molding method and which has been subjected to degreasing to obtain a degreased body forming the nozzle body. Likewise, separately, the nozzle tip outer surface member is formed of a mold which has been molded into a predetermined shape by a metal powder injection molding method and which has been subjected to degreasing to obtain a degreased body forming the nozzle tip outer surface member. The degreased body forming the nozzle tip outer surface member is superimposed on the degreased body forming the nozzle body to cover the tip outer surface side of the degreased body forming the nozzle body and is subjected to diffusion sintering to thereby integrally unite them. It is preferable that a hot isostatic pressing operation be performed after the diffusion sintering.

Owner:NIPPON PISTONRING CO LTD +1

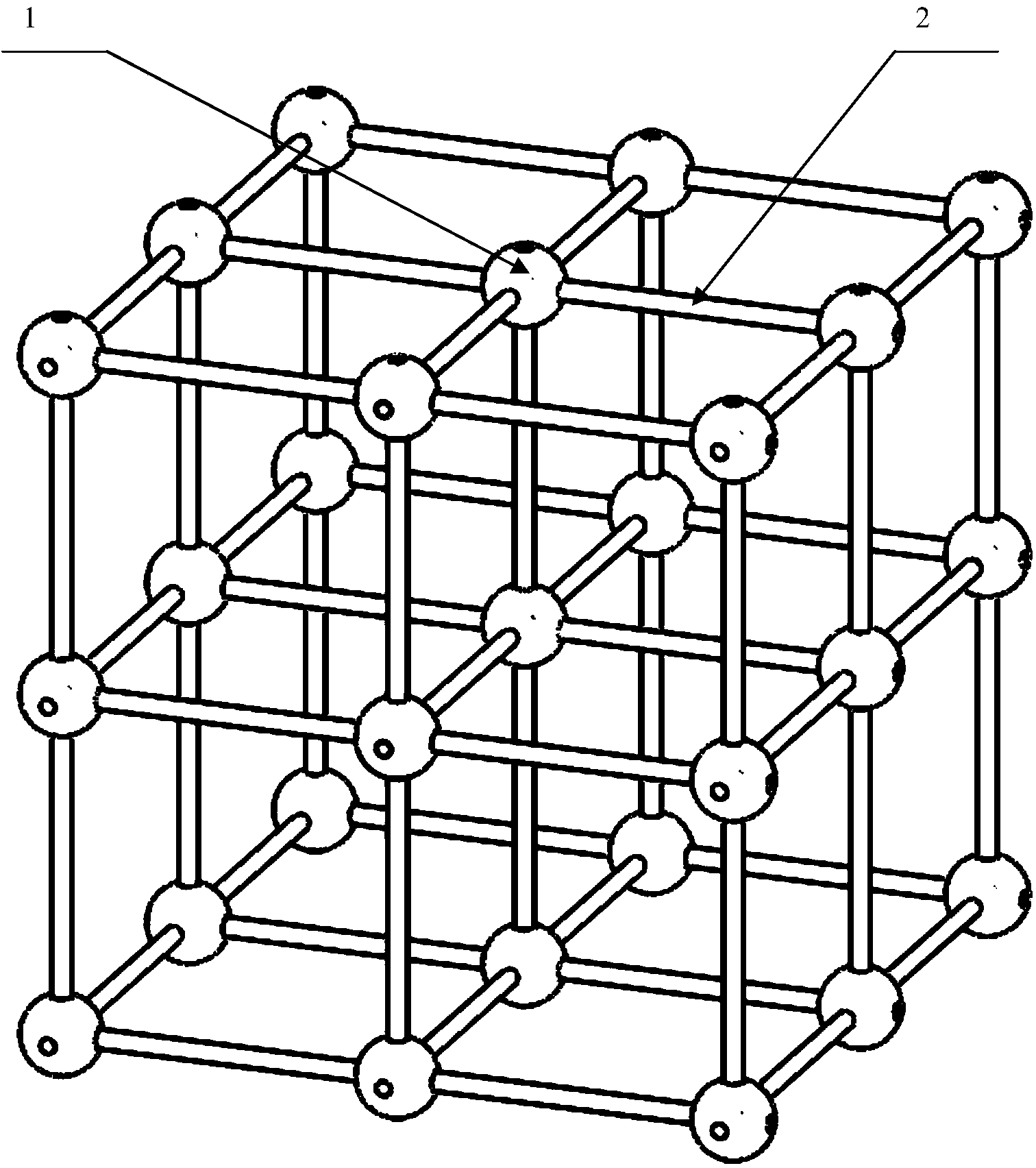

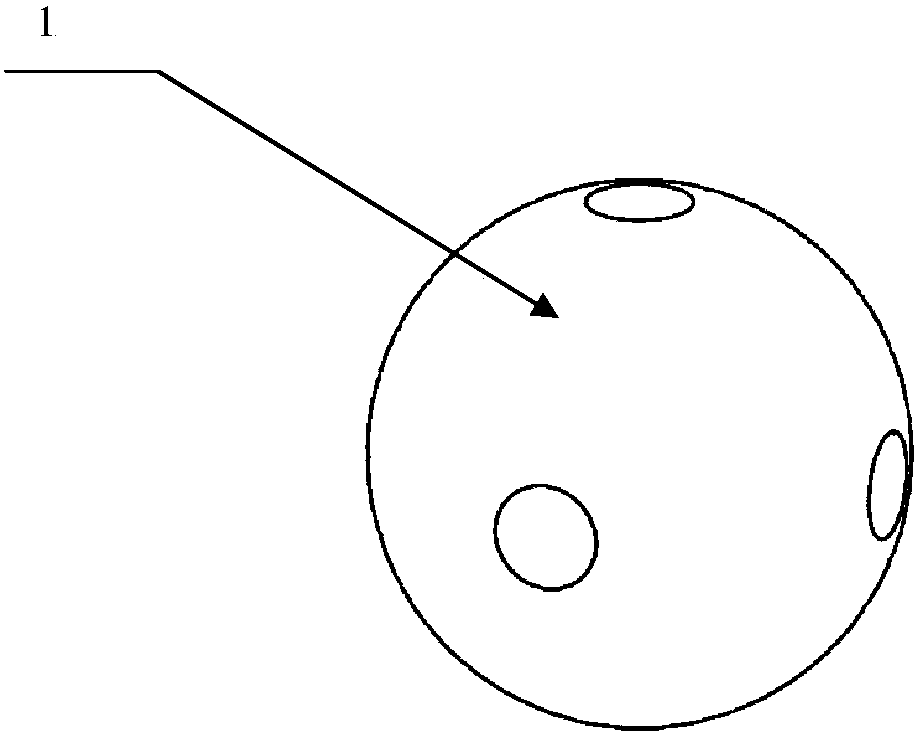

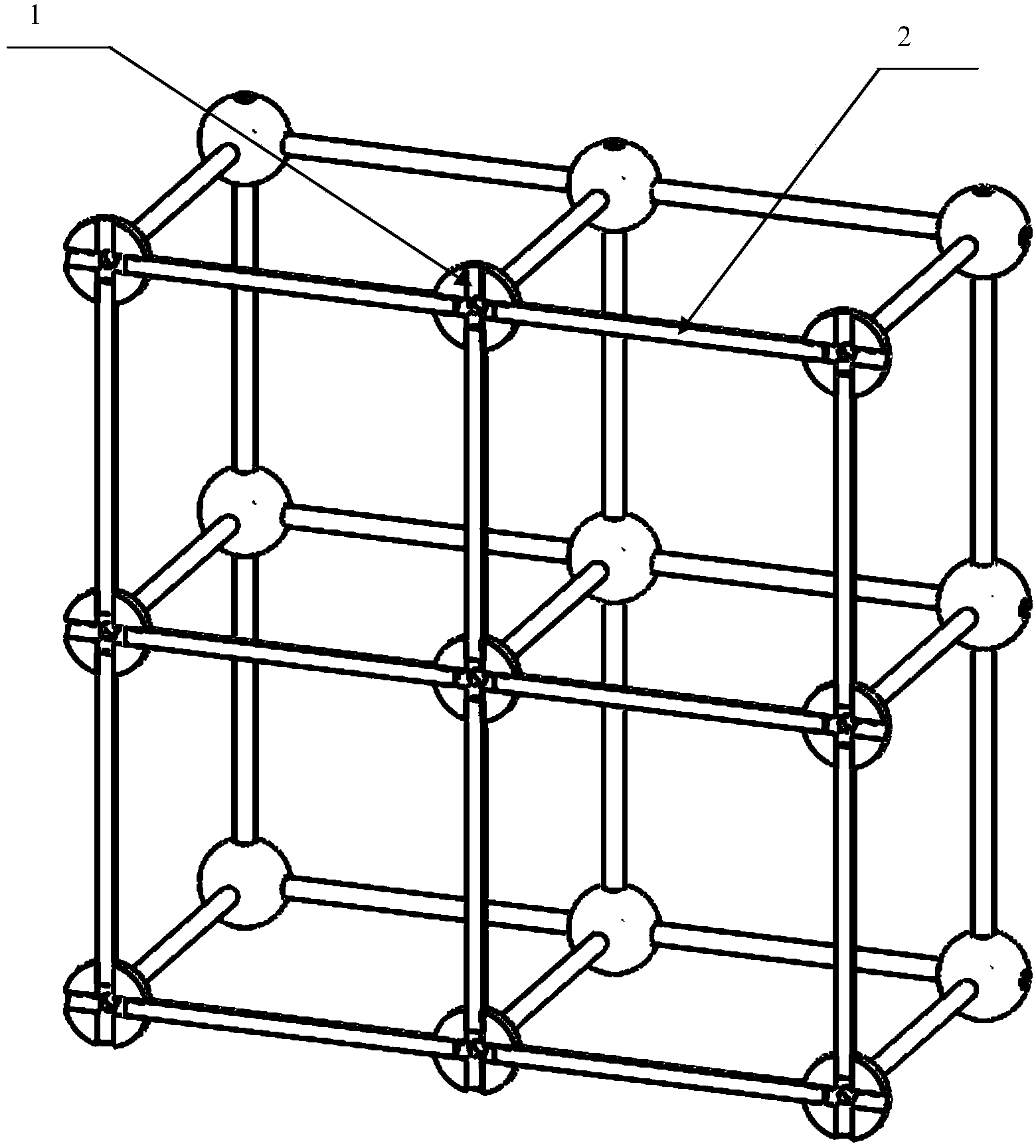

Camera three-dimensional truss calibrating target for automotive visual detection system

InactiveCN104101299AEasy to carryReduce difficultyImage analysisUsing optical meansVisual perceptionMachining

The invention discloses a camera three-dimensional truss calibrating target for an automotive visual detection system. The camera three-dimensional truss calibrating target for the automotive visual detection system aims at solving the problems that the existing three-dimensional calibrating object is large in size and complex in machining, cannot obtain three-dimensional data points of spatial general positions in a space coordinate system and is difficult to achieve site calibrating which is high in requirement for practicability. The camera three-dimensional truss calibrating target for the automotive visual detection system is mainly formed by target balls (1) and connecting rods (2). The camera three-dimensional truss calibrating target for the automotive visual detection system has the advantages of being simple in structure, high in detection accuracy, small in accumulative error, complete in function, simple in operation, easy to install, strong in universality, low in cost and reliable in performance and satisfying an automotive detection industry requirement for visual detection of an automobile body.

Owner:JILIN UNIV

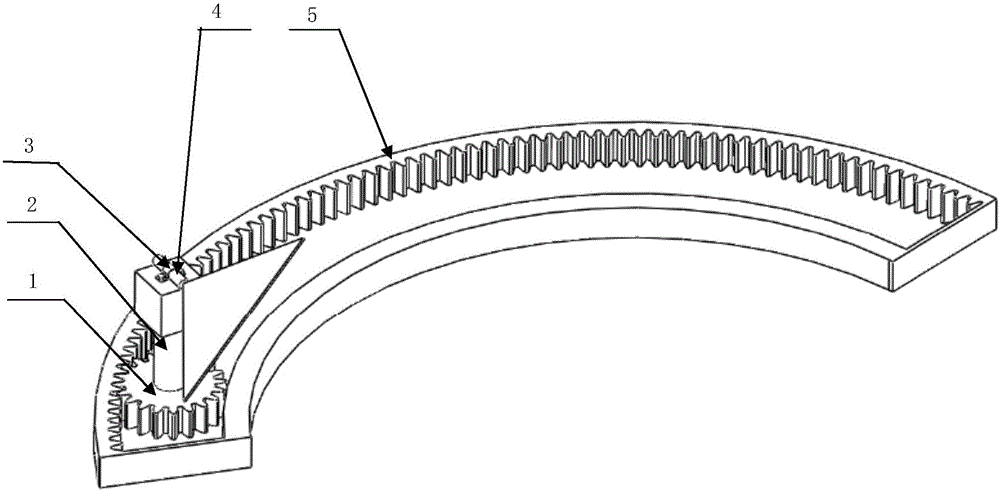

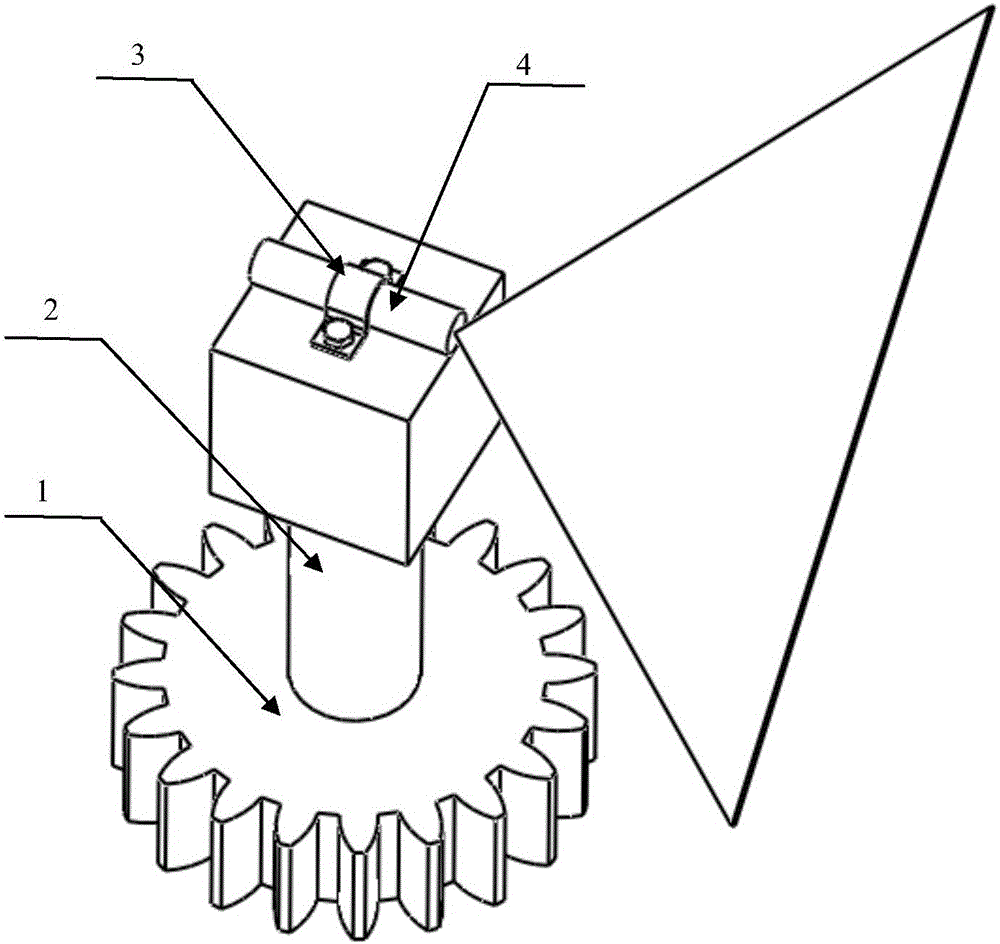

Automobile wheel rim appearance arcuate path visual reconstruction system

InactiveCN105928471ARealize arc trajectory scanning reconstructionImprove detection accuracyUsing optical meansSmall footprintEngineering

The invention discloses an automobile wheel rim appearance arcuate path visual reconstruction system. The system comprises a gear (1), a motor (2), a clamp (3), a laser demarcation device (4) and an arcuate rail (5). A round hole in the gear (1) passes through an output shaft of the motor (2) and is in key joint with a stepped shaft intermediate section of the motor (2). A nut is in fixed threaded connection with the end part of the output shaft of the motor (2). The gear (1) is placed in the arcuate rail (5) and is engaged with an arcuate rack of the arcuate rail (5). The laser demarcation device (4) is placed between two threaded holes in the top of the motor (2). Two bolts run into round holes on both sides of the clamp (3) and two threaded holes in the top of the motor (2) to be in fixed threaded connection with the motor (2). The system provided by the invention has the advantages of small footprint, simple structure, high detection precision, easy operation and easy installation.

Owner:JILIN UNIV

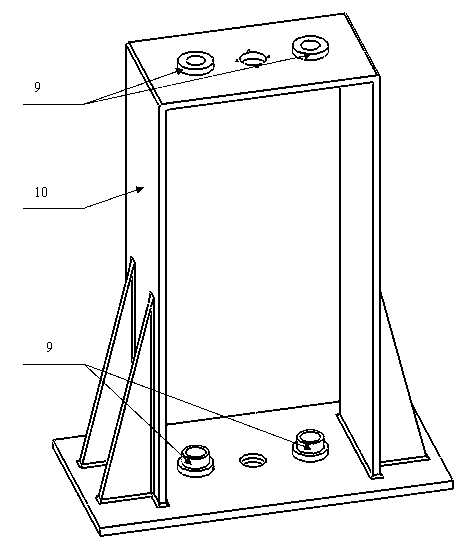

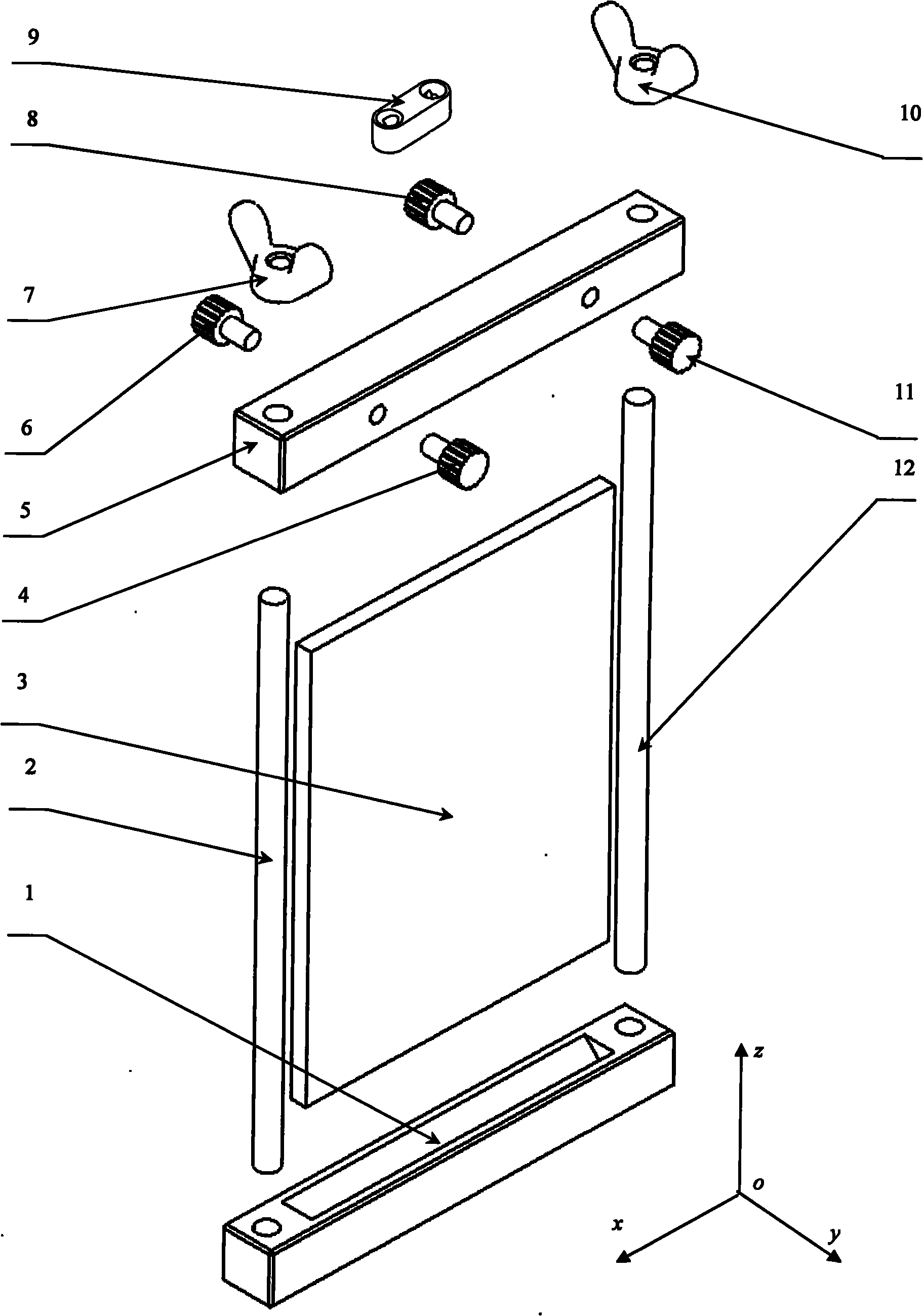

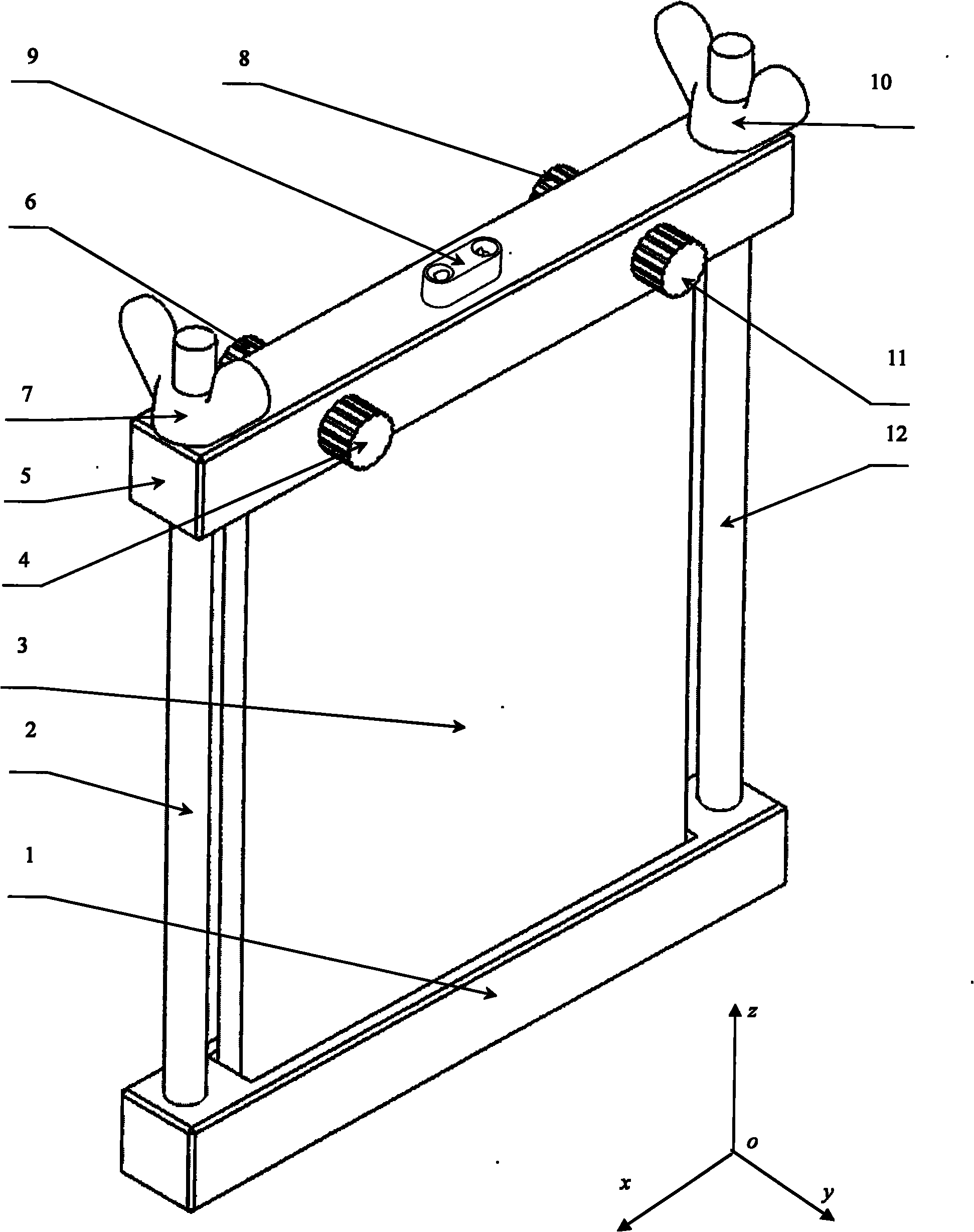

Plane mirror positioning device capable of adjusting position

InactiveCN101979906AEasy to adjustGuaranteed levelStands/trestlesUsing optical meansPlane mirrorPhysics

The invention discloses a plane mirror positioning device capable of adjusting the position, and belongs to the field of industrial measurement. The plane mirror positioning device aims to solve the problem that the installation position of a plane mirror cannot be positioned and adjusted accurately. The system comprises a support (1), a first support pillar (2), a plane mirror (3), a first positioning knob (4), an upper support (5), a second positioning knob (6), a first adjustment nut (7), a third positioning knob (8), a level bubble (9), a second adjustment nut (10), a fourth positioning knob (11) and a second support pillar (12). The detection system can adjust the position of the plane mirror quickly and accurately.

Owner:JILIN UNIV

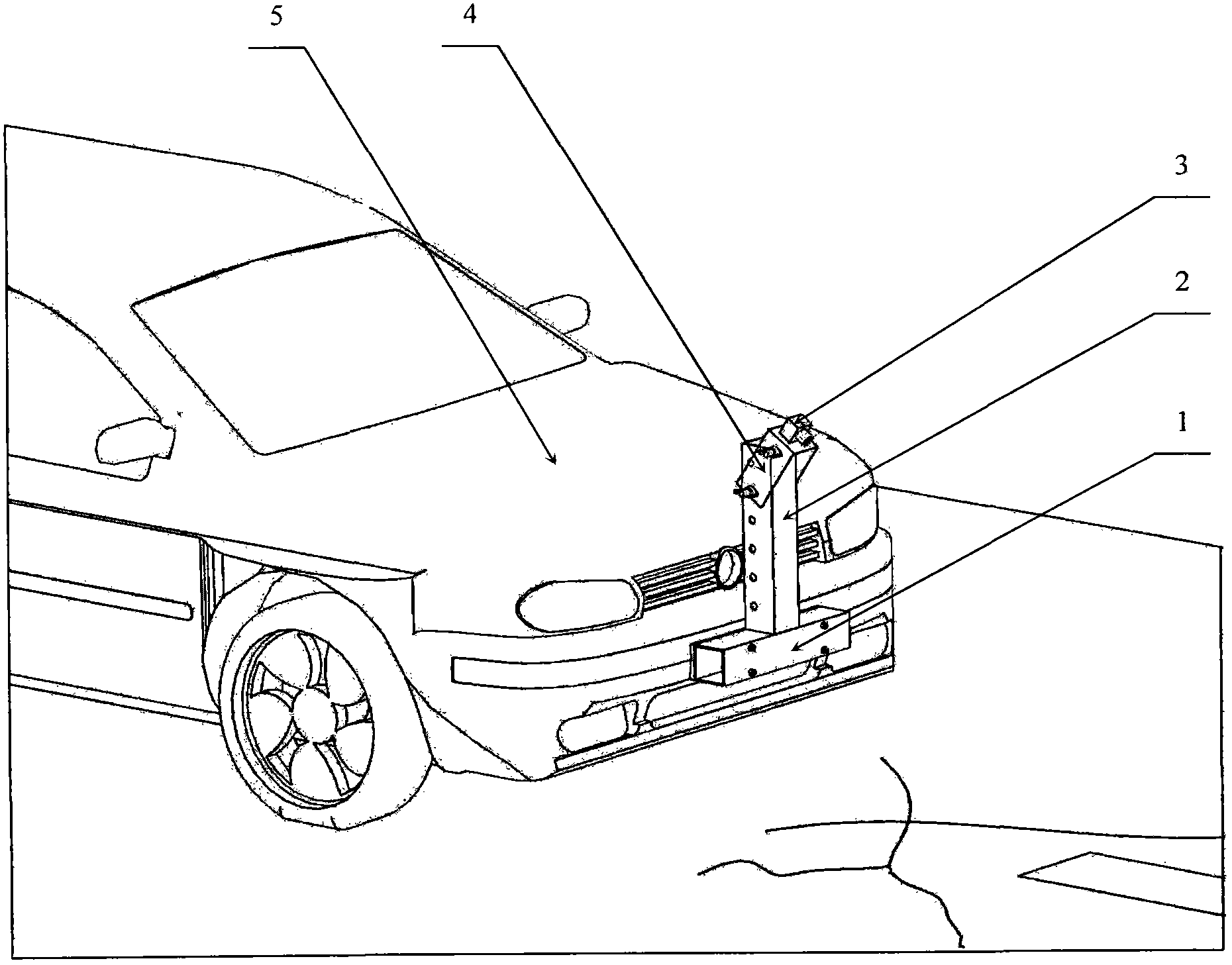

Vehicle-mounted movable machine vision inspection system for highway pavement cracks

InactiveCN103255700AAvoid heavy laborImprove detection accuracyRoads maintainenceMachine visionRoad surface

The invention discloses a vehicle-mounted movable machine vision inspection system for highway pavement cracks and aims to overcome the problem that pavement crack image acquisition and pavement condition evaluation cannot be realized. The system comprises a crossbeam (1), a longitudinal beam (2), a camera (3), an adjusting rack (4) and an automobile (5). The system provided by the invention is a vehicle-mounted movable non-contact automatic detection system capable of automatic acquisition of pavement images through machine vision and evaluation of pavement damage conditions.

Owner:JILIN UNIV

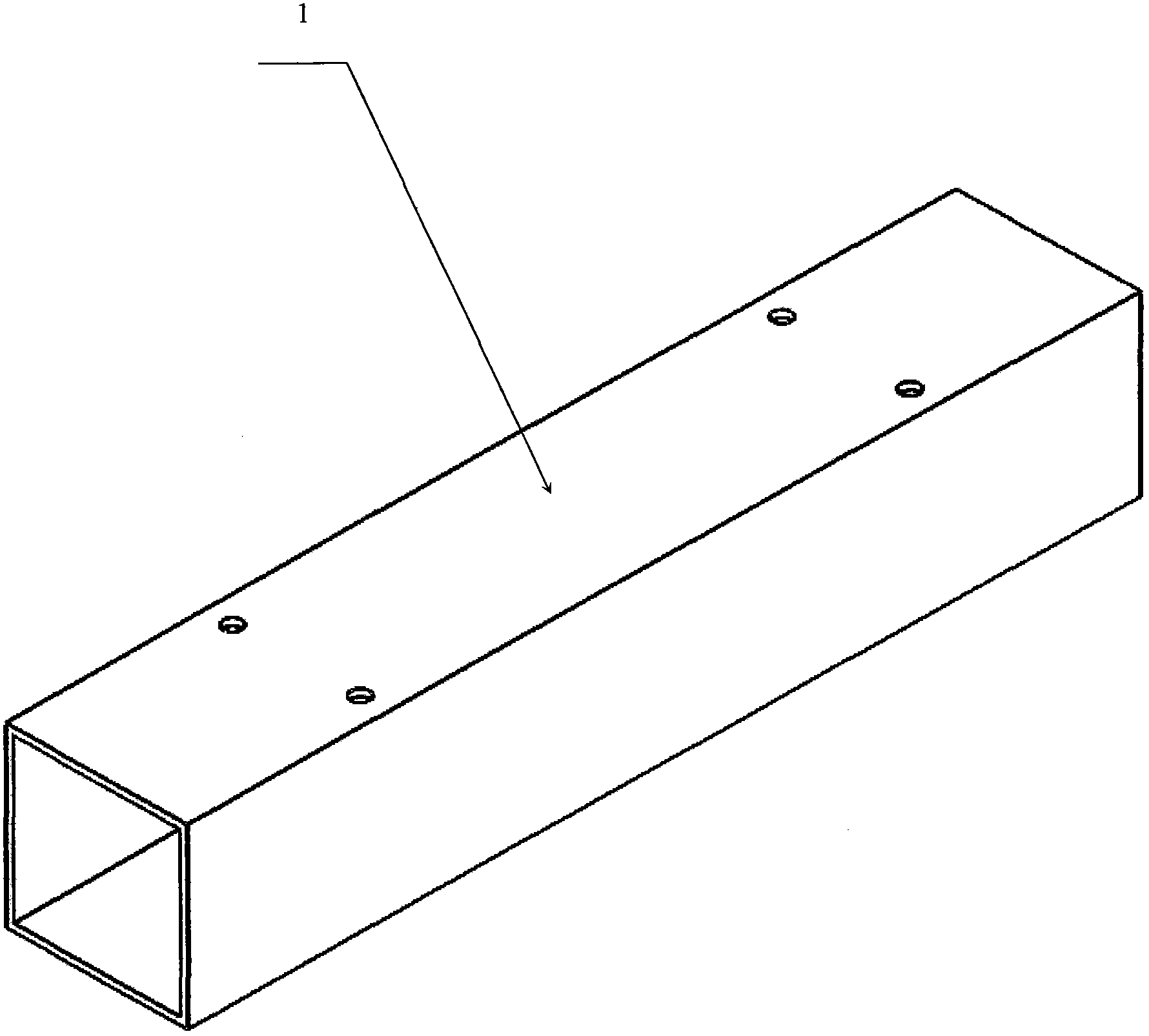

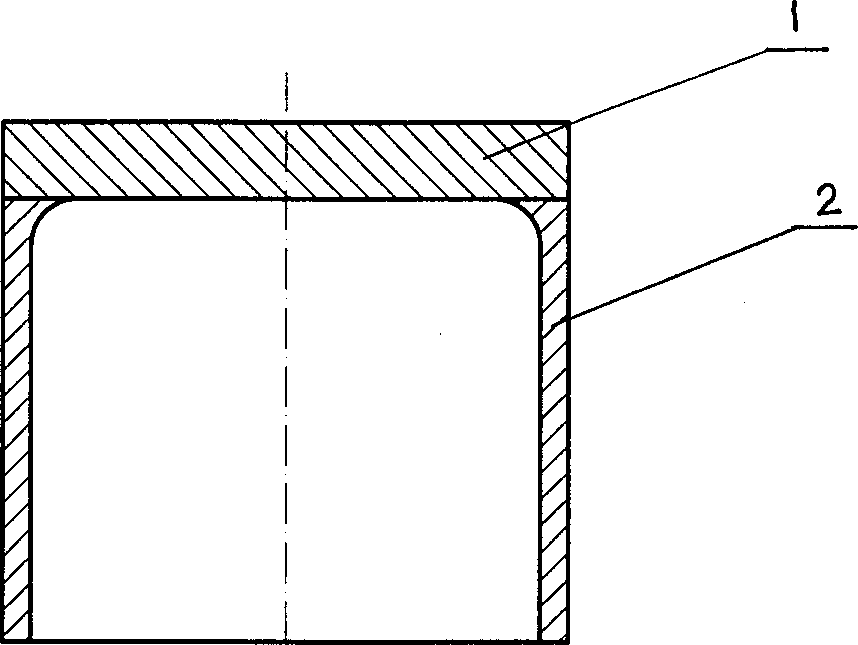

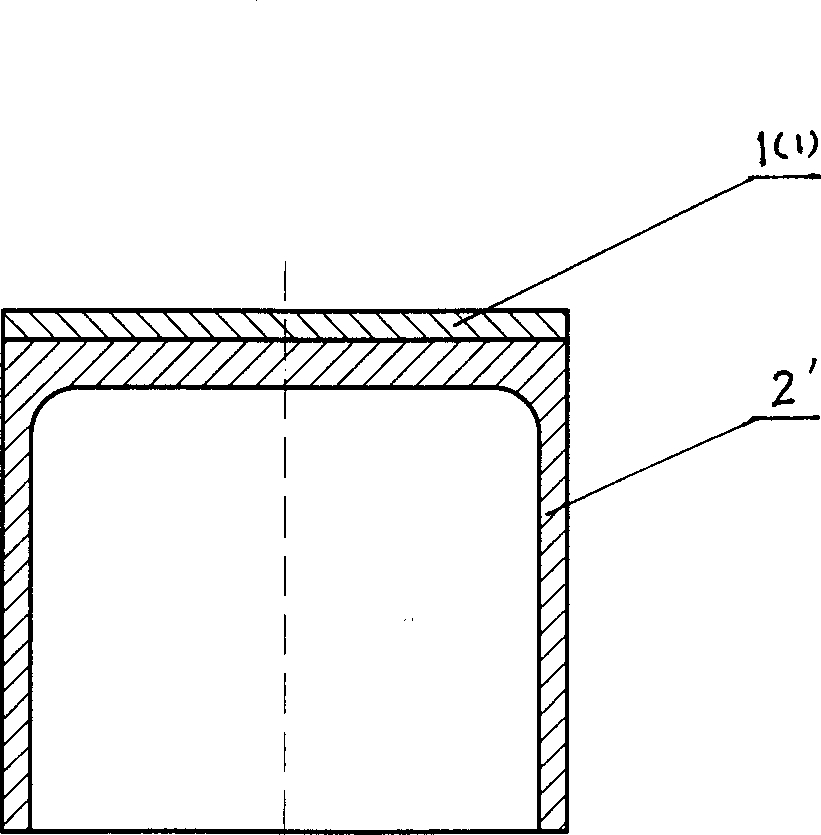

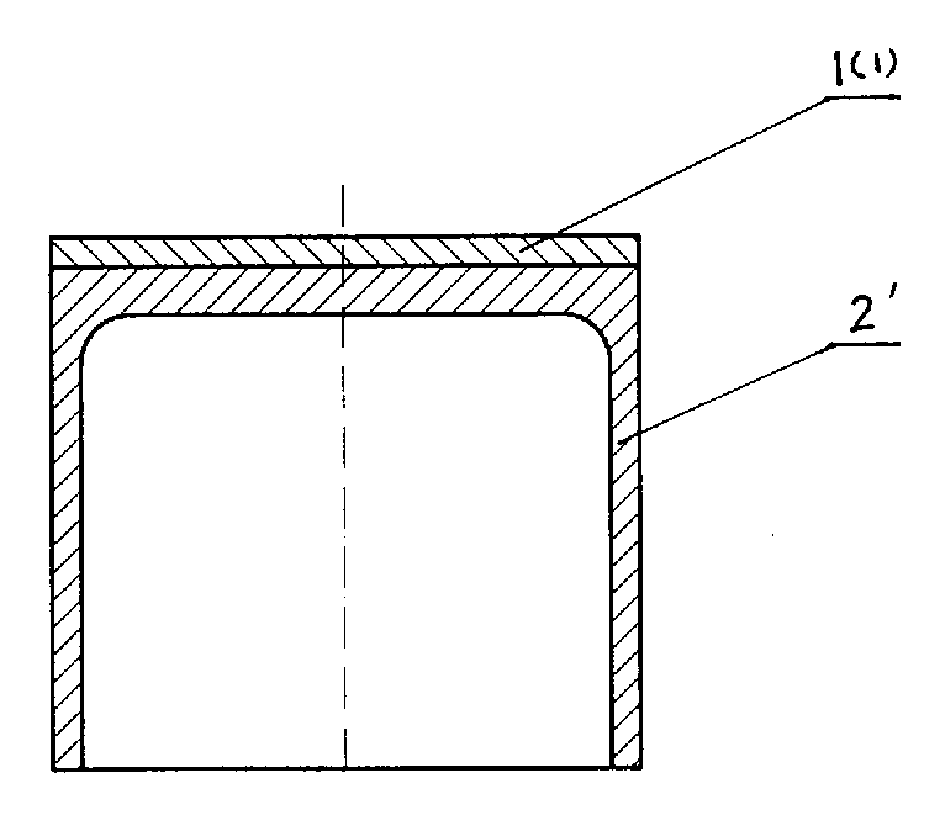

Engine valve guide tube of composite powder metallurgy material and its manufacture

The engine valve guide tube has its top made of material B and other parts made of material A. The material A consists of Cu 0.5-2 wt%, Ni 1-3 wt%, Mo 0.5-1 wt%, C 0.5-1 wt%, NbC 5-12 wt% and P 0.3-0.6 wt% other than Fe and inevitable impurity; and the material B consists of Cu 2-4 wt%, Ni 2-4 wt%, Mo 1-2 wt%, C 0.5-1.5 wt%, NbC 10-20 wt% and P 0.3-0.6 wt% other than Fe and inevitable impurity. It is manufactured through the processes of compounding material, mixing, hot pressing to form and sintering to obtain product. The valve guide tube manufactured through once pressing and sintering hashigh strength and high hardness and wear resistance.

Owner:SOUTH CHINA UNIV OF TECH

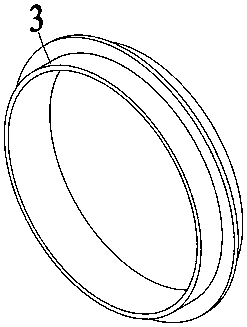

Machining technology method of swirler assembly

ActiveCN108161375AMature metallurgical processSimple metallurgical processAircraft componentsAviationCombustion chamber

The invention relates to the field of aero-engines and gas turbines, in particular to a machining technology method of a swirler assembly in an aero-engine combustion chamber. The swirler assembly iscomposed of a swirler sleeve and a swirler. The swirler sleeve and the swirler each adopt a forged piece as a raw material. The machining technology method of the swirler assembly comprises the stepsof (1) turning, (2) milling or electrosparking, (3) cleaning, (4) trial assembly, (5) positioned welding, (6) brazing filler metal prearrangement, (7) vacuum brazing, (8) pincers machining and (9) finish turning. The machining technology method is simple in operation; and the problems that in the prior art, after precision casting is adopted, a swirler assembly manufactured in a precision machining manner is high in production cost and long in period, the requirements for personnel and skills are high, metallurgical defects are hard to avoid, the size and quality of a casting are instable, therate of finished products is not high, and consequently the service life of a combustion chamber is shortened, and adverse effects are generated to the overall performance of an aero-engine are solved.

Owner:广汉天空动力机械有限责任公司

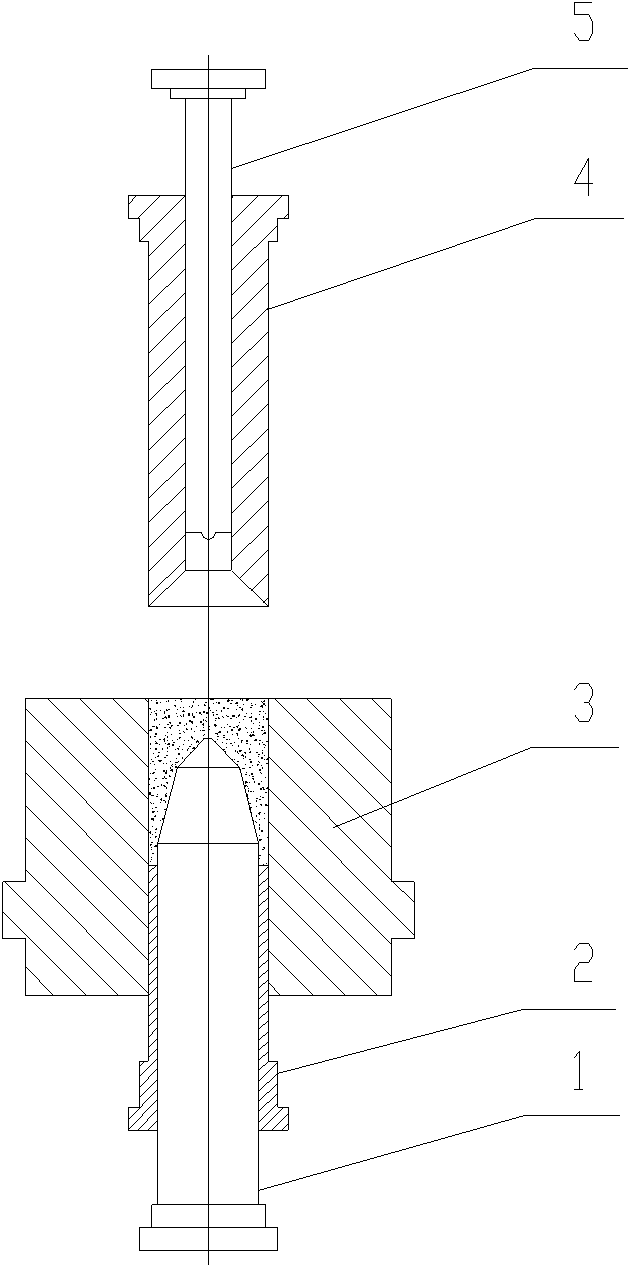

Composition of powder metallurgical perforating charge shell material, professional die and manufacturing method of the powder metallurgical perforating charge shell material

The invention relates to a composition of a powder metallurgical perforating charge shell material, a professional die and a manufacturing method of the powder metallurgical perforating charge shell material. The invention mainly solves the problems that the traditional perforating charge shell machining process is complicated and has low machining efficiency and high cost. The powder metallurgical perforating charge shell material comprises the following raw materials in percentage by weight: 0.8 percent of carbon powder, 1 to 3 percent of copper powder, 1 to 3 percent of nickel powder, 0.1 to 1 percent of molybdenum powder, 91.2 to 97 percent of iron powder, and 0.1 to 1 percent of bonding agent; and the powder metallurgical perforating charge shell material is prepared by mixing the raw materials,pressing and molding, sintering, finishing and preservative treatment. The powder metallurgical perforating charge shell adopted the powder pressing molding method to prepared, realizes iron scrap-free processing, has high processing efficiency and reduces the processing cost; and the penetrating performance of a perforating charge manufactured by using the powder shell exceeds the penetrating index of the traditional steel shell, and meanwhile, the perforating charge has the characteristic of low scrap and is suitable for the special operation requirements of full-bore perforations and the like in the petroleum industry.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Automobile appearance motion-unrestricted detection instrument based on three-dimensional rectangular coordinates

InactiveCN106225720AReduced areaReduce volumeUsing optical meansMechanical measuring arrangementsRectangular coordinatesSteel ball

The invention discloses an automobile appearance motion-unrestricted detection instrument based on three-dimensional rectangular coordinates, and aims at solving the problems to realize the automobile appearance motion-unrestricted detection by using three-dimensional rectangular coordinates. The automobile appearance motion-unrestricted detection instrument based on three-dimensional rectangular coordinates is characterized by consisting of a long rod (2), a light emitting diode (3), a calibration cube (4), a cross line laser (5), a spring (6), a steel ball (7) and a camera (8). The automobile appearance motion-unrestricted detection instrument based on three-dimensional rectangular coordinates is systematically provided and has the advantages that the structure is simple; the operation is simple and convenient; the installation is easy; the cost is low; the performance is reliable.

Owner:JILIN UNIV

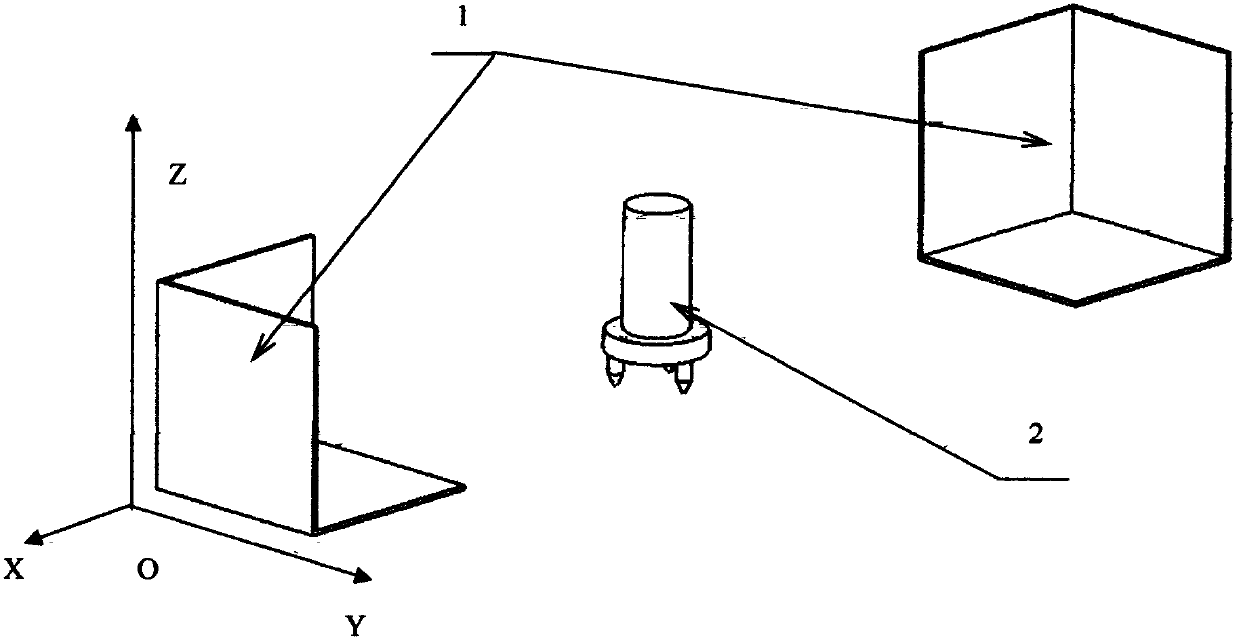

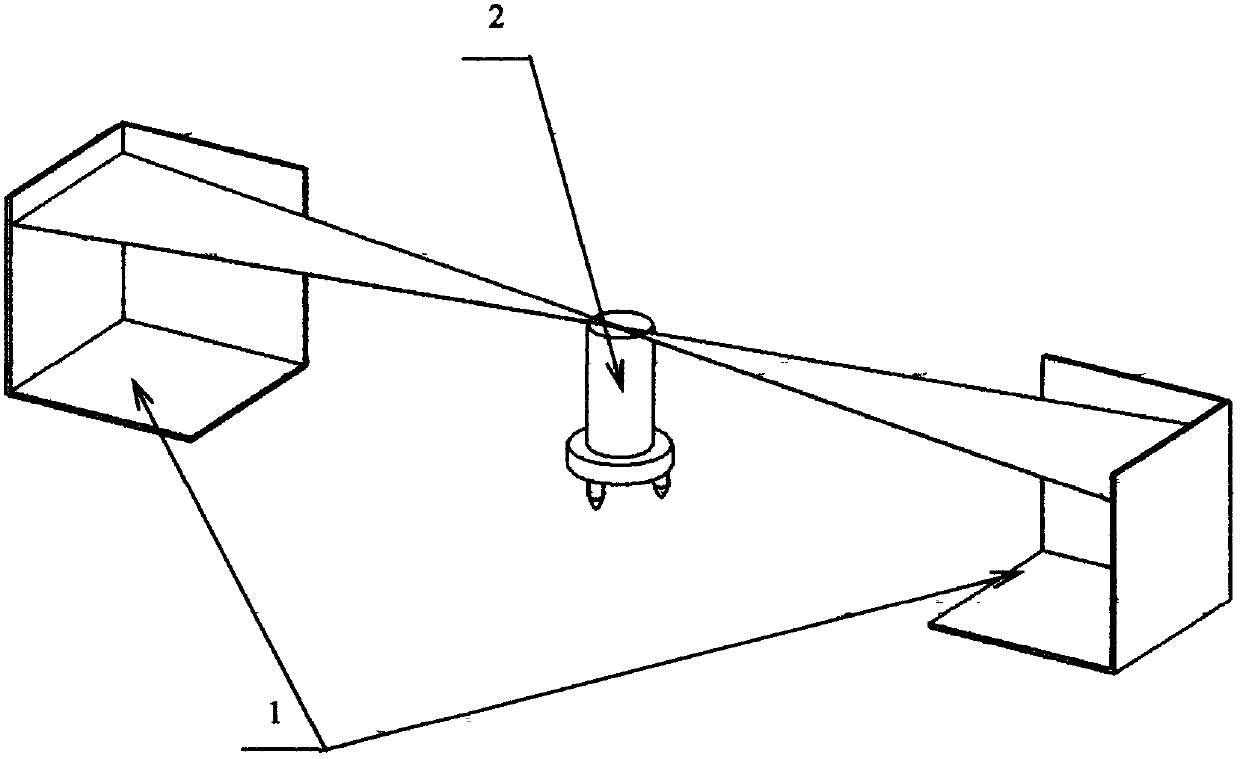

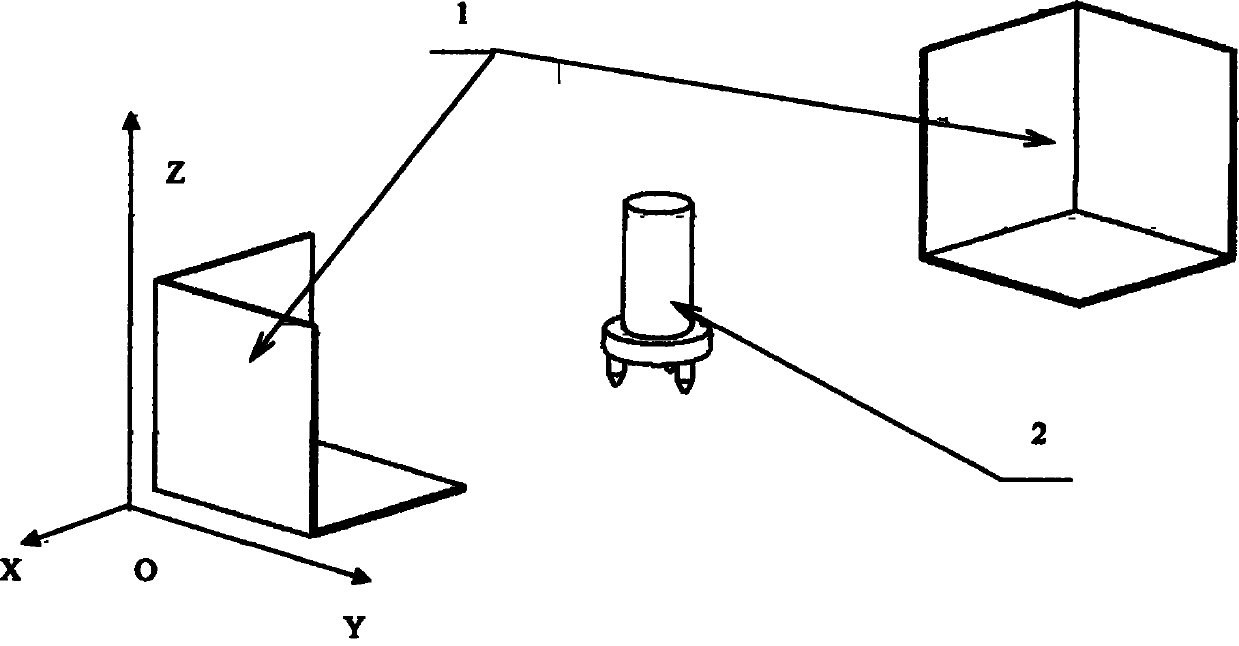

Calibration system for commercial vehicle vision measurement based on longitude and altitude spatial positioning principle

InactiveCN102679877AHigh measurement accuracyIncrease productionUsing optical meansSpatial positioningMachine vision

The invention discloses a calibration system for commercial vehicle vision measurement based on a longitude and altitude spatial positioning principle and aims to overcome the defect that three degree-of-freedom adjustment of an automobile vehicle positioning parameter stereoscopic vision detection system cannot be realized. The calibration system comprises two calibration plates (1) and a cross laser line (2). Due to adoption of the structures of the two calibration plates (1) and the cross laser line, the calibration plates (1) can be randomly adjusted and calibrated on a large-scale spatial range of commercial vehicles, so that the problem that the vision measurement accuracy is decreased outside the space determined by the calibration plates (1) because the calibration plates (1) are too small is solved. The calibration system has the characteristics of relatively small size, convenience in operation, reliable performance, high generality, low manufacturing cost, high precision and the like, and has great significance for technical progress in the field of machine vision detection.

Owner:JILIN UNIV

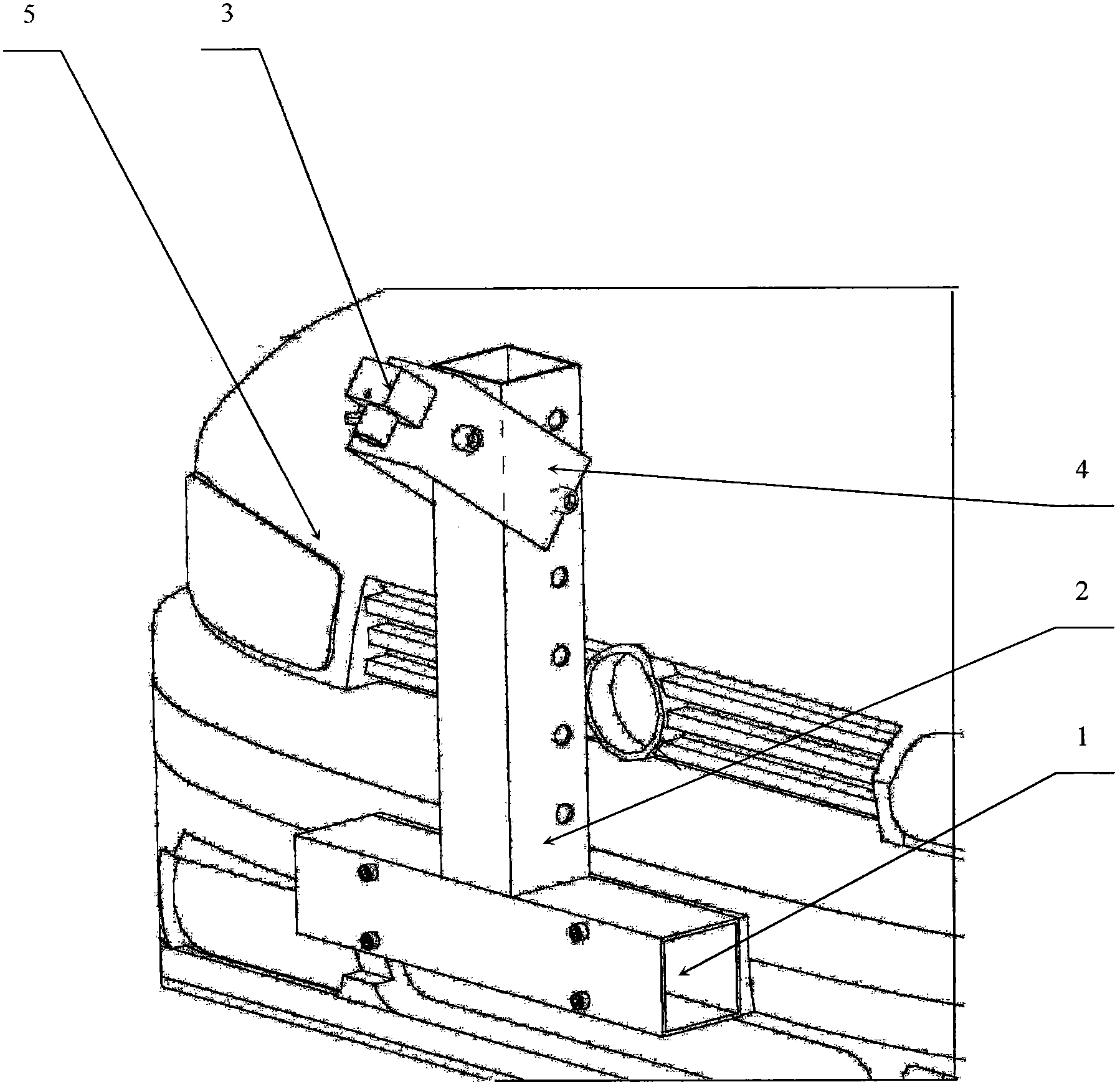

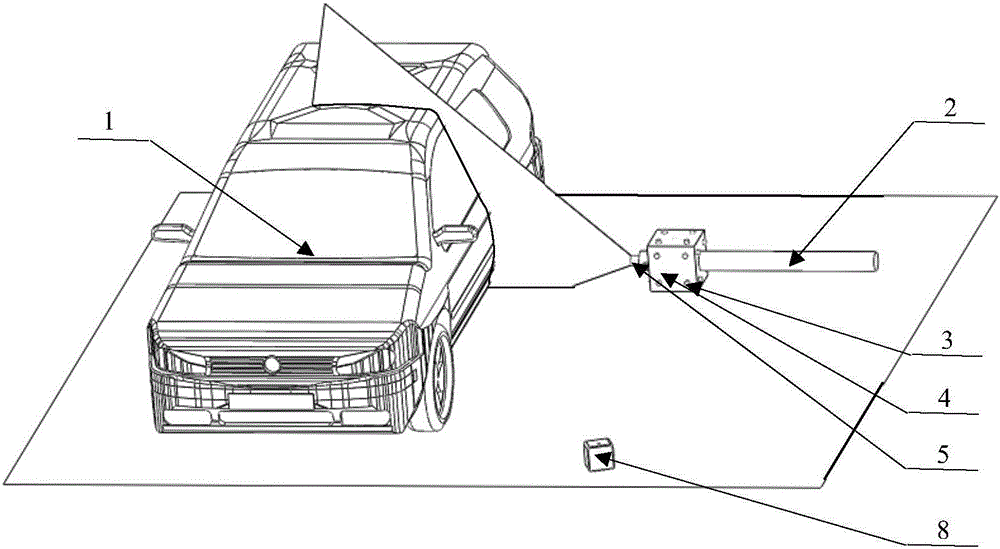

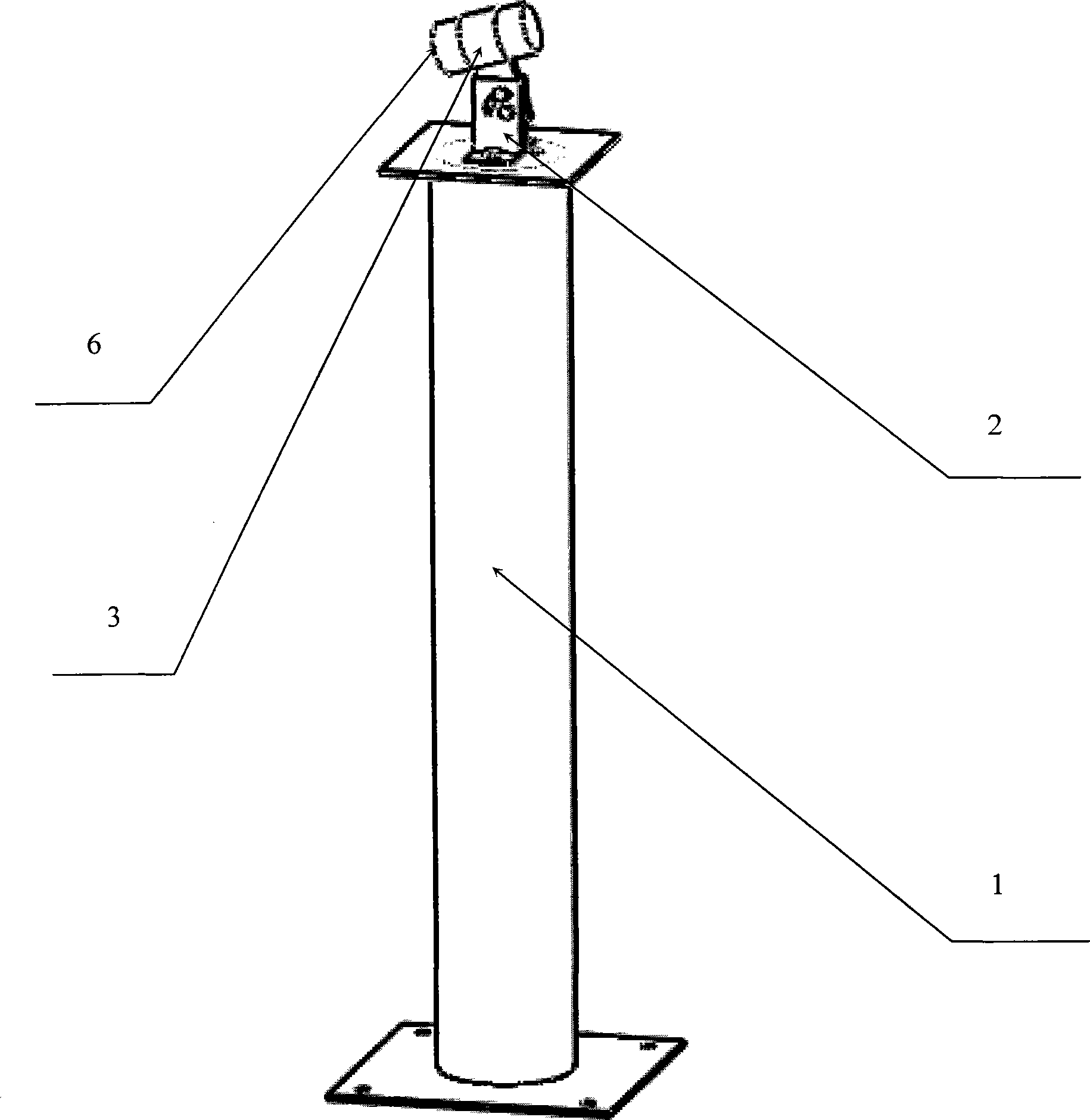

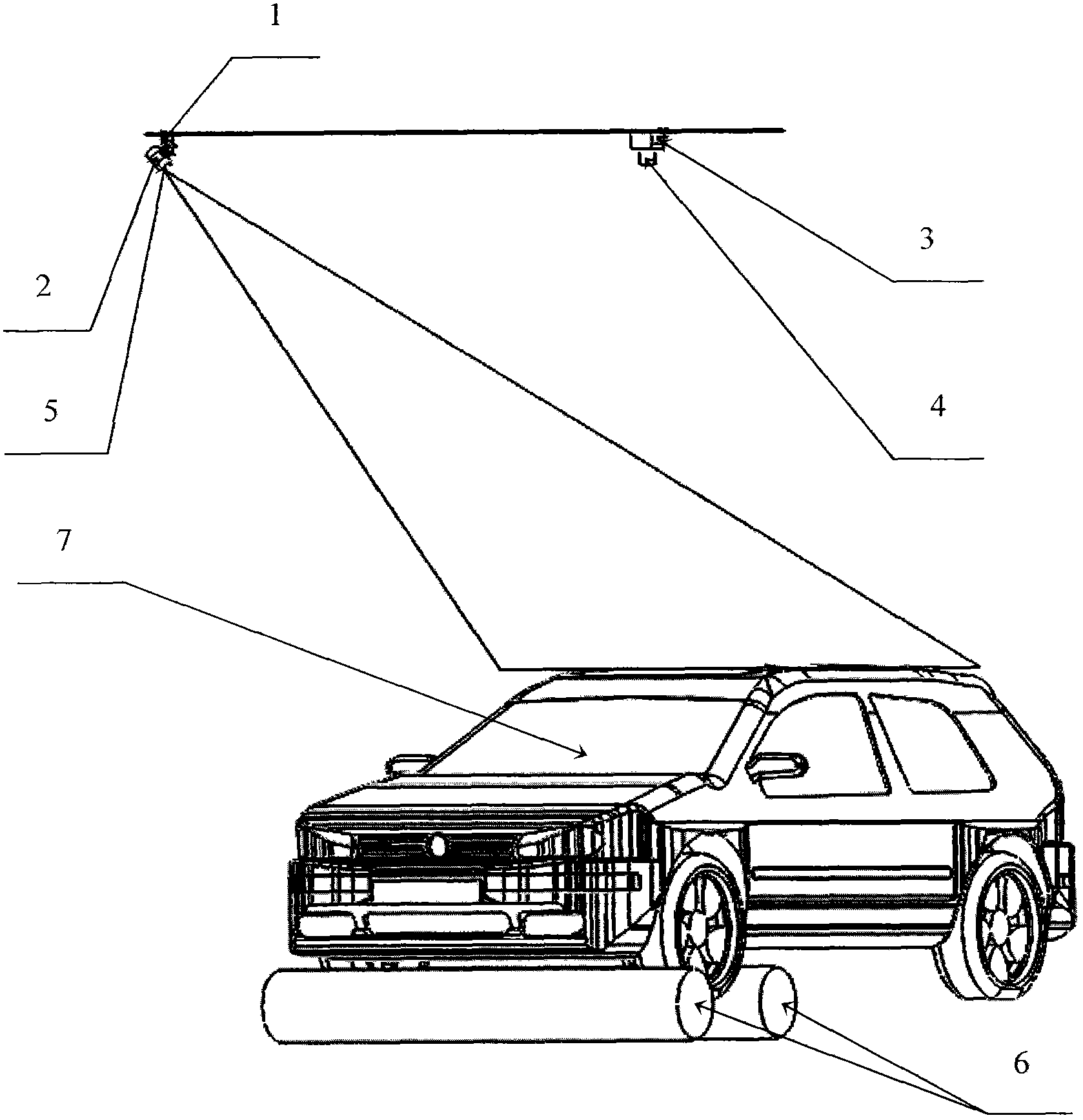

Laser ground projection type commercial car body length initiative visual detection system

InactiveCN103196377AAvoid interferenceReduce processingVehicle testingUsing optical meansMachine visionEngineering

The invention discloses a laser ground projection type commercial car body length initiative visual detection system which aims at solving the problems that length direction image collection and initiative visual measurement of a whole large size commercial car can not be achieved. The system comprises a line projector assembly body base (1), a line projector seat (2), a line projector clamp (3), a camera seat (4), a camera (5), a line projector (6) and a drum-type braking test table (7). According to the laser ground projection type commercial car body length initiative visual detection system, a non-contact automatic measuring system capable of automatically collecting car body laser projecting rays and measuring the length of a car body through initiative machine visual sense.

Owner:JILIN UNIV

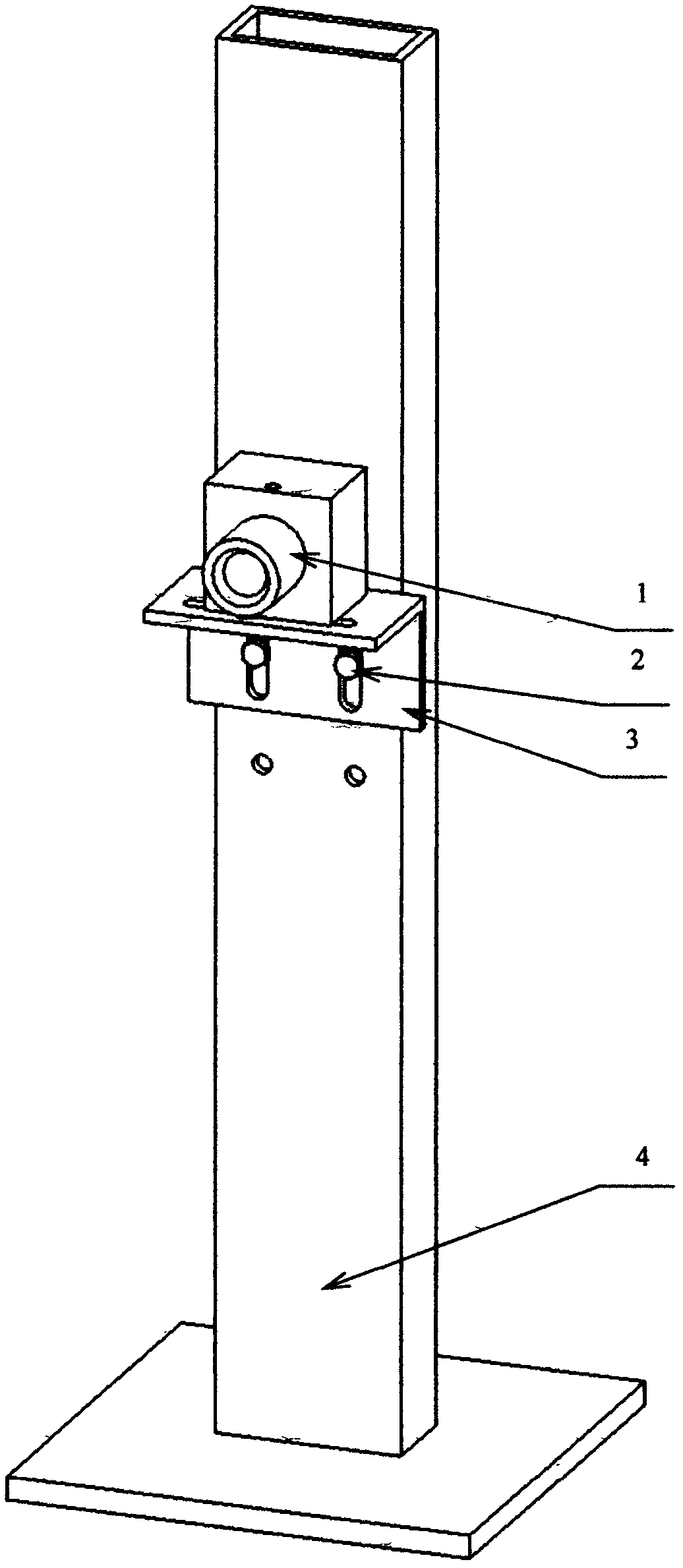

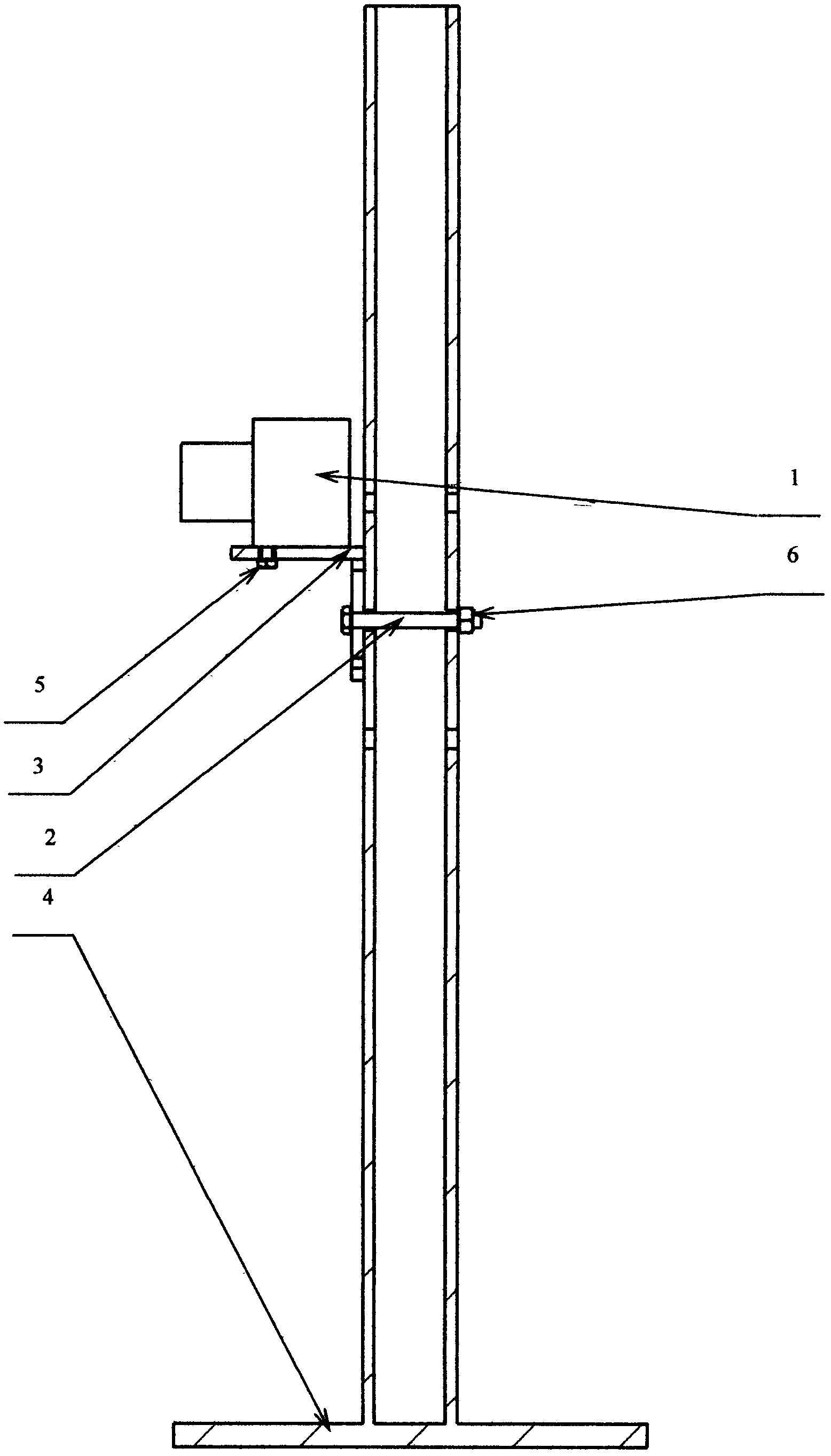

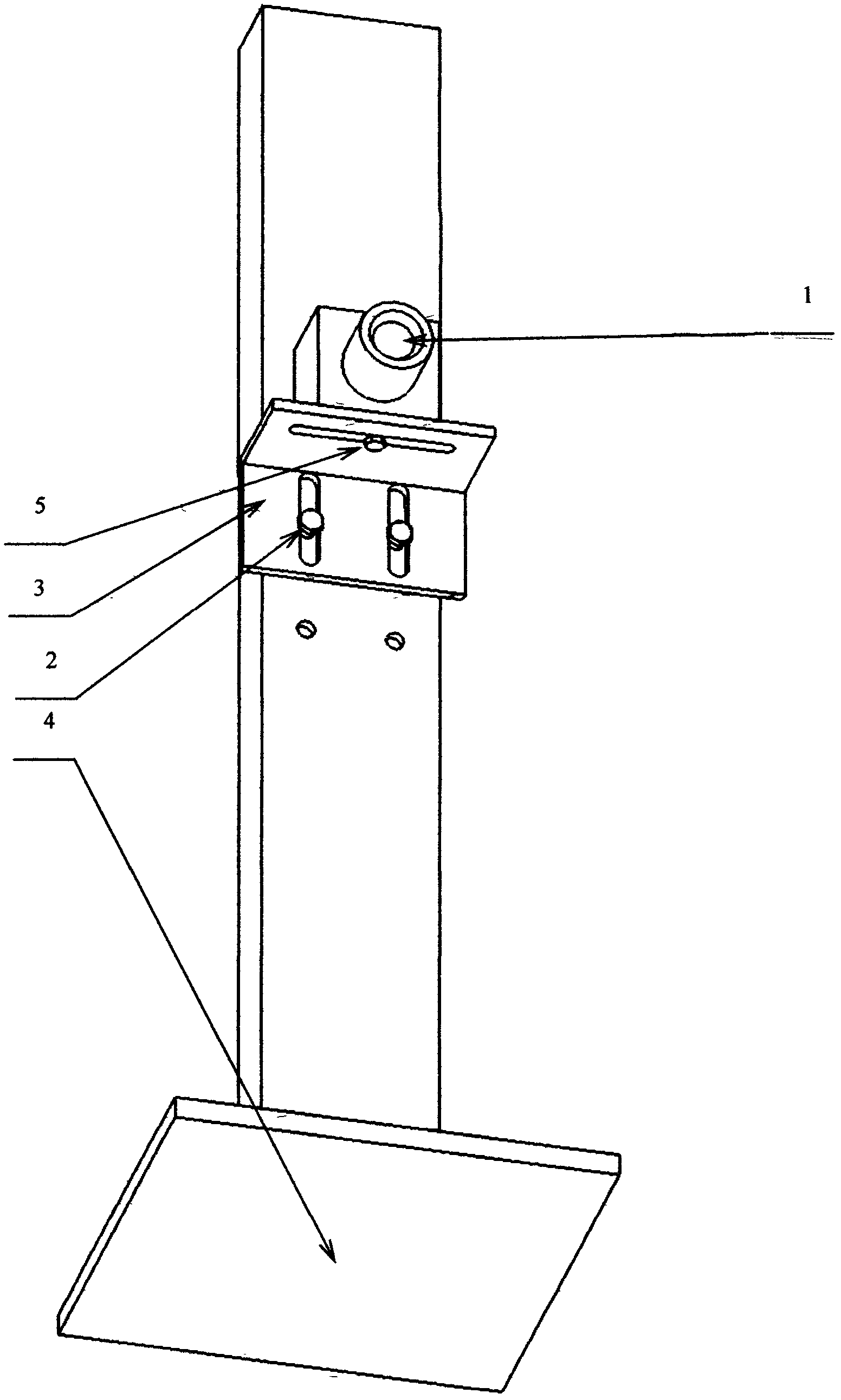

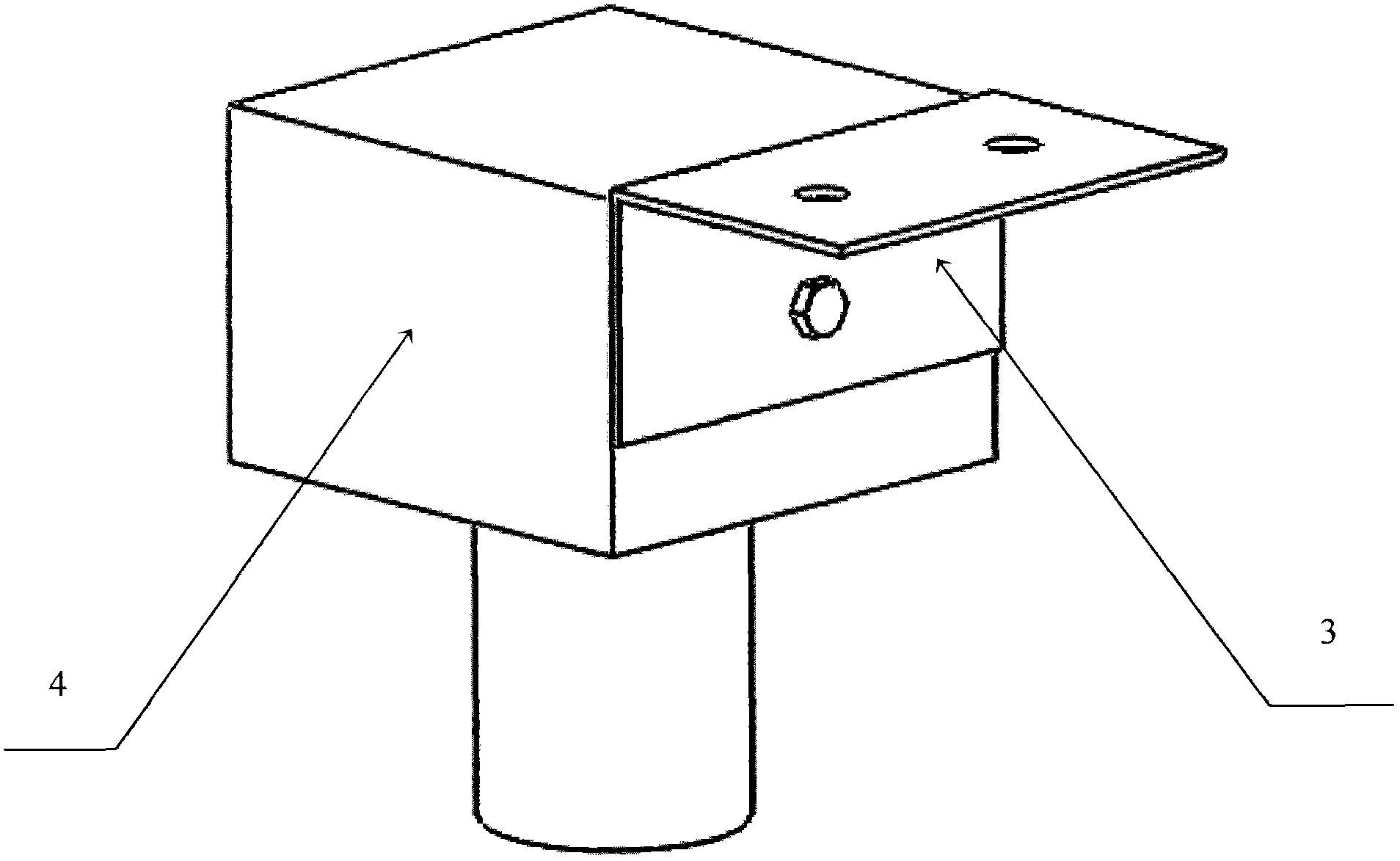

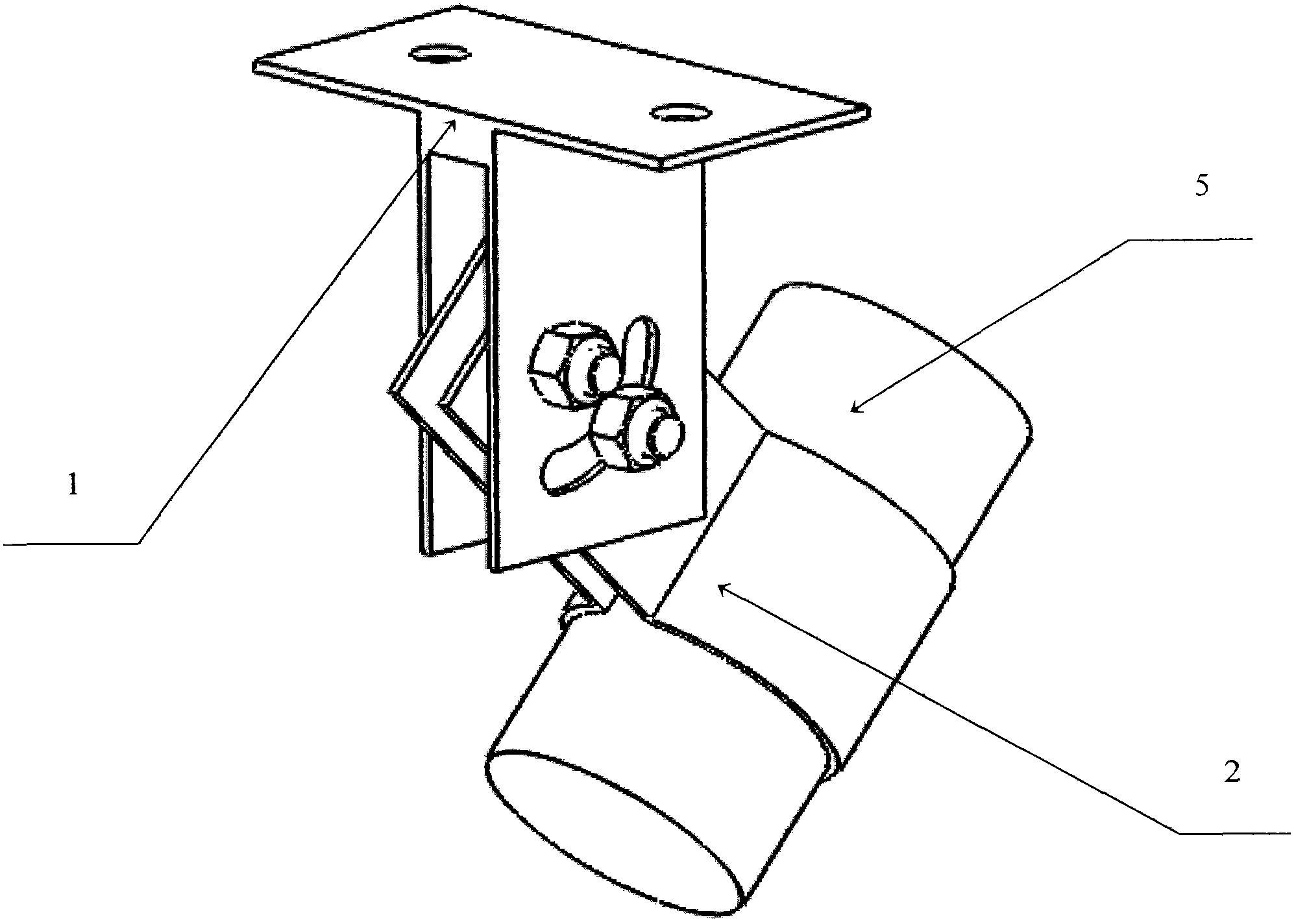

Position-adjustable camera assembly system

InactiveCN102628540AEasy to adjustAchieve installationStands/trestlesCamera body detailsEngineeringMeasurement precision

The invention discloses a position-adjustable camera assembly system, which aims to solve the problem that the assembly position of a camera cannot be adjusted in the measurement process. The system comprises a camera (1), a bracket fixing bolt (2), an adjusting bracket (3), a base (4), a camera fixing bolt (5) and a nut (6). The detection system can quickly adjust and assemble the camera in the industrial measurement process and has important significance of improving the measurement precision.

Owner:JILIN UNIV

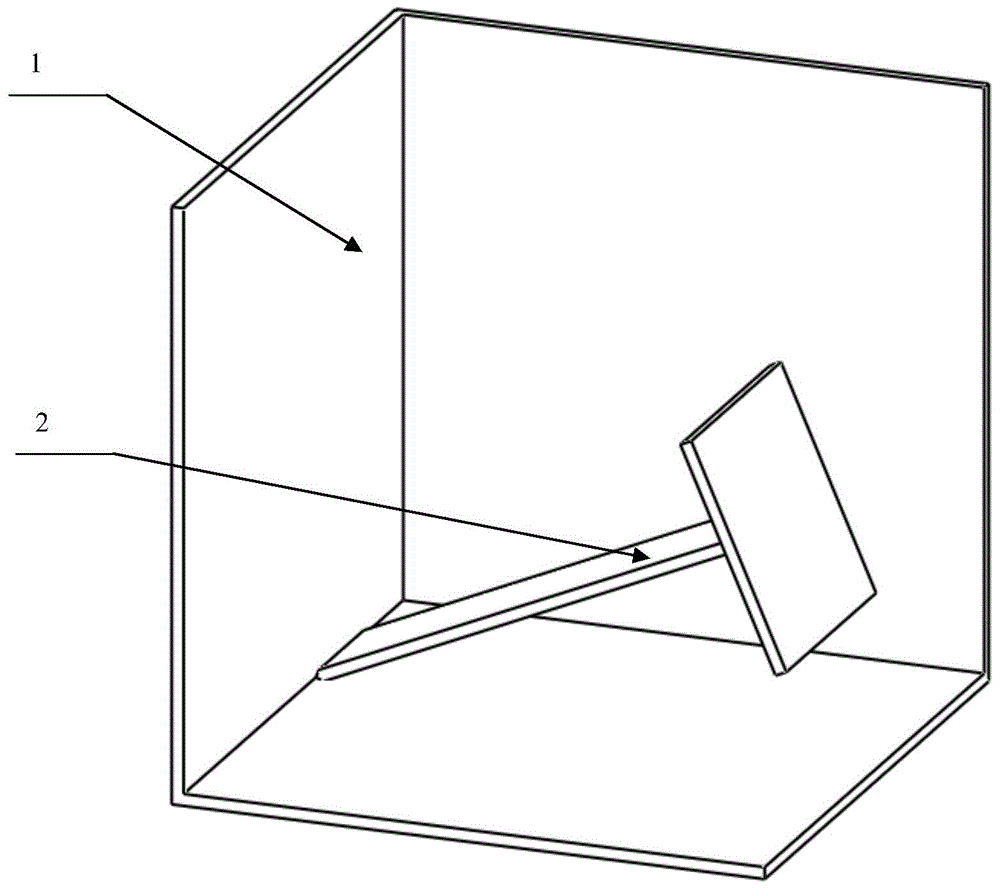

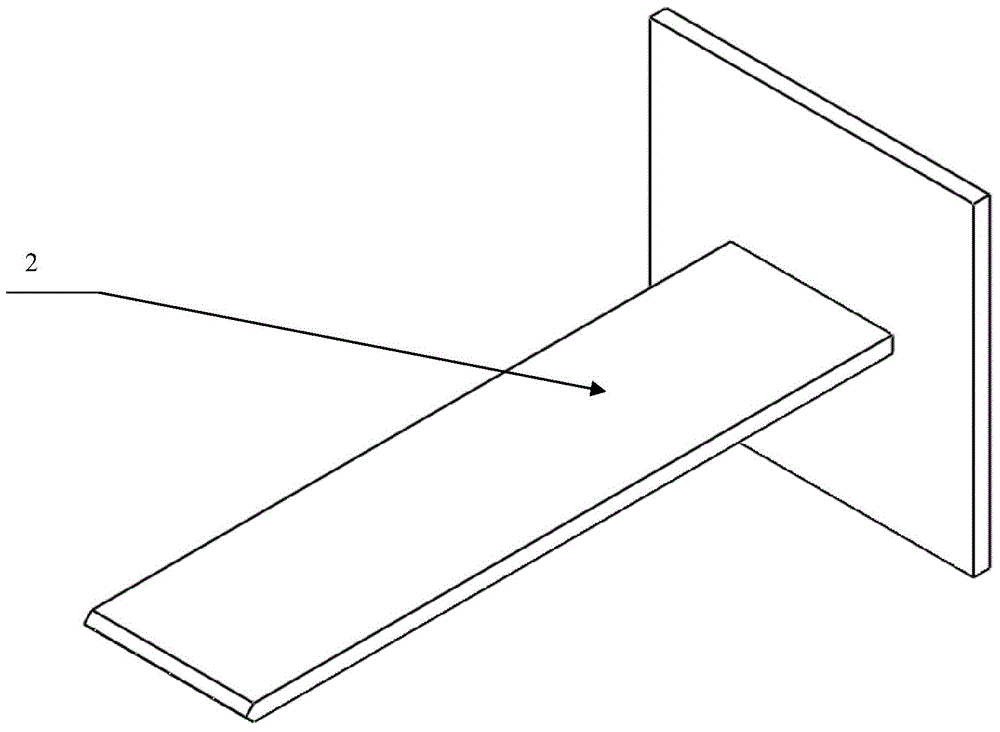

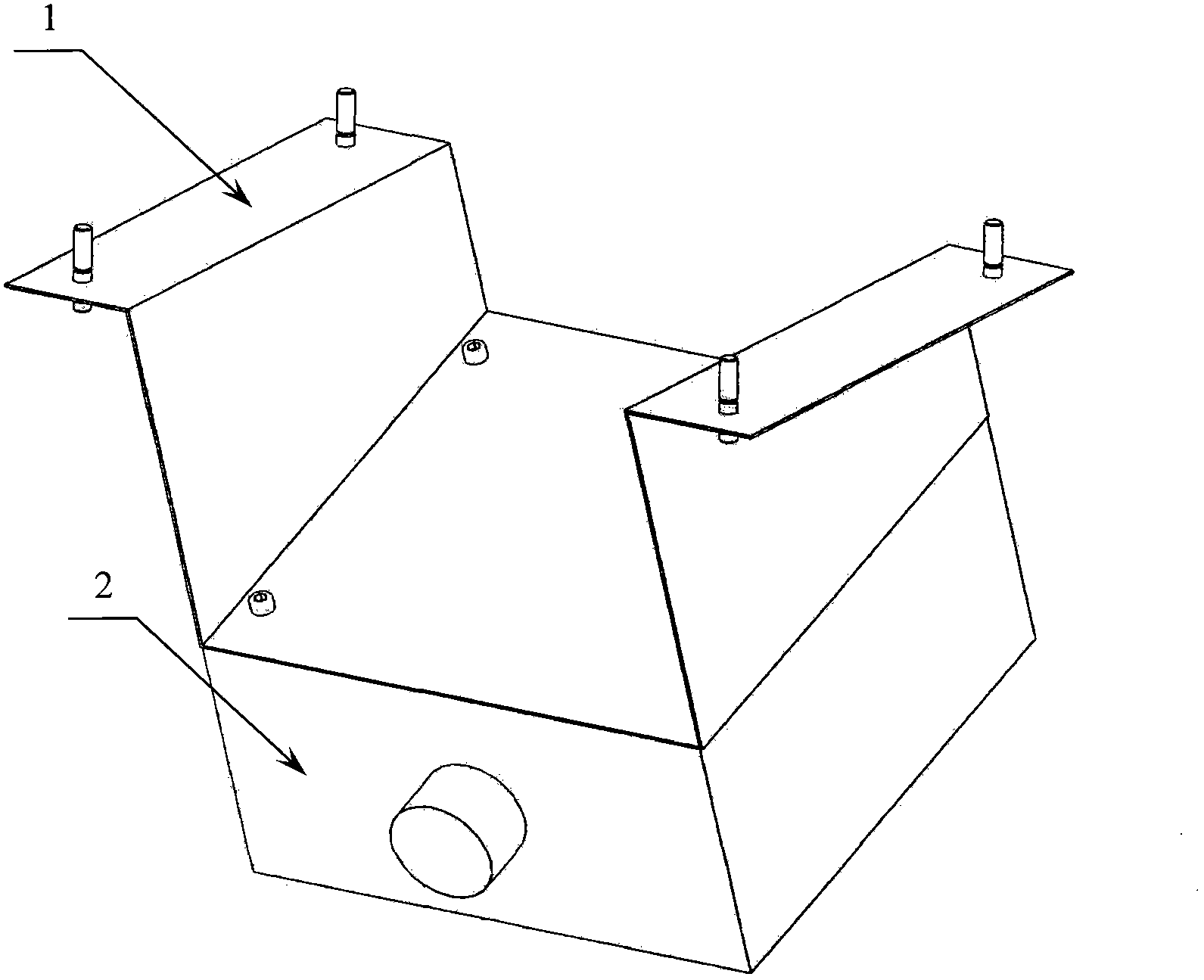

Automobile appearance detection structured light calibration system based on point to coordinate axis distance constraint

InactiveCN104374321AAchieve coincidenceImprove calibration accuracyUsing optical meansFeature completeVisual perception

The invention discloses an automobile appearance detection structured light calibration system based on point to coordinate axis distance constraint and aims at solving the problem that a laser plane equation under a world coordinate system cannot be directly acquired through currently-existing calibration methods. The automobile appearance detection structured light calibration system is mainly composed of a three-dimensional calibration plate (1) and a T-shaped calibration plate (2). The automobile appearance detection structured light calibration system is simple in structure, high in detection accuracy, small in accumulative error, complete in function, simple and convenient to operate, easy to mount, high in universality, low in cost and reliable in performance, and can meet visual detection requirements on automobile bodies in automobile detection industry.

Owner:JILIN UNIV

Light filtering type finished automobile image acquiring system for automobiles

InactiveCN102944175AExpand collection rangeHigh Acquisition AccuracyUsing optical meansLight filterLarge size

The invention discloses a light filtering type finished automobile image acquiring system for automobiles, and aims to overcome the problem that the once rapid acquiring and processing on a large-size service finished automobile image in the length direction can not be realized. The system comprises a base (1), a light filter base (2), a camera base (3), a line laser base (4), a convex lens base (5), a convex lens (6), a light filter (7), a camera (8) and a line laser (9). The light filtering type finished automobile image acquiring system for the automobiles can automatically cast mark lines, acquires effective light bar images, and is small in size, simple and convenient to operate, reliable in performance, high in generality, easy to install, simple in system calibration, low in manufacturing cost and high in precision, and the requirements of national measurement and quality surveillance departments and production factories on acquiring the finished automobile images are met.

Owner:JILIN UNIV

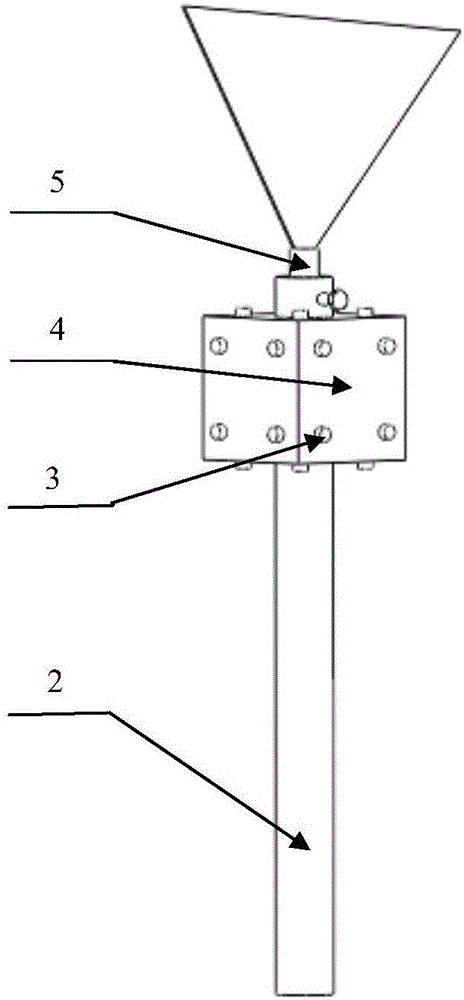

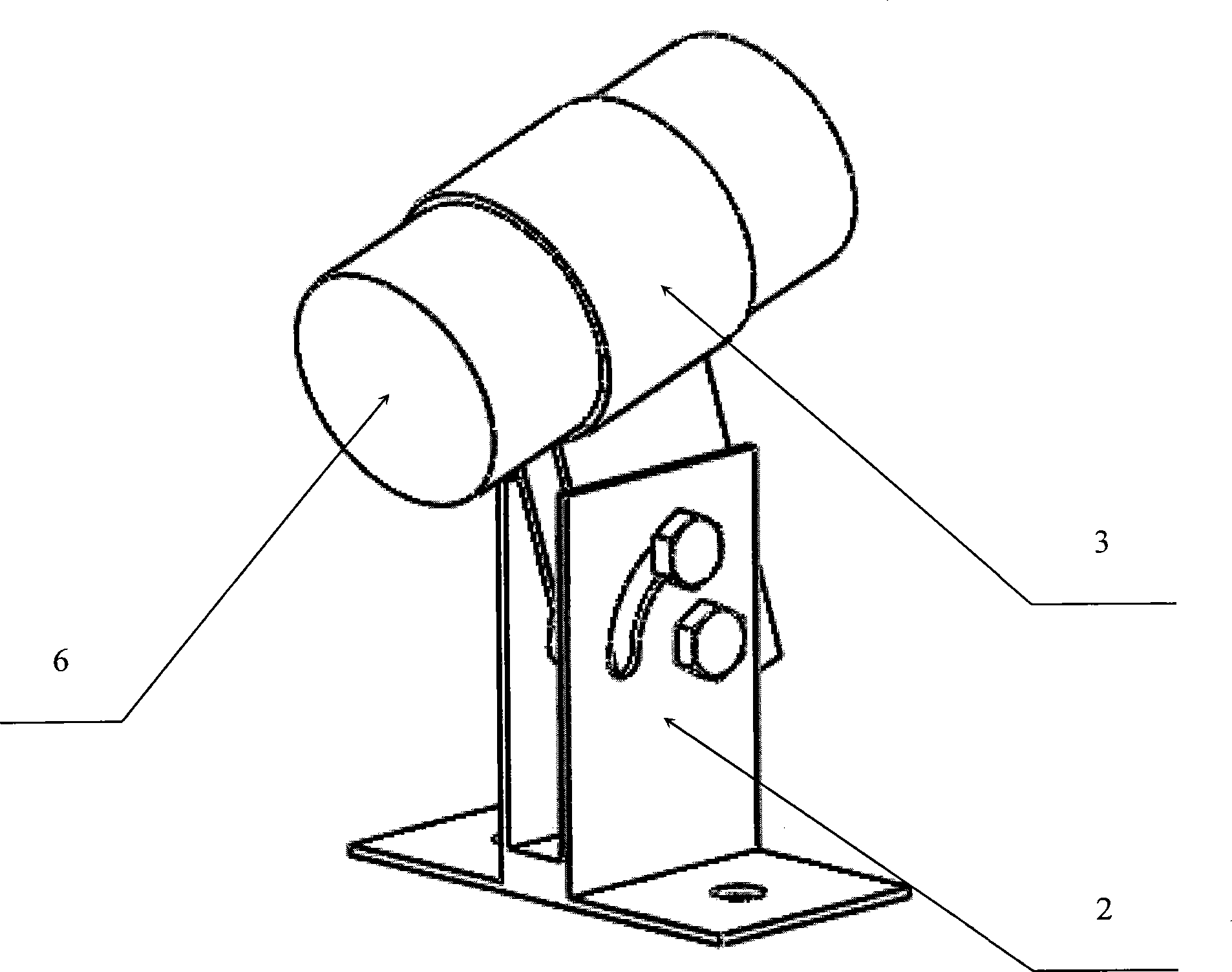

Body projection type commercial vehicle body length detection system based on active vision

The invention discloses a body projection type commercial vehicle body length detection system based on active vision, and aims to solve the problems that image acquisition of a large-sized commercial vehicle in the overall length direction and active vision measurement cannot be realized. The system comprises a line projector seat (1), a line projector clamp (2), a camera seat (3), a camera (4), a line projector (5) and a drum-type braking bench (6). The invention provides a noncontact automatic measurement system capable of automatically acquiring body laser projected lines through active machine vision and measuring the body length.

Owner:JILIN UNIV

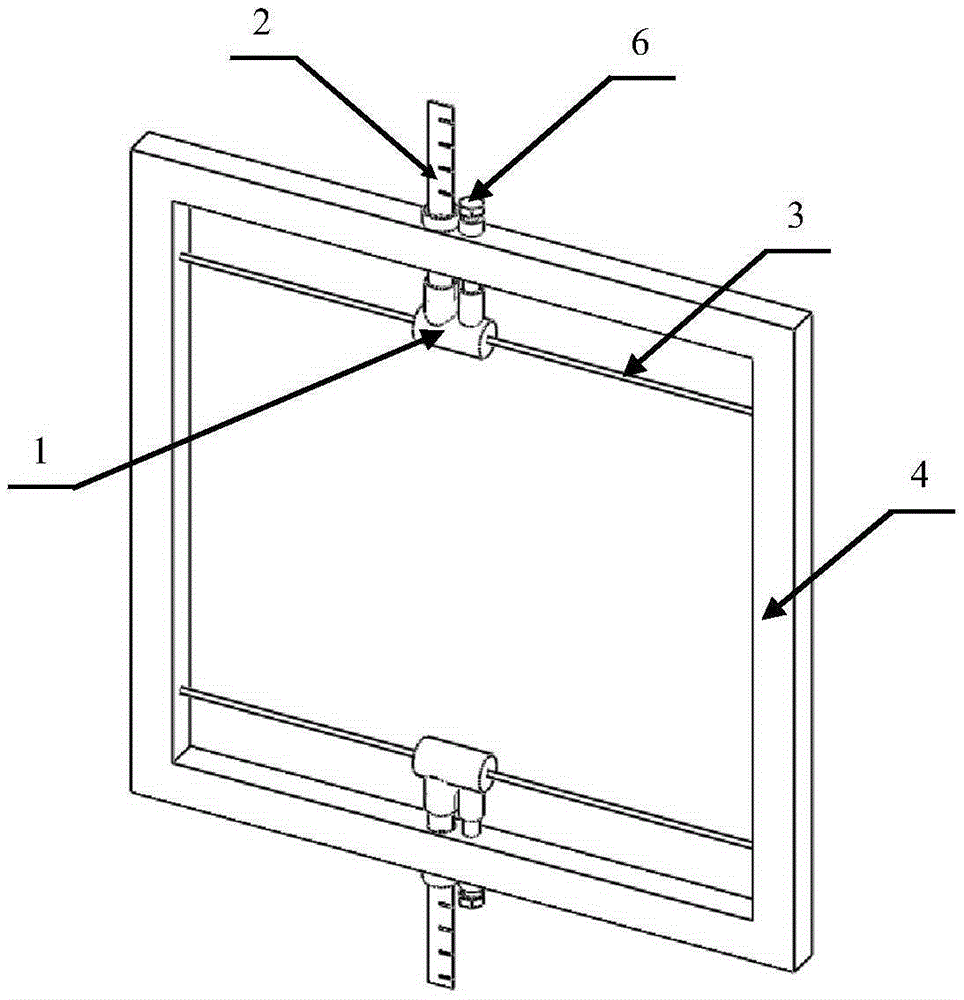

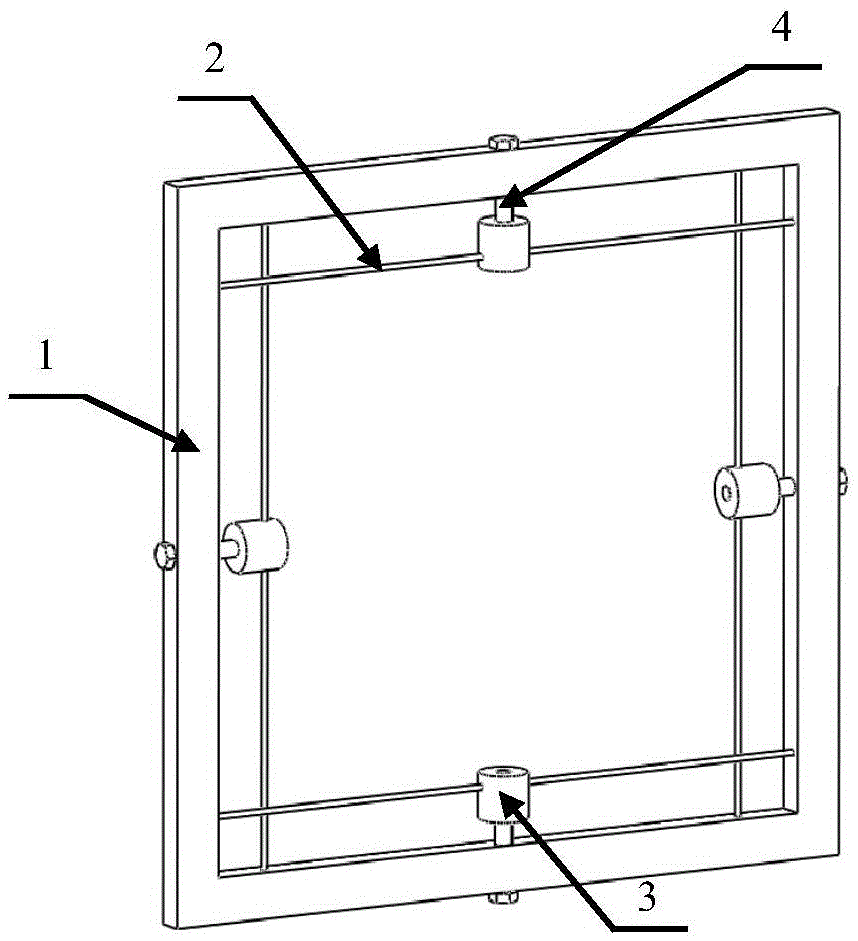

Scale type distortion coefficient measuring instrument for automobile topography measurement system

The invention discloses a scale type distortion coefficient measuring instrument for an automobile topography measurement system and aims to solve the problem that a camera lens distortion coefficient of an automobile topography visual detection system cannot be simply and conveniently measured. The scale type distortion coefficient measuring instrument for the automobile topography measurement system mainly comprises sleeves (1), scale rulers (2), steel wires (3), a square steel frame (4) and adjusting bolts (6); the steel wires in a distortion image are changed to be original straight lines by controlling stretching of the steel wires through the adjusting bolts (6), and the distortion coefficient is acquired according to displacement of the adjusting bolts (6). The scale type distortion coefficient measuring instrument for the automobile topography measurement system is simple in structure, high in detection accuracy, simple and convenient to operate, easy to mount, lower in cost and reliable in performance.

Owner:JILIN UNIV

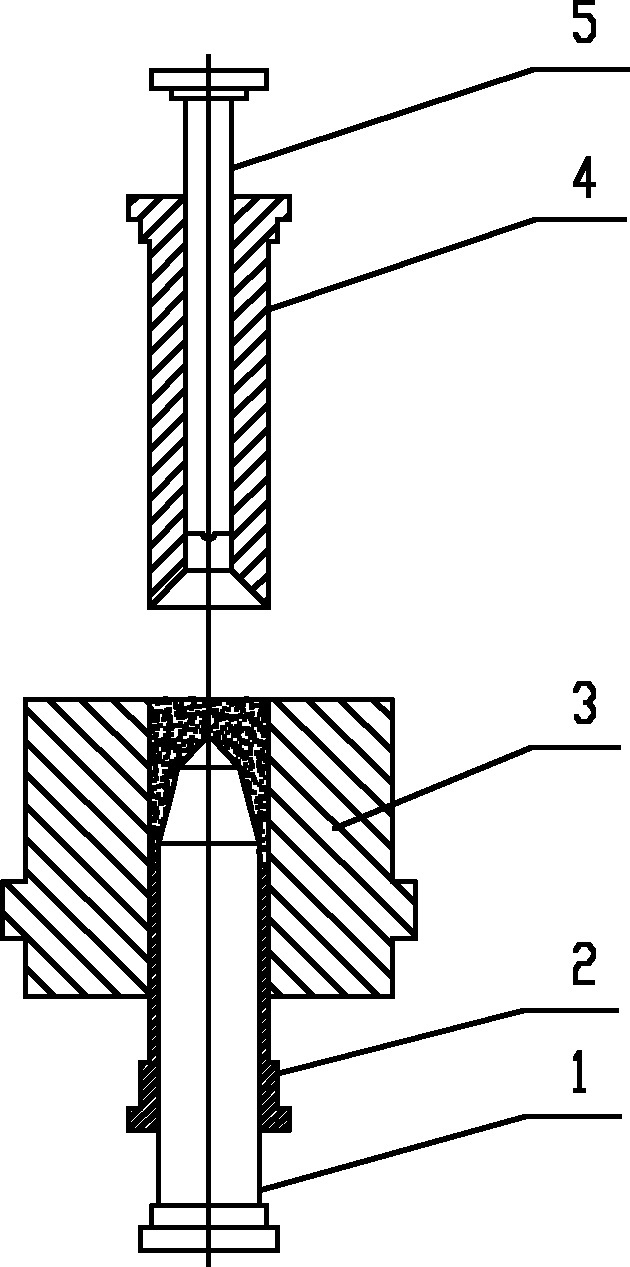

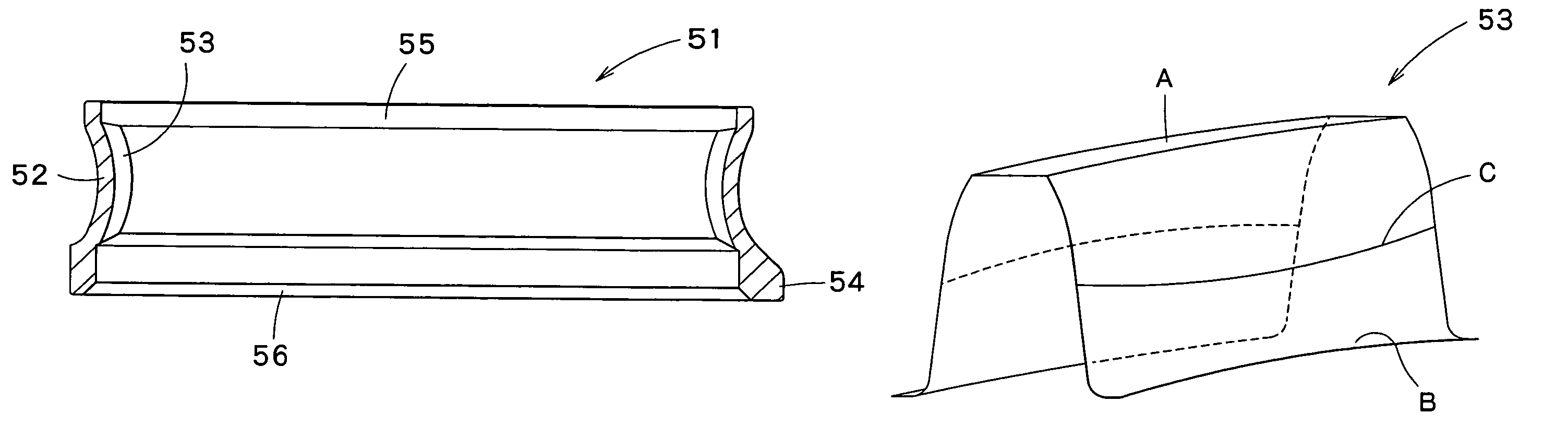

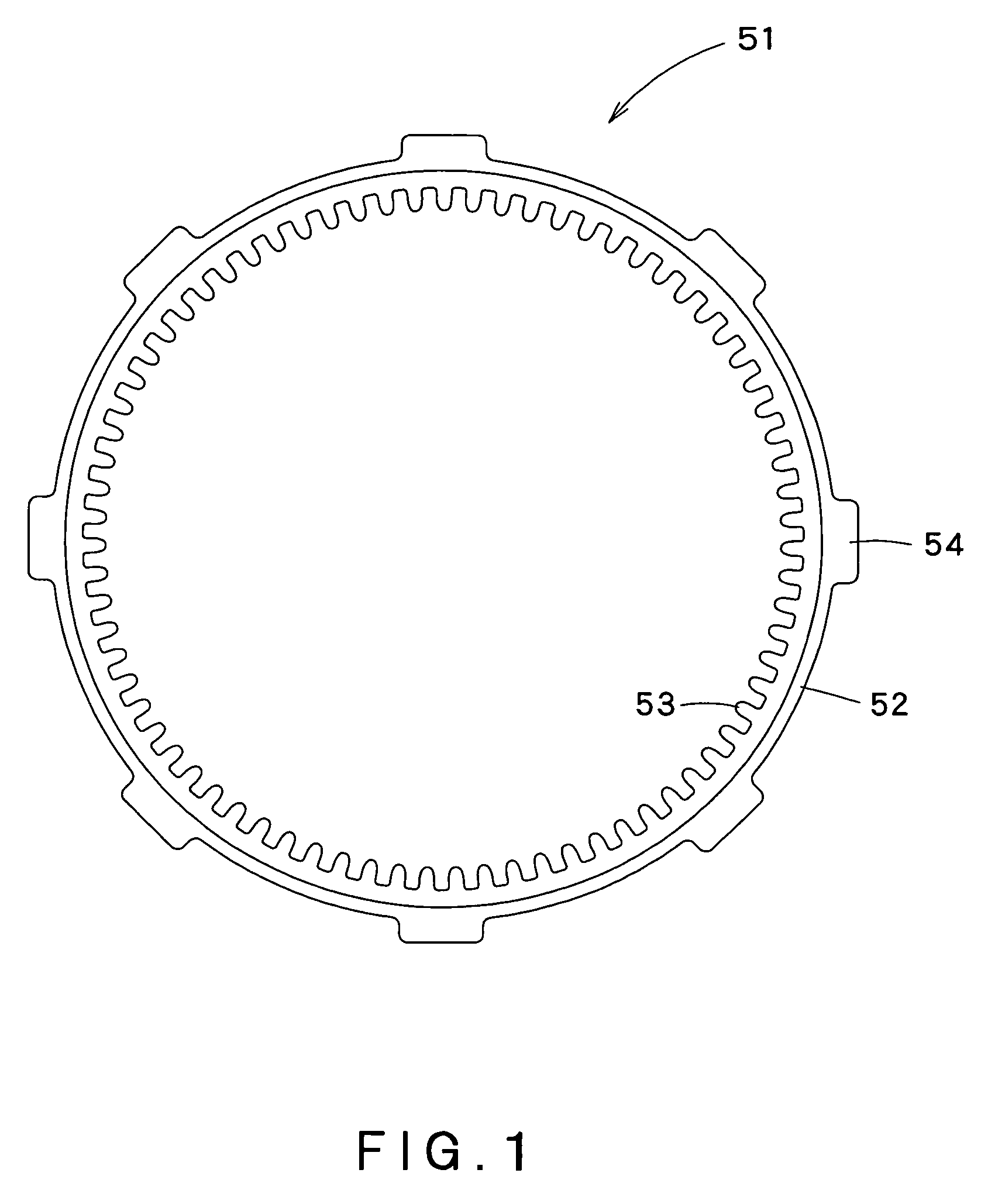

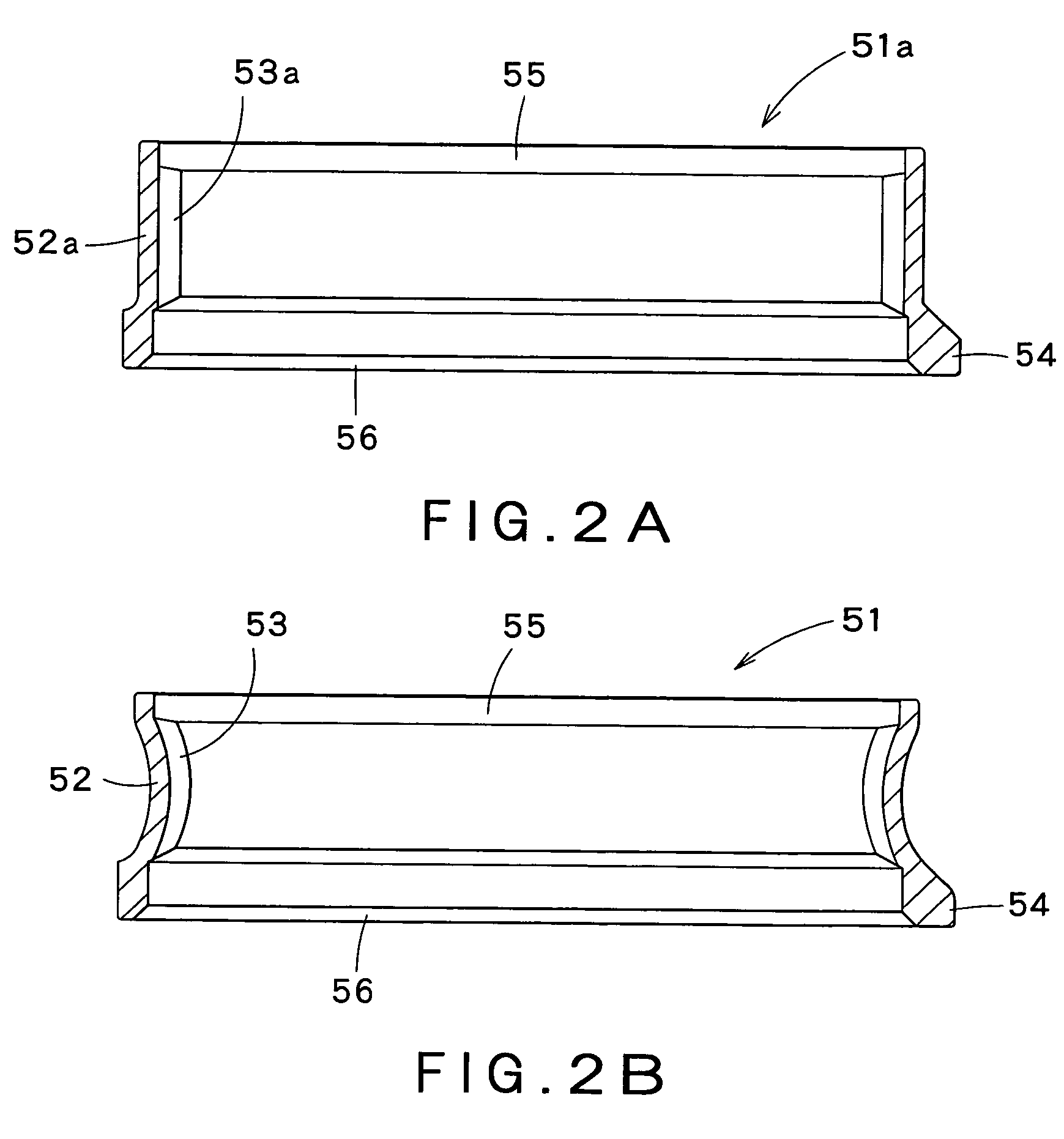

Forming method of tooth trace of gear

InactiveUS8006385B2Simple processing technologyLess machining processShaping toolsFurnace typesGear wheelEngineering

A forming method of a tooth trace of a gear according to the present invention includes: a first step of preparing a preformed gear made of metal including a cylindrical main body and a tooth part having a flat tooth flank having a uniform thickness in a tooth trace direction inside of the main body; and a second step of conducting a surface treatment locally to an outside surface of the main body in order to deform the outside surface of the main body in such a manner that the same becomes concave, so that a crowning bulging in the tooth trace direction is formed on the tooth flank of the tooth part.

Owner:MUSA PRECISION IND CO LTD

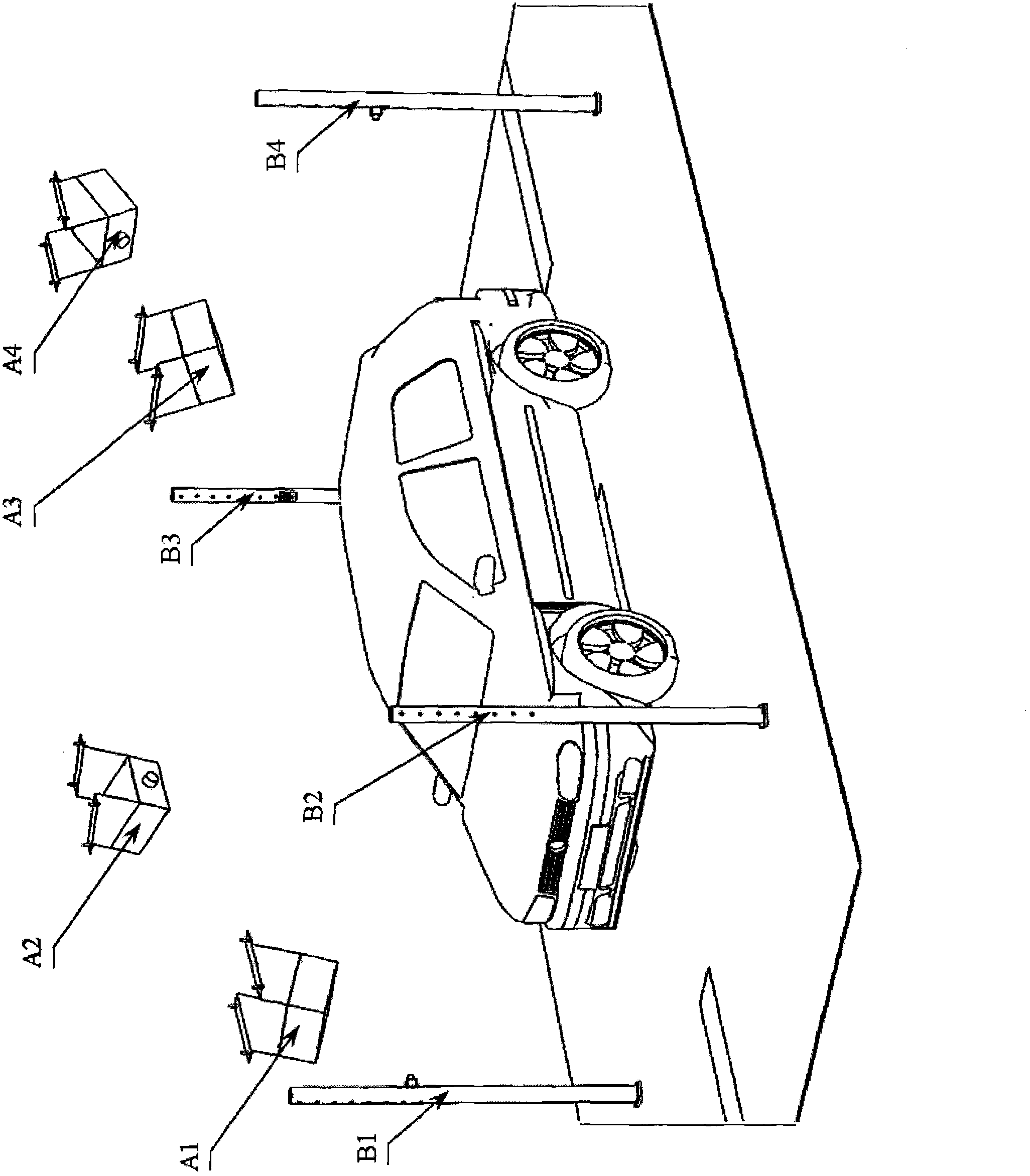

Automobile morphology grating field projection initiative vision measurement system

InactiveCN103196394AAvoid heavy laborImprove detection accuracyUsing optical meansGratingMachine vision

The invention discloses an automobile morphology grating field projection initiative vision measurement system and aims at solving the problem that road surface crack image collection and road surface condition evaluation can not be achieved. The automobile morphology grating field projection initiative vision measurement system comprises a front grating projection system (A1), a right grating projection system (A2), a left grating projection system (A3), a back grating projection system (A4), a front-right image collection system (B1), a front-left image collection system (B2), a back-right image collection system (B3) and a back-left image collection system (B4). According to the automobile morphology grating field projection initiative vision measurement system, automobile morphology can be automatically reconstructed by machine vision through grating field projection construction feature points.

Owner:JILIN UNIV

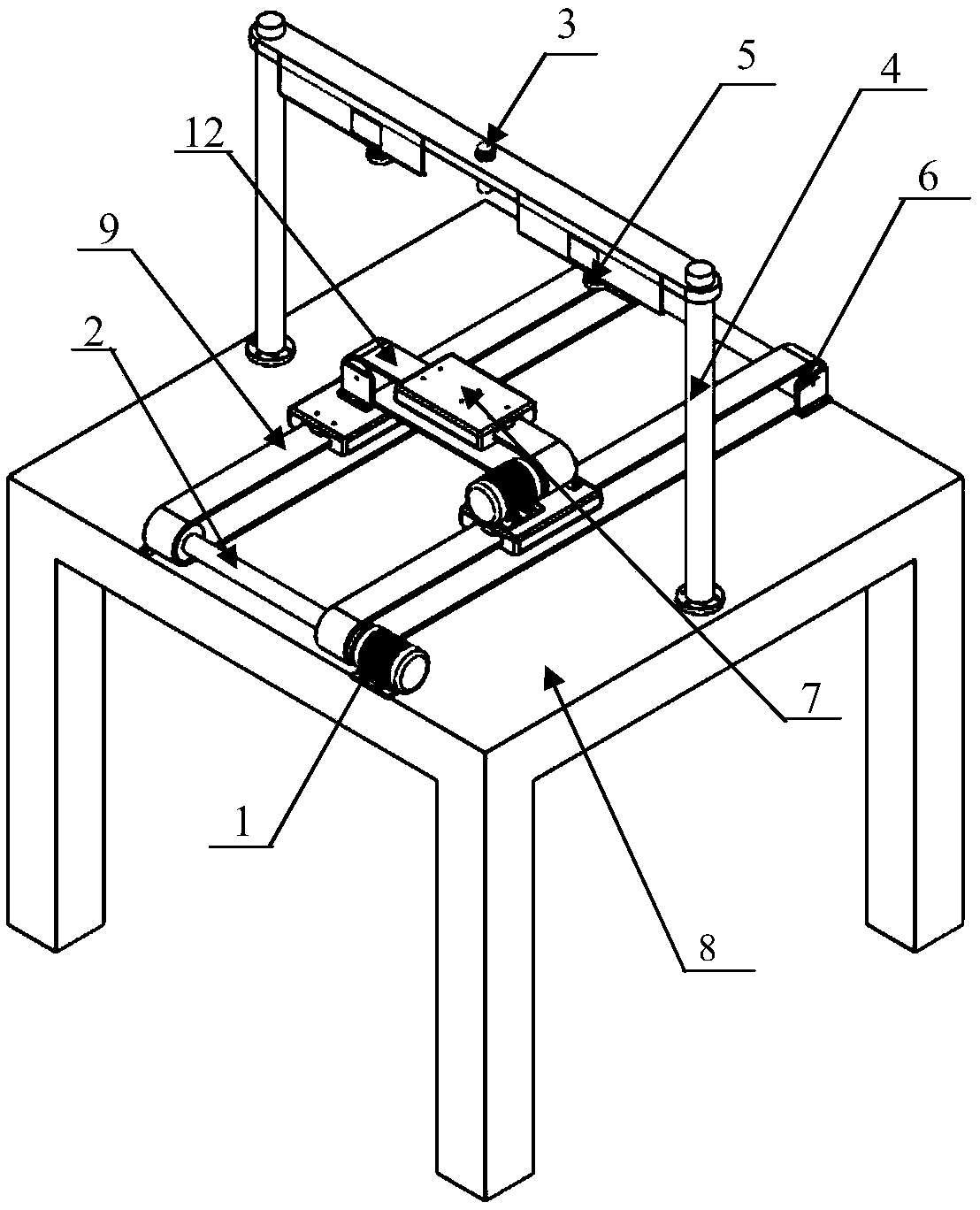

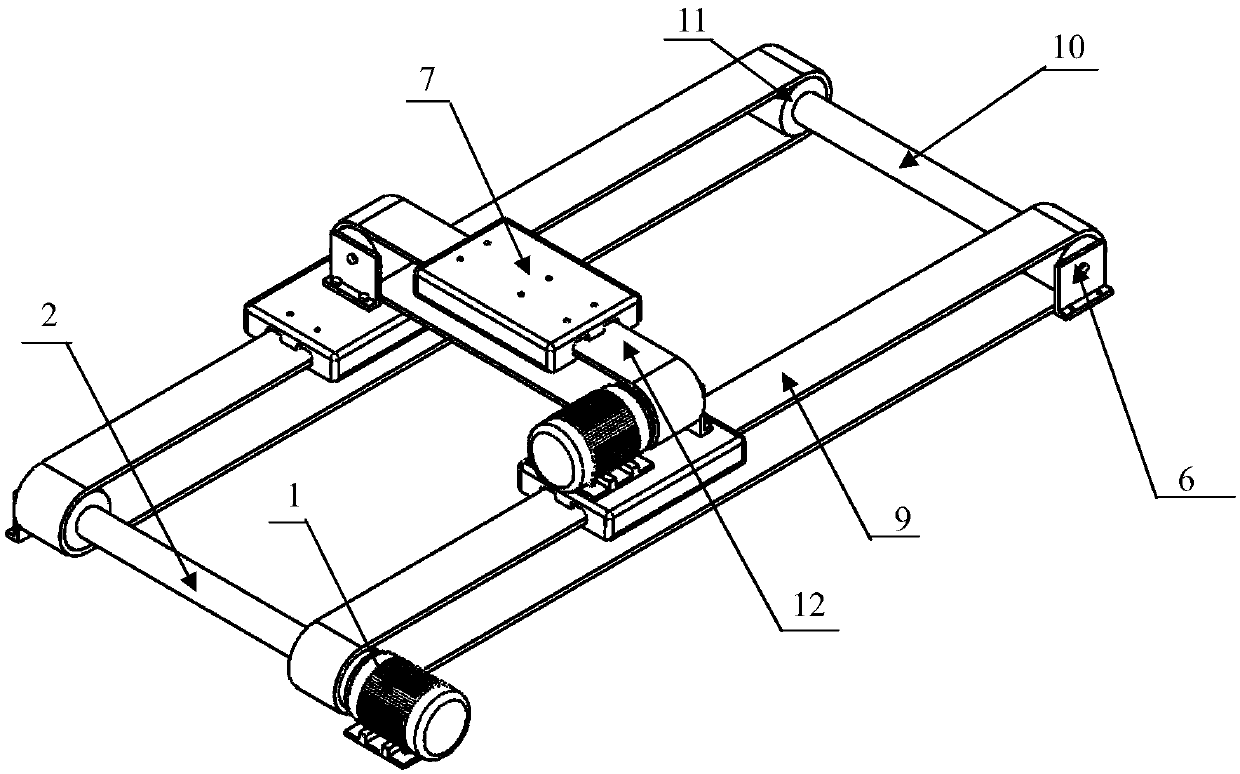

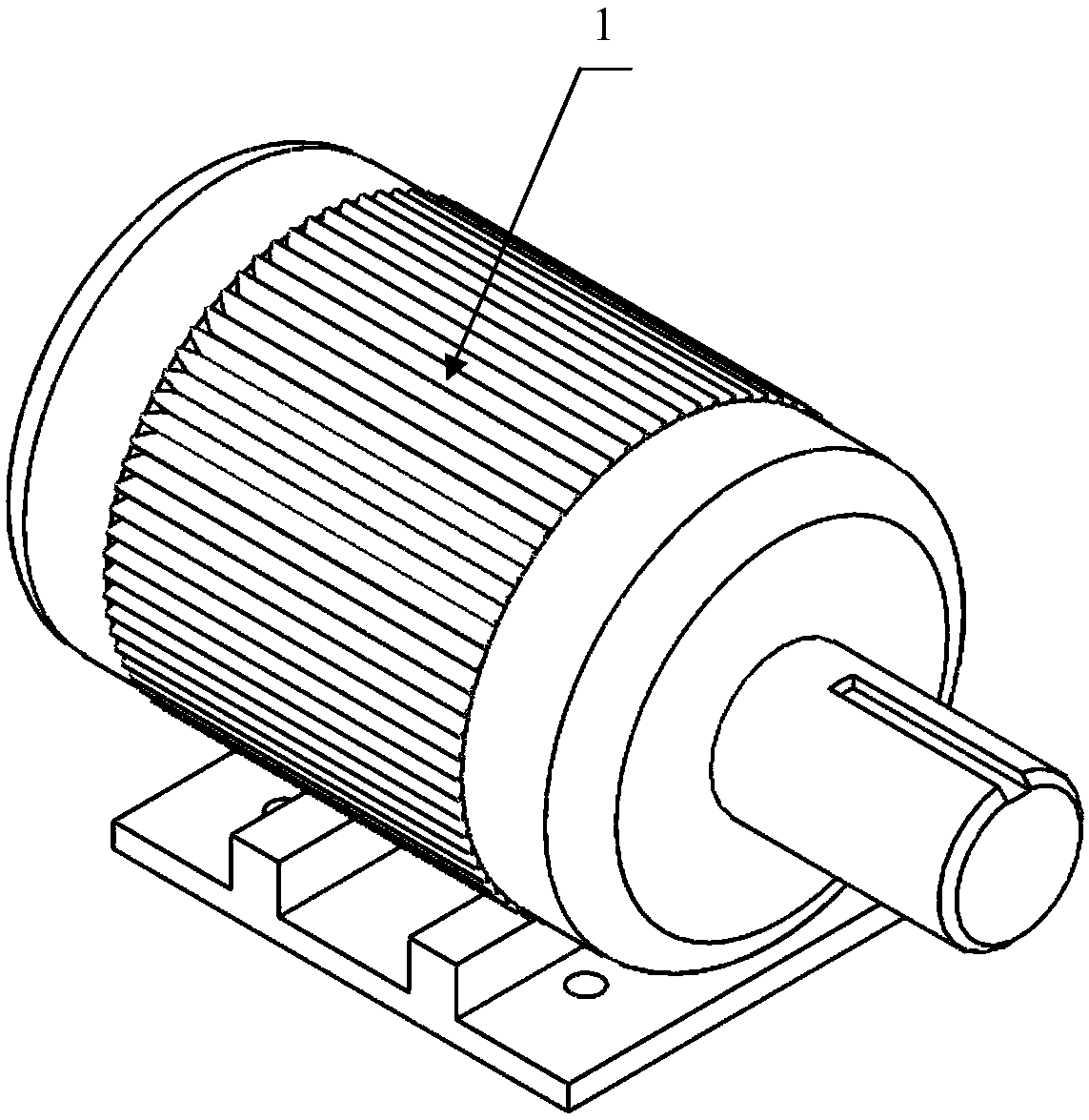

Orthogonal detection system for rail vehicle shaft end ground connection device wear extent

The invention discloses an orthogonal detection system for a rail vehicle shaft end ground connection device wear extent, and aims to solve the problem of the orthogonal detection of the rail vehicleshaft end ground connection device wear extent. The orthogonal detection system for the rail vehicle shaft end ground connection device wear extent mainly consists of a motor (1), a sliding rail driving shaft (2), a laser level (3), a gantry crane (4), line scan cameras (5), sliding rail fixing seats (6), a sliding block (7), a workbench (8), long synchronous belts (9), a sliding rail driven shaft(10), tooth-form belt wheels (11) and a short synchronous belt (12), wherein the laser level (3) is tightly pressed into a positioning hole on the top of the gantry crane (4); two line scan cameras (5) are independently sheathed into two C-shaped grooves on the top of the gantry crane (4); and the fields of view of two line scan cameras (5) coincide and are positioned on the laser plane of the laser level (3). The invention provides the orthogonal detection system, which has the advantages of simple structure and reliable performance, for the rail vehicle shaft end ground connection device wear extent.

Owner:JILIN UNIV

Clamping device for renewable automotive accumulator

InactiveCN102126483ASmooth rotationQuick clampingElectric propulsion mountingElectric/fluid circuitEngineeringRenewable resource

The invention discloses a clamping device for a renewable automotive accumulator in the field of renewable resource utilization of automobiles, aiming at solving the problems that the renewable automotive accumulator cannot be quickly and reliably clamped in a transporting process. The system comprises a handle (1), a pull rod (2), a steel wire rope (3), a clamp block (4), a spring (5) and a rotating shaft (6). The detection system can complete quick and reliable clamping and transportation on the renewable automotive accumulator.

Owner:JILIN UNIV

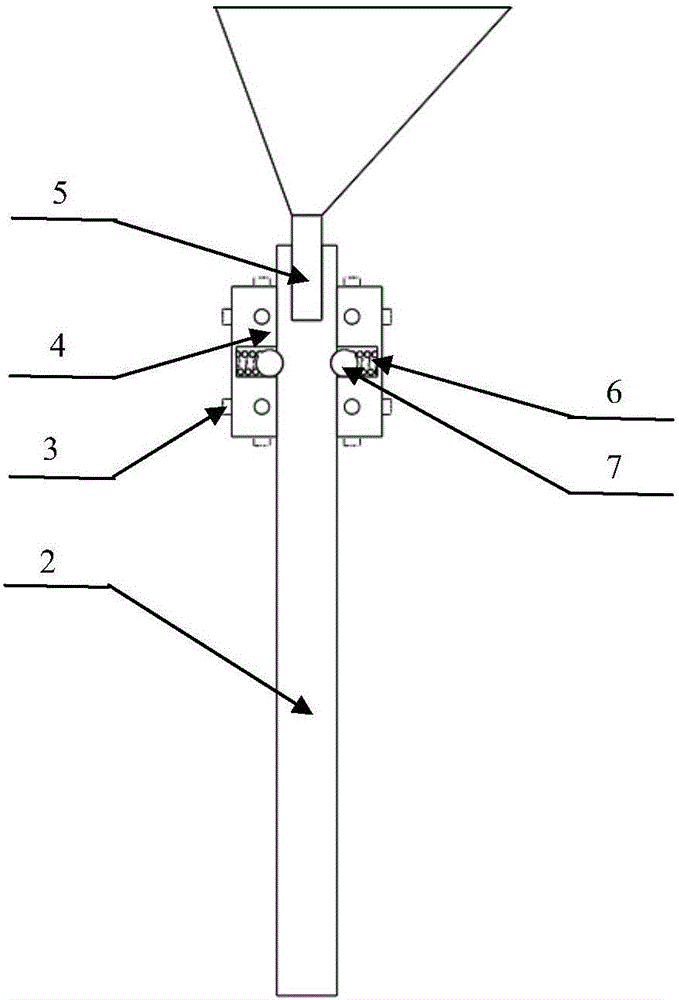

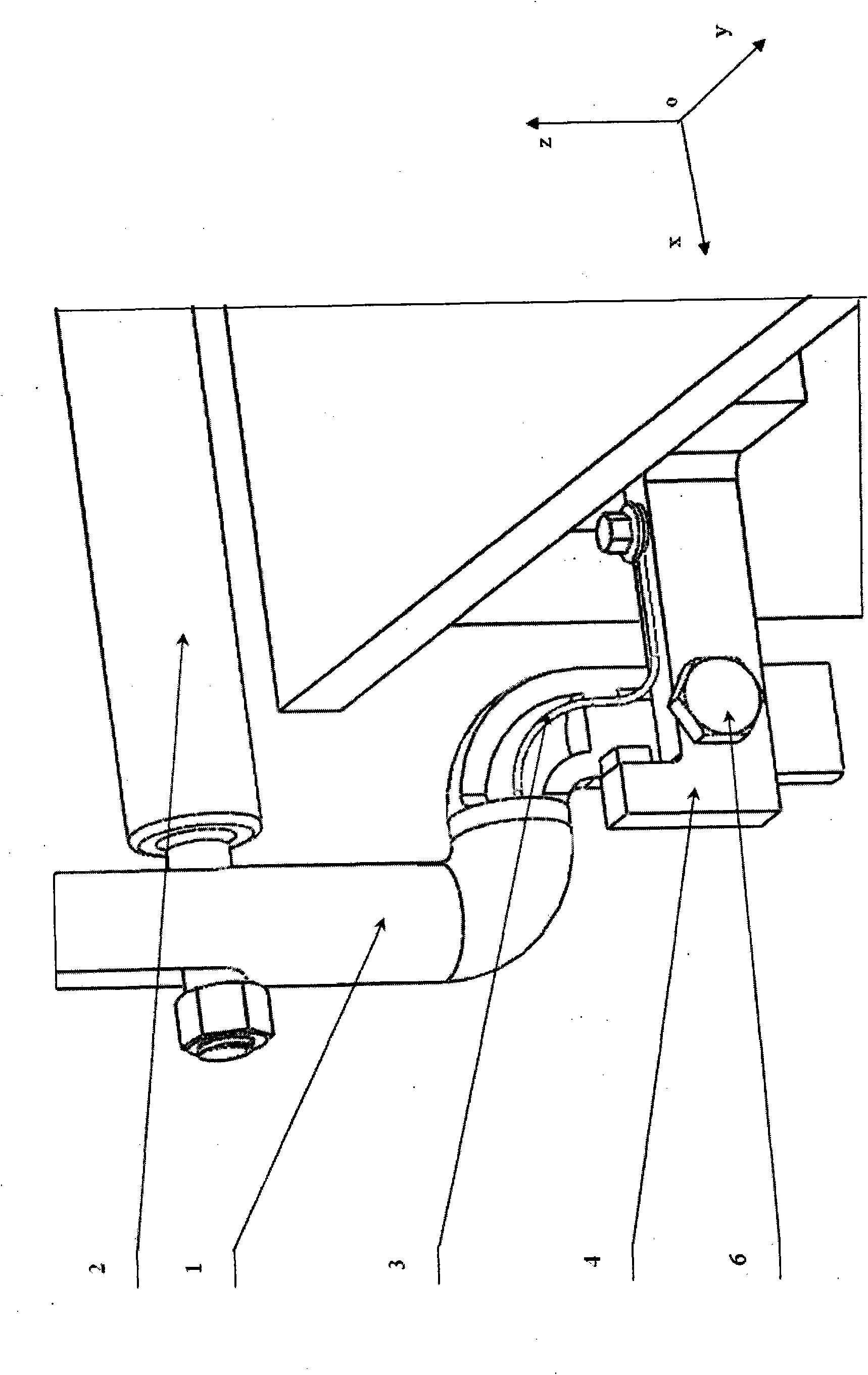

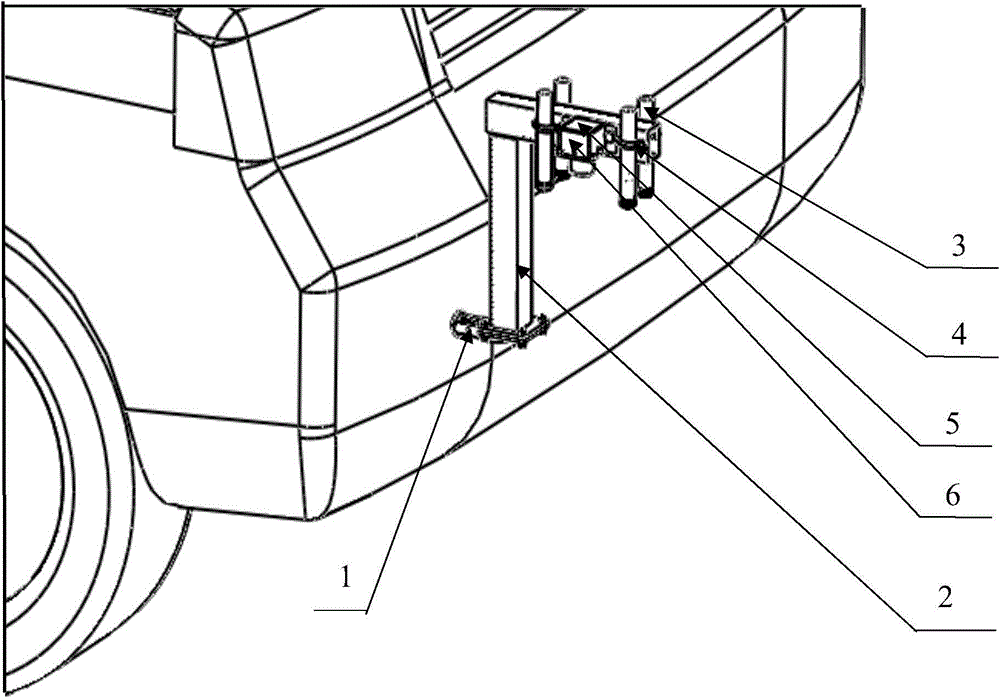

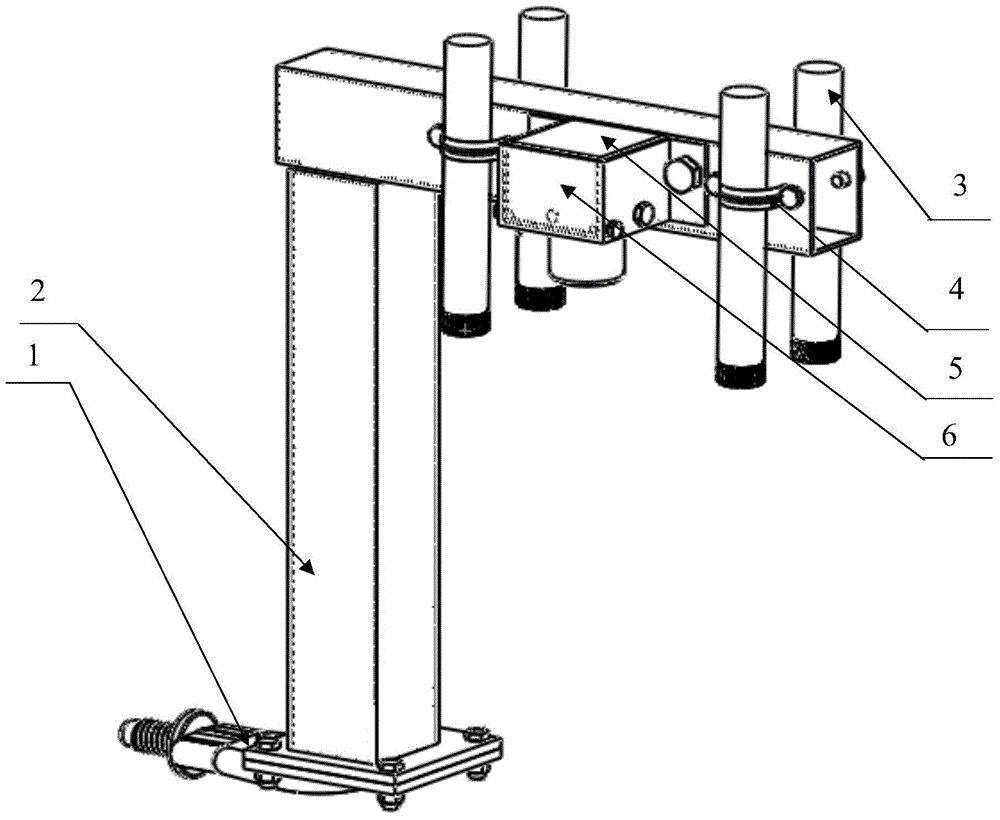

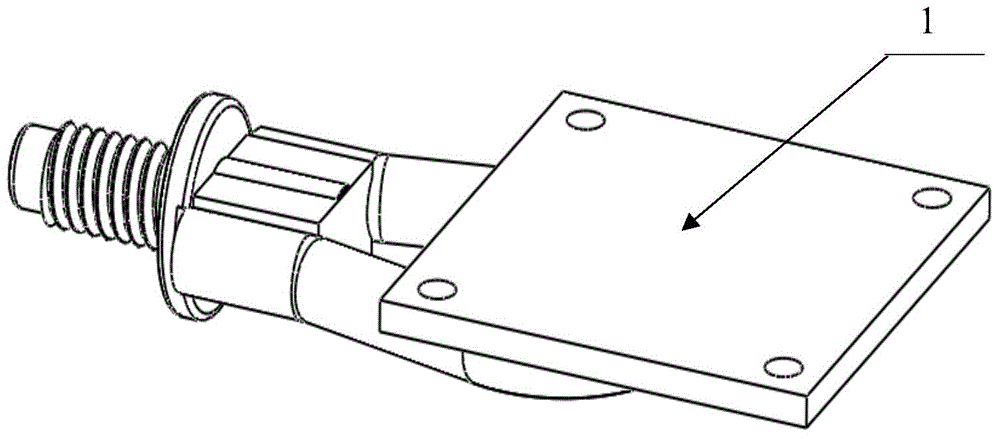

Linear structure light dynamic measurement benchmark-based vehicular pavement primary crack collection system

InactiveCN104359913AAchieve precise correctionAvoid heavy laborOptically investigating flaws/contaminationCollection systemRoad surface

The invention discloses a linear structure light dynamic measurement benchmark-based vehicular pavement primary crack collection system, and aims at solving the problem that a pavement crack image cannot be corrected in real time when an automobile is in a motion state. The linear structure light dynamic measurement benchmark-based vehicular pavement primary crack collection system comprises a draw hook frame (1), a bracket (2), a cast instrument (3), a cast instrument clamp (4), a vidicon (5) and a vidicon clamping plate (6). The linear structure light dynamic measurement benchmark-based vehicular pavement primary crack collection system disclosed by the invention is relatively low in cost, simple in structure, high in detection accuracy, simple to operate, easy to install and reliable in performance.

Owner:JILIN UNIV

Forming method of tooth trace of gear

InactiveUS20060021225A1Increase of machine processIncrease in costShaping toolsIncreasing energy efficiencyEngineeringTooth part

A forming method of a tooth trace of a gear according to the present invention includes: a first step of preparing a preformed gear made of metal including a cylindrical main body and a tooth part having a flat tooth flank having a uniform thickness in a tooth trace direction inside of the main body; and a second step of conducting a surface treatment locally to an outside surface of the main body in order to deform the outside surface of the main body in such a manner that the same becomes concave, so that a crowning bulging in the tooth trace direction is formed on the tooth flank of the tooth part.

Owner:MUSA PRECISION IND

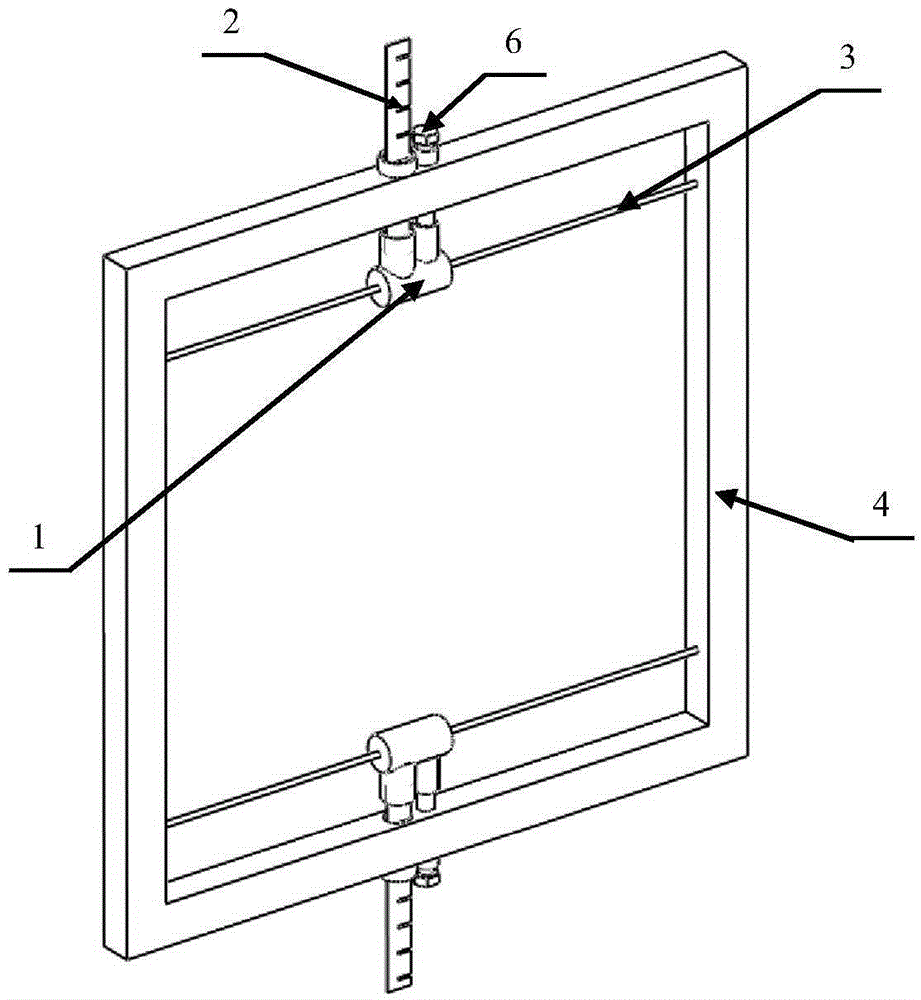

Automobile morphology measurement system mechanical distortion coefficient measuring instrument

InactiveCN105423952ADistortion coefficient is convenient and fastDistortion coefficients can be easily and quickly obtainedUsing optical meansCamera lensMeasuring instrument

The invention discloses an automobile morphology measurement system mechanical distortion coefficient measuring instrument, and aims at solving the problem that an automobile morphology visual detection system camera lens distortion coefficient cannot be easily and conveniently measured. The automobile morphology measurement system mechanical distortion coefficient measuring instrument is mainly composed of a square frame (1), steel wires (2), sleeves (3) and adjusting screws (4). Stretching of the steel wires is controlled by the adjusting screws (4) so that steel wire images in distortion images are enabled to be changed into original straight lines, and the distortion coefficient is obtained according to the number of rotation turns of the adjusting screws (4). The automobile morphology measurement system mechanical distortion coefficient measuring instrument is simple in structure, high in detection precision, easy and convenient to operate, easy to install, relatively low in cost and reliable in performance.

Owner:JILIN UNIV

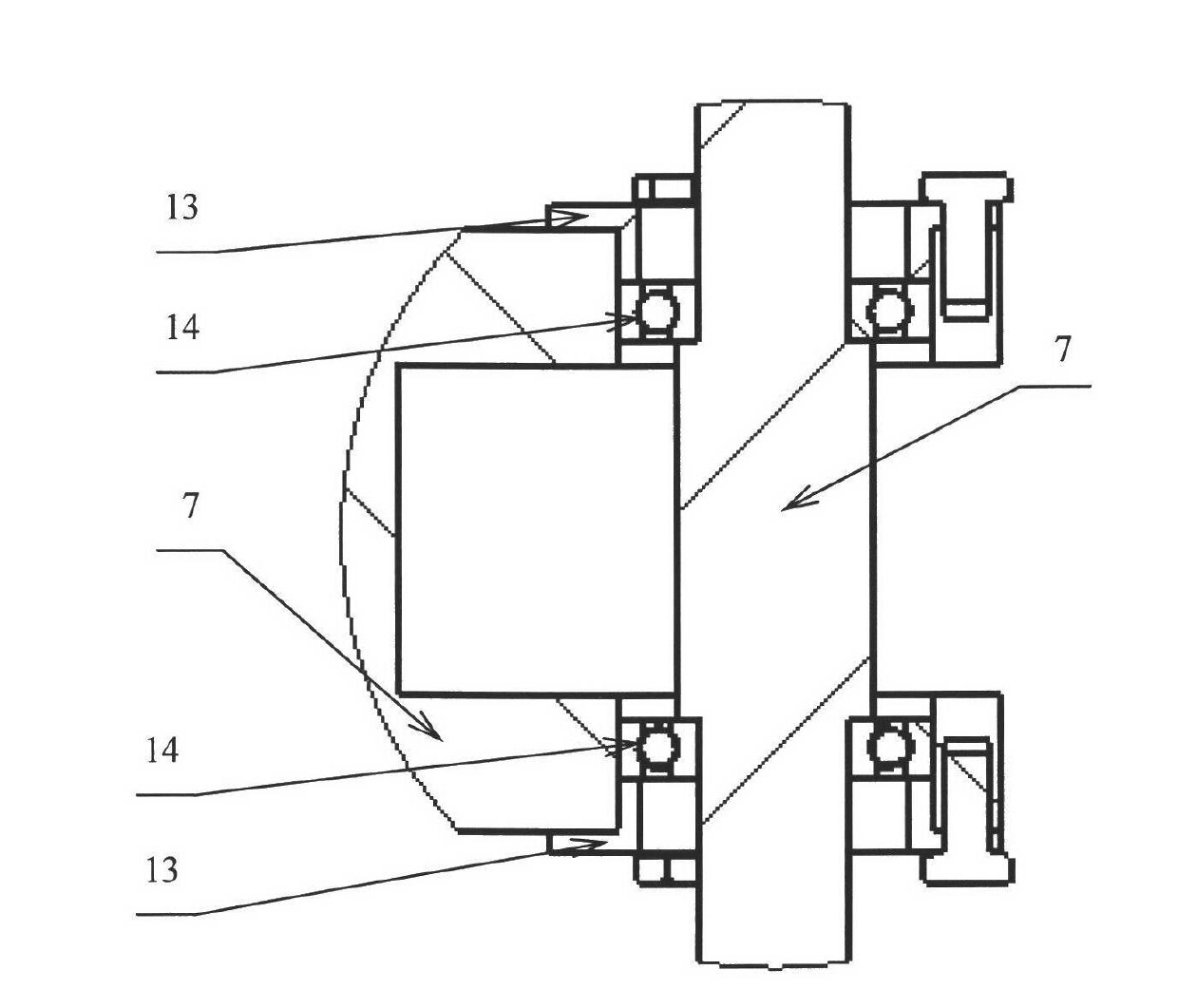

Quick calibrating apparatus for turning disc of automobile wheel positioning instrument

The invention discloses a quick calibrating apparatus for a turning disc of an automobile wheel positioning instrument, aiming at solving the problem that the turning disc of the automobile wheel positioning instrument can not be rapidly and accurately calibrated. The quick calibrating apparatus for the turning disc of the automobile wheel positioning instrument comprises a compression bar (1), asleeve (2), a base (3), a pressure spring (4), a stud (5) provided with a hole, a support seat (6), a bearing seat (7), a rotating shaft (8), a pressure plate (9), an elastic rubber pad (10), an encoder (11), a locating bolt (12), a bearing end cover (13) and a bearing (14). The quick calibrating apparatus can be used for completing the quick calibration for turning disc of the automobile wheel positioning instrument.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com