Calibration system for commercial vehicle vision measurement based on longitude and altitude spatial positioning principle

A technology for visual measurement and calibration system, which is applied in the field of calibration system for visual measurement of commercial vehicles, can solve problems such as the decline of measurement accuracy of vision system, and achieve the effects of reliable performance, adjustable position and angle, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

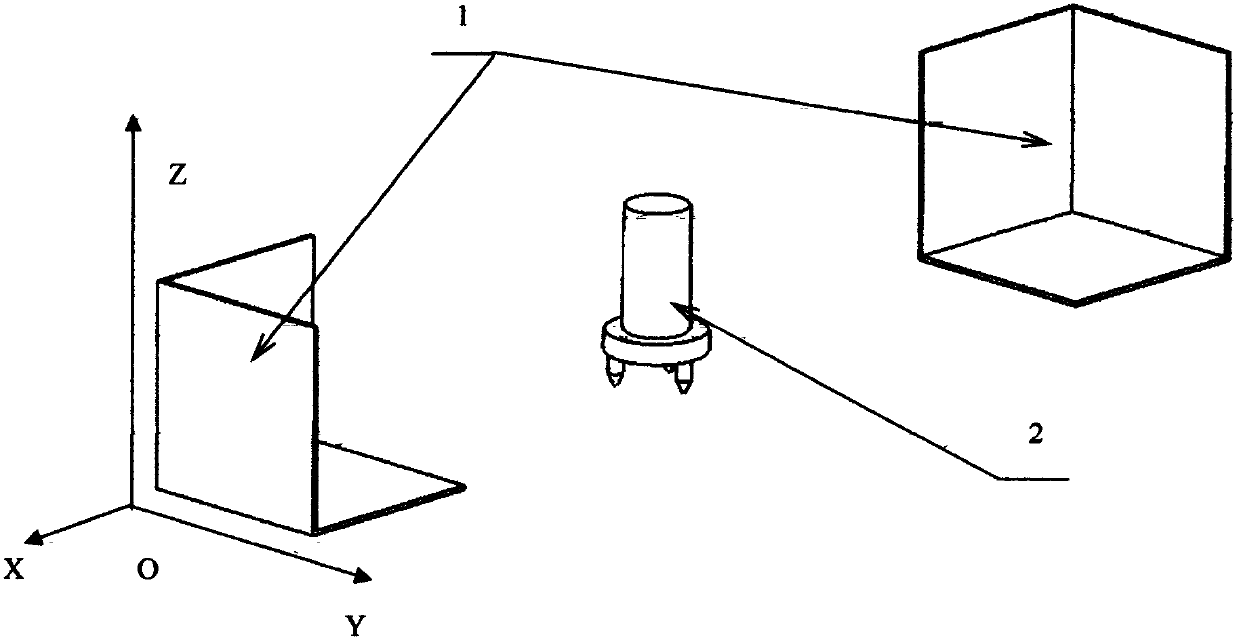

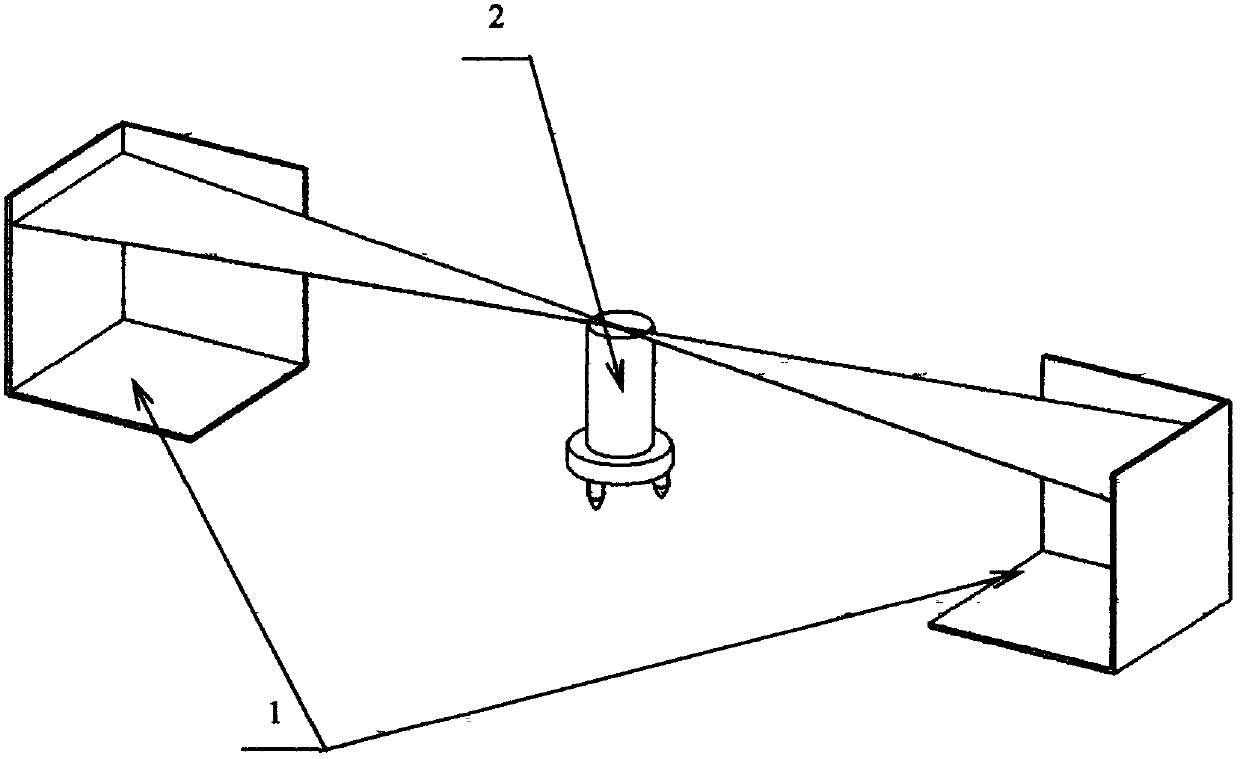

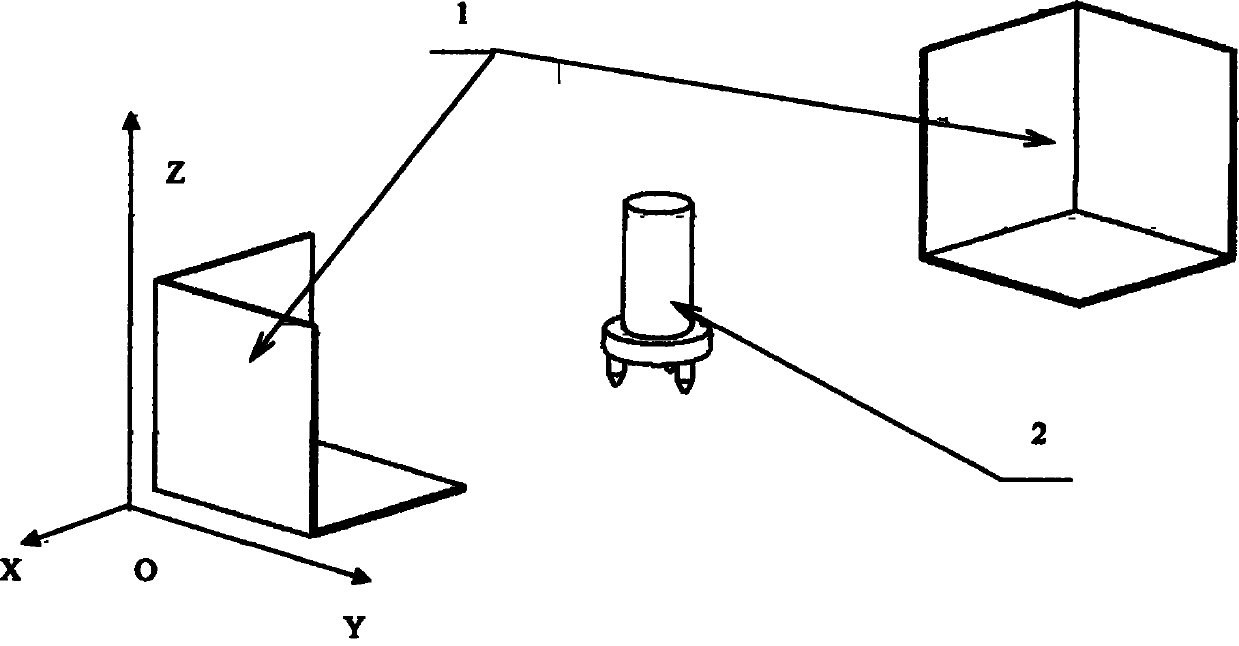

[0014] refer to Figure 1 to Figure 2 , the calibration system of visual measurement of commercial vehicles based on the principle of spatial latitude and longitude positioning includes a calibration board 1 and a laser line projector 2 .

[0015] The calibration plate 1 is a part vertically welded by three equal-sized square steel plates, and the surface is pasted with printed equidistant straight lines, checkerboard squares or square paper.

[0016] The two calibration plates 1 are symmetrically placed on the horizontal ground, the two faces of the two calibration plates 1 that are parallel to the XOZ plane coincide, the two faces of the two calibration plates 1 that are parallel to the XOY plane coincide, and the two faces of the two calibration plates 1 coincide with the YOZ plane. The distance between the two parallel planes is 1.8 to 26 meters. The laser li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com