Automobile morphology measurement system mechanical distortion coefficient measuring instrument

A topography measurement and distortion coefficient technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as large measurement errors, and achieve the effects of fewer machining processes, large output, and guaranteed measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

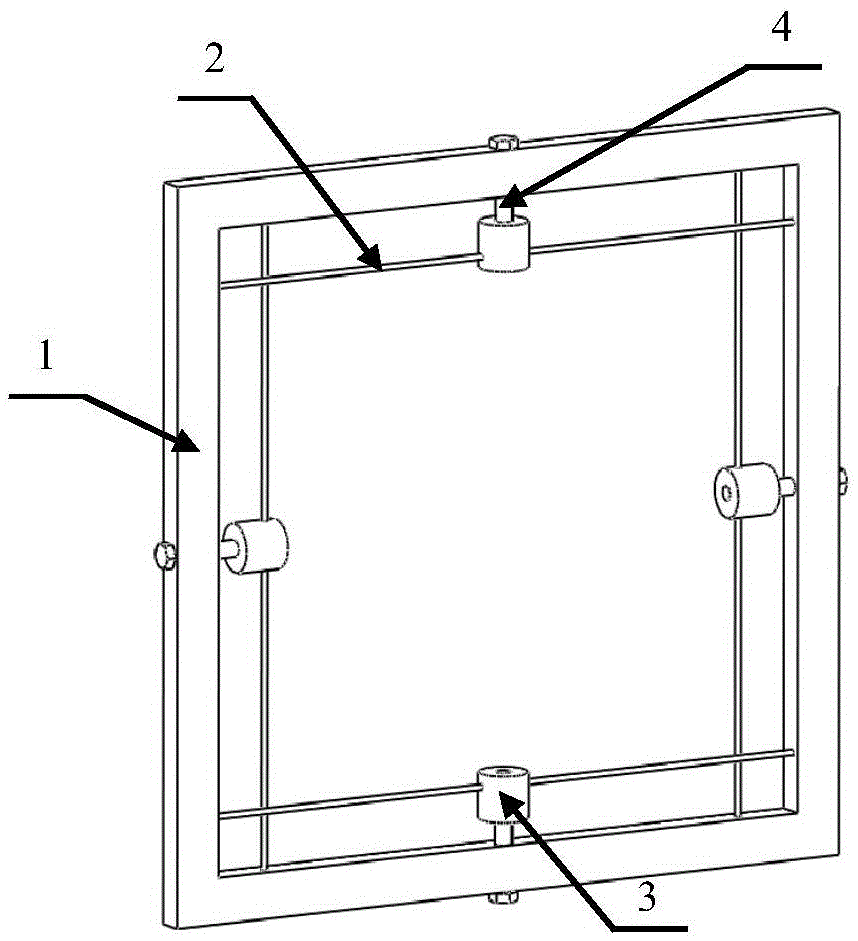

[0018] refer to Figure 1 to Figure 4 , The mechanical distortion coefficient measuring instrument of the automobile shape measuring system includes a square frame 1, a steel wire 2, a sleeve 3 and an adjusting screw 4.

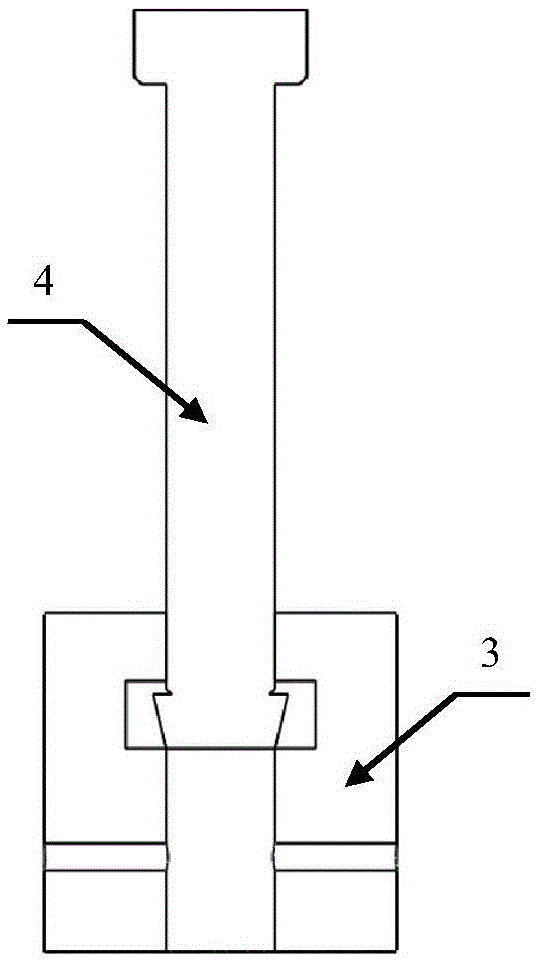

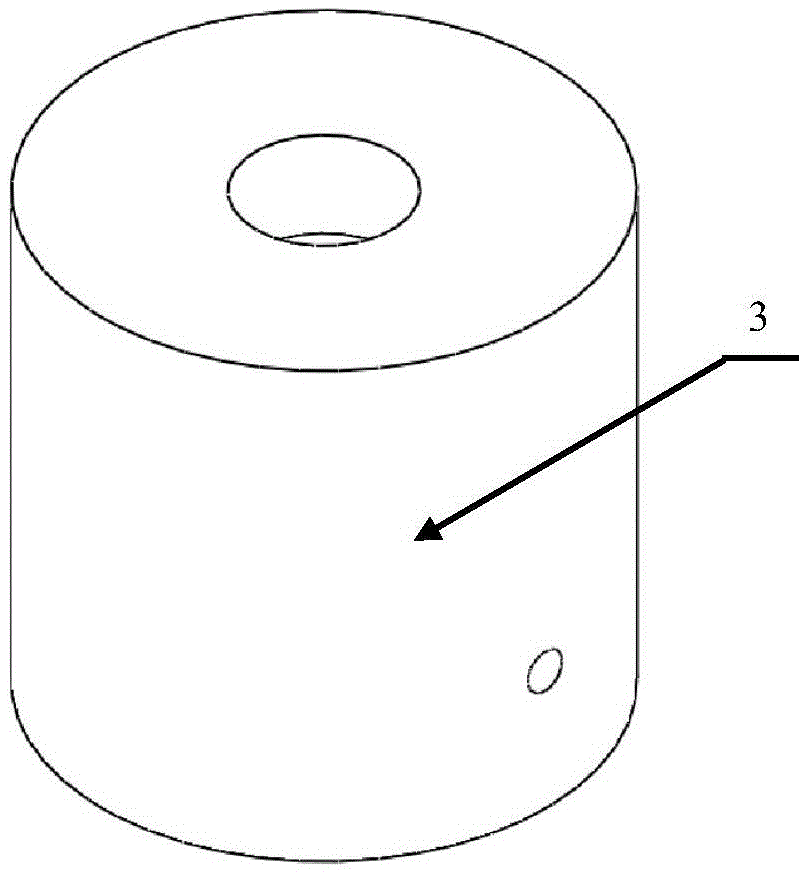

[0019] Square frame 1 is a rectangular frame welded by square steel. A threaded hole is processed in the middle of the inner surface of the four sides of the rectangular frame. The sleeve 3 is a cylindrical steel part. A circular through hole is machined radially at the bottom.

[0020] The adjustment screw 4 is made by welding the standard hexagonal bolt and the trapezoidal table. The diameter of the bottom surface of the small diameter of the trapezoidal table is the same as the diameter of the bolt. The length of the short side of the trapezoidal circular platform is 1 mm, and the standard hexagonal bolts of the four adjustment screws 4 pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com