Machining technology method of swirler assembly

A processing technology, vortex technology, applied in the processing technology field of vortex components, can solve the problems of high production cost, unstable casting size and quality, high personnel and technical requirements, etc., to reduce raw material costs, shorten material preparation cycle, metallurgical Good quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

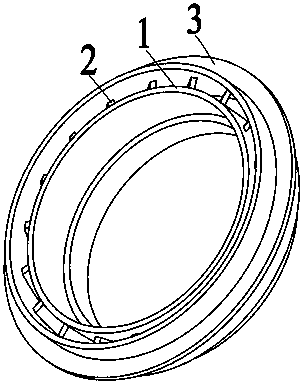

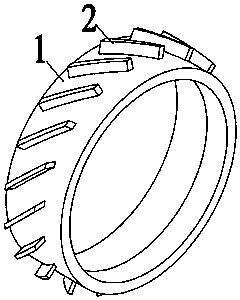

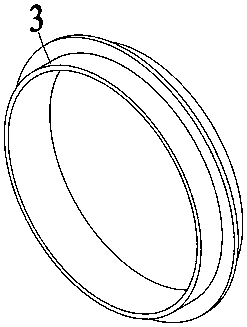

[0039] as attached figure 1 , attached figure 2 , attached image 3As shown in this embodiment, a processing method of a vortex assembly includes a vortex 1, blades 2, and a vortex sleeve 3. The metallurgical process of the metal forging is mature and the operation method is simple, so the vortex sleeve 3 and the vortex 1 are respectively Compared with the integral vortex components of precision casting, the use of forgings as raw materials does not require special casting equipment and high-precision casting molds, cores and pouring systems, which greatly reduces the preparation time in the early stage and saves costs; forgings have good metal properties, so machine tools are used The metal performance of the blade 2 formed on the outer circular surface of the processed vortex forging is more stable than that of the cast-formed vortex blade 2, which avoids defects such as looseness, shrinkage cavity, and holes in the casting process; the wall thickness of the vortex sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com