A large stainless steel pool module isolation pad welding device and its welding method

A technology of stainless steel and isolation pads, which is applied in welding equipment, resistance welding equipment, manufacturing tools, etc., can solve the problems of large welding deformation of stainless steel pool modules, high dependence on welder skill level, unstable joint quality, etc., and achieve easy mechanization and Effects of automation, improvement of working conditions, and improvement of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

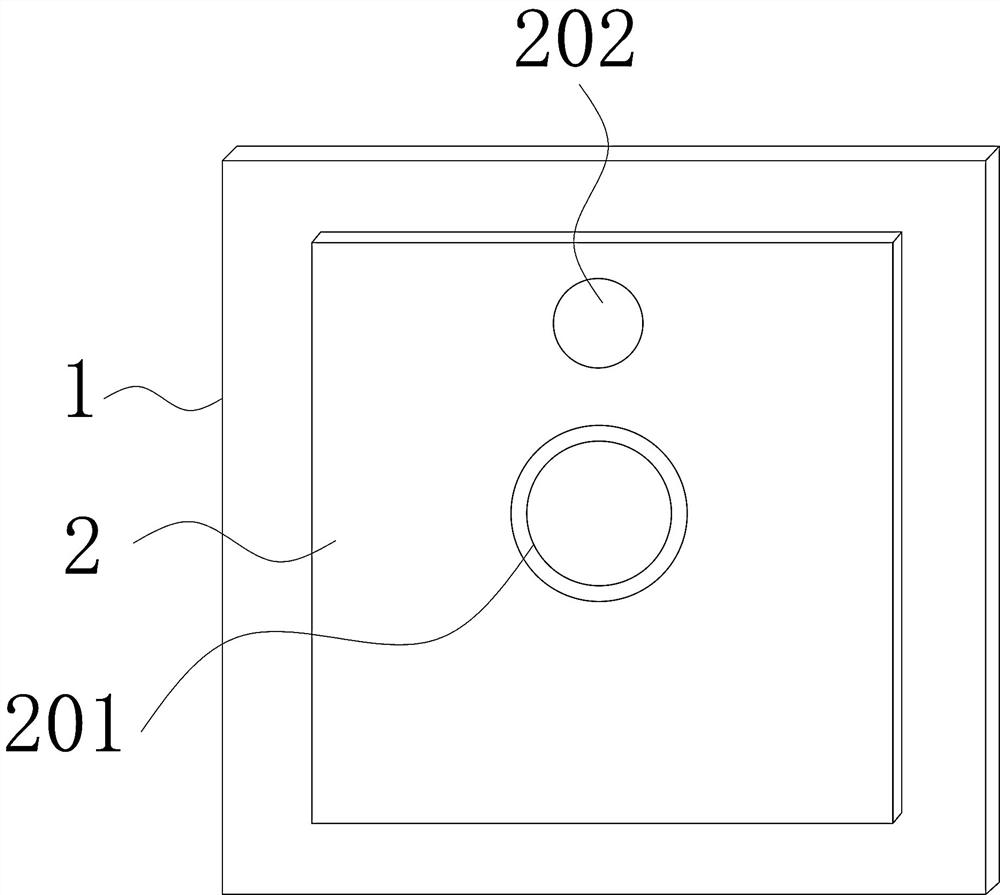

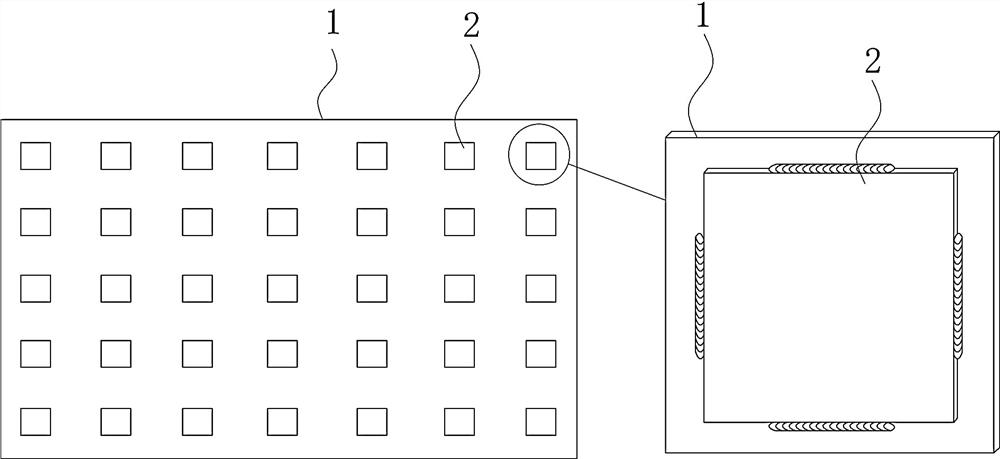

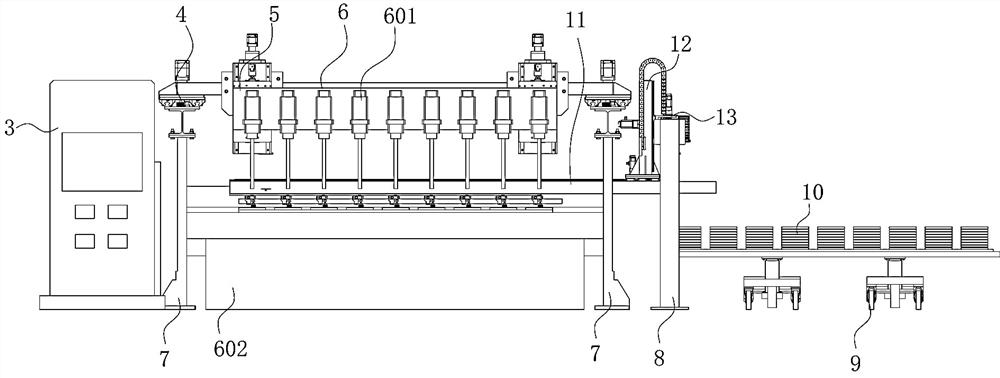

[0046] Such as Figure 1~13 As shown, a large-scale stainless steel pool module isolation pad welding device includes a gantry resistance welding torch frame and an automatic feeding device. The automatic feeding device is arranged on one side of the gantry resistance welding torch frame. On the welding torch frame 6, the welding torch frame 6 is slidingly arranged on the horizontal frame 401 of the gantry horizontal sliding frame 4, the two ends of the horizontal frame 401 are slidably connected with the gantry vertical frame 404, and the two ends of the gantry vertical frame 404 are arranged on the gantry support frame 7, The structure of the automatic feeding device is as follows: comprising a retrieving horizontal frame 11, the retrieving horizontal frame 11 is slidably connected with the vertical sliding frame 12, the vertical sliding frame 12 is slidably connected with the longitudinal sliding frame 13, and the two ends of the vertical sliding frame 13 are arranged on the...

Embodiment 2

[0061] Further description in conjunction with embodiment 1, as Figure 1-13 As shown, the spacers 2 are neatly stacked on the discharge rack 9, and the discharge rack 9 is placed on one side of the retrieving support frame 8, and is kept vertical to the retrieving support frame 8.

[0062] The reclaiming horizontal frame 11 slides to the top of the discharge rack 9 driven by the first motor 1102, and the vertical sliding frame 12 is driven down by the second motor 1202, so that the reclaiming horizontal frame 11 is lowered to the discharging position of the discharge rack 9, The third motor 1304 is driven to slide left and right to the slide frame 12, so that the reclaiming horizontal frame 11 can adjust its position left and right.

[0063] The suction nozzle 14 of the reclaiming horizontal frame 11 is adjusted to the suction point 202 of the isolation pad 2, the air pump is turned on, and the suction nozzle 14 sucks the isolation pad 2.

[0064] The take-up horizontal fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com