Orthogonal detection system for rail vehicle shaft end ground connection device wear extent

A technology for grounding devices and rail vehicles, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as the detection of the wear amount of the axle end grounding devices of rail vehicles, and achieve the effects of simple structure, large output, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

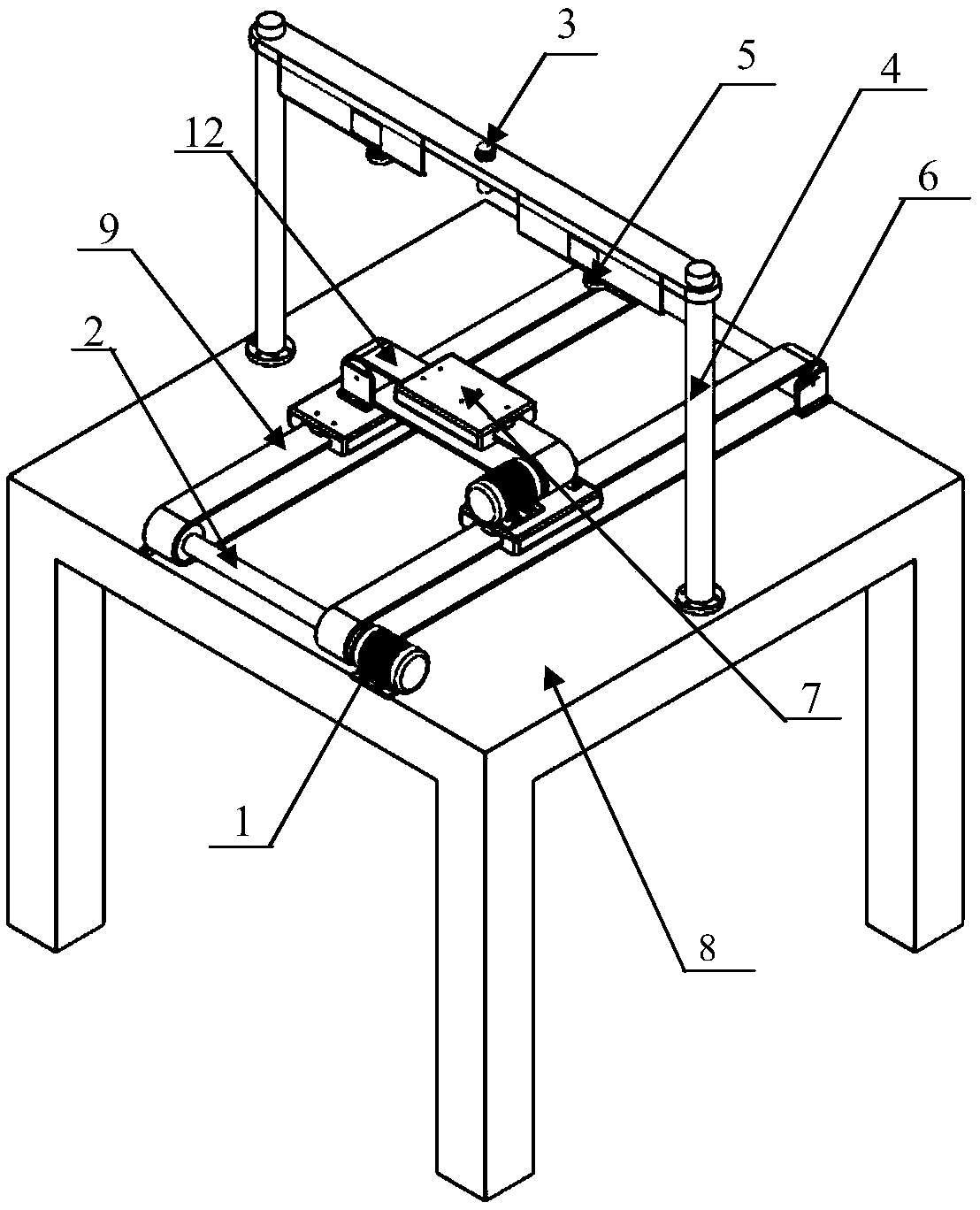

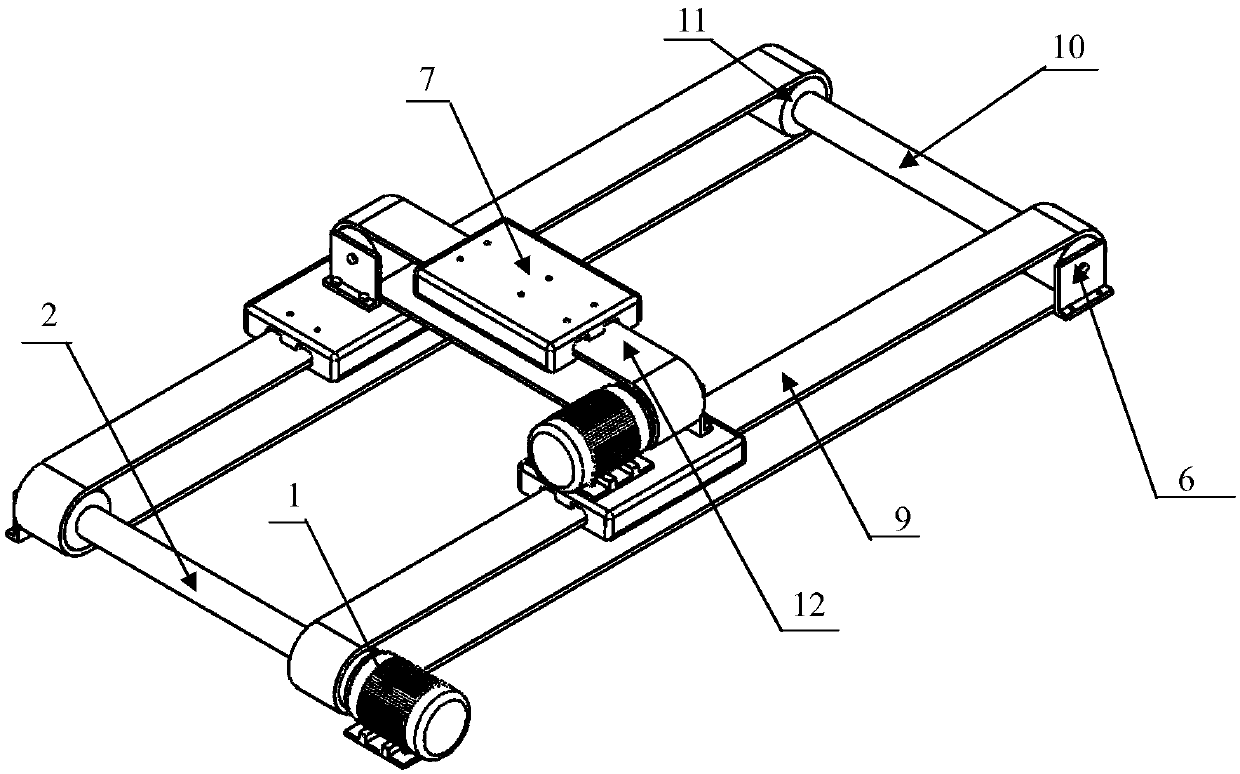

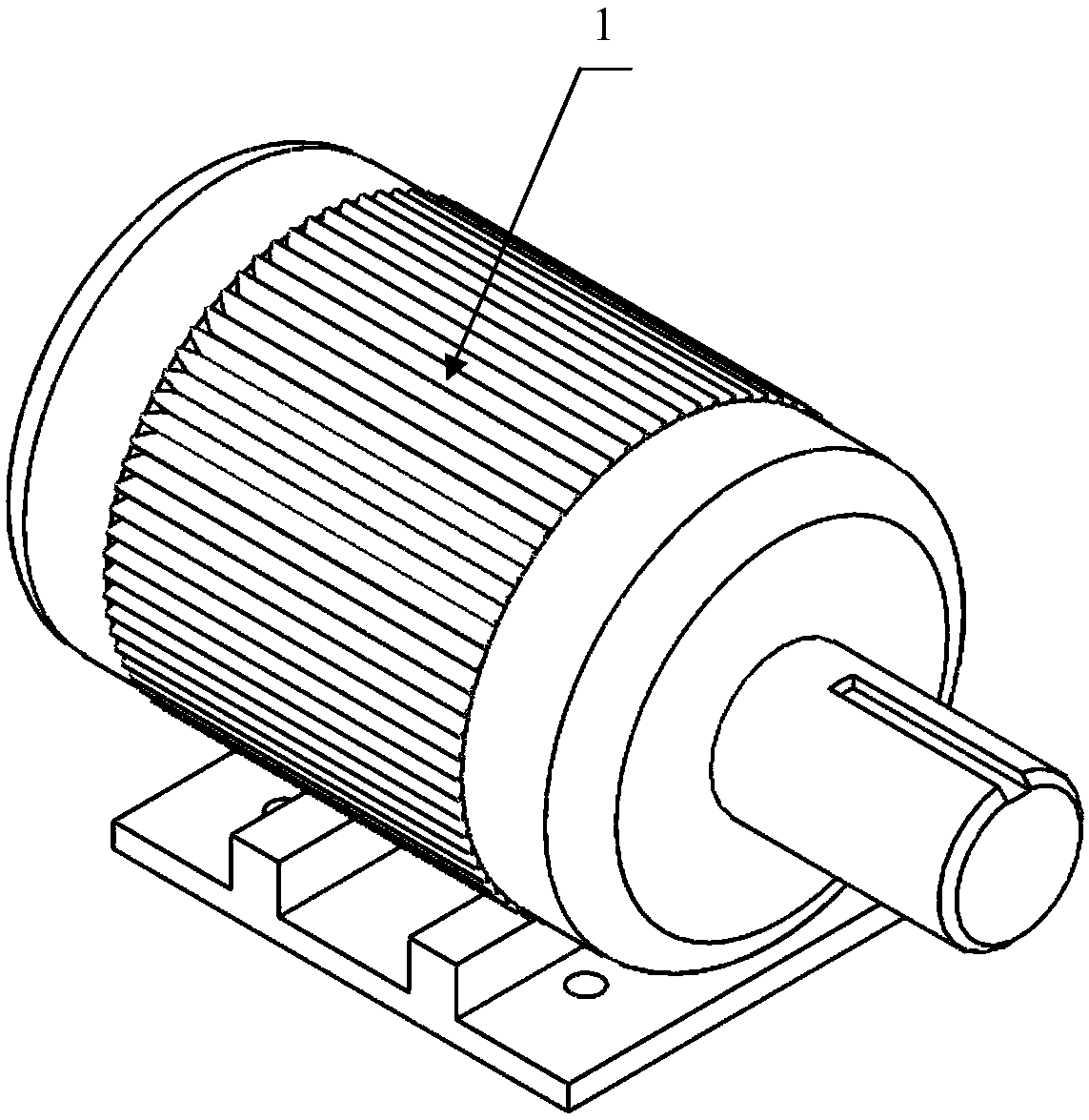

[0035] refer to Figure 1 to Figure 11 , the orthogonal detection system for the amount of wear of the grounding device at the shaft end of the rail vehicle includes a motor 1, a drive shaft of the slide rail 2, a laser line projector 3, a gantry 4, a line array camera 5, a slide rail fixing seat 6, a slider 7, and a working Platform 8, long synchronous belt 9, slide rail driven shaft 10, toothed pulley 11 and short synchronous belt 12.

[0036]Workbench 8 is a steel workbench welded by a rectangular steel plate with a set of threaded holes on the surface and four square steel pipes. The workbench 8 is placed on the level ground, and the slider 7 is threaded on the top and bottom A cuboid part with a through groove, the long synchronous belt 9 is a standard toothed belt made of rubber, and the through grooves of the two sliders 7 are respectively set on the two long s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com