Composition of powder metallurgical perforating charge shell material, professional die and manufacturing method of the powder metallurgical perforating charge shell material

A powder metallurgy and shell material technology is applied in the field of manufacturing powder metallurgy perforating bullet shells and the composition of powder metallurgy perforating bullet shell materials, which can solve the problems that cannot meet the needs of special perforating operations and cannot form small debris, etc. Achieve the effect of satisfying full-diameter perforation operations, reducing processing costs and improving processing efficiency

Active Publication Date: 2011-06-15

DAQING PETROLEUM ADMINISTRATION +1

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In some special perforating operations such as full-bore perforation in the petroleum industry, powder metallurgy shells that all form small debris after the explosion of the perforating charges are required. High-quality carbon steel shells, especially No. 20 steel shells, cannot Small debris is formed, which cannot meet the needs of special perforating operations

Method used

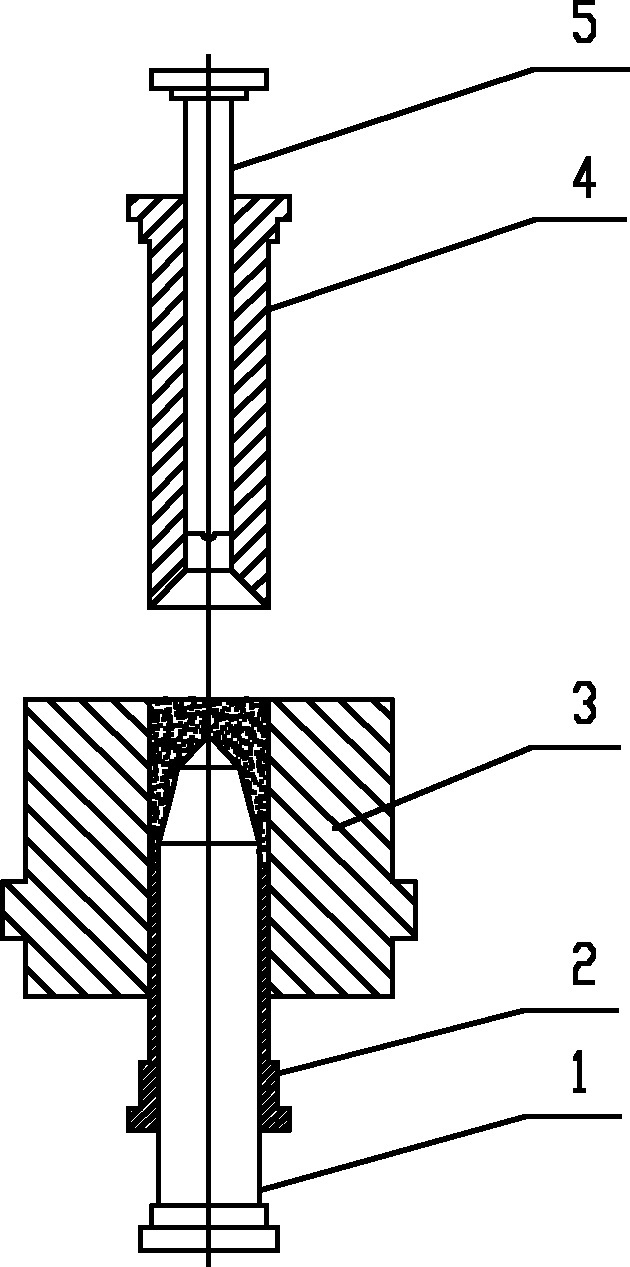

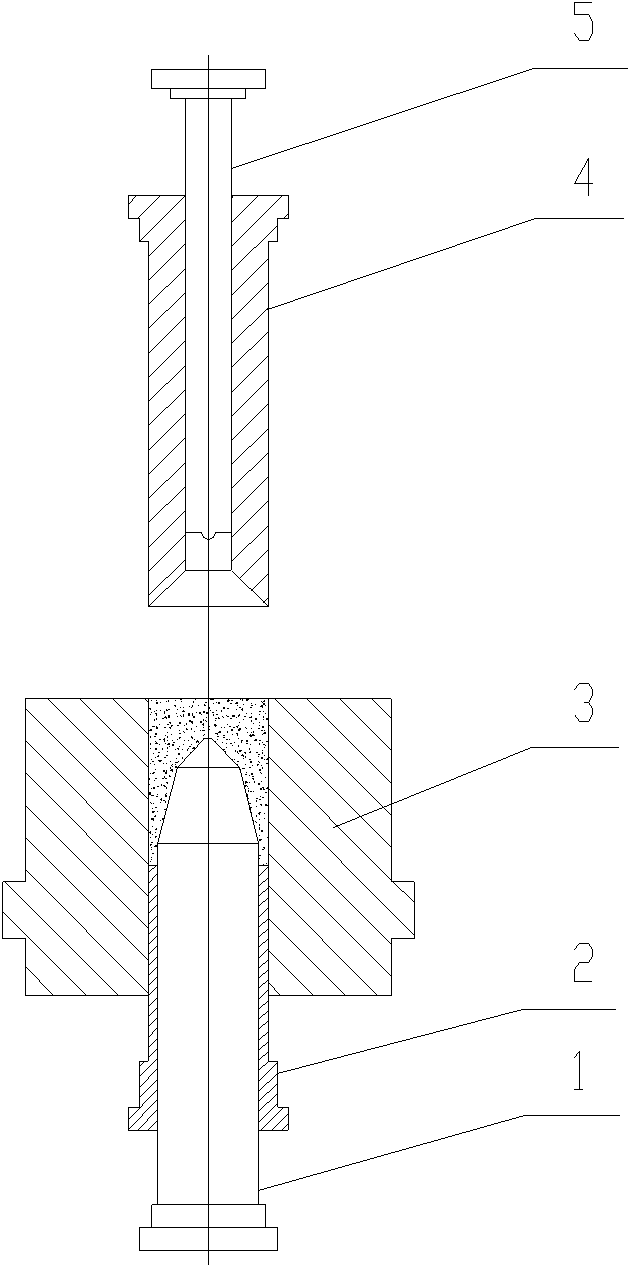

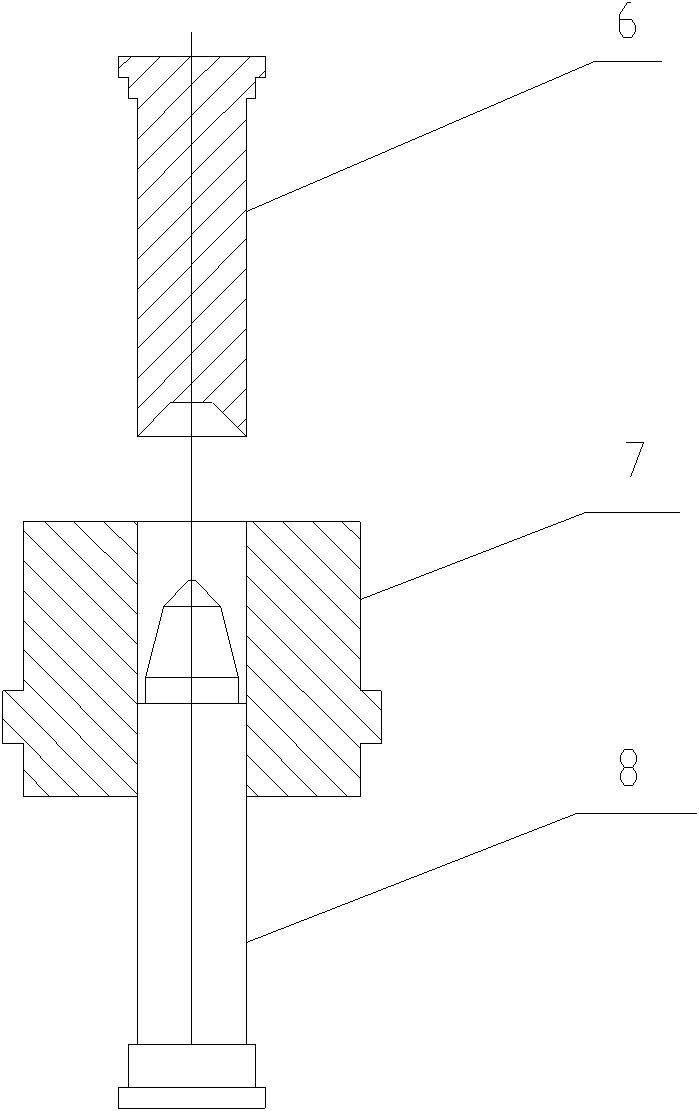

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a composition of a powder metallurgical perforating charge shell material, a professional die and a manufacturing method of the powder metallurgical perforating charge shell material. The invention mainly solves the problems that the traditional perforating charge shell machining process is complicated and has low machining efficiency and high cost. The powder metallurgical perforating charge shell material comprises the following raw materials in percentage by weight: 0.8 percent of carbon powder, 1 to 3 percent of copper powder, 1 to 3 percent of nickel powder, 0.1 to 1 percent of molybdenum powder, 91.2 to 97 percent of iron powder, and 0.1 to 1 percent of bonding agent; and the powder metallurgical perforating charge shell material is prepared by mixing the raw materials,pressing and molding, sintering, finishing and preservative treatment. The powder metallurgical perforating charge shell adopted the powder pressing molding method to prepared, realizes iron scrap-free processing, has high processing efficiency and reduces the processing cost; and the penetrating performance of a perforating charge manufactured by using the powder shell exceeds the penetrating index of the traditional steel shell, and meanwhile, the perforating charge has the characteristic of low scrap and is suitable for the special operation requirements of full-bore perforations and the like in the petroleum industry.

Description

Composition of powder metallurgy perforating shell material, professional mold and its manufacturing method technical field The invention relates to a perforating bullet casing used in the field of petroleum perforating bullet manufacturing, in particular to a powder metallurgy perforating bullet casing material composition. The invention also relates to a professional mold for manufacturing powder metallurgy perforating charge shells and a manufacturing method thereof. Background technique At present, in the field of perforating bullet shell manufacturing, the widely used perforating bullet shells are mainly made of high-quality carbon steel (such as No. 20 steel) for mechanical processing. The processing procedures are complicated, the processing speed is slow, the processing cycle is long, and a large processing allowance needs to be reserved, resulting in waste of raw materials and high manufacturing costs. The internal tissue structure of the shell material affects t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22F1/00B22F3/03B22F5/10

Inventor 熊健郭忠万潘永新徐志国廉宏峰崔佳丽王伟李晓峰顾军汤占军

Owner DAQING PETROLEUM ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com