Camera three-dimensional truss calibrating target for automotive visual detection system

A technology for visual inspection and three-dimensional truss, which is applied in measurement devices, image analysis, image data processing, etc., can solve the problems of inability to obtain three-dimensional data points, difficult practicability on-site calibration, and large volume of three-dimensional calibration objects, and achieves easy image processing. and target recognition, light weight, and fewer machining steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

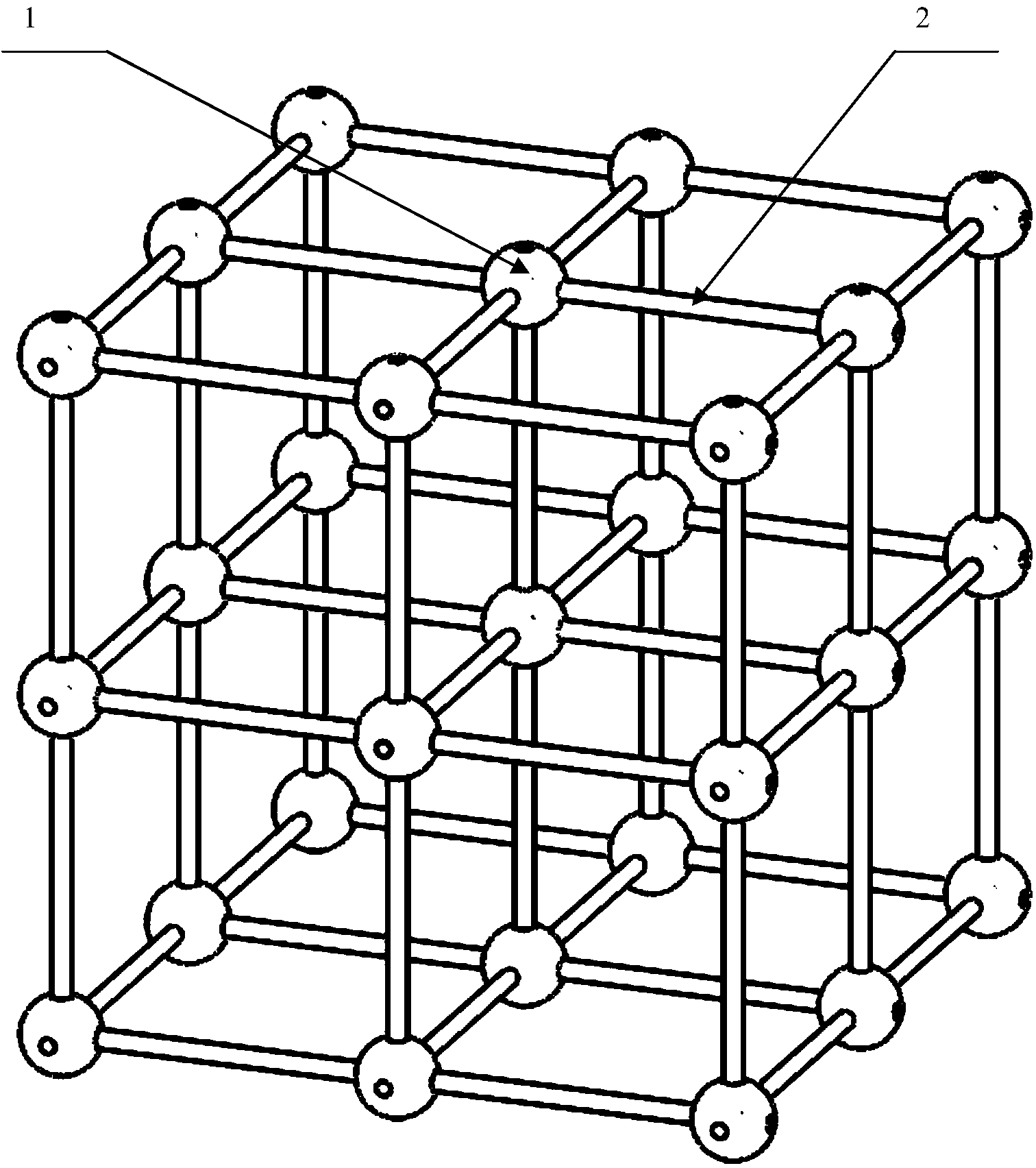

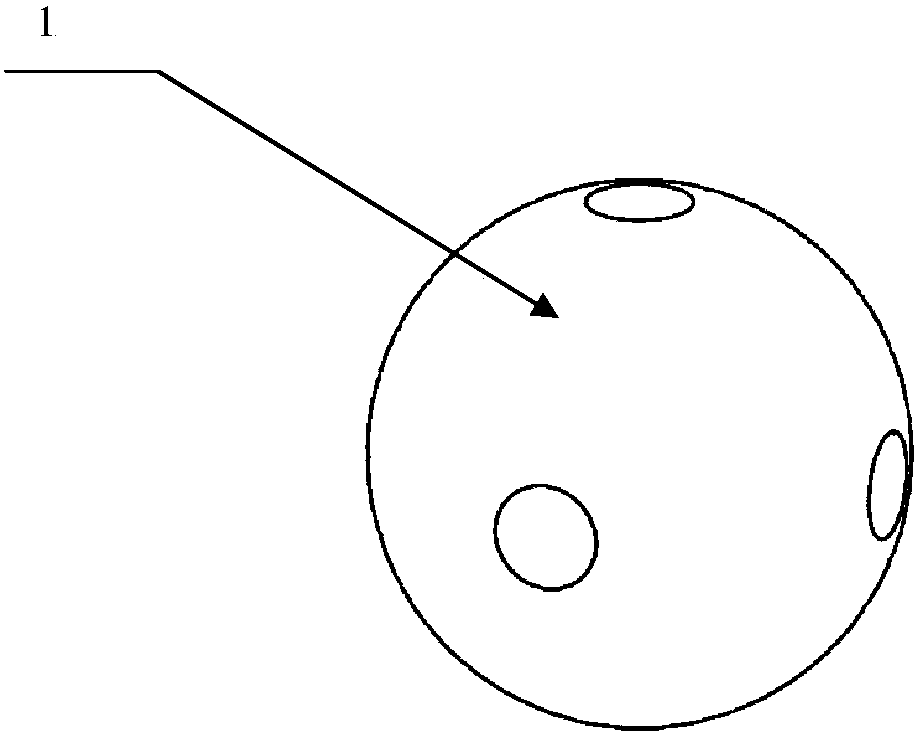

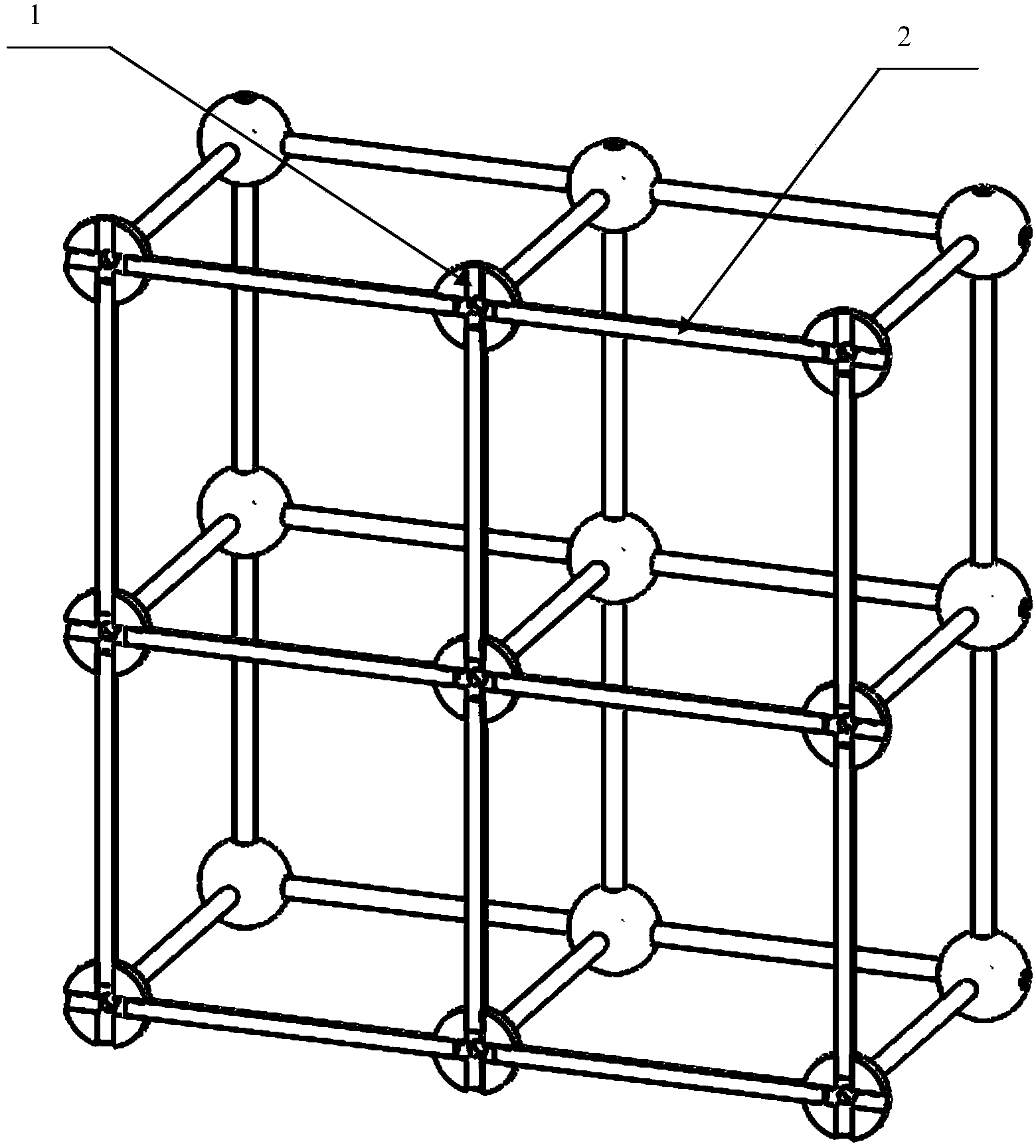

[0018] refer to Figure 1 to Figure 3 , the camera three-dimensional truss calibration target of the automobile vision detection system includes a target pill 1 and a connecting rod 2 .

[0019] The spherical steel parts of the target shot 1 are quenched and tempered, the surface of the target shot 1 is blackened, and the target shot 1 is processed with three threaded through holes along the three mutually perpendicular axis directions passing through the center of the ball, and the connecting rod 2 is processed by steel rods. The formed rod-shaped parts are quenched and tempered, the surface of the connecting rod 2 is electroplated, and the two ends of the connecting rod 2 are threaded. The target shot 1 inside the system is fixedly connected with the six connecting rods 2. The target shot inside the side 1 is fixedly connected with five connecting rods 2, the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com