Automobile appearance detection structured light calibration system based on point to coordinate axis distance constraint

A technology of distance constraint and detection structure, which is applied in the direction of measuring device, optical device, instrument, etc., to achieve the effect of low production cost, large output and less machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

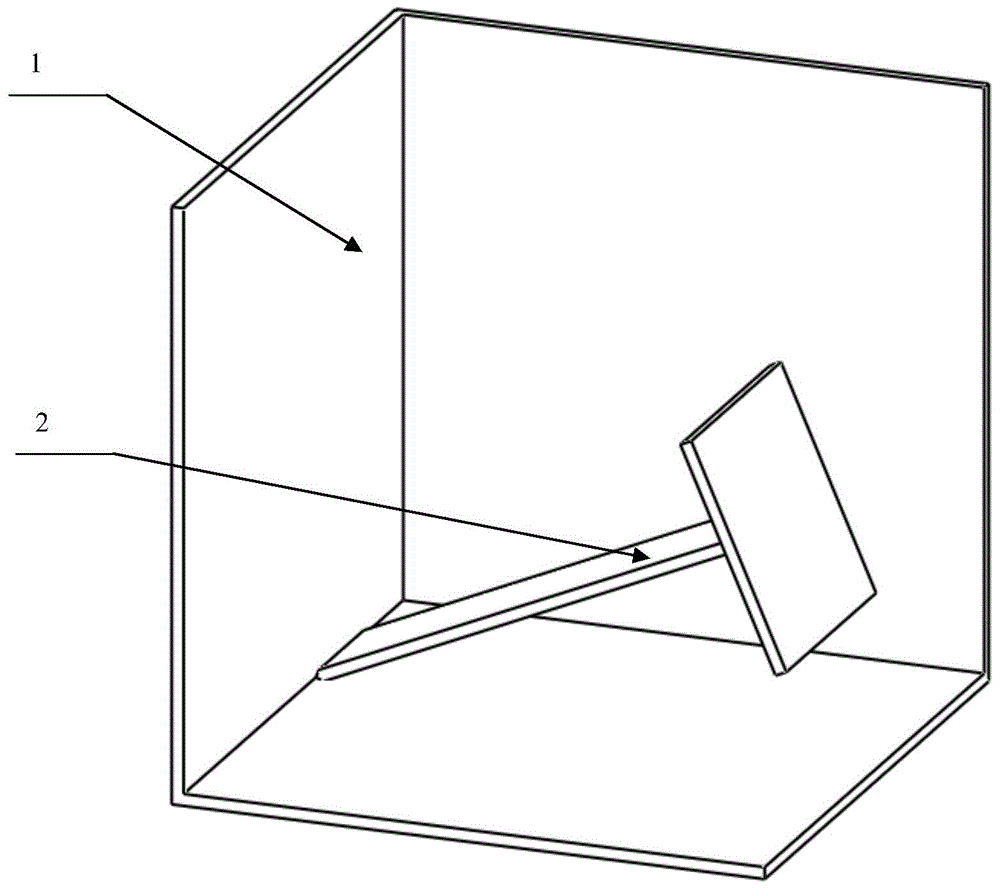

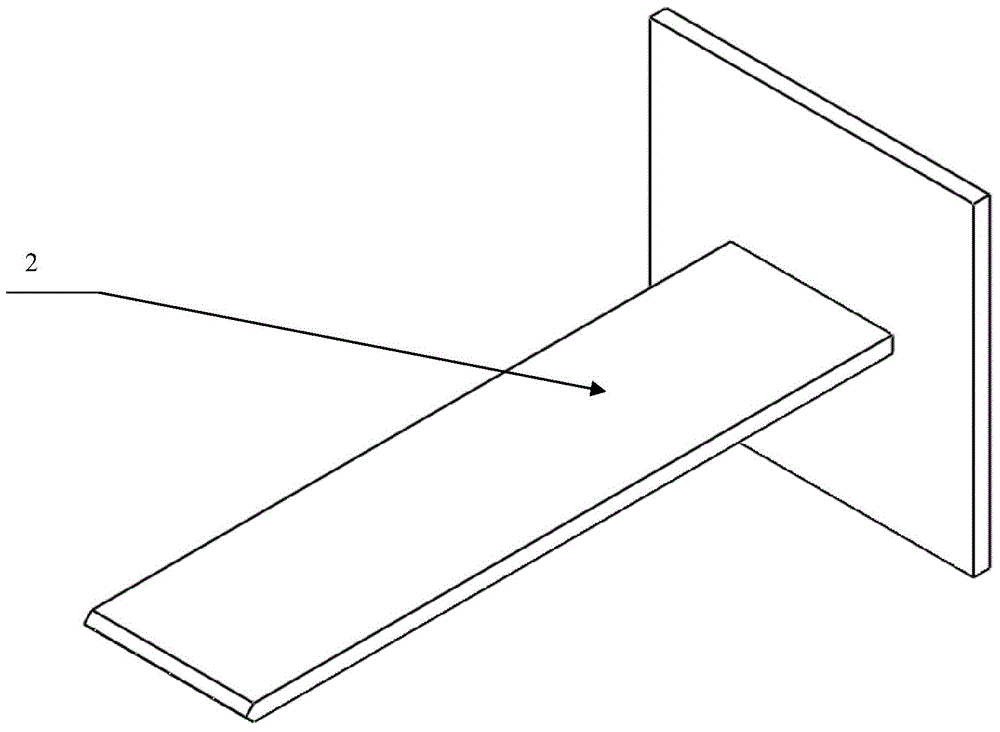

[0015] refer to Figure 1 to Figure 2 , the structured light calibration system for vehicle shape detection based on distance constraints from points to coordinate axes includes a three-dimensional calibration board 1 and a T-shaped calibration board 2 .

[0016] The three-dimensional calibration plate 1 is formed by three rectangular steel plates welded perpendicular to each other, and a checkerboard pattern is pasted on the inner surface of the three-dimensional calibration plate 1 .

[0017] The T-shaped calibration plate 2 is made of two rectangular standard steel plates. The bottom end of the long rectangular steel plate at the lower part of the T-shaped calibration plate 2 is processed into a wedge shape, and the top is welded vertically to the middle of the upper rectangular steel plate, and a checkerboard is pasted on the top surface of the upper rectangular st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com