Bent pipe device

A pipe bending device and pipe bending technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of less bending specifications of pipe bending, and achieve the effect of reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

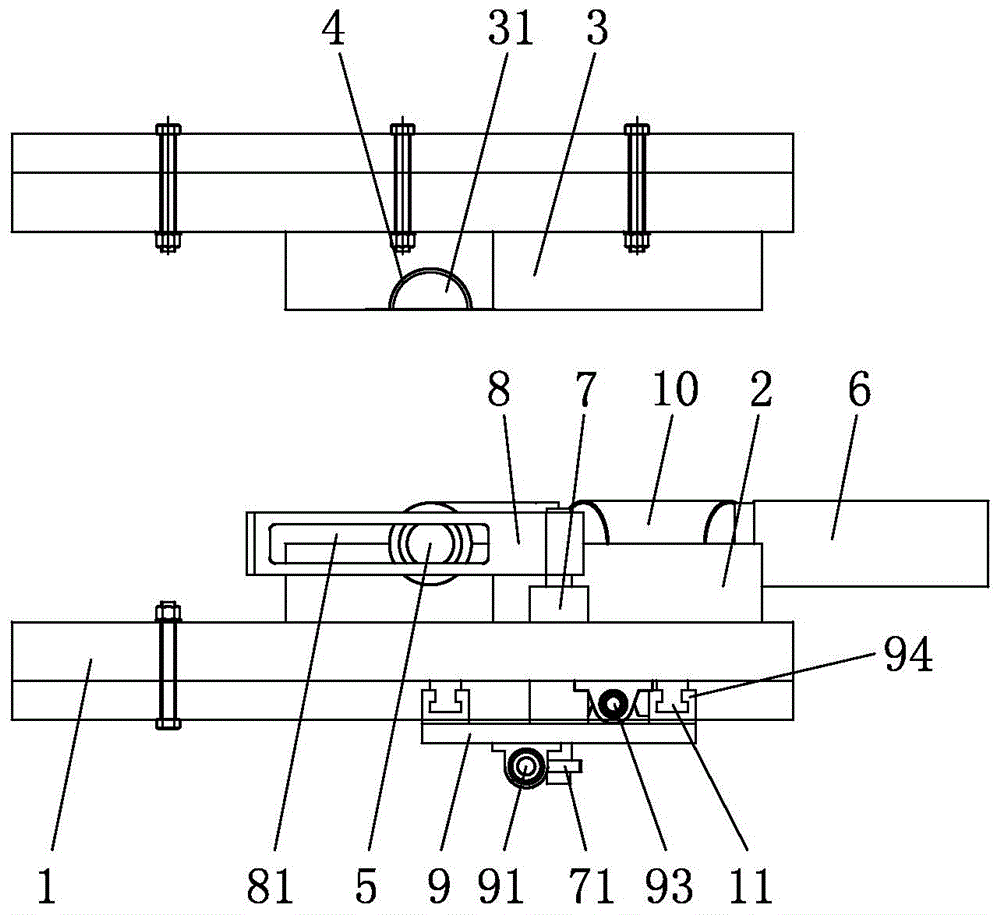

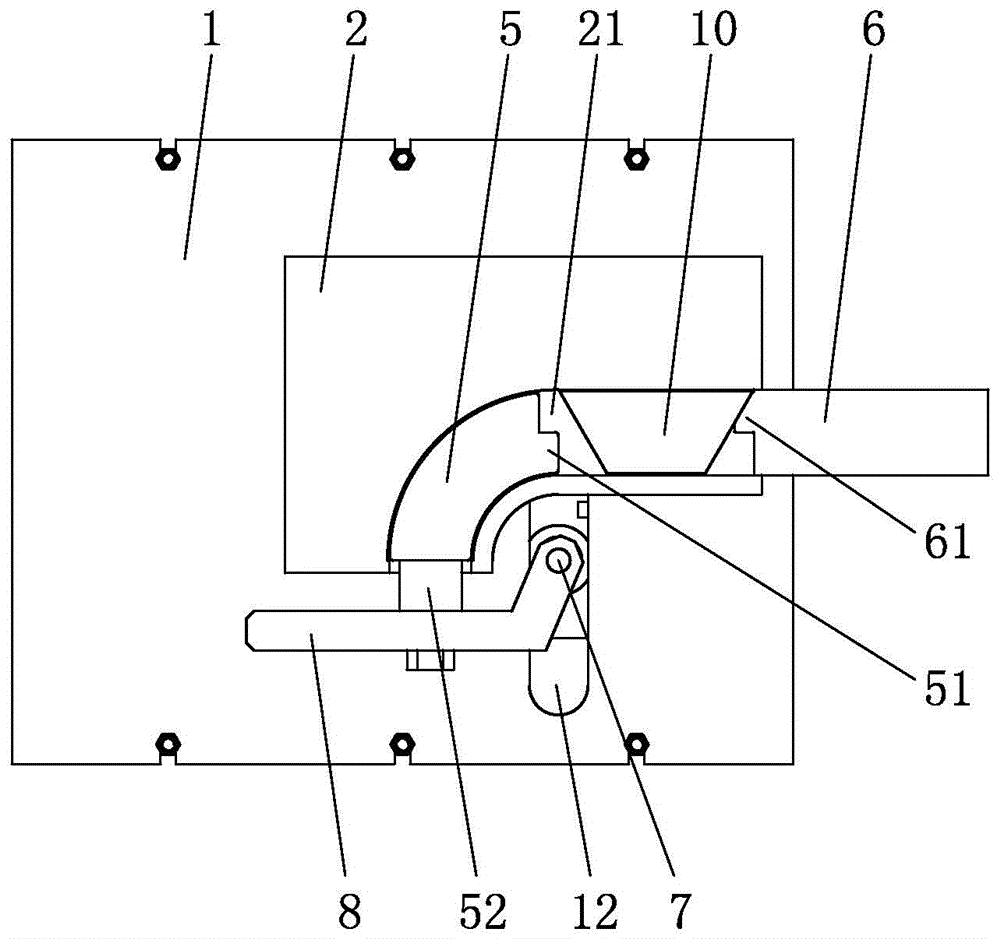

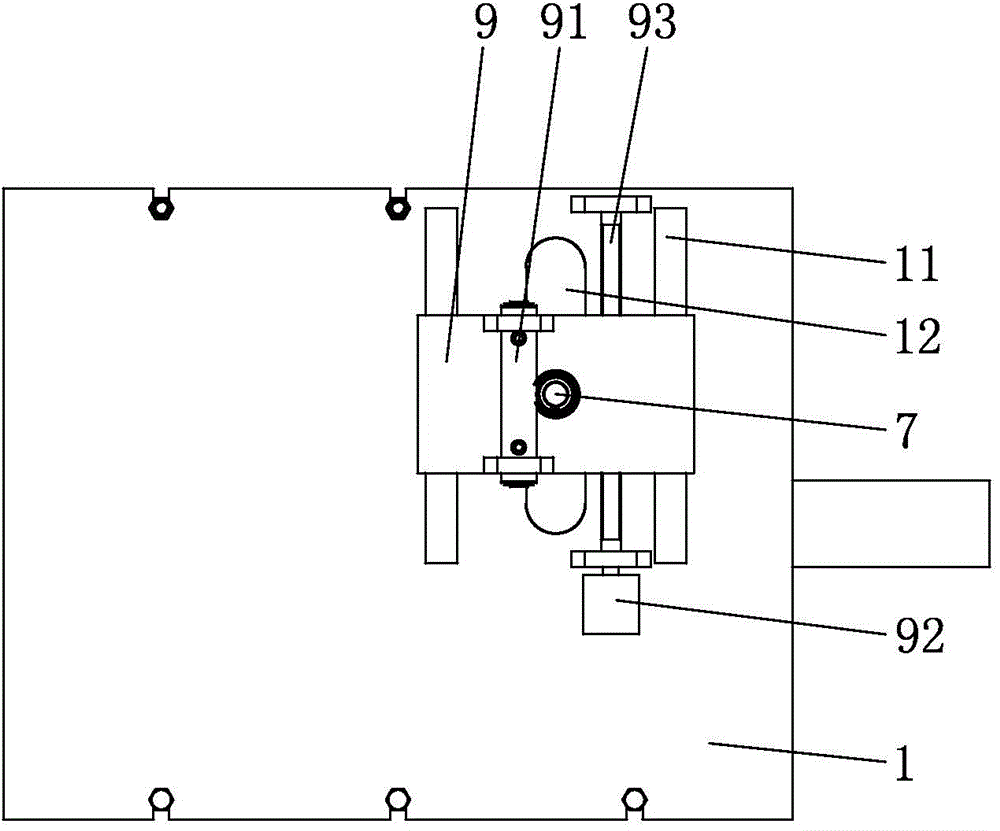

[0019] refer to figure 1 , a pipe bending device, comprising a base plate 1, the top surface of the base plate 1 is provided with a pipe bend forming die, the pipe bend forming die includes an upper die 3 and a lower die 2 fixed on the base plate 1, the upper die 3 is located at the bottom of the lower die 2 Directly above, the bottom surface of the upper mold 3 is provided with a first groove 31 with an opening downward, and the top surface of the lower mold 2 is provided with a second groove 21 with an upward opening. After the top end surface, the first groove 31 and the second groove 21 can be spliced into an elbow forming cavity. The elbow forming cavity is provided with a straight section and an arc section. The port at the end of the straight section away from the arc section is the feed port, and the punch 6 moves axially through the feed port and is inserted into the elbow forming cavity. The port at one end of the section away from the straight section is the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com