Contact element for submerged arc furnace electric conduction and manufacturing method thereof

A contact element and submerged arc furnace technology, which is applied in the manufacture of contact parts, contact parts, furnace components, etc., can solve the problems of high processing cost, penetration of the pipe wall, and difficult processing, etc., to shorten the processing cycle and improve the processing yield High, overcoming difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

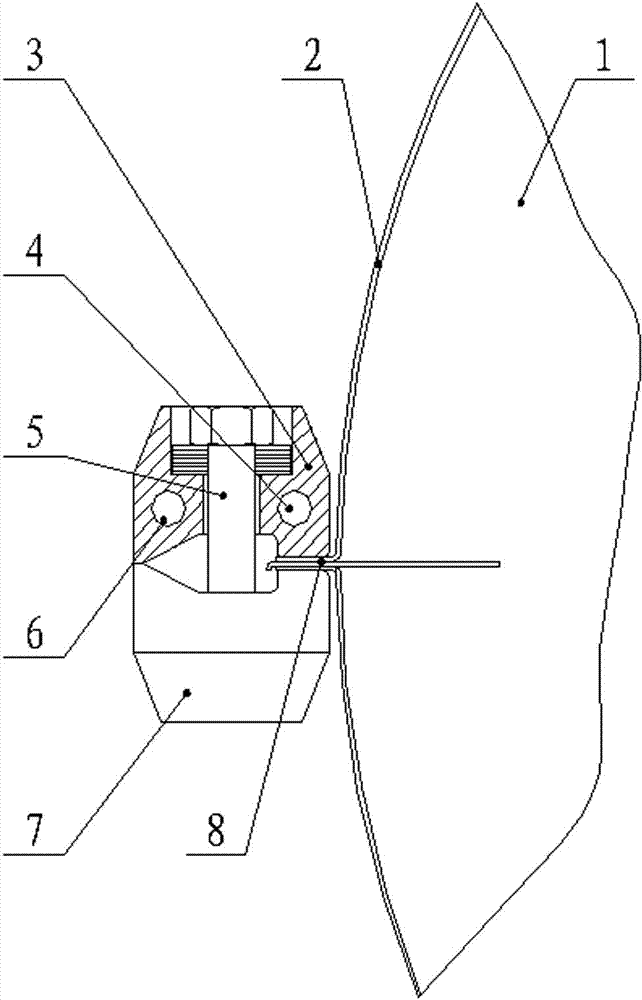

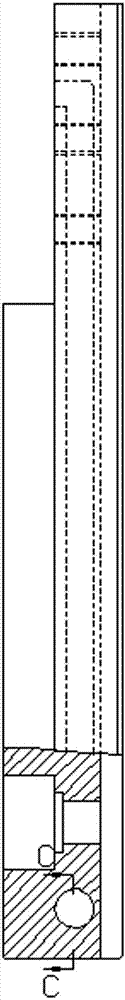

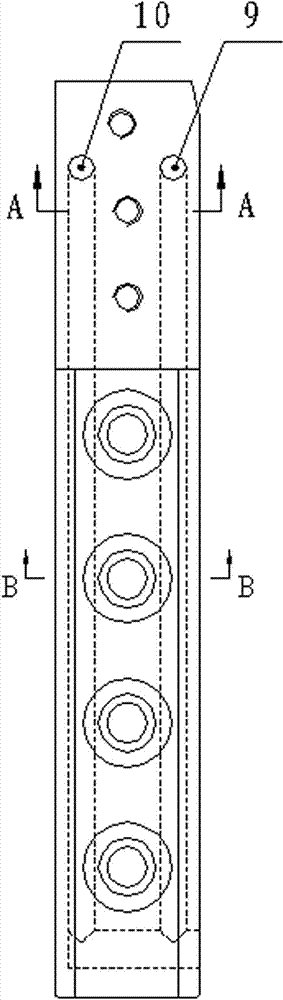

[0028] A contact element for a conductive system of a submerged arc furnace, comprising a contact element body composed of a symmetrical structure of a left element 3 and a right element 8, the left element 3 and the right element 6 are respectively provided with a water inlet channel 4 and a The water outlet channel 6, the water inlet channel 4 and the water outlet channel 6 are two elongated round holes parallel to the length direction of the contact element body, the ratio of their diameter to length is 1:30, and the ends of the two channels are connected by a transverse round hole 7 , which is U-shaped, and the other end is connected with a water inlet 10 and a water outlet 11 respectively. The contact element needs to be cooled by water when in use, and the cooling water flows in from the water inlet 10 and flows out from the water outlet 11 through the cooling water channel. The left component 3 and the right component 8 are connected and adjusted through the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com