Automatic travel regulating device for pressing machine

An automatic adjustment and press technology, applied in the field of presses, can solve the problems of difficult automatic adjustment of the stroke, manual adjustment is time-consuming and laborious, not suitable for high automation, etc., and achieves the effect of large bearing capacity, simple and compact structure, and rapid action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

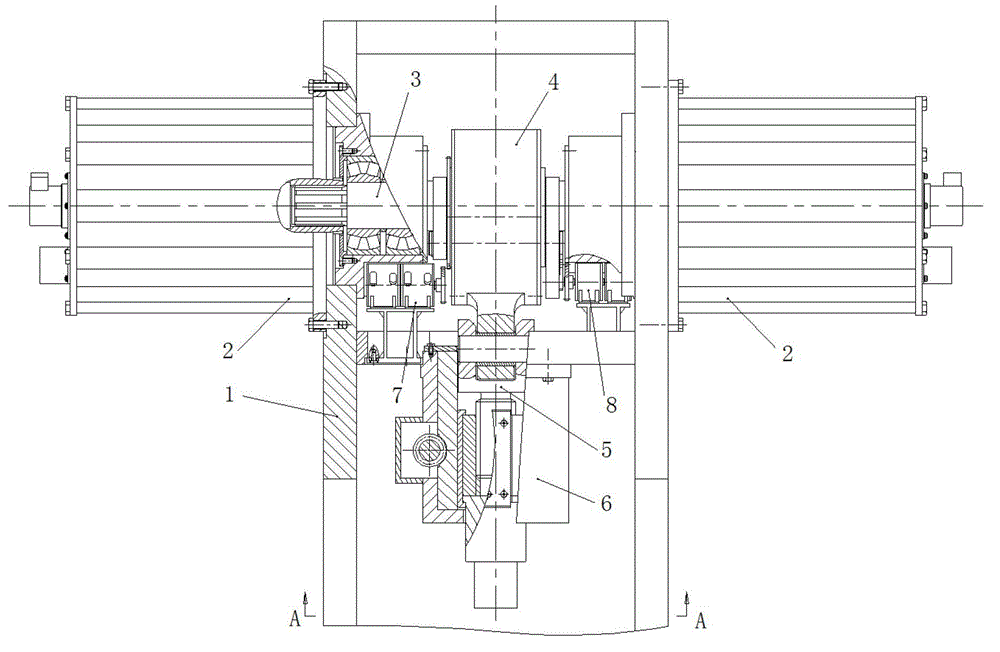

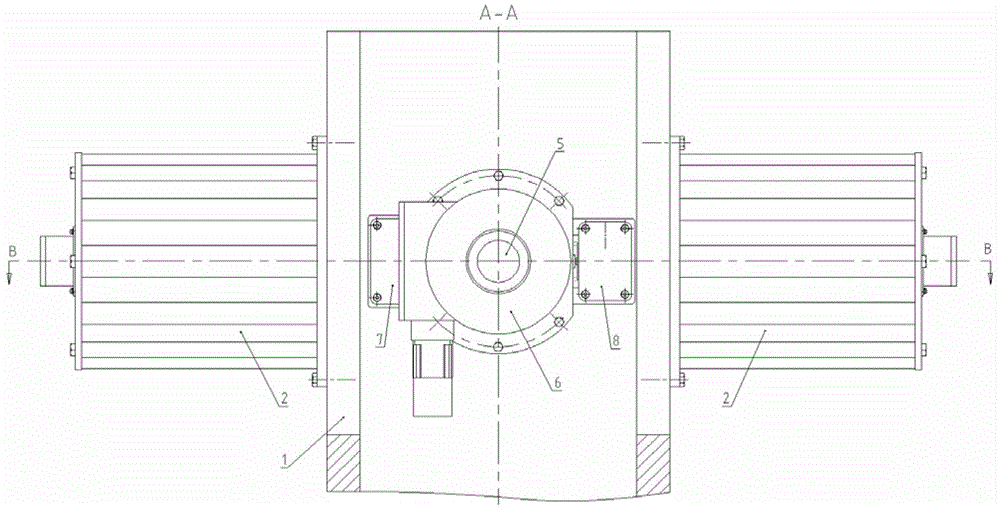

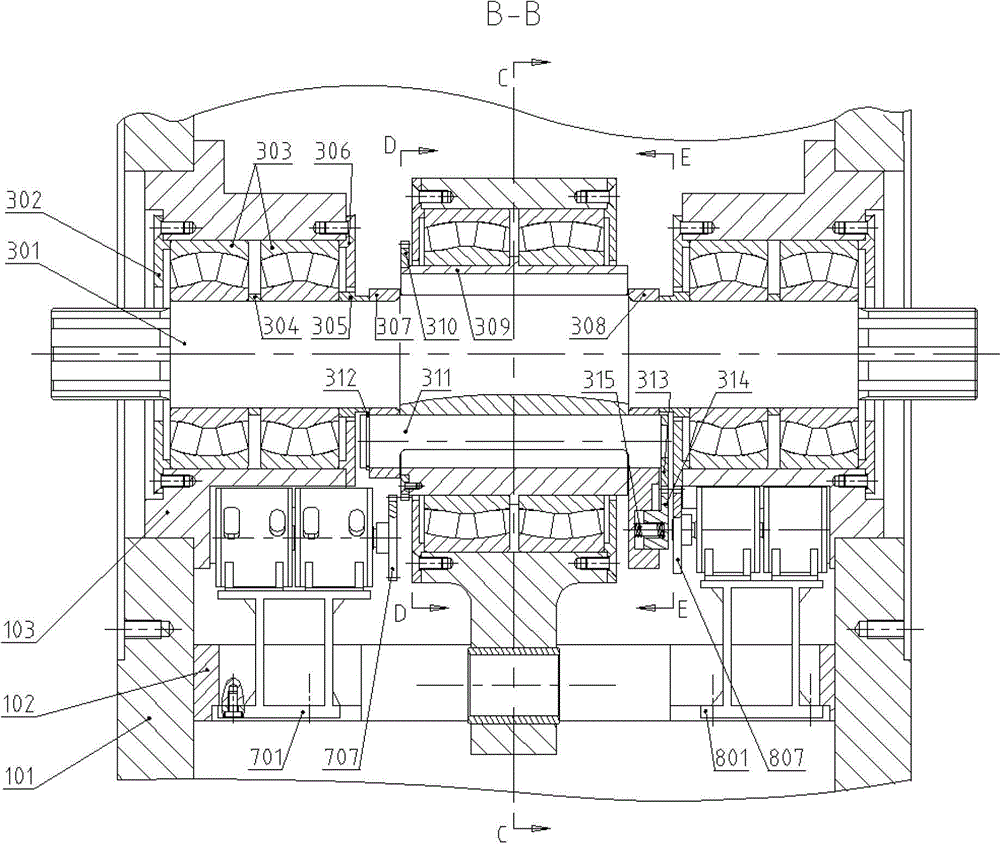

[0028] combine figure 1 and figure 2 , an automatic stroke adjustment device for a press, which is symmetrical as a whole, including a frame 1, a pair of main motors 2 are symmetrically installed on both sides of the frame 1 through bolt connections, and are positioned in cooperation with cylindrical holes provided on the frame 1, The eccentric shaft sleeve mechanism 3 is installed inside the frame, and the shaft ends on both sides are inserted into the main motor 2 through a spline connection, so that the main motor 2 can drive the eccentric shaft sleeve mechanism 3 to rotate, and then drive the link mechanism 4 and the slider mechanism 5 Realize the pressure stroke. The connecting rod mechanism 4 is set on the eccentric part of the middle part of the eccentric sleeve mechanism 3 through the bearing, the slider mechanism 5 is located under the connecting rod mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com