Production technique of high-performance permanent magnetic ferrite pre-sintered material

A permanent magnet ferrite and production process technology, which is applied in the production process field of pre-sintered materials, can solve the problems of increased production cost, production waste, and sintered products with different sizes, so as to improve the overall strength, reduce the production cycle, The effect of reducing production waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A production process of high-performance permanent ferrite pre-fired material, the specific steps include: placing the mixture of ferrite red iron and strontium carbonate in a mixing tower, adding water, grinding, and passing through an X-ray fluorescence analyzer Carry out iron red and strontium carbonate composition correction, the mass percentage of iron red and strontium carbonate is 6.4; the composition corrected mixture is transported to the centrifugal dehydrator mixing tower for dehydration; then the high-concentration slurry is transported to the rotary kiln for pre-burning and cooling The kiln is cooled, and finally enters the ball mill for pulverization, and is ready; in the centrifugal dehydration stage, the water content of the mixed slurry is controlled at 35%; in the pre-sintering stage, the sintering feed rate is controlled at 1.5T / h, and the feed end The temperature of the kiln box is controlled at 330℃, and the high temperature sintering temperature of t...

Embodiment 2

[0022] A production process of high-performance permanent ferrite pre-fired material, the specific steps include: placing the mixture of ferrite red iron and strontium carbonate in a mixing tower, adding water, grinding, and passing through an X-ray fluorescence analyzer Carry out iron red and strontium carbonate composition correction, the mass percentage of iron red and strontium carbonate is 6.6; the composition-corrected mixture is transported to the centrifugal dehydrator mixing tower for dehydration; then the high-concentration slurry is transported to the rotary kiln for pre-burning and cooling The kiln is cooled, and finally enters the ball mill for pulverization, which is finished; in the centrifugal dehydration stage, the water content of the mixed slurry is controlled at 40%; in the pre-sintering stage, the sintering feed rate is controlled at 2.0T / h, and the feed end The temperature of the kiln box is controlled at 340℃, and the high temperature sintering temperature...

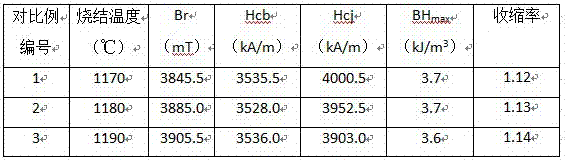

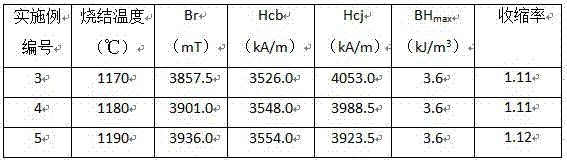

Embodiment 3~5

[0025] In Examples 3 to 5, 500g of permanent ferrite pre-fired material, 8.5 calcium carbonate, 3g boric acid, 3g alumina and 1.5g ammonium bicarbonate were placed in a ball mill, 1000g of water was added, and the ball milled to an average particle size of 0.8μm. Slurry, the ball milled slurry is filtered and precipitated to a water content of 33wt%; the filtered and precipitated slurry is injected into the mold, and the magnetic field strength is 530kA / m, the pressure is 15Mpa, and the pressure is 65s to form a diameter of Φ30 .1mm round cake shaped green body; put the formed green body into a sintering electric kiln at a heating rate of 3°C / min, at 1170~1190°C (see Table 1 for the temperature of each embodiment), sinter for 120min, The upper and lower surfaces of the sintered round cake are ground and polished to obtain permanent ferrite.

[0026] The TYU-2000 type magnetic material automatic measuring device is used to test the magnetic properties of the products. The test res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com