Toughening-type high-temperature iridium rhodium thermocouple

A thermocouple and toughening technology, which is applied to thermometers, thermometers, and heat measurement of directly heat-sensitive electric/magnetic elements, can solve problems such as catalytic effect and high brittleness of iridium-rhodium thermocouples, etc., to achieve The effect of solving the catalytic effect, avoiding the fracture phenomenon and eliminating the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

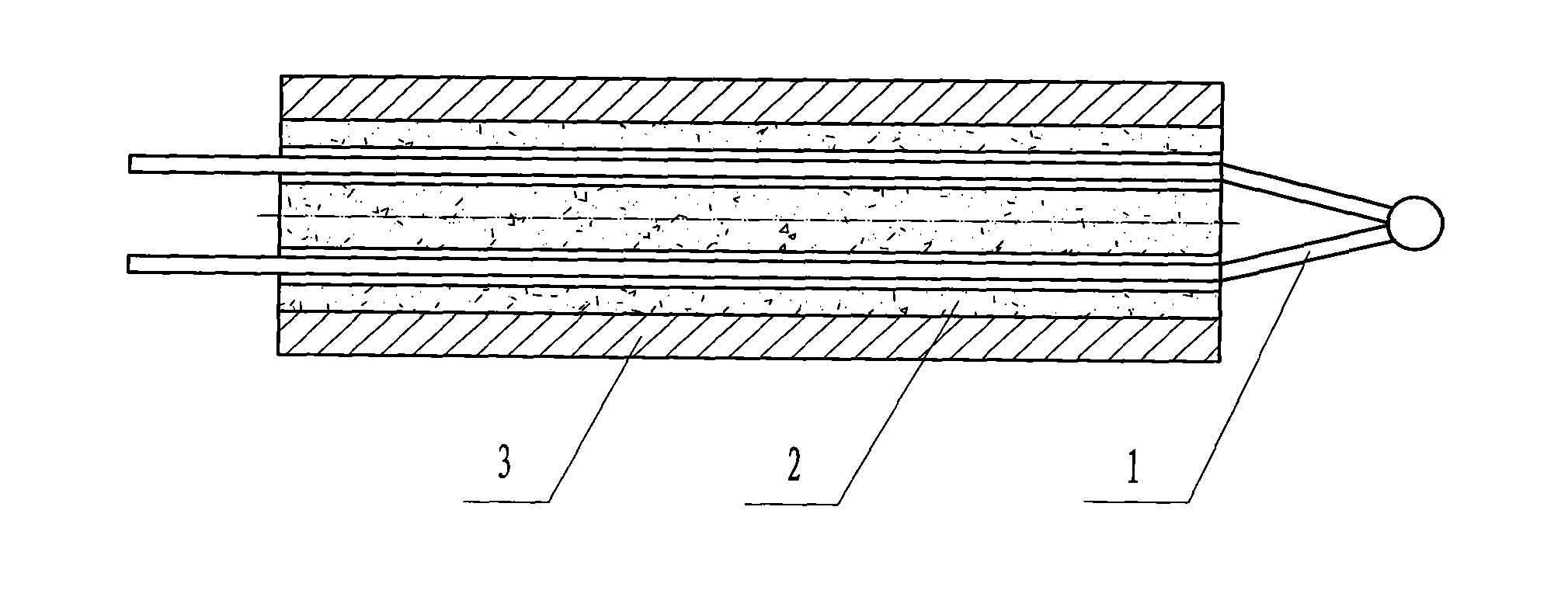

[0019] A kind of toughened high temperature iridium-rhodium thermocouple of the present invention comprises thermocouple wire, insulating porcelain tube, protective shell, such as figure 1 As shown; the connection relationship is: the thermocouple wire is placed inside the insulating porcelain tube; the insulating porcelain tube is covered with a protective shell; between the thermocouple wire and the insulating porcelain tube, and between the insulating porcelain tube and the protective shell are filled with high-temperature bonding Agent for fixing and sealing.

[0020] The positive and negative poles of the thermocouple all adopt IrRh alloy (iridium-rhodium alloy), and the weight percentage of Ir (iridium) in the positive pole is respectively 50%, and the weight percentage of Rh (rhodium) is respectively 50%; ) are 90% by weight, and Rh (rhodium) is 10% by weight respectively.

[0021] The insulating porcelain tube is high-purity double-hole magnesium oxide.

[0022] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com