Device for cutting insulation support for transformer body

A technology of insulating brackets and cutting devices, which is applied in the field of transformers, can solve problems such as potential safety hazards, and achieve the effects of improving work efficiency, high efficiency, reliable and flexible positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

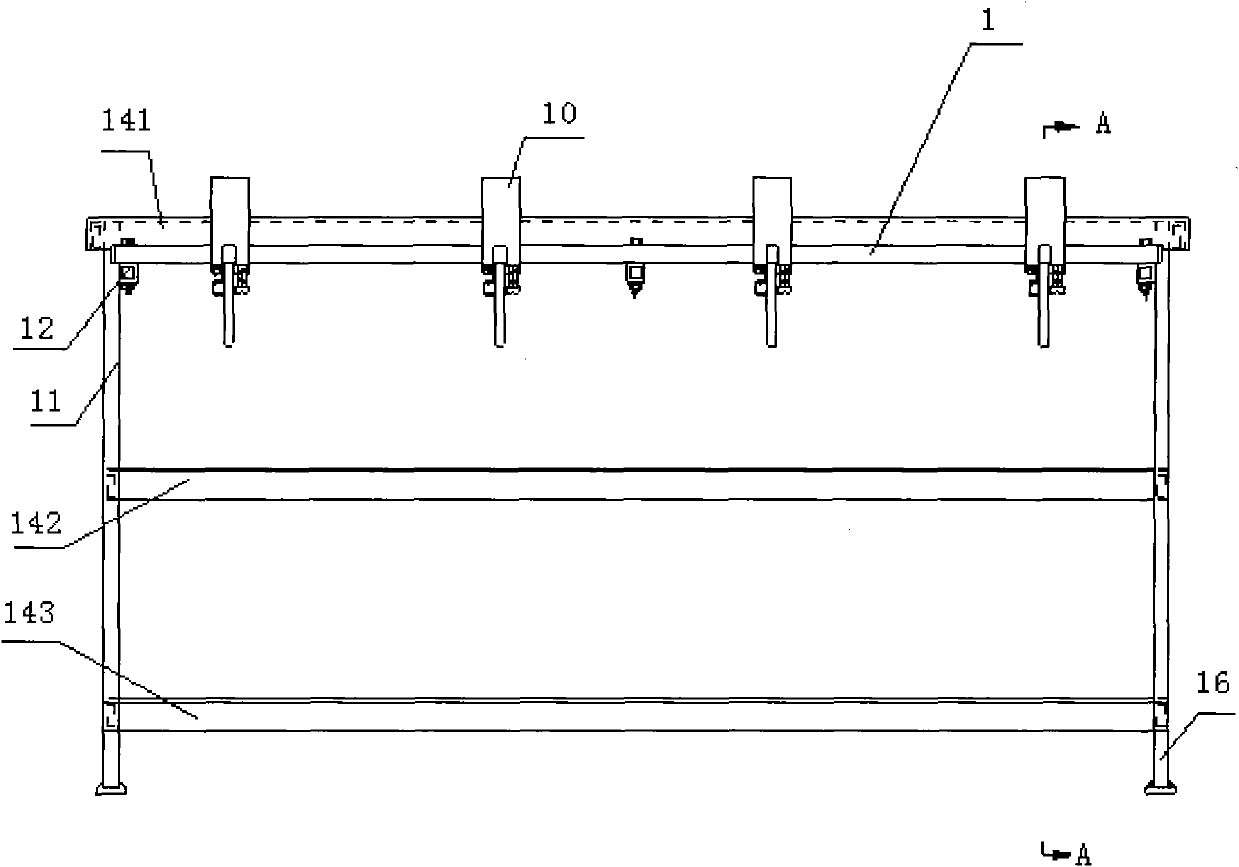

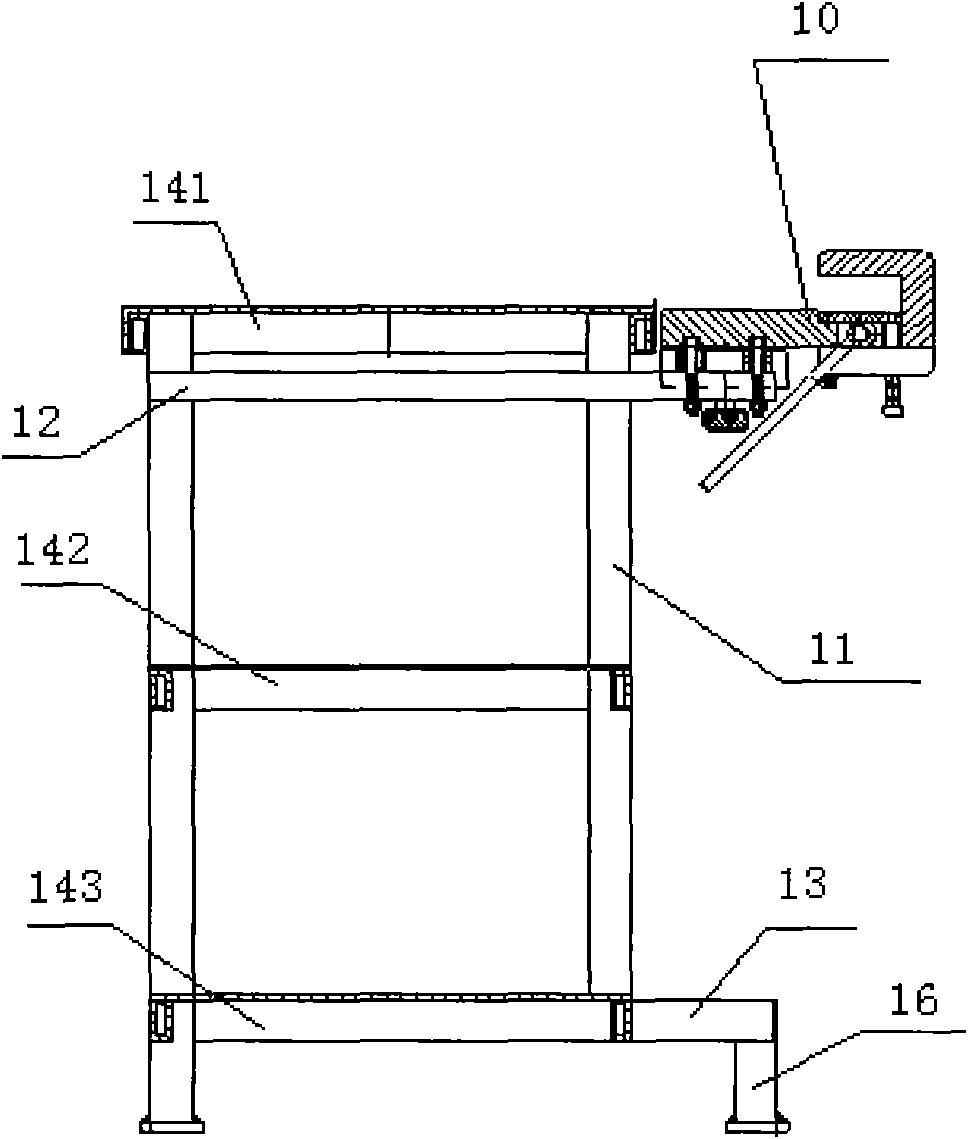

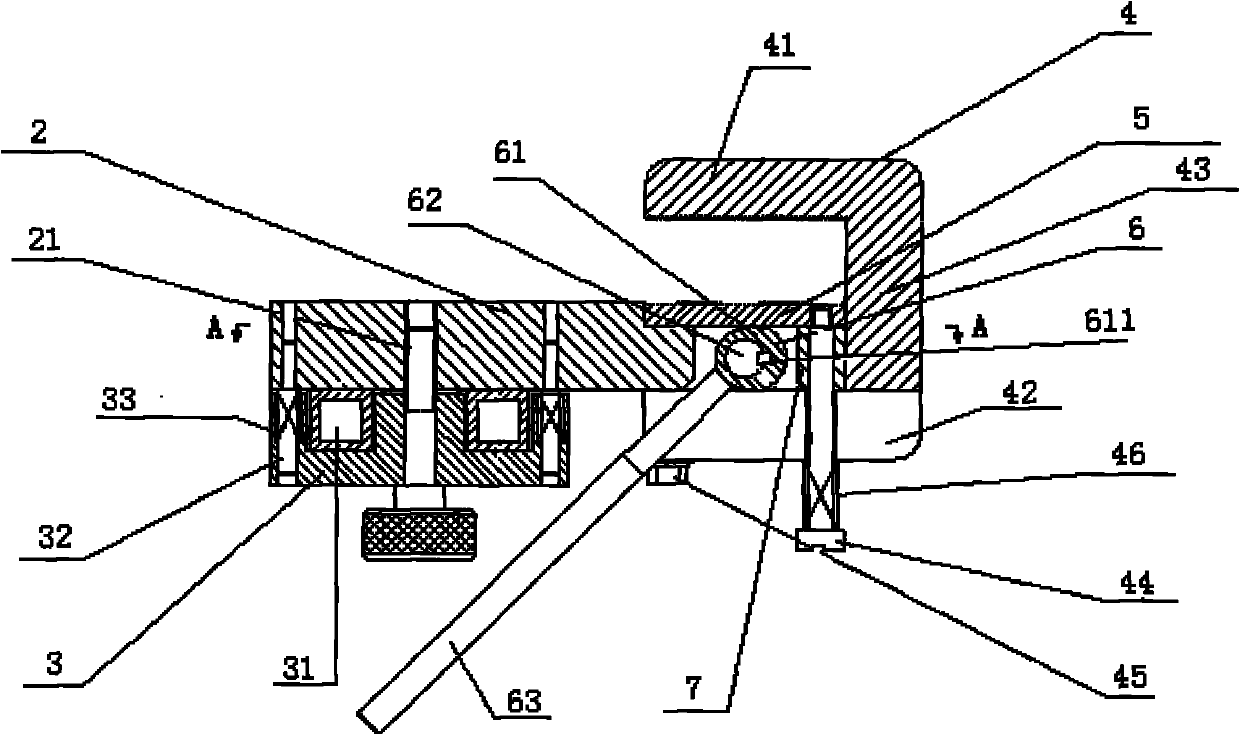

[0032] see figure 1 with figure 2 , the figure shows a transformer body insulation bracket cutting device of the present invention, including a workbench body, the workbench itself includes the worktable and four rectangular tubes 11 below it to support the worktable, and also includes three tubes fixed on the The cantilever 12 on the workbench body and protruding from the worktable surface, the two guide rails 1 arranged in parallel on the cantilever 12, and the four moving guide plates 10 that pass through the two guide rails 1 and are movable and fixed, the workbench body also includes an extension Plate 13, the body of the workbench can cut transformer body insulation brackets with various capacities from 15kVA to 2500kVA, among which:

[0033] The working table includes an upper working table 141, a middle working table 142, and a lower working table 143. The workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com