Patents

Literature

35results about How to "Quick positioning and locking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seatbelt retractor having an inertial sensor weight with a guide surface

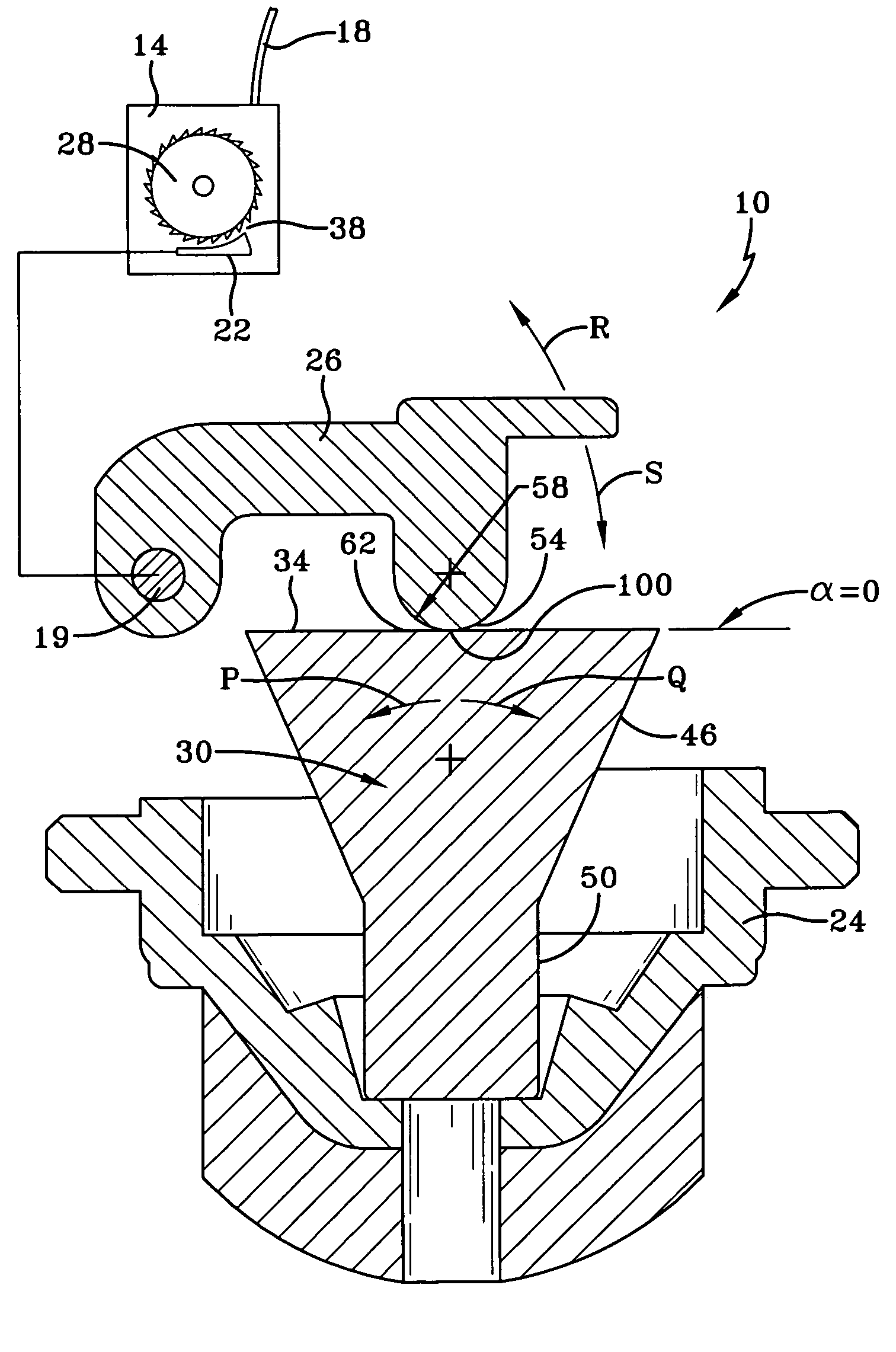

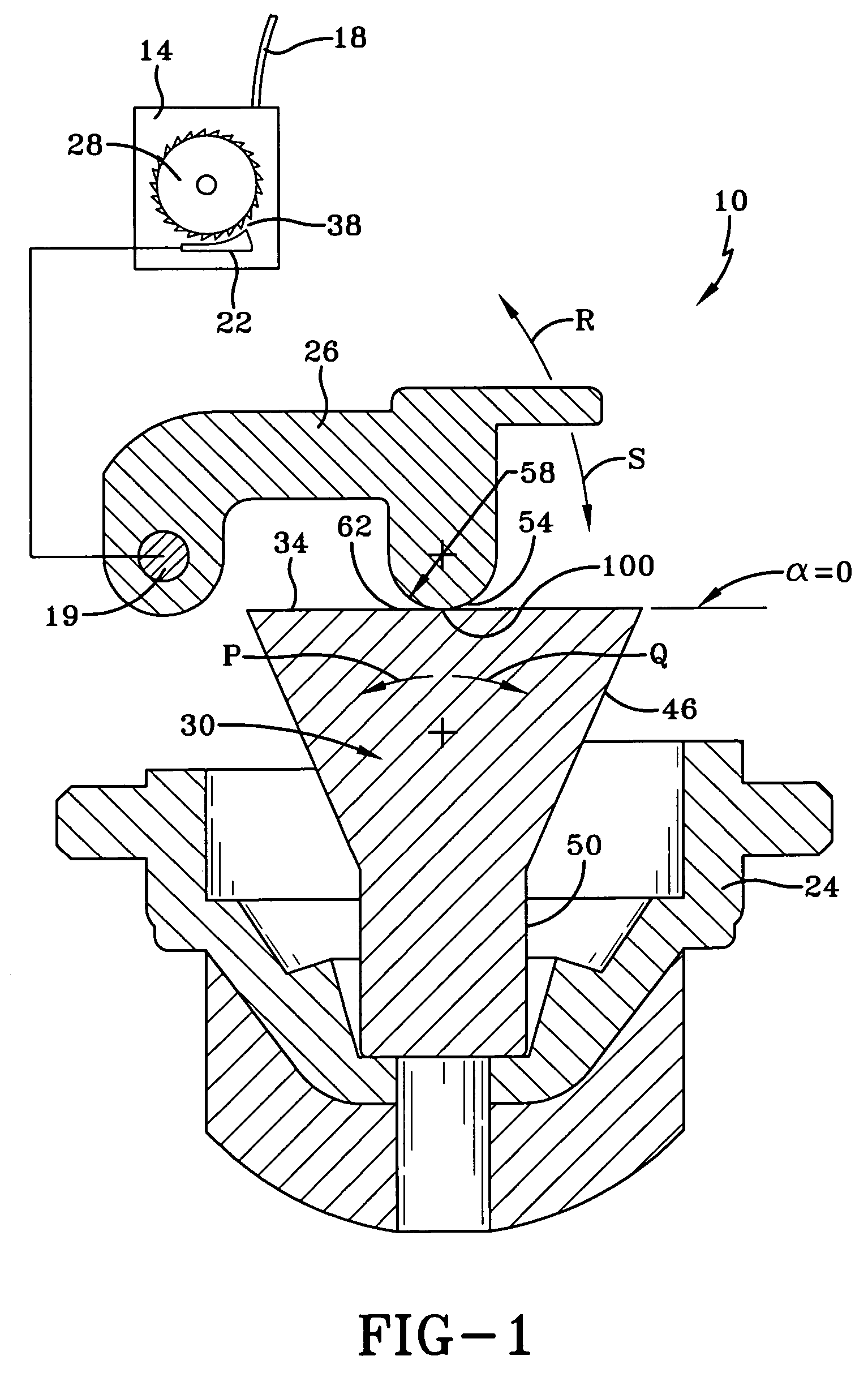

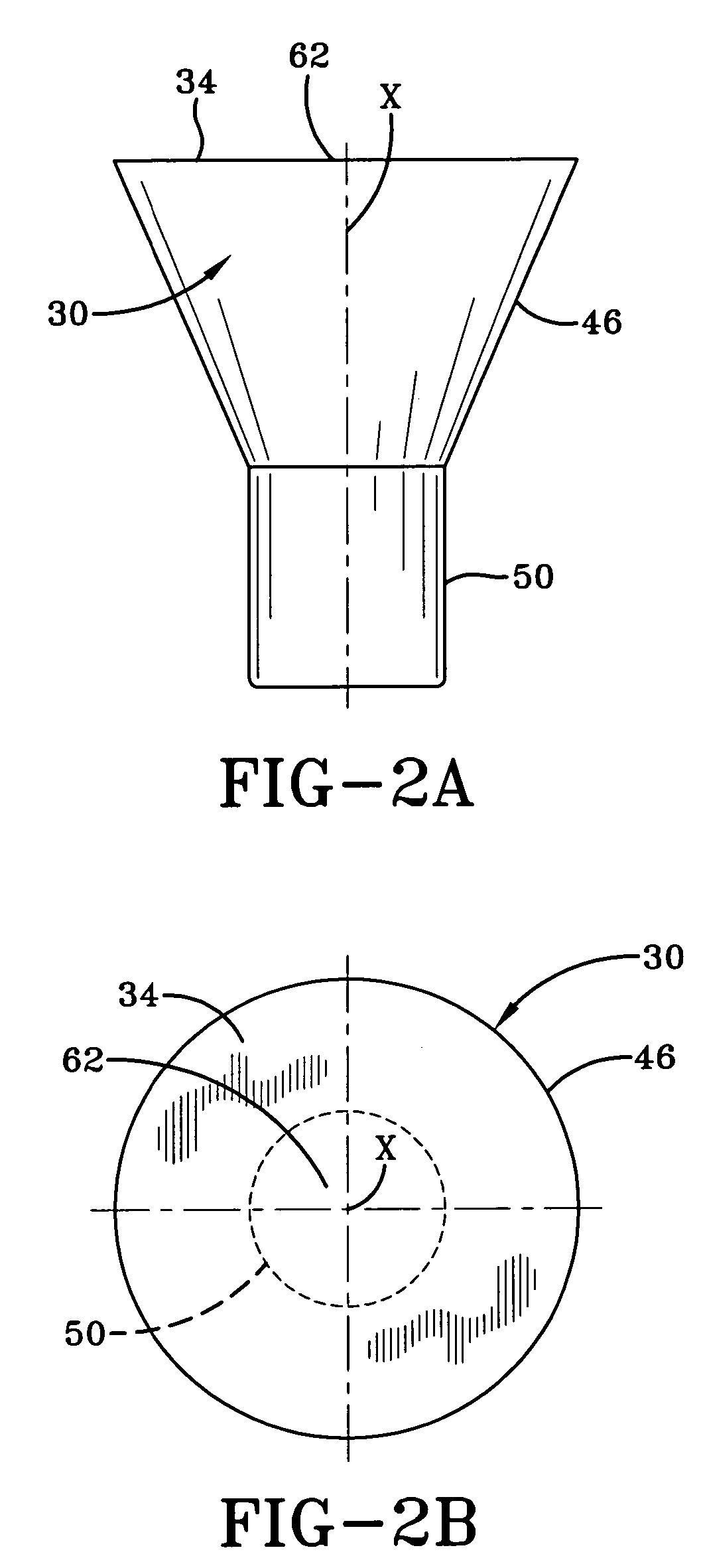

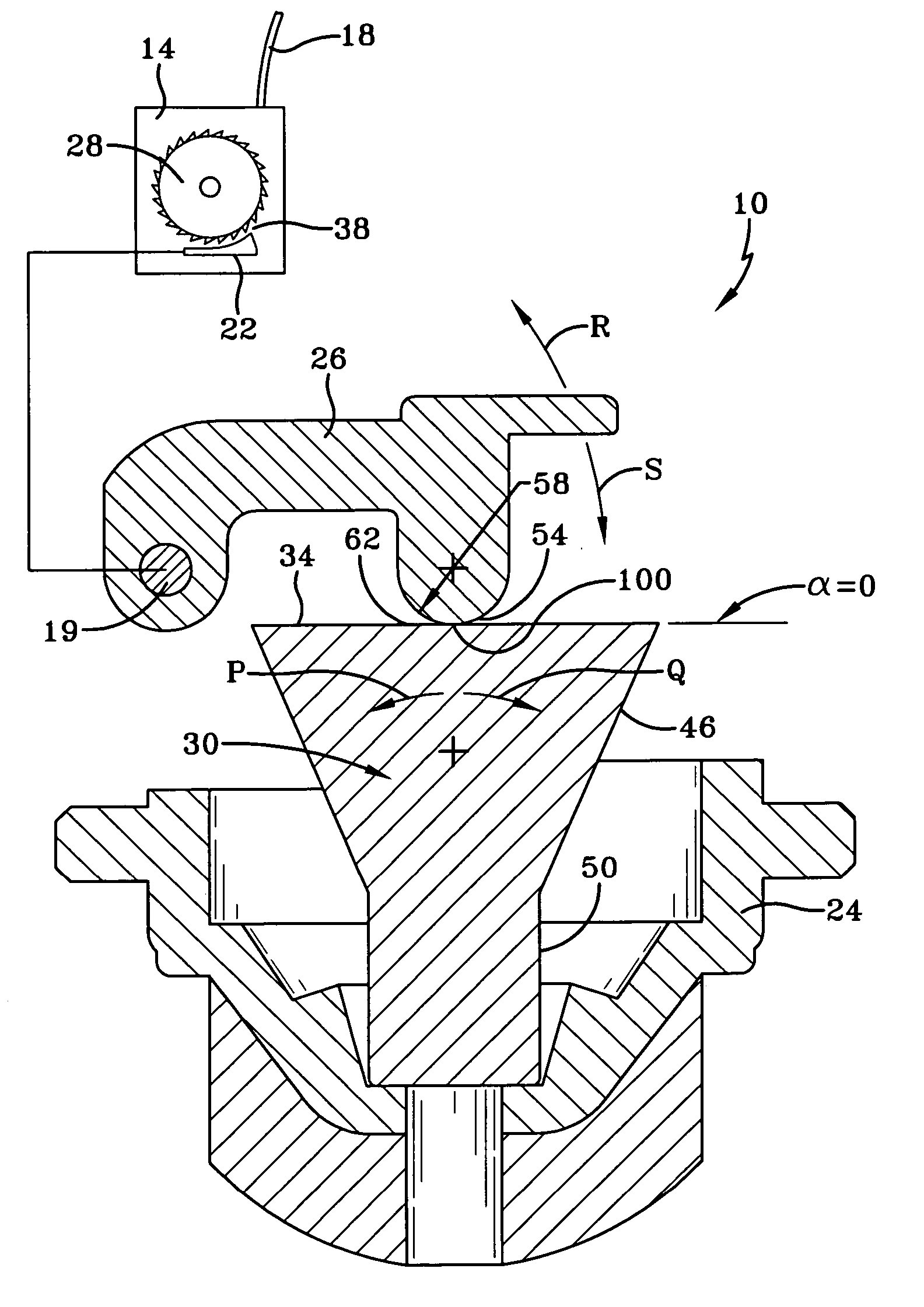

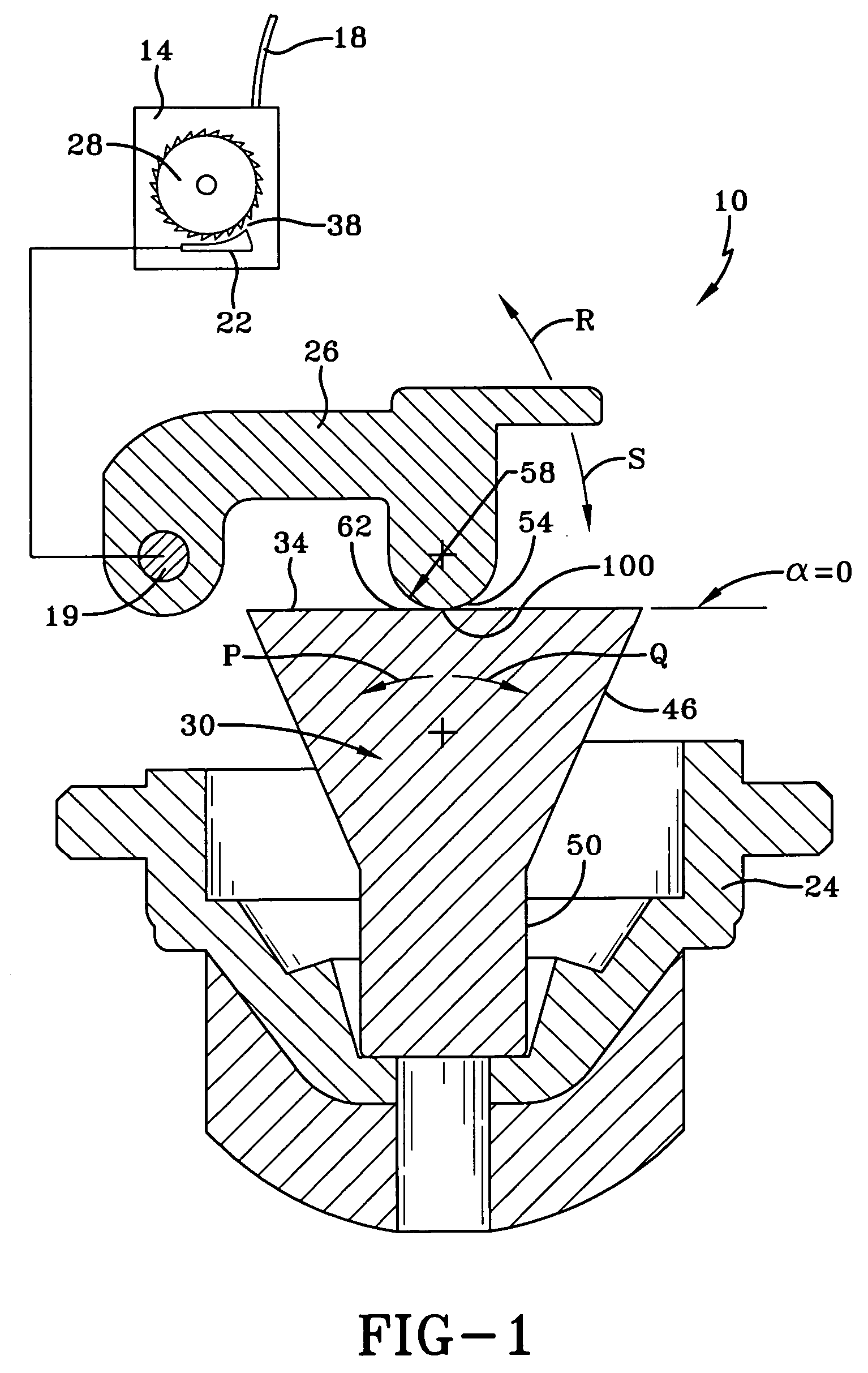

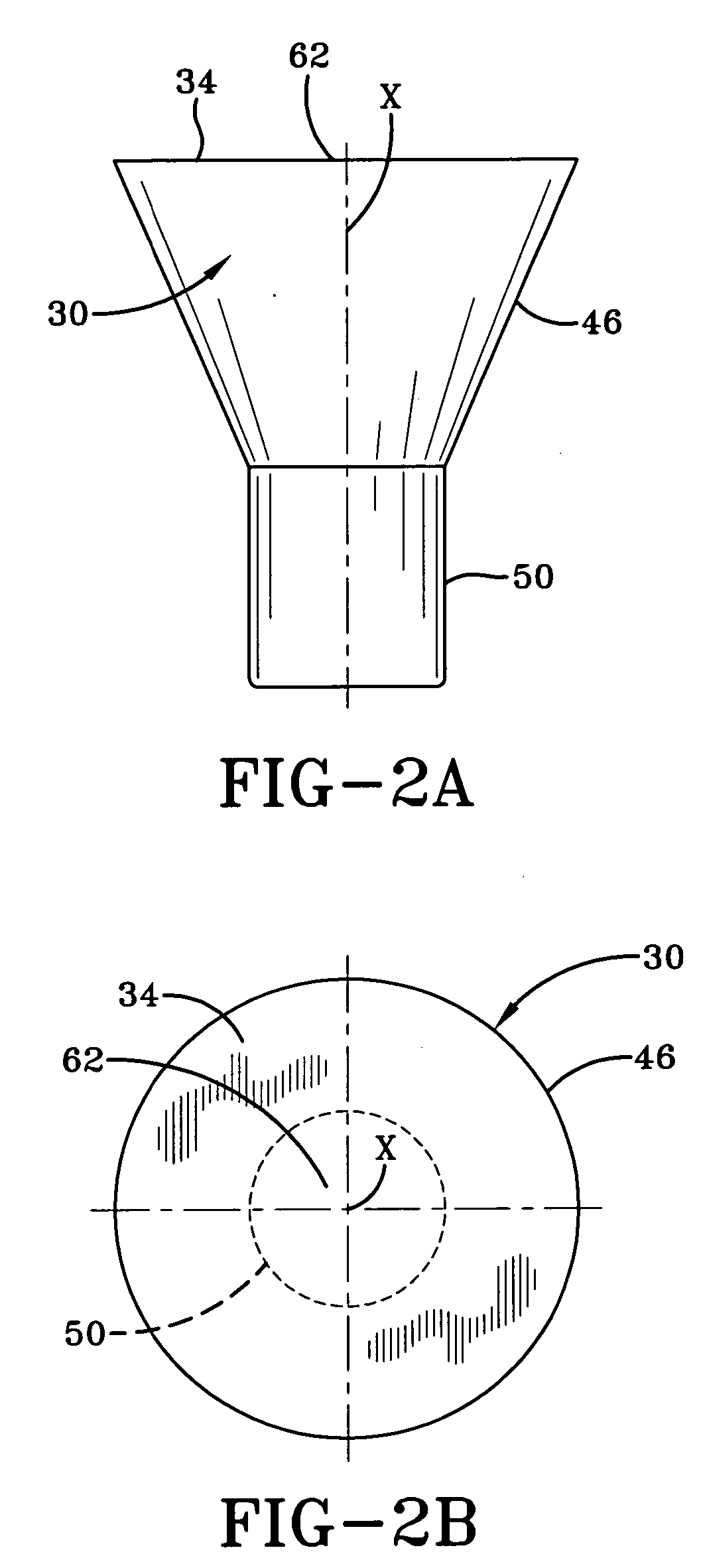

A seatbelt retractor assembly (10) has a seatbelt retractor (14) and an actuator (26) for locking and unlocking the seatbelt retractor (1). An inertial sensor mass (30, 32, 33) detects changes in vehicle speed. The mass (30, 32, 33) has a guide surface (34, 35, 36) for interacting with the actuator (26). The guide surface (34, 35, 36) moves between an unlocking position in which the actuator (26) unlocks the seatbelt retractor (14) and a locking position in which the actuator (26) locks the seatbelt retractor (14). The guide surface (30) has an inner profile portion (62) and at least an outer profile portion (64). The actuator (26) is in contact with the inner profile portion (62) in the unlocking position while moving into contact with the outer profile portion (64) as the actuator (26) moves towards the locking position. The inner profile portion (62) causes a different acceleration of the actuator (26) than the outer profile portion (64).

Owner:KEY SAFETY SYST

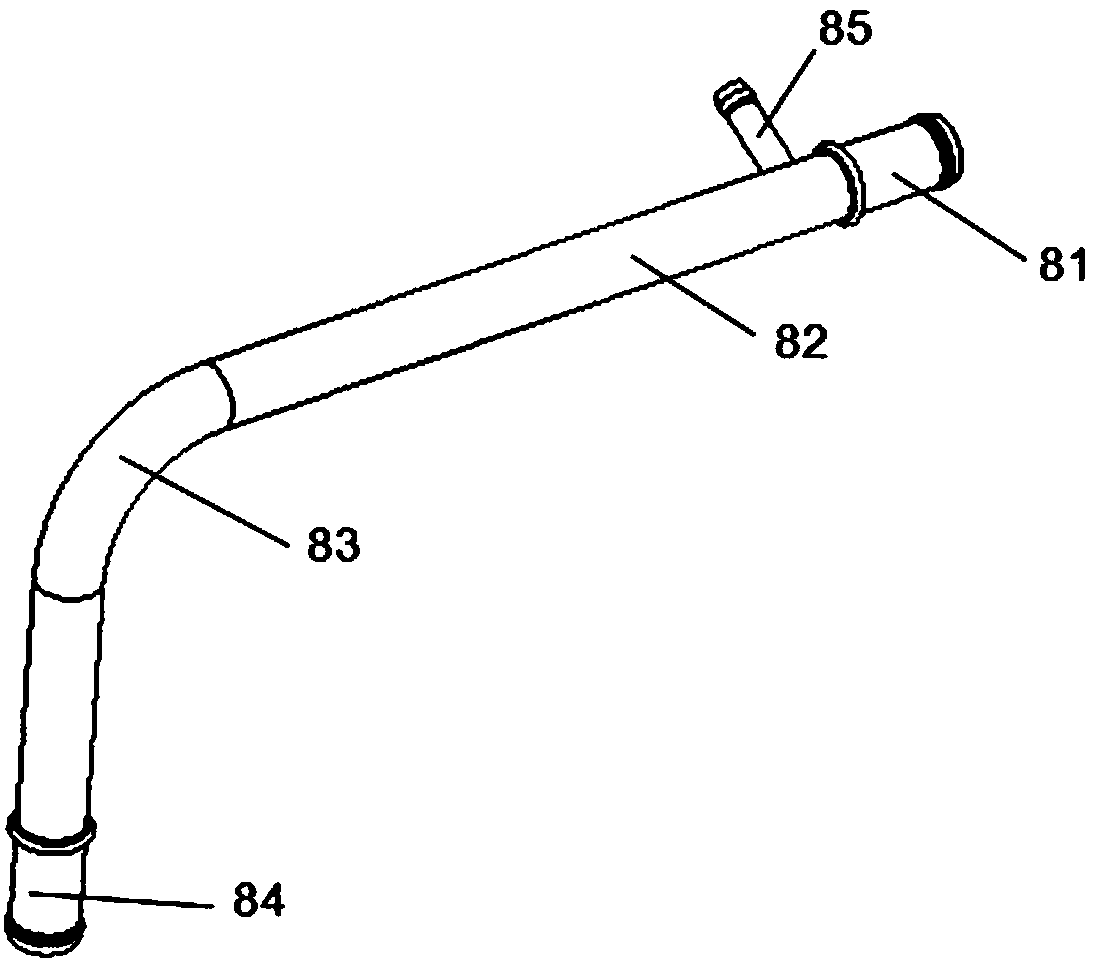

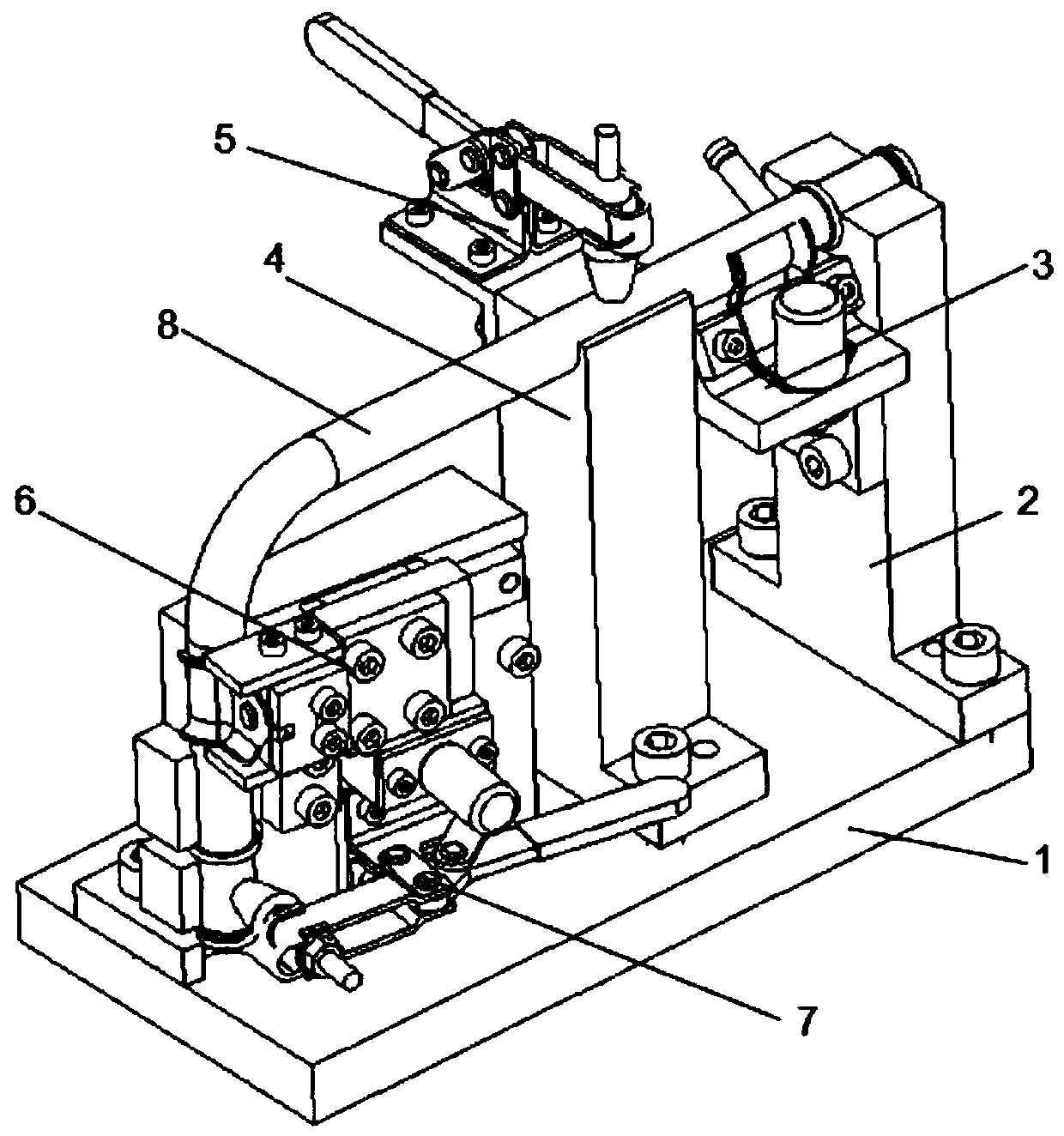

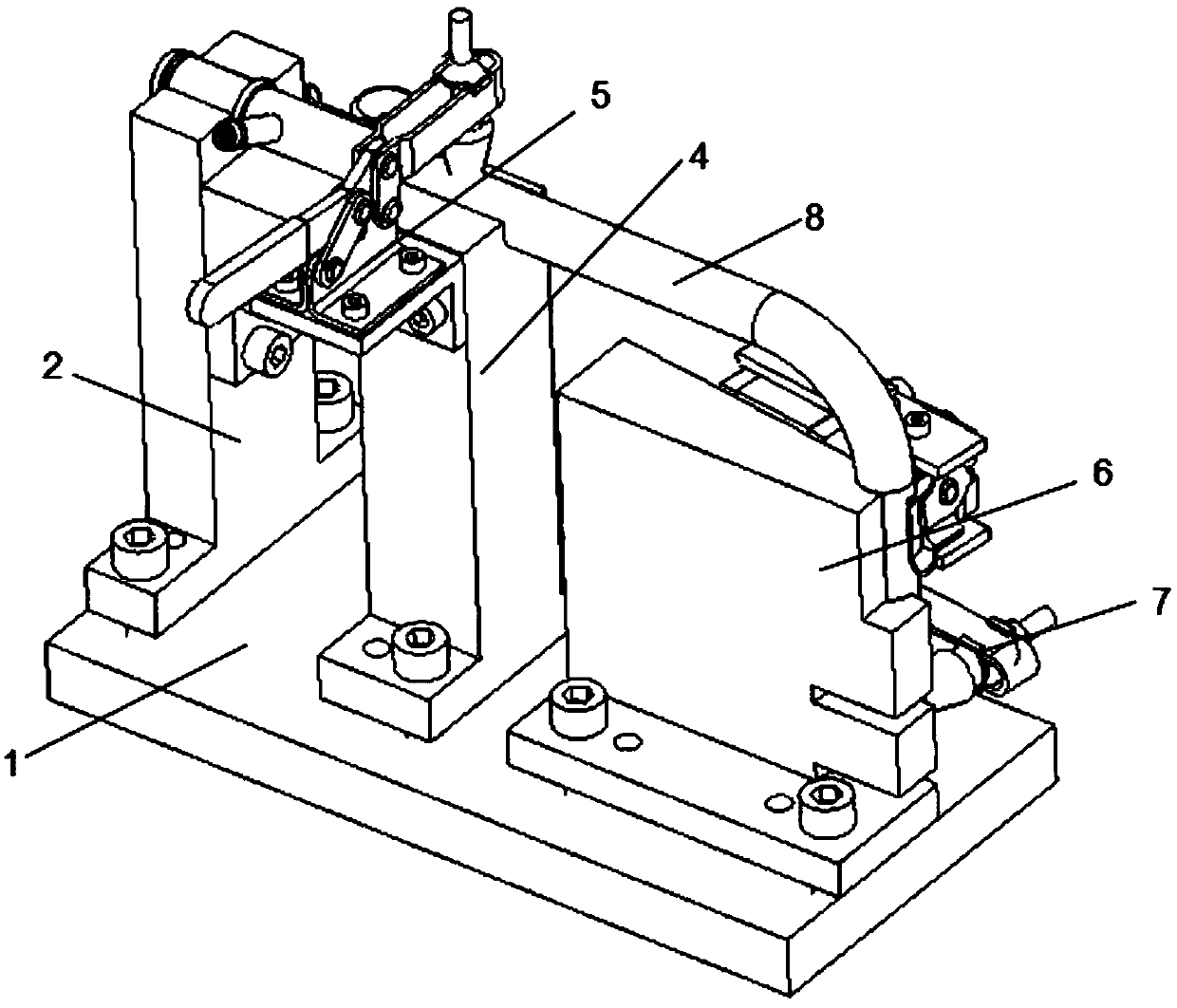

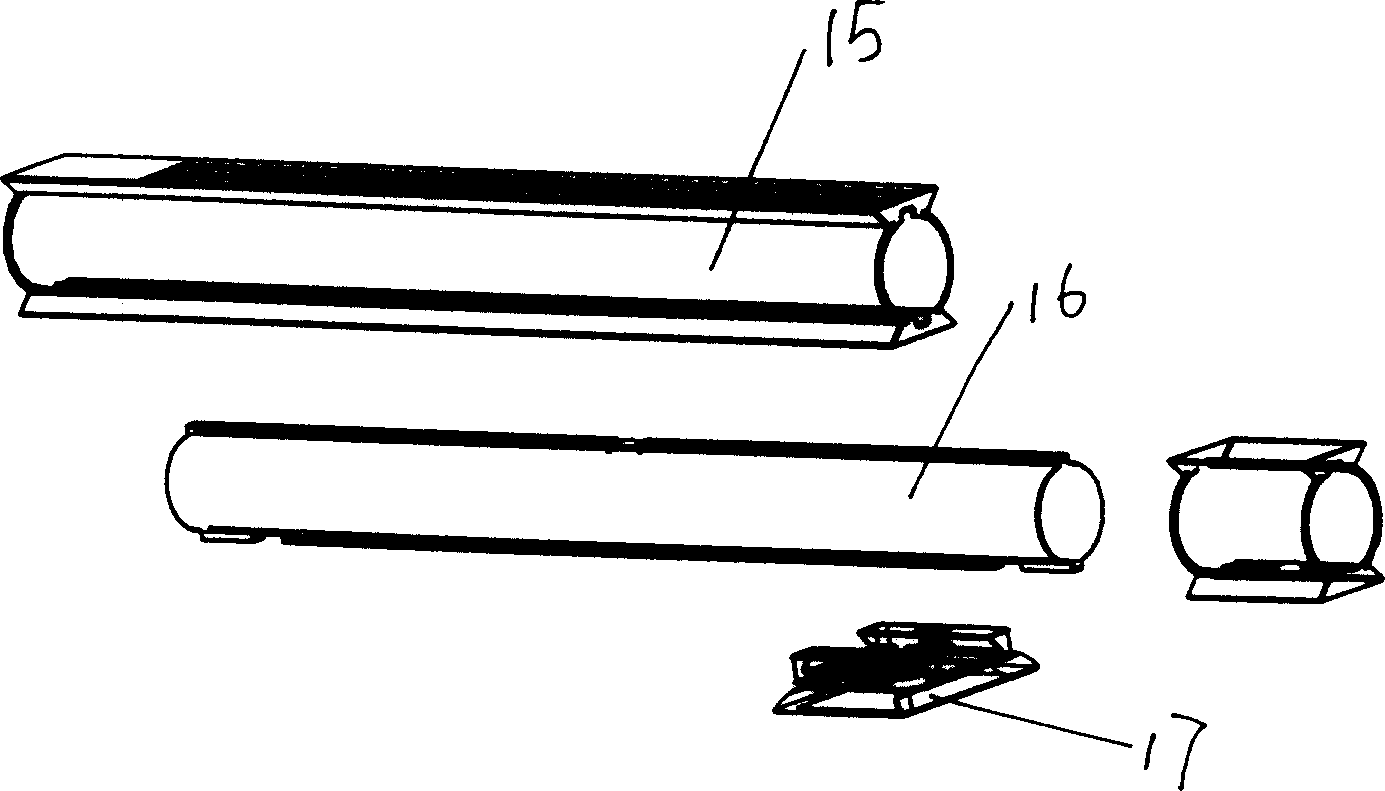

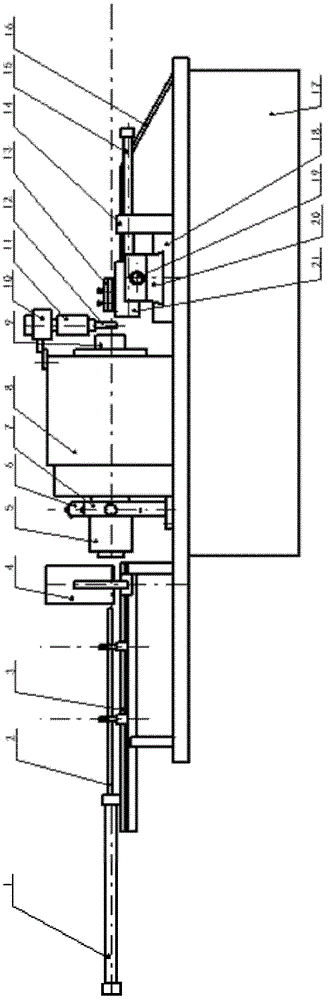

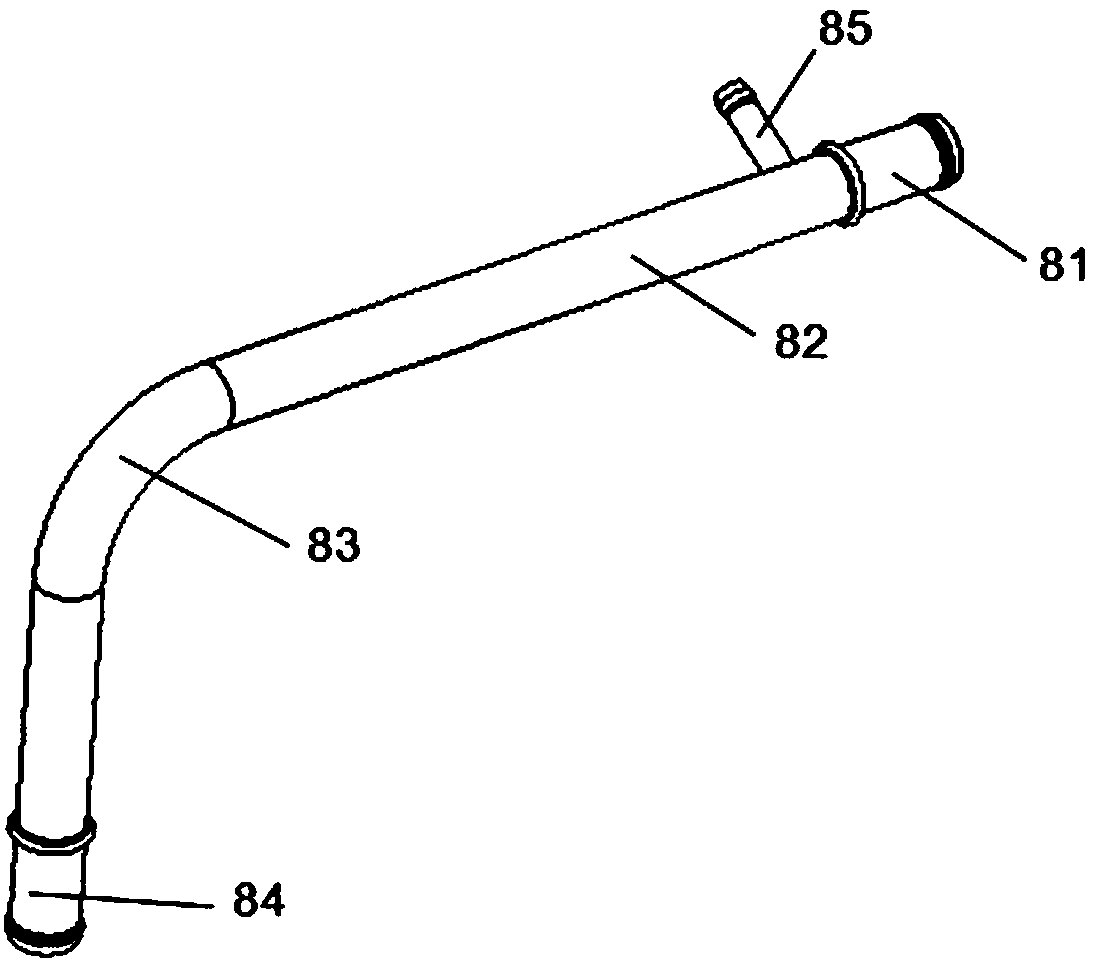

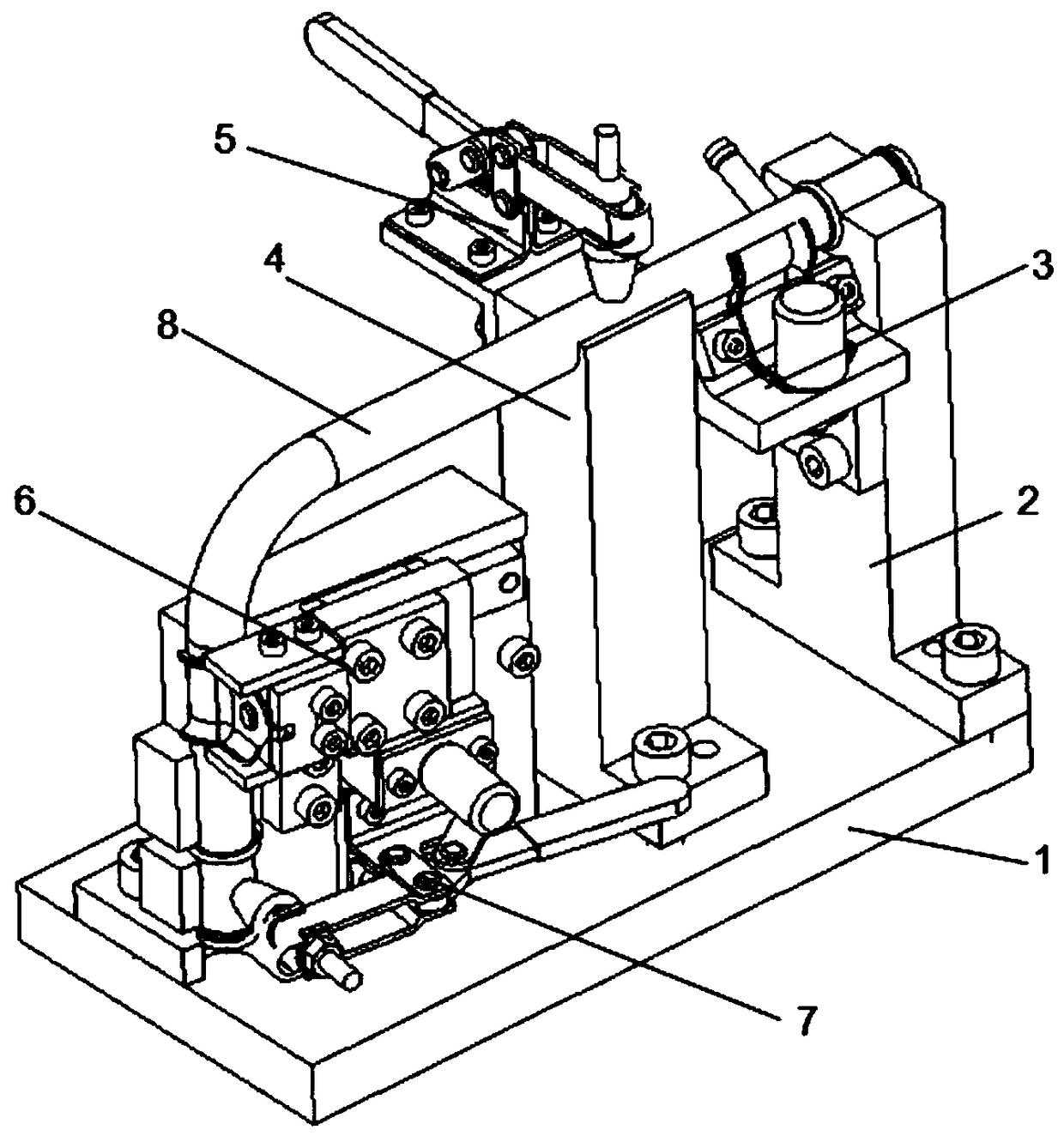

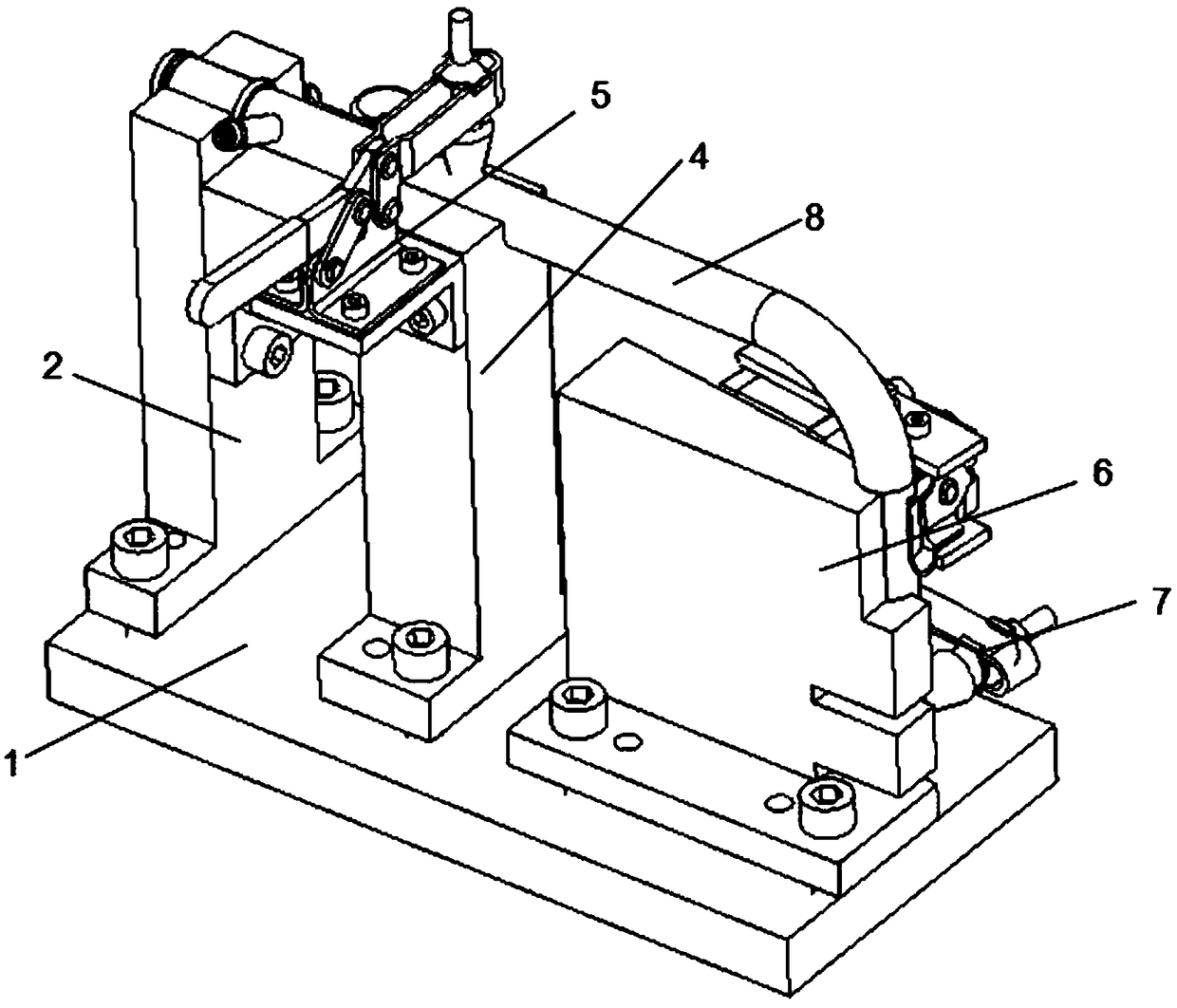

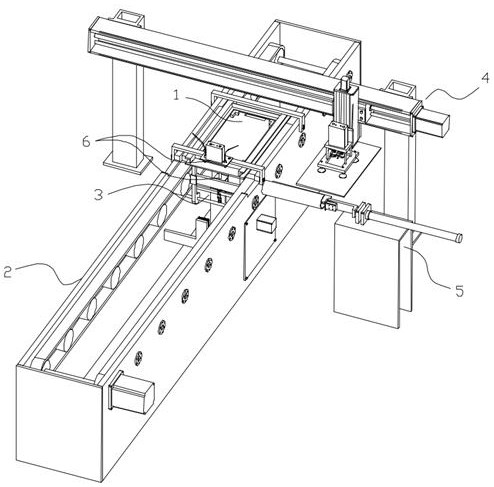

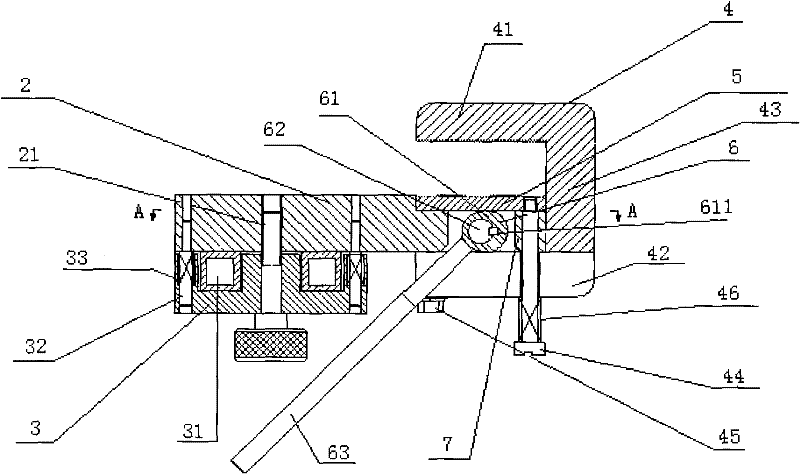

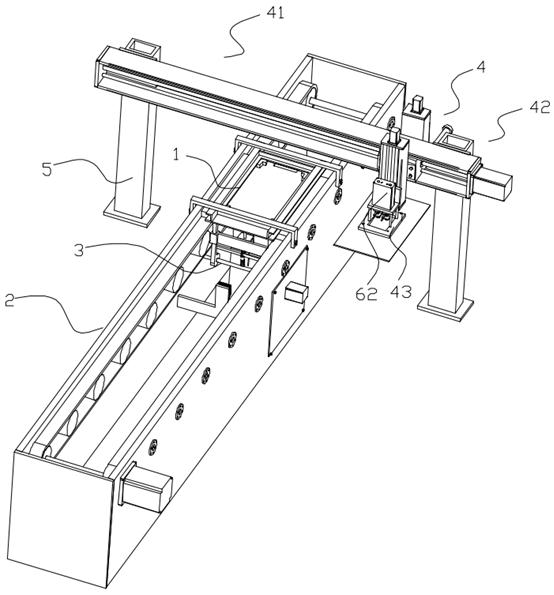

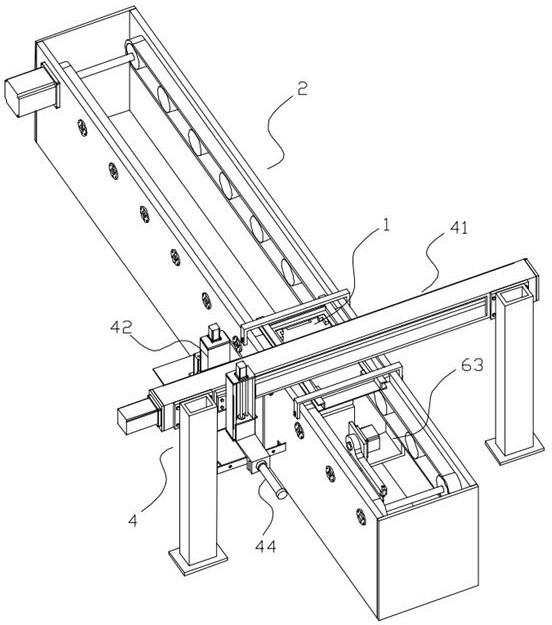

Bent pipe welding, positioning and locking device

ActiveCN107617847AImprove efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingEngineering

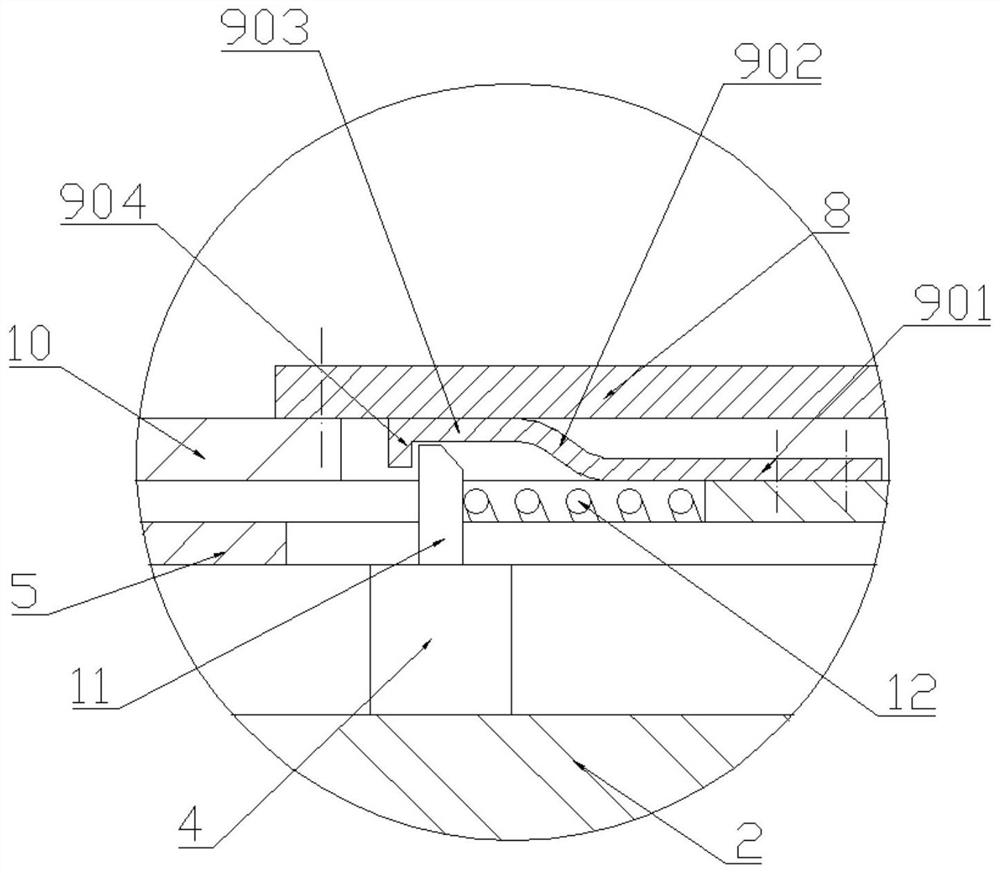

The invention provides a bent pipe welding, positioning and locking device. The device comprises a base; a first support base, a second support base and a bent pipe positioning mechanism are mounted on the base in sequence from right to left side by side; a branch pipe positioning mechanism is mounted between the first support base and the second support base; a first locking fixture is mounted onthe second support base; the bent pipe positioning mechanism is mounted on the left side of the second support base; and a second locking fixture is fixed on the side wall of the bent pipe positioning mechanism, and is positioned below a positioning and locking block. The bent pipe welding, positioning and locking device can realize quick positioning and butt joint of pipe fittings with differentshapes and guarantee the butt joint quality through presetting the first support base, the second support base, the first locking fixture, the bent pipe positioning mechanism and the second locking fixture; the branch pipe positioning mechanism can guarantee welding angles of a branch pipe with a first pipe tube and a second pipe tube to meet requirements; and the first locking fixture and the second locking fixture can realize quick locking of a straight pipe and the second pipe tube.

Owner:GUANGDONG JUNCHI TECH HLDG

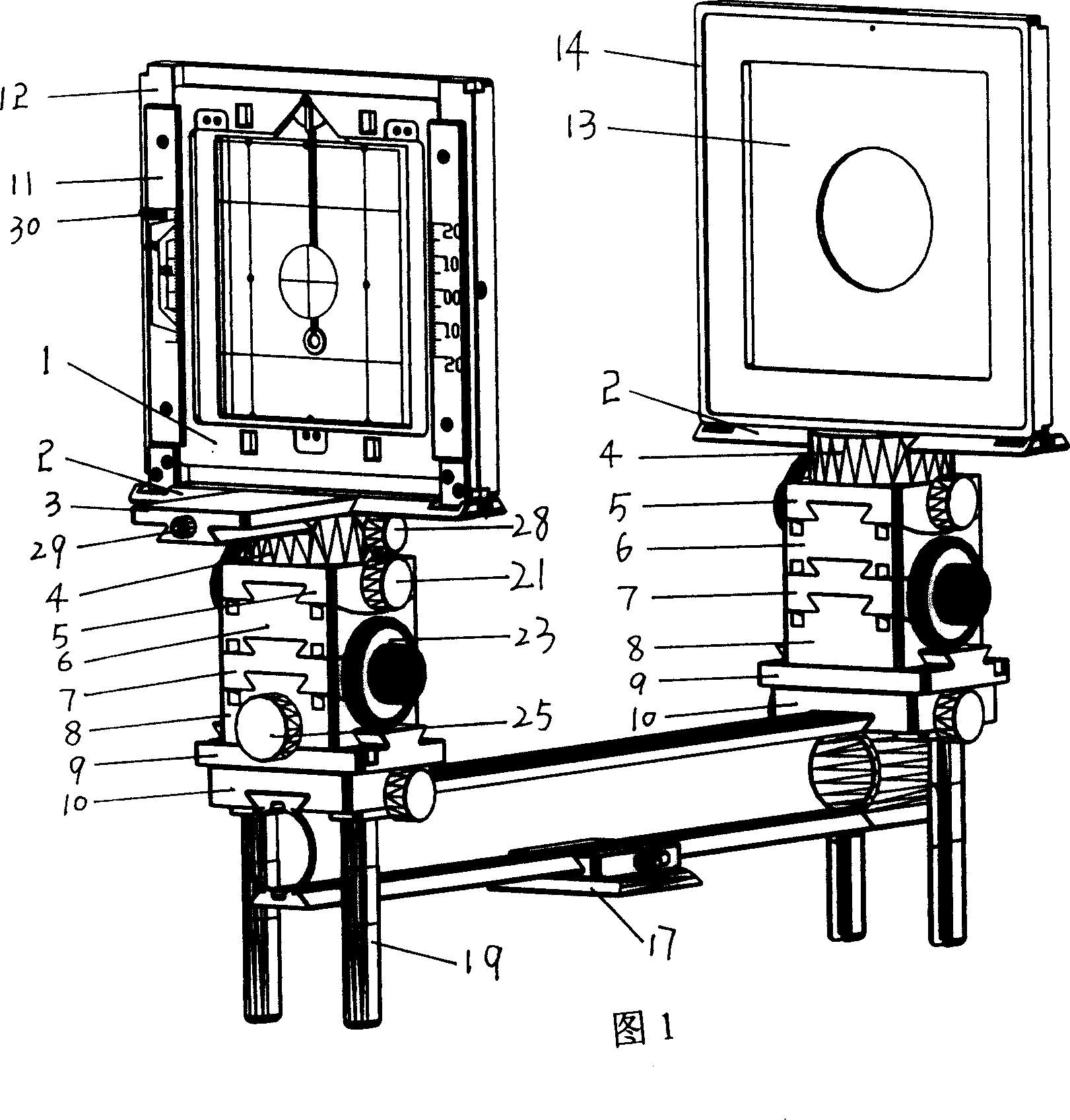

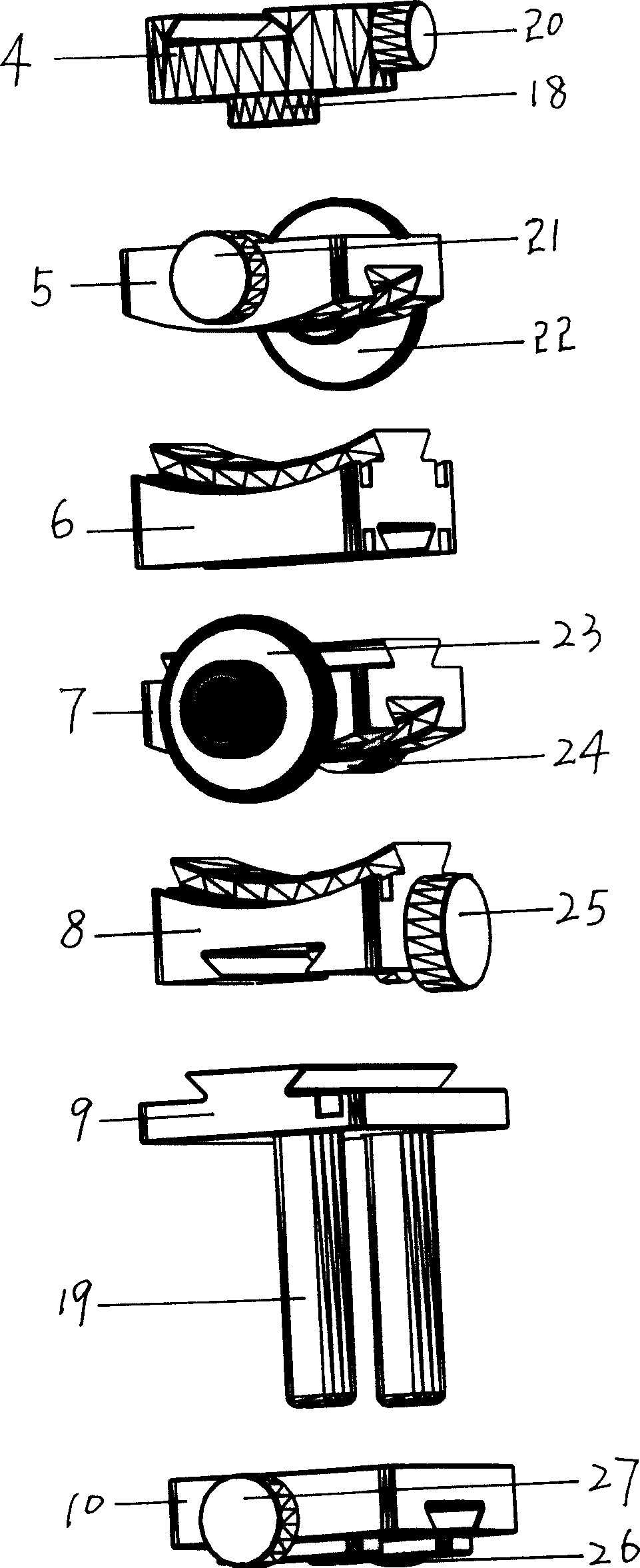

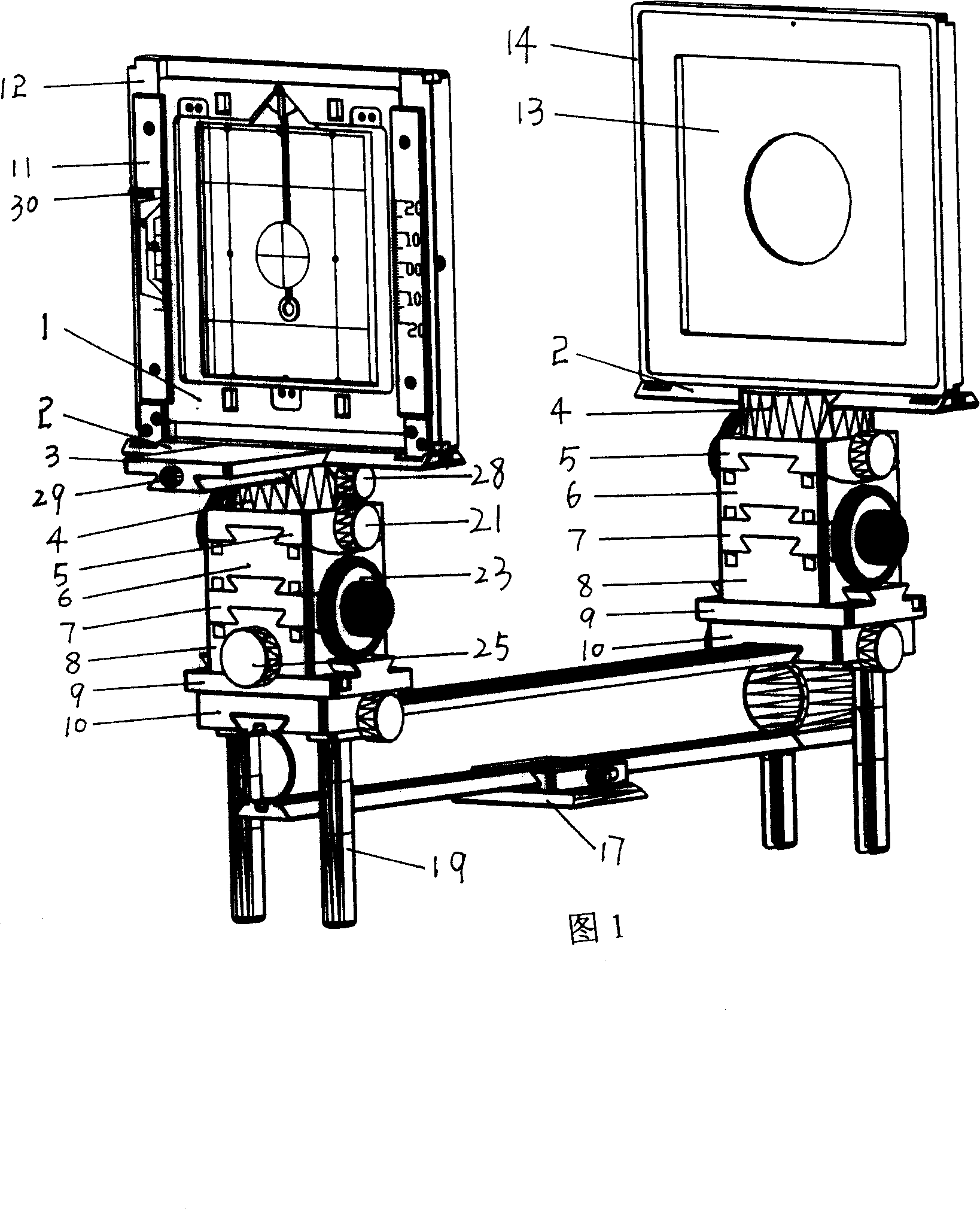

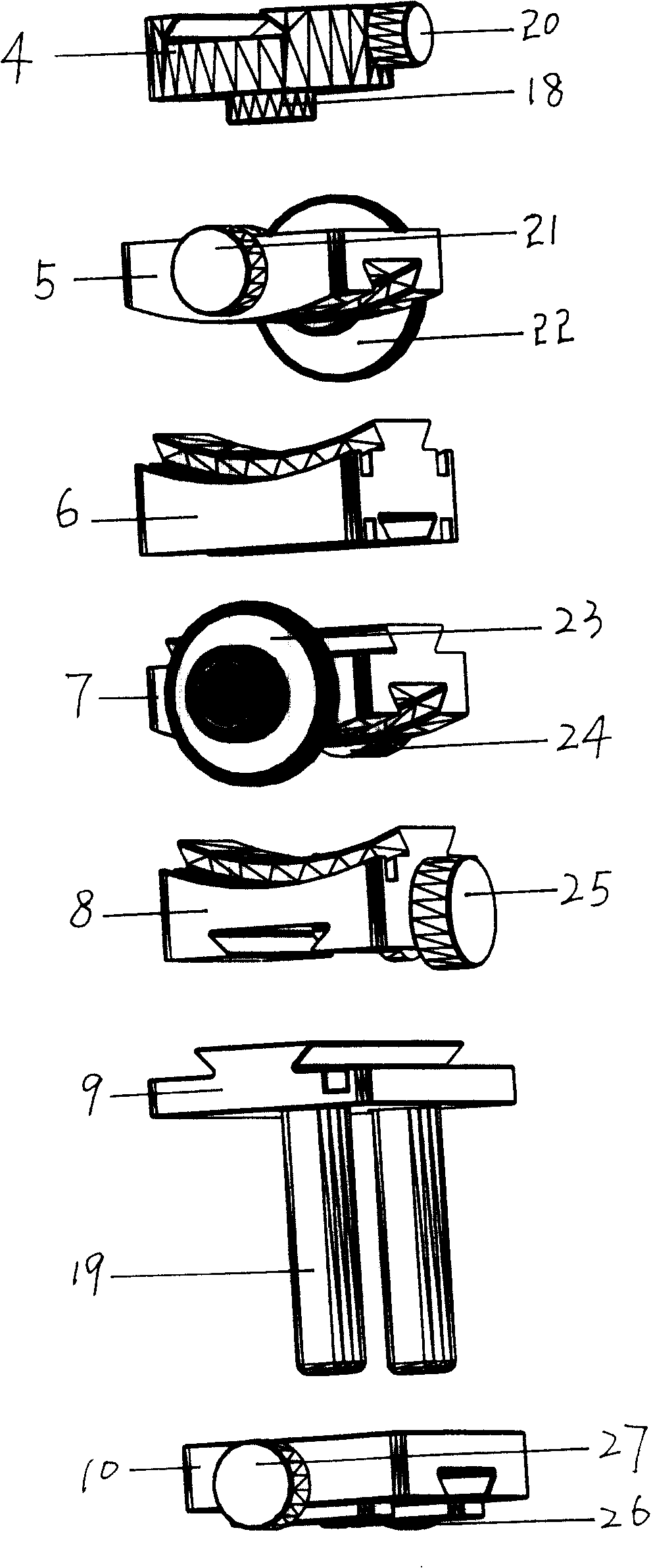

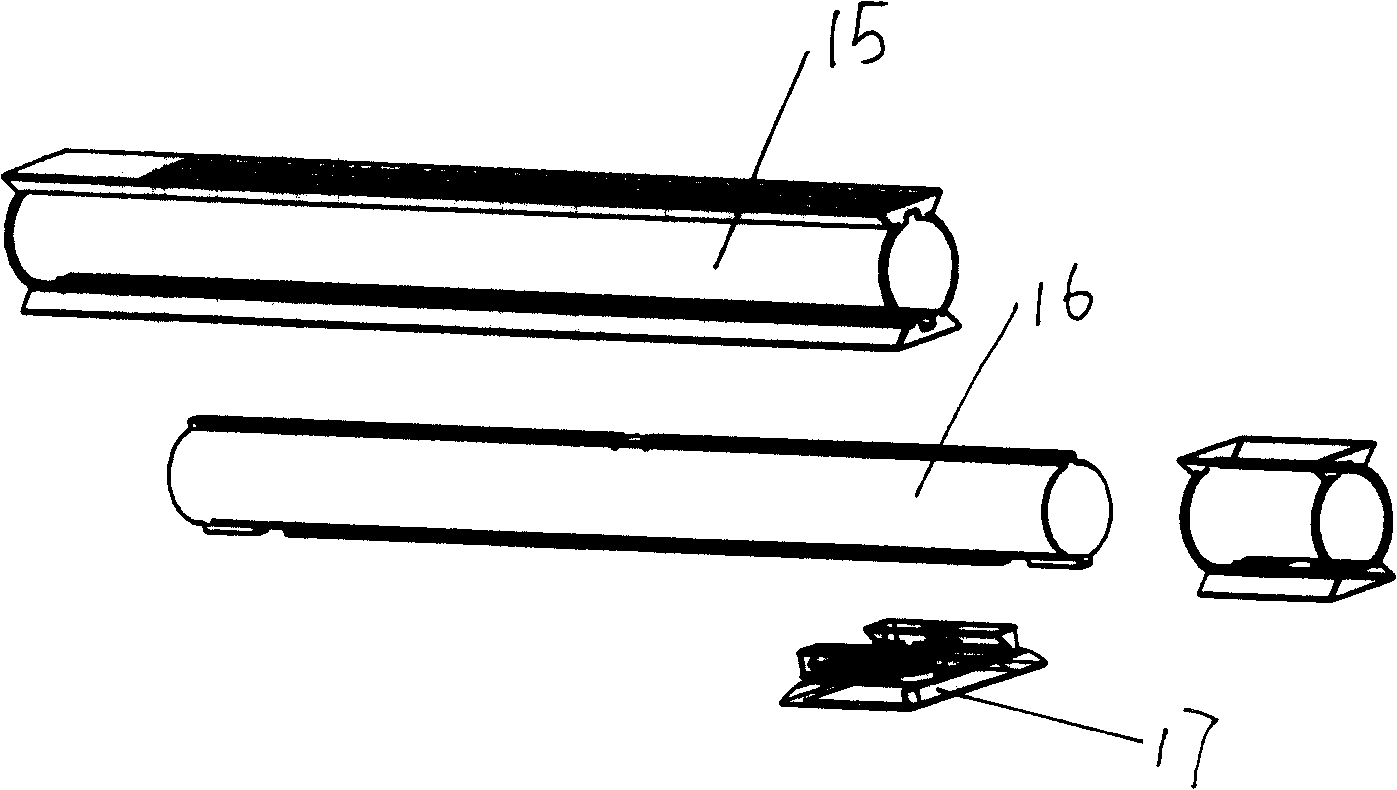

Monorail swing and tilt big range changeable camera

InactiveCN1908803AQuick focusClear division of laborCamera body detailsComputer engineeringRotating disc

The disclosed single-track shift large-frame camera comprises: a guide rail with the front and back base formed by from top to bottom a horizontal rotating disk, a vertical pitch coarse / fine turning plate with arc slide slot center as the camera zero point on the horizontal disk shaft, a front-back micro-distance plate, a left-right / top-bottom coarse plate, and a front-back coarse plate on the rail, all combined by dovetail groove; a lens frame arranged on the horizontal disk, a back frame connected with the horizontal plate. This smart invention has clear work division on adjustment with small volume and light weight, and fit to operate stably.

Owner:张云

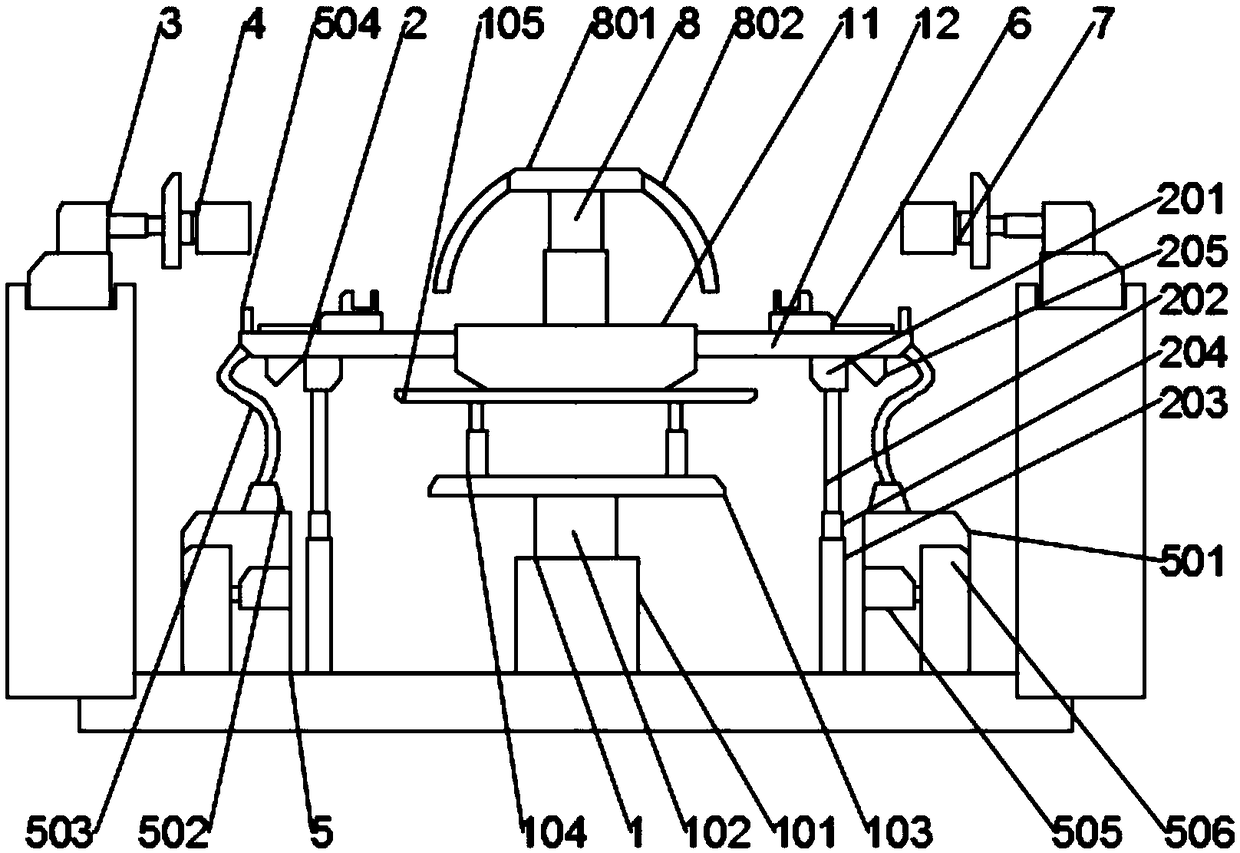

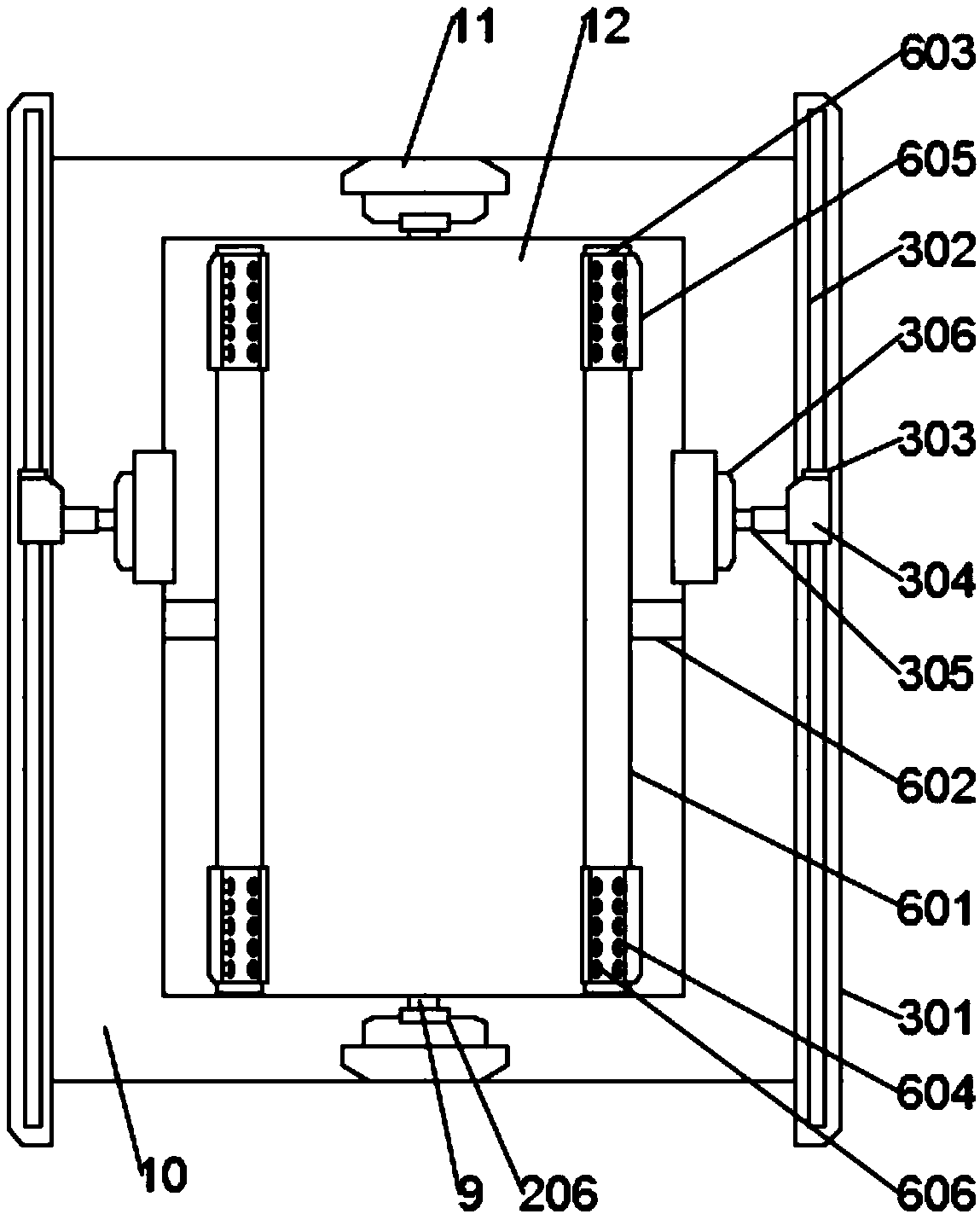

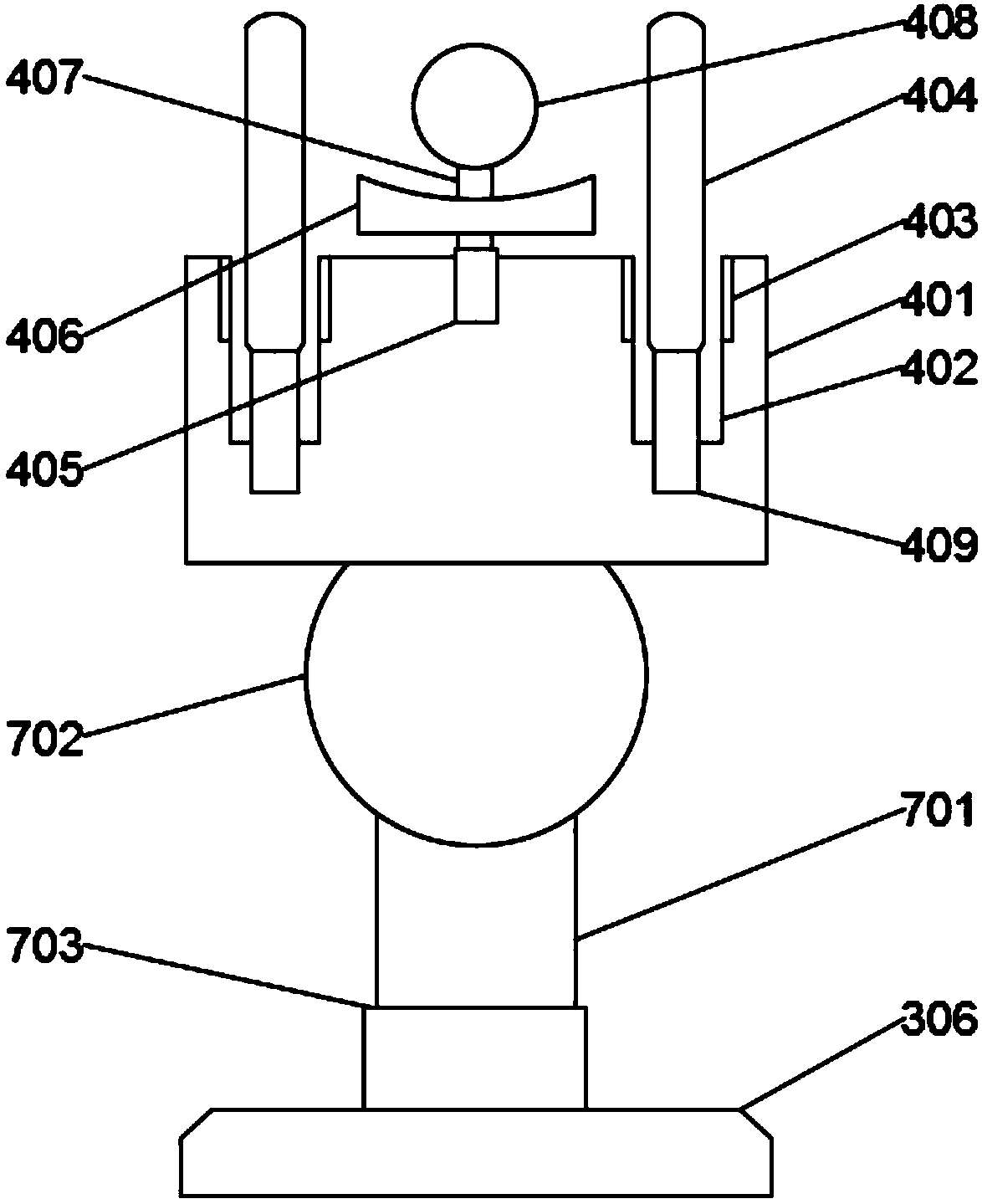

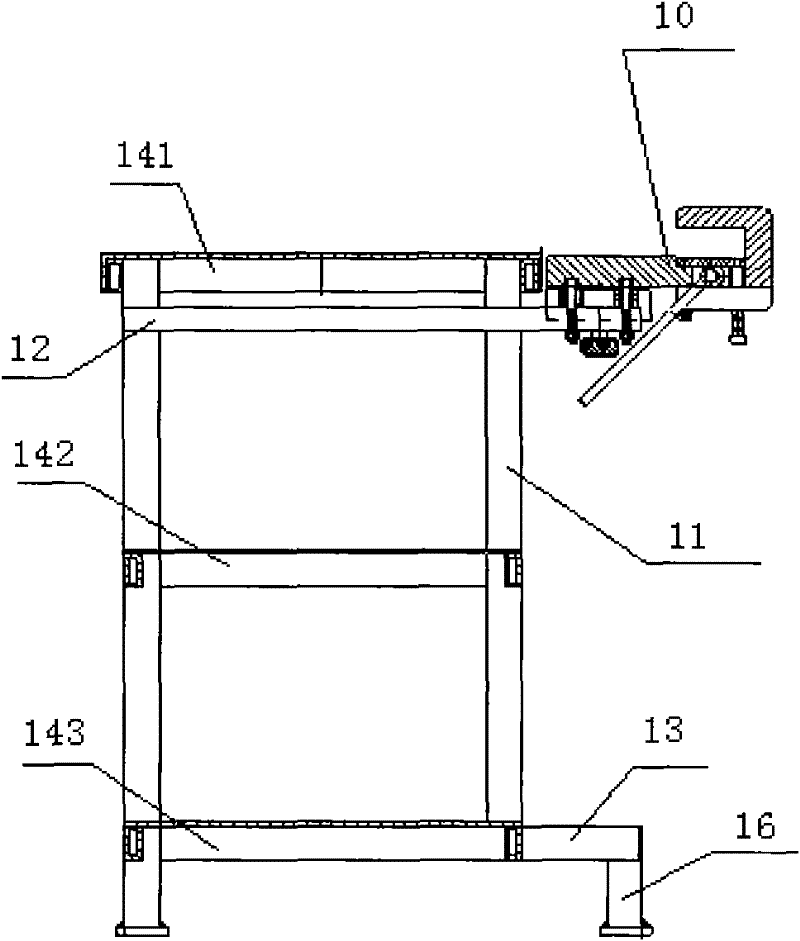

Turnover type automotive body polishing facility

ActiveCN108789079AConvenient grinding workQuick switchGrinding carriagesGrinding machinesLocking mechanismDrive shaft

The invention discloses a turnover type automotive body polishing facility. The turnover type automotive body polishing facility comprises a supporting base. Lifting frames are installed at the two ends of the supporting base, and locking bases are installed at the top ends of the two lifting frames. A working platform is connected between the two locking bases, the two ends of the working platform are connected with the locking bases through transmission shafts, and turnover mechanisms which conduct turnover on the working platform are installed on the locking bases. Combined type polishing mechanisms are installed on the two sides of the supporting base through adjusting assemblies, recovery mechanisms which are used for collecting scraps are installed on the supporting base, and locating locking mechanisms which are used for tightly clamping an automotive body are installed on the working platform. By the adoption of the turnover type automotive body polishing facility, turnover adjustment is conveniently conducted by the turnover mechanisms when the automotive body is locked, the polishing work is accomplished at different angles, and therefore the requirement for overall polishing of the automotive body is met. In addition, the combined polishing mechanisms are good in polishing effect and high in accuracy, and the polishing quality of an automobile can be improved advantageously.

Owner:芜湖众梦电子科技有限公司

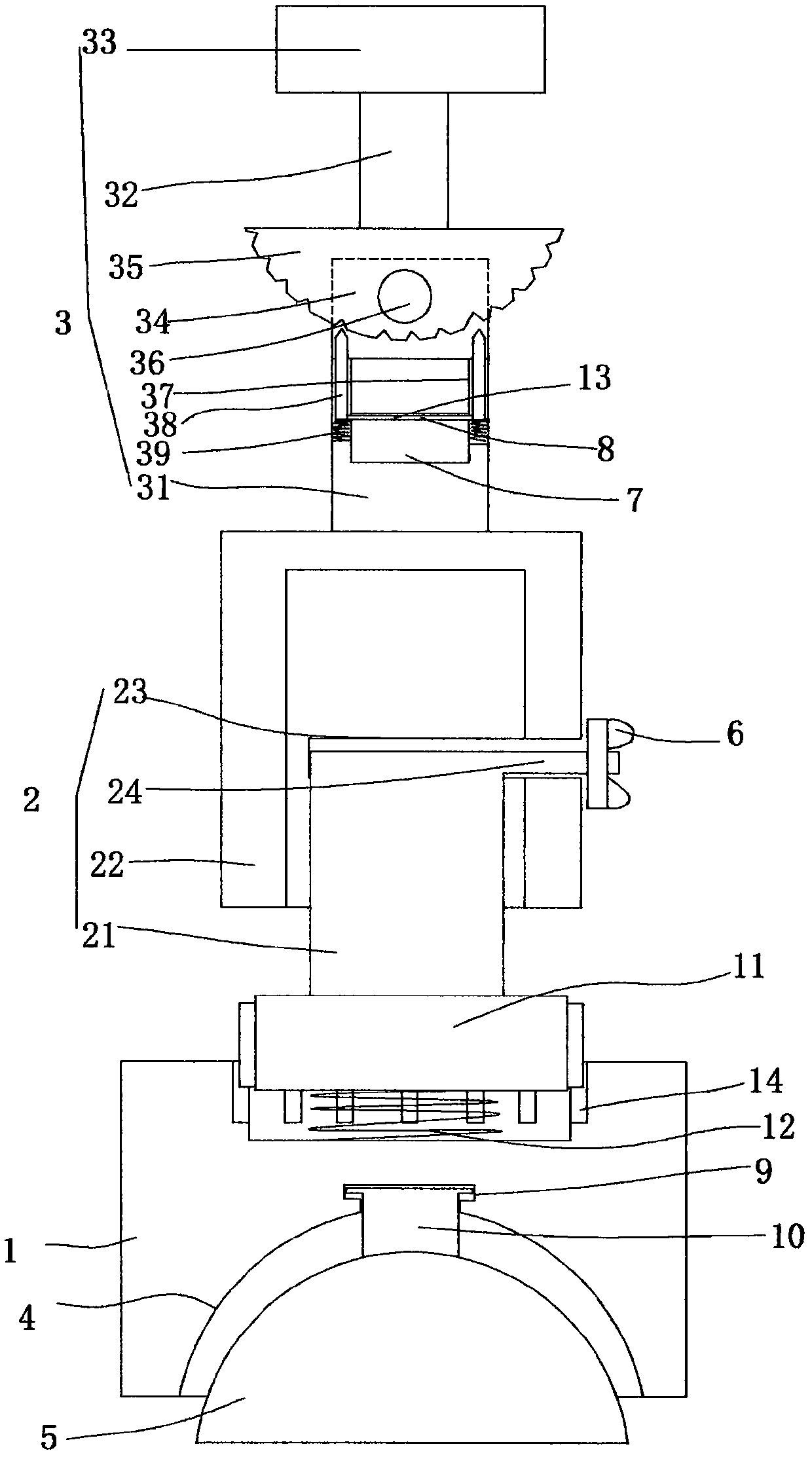

Multifunctional integrated machining machine

InactiveCN103331649AIncrease productivityQuick lockChucksMetal working apparatusEngineeringHorizontal and vertical

The invention relates to a multifunctional integrated machining machine. A main engine is fixedly mounted on a working platform, and is driven by a belt pulley of a motor to rotate; a push rod rack is coaxially mounted on the working platform at the rear part of the main engine; a push rod oil cylinder is coaxially and fixedly mounted at the tail end of the push rod rack; a push rod is coaxially connected with a plunger end of the push rod oil cylinder under the orientation of the push rod rack; two tool bases, two horizontal sliding blocks, two vertical sliding blocks and two tool rests are in axial symmetry; each horizontal sliding block is mounted with a horizontal oil cylinder; each vertical sliding block is mounted with a vertical oil cylinder through an oil cylinder bracket. Two symmetric tool rests are arranged on the working platform to perform horizontal and vertical displacement in respective dovetail grooves through the oil cylinders, so that at least two tools can be mounted simultaneously, machining in multiple operation can be performed without second-time assembly debugging, as a result, the application range of a machine tool can be effectively improved, and the production efficiency can be improved at the same time.

Owner:TIANJIN XINHUAMEI STANDARD PART MFG

Support fixed structure with locking structure

PendingCN107830344AReasonable structureEasy to adjust the angleStands/trestlesContact pressureEngineering

The invention discloses a support fixed structure with a locking structure. The support fixed structure with the locking structure comprises a sucker base, a support rod arranged on the sucker base, and a fixed frame arranged at the top of the support rod; a sucker pressing cavity opened on the bottom surface is arranged in the sucker base; a sucker is arranged in the sucker pressing cavity; the support rod comprises a bottom rod and a top cylinder; the top cylinder is provided with an arc groove; a transverse screw rod is fixed at the top of the bottom rod; the fixed frame comprises a first connecting rod, a second connecting rod and a mounting fixture; the first connecting rod is provided with a n-shaped groove; an arc tooth disc is fixed on the second connecting rod; a clamping groove is formed in the side wall of the first connecting rod; a locking insertion plate is arranged in the clamping groove; and a butting spring is fixed between the locking insertion plate and the end wallof the clamping groove. The support fixed structure with the locking structure is reasonable in structural setting, is convenient to adjust the angle, can quickly finish locking and positioning, improves the use convenience, meanwhile, can guarantee the use reliability, and is excellent in use stability, high in applicability and excellent in practicability.

Owner:浙江西维亚进出口有限公司

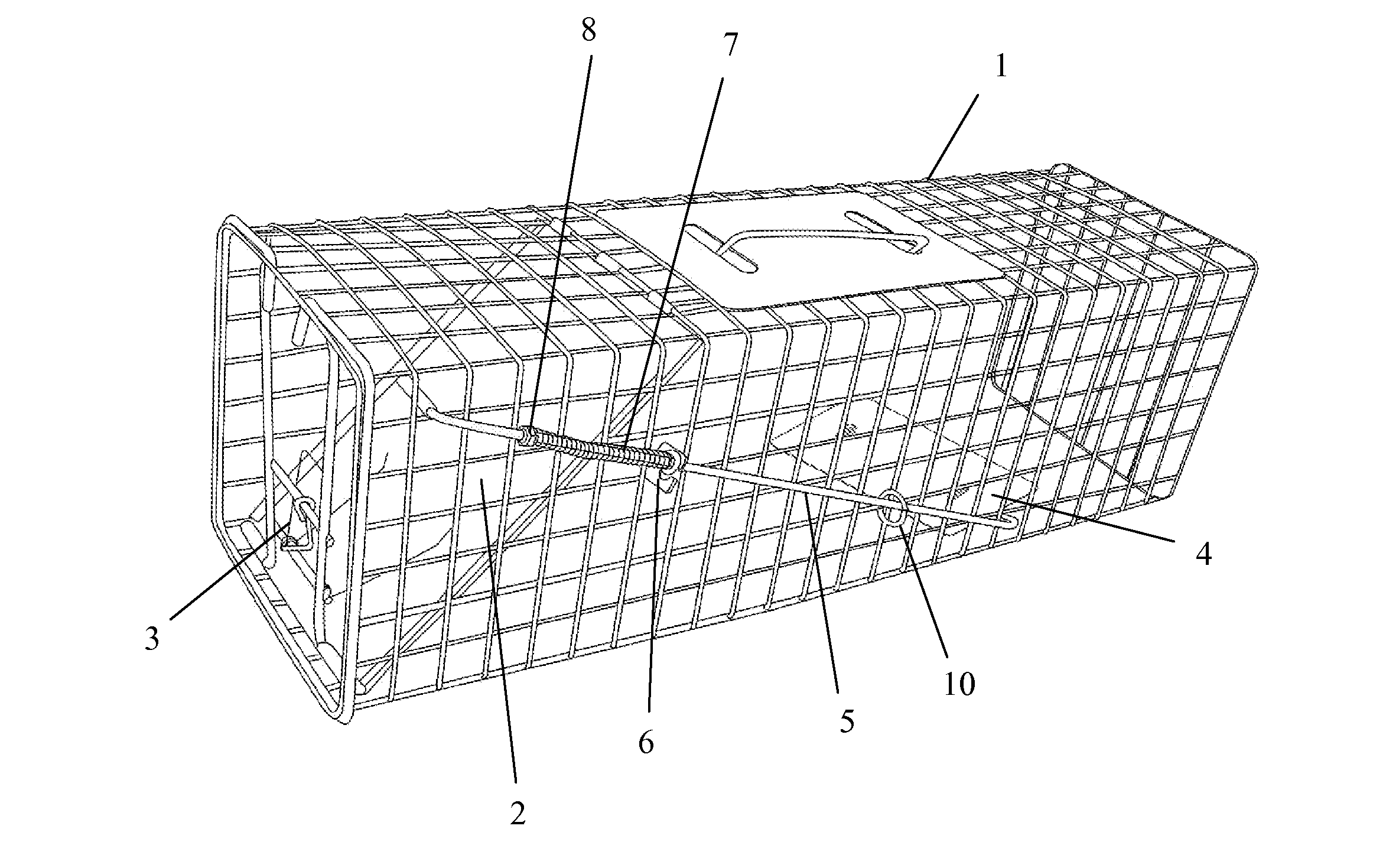

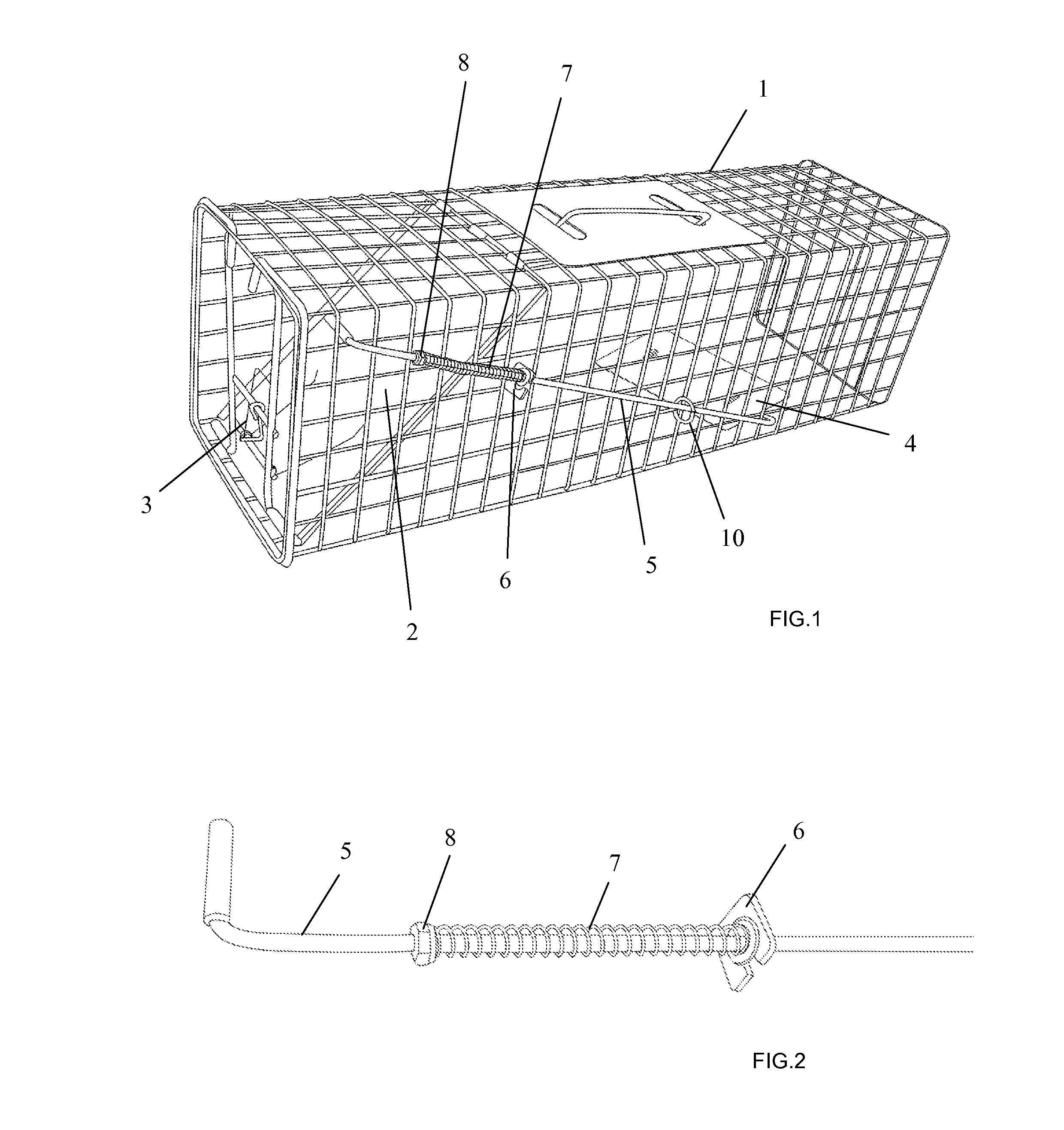

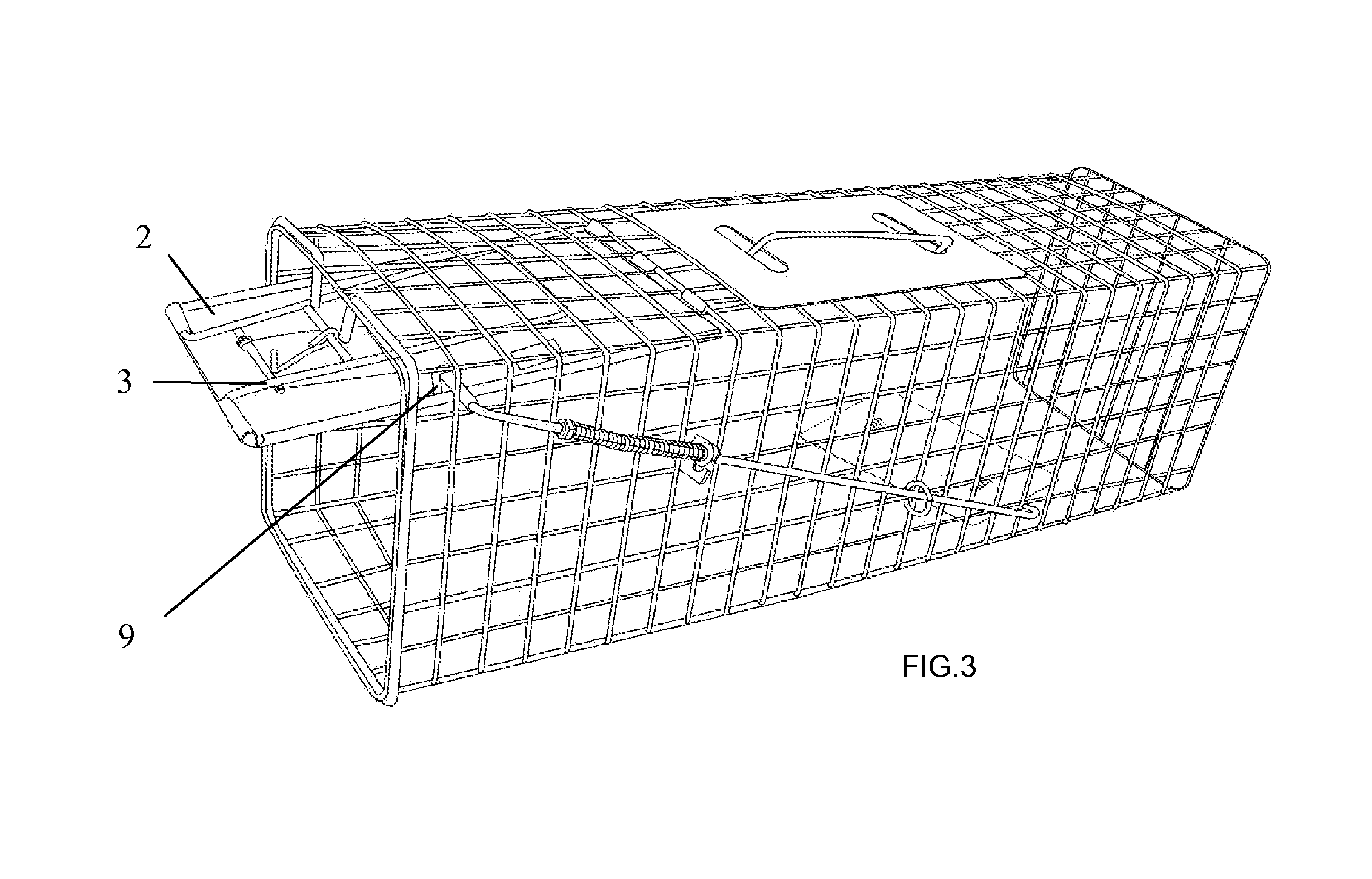

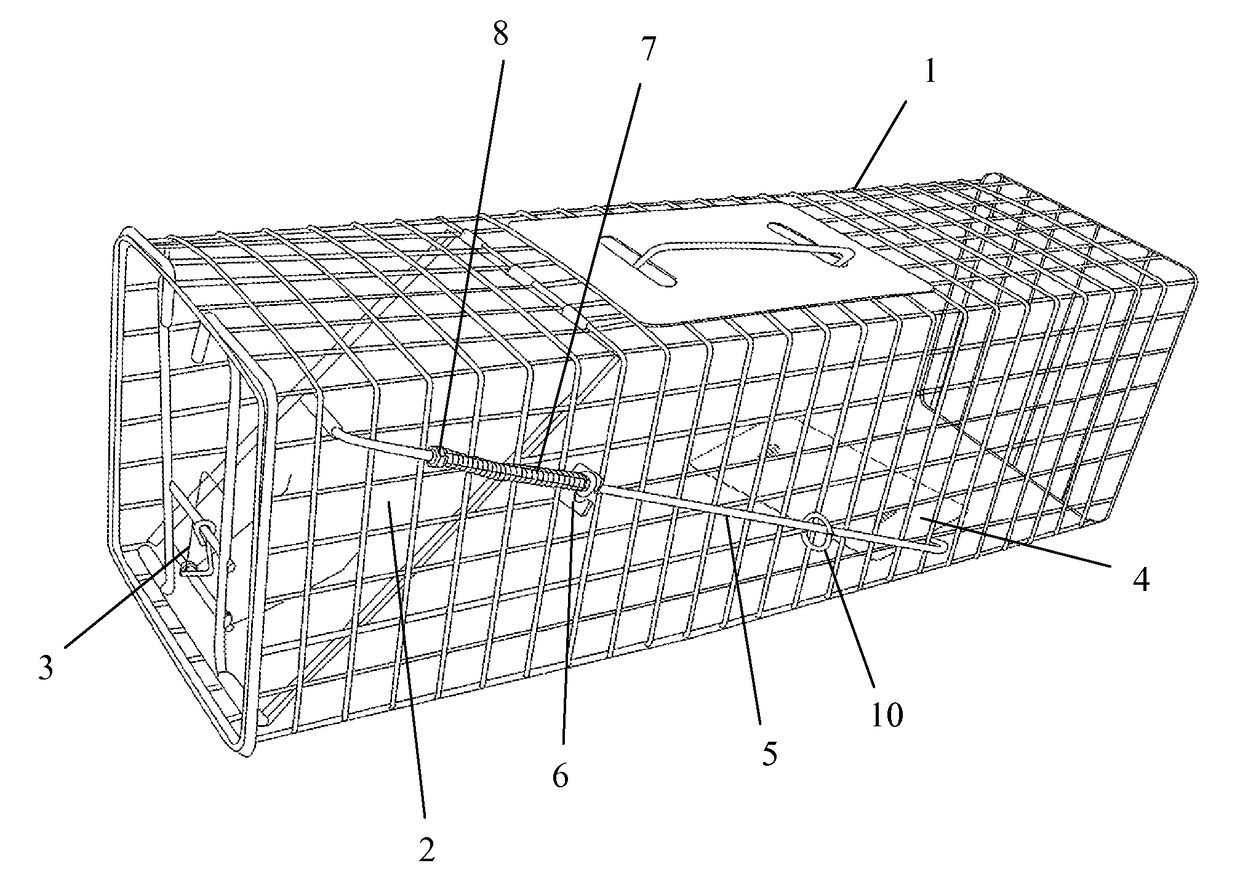

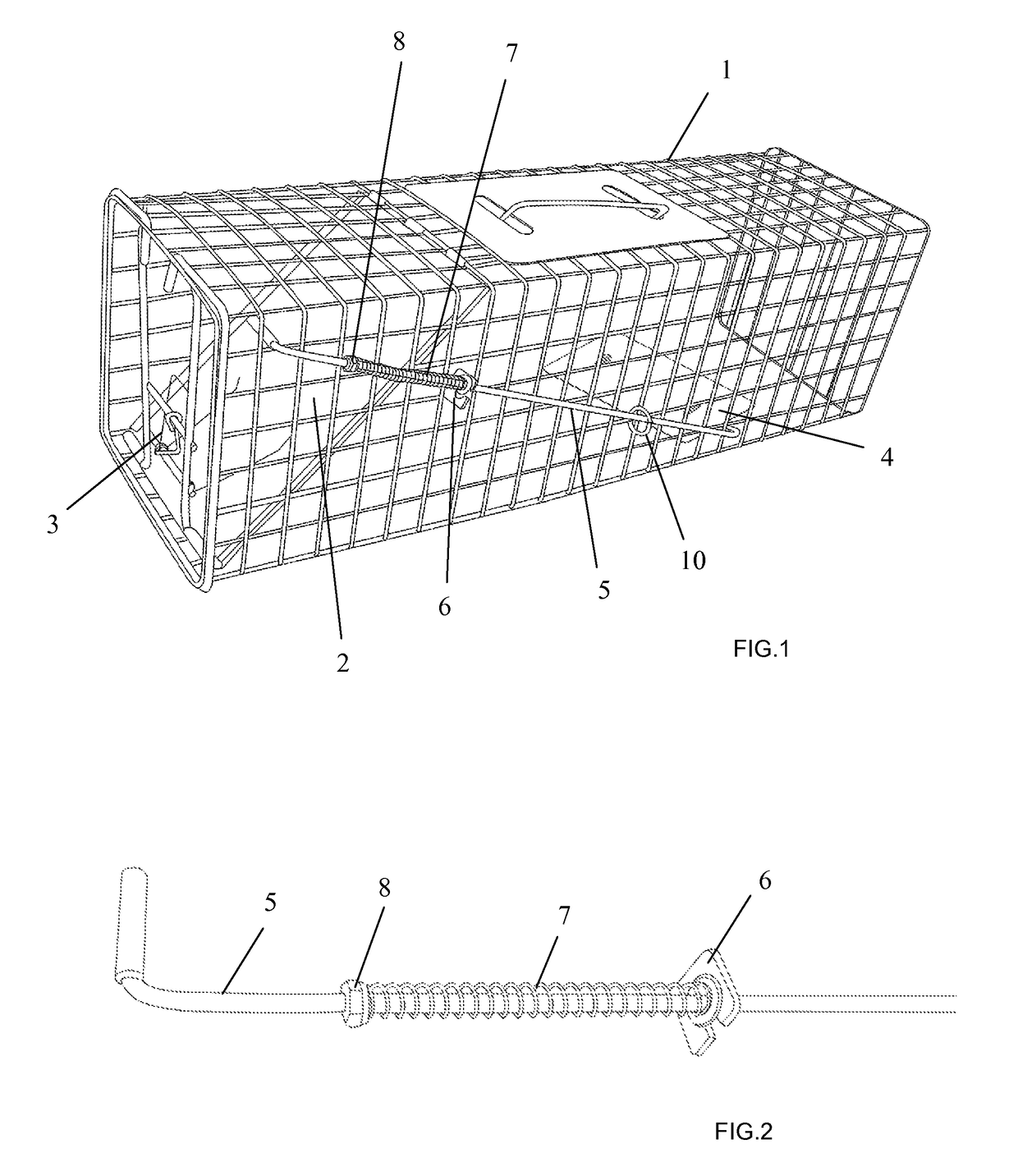

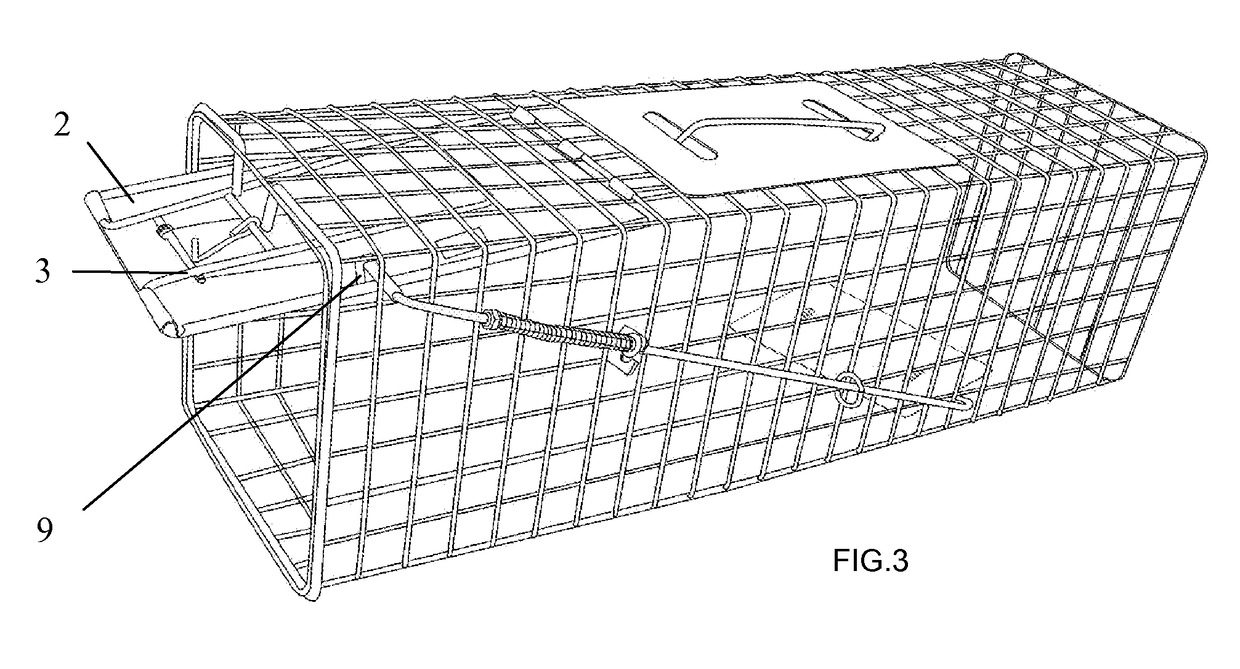

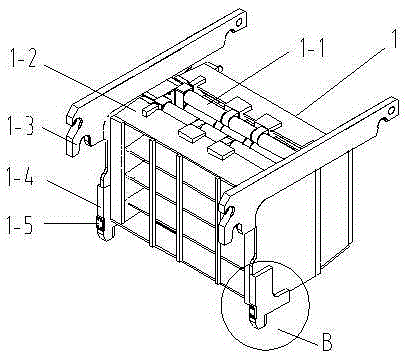

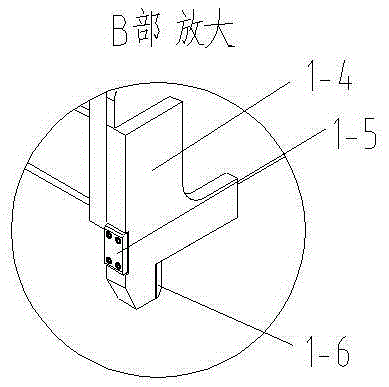

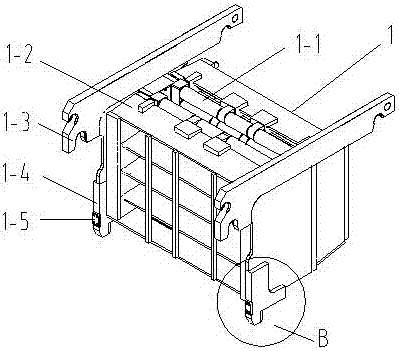

Cage having an automatic door

Owner:ZHU HONGWEN

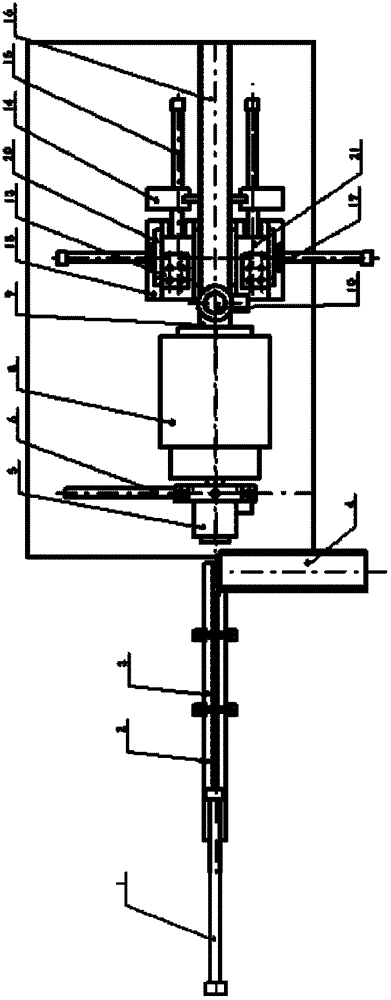

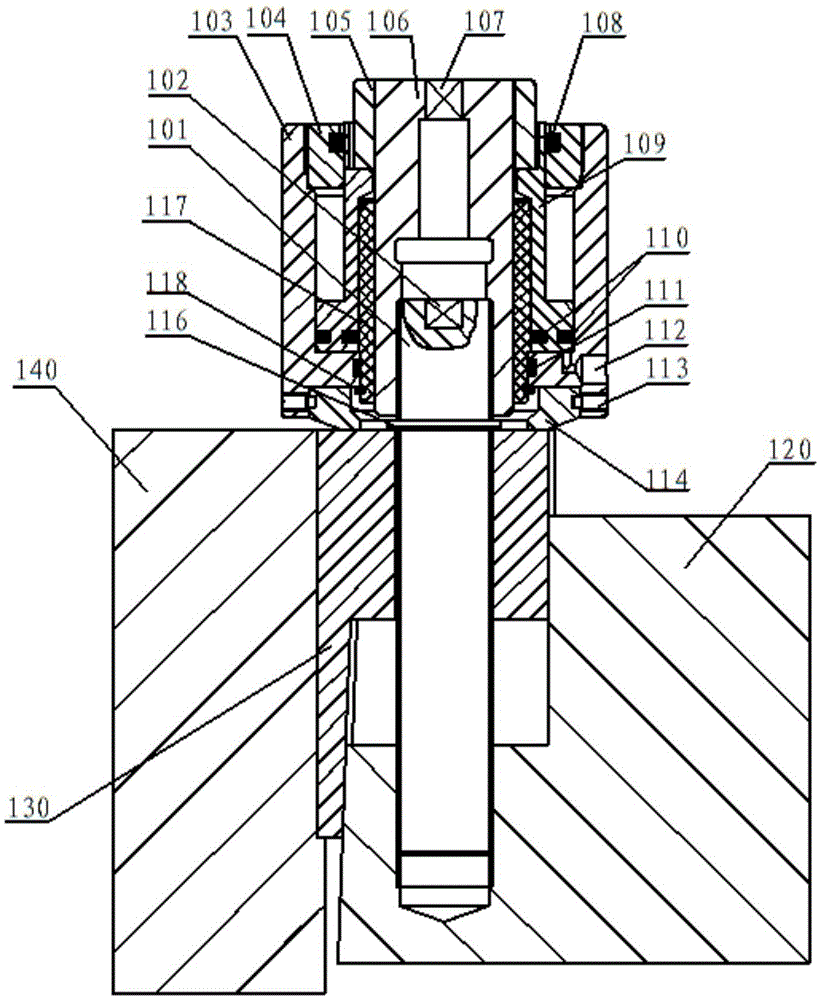

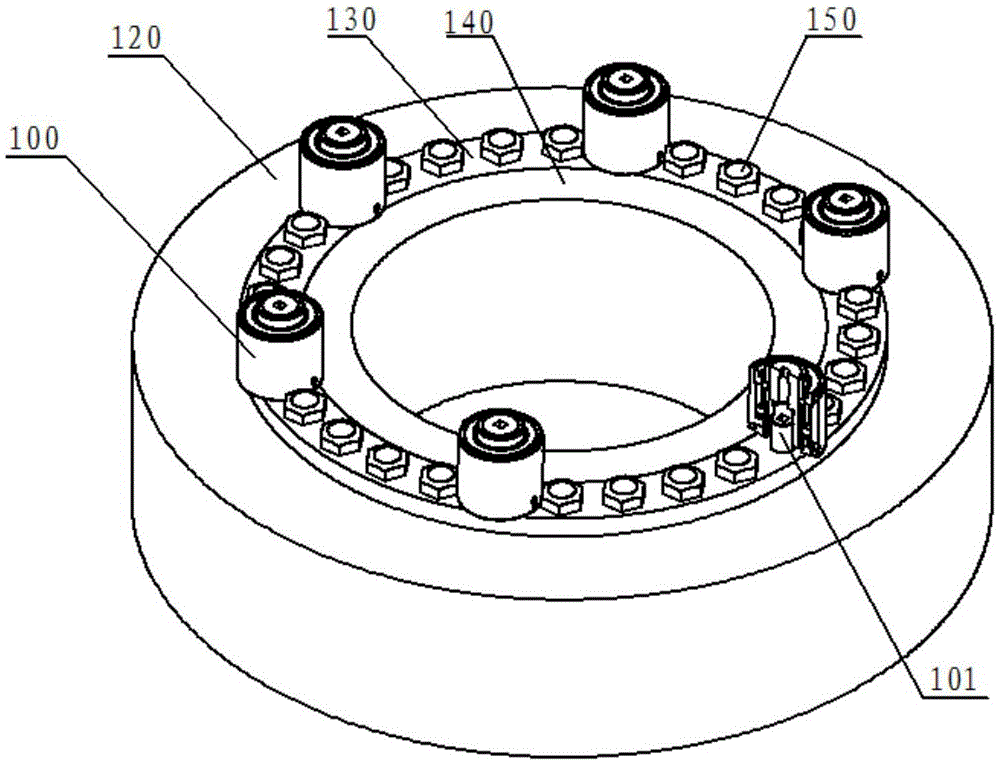

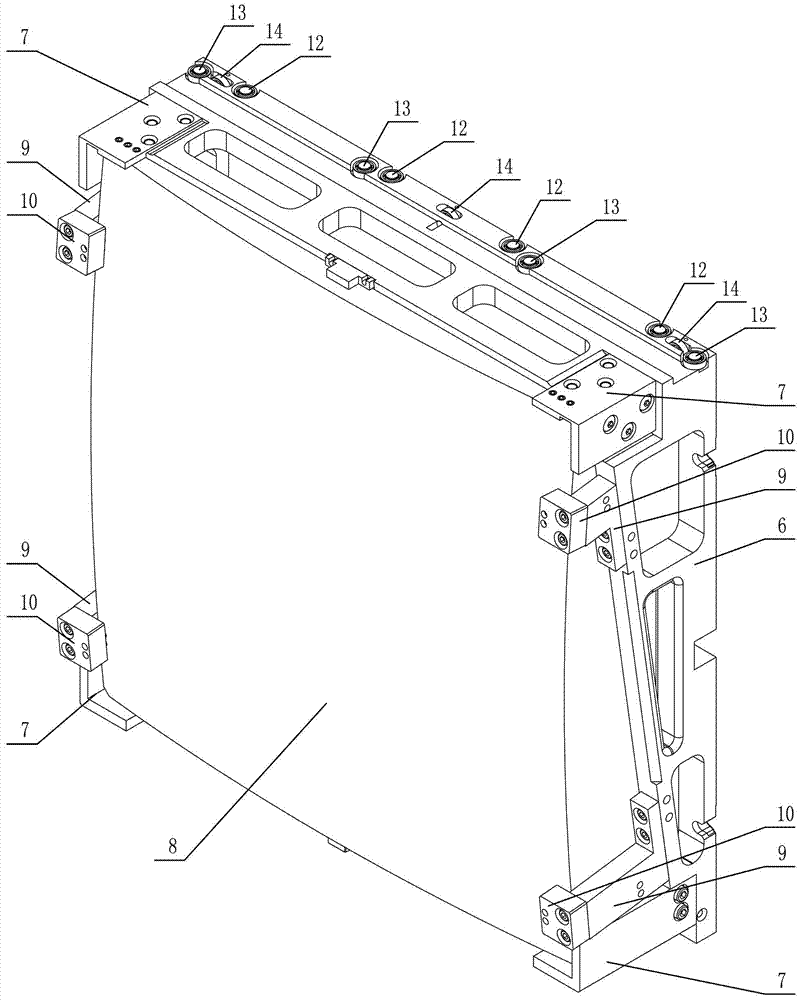

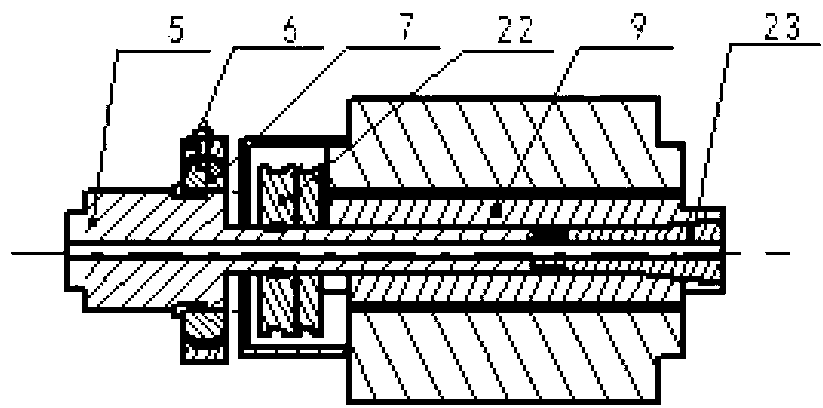

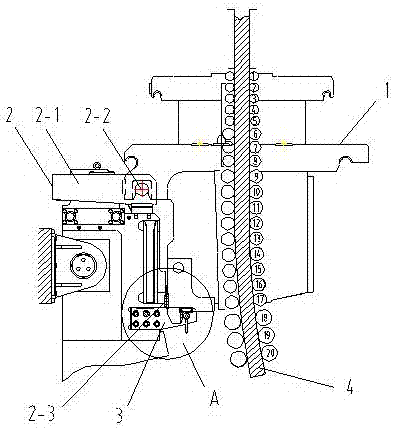

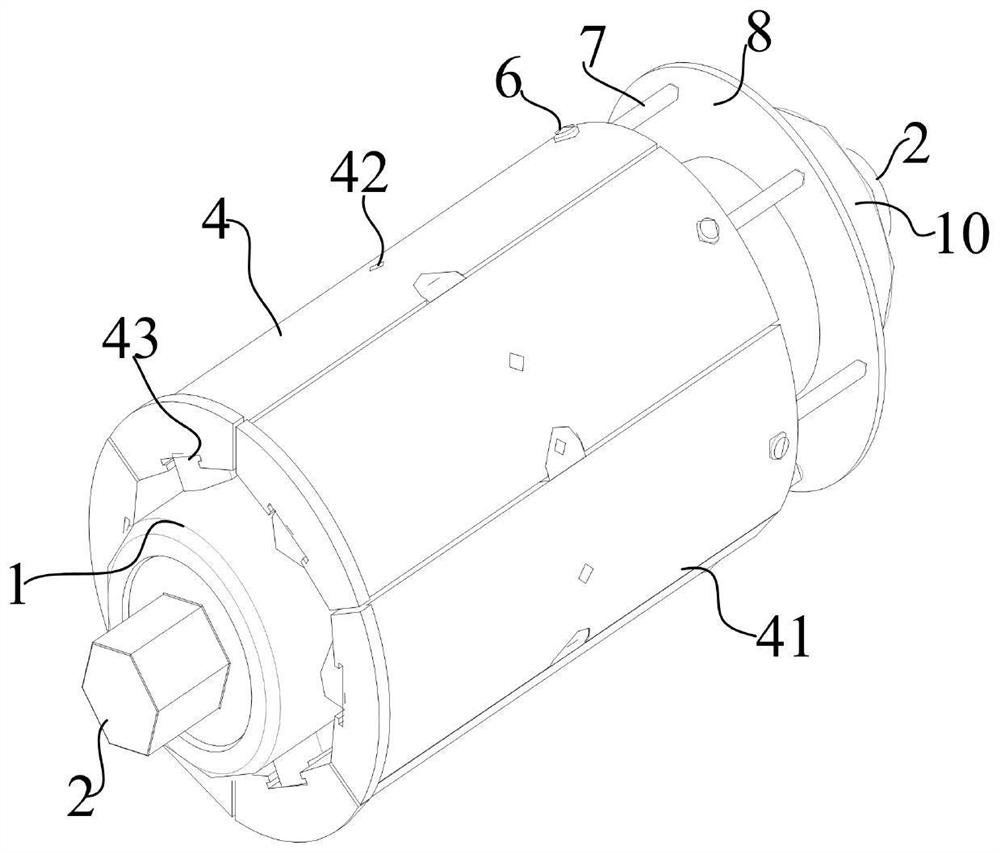

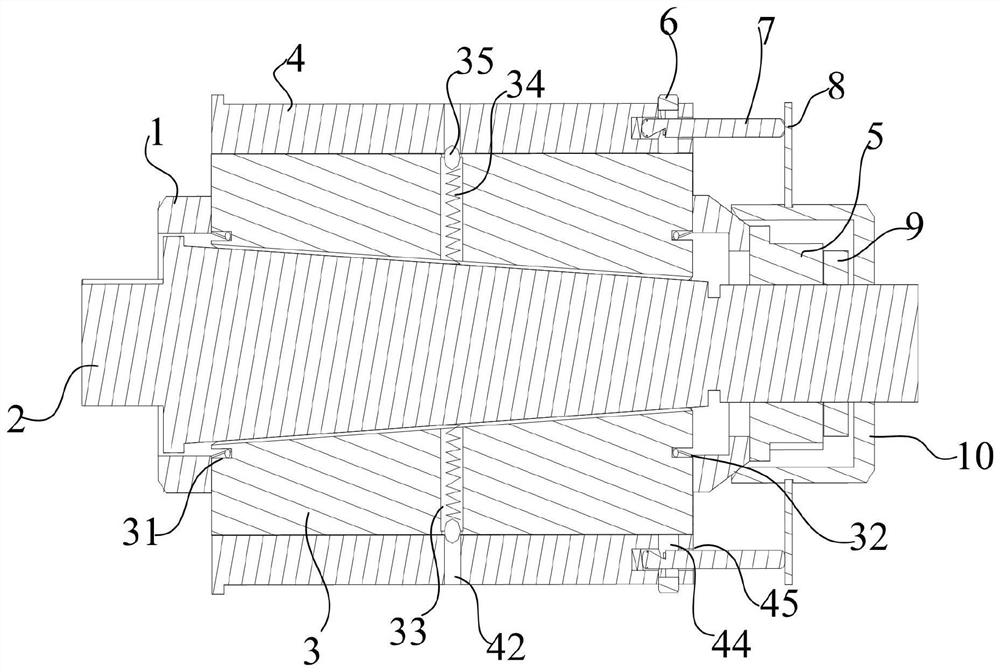

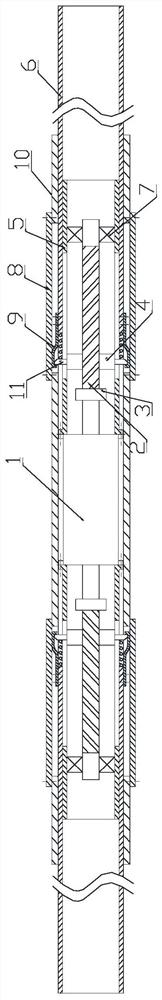

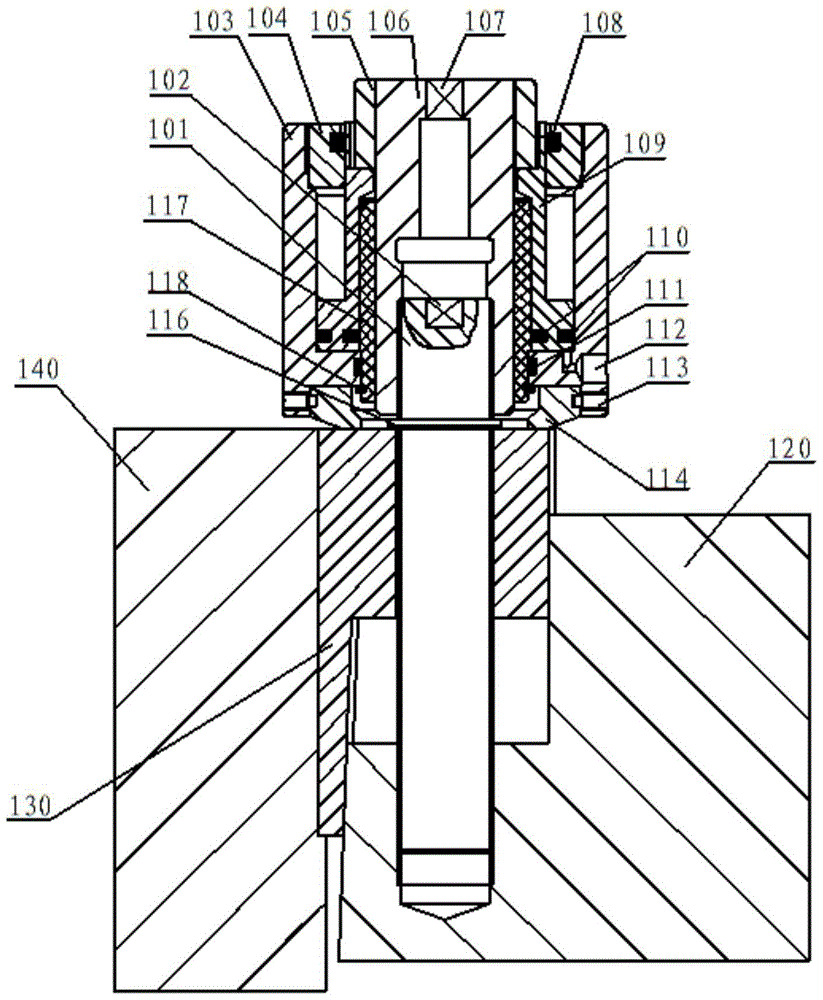

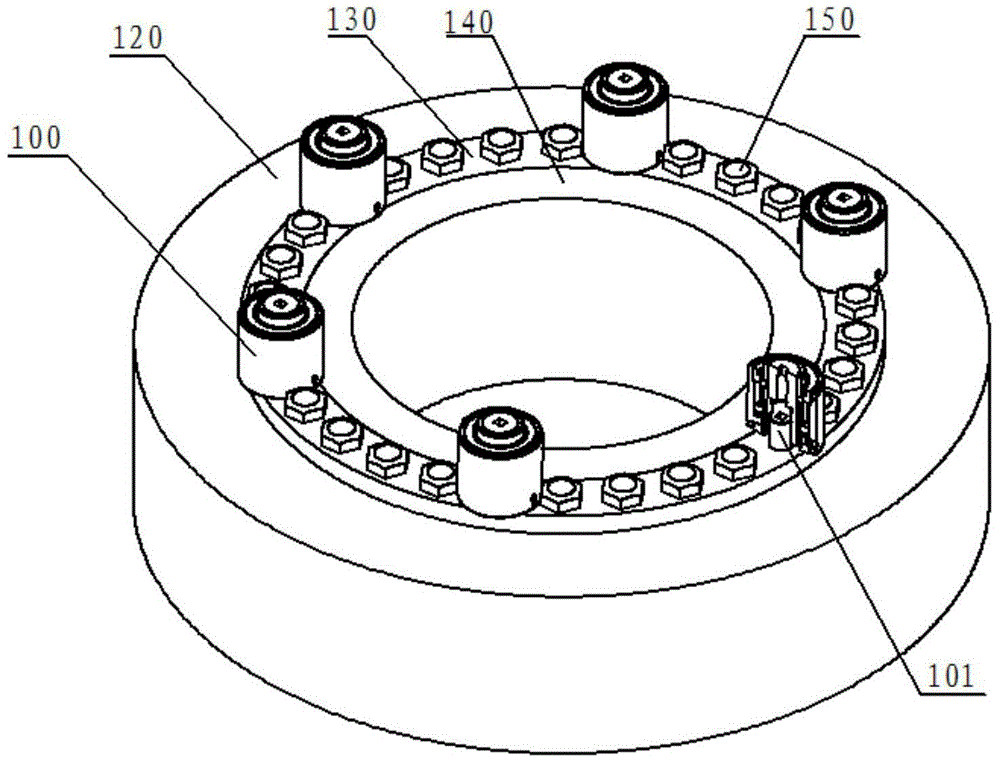

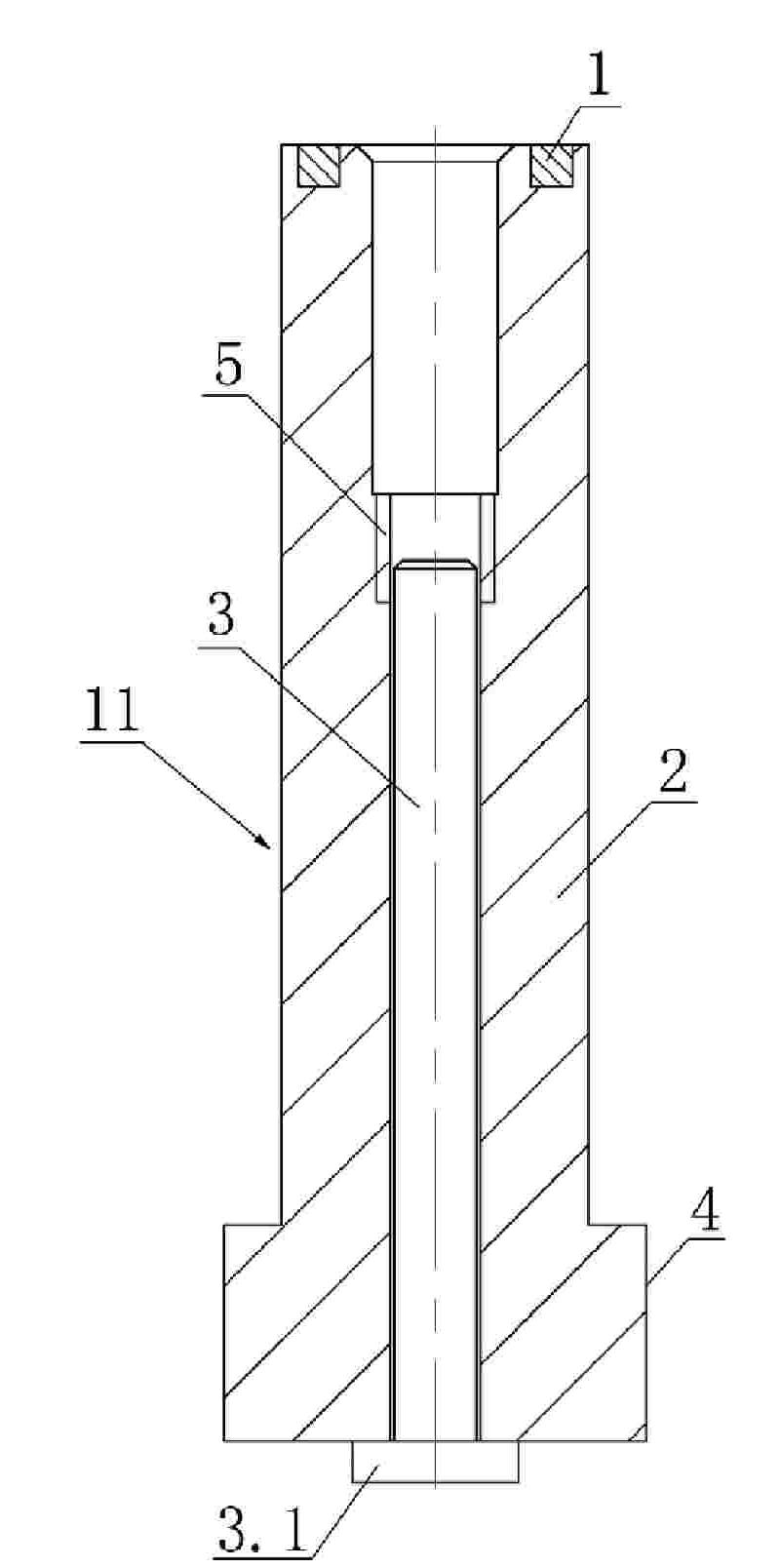

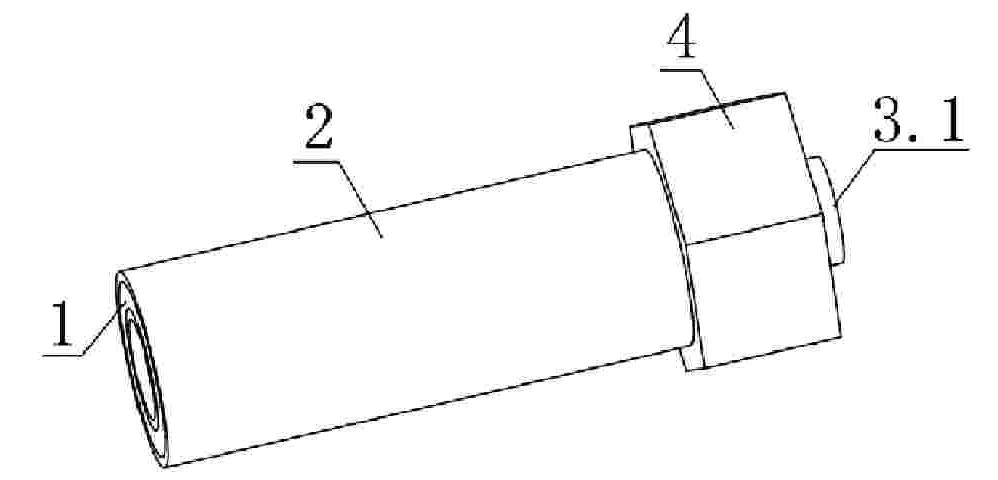

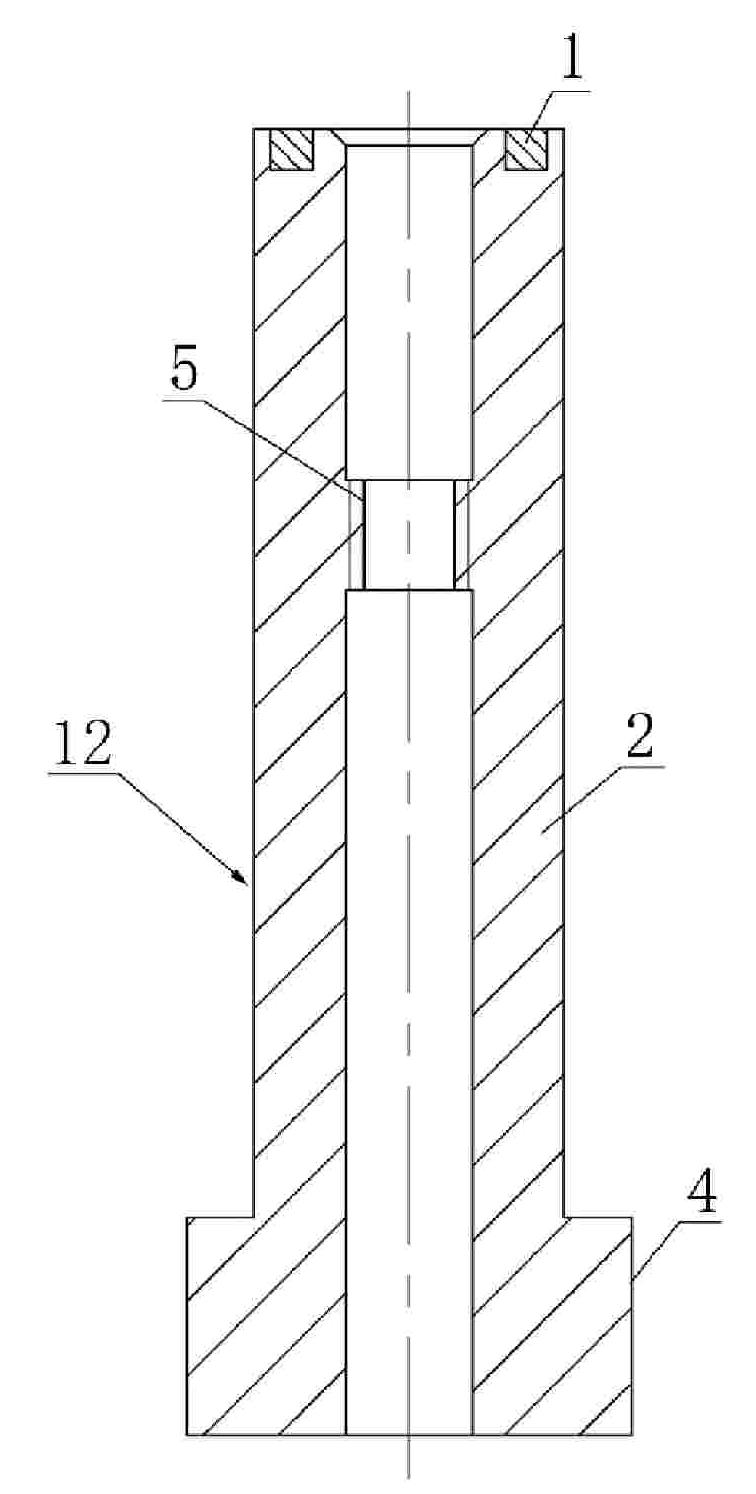

Locking disc assembling prepositioning device and assembling method

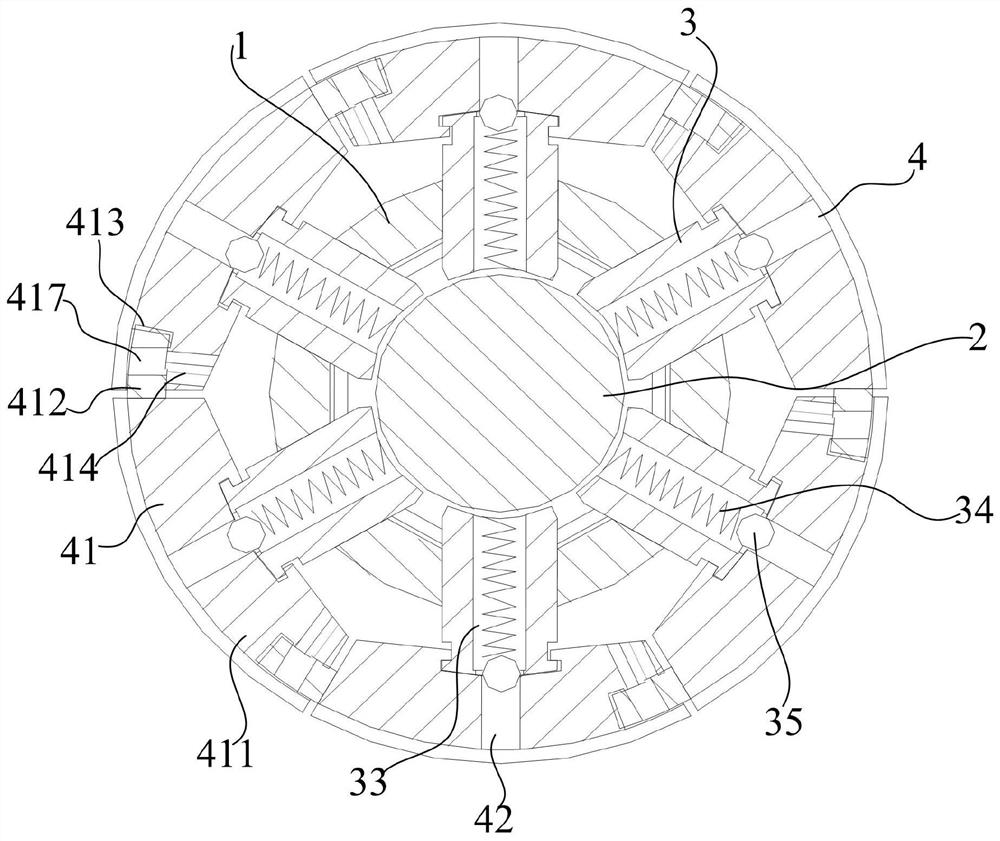

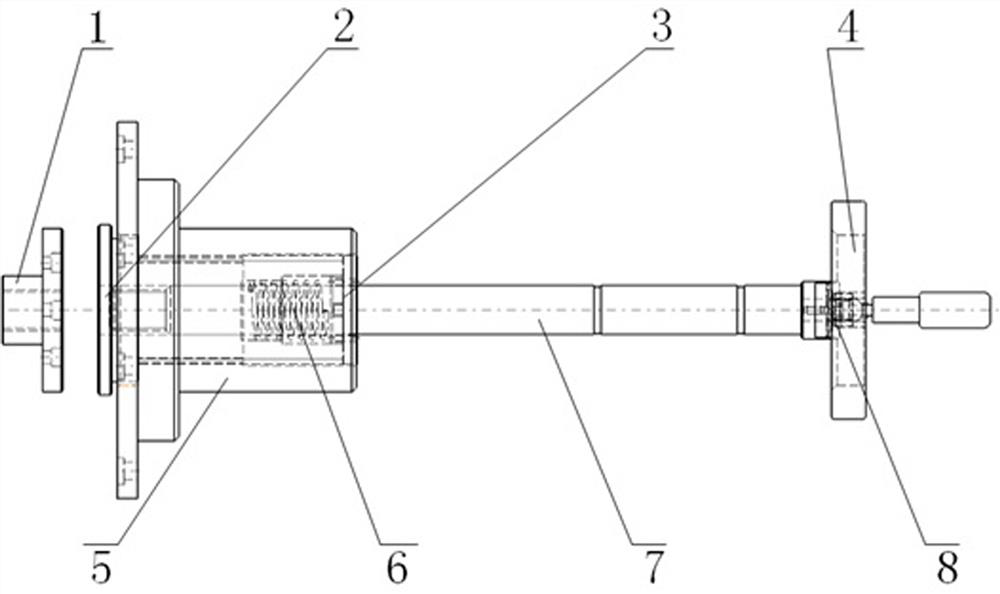

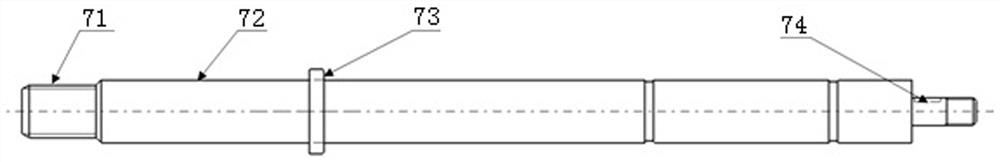

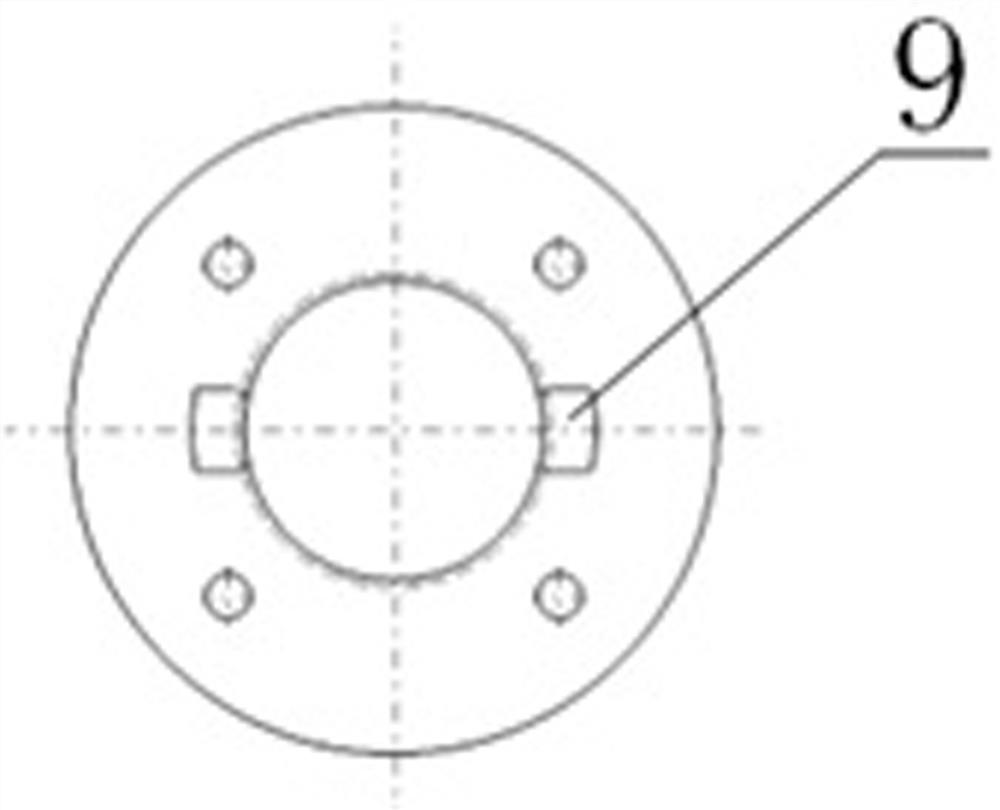

ActiveCN105459021AQuick positioning and lockingAccurate locking positioningMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a locking disc assembling prepositioning device and an assembling method, and belongs to the field of locking discs. The problems that an existing locking disc assembling process is complex, labor and time are wasted and the assembling effect is poor are solved. The device comprises a screw rod and further comprises a cylinder and a piston arranged inside the cylinder. The lower end of the piston and the cylinder form an oil cavity. An oil inlet hole communicated with the oil cavity is formed in the outer wall of the cylinder. The lower end of the piston is fixedly connected with the screw rod. Prepositioning of an inner ring of the locking disc, a shaft sleeve and an outer ring can be achieved at a time, prepositioning is accurate and balanced, the bolt locking installation time is saved, labor force is saved, the assembling efficiency is improved, and the locking disc assembling prepositioning device has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:MAS JHJX MACHINERY MFG CO LTD

An elbow welding positioning and locking device

ActiveCN107617847BImprove efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention provides an elbow welding positioning and locking device, comprising: a base; a first support base, a second support base and an elbow positioning mechanism installed in parallel on the base from right to left; and the branch pipe positioning mechanism between the second support base; the first locking fixture installed on the second support base; the elbow positioning mechanism is installed on the left side of the second support base; fixed on the side wall of the elbow positioning mechanism and located Position the second locking clamp below the locking block. The elbow welding positioning and locking device can realize the rapid positioning and docking of pipe fittings of different shapes through the preset first support seat, second support seat, first locking fixture, elbow positioning mechanism, and second locking fixture, and ensure Butt joint quality, the branch pipe positioning mechanism can ensure that the welding angle between the branch pipe and the first tube and the second tube meets the requirements, and the straight pipe and the second tube can be realized through the first locking fixture and the second locking fixture quick lock.

Owner:GUANGDONG JUNCHI TECH HLDG

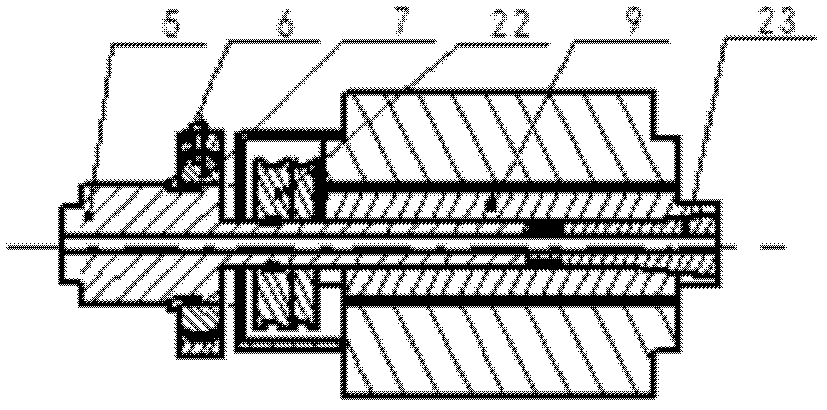

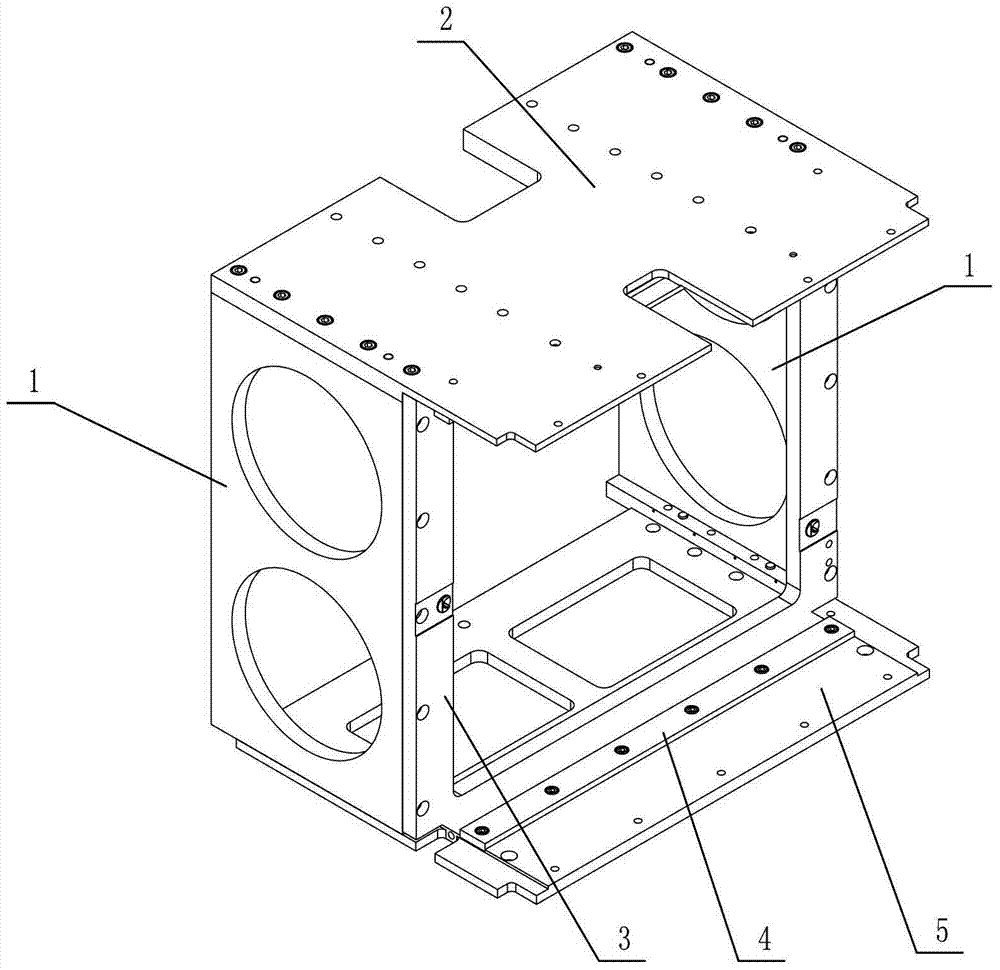

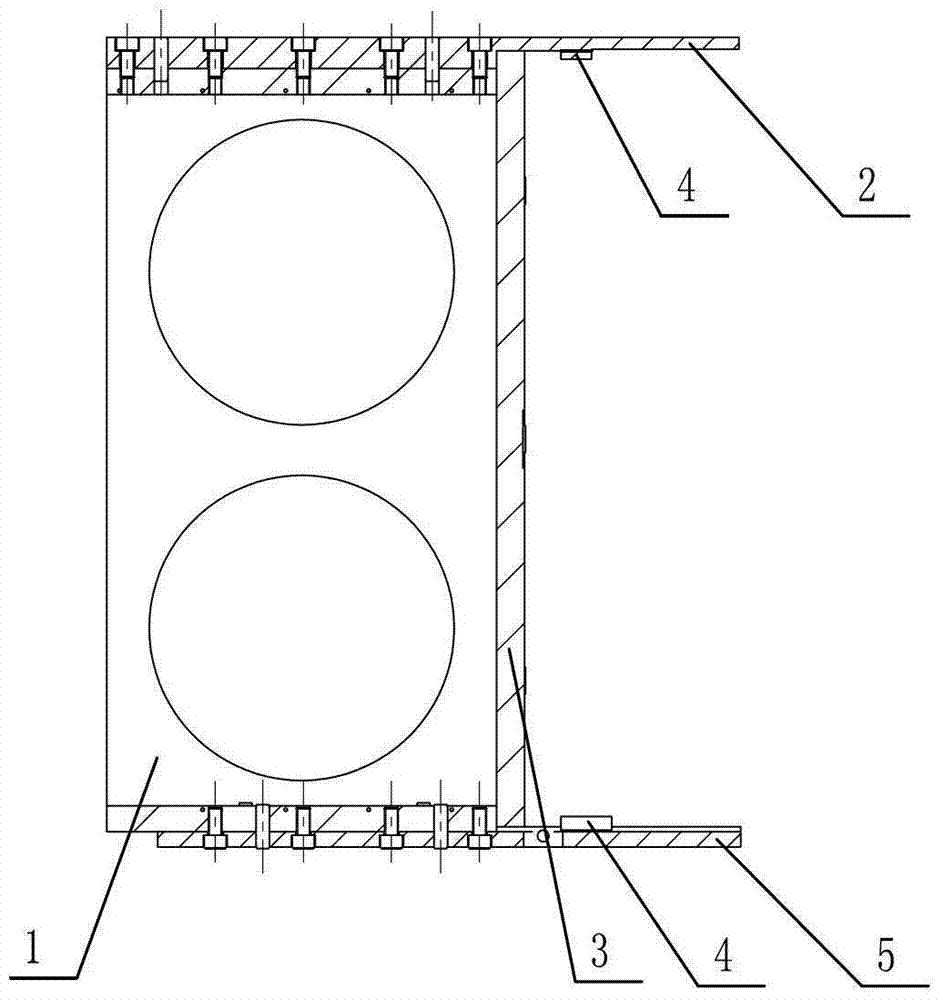

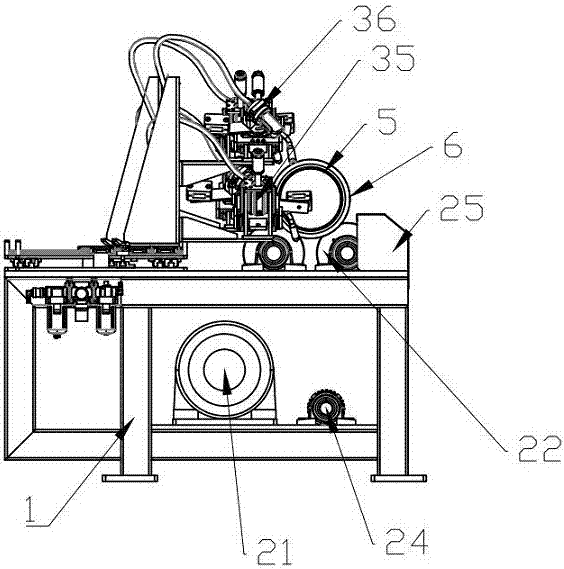

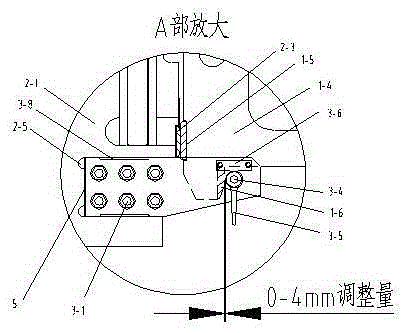

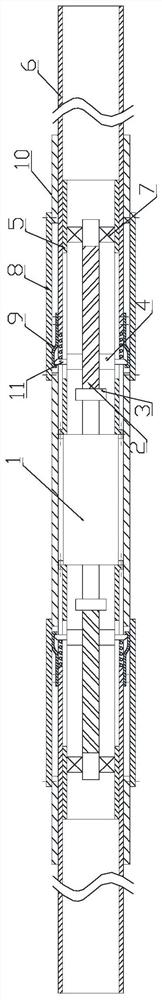

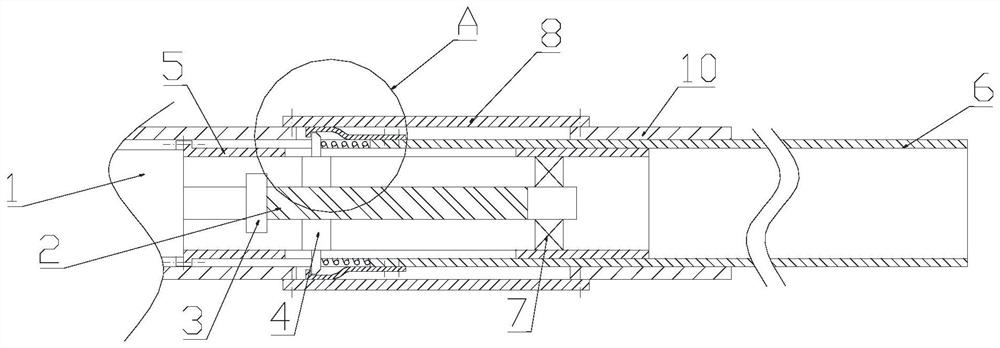

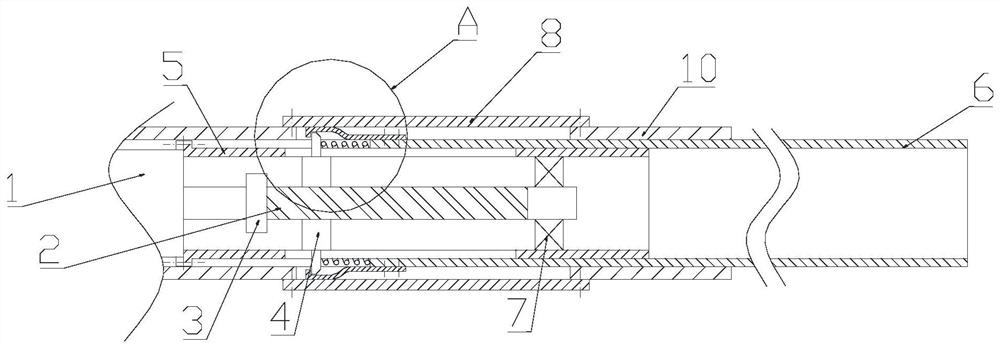

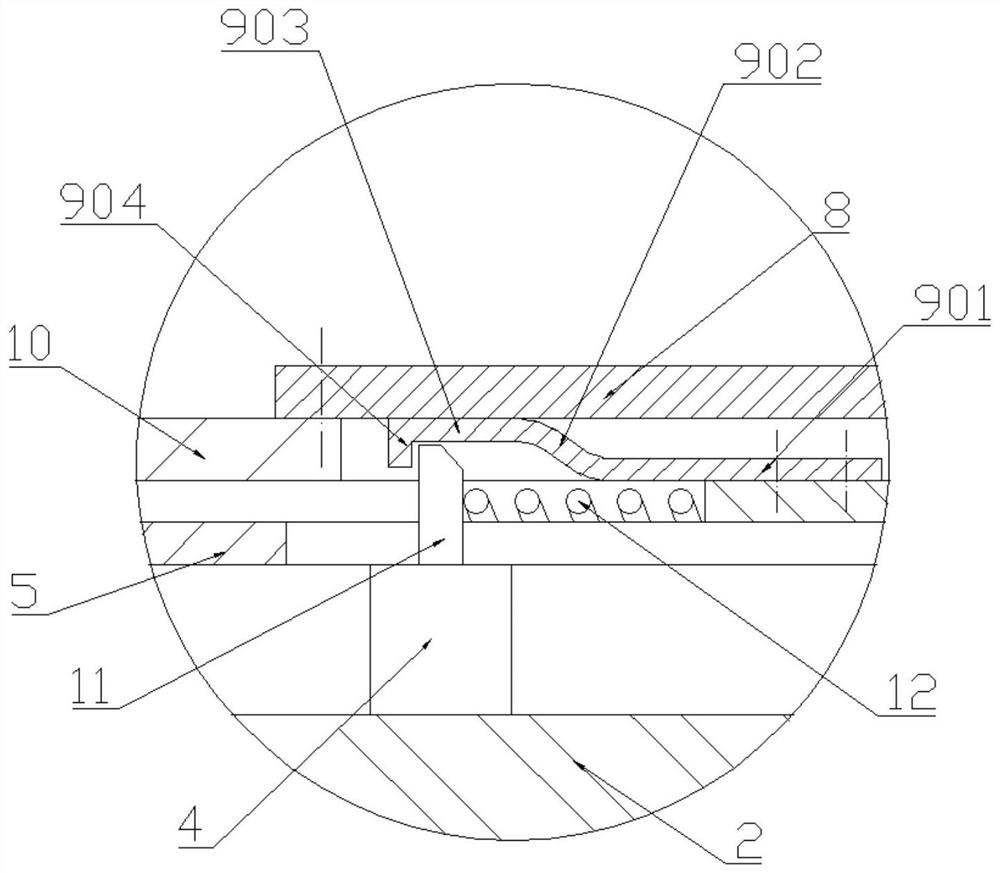

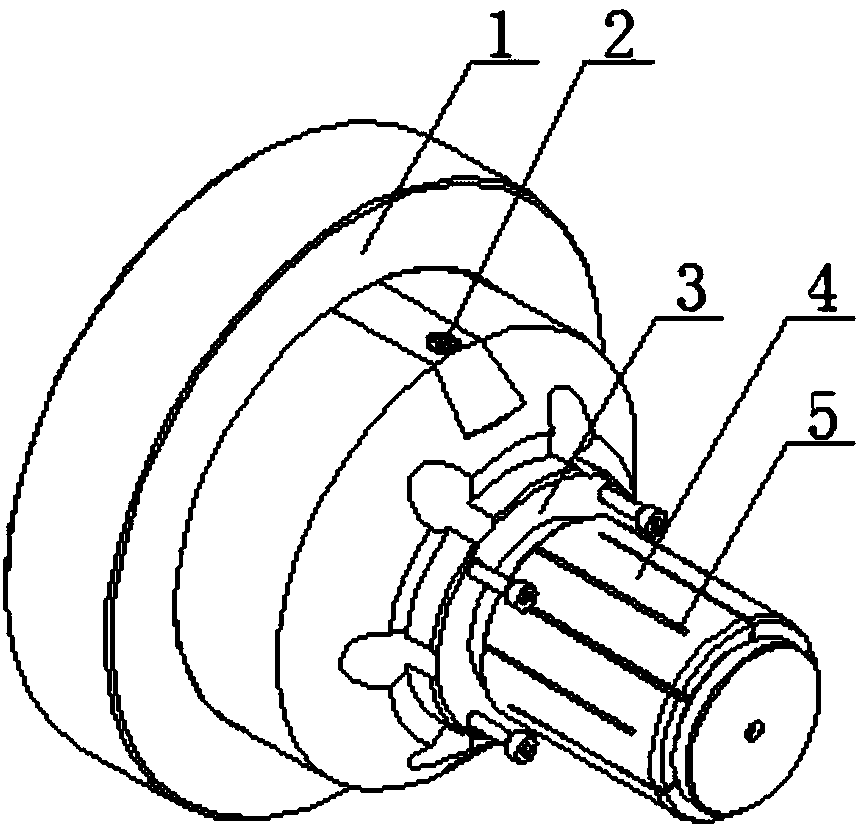

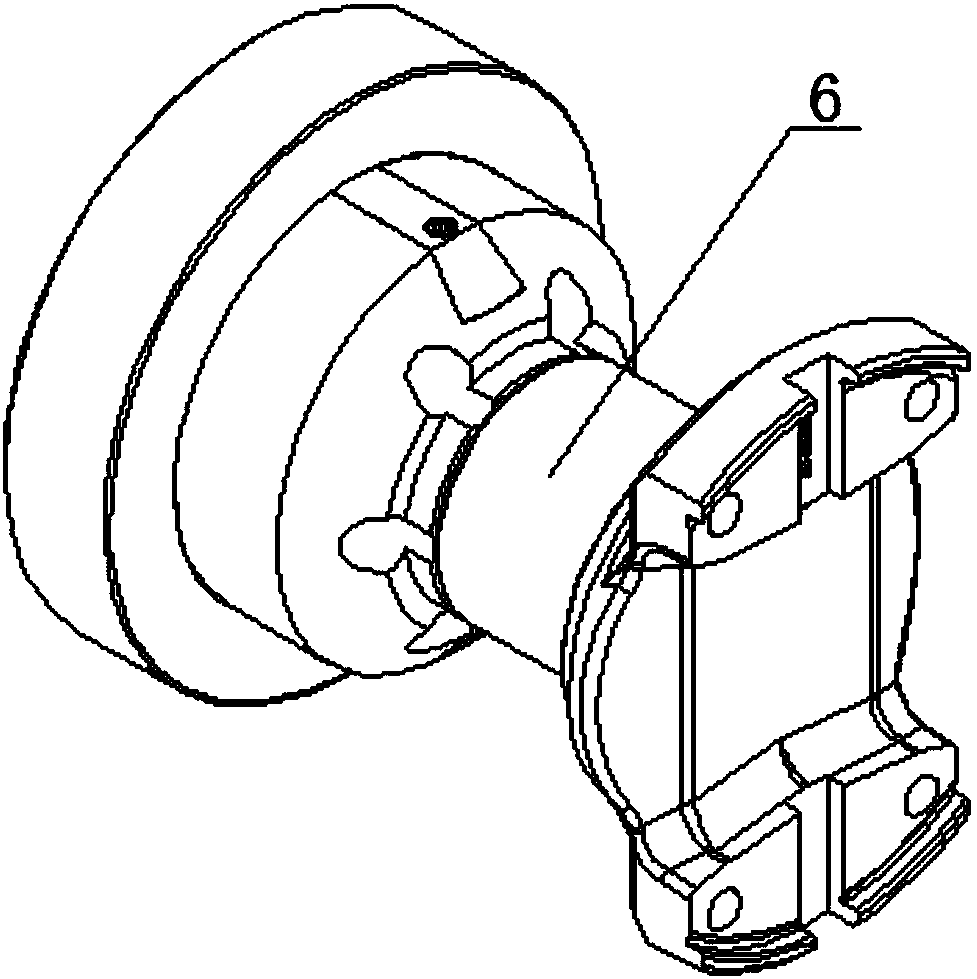

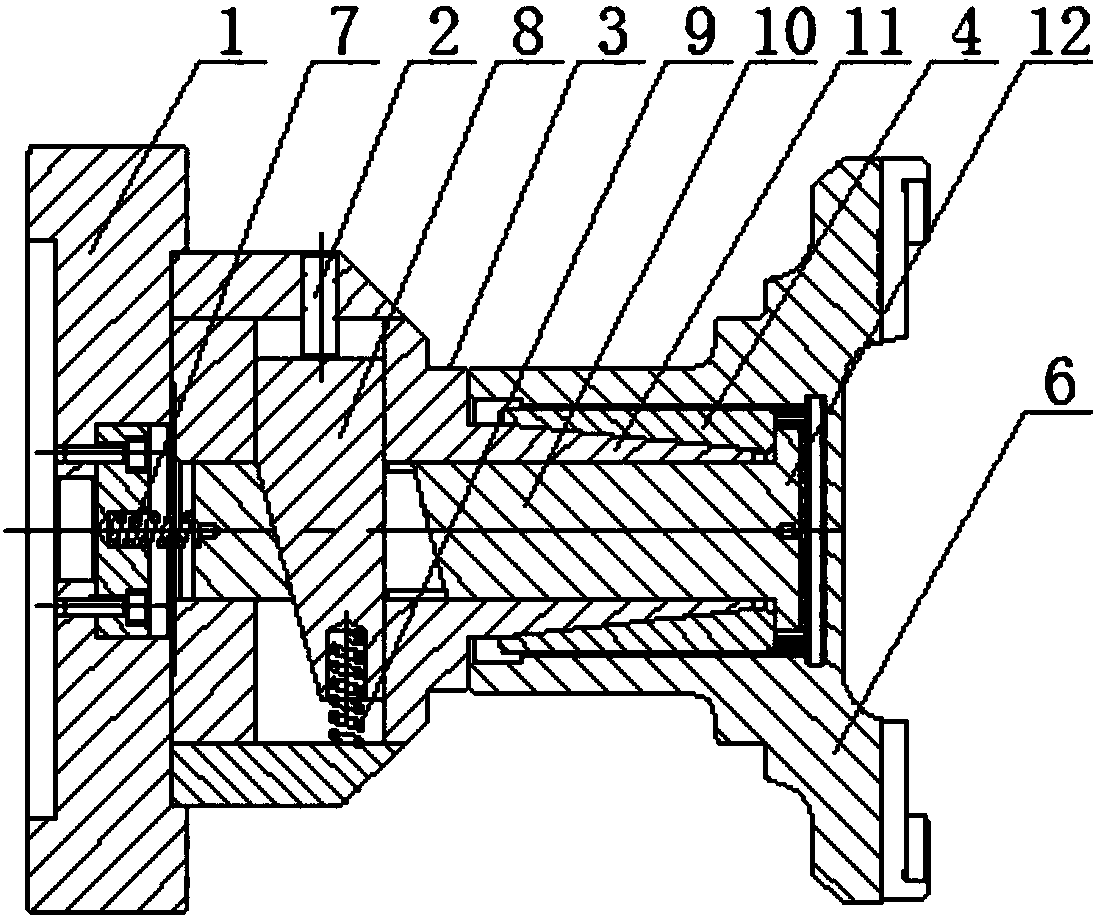

Online dismounting and fast positioning and locking mechanism of large-diameter lens

ActiveCN103207436AQuick positioning and lockingImprove operational efficiencyMountingsLocking mechanismEngineering

The invention discloses an online dismounting and fast positioning and locking mechanism of a large-diameter lens, relates to a lens positioning and locking mechanism, and aims to solve the problem that the large-diameter wedged lens is quickly changed online to avoid use of large mechanical device for integrally detaching a large-diameter optical focusing and frequency converting system to lead to low efficiency. A top plate, a bottom plate and a side plate of a lens mobile frame body encircle the lens mobile frame body; an embedding piece of the lens mobile frame body is connected to the side plate of the lens mobile frame body; the top and bottom plates of the lens mobile frame body are provided with focusing lens guiding plates; a lens orientation angle is arranged at the edge of the wedged lens positioning frame; the large-diameter lens is fixedly arranged in the wedged lens positioning frame through a lens locking seat plate on a lens locking seat; lens assembly dismounting guiding bearing groups are arranged on the upper and lower side faces of the wedged lens positioning frame; the lens assembly dismounting guiding bearing groups are contacted with the mobile frame assembly; and the lens assembly is inserted into the mobile frame body assembly with the focusing lens guiding plate as a guide. The mechanism disclosed by the invention is used for online dismounting and fast positioning and locking of the large-diameter lens.

Owner:HARBIN INST OF TECH

Locking device of machining machine tool for standard component

InactiveCN103286584AQuick lockQuick positioning and lockingOther manufacturing equipments/toolsPositioning apparatusAxial displacementEngineering

The invention relates to a locking device of a machining machine tool for a standard component. The locking device is mounted on a workbench and comprises a moving shaft sleeve, a moving handle, a moving support and a clamping sleeve. The moving shaft sleeve is coaxially mounted on the moving support, the moving support is hinged to a moving sleeve in an arc mode through a spherical pair, and the moving shaft sleeve achieves the axial displacement of the moving shaft sleeve through the moving handle which is fixedly arranged in the radial direction. The moving shaft sleeve is coaxially meshed with the clamping sleeve which is provided with three jaws inside a spindle, the conical surface of the clamping sleeve with the three jaws is matched with the conical surface formed by the end face of the moving shaft sleeve, and stretchy holes are formed in the clamping sleeve with the three jaws. According to the locking device of the machining machine tool for the standard component, a locking positioning device of workpieces is scientifically designed, thus quick positioning and quick locking can be achieved for the machined standard component, and production efficiency is facilitated to be improved.

Owner:TIANJIN XINHUAMEI STANDARD PART MFG

Cage having an automatic door

ActiveUS9661839B2The process is simple and fastQuick positioning and lockingAnimal trapsEngineeringFootplate

Owner:ZHU HONGWEN

Anti-falling pipe fitting lifting device with protection structure for aviation equipment production

PendingCN113753746AProtective structureImprove positional stabilityBase supporting structuresBraking devices for hoisting equipmentsAviationMarine engineering

The invention discloses an anti-falling pipe fitting lifting device with a protection structure for aviation equipment production. The anti-falling pipe fitting lifting device comprises a base body, a driving assembly, an abutting part, a butt joint handle and a fixing part, wherein the driving assembly is mounted at the upper end of the base body through a bolt; a lifting rope is mounted at the output end of the driving assembly in a nested manner, and the lower end of the lifting rope is fixedly connected with a supporting part; meanwhile, the supporting part is connected with the outer end of the base body; and a first pull rope is mounted at the outer side of the base body in a nested manner, and the first pull rope is connected with the outer end of the supporting part. According to the anti-falling pipe fitting lifting device with the protection structure for aviation equipment production, the lifting rope drives the supporting part to upwards lift an object, the first pull rope moving to a corresponding state is wound along with the supporting part, then a limiting part at the tail end is driven to move in the opposite direction, so that the inner end of a pipe fitting is subjected to self-adaptive nested contact; and the positioning stability is continuously improved along with the increase of the height, therefore, the lifting safety is ensured.

Owner:张绅

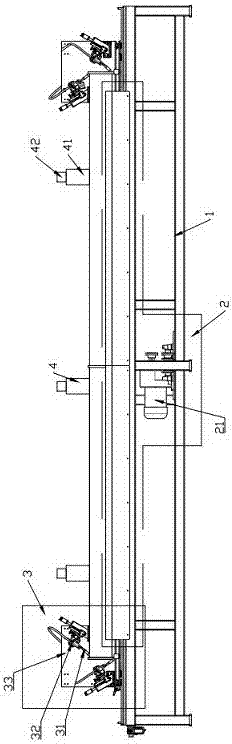

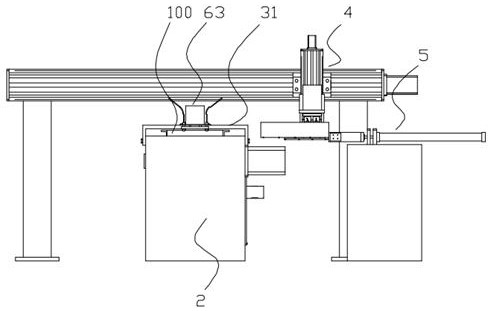

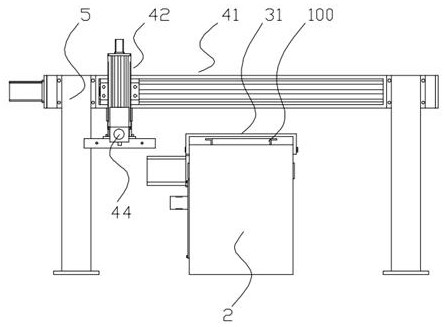

Automatic welding machine for slurry pipe hoops

PendingCN107225335AThe overall structure is compactHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectric machinery

The invention relates to an automatic welding machine for slurry pipe hoops. By means of the automatic welding machine for the slurry pipe hoops, the problem of poor welding quality in the prior art is solved, and a controller is in electric signal connection with a transmission mechanism, a gun feed mechanism and a pressing mechanism which are installed on a rack. The transmission mechanism comprises a bottom rotating roller set driven by a transmission motor. The bottom rotating roller set comprises two rotating rollers which are arranged correspondingly and are the same in rotation direction. The interval between the rotating rollers is no larger than the outer diameter of a pipeline welded by the automatic welding machine. The pressing mechanism comprises two pressing wheels installed on a pressing frame, and the pressing wheels are installed above the pipeline welded by the automatic welding machine correspondingly. The automatic welding machine for the slurry pipe hoops has the beneficial effects that the automatic welding machine is designed as a vertical four-gun automatic welding machine according to the welding process requirement of the slurry pipe hoops, workpieces can be rotated, welding guns are fixed, and a PLC microcomputer control system is adopted for control, so that the automatic welding machine is stable in performance and reliable.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

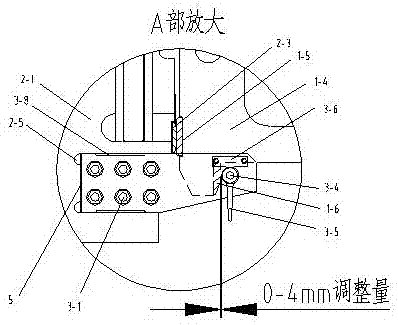

Slab continuous casting fan-shaped segment locating and locking device and assembling method

ActiveCN105414502AImprove arc connection accuracyImprove and stabilize arc connection accuracySlab casterLocking mechanism

The invention belongs to metal continuous casting equipment, relates to a slab continuous casting fan-shaped segment locating and locking device and an assembling method, in particular to slab continuous casting machine auxiliary equipment. The device comprises a first fan-shaped segment, a second fan-shaped segment and a bearing mechanism. The fan-shaped segments are formed by connecting line rollers and roller frames. The first fan-shaped segment is fixed to the second fan-shaped segment. The first fan-shaped segment is connected with a lower opening of a crystallizer. Roller frame hooks are hung on bearing frame hanging pins. The device is characterized in that rectangular deep grooves of 8-12 mm are formed in the two sides below the right portion of each bearing frame, and locating and locking mechanisms with adjustable locking hole grooves are fixed in the rectangular grooves by fixing bolts; and brackets below the roller frames fall down to be inserted in the locking hole grooves, and zero clearance is kept during locking. The device has the beneficial effects that the concept is novel, the structure is simple, compact and reasonable, and running is stable and reliable; after online mounting and arc jointing, fast locating and locking are carried out, mounting and demounting are convenient, time is saved, and the fan-shaped segment arc jointing precision is improved and stabilized; and the casting blank quality is effectively improved, the accidents of blank stagnation and steel leakage are reduced, and it is guaranteed that continuous casting production is carried out smoothly.

Owner:MAANSHAN IRON & STEEL CO LTD

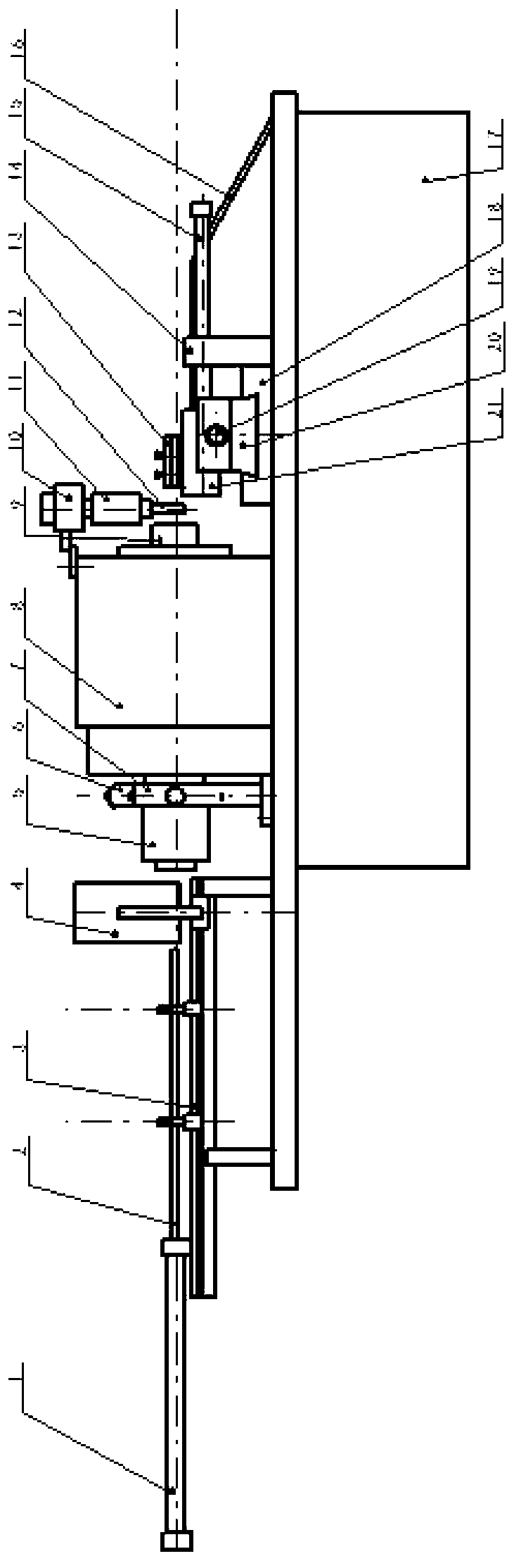

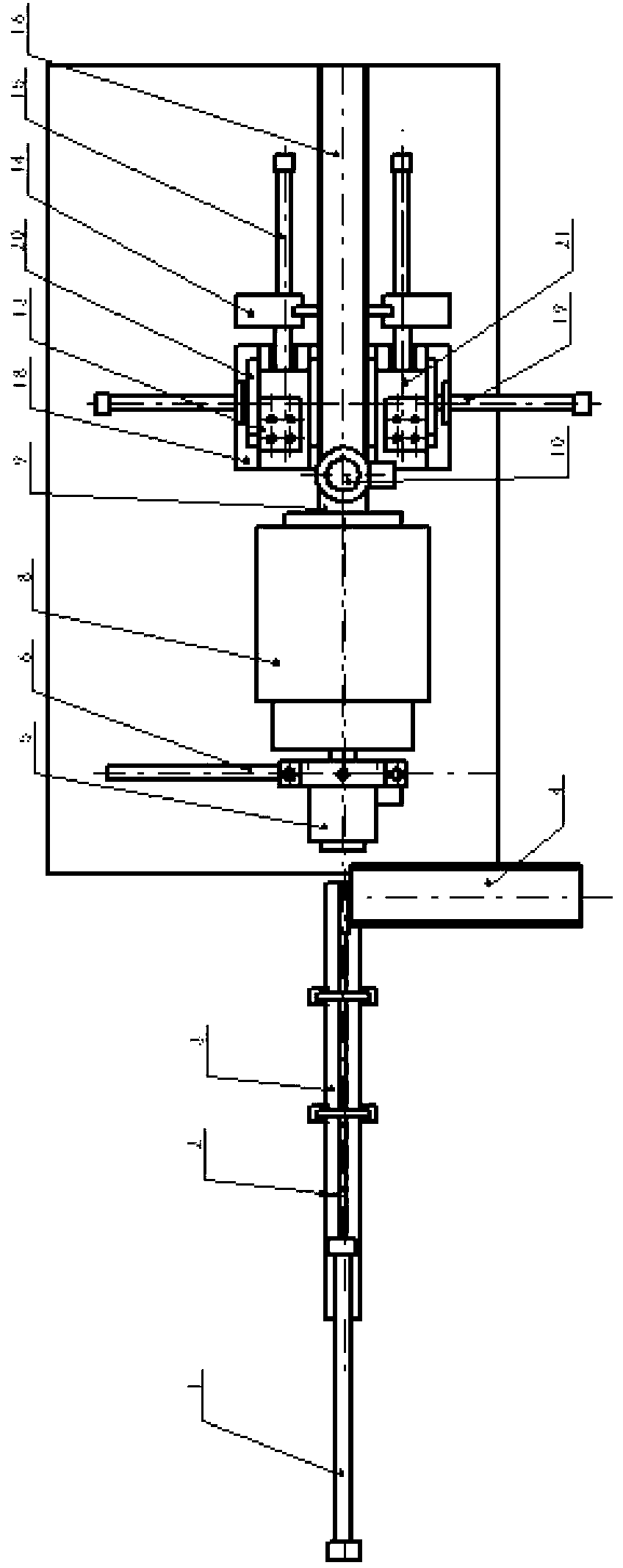

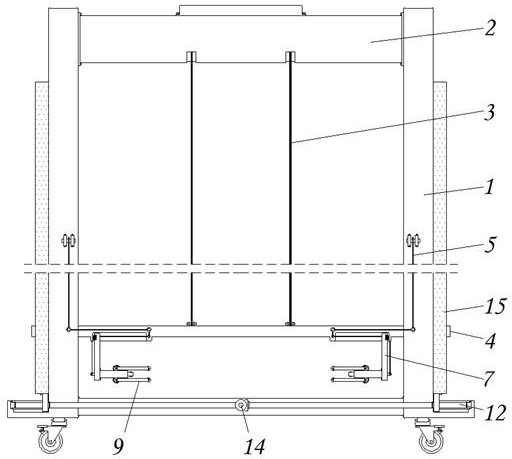

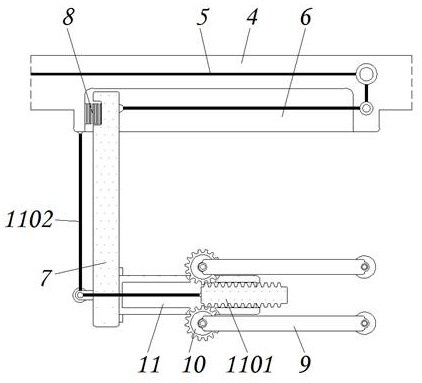

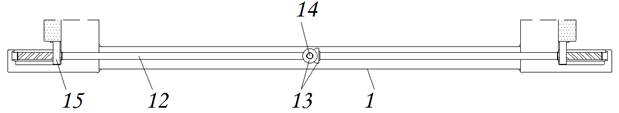

Platform supporting device for automatic elevator mounting equipment

The invention discloses a platform supporting device for automatic elevator mounting equipment. The platform supporting device for the automatic elevator mounting equipment comprises supporting rods and a supporting, locking and driving mechanism; the supporting, locking and driving mechanism comprises driving pieces and a linear driving mechanism; the supporting rods are arranged on a rack, and the two ends of the supporting rods extend outwards and are connected to the driving pieces separately; locking pieces are provided on the supporting rods at each end; after the linear driving mechanism drives the driving pieces to synchronously and reversely move separately so as to enable the supporting rods at the two ends of the rack to synchronously and reversely stretch out and be tightly supported on a shaft wall surface, the linear driving mechanism continues to drive the driving pieces to move, so that the locking pieces on the supporting rods abut against the rack, and the effect of fixing the working platform for installing the equipment to the shaft wall surface is achieved. According to the platform supporting device for the automatic elevator mounting equipment, the working platform can be positioned and locked when the working platform reaches a specific mounting position, so that the working platform is prevented from shaking in the construction process, and the construction precision is guaranteed.

Owner:广州明森合兴科技有限公司

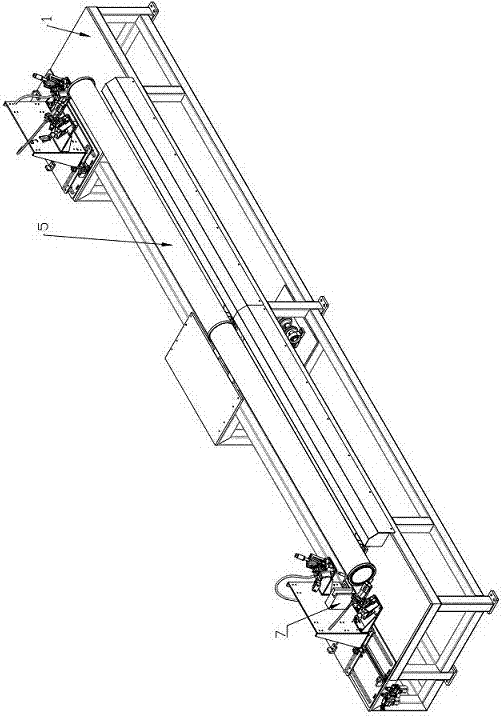

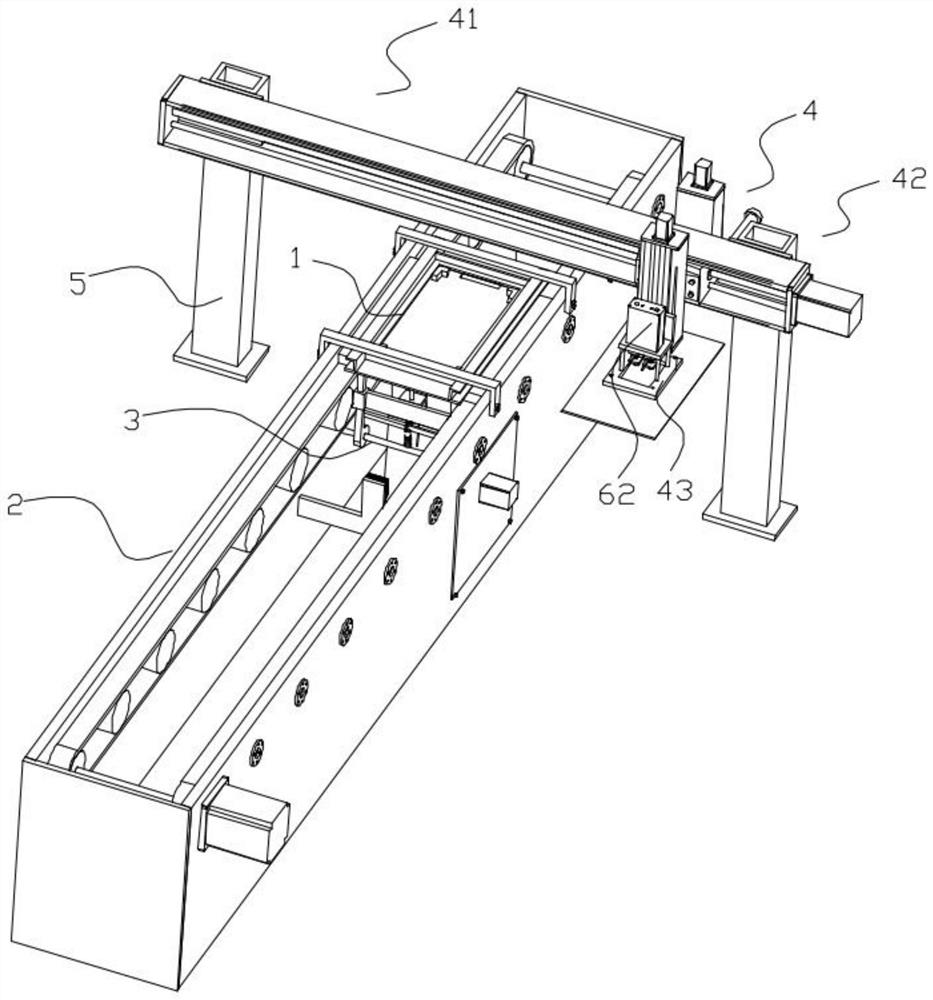

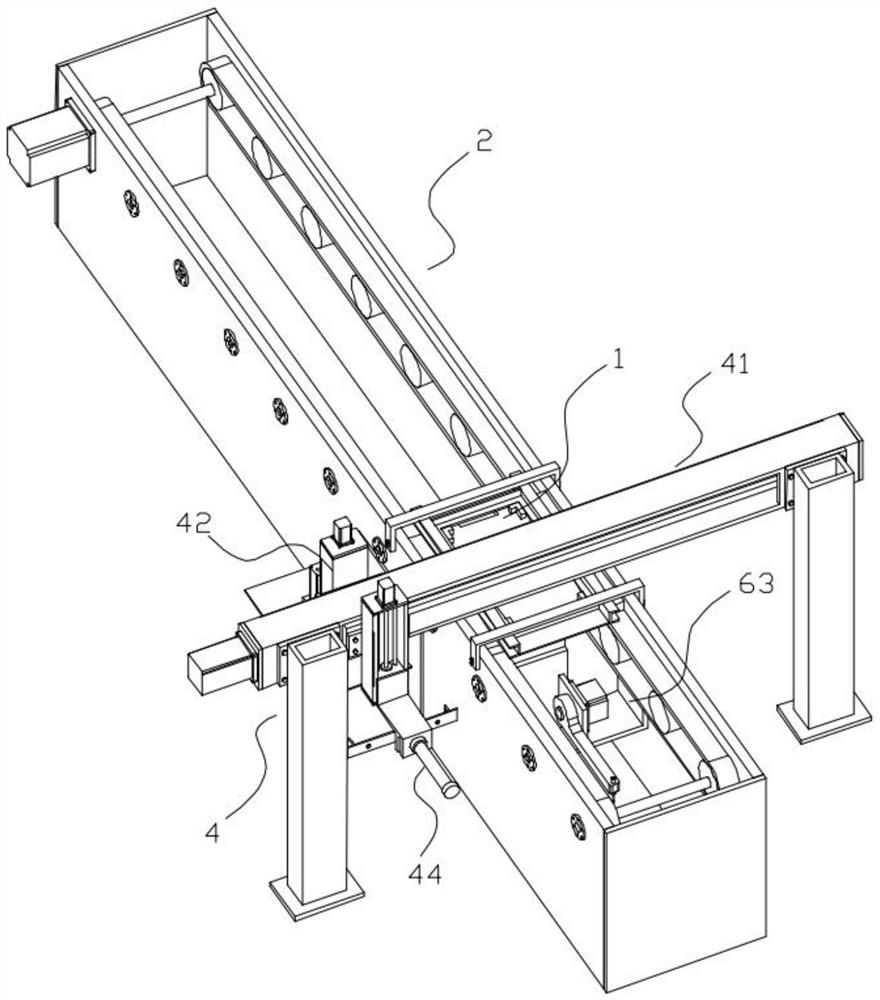

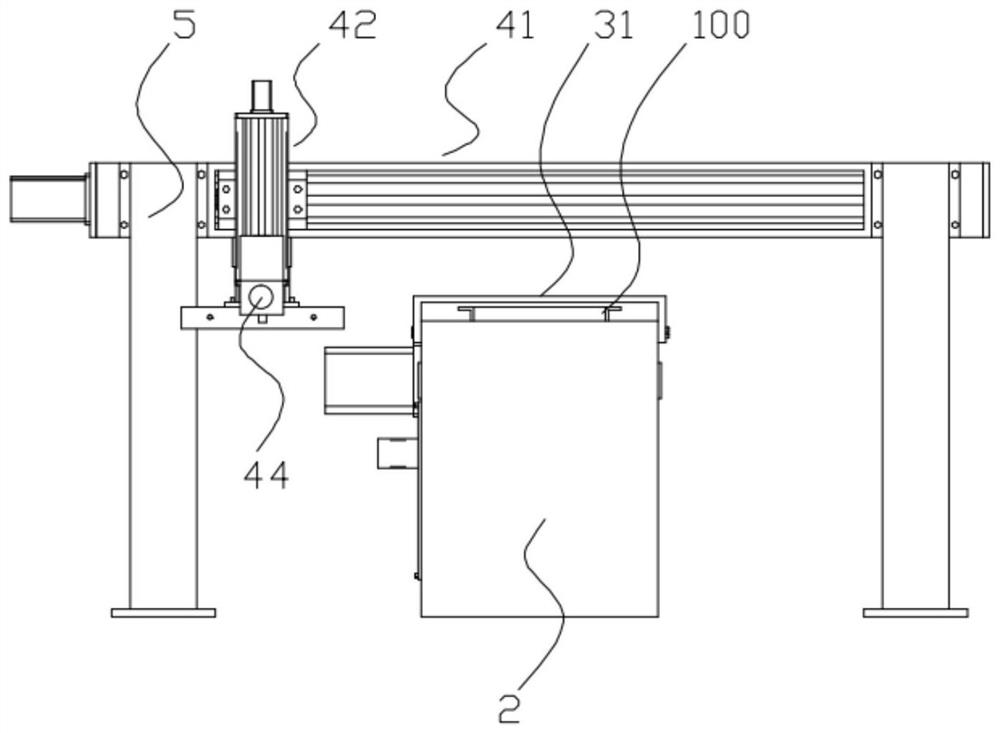

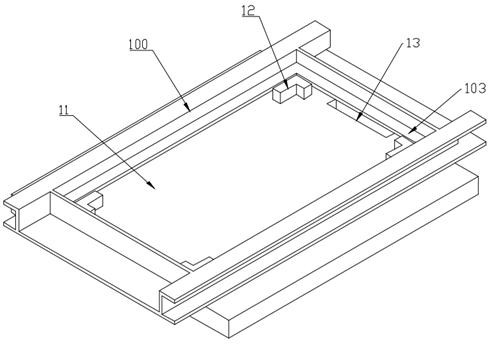

Roof steel member machining production line

ActiveCN111874606AQuick assemblyImprove assembly efficiencyConveyorsConveyor partsBuilding productProduction line

The invention discloses a roof steel member machining production line, and relates to the technical field of building product processing. The roof steel member processing production line comprises a fixing tool, a conveying mechanism, an intercepting mechanism, a material taking mechanism and a spot welding mechanism, an assembly line type production mode is adopted in the roof steel member machining production line, and rapid assembly operation of roof steel members is achieved. Compared with traditional manual work, assembling efficiency and the assembling precision are remarkably improved,and the labor cost is saved.

Owner:江苏德丰建设集团建筑科技有限公司

A processing line for eaves steel components with rainwater collection function

ActiveCN111906427BQuick assemblyImprove assembly efficiencyMetal working apparatusResistance welding apparatusProduction lineBuilding product

The invention discloses a production line for processing eave steel components with the function of collecting rainwater, relates to the technical field of building product processing, and includes fixed tooling, a conveying mechanism, an intercepting mechanism, a material picking mechanism, an assembling mechanism and a spot welding mechanism. The assembly line production method realizes the rapid assembly operation of the eaves steel components. Compared with the traditional manual work, it significantly improves the assembly efficiency and assembly accuracy, and saves labor costs.

Owner:江苏德丰建设集团建筑科技有限公司

Slab Continuous Casting Segment Positioning and Locking Device and Assembly Method

ActiveCN105414502BImprove arc connection accuracyImprove and stabilize arc connection accuracySlab casterLocking mechanism

The invention belongs to metal continuous casting equipment, relates to a slab continuous casting fan-shaped segment locating and locking device and an assembling method, in particular to slab continuous casting machine auxiliary equipment. The device comprises a first fan-shaped segment, a second fan-shaped segment and a bearing mechanism. The fan-shaped segments are formed by connecting line rollers and roller frames. The first fan-shaped segment is fixed to the second fan-shaped segment. The first fan-shaped segment is connected with a lower opening of a crystallizer. Roller frame hooks are hung on bearing frame hanging pins. The device is characterized in that rectangular deep grooves of 8-12 mm are formed in the two sides below the right portion of each bearing frame, and locating and locking mechanisms with adjustable locking hole grooves are fixed in the rectangular grooves by fixing bolts; and brackets below the roller frames fall down to be inserted in the locking hole grooves, and zero clearance is kept during locking. The device has the beneficial effects that the concept is novel, the structure is simple, compact and reasonable, and running is stable and reliable; after online mounting and arc jointing, fast locating and locking are carried out, mounting and demounting are convenient, time is saved, and the fan-shaped segment arc jointing precision is improved and stabilized; and the casting blank quality is effectively improved, the accidents of blank stagnation and steel leakage are reduced, and it is guaranteed that continuous casting production is carried out smoothly.

Owner:MAANSHAN IRON & STEEL CO LTD

Multipurpose quick-change positioning device with limiting function

PendingCN112628260AQuick lock positioningGuaranteed installation accuracyFouling preventionNutsStructural rigidityEngineering

The invention belongs to the field of accurate positioning transmission mechanisms, and particularly relates to a multipurpose quick-change positioning device with a limiting function. The multipurpose quick-change positioning device comprises a tubular guide support and a conical mandrel sleeved with the guide support, wherein the diameter of one end of the conical mandrel is larger than that of the guide support, the other end of the conical mandrel extends out of the guide support, conical guide blocks are arranged on the outer side of the guide support, guide holes used for containing the conical guide blocks are formed in the guide support, the conical guide blocks and the conical mandrel are matched in a contact manner, the conical guide blocks are annularly and evenly distributed on the guide support, and an locking outer ring sleeves the periphery of the conical guide blocks. By the adoption of a multi-set combined structure, rapid locking and positioning can be achieved, modular assembling and disassembling can be achieved conveniently, the installation precision can be guaranteed, and interchangeable replacement can be conducted. The working efficiency is greatly improved, the multipurpose quick-change positioning device can be suitable for various working conditions, the shaft hole positioning precision is guaranteed, and meanwhile enough structural rigidity is achieved.

Owner:山东颐杰鸿丰能源装备有限公司

A fast positioning latch locking device

The invention discloses a fast positioning bolt locking device, which comprises a flange seat provided with an internal thread inside, a pressing nut provided with an external thread on the outside, a positioning pin embedded in the pressing nut, and a fixing pin for fixing the positioning pin. Pin seat, the middle part of the fixed pin seat is provided with a fixing hole, the end is provided with a flange; The flange plate of the pressing nut matches the flange plate at the end of the fixed pin seat, and the other end of the pressing nut placed in the flange seat is provided with a tooth cover; the middle part of the positioning pin is provided with a tooth plate matching the tooth cover. The invention makes up the gap between the tooling equipment and the fixed guide rail platform through the staged engagement and separation of the tooth cover and the tooth plate, and generates a great locking force, which can effectively solve the disadvantages of the traditional positioning method, and achieve fast and convenient locking. Tight positioning action; to avoid bending damage caused by the bolt, resulting in positioning failure, suitable for wide application.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

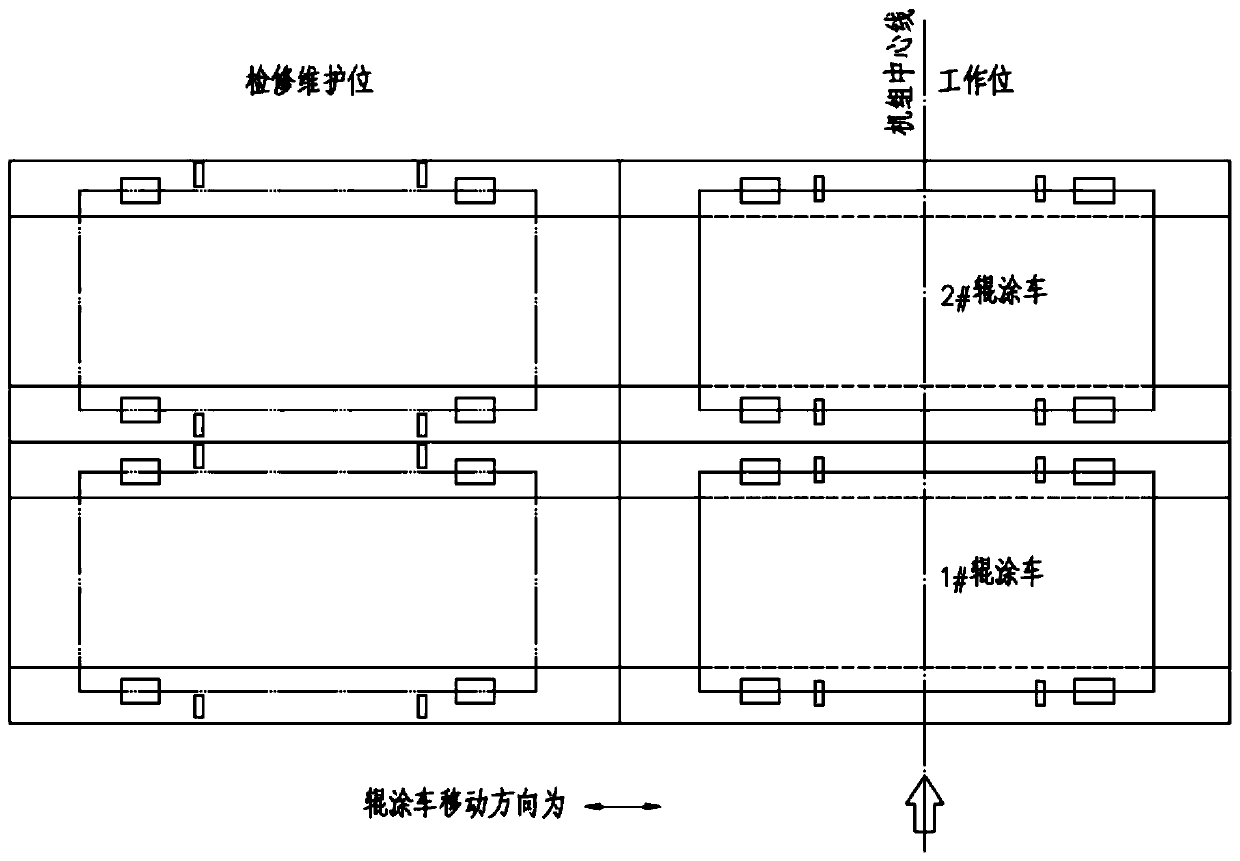

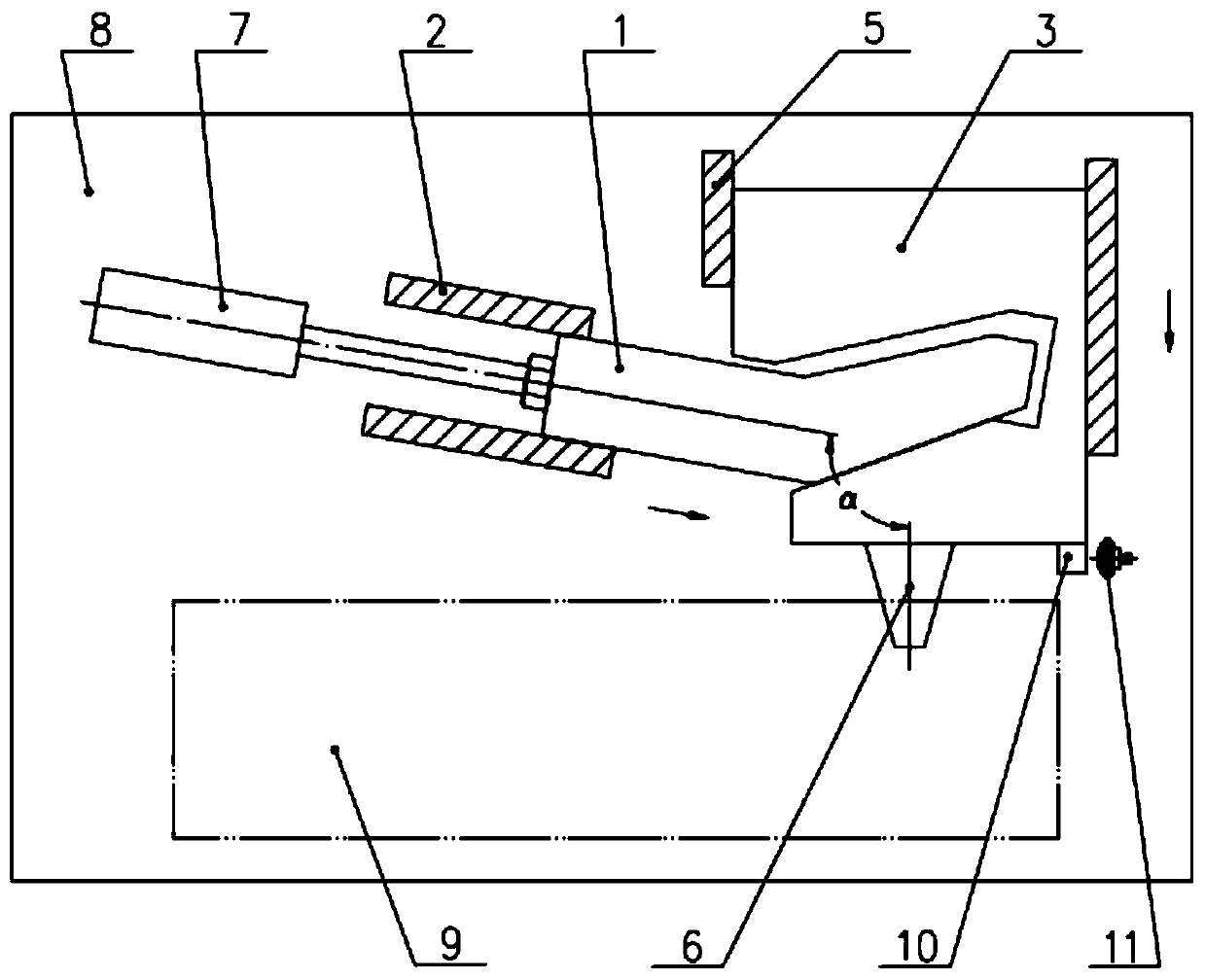

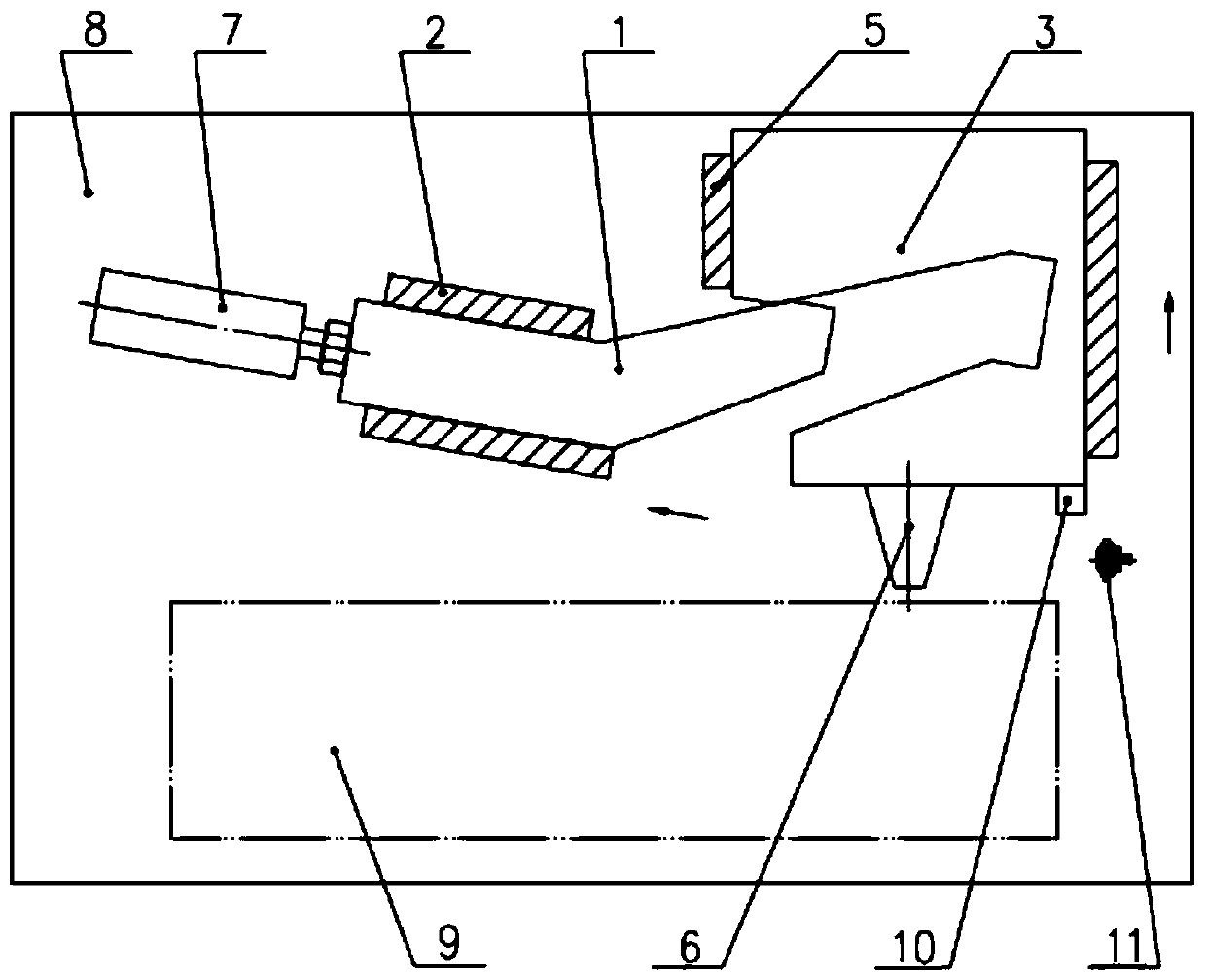

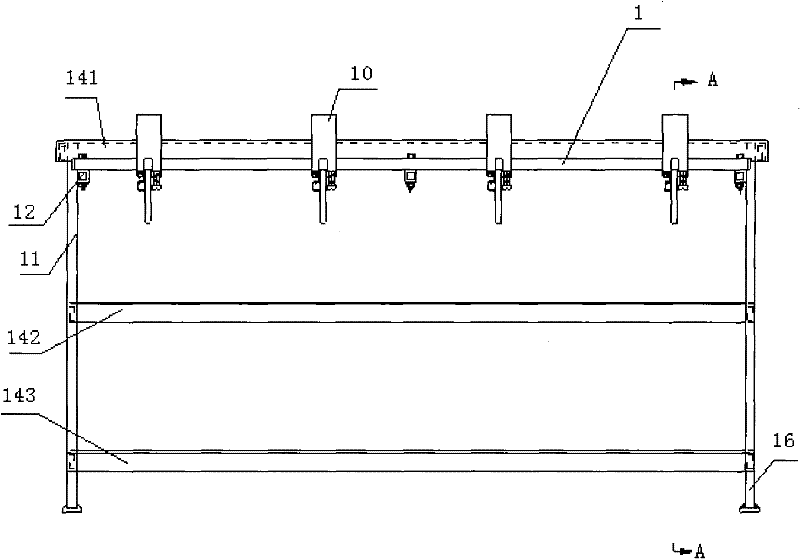

Roller coating unit

PendingCN110538763AOptimize layoutSmall footprintLiquid surface applicatorsCoatingsPulp and paper industryCoating

The invention relates to a roller coating unit. A positioning machine is used for implementing locking and unlocking of a roller coating trolley; the positioning machine comprises a double-surface inclined wedge block, a guide slide way, a positioning base and a positioning part, wherein the positioning base is slidably arranged on the guide slide way; the positioning part is arranged at the frontend of the positioning base; the positioning base is provided with a driven groove; the driven groove comprises two driven surfaces which are sequentially arranged in the sliding direction of the positioning base; the two driven surfaces are each of a bevel which forms an included angle with the sliding direction of the positioning base; and the two wedge surfaces of the double-surface inclined wedge block are matched with the two driven surfaces so that the positioning part is inserted into a positioning gap of the roller coating trolley or is released from the inside of the positioning gapof the roller coating trolley. The roller coating unit realizes locking and unlocking of the roller coating trolley by cooperation of the double-surface inclined wedge block and the positioning base comprising the driven grooves, can replace complicated manual assembly and disassembly of the positioning part and can effectively improve the maintenance efficiency of equipment; the positioning machine is easy to arrange, occupies a small space and can preferably adapt to the work condition that the space between adjacent roller coating machines of the roller coating unit is narrow and small, sothe labor cost is lowered and the maintenance risks are reduced.

Owner:WISDRI ENG & RES INC LTD

Device for cutting insulation support for transformer body

The invention discloses a device for cutting an insulation support for a transformer body, comprising a workbench body. The workbench body comprises a workbench surface, four rectangular tubes which are arranged under the workbench surface to support the workbench surface, three cantilevers which are fixed on the workbench body and bulge out of the workbench surface, two guide rails which are arranged on the cantilevers in parallel and four moving guide plates which can move and be fixed by passing through the two guide rails. The device improves the working efficiency and can conveniently finishing cutting the insulation support for the transformer body and save time and labor, and the cut insulation support has flat paperboard, thus greatly improving the production quality and the production efficiency. The jig saw is held by both hands so that the jig saw is stable with force, and both hands are not contacted with the paperboard of the insulation support, thus avoiding the possibility that the jig saw is liable to hurting own hands in the original cutting mode.

Owner:SHANGHAI ZHIXIN INTELLIGENT ELECTRIC CO LTD +2

A platform support device for elevator automation installation equipment

The invention discloses a platform supporting device for elevator automatic installation equipment, which includes a supporting rod and a supporting and locking driving mechanism; the supporting and locking driving mechanism includes a driving member and a linear driving mechanism, wherein the supporting rod is arranged on On the frame, the two ends extend outwards and are respectively connected with the drive parts; the support rods at each end are provided with locking parts, when the linear drive mechanism respectively drives the drive parts to move in reverse synchronously to promote the support at both ends of the frame. After the rods are synchronously extended in reverse and braced against the wall of the hoistway, the linear drive mechanism continues to drive the driving member to move, prompting the locking member on the support rod to press against the frame, thereby realizing the The effect of fixing the working platform on which the equipment is installed and the wall of the hoistway. The platform supporting device of the present invention can position and lock the working platform when the working platform reaches a specific installation position, so as to prevent the working platform from shaking during the construction process, which is beneficial to ensure the construction accuracy.

Owner:广州明森合兴科技有限公司

Spline housing rapid clamping connector

InactiveCN109968197AQuick positioning and lockingHigh card loading accuracyGrinding work supportsEngineeringRejection rate

The invention relates to a spline housing rapid clamping connector. The spline housing rapid clamping connector comprises a grinding machine connection disc, an expansion core shaft, a pull rod, an expansion housing and a wedge block; the expansion core shaft is coaxially mounted on the front end of the grinding machine connection disc, the pull rod is coaxially arranged in the expansion core shaft in a penetrating manner, the rear end of the pull rod is connected with the grinding machine connection disc, the wedge block is arranged on the pull rod in a penetrating manner, the wedge block isin slope connection with the inner wall of the pull rod, the front end of the pull rod extends to the outer side of the front end of the expansion core shaft, a blocking disc is arranged on the frontend of the pull rod, the expansion housing is coaxially mounted on the outer side of the expansion core shaft, the expansion bushing is located between an annular positioning boss and the pull rod blocking disc, and the expansion bushing and the expansion core shaft are in slope contact. The spline housing rapid clamping connector is reasonable in structure, convenient to use, and high in practicability. The connector can reduce clamping difficulty, work efficiency is improved, machining precision is improved, and the rejection rate is reduced. In addition, the connector is wide in applicationrange and is suitable for machining of spline housings of two specifications.

Owner:天津市臣涛精密机械设备有限公司

A processing line for roof steel components

ActiveCN111874606BQuick assemblyImprove assembly efficiencyConveyorsConveyor partsProduction lineBuilding product

The invention discloses a processing production line for roof steel components, which relates to the technical field of building product processing, and includes fixed tooling, a conveying mechanism, an intercepting mechanism, a material picking mechanism and a spot welding mechanism. The assembly line production method is adopted in the invention to realize Compared with traditional manual work, the rapid assembly operation of roof steel components has significantly improved assembly efficiency and assembly accuracy, and saved labor costs.

Owner:江苏德丰建设集团建筑科技有限公司

A locking disc assembly pre-positioning device and assembly method

ActiveCN105459021BQuick positioning and lockingAccurate locking positioningMetal-working hand toolsEngineeringPiston

The invention discloses a locking disc assembling prepositioning device and an assembling method, and belongs to the field of locking discs. The problems that an existing locking disc assembling process is complex, labor and time are wasted and the assembling effect is poor are solved. The device comprises a screw rod and further comprises a cylinder and a piston arranged inside the cylinder. The lower end of the piston and the cylinder form an oil cavity. An oil inlet hole communicated with the oil cavity is formed in the outer wall of the cylinder. The lower end of the piston is fixedly connected with the screw rod. Prepositioning of an inner ring of the locking disc, a shaft sleeve and an outer ring can be achieved at a time, prepositioning is accurate and balanced, the bolt locking installation time is saved, labor force is saved, the assembling efficiency is improved, and the locking disc assembling prepositioning device has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:MAS JHJX MACHINERY MFG CO LTD

Mounting nut of prestressed steel bar

InactiveCN101664960BImprove prefab speedIncrease productivityMouldsPre stressArchitectural engineering

The invention discloses a mounting nut of a prestressed steel bar, which comprises a fixed-end mounting nut and a stretch-end mounting nut that are respectively provided with a threaded sleeve; the inside diameter of the threaded sleeve is slightly larger than the diameter of the prestressed steel bar; the middle part of the inner wall of the threaded sleeve is provided with a section of threads;the end surface of the tail part of the threaded sleeve is embedded with a magnet ring in a concentric way; the sleeve end of the threaded sleeve expands and forms a locating surface towards one sideof the tail part of a locating column; and the sleeve end of the fixed-end mounting nut is fixed with the locating column with a locating column end inwards to the thread section. The nut has simple and reliable structure, convenient manufacture and low cost, ensures the reliable installation of an anchor backing plate, simplifies the installation process of the anchor backing plate, reduces the tool kind and amount in the construction site and the labor intensity of the workers, quickens the construction progress, saves a great deal of working hours, and realizes the fast installation of theprestressed steel bar.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

Seatbelt retractor having an inertial sensor weight with a guide surface

InactiveUS20060219833A1Reduces sensitivity of sensorIncrease reaction sensitivityBelt retractorsIn vehicleEngineering

A seatbelt retractor assembly (10) has a seatbelt retractor (14) and an actuator (26) for locking and unlocking the seatbelt retractor (1). An inertial sensor mass (30, 32, 33) detects changes in vehicle speed. The mass (30, 32, 33) has a guide surface (34, 35, 36) for interacting with the actuator (26). The guide surface (34, 35, 36) moves between an unlocking position in which the actuator (26) unlocks the seatbelt retractor (14) and a locking position in which the actuator (26) locks the seatbelt retractor (14). The guide surface (30) has an inner profile portion (62) and at least an outer profile portion (64). The actuator (26) is in contact with the inner profile portion (62) in the unlocking position while moving into contact with the outer profile portion (64) as the actuator (26) moves towards the locking position. The inner profile portion (62) causes a different acceleration of the actuator (26) than the outer profile portion (64).

Owner:KEY SAFETY SYST

Monorail swing and tilt big range changeable camera

The disclosed single-track shift large-frame camera comprises: a guide rail with the front and back base formed by from top to bottom a horizontal rotating disk, a vertical pitch coarse / fine turning plate with arc slide slot center as the camera zero point on the horizontal disk shaft, a front-back micro-distance plate, a left-right / top-bottom coarse plate, and a front-back coarse plate on the rail, all combined by dovetail groove; a lens frame arranged on the horizontal disk, a back frame connected with the horizontal plate. This smart invention has clear work division on adjustment with small volume and light weight, and fit to operate stably.

Owner:张云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com