A fast positioning latch locking device

A technology for positioning bolts and locking devices, applied in threaded fasteners, connecting components, screws, etc., can solve the problems of positioning failure, bending of bolts, large inertia, etc., to achieve perfect functions, avoid bending damage, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

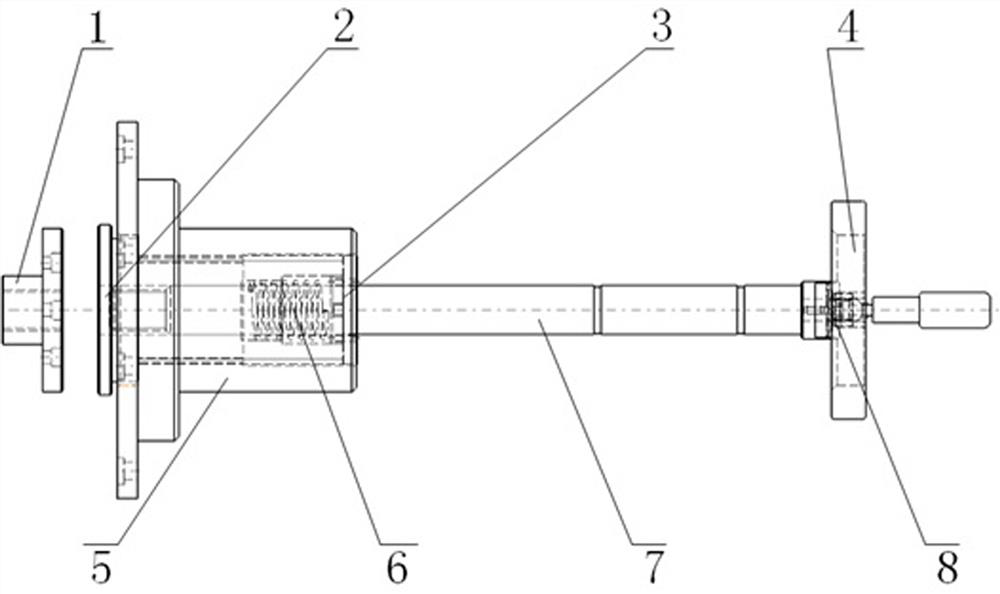

[0027] The main structure of this embodiment, such as figure 1 As shown, it includes a flange seat 5 with an internal thread, a pressing nut 2 with an external thread, a positioning pin 7 embedded in the pressing nut 2, and a fixing pin seat 1 for fixing the positioning pin 7, so The fixing pin base 1 is provided with a fixing hole in the middle, and a flange plate is provided at the end; The flange of the pressing nut 2 is matched with the flange at the end of the fixed pin seat 1, and the other end of the pressing nut 2 placed in the flange seat 5 is provided with a tooth cover 3; the middle part of the positioning pin 7 A tooth plate 73 matching the tooth cap 3 is provided.

[0028] The specific implementation process is as follows: Image 6 As shown, the locking process:

[0029] Step 1: The tooling equipment is transferred in place.

[0030] Step 2: Manually rotate the positioning pin 7 (action 1) At this time, the tooth plate 73 of the positioning pin 7 is engaged wi...

Embodiment 2

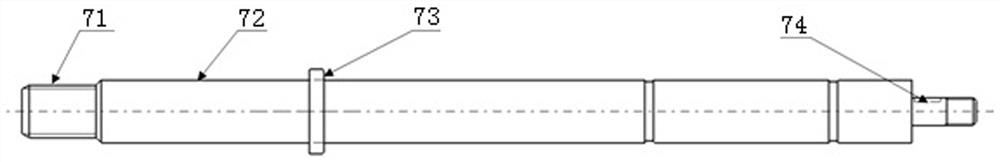

[0033] On the basis of the above-mentioned embodiment, this embodiment further defines the structure of the positioning pin 7, such as figure 2 As shown, the positioning pins 7 are, from left to right, an insertion portion 71 inserted into the fixing hole in the middle of the fixing pin base 1 , an optical axis portion 72 placed in the pressing nut 2 and matched with its hole axis, and the tooth cover 3 . The matching chainring 73 and the driving end 74 that drives the positioning pin 7 to move. The other parts of this embodiment are the same as the above-mentioned embodiments, and are not repeated here.

Embodiment 3

[0035] On the basis of the above-mentioned embodiment, this embodiment further defines the structure of the positioning pin 7, such as figure 1 , 2, the insertion part 71 of the positioning pin 7 is provided with an external thread, the fixing hole in the middle of the fixing pin base 1 is provided with an internal thread, the insertion part 71 of the positioning pin 7 and the fixing hole in the middle of the fixing pin base 1 are threaded connect. The other parts of this embodiment are the same as the above-mentioned embodiments, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com