Multifunctional integrated machining machine

A processing machine, multi-functional technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome processing of standard parts, low production efficiency, and no published patent documents have been found, so as to promote production efficiency and improve production. Efficiency, the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

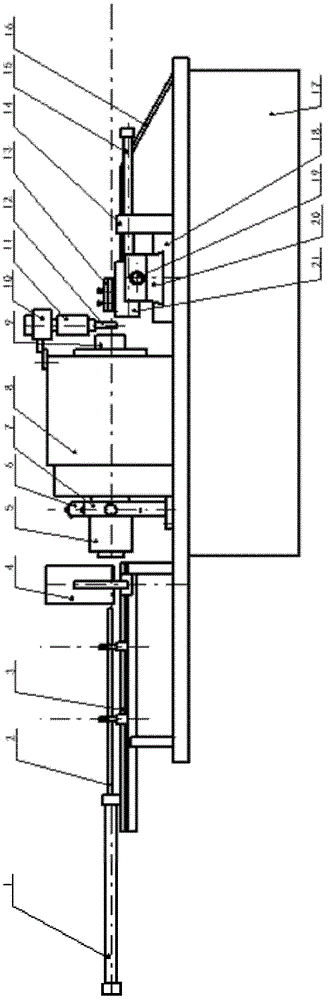

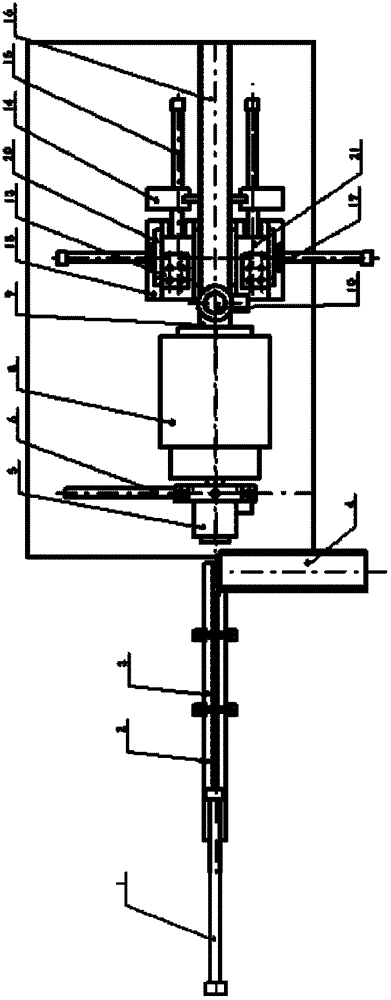

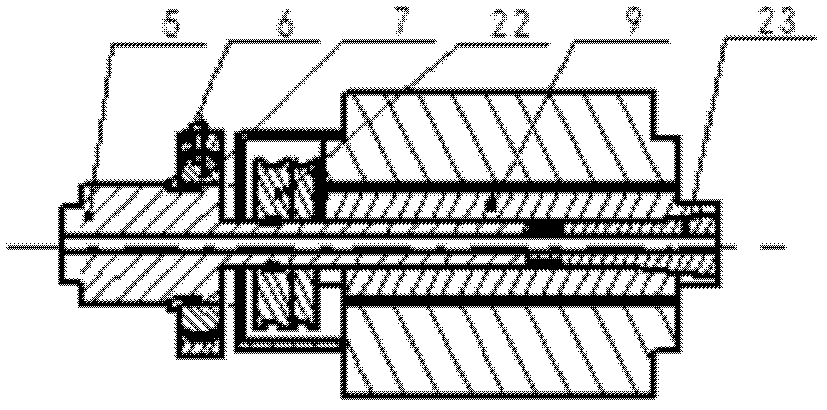

[0019] A multifunctional integrated processing machine, comprising a workbench 17, a host machine 8, a locking device, a tool base 18, a transverse slider 20, a longitudinal slider 21, a tool holder 13, a longitudinal oil cylinder 15, a transverse oil cylinder 19 and a push rod frame 3. Push rod oil cylinder 1, the main engine is fixed on the workbench, the main engine is driven by the pulley 22 of the motor to rotate the main shaft 9, the clamping sleeve 23 is coaxially embedded in the front of the main shaft, and the movement is coaxially installed at the rear of the main shaft Bushing 5, see image 3 Install the tool base on the workbench in front of the host, slide and install the horizontal slider on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com