Patents

Literature

141results about How to "Convenient grinding work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

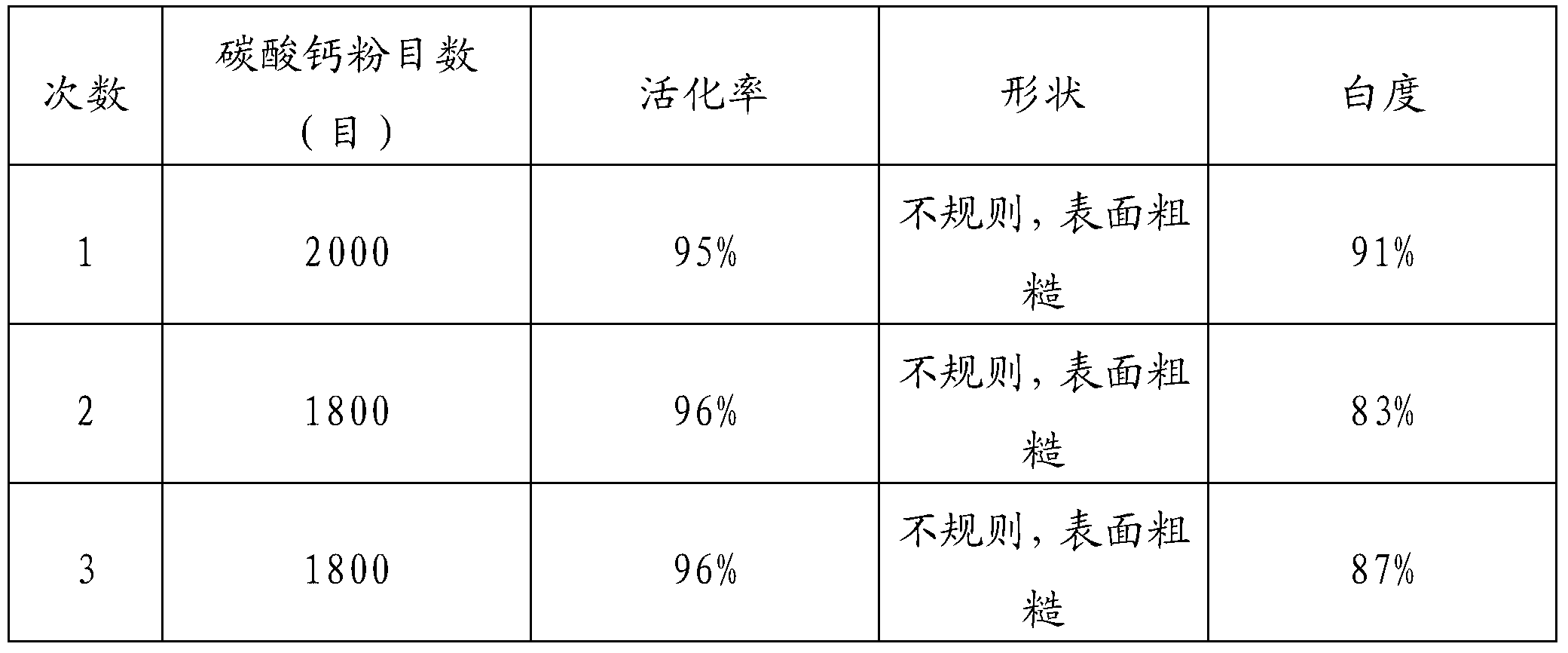

Preparation method of superfine modified ground limestone

ActiveCN103232732AConvenient grinding workImprove grinding effectPigment treatment with macromolecular organic compoundsPigment physical treatmentMaterials scienceSlurry

The invention relates to a preparation method of superfine modified ground limestone. The preparation method of the superfine modified ground limestone comprises the following steps of: (1) steeping slurry; (2) grinding in a four-level wet-method grinding manner; (3) drying: carrying out spray drying on the slurry by using a spray drying device; and (4) modifying: grinding and dispersing the collected ground limestone powder by a dry method at the grinding rate of 1460r / min, and adding modifiers in the grinding process so as to obtain the superfine modified ground limestone. By using the four-level wet-method grinding manner and a method of modifying subjected to drying, the problem of waste of modifiers during liquid modification is solved, and the activating rate and whiteness of the product are improved.

Owner:潍坊双冠新材料有限公司

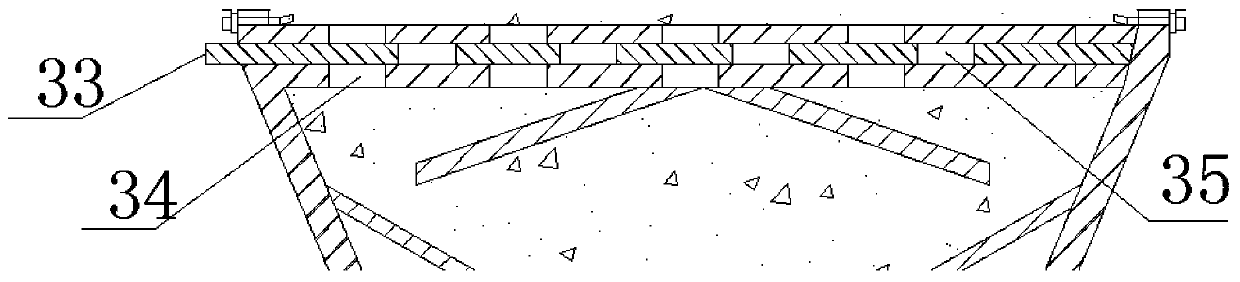

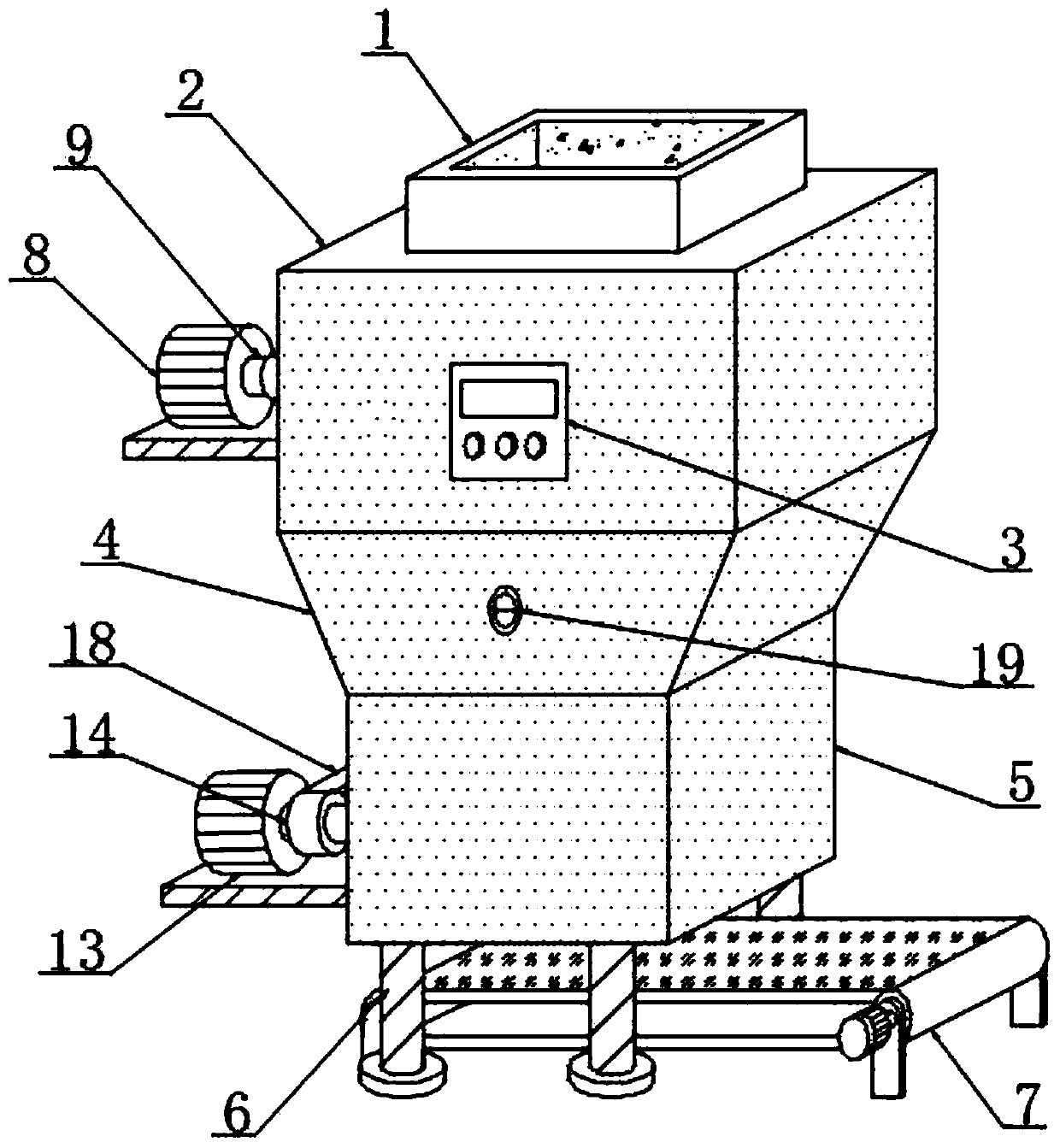

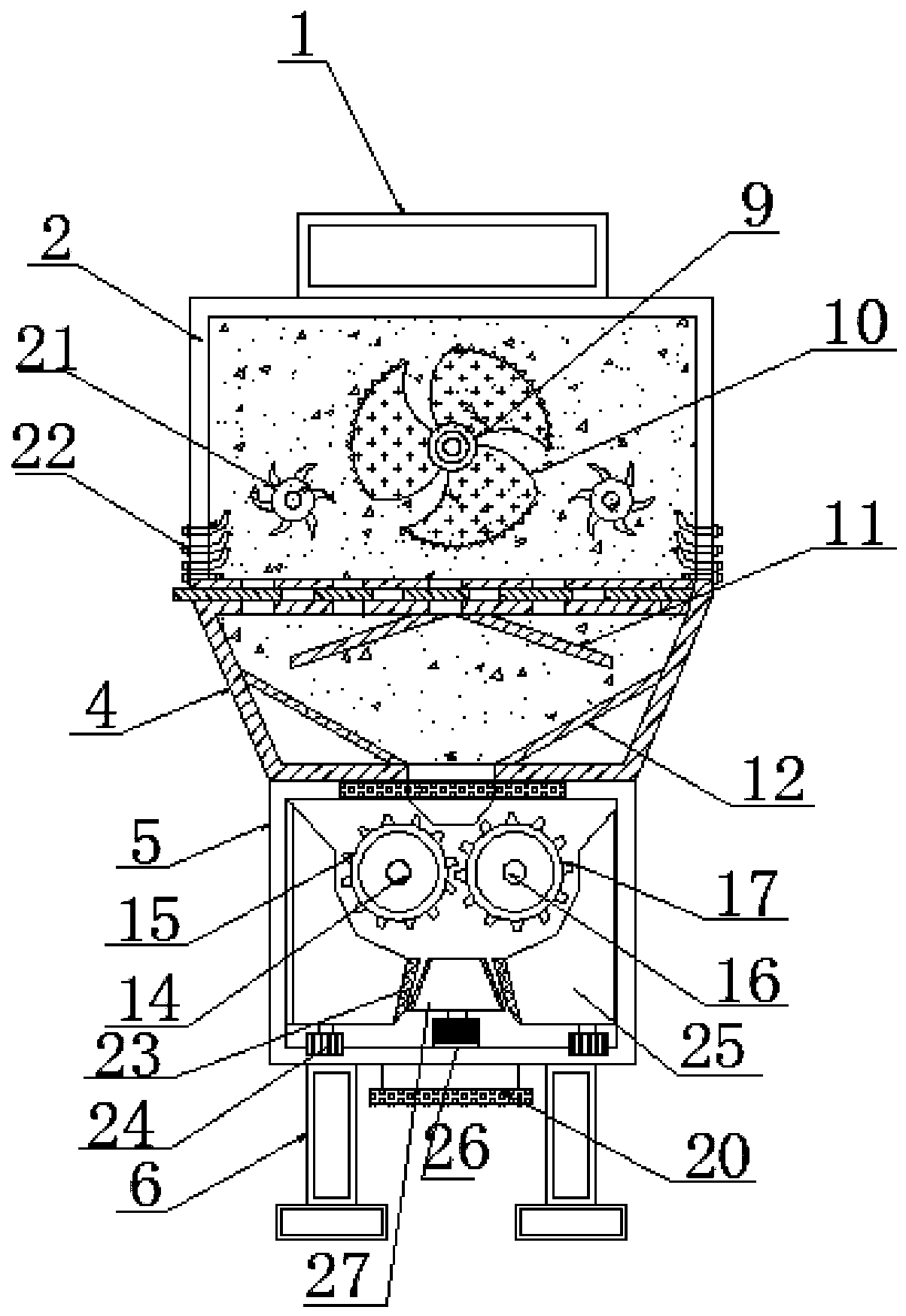

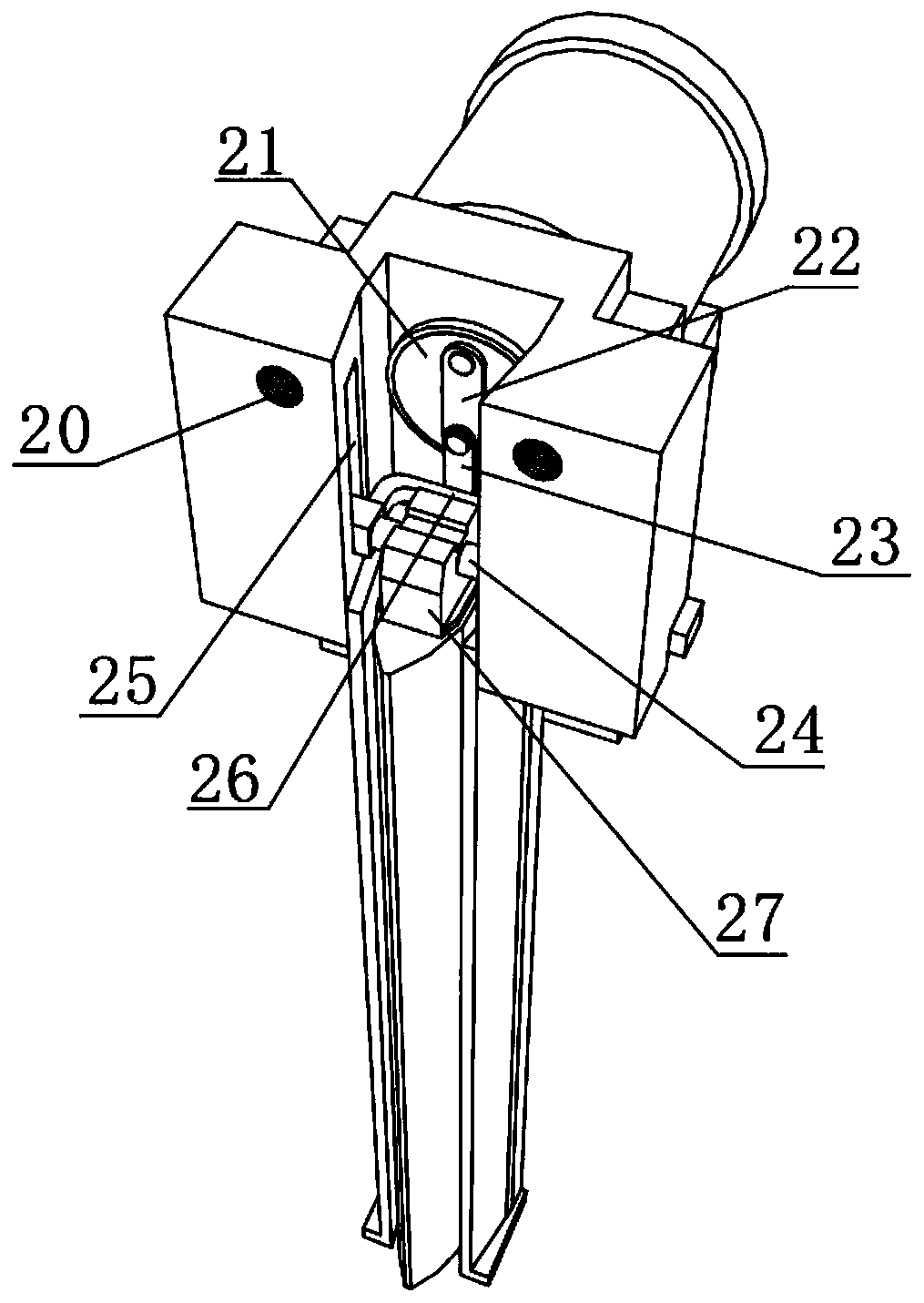

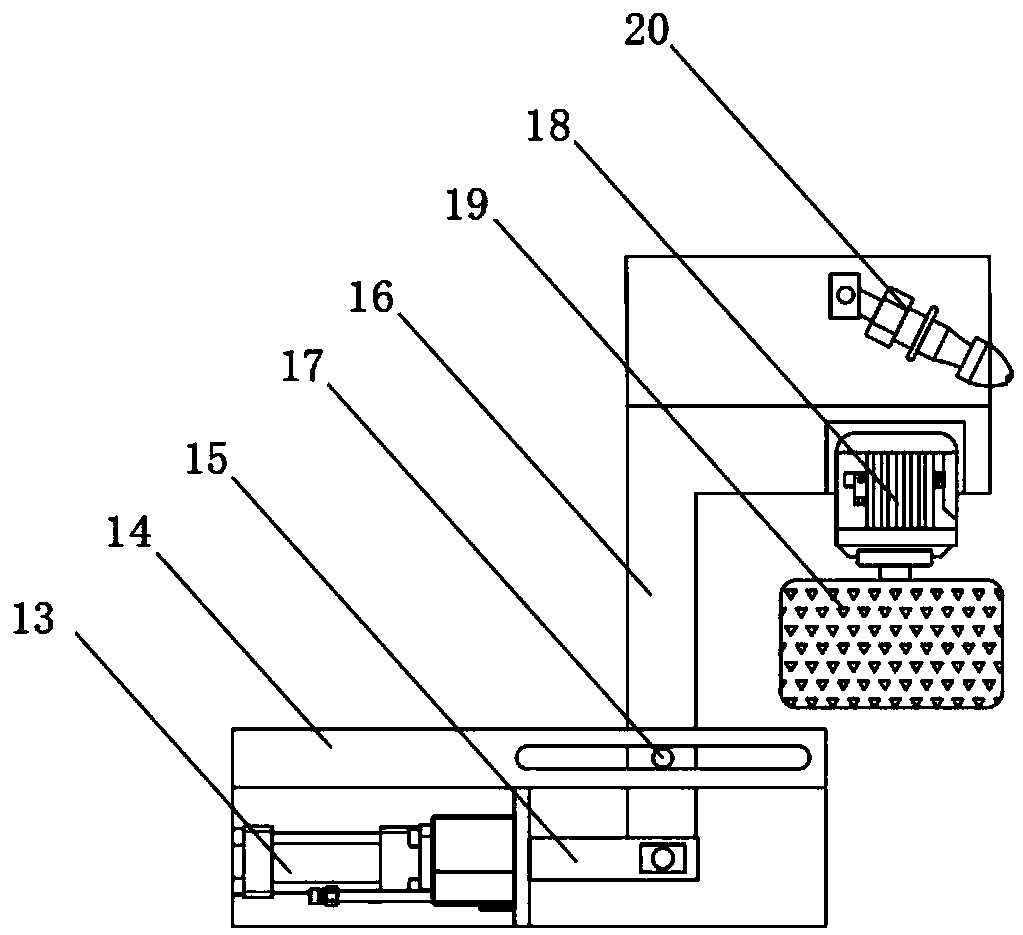

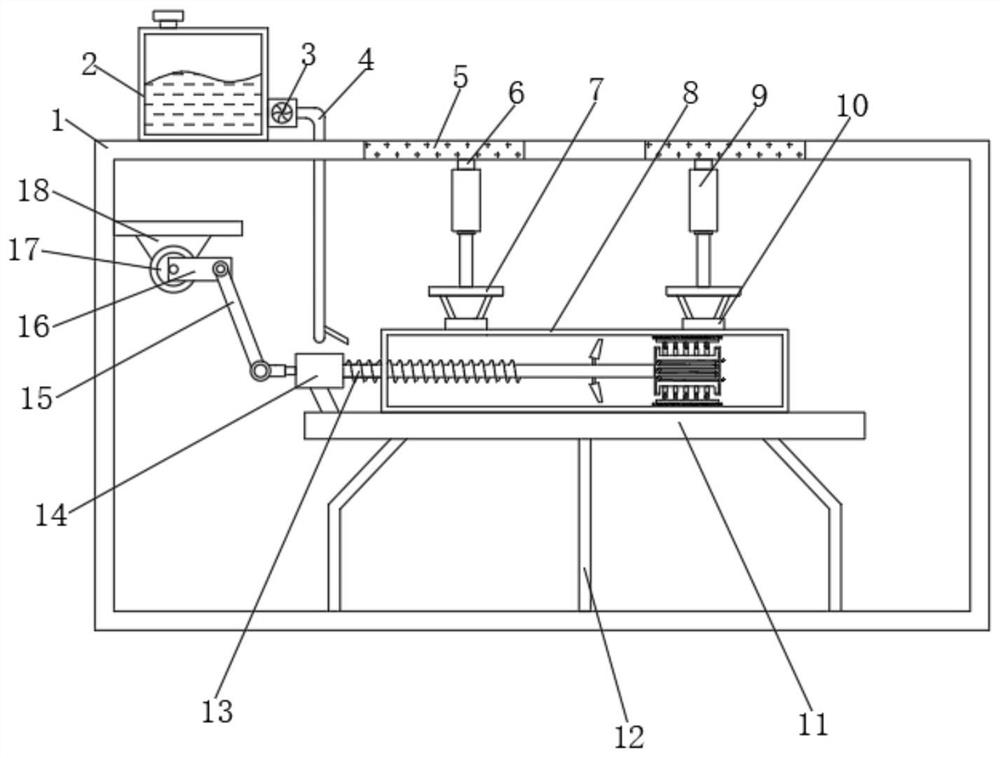

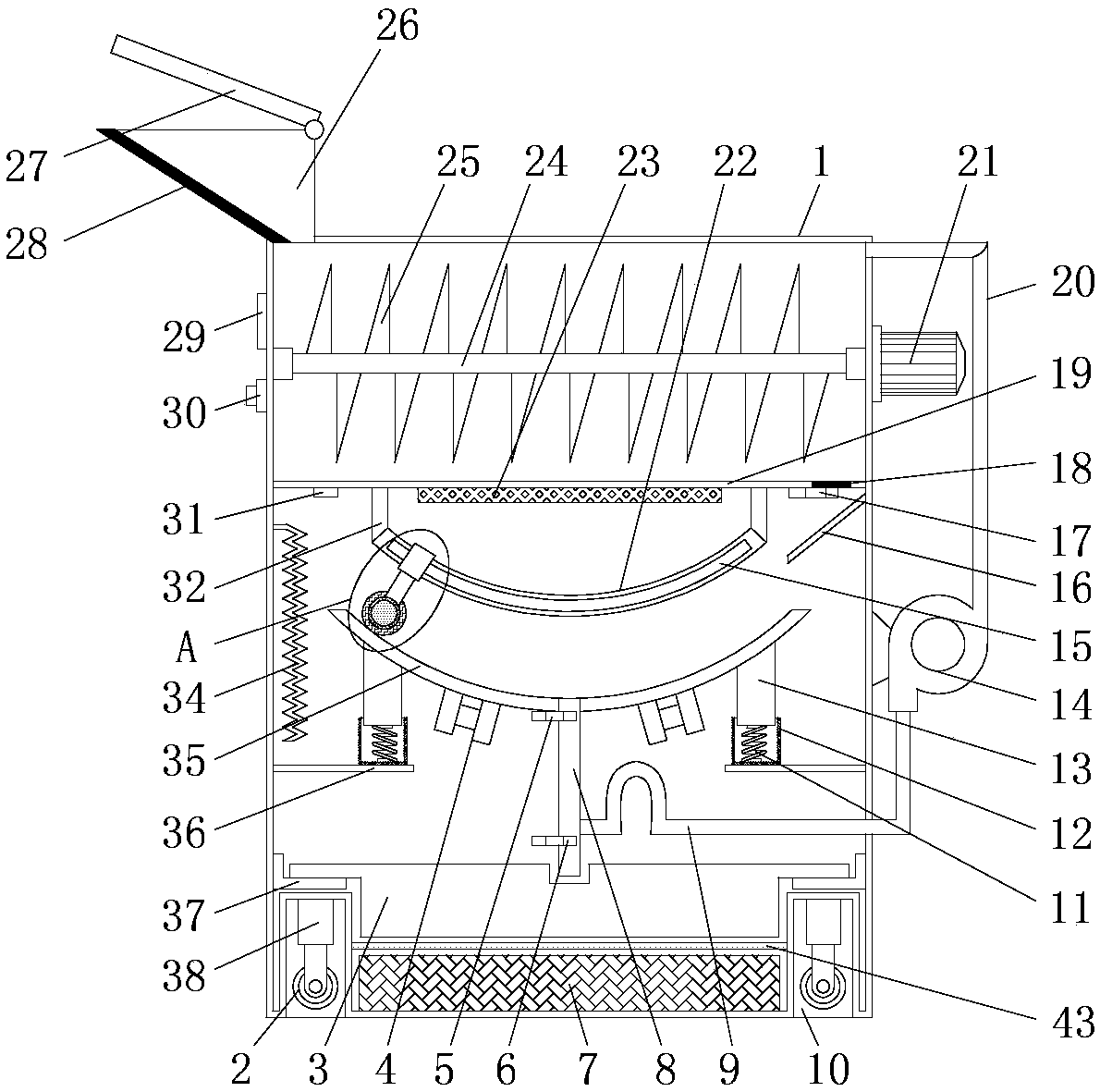

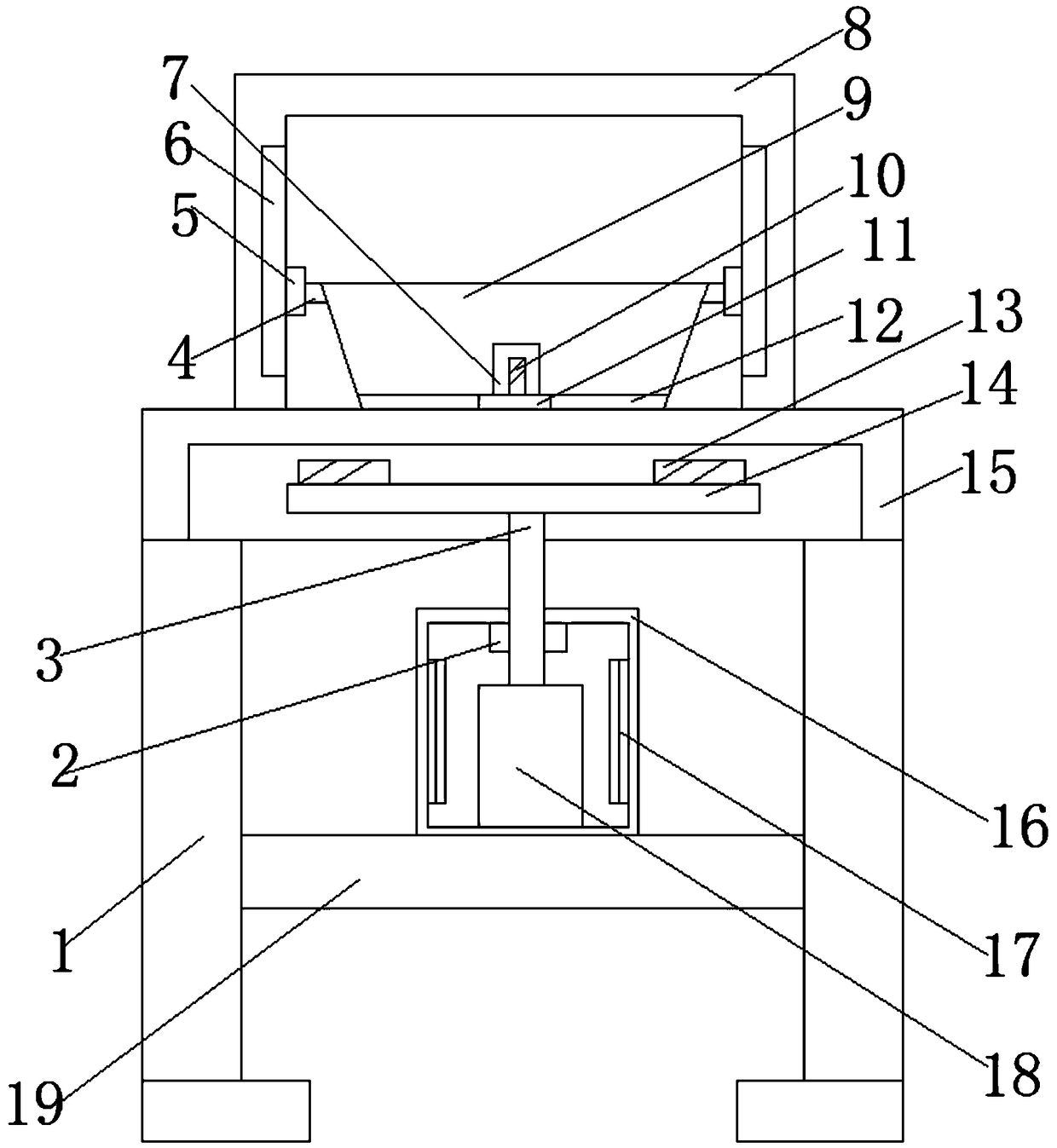

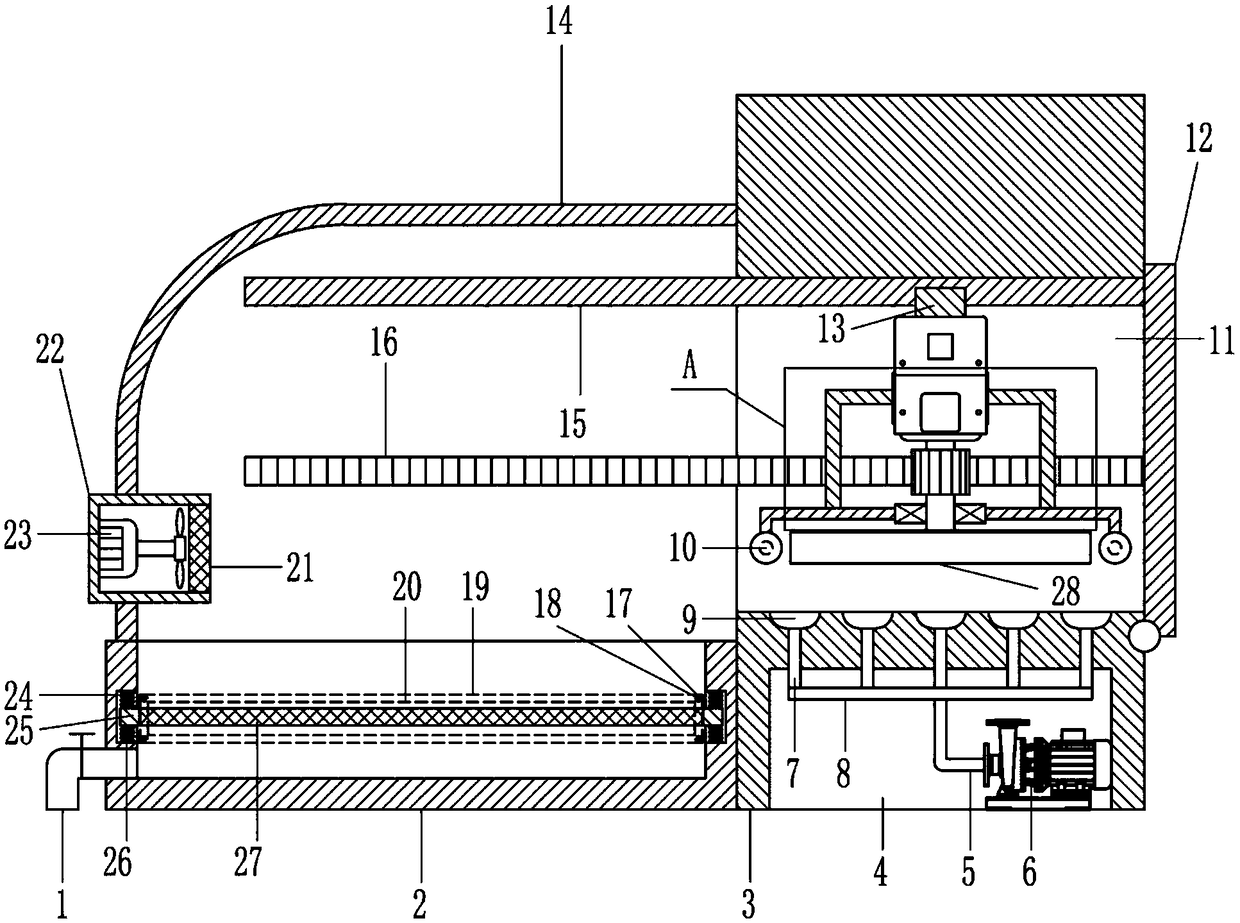

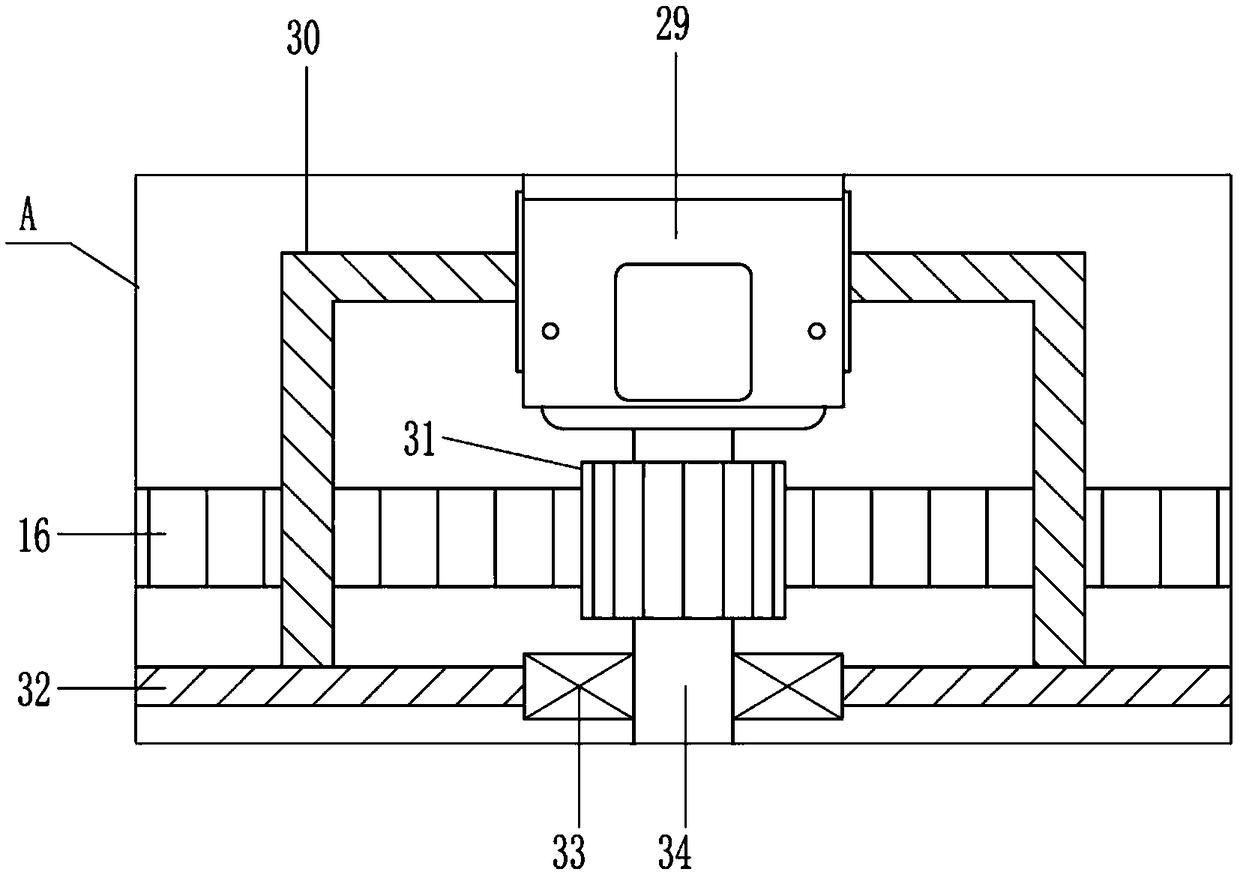

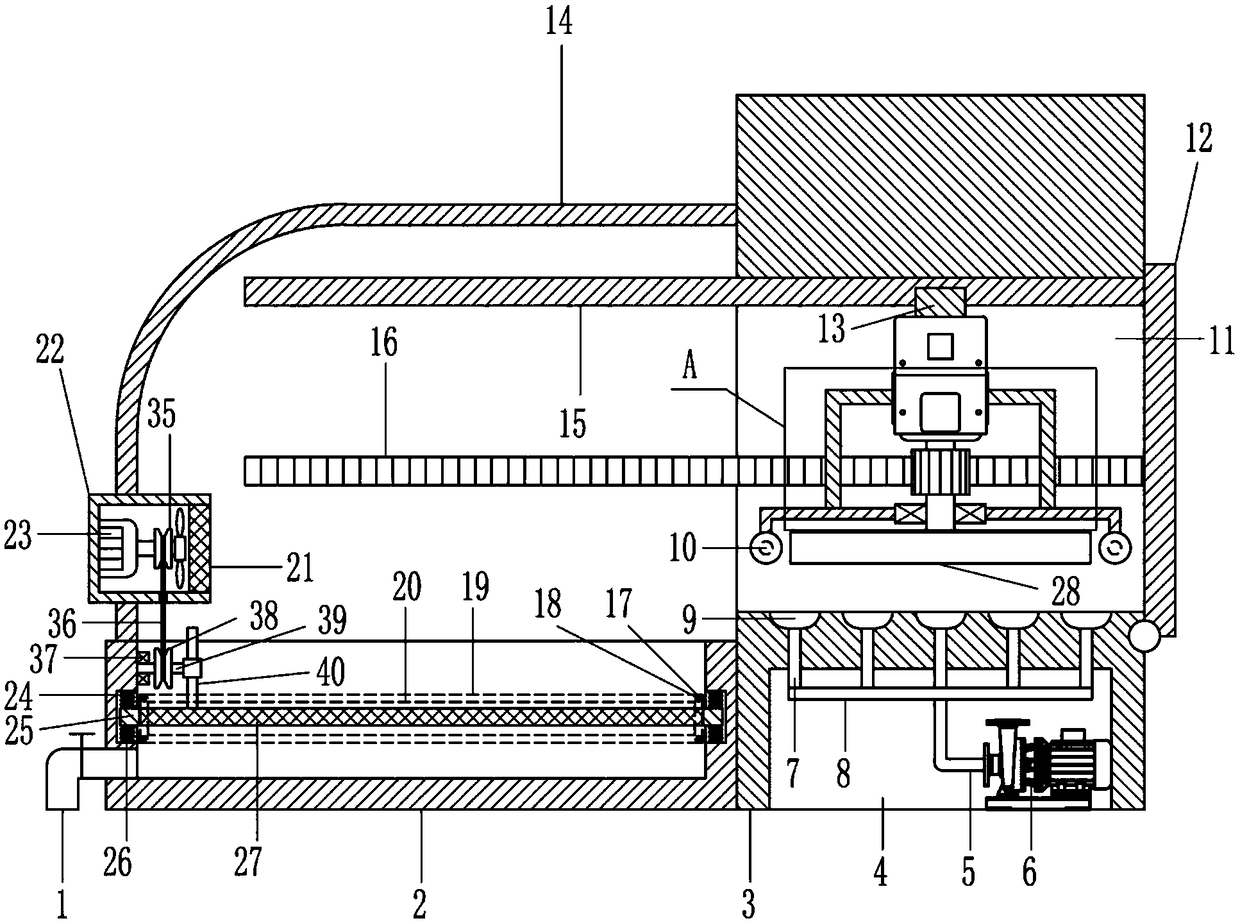

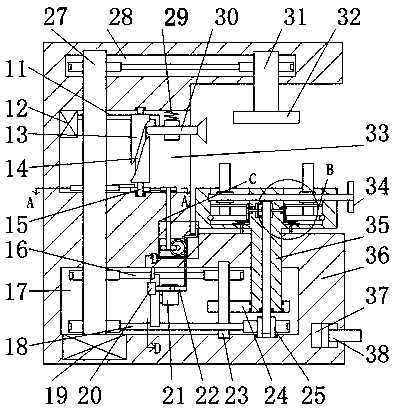

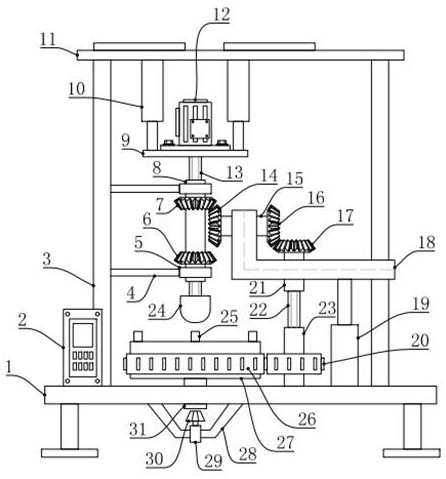

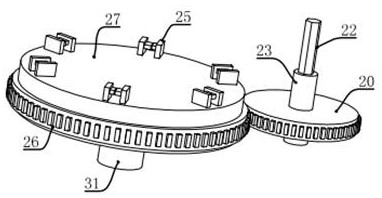

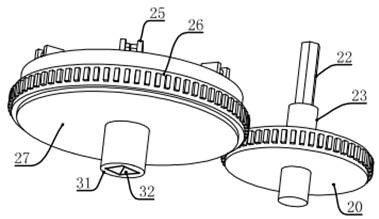

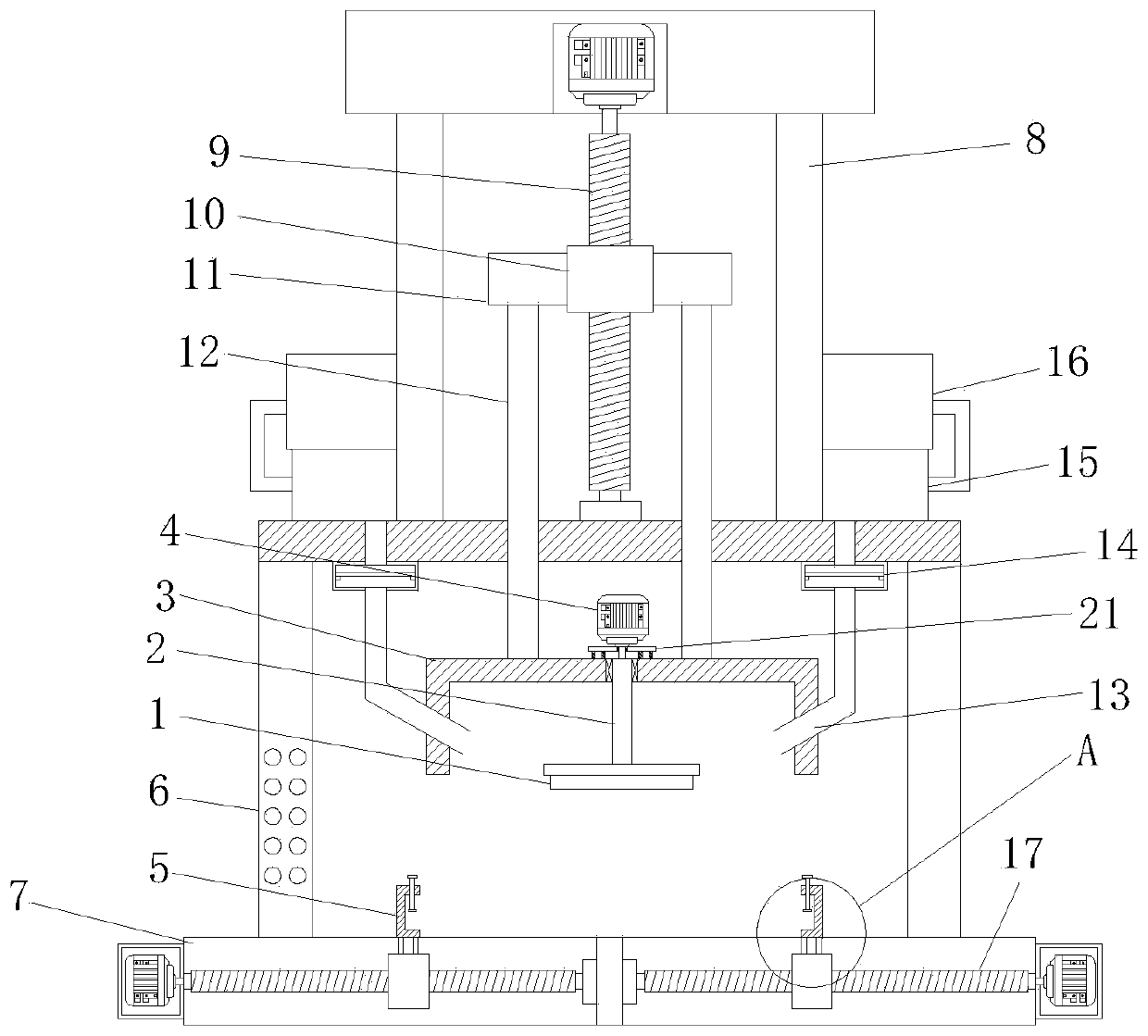

Temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products

ActiveCN109833951ARealize crushing workRealize the drying workFeeding-stuffWeld torches cleaningTemperature controlAquatic product

The invention discloses a temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products. An opening and closing control assembly is arrangedbetween a crushing box and a drying box so as to control discharging of materials in the crushing box, and the crushing box is internally provided with a flying stirring assembly enabling the to-be-crushed materials to move upwards, so that the materials can fly to the crushing assembly to be crushed; and the grinding assembly comprises a primary rough grinding assembly and a secondary fine grinding assembly, the primary rough grinding assembly is used for primary coarse grinding of the materials, the secondary fine grinding assembly is used for secondary fine grinding of the materials, the temperature of the inside of the drying box can be monitored in real time through the temperature sensors arranged at the same time, the temperature can be conveniently adjusted according to the humidity of the raw materials, and the grinding treatment of the feed raw materials is realized through the arranged grinding box; and a conveying machine is arranged, so that the automatic conveying work ofthe materials after grinding can be realized, the labor is saved, and the working efficiency is improved.

Owner:惠安先锋机械有限公司

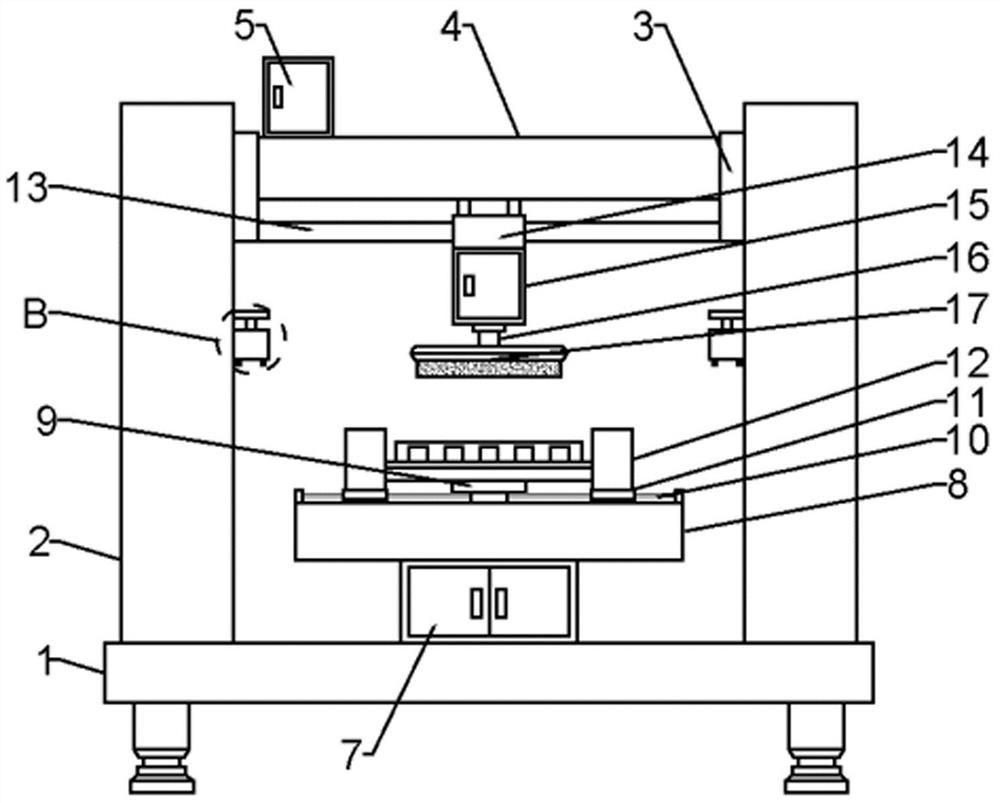

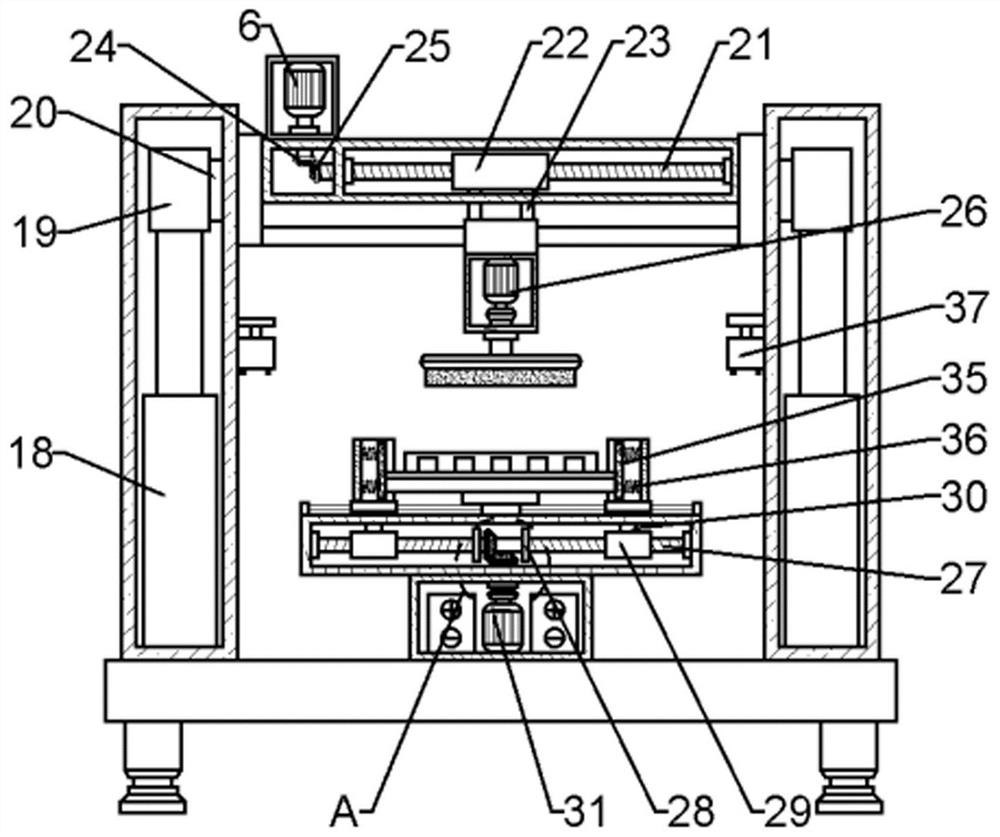

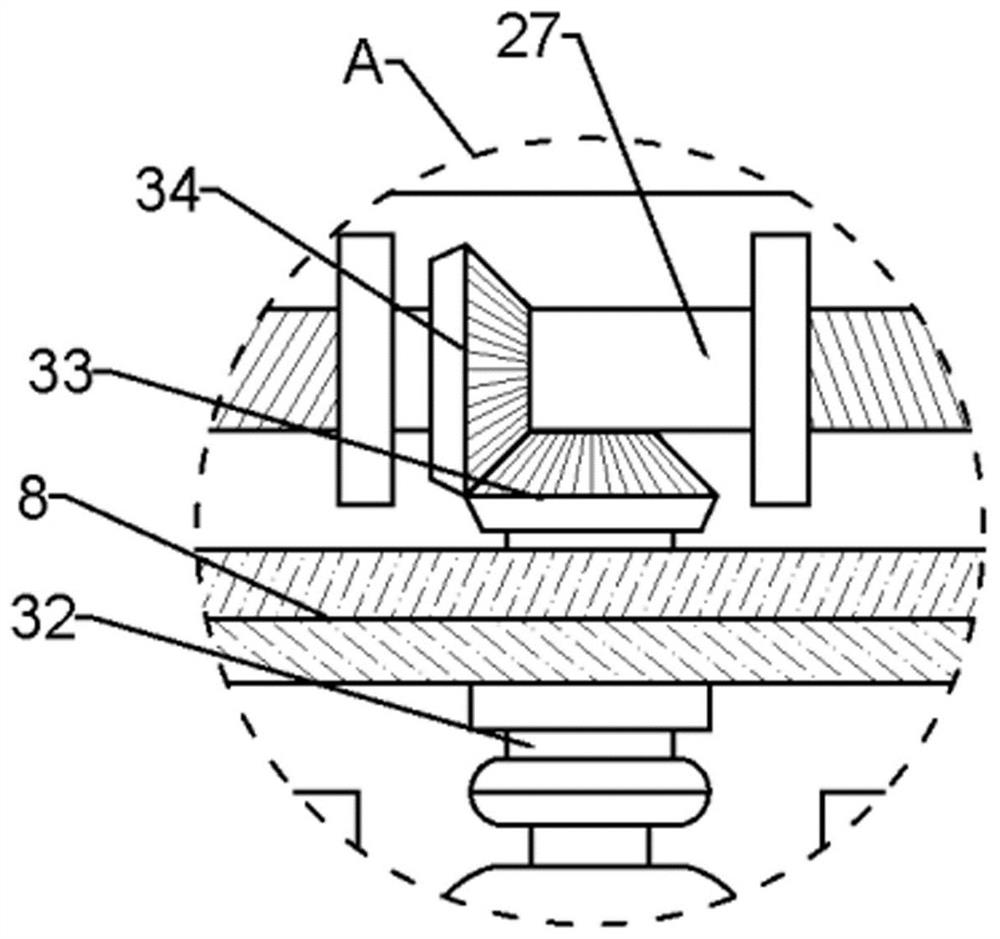

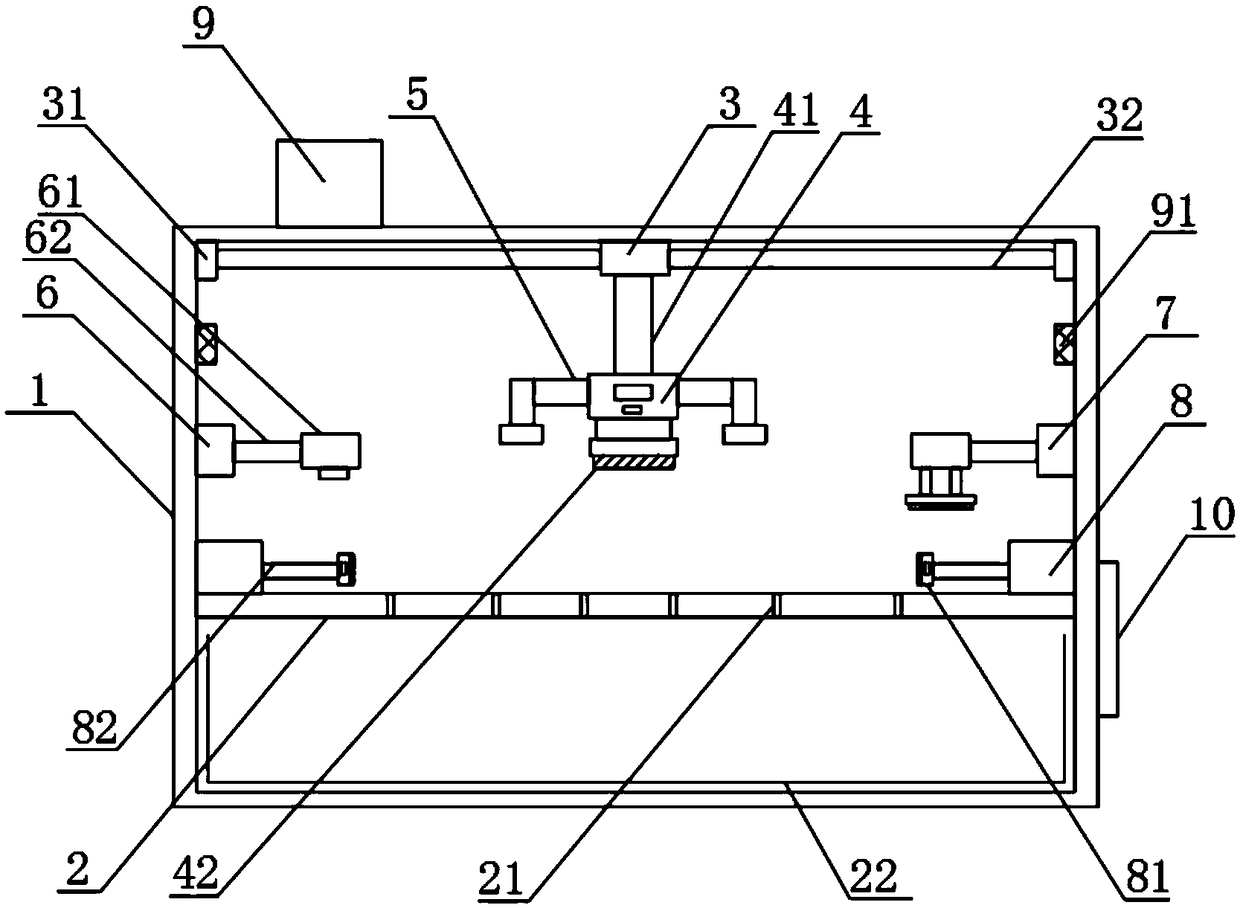

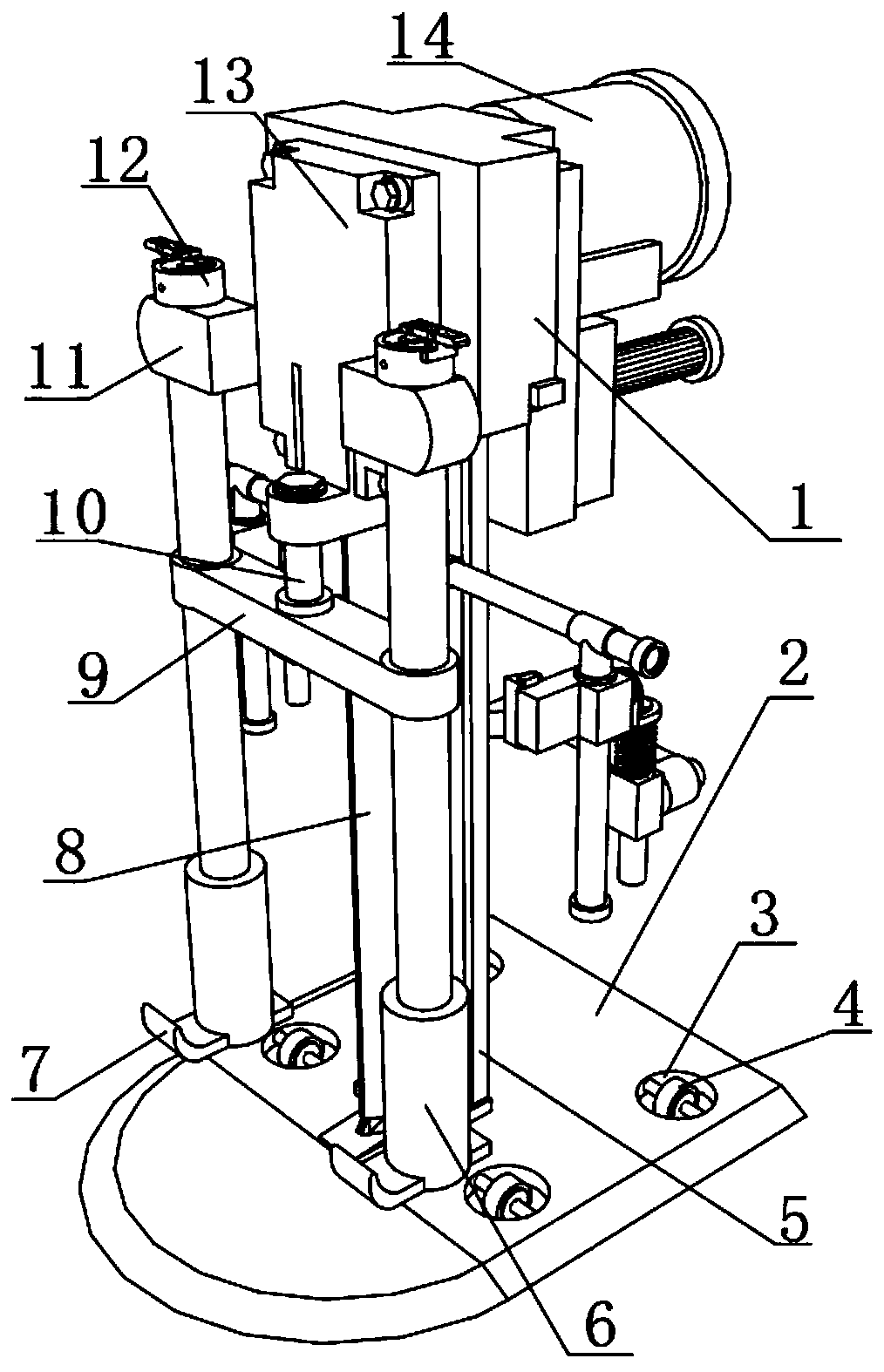

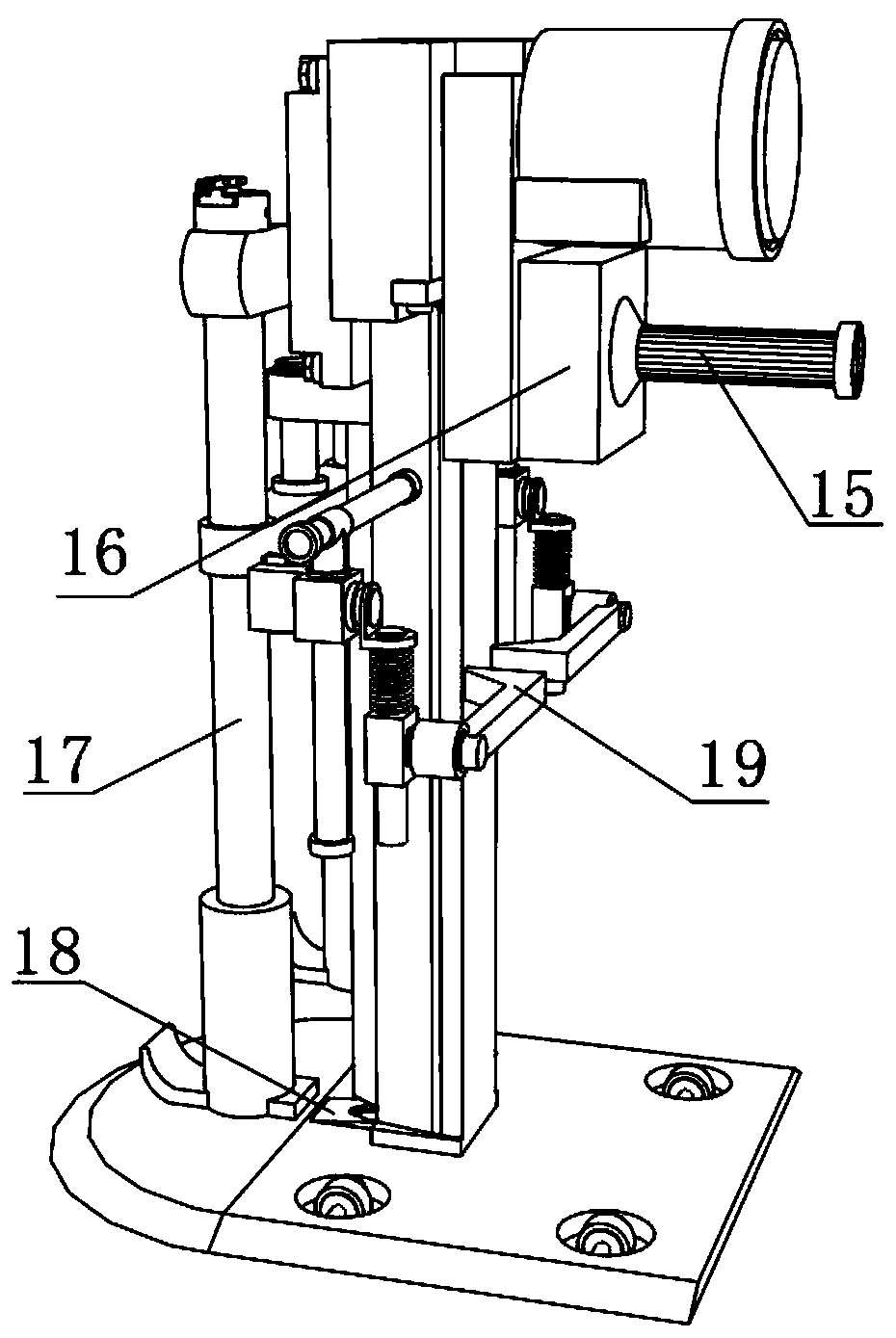

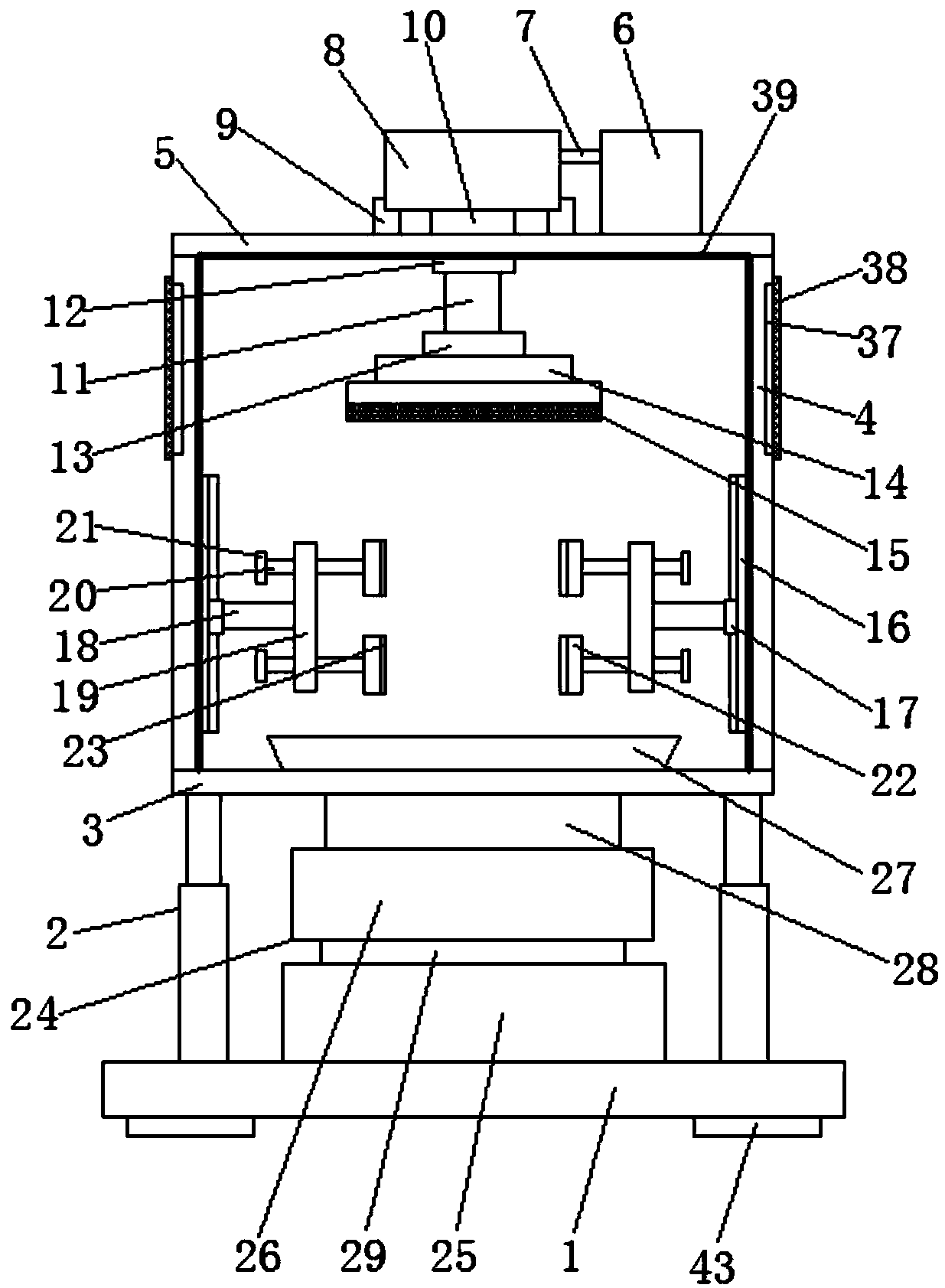

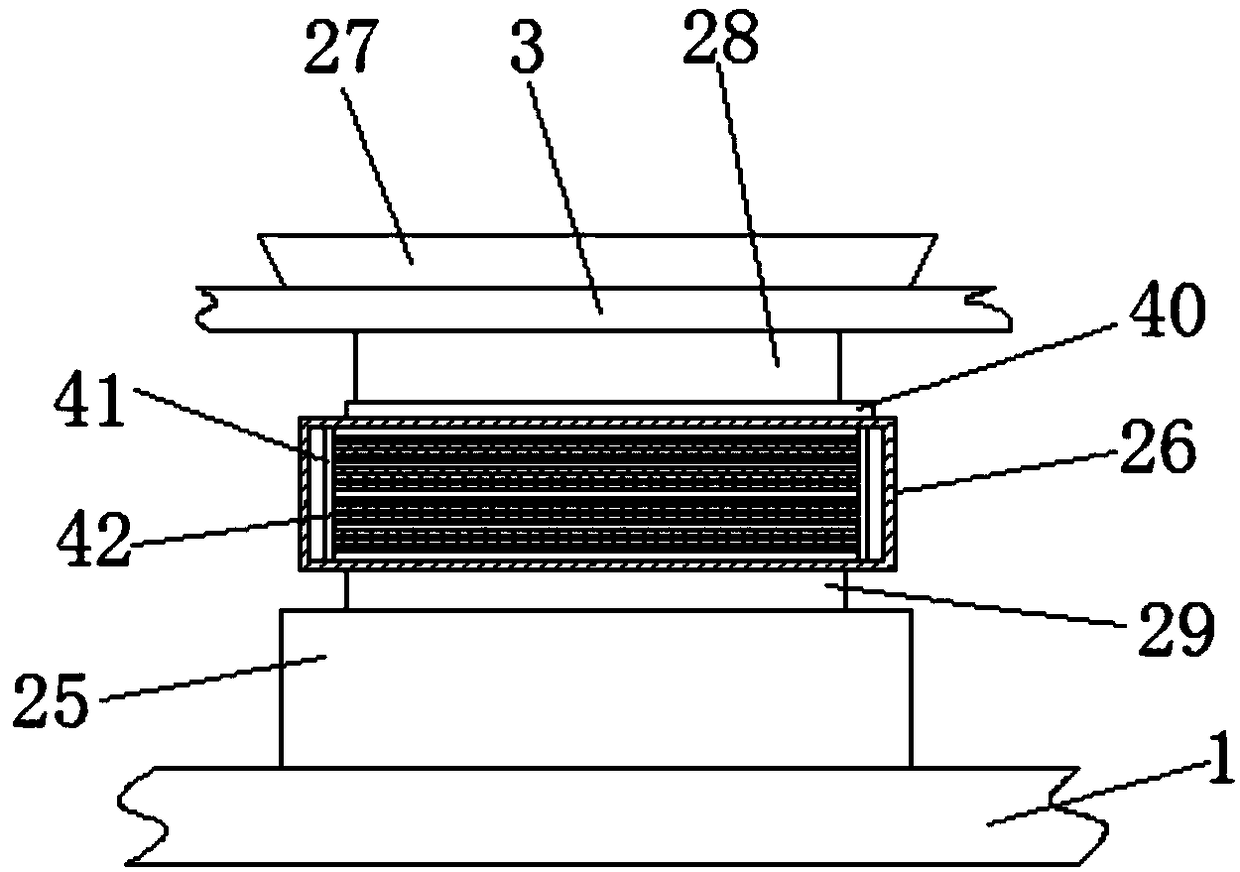

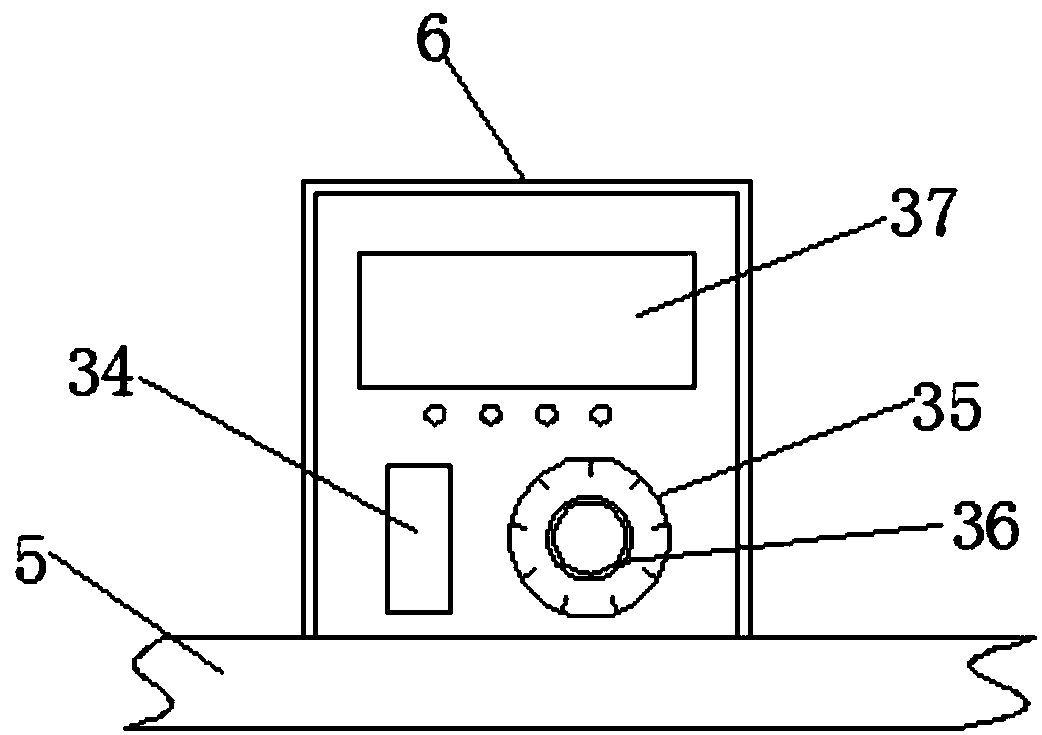

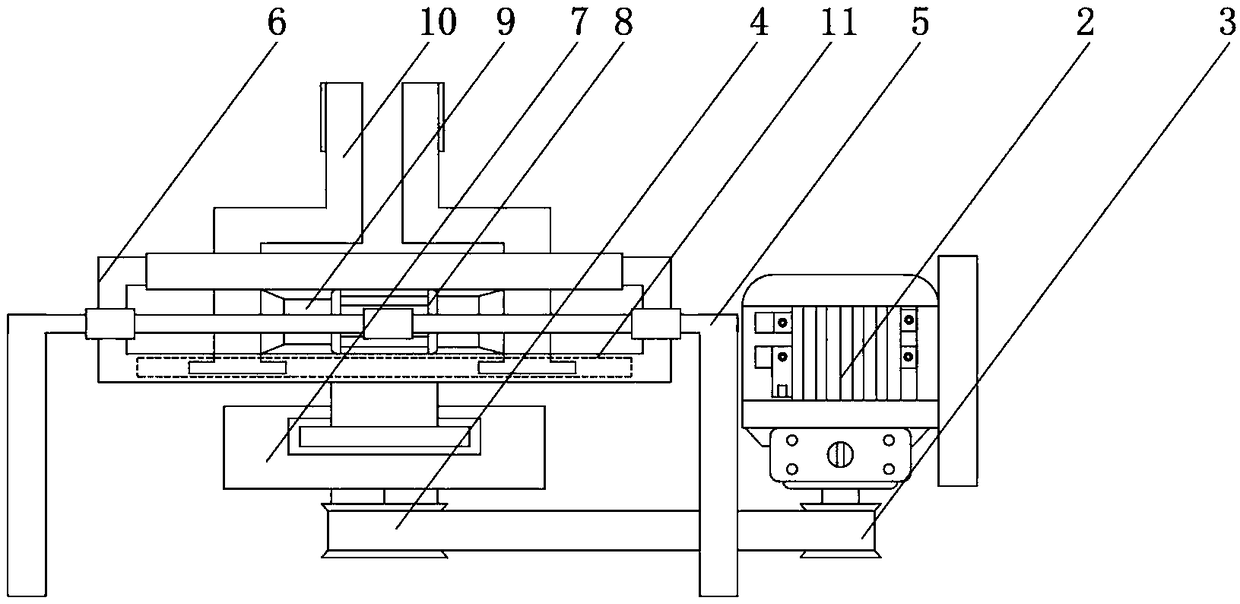

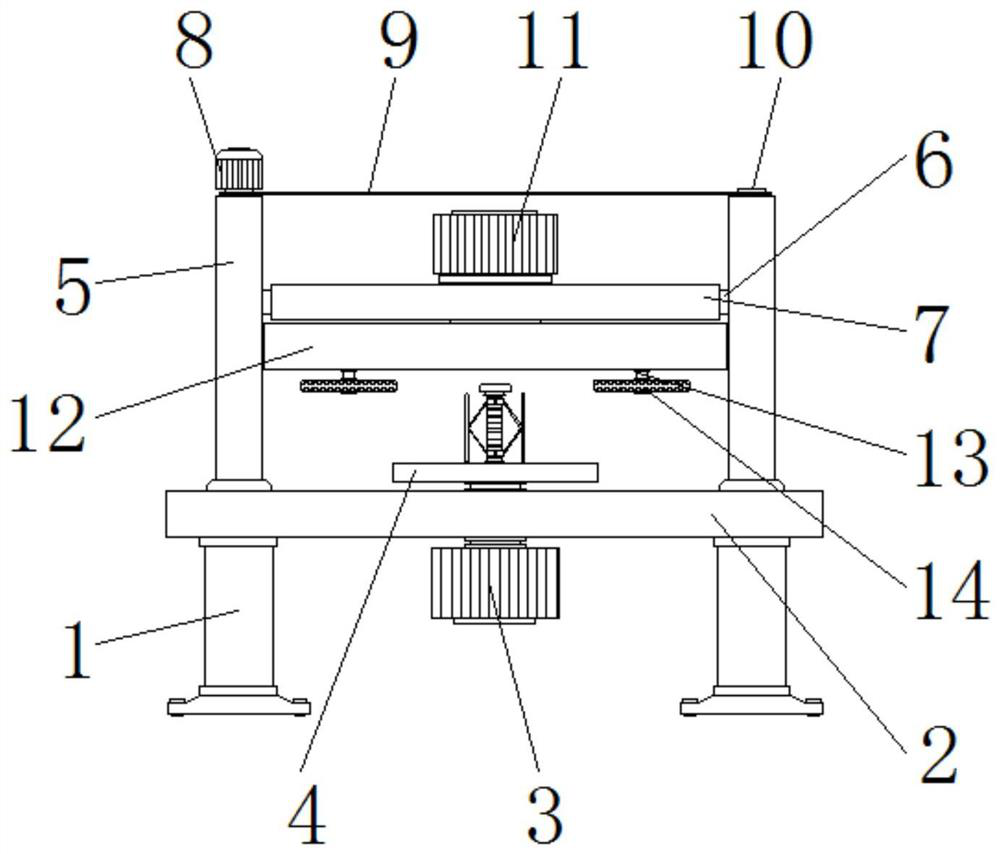

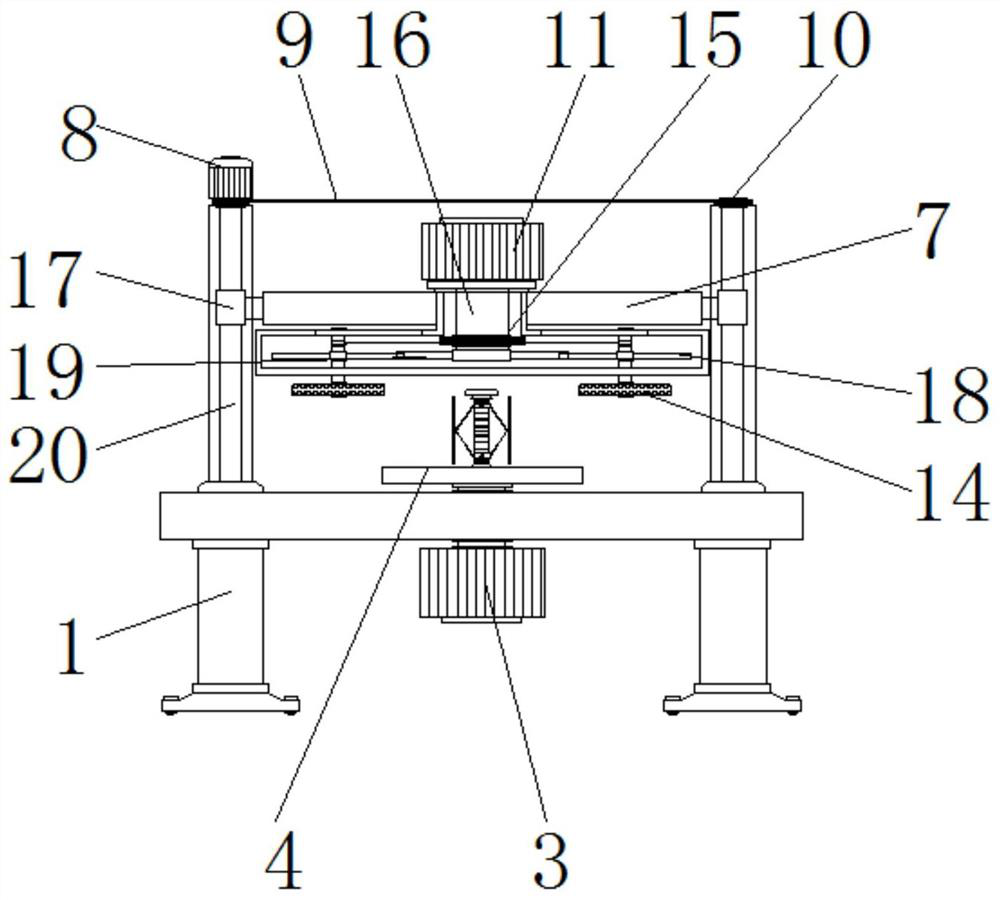

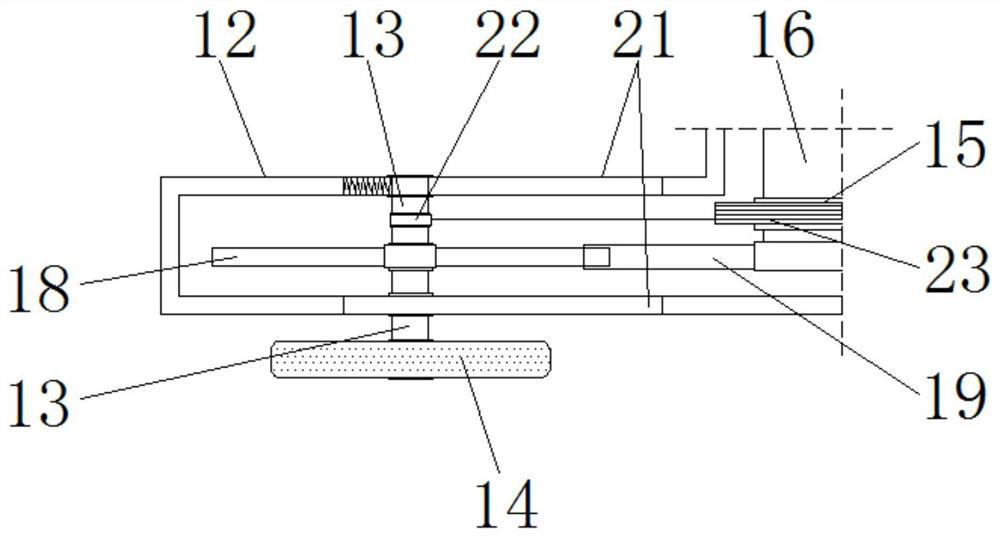

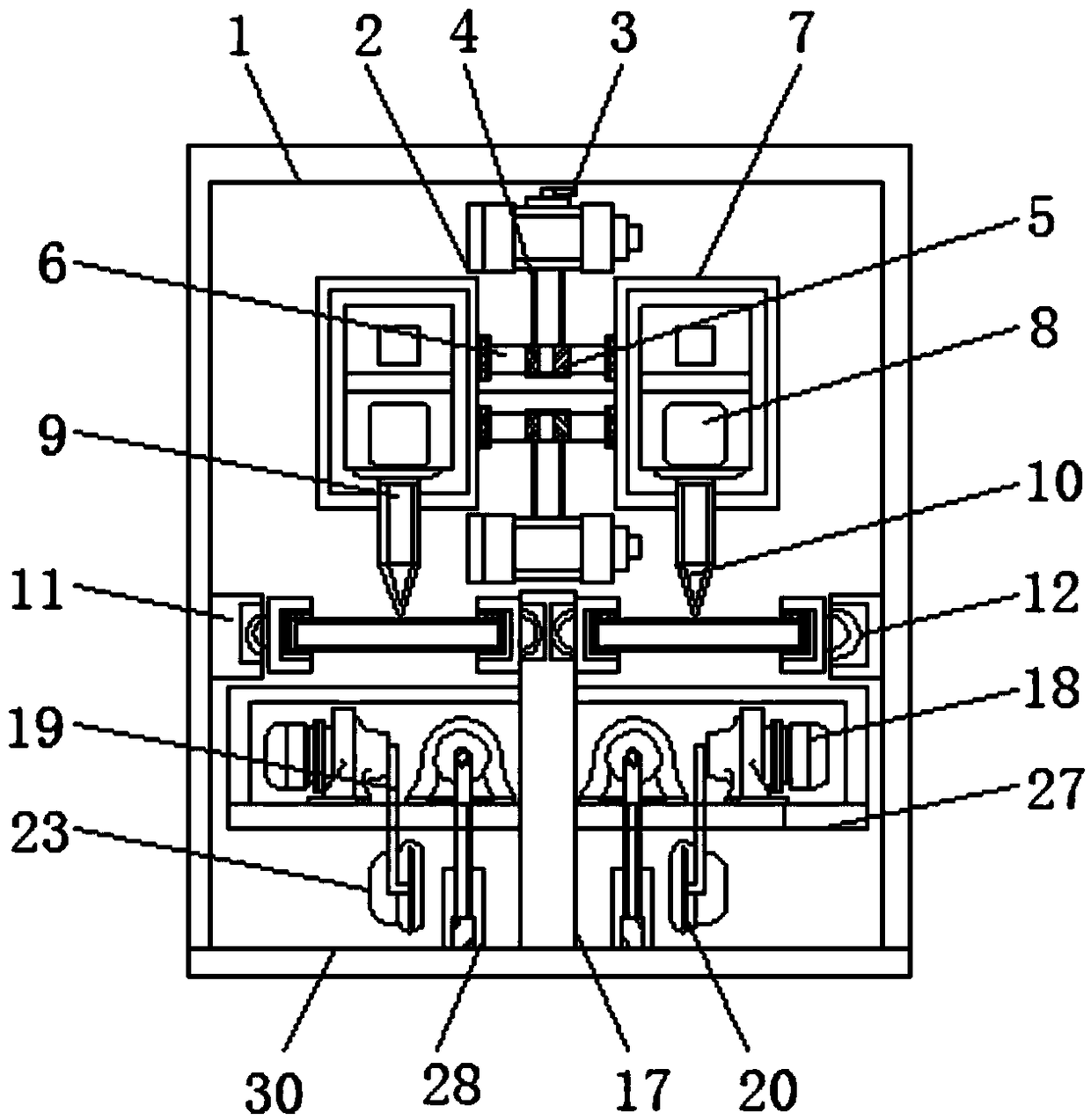

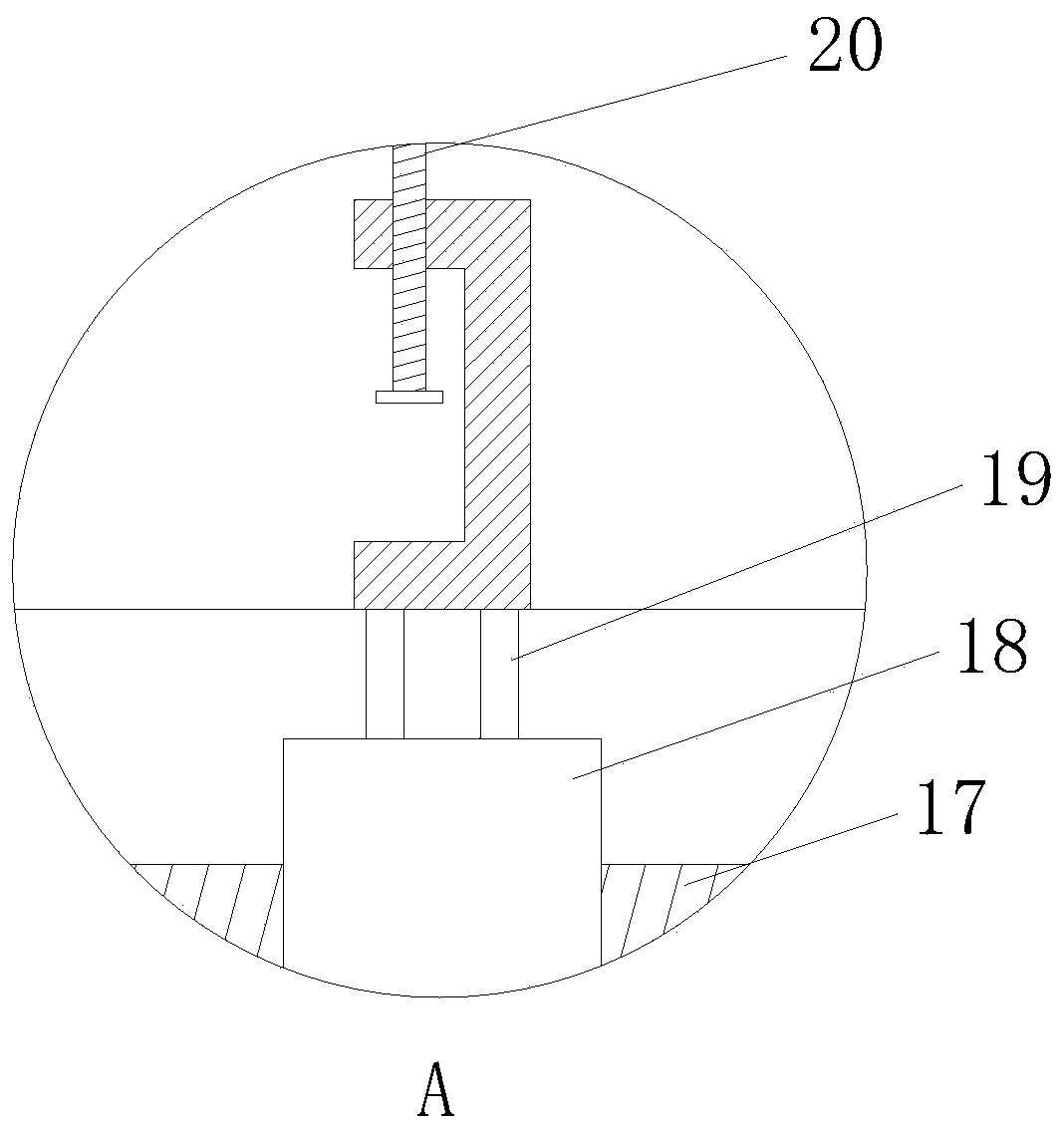

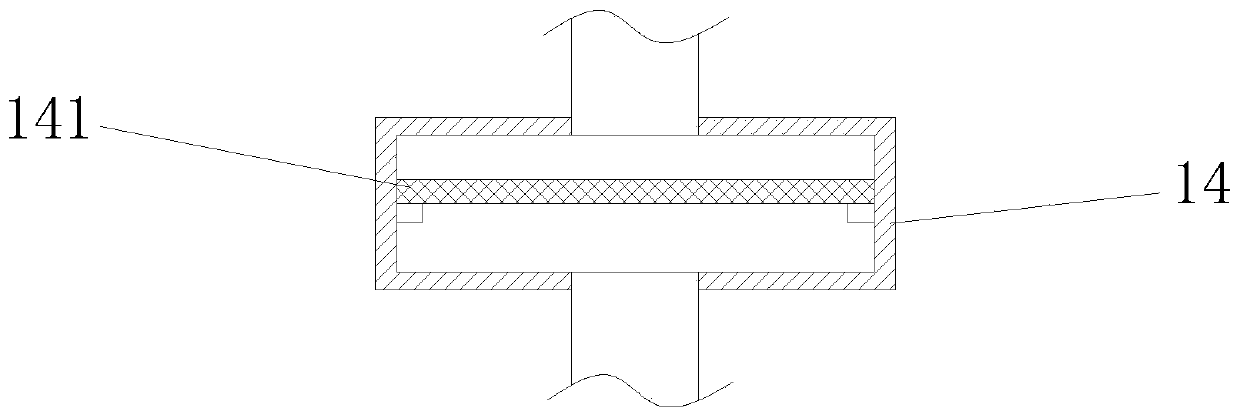

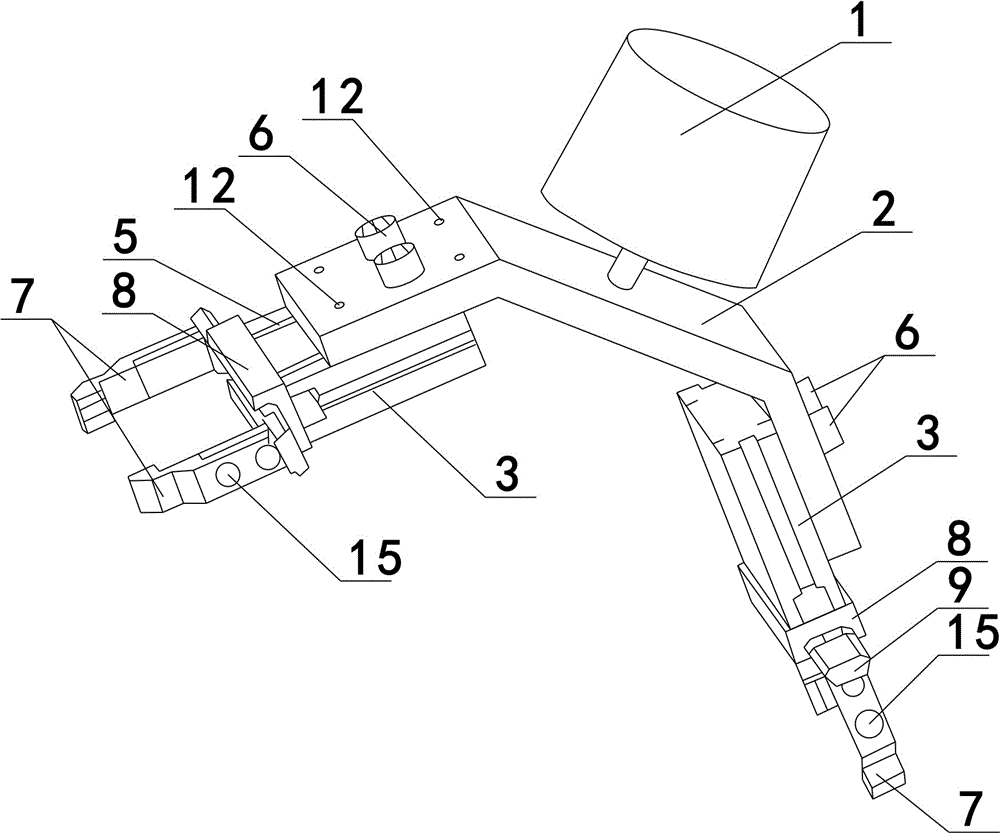

Grain processing device for semiconductor graphite wafer and operation method thereof

InactiveCN111975507AReduce extrusion, wearIncrease the scope of clamping useGrinding carriagesGrinding drivesStructural engineeringManufacturing engineering

The invention discloses a grain processing device for a semiconductor graphite wafer. The device includes a base, stand columns are arranged in the middles of two sides of the top face of the base, anequipment tank is arranged on the top face of the base, a bearing table is arranged on the top face of the equipment tank, a rubber carrying plate is arranged at the top end of a fixing block, T-shaped guide rails are arranged on the top face of the bearing table on two sides of the fixing block, an arc-shaped clamp plate is arranged on the top face of each sliding plate, wafer plates are placedon the top face of the rubber carrying plate, a driving tank is arranged at the bottom of a sleeve pipe, a rotating shaft is arranged on the inner bottom face of the driving tank, and a grinding wheelsleeves the bottom end of the rotating shaft. The device is convenient to operate, through a driving assembly and an adjusting assembly, the problems that the wafer plates are prone to damaging during clamping, the wafer plates with different size are not convenient to clamp and the clamping efficiency is comparatively low can be solved, and through a moving assembly and a lifting assembly, the problem that the operation is not convenient when an existing grain grinding device grinds grains on the wafer plates can be solved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

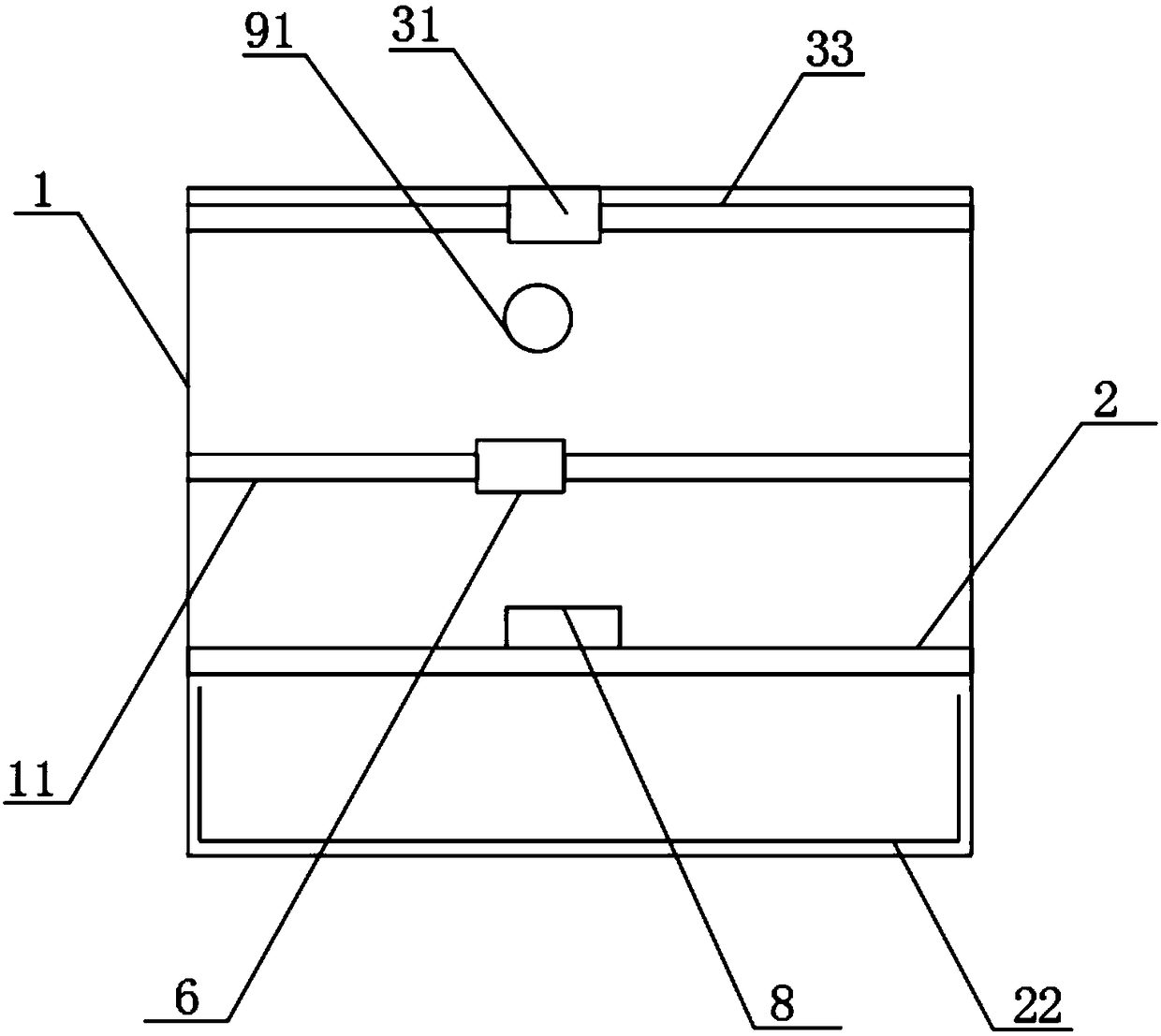

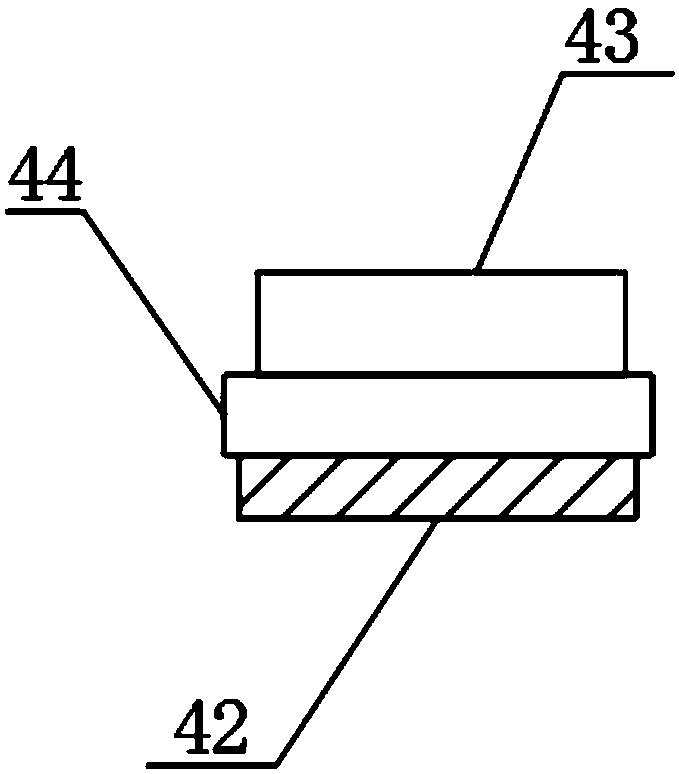

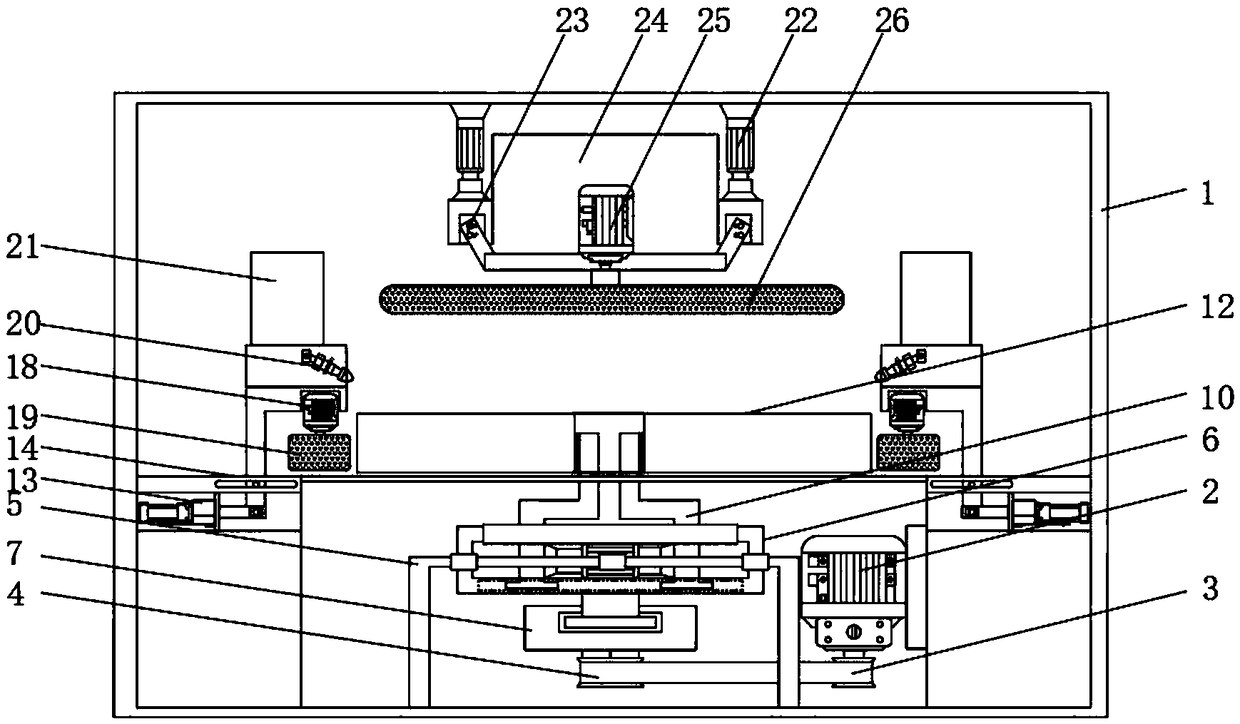

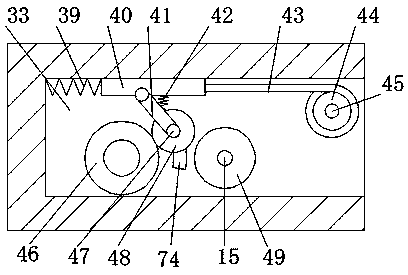

Maintaining device for mold

ActiveCN108747720AConvenient grinding workImprove the efficiency of grinding and rust removalGrinding feed controlGrinding machinesEngineeringRust remover

The invention discloses a maintaining device for a mold. The maintaining device comprises a shell. A working panel is arranged in the shell, and a first sliding block is arranged at the top of the inner wall of the shell. A lifting seat is arranged at the bottom of the first sliding block, and dust blowing devices are arranged on the two sides of the lifting seat correspondingly. A side block is arranged on one side of the inner wall of the shell, and a smearing device is arranged on the other side of the inner wall of the shell. A fixing seat is arranged at the top of the working panel, and the side block and the smearing device are both arranged at the top of the fixing seat. A water storage chamber is formed in the top of the shell. By arranging the fixing seat and a pressing plate, a sixth electric push rod pushes the pressing plate to move, and thus the mold needing to be maintained can be fastened from the side face and is ground from the top conveniently; and by forming a liquidstorage chamber and the smearing device, a rust remover can be sprayed to the portion, needing to be ground, of the mold through a liquid spraying head at the bottom of the liquid storage chamber before grinding, the grinding and dust removing efficiency is improved, the mold is smeared through lubricating oil in an oil storage chamber after grinding, and the anti-oxidation effect is achieved.

Owner:ANHUI ANLAN MOLD

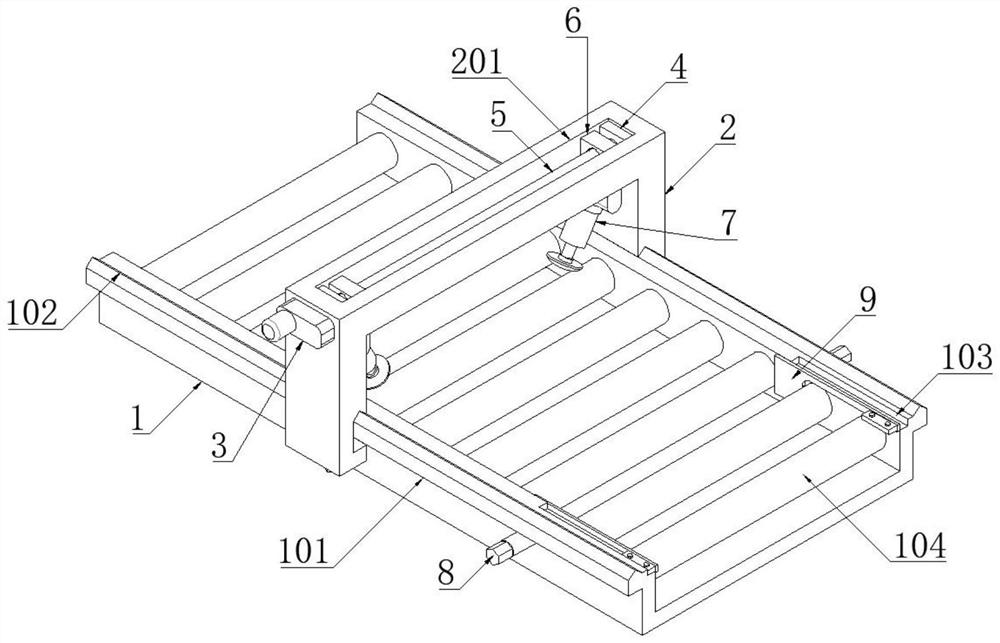

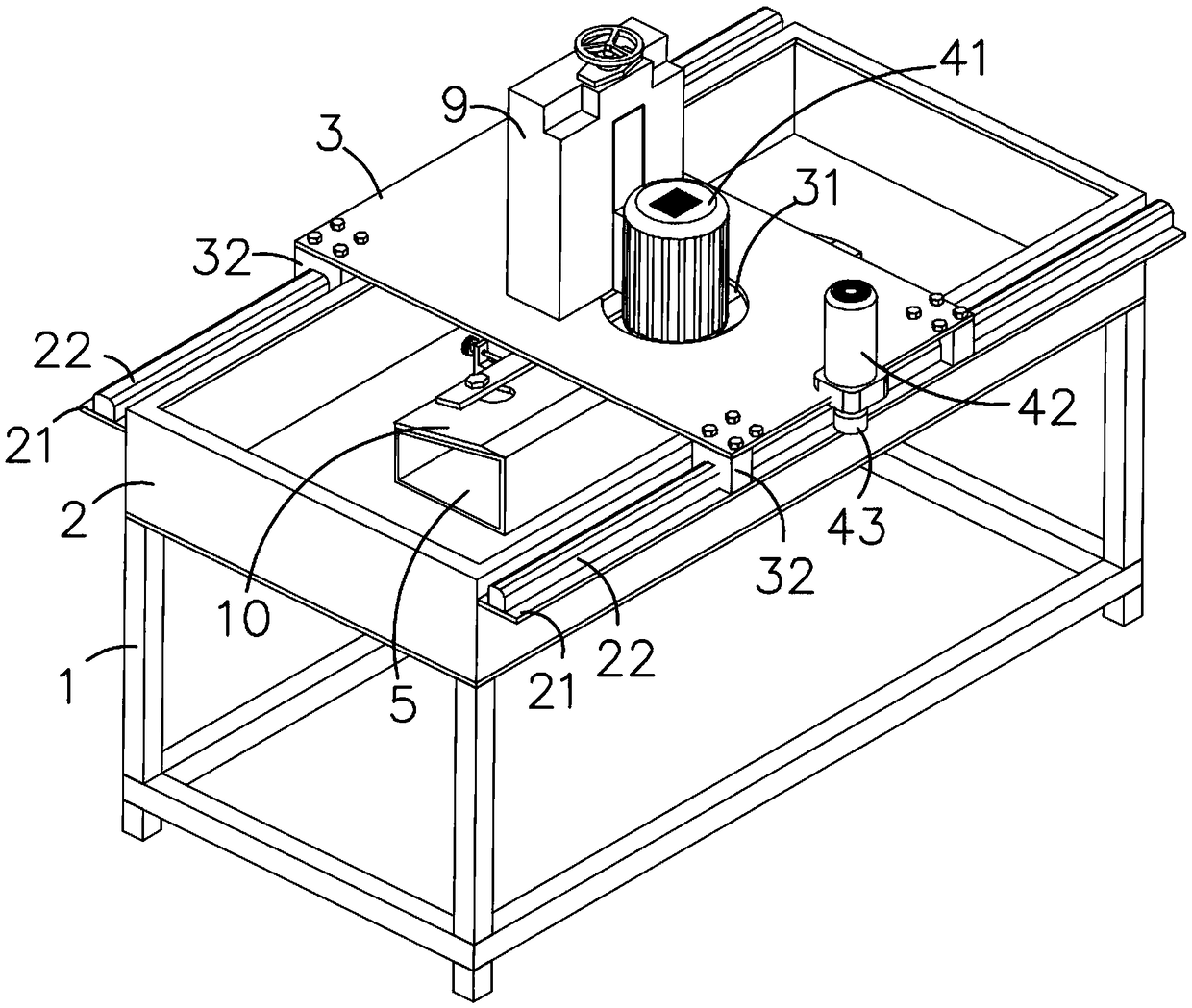

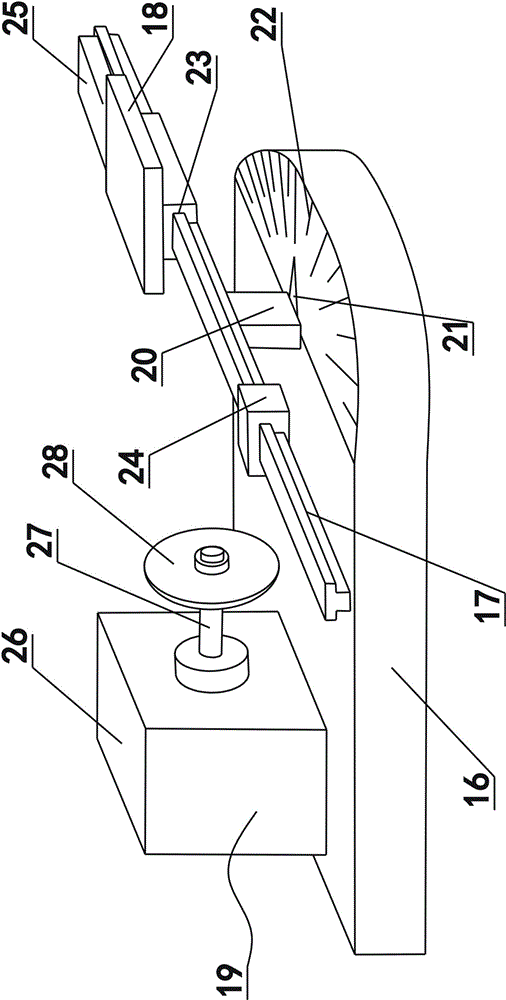

Cloth cutting device for clothing manufacture

ActiveCN110685144APlay a cutting roleLow costGrinding carriagesGrinding drivesStructural engineeringKnife holder

The invention discloses a cloth cutting device for clothing manufacture and relates to the technical field of cloth cutting, aiming to solve the problem that conventional bench type cutting devices are not adaptable to mass cutting of cloth. The cloth cutting device comprises a rack and a lower cutting plate; a blade carrier is arranged on the outer wall of the bottom of the rack, and the outer wall of the bottom of the blade carrier is welded to the outer wall of the top of the lower cutting plate; four mount holes are formed on the outer wall of the top of the lower cutting plate, and four rollers are respectively arranged inside the four mount holes; slide slots are respectively formed on the inner walls of two sides of the rack, two first sliders are slidably connected to the inner walls of two sides of the two slide slots respectively, the two first sliders are the same, mounting shafts are welded to outer walls of opposite sides of the two first sliders respectively, and holderssleeve the outer peripheral walls of the mounting shafts respectively; a cutting blade is fastened to the outer wall of the bottom of the holder, a U-shaped connecting frame is welded to the outer walls of backs of the two first sliders, and a second connecting plate is rotationally connected to the outer wall of the back of the U-shaped connecting frame. In application of the cloth cutting device, squeezing and fixing to single-layer or multi-layer cloth are facilitated, and accordingly, the cutting quality of the cutting blade is improved.

Owner:湖南浚林服饰有限公司

Grinding device for mechanical processing

InactiveCN109048563AEasy to clamp and fixEasy to polishGrinding drivesGrinding machinesCouplingMachining

The invention discloses a grinding device for mechanical processing. The grinding device comprises a base. The top of the base is symmetrically arranged with supporting devices. The top of the supporting device is arranged with a supporting plate. The top of the supporting plate is symmetrically arranged with side plates. The top of the side plate is arranged with a top plate. The top of the top plate is arranged with a controller. One side edge of the controller is arranged with a connecting wire, and one end, far away from the controller, of the connecting wire is arranged with a motor. Thebottoms of the supporting plates are both connected with the tops of the top plates. The middle of the bottom end of the motor is arranged with a coupler. The bottom of the coupler is arranged with arotating shaft. The bottom of the rotating shaft penetrates through the top plate and extends below the top plate. The bottom of the top plate is arranged with a fixing ring. The fixing ring is sleeved on the outer side of the rotating shaft. The bottom of the rotating shaft is arranged with a connecting block. The bottom of the connecting block is arranged with a turntable. The bottom of the turntable is arranged with a grinding table.

Owner:JIAXING TANGDONG AUTO PARTS CO LTD

Automobile brake disc grinding device

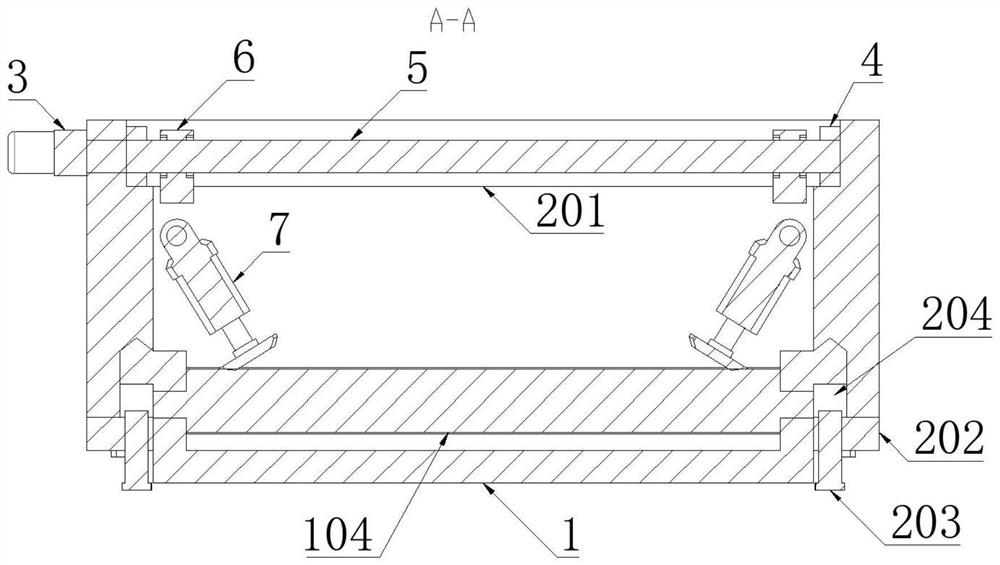

InactiveCN108942525AEasy to fixEasy side grindingGrinding machinesGrinding/polishing safety devicesEngineeringRotating disc

The invention discloses an automobile brake disc grinding device. The grinding device comprises a working frame, the lower part of the interior of the working frame is fixedly connected with a rotating motor, the rotating motor is connected with a belt wheel I in the rotating mode through an output shaft, the belt wheel I is connected with a belt wheel II in the rotating mode through a belt, the bottom of the inner wall of the working frame is fixedly connected with a rotating frame, a rotating mounting disc is connected with the inner side of the rotating frame in a rotating mode, a rotatingdisc is arranged at the bottom of the rotating mounting disc, the bottom of the rotating disc is fixedly connected with the belt wheel II, and the inner side of the rotating mounting disc is connectedwith a brake disc mounting base in a sliding way. The grinding device relates the technical field of automobile part machining. According to the automobile brake disc grinding device, the purpose ofgrinding the brake disc is achieved, grinding efficiency of the brake disc can be improved due to multi-azimuth grinding at the same time; a controllable pushing device is used, so movement of the grinding machine is convenient; material changing can be carried out rapidly when the grinding work is stopped, and workload of workers is reduced.

Owner:ANHUI TIANYU AUTO PARTS MFG

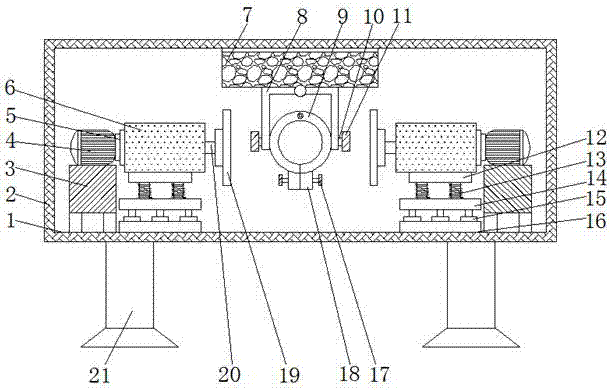

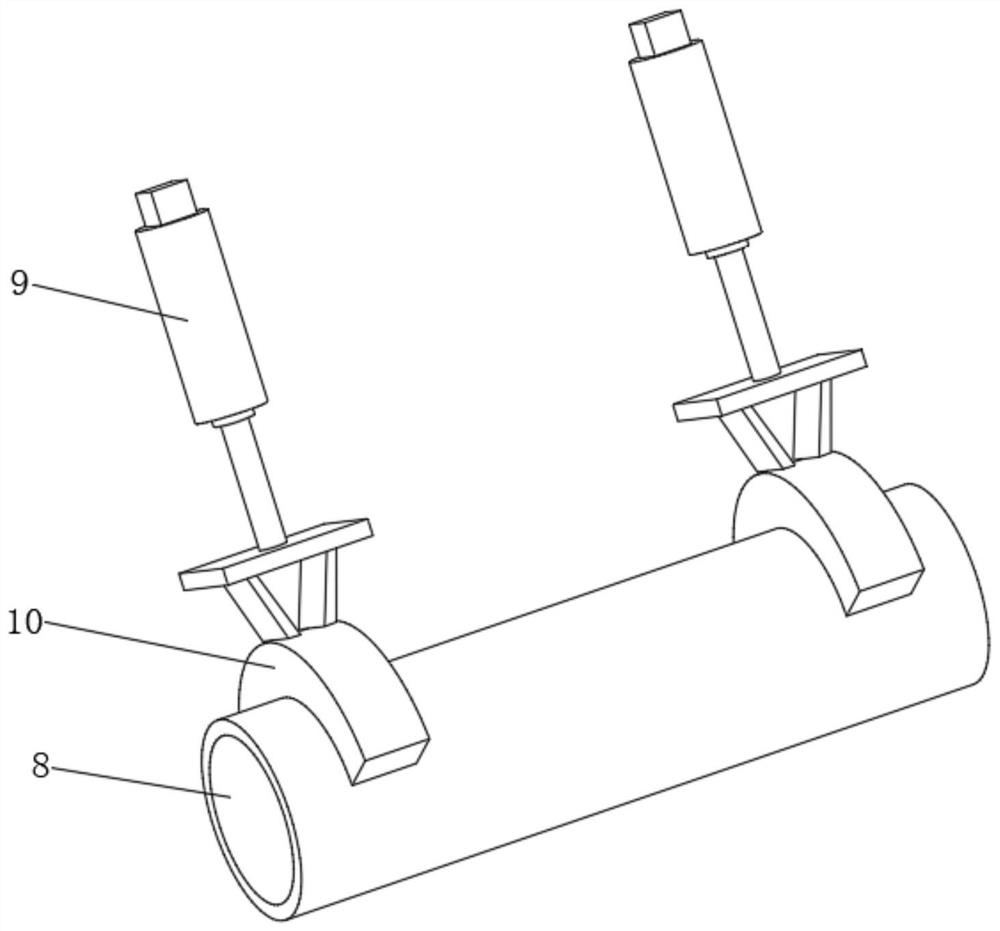

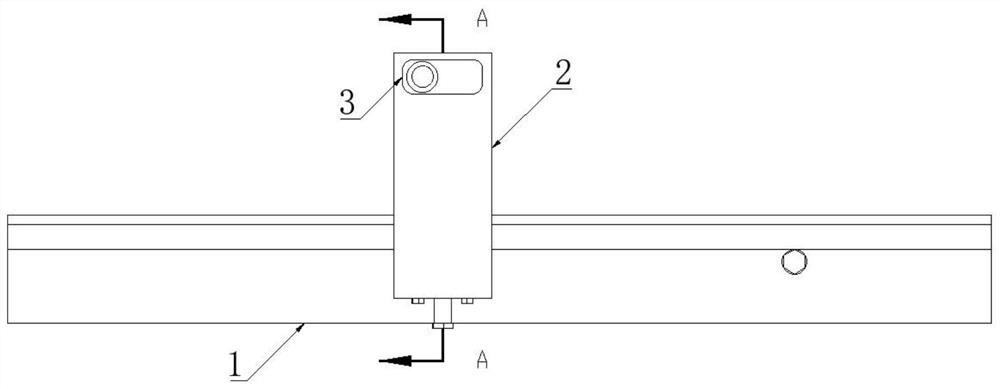

Steel pipe grinding machine

ActiveCN106863033APrecise positioningReduce shock forceRevolution surface grinding machinesGrinding work supportsArchitectural engineering

The invention discloses a steel pipe grinding machine which comprises a workbench. Motor racks are installed on the two sides of the bottom of an inner cavity of the workbench. Motors are installed on the tops of the motor racks. One side of each motor is connected with an output shaft, and one side of each output shaft is connected with an operation table. A sliding block is movably connected to the top of the inner cavity of the workbench. A fixing base is installed at the bottom of the sliding block. A clamping ring is arranged in an inner cavity of the fixing base. The two sides of the clamping ring are each connected with a screw rod. One side of each screw rod is connected with a nut. The bottom of the clamping ring is fixedly connected with a clamping block. The two sides of the clamping block are movably connected with hinge pins. The steel pipe grinding machine is simple in structure and convenient to use, a steel pipe can be fixed with the clamping ring, and thus, a worker can perform the grinding work more conveniently; the clamping ring can be fixed by inserting the hinge pins into the clamping block, so that the steel pipe grinding work is more stable; and the clamping ring can be fixed in the fixing base through the nuts and the screw rods so that the clamping ring can be prevented from shifting.

Owner:宁远县新诚投资发展有限公司

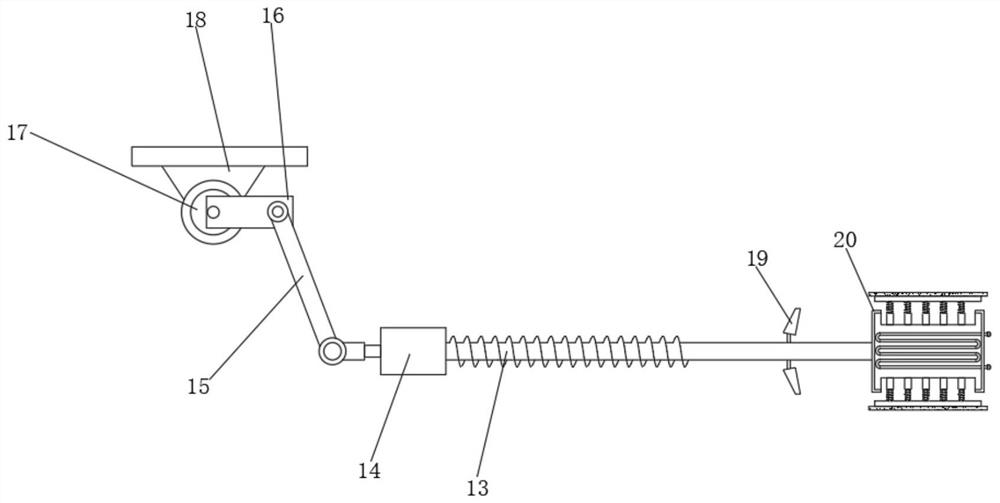

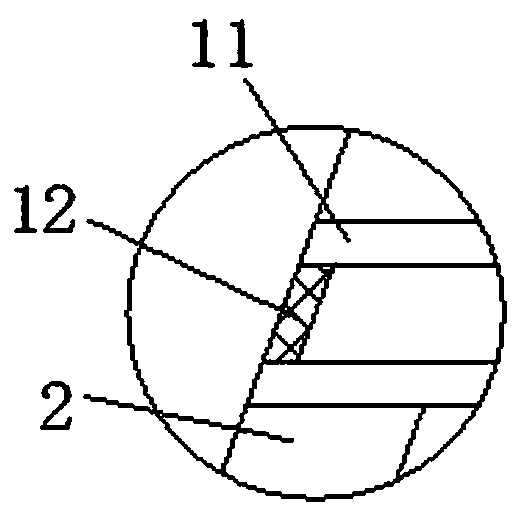

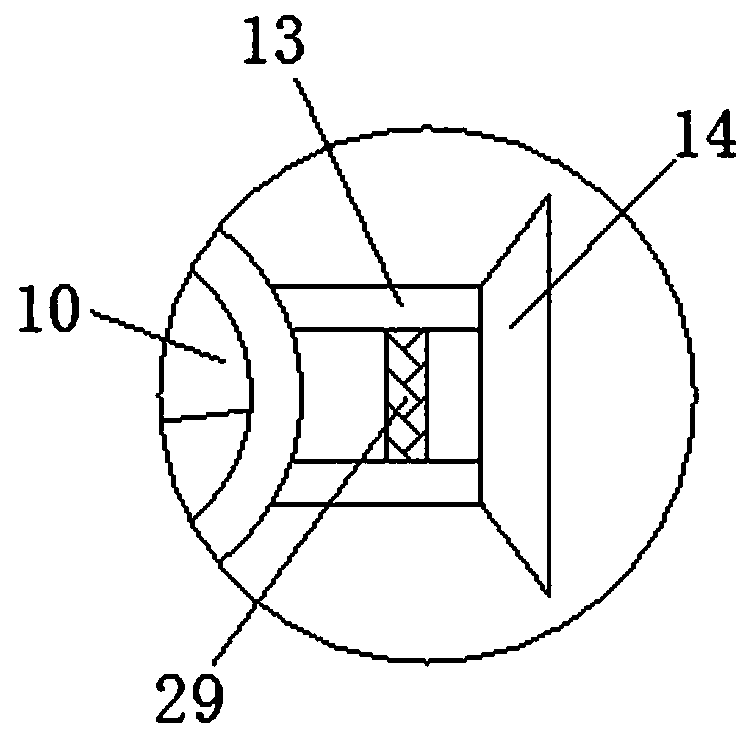

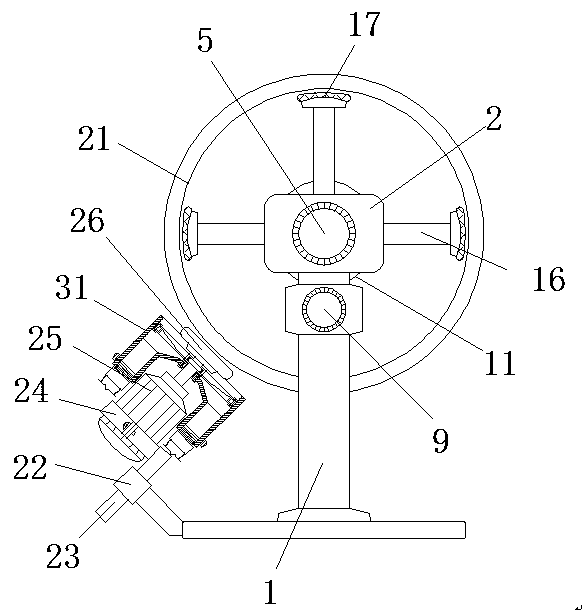

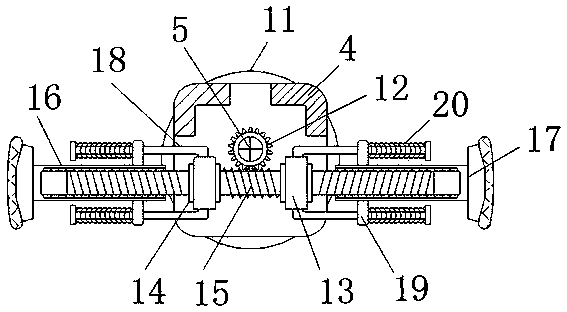

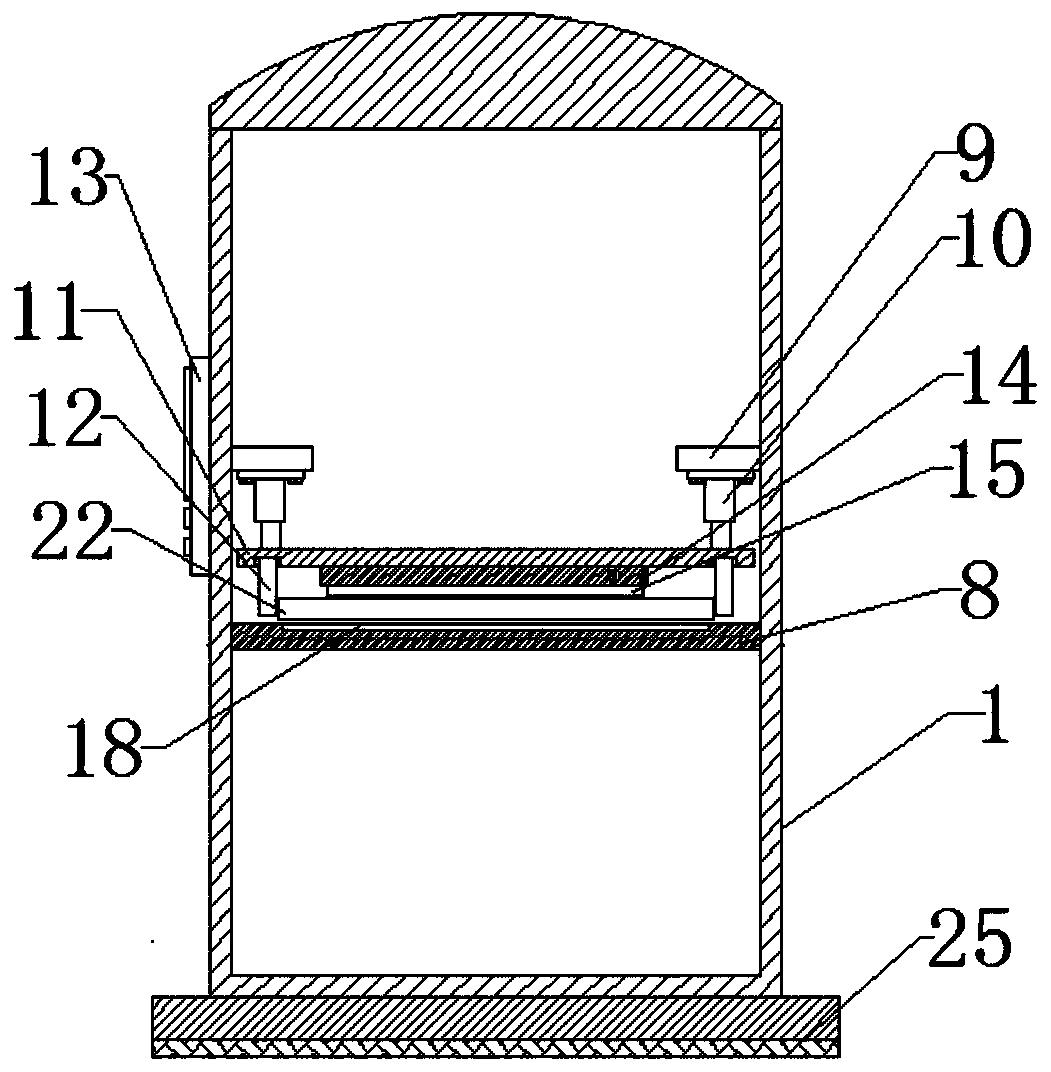

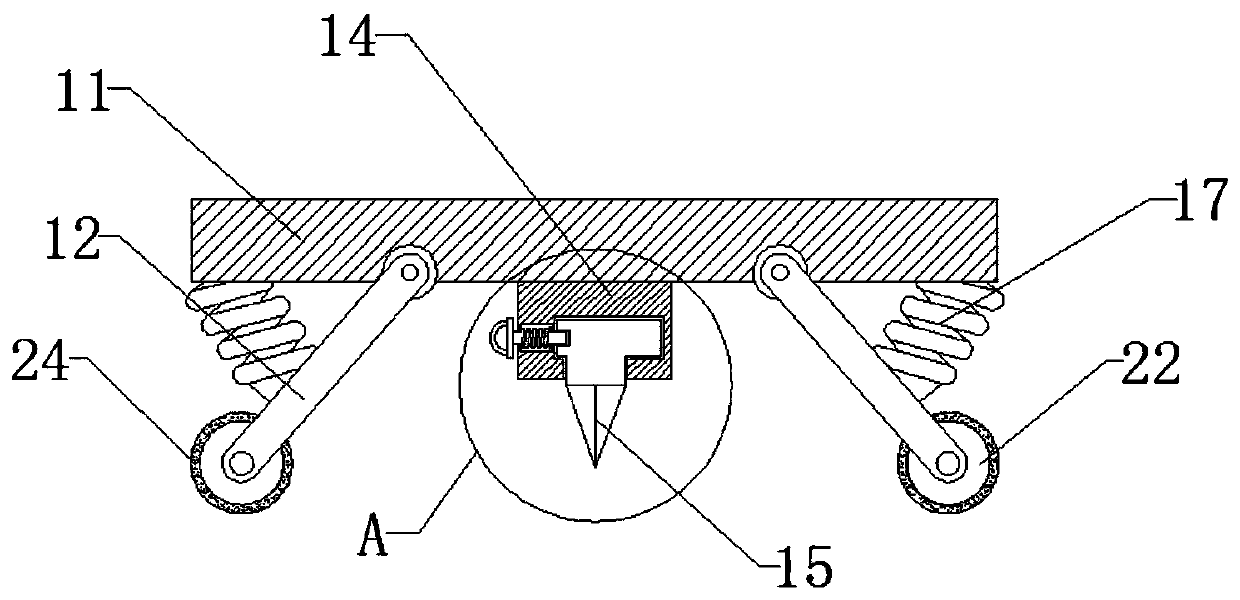

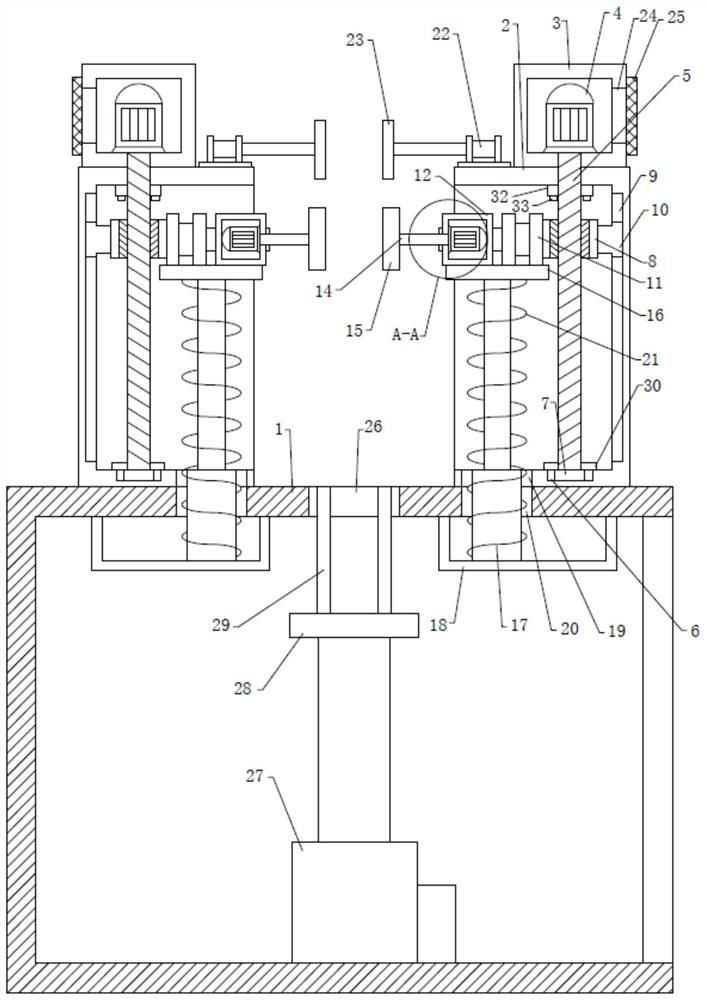

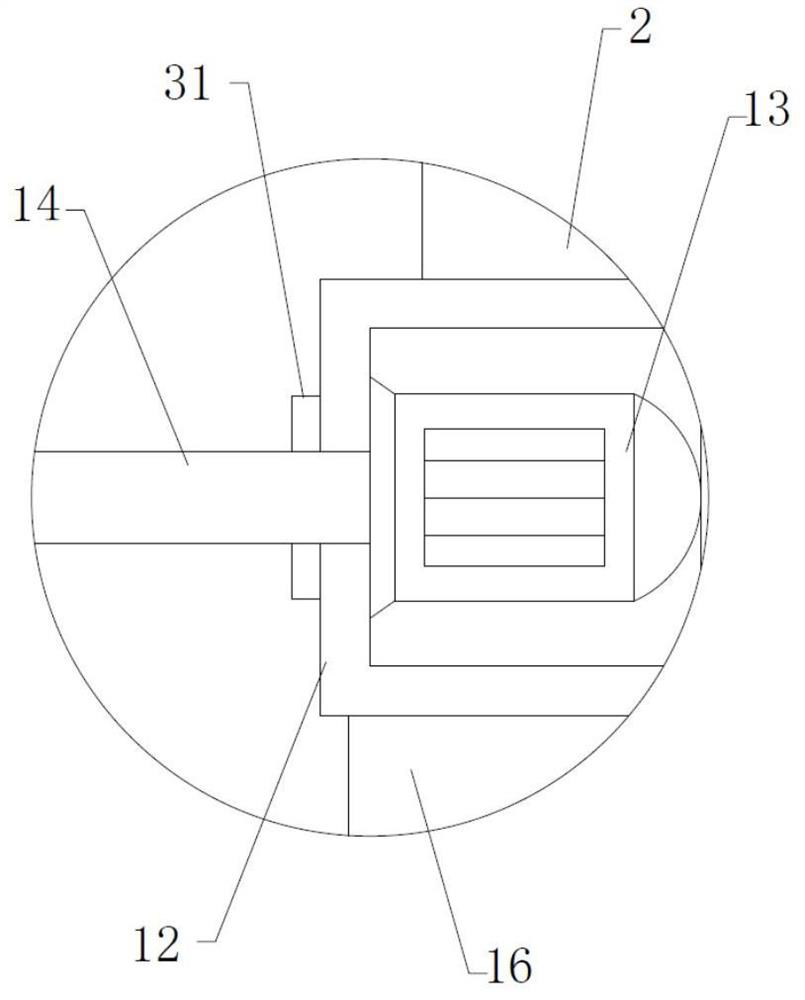

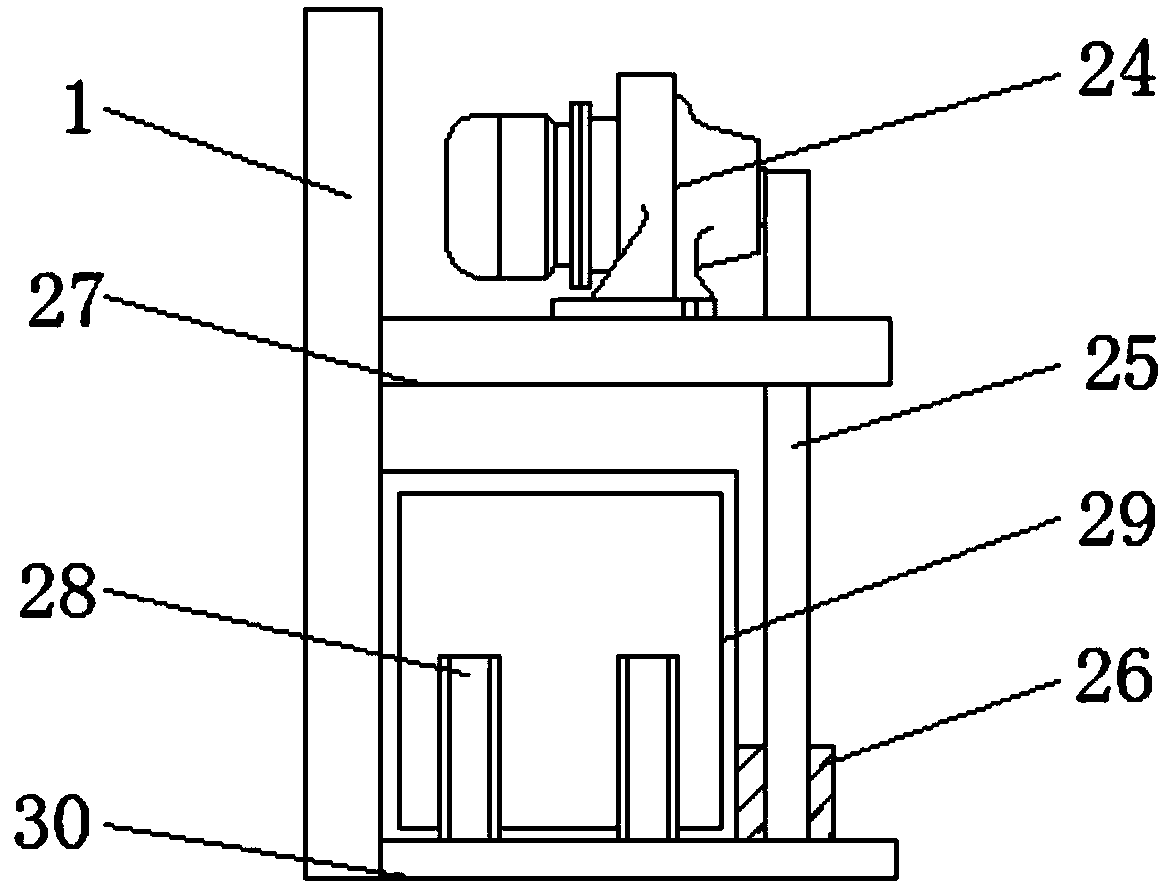

Round tube inner wall grinding device for mechanical manufacturing

InactiveCN111660152AHighly corporatedReduce work intensityGrinding carriagesRevolution surface grinding machinesCrankMachine building

The invention discloses a round tube inner wall grinding device for mechanical manufacturing. The device comprises a box body, supporting legs are mounted on the inner wall of the bottom of the box body, a worktable is arranged on the outer walls of the tops of the supporting legs, a cylinder body is arranged on the outer wall of the top of the worktable, a supporting plate is arranged on the inner wall of one side of the box body, a fixed base is arranged on the outer wall of the bottom of the supporting plate, a motor is arranged on the outer wall of the bottom of the fixed base, the outer wall of an output shaft of the motor is sleeved with a crank, the outer wall of one side of the crank is connected with a connecting rod through a rotating shaft, a person can start the motor, the motor drives the crank to rotate, meanwhile, the crank is connected with the connecting rod through a hinge, therefore, the connecting rod can drive a thread rod to transversely move, the thread rod transversely moves and can make contact with the inner wall of a thread sleeve, the thread rod can drive a grinding ring to grind the inner wall of a cylinder body, the cooperation degree between the structures can be improved, and the work intensity of persons can be reduced.

Owner:青欣智能科技(烟台)有限公司

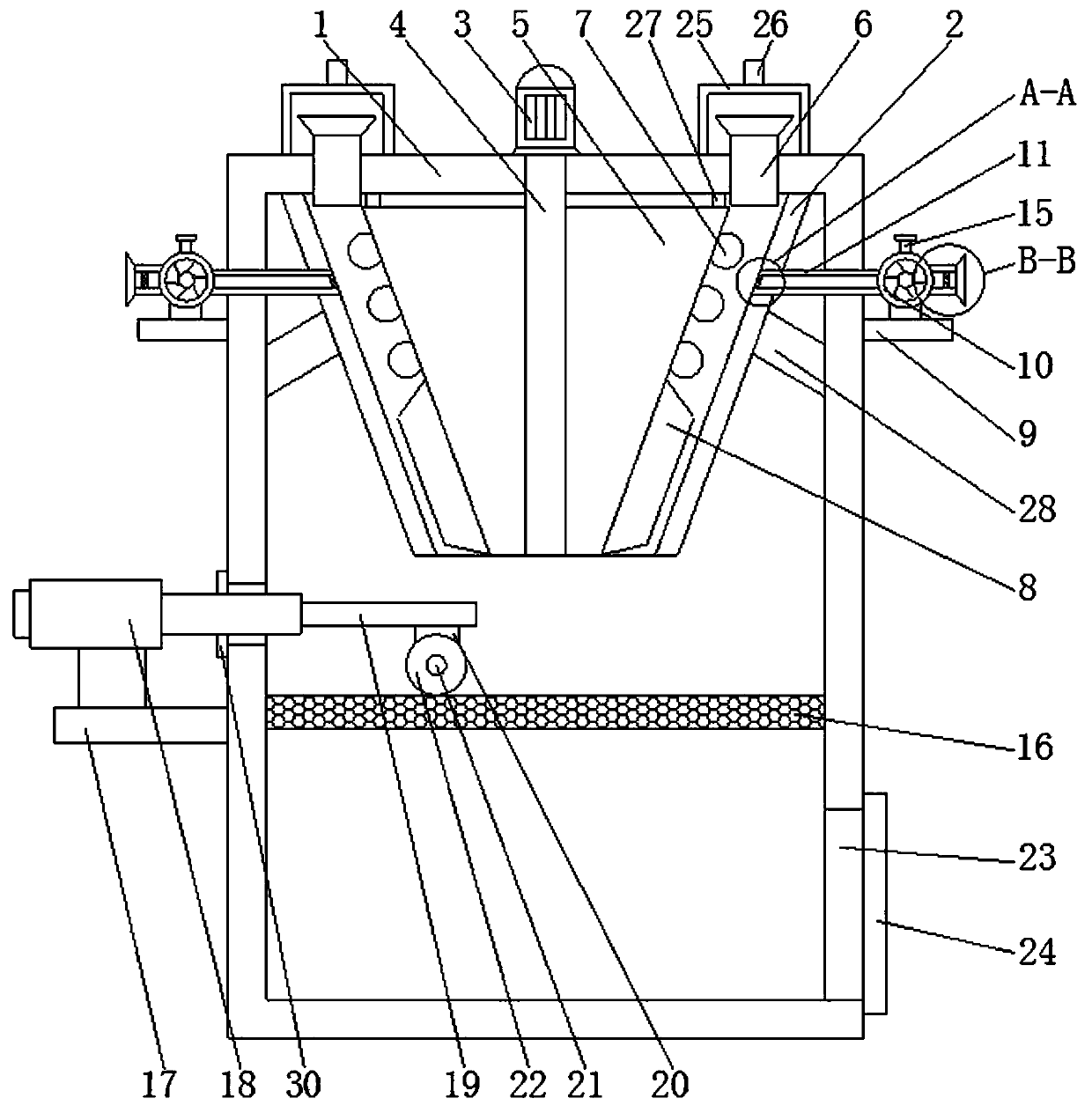

Grain grinding device for agricultural production

The invention discloses a grain grinding device for agricultural production. The grain grinding device for agricultural production comprises a shell, wherein a grinding shell is fixedly connected to the top part of the inner wall of the shell; a grinding motor is fixedly connected to the top part of the shell; a grinding rotary shaft is fixedly connected onto an output shaft of the grinding motor;and the bottom end of the grinding rotary shaft penetrates through the shell and extends into the grinding shell. According to the grain grinding device for agricultural production provided by the invention, through the interaction of the grinding shell, the grinding motor, the grinding rotary shaft, a grinding block, a feeding pipe, a grinding ball, a grinding plate, a fan, a filter screen, a sieve plate, an electric push rod, a rotary shaft and a grinding wheel, in the process of grinding grain, the grinding motor drives the grinding block to rotate, the grinding block drives the grinding ball and the grinding plate to grind the grain, and the fan is matched for blowing grain so as to enable the grain to turn over, so that the grain can be conveniently ground sufficiently; and then thegrain is re-ground through the grinding wheel so as to be sufficiently ground, so that the grain is thoroughly ground, and great convenience is brought for the grinding work of the grain.

Owner:广西永福金穗生态农业发展有限公司

Corner polishing device for glass fiber reinforced plastic processing

ActiveCN110170896AImprove work efficiencyConvenient grinding workEdge grinding machinesGrinding drivesEngineeringTurbofan

The invention discloses a corner polishing device for glass fiber reinforced plastic processing. The corner polishing device for glass fiber reinforced plastic processing comprises a fixed support, afirst motor, a second motor, a connecting support, a hydraulic rod and a turbofan, wherein a locating ring is fixedly arranged on the edge of the top of the fixed support; the first motor is fixedly arranged on the outer wall of a locating shell; an electrified wire is connected to the first motor; the second motor is arranged on the fixed support; a fixed link and a locating pipe are respectivelyfixed to the outer walls of a spacing ring and a supporting pipe; the connecting support is fixed to the fixed support; a polishing sheet is fixed to the end of an output shaft of a third motor; a connecting block is fixed to the outer side of the turbofan; and a gear shaft is arranged on the outer wall of an output shaft of the third motor. The corner polishing device for glass fiber reinforcedplastic processing facilitates the installation and location of glass fiber reinforced plastics of different sizes, polishes the corners of the glass fiber reinforced plastic in the rotating process of the glass fiber reinforced plastic, improves the working efficiency, and meanwhile continuously absorbs dust generated by the grinding work to maintain the working environmental sanitation.

Owner:宿迁匠心复合材料有限公司

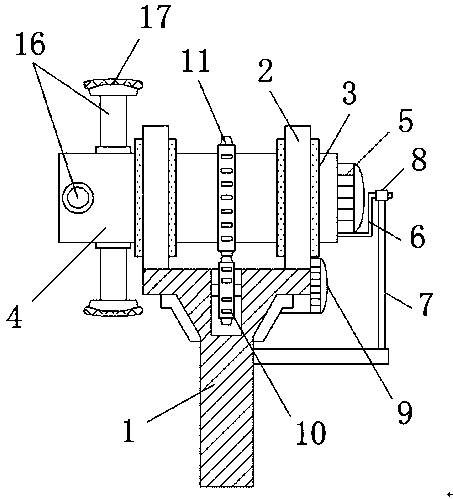

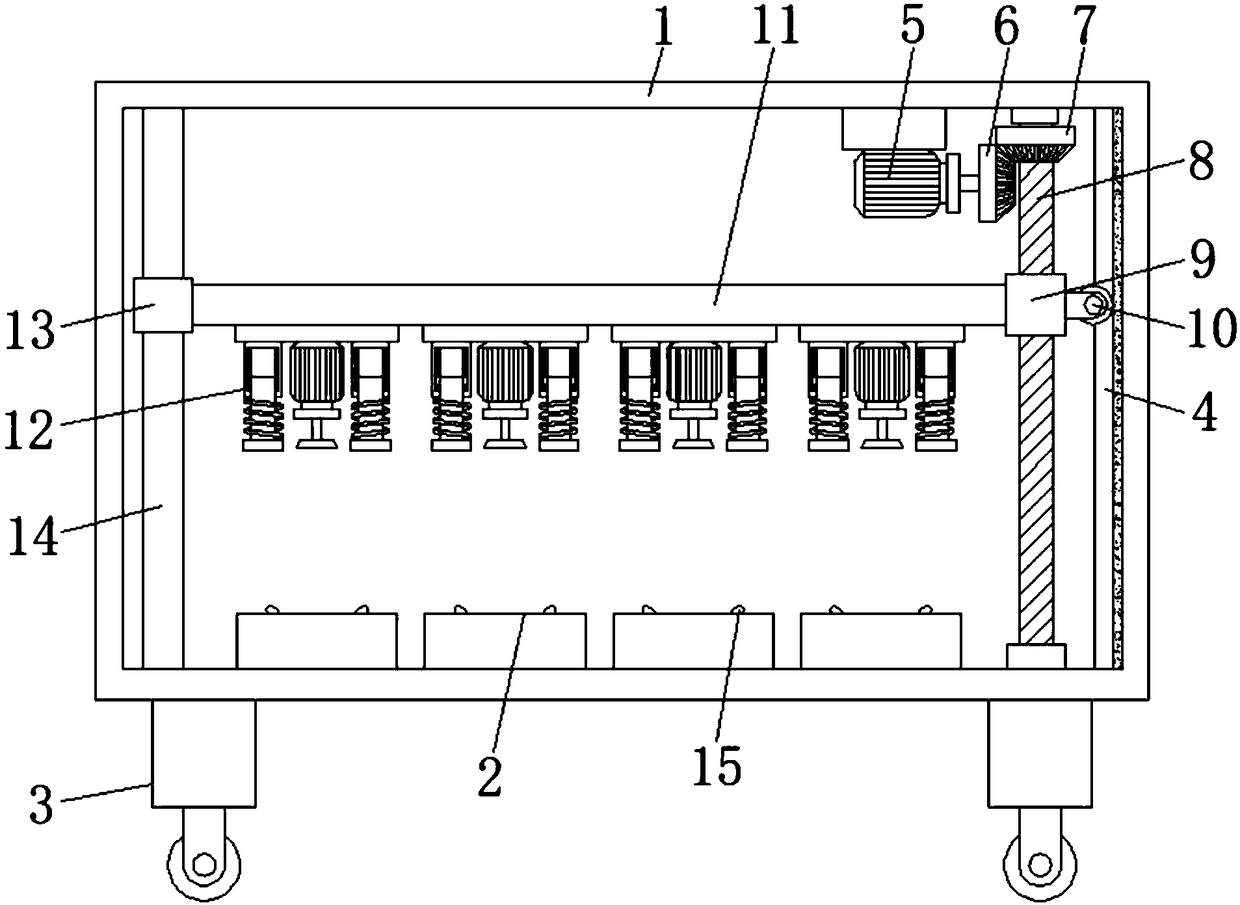

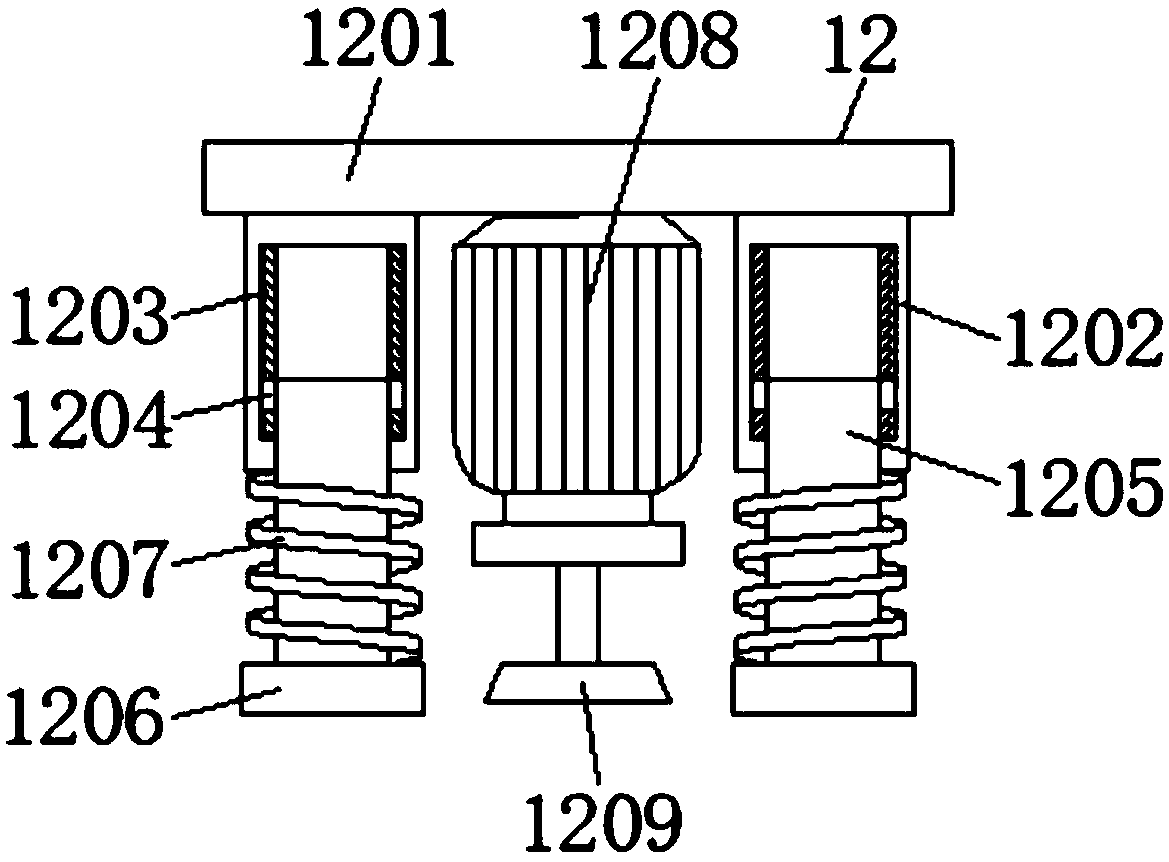

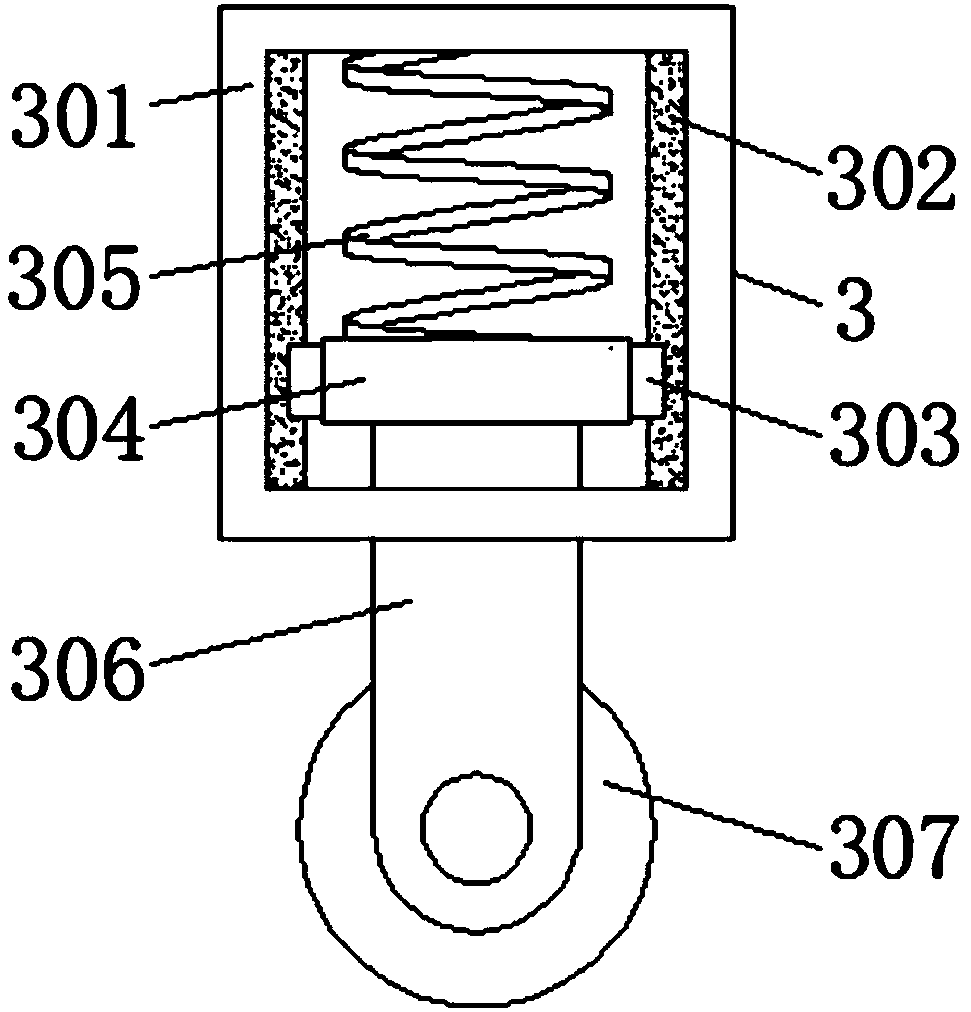

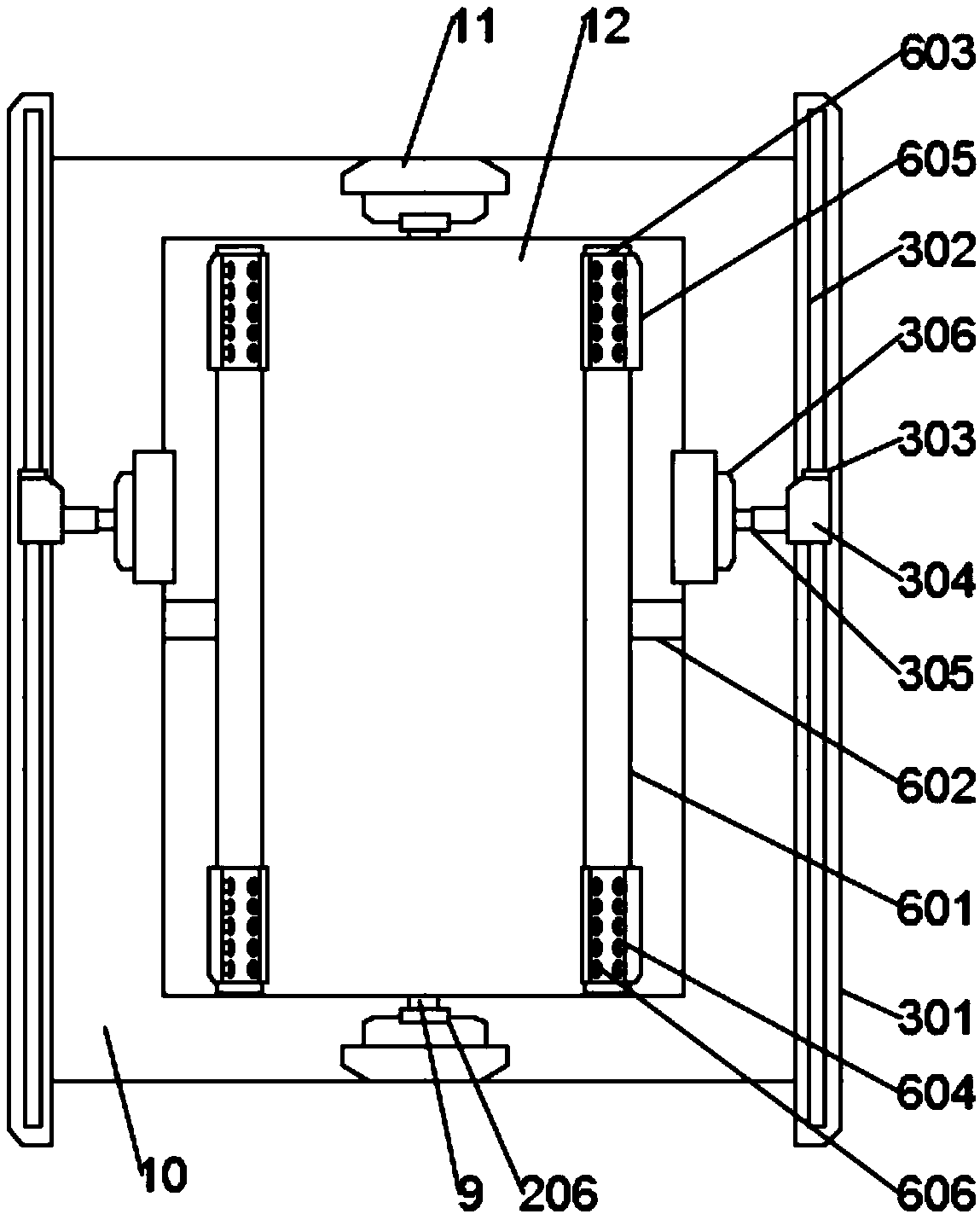

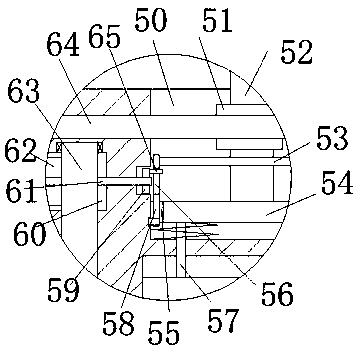

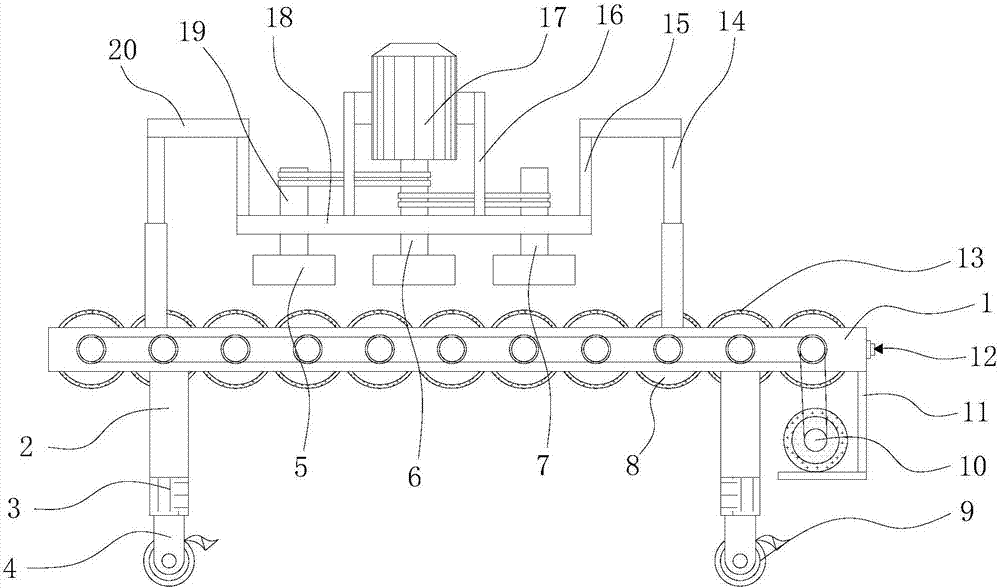

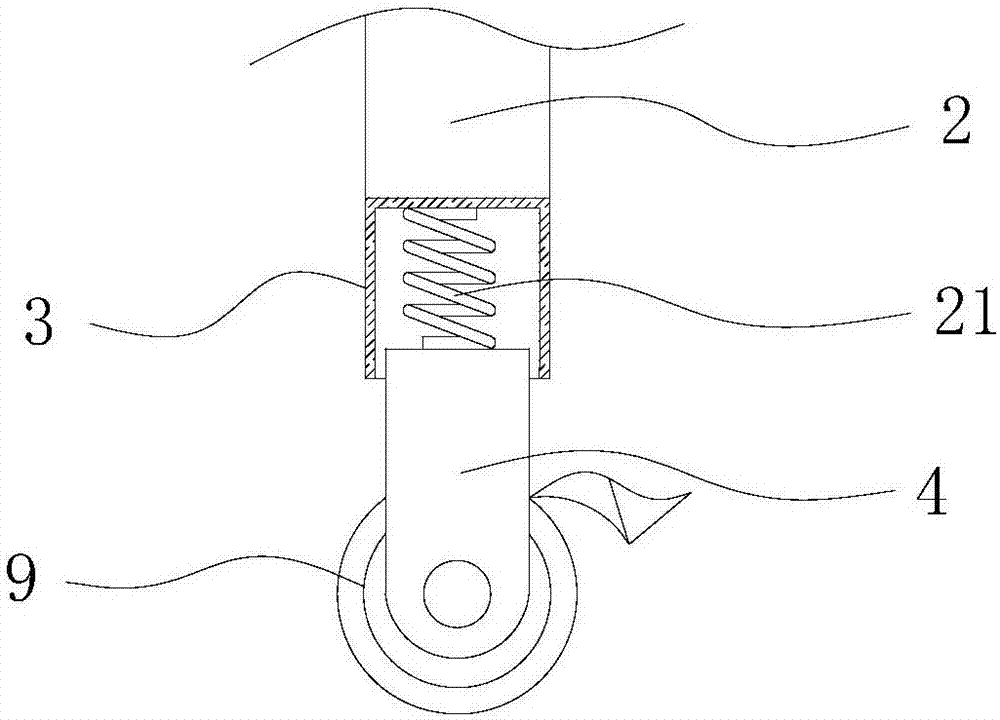

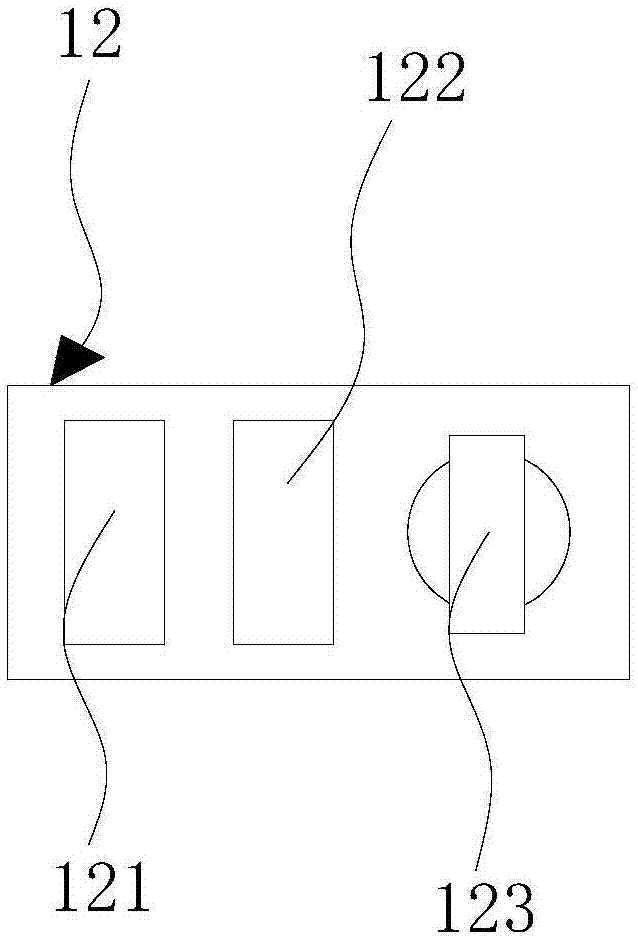

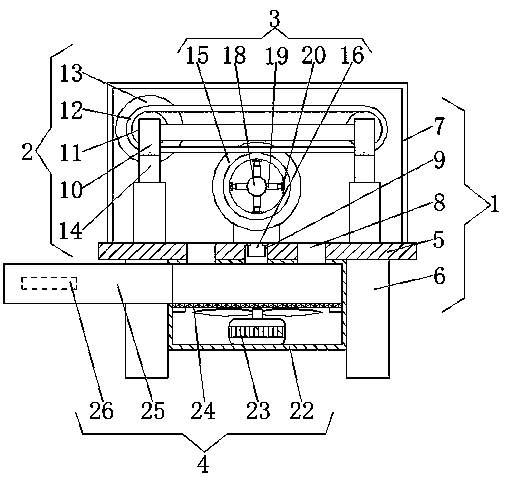

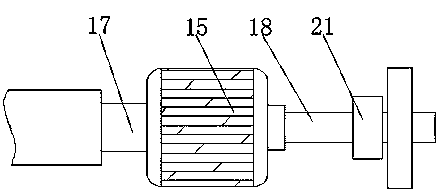

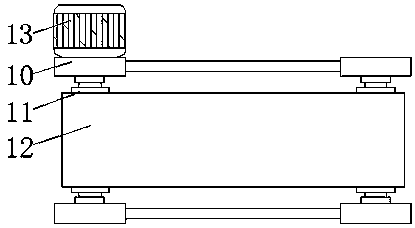

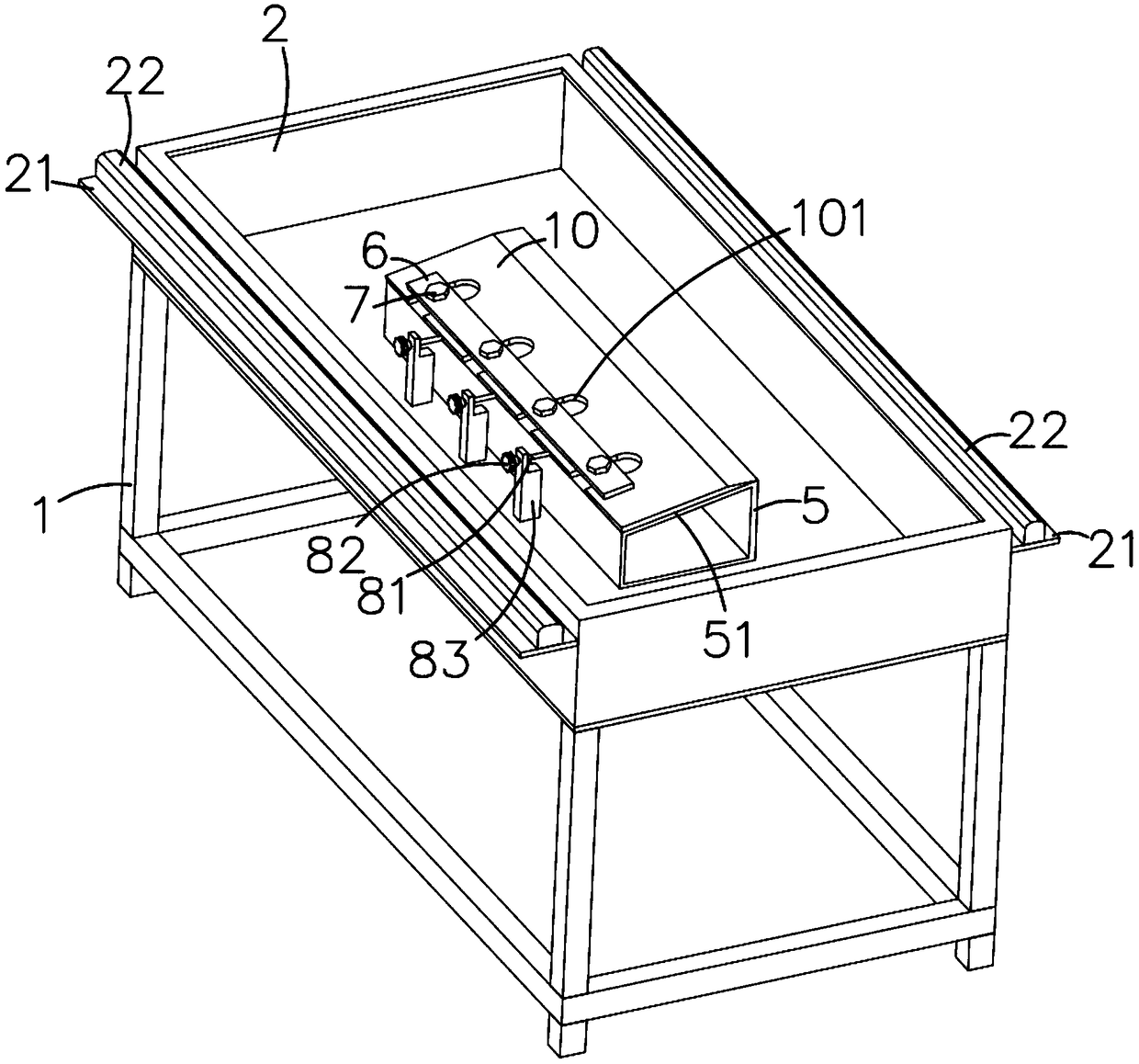

Watch glass grinding equipment for photovoltaic solar panel

ActiveCN108527044AEffective clamping and positioningConvenient grinding workGrinding carriagesGrinding drivesWatch glassDrive shaft

The invention relates to the technical field of manufacturing of photovoltaic products and discloses watch glass grinding equipment for a photovoltaic solar panel. The watch glass grinding equipment comprises an equipment body; four clamping devices which are arranged at an equal interval are fixedly installed at the inner bottom wall of the equipment body; the four corners of the bottom of the equipment body are each fixedly provided with a moving device; the right side of the inner wall of the equipment body is fixedly connected with a guide rail; the inner top wall of the equipment body isfixedly connected with a first motor through a fixing block; an output shaft of the first motor is fixedly connected with a first bevel gear through a transmission shaft; the right side of the first bevel gear is engaged with a second bevel gear; an inner ring of the second bevel gear is connected with a threaded rod in a sleeving manner; and the top end and the bottom end of the threaded rod areboth movably connected with the inner top wall and the inner bottom wall of the equipment body through bearing seats. The watch glass grinding equipment disclosed by the invention solves the problemsthat the existing glass grinding machine is low in work efficiency, the shake generated in grinding affects the grinding quality and transportation is inconvenient, and achieves the effects of high machining efficiency, good machining quality and convenient operation.

Owner:SHAOXING UNIVERSITY

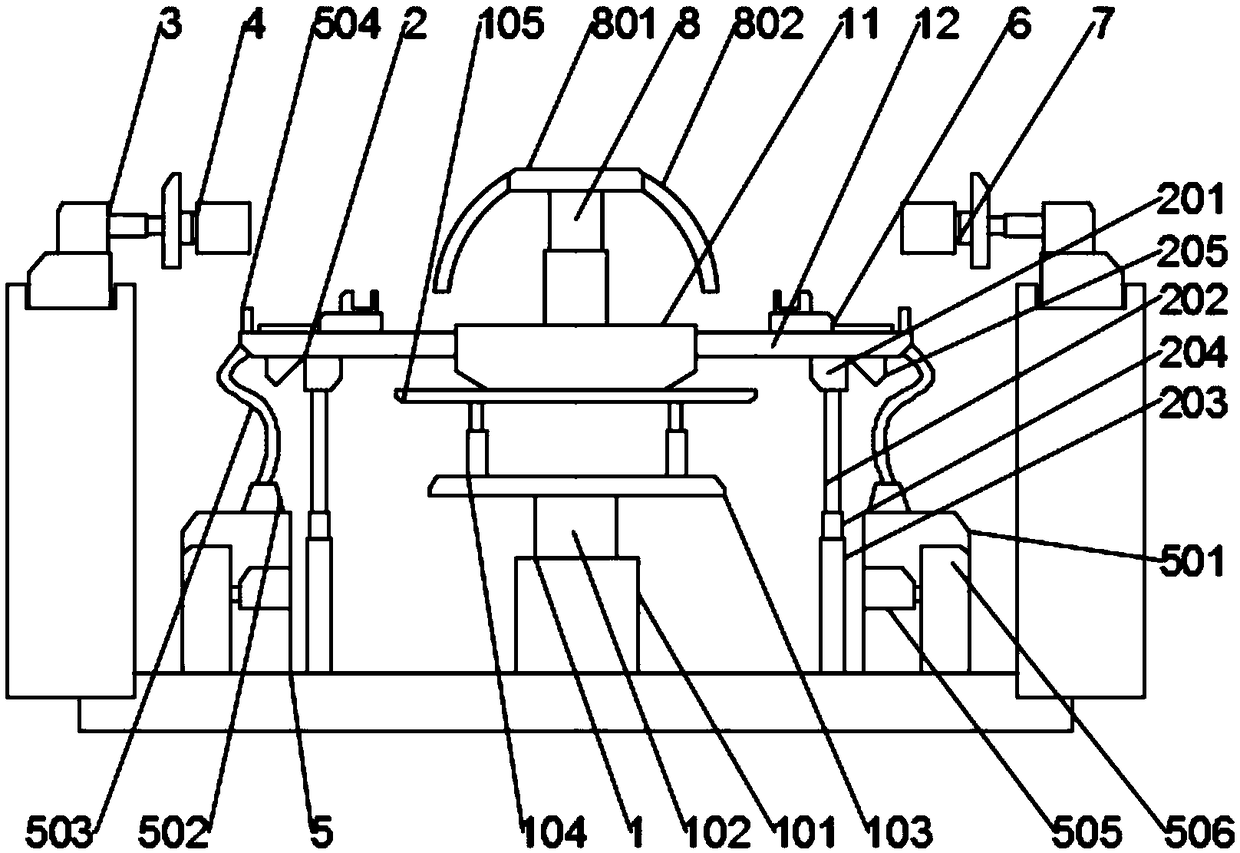

Turnover type automotive body polishing facility

ActiveCN108789079AConvenient grinding workQuick switchGrinding carriagesGrinding machinesLocking mechanismDrive shaft

The invention discloses a turnover type automotive body polishing facility. The turnover type automotive body polishing facility comprises a supporting base. Lifting frames are installed at the two ends of the supporting base, and locking bases are installed at the top ends of the two lifting frames. A working platform is connected between the two locking bases, the two ends of the working platform are connected with the locking bases through transmission shafts, and turnover mechanisms which conduct turnover on the working platform are installed on the locking bases. Combined type polishing mechanisms are installed on the two sides of the supporting base through adjusting assemblies, recovery mechanisms which are used for collecting scraps are installed on the supporting base, and locating locking mechanisms which are used for tightly clamping an automotive body are installed on the working platform. By the adoption of the turnover type automotive body polishing facility, turnover adjustment is conveniently conducted by the turnover mechanisms when the automotive body is locked, the polishing work is accomplished at different angles, and therefore the requirement for overall polishing of the automotive body is met. In addition, the combined polishing mechanisms are good in polishing effect and high in accuracy, and the polishing quality of an automobile can be improved advantageously.

Owner:芜湖众梦电子科技有限公司

Cosmetics grinding machine

InactiveCN107737652AOverall small sizeImprove grinding efficiencyGrain treatmentsSolenoid valveEngineering

The present invention discloses a grinding machine for cosmetics, including the shell, which has the first partition the upper end of the internal cavity of the shell.The bottom activity of the mouth is installed with the first solenoid valve. The left end of the first partition bottom is fixed with a temperature sensor. The mid -end fixing connection at the bottom of the first partition has ultraviolet lamps.The outer side of the UV lamp tube is fixed with a slide.The exterior of the invention is fixed on the outer surface of the rolling axis, which can be connected to crushing teeth, which can be crushed to the materials, reducing the volume of the material, and improving its grinding efficiency. At the same timeThe role of pipes and raw management can meet people's repeated grinding needs for materials, so that people can obtain different particle size materials, which brings great convenience to the grinding of cosmetics.

Owner:吕丽娅

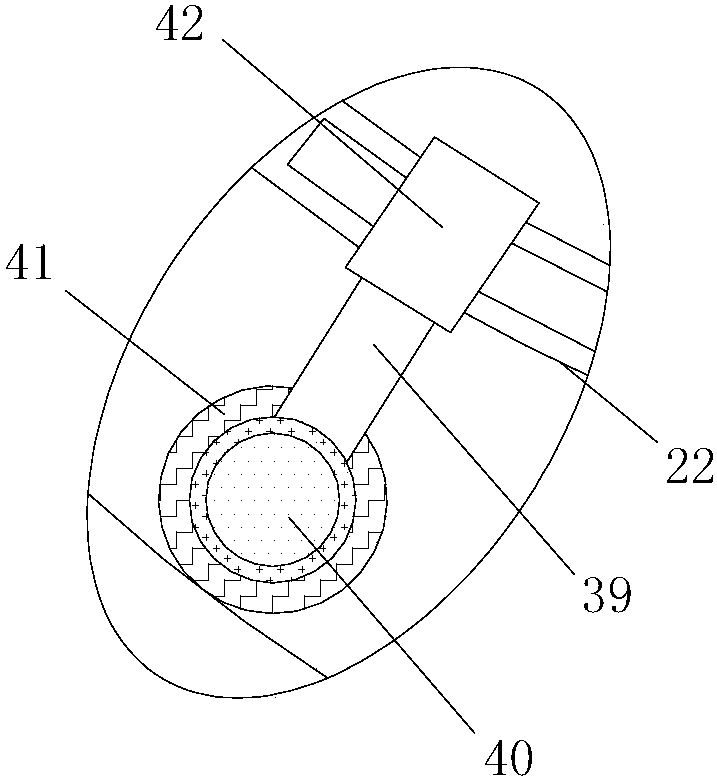

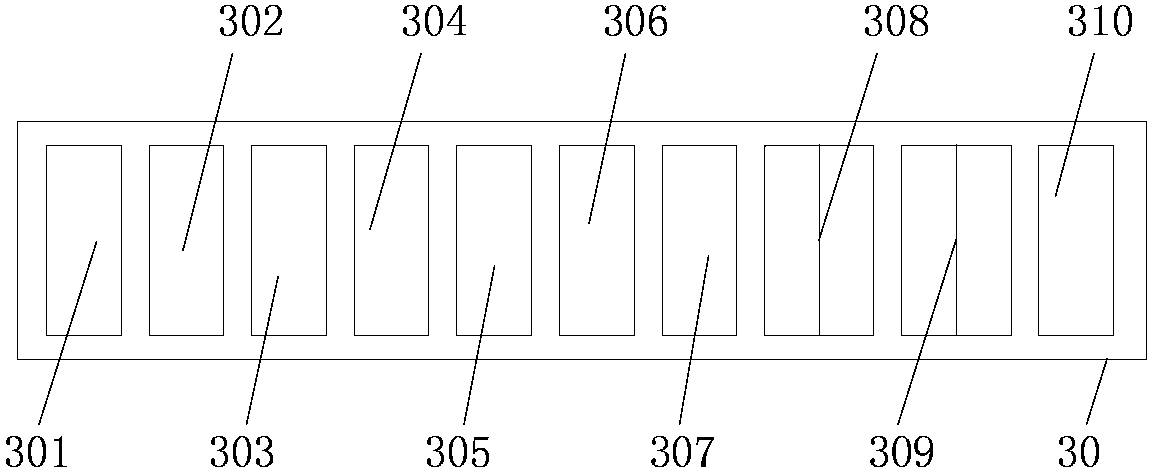

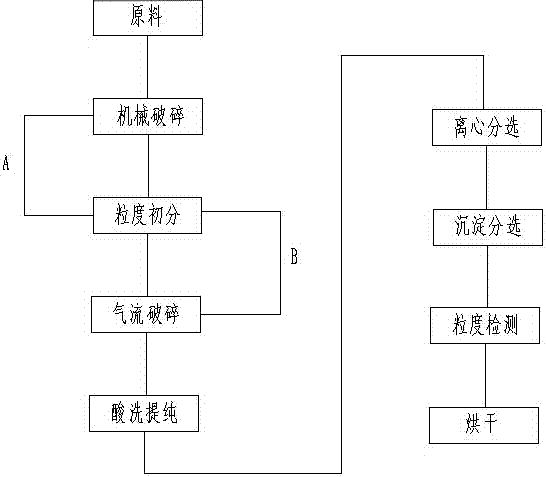

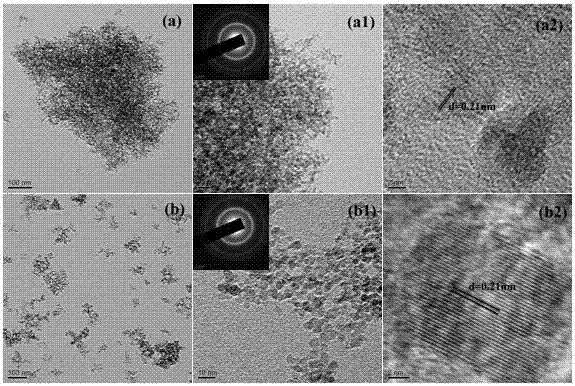

A nanocarbon crystal

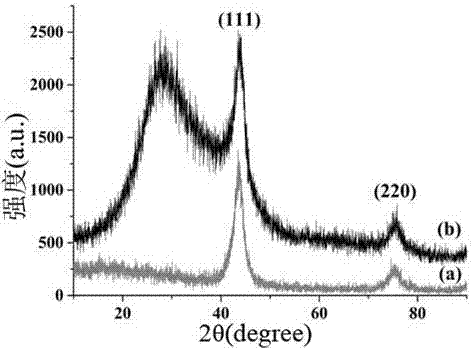

ActiveCN105384160BHigh purityNarrow particle size distributionDiamondNanotechnologyCrystallinityNanostructured carbon

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

Adjustable magnetic grinding machine

InactiveCN108608309AIncrease the areaImprove connection stabilityEdge grinding machinesPolishing machinesMagnetEngineering

The invention provides an adjustable magnetic grinding machine, and relates to the field of magnetic grinding machines. The adjustable magnetic grinding machine comprises a support leg; the inner sideof the support leg is fixedly connected with a connecting plate; the top of the connecting plate is fixedly connected with a chassis; a servo motor is fixedly mounted at the bottom in the chassis; one end of a rotating shaft of the servo motor is in transmission connection with a connecting shaft; the top end of the connecting shaft penetrates through the top of the chassis, and extends above thechassis; the top end of the connecting shaft is fixedly connected with a rotating plate; and the top of the rotating plate is fixedly connected with a magnet. The adjustable magnetic grinding machineis provided with a second thread groove, a mounting rod, a clamping groove and a second support cylinder; a clamping rod is in butt joint with a first support cylinder through connection between an internal thread and an external thread; the first support cylinder stands in the bottom center of a holding device; a clamping bar and the clamping groove are clamped to install the second support cylinder; and the area of the occupied center is increased, and can be adjusted according to the sizes of objects, so that the grinding work is convenient to carry out.

Owner:苏州圣亚精密机械有限公司

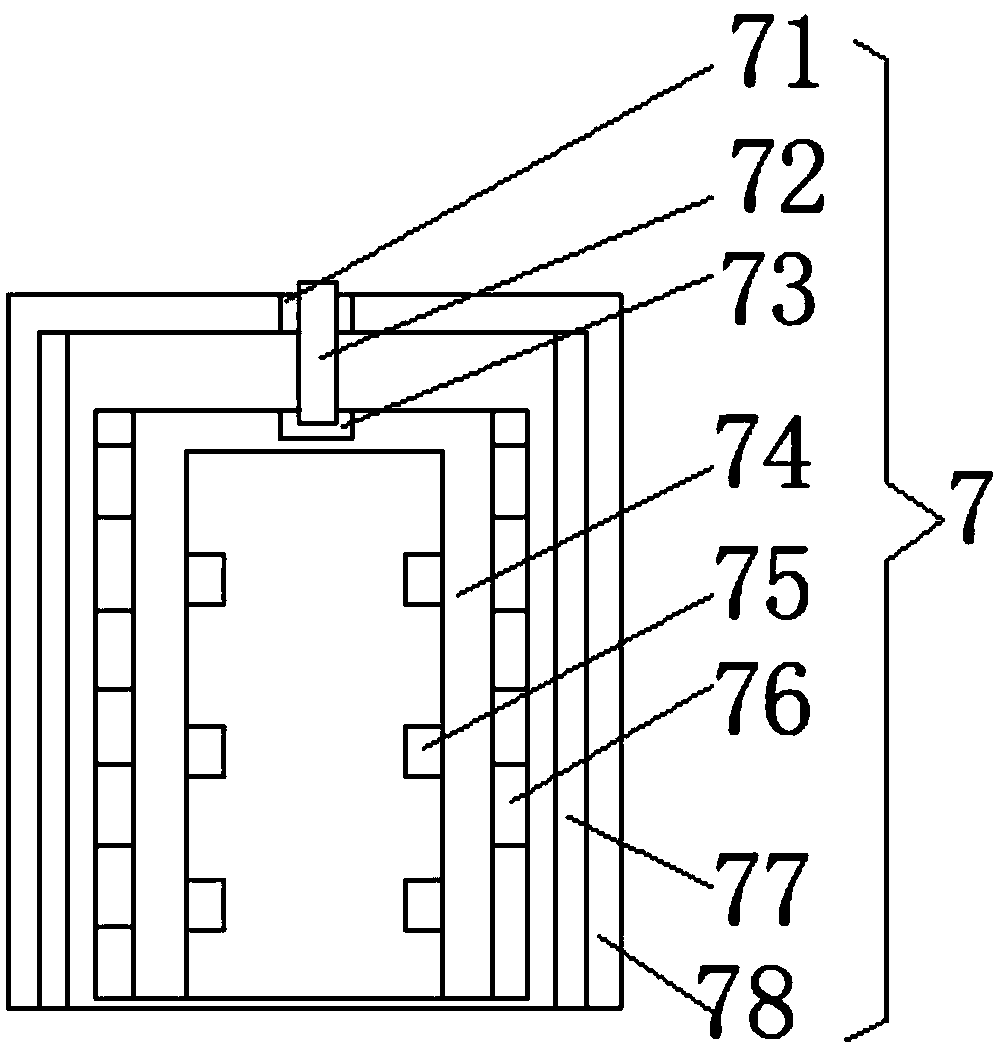

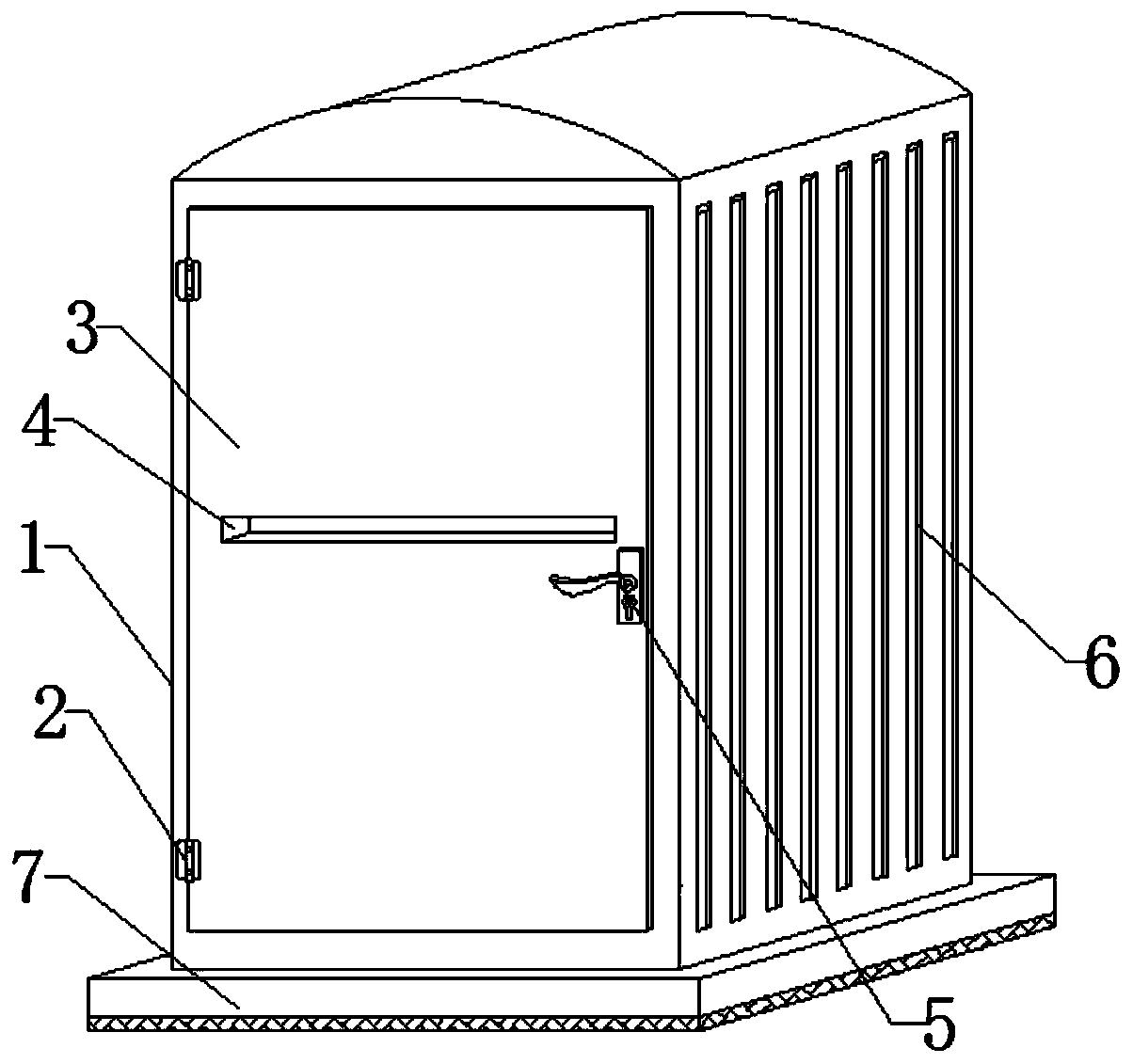

Automatic film cutting mechanism for circuit board film laminating machine

InactiveCN110996544AEasy to cutAvoid wear and tearNon-metallic protective coating applicationEngineeringMechanical engineering

The invention discloses an automatic film cutting mechanism for a circuit board film laminating machine, and relates to the antenna installation field. The automatic film cutting mechanism comprises alaminating machine body, the outer surface of the laminating machine body is connected with a maintenance door through a hinge, and a through hole penetrates through the outer surface of the maintenance door. A heat dissipation groove is formed at one side of the laminating machine body, and a bottom plate is fixed at the bottom of the laminating machine body. During mounting, a worker also pullsa pull ring to enable a limiting rod to overcome the resistance of a second spring to contract, then, the worker aligns one end of a mounting piece at a mounting groove, then, pushes the mounting piece into the mounting groove, and when the mounting piece is pushed to a certain extent and can not move continuously, the worker loosens the pull ring, so that one end of the limiting rod is driven tobe inserted into a limiting groove under the reset capacity of the second spring, the mounting piece is limited, and the mounting piece and a cutter are prevented from automatically sliding out of the mounting groove during working to influence the cutting. The automatic film cutting mechanism is easy to mount and dismount, is convenient to replace and maintain the cutter, and is practical and convenient.

Owner:湖南东神自动化设备有限公司

Equipment for grinding surface of plate for manufacturing unmanned vehicle

ActiveCN109202572AEasy to recycleEasy to fixGrinding work supportsPlane surface grinding machinesCar manufacturingSurface grinding

The invention relates to the field of automobile manufacturing, in particular to equipment for grinding the surface of a plate for manufacturing an unmanned vehicle. The equipment for grinding the surface of the plate for manufacturing the unmanned vehicle has the advantages that the grinding is smooth, and the equipment facilitates recovery and treatment of dust generated during grinding as wellas the fixation of an automobile sheet, and the later use effect of the automobile sheet is improved. The equipment for grinding the surface of the plate for manufacturing the unmanned vehicle comprises a faucet, a filter box, a base, a first air pipe, a vacuum generator, second air pipes, a gas-distributing pipe, vacuum chucks, cleaning rollers, a cover plate, a first sliding block, a sealing cover, a sliding rail, a rack, butterfly bolts, a sealing plate, a net plate, a mounting frame and the like. According to the equipment, the effects that the grinding is smooth, and the equipment facilitates recovery and treatment of the dust generated during grinding as well as fixation of the automobile sheet, and the later use quality of the automobile sheet is improved

Owner:肖艳梅

Stainless steel precision casting edge grinding treatment equipment

ActiveCN111644925AConvenient grinding workFlexibility to adjust workEdge grinding machinesGrinding carriagesElectric machineryStructural engineering

The invention discloses a stainless steel precision casting edge grinding treatment equipment. The stainless steel precision casting edge grinding treatment equipment comprises a base, a transverse plate, a first motor and a grinding plate, wherein the transverse plate is fixedly installed at the top end of the upper part of the base, vertical rods are fixedly installed on the two side positions of the top end of the transverse plate, first screw rods are connected to the middle positions of the top ends of the vertical rods through bearings, first rotating sleeves are in threaded connection with the outer parts of the first screw rods, rotating plates are coaxially connected to the top ends of the first screw rods, the rotating plates are connected through a belt. When the stainless steelprecision casting edge grinding treatment equipment is used, the interior of a hollow casting can be clamped and fixed inside the casting, it is guaranteed that clamping work cannot be conducted outside the casting, the subsequent thorough grinding work on the surface of the casting is facilitated, and when grinding is conducted, the position of the grinding plate can be flexibly adjusted at thebottom of a fixing seat, so that the exteriors of castings with different diameters can be conveniently ground.

Owner:浙江展博新材科技有限公司

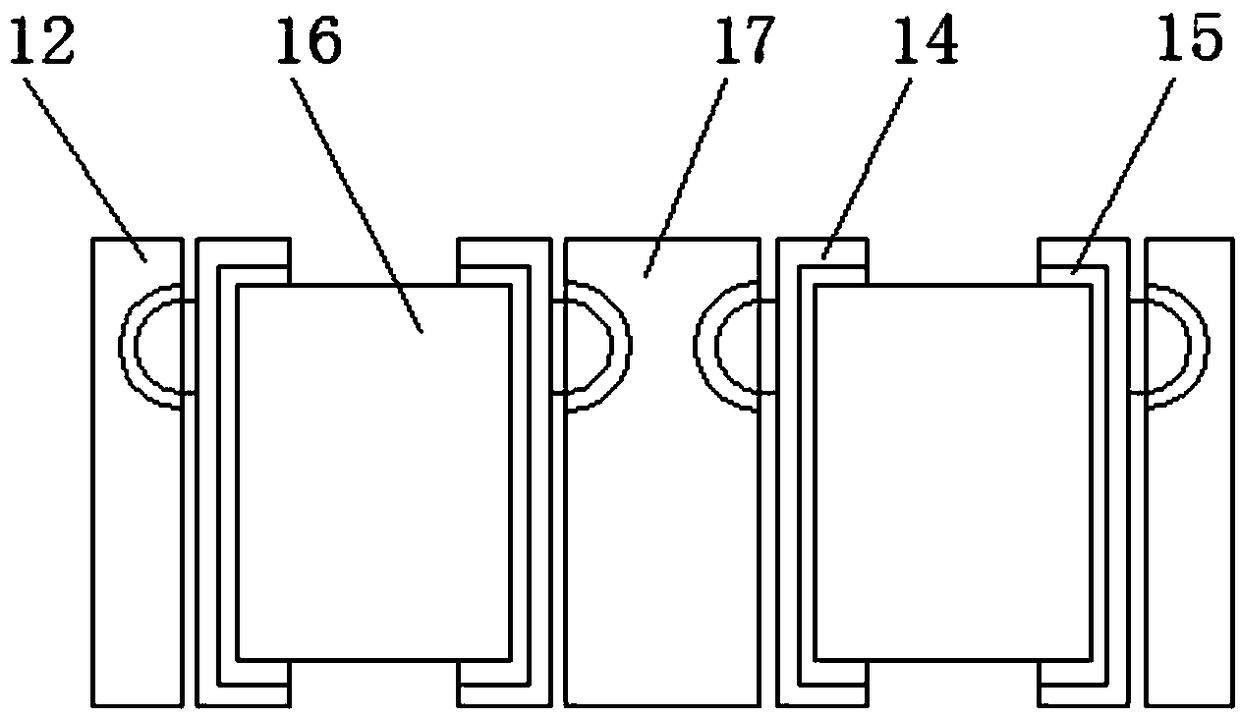

Plank grinding device with double-sided grinding

InactiveCN111716175AConvenient grinding workGrinding speed is fastGrinding carriagesGrinding drivesRolling-element bearingElectric machinery

The invention discloses a plank grinding device with double-sided grinding. The plank grinding device with double-sided grinding comprises a shell body, machine shells are fixedly connected to the left side and the right side of the top of the shell body, the tops of the machine shells are fixedly connected with first machine boxes, the bottoms of the inner walls of the first machine boxes are fixedly connected with driving motors, output shafts of the driving motors are fixedly connected with threaded rotary shafts, and the bottom ends of the threaded rotary shafts penetrate through the firstmachine boxes and the machine shells from top to bottom in sequence and extend to the interiors of the machine shells. Through the mutual cooperation of the driving motors, the threaded rotary shafts, grooves, rolling bearings, thread blocks, chutes, sliders, first cylinders, second machine boxes, grinding motors, grinding rotary shafts, grinding heads, fixed plates, telescopic rods, machine cases, first through slots, second through slots, springs, second cylinders and clamping plates, a plank is ground in a two-side grinding mode, the time is shortened and the labor is saved, the grinding speed is improved, the grinding efficiency is improved, and great convenience is brought for plank grinding work.

Owner:淮北辰威科技有限公司

Edge cutting and polishing device for tempered glass production

ActiveCN108839268AFast cutting speedReduce oppressionEdge grinding machinesGrinding drivesScrapEngineering

The invention discloses an edge cutting and polishing device for tempered glass production. The edge cutting and polishing device comprises a base body, an extending arm, a supporting plate and an operation platform; and a hydraulic cylinder is fixed to the surface of the base body, a sliding rail is formed in the extending arm, a sliding block is mounted in the sliding rail, an elastic plate is arranged in a first clamp, a second motor is arranged on the upper portion of the supporting plate, a three-phase asynchronous motor is arranged on the inner side of the second motor, a frosting layeris closely attached to the outer side of the lower end of a lead screw, a supporting platform is mounted on the lower portion of the three-phase asynchronous motor, and a second clamp is fixed to thesurface of the operation platform. According to the edge cutting and polishing device for tempered glass production, the structure is perfect, cutting and polishing work can be conducted simultaneously, thus the working efficiency of the edge cutting and polishing device is high, when polishing operation is conducted on the edge of tempered glass, residual waste scraps can be processed in a centralized mode, and the health of workers is facilitated.

Owner:新沂市晶彩玻璃有限公司

Building material grinding device

InactiveCN111300204ASimple structureEasy to operateEdge grinding machinesGrinding drivesElectric machineryGrinding

The invention discloses a building material grinding device which comprises a base. A motor cavity is arranged in the base. A motor is fixedly mounted on the bottom wall of the motor cavity. The building material grinding device is characterized in that the motor is in power connection with a motor shaft; a belt cavity is formed on the upper side of the base; a friction rotating shaft penetratingthrough the belt cavity is rotationally mounted on the bottom wall of the belt cavity; the position, outside the base, of the lower side of the friction rotating shaft is fixedly connected with a friction plate; the motor shaft extends upwards to penetrate through the wall between the motor shaft and the belt cavity; the upper side of the motor shaft is in belt transmission connection with the friction rotating shaft in the belt cavity; a moving groove with an opening being rightward is arranged at the position, between the belt cavity and the motor cavity, of the base; and a moving device forcontrolling a dust collection device to work is arranged in the moving groove.

Owner:福州晋安汇星针科技有限公司

Grinder for refractory material

InactiveCN106944915AImprove single grinding areaSolve the problem of low efficiency of single grindingGrinding carriagesGrinding drivesMotor driveRefractory

The invention discloses a grinder for a refractory material. The grinder comprises a supporting seat; the inner surface of the supporting seat is movably provided with a driving roller; the periphery of the bottom of the supporting seat is fixedly connected with fixed legs; the bottom of each fixed leg is fixedly connected with a sleeve; the top end of an inner cavity of each sleeve is movably connected with a movable leg by a spring; the bottom of each movable leg is movably provided with a traveling wheel; the right end of the bottom of the supporting seat is fixedly provided with a first motor support; the upper surface of the first motor support is fixedly connected with a first motor; the first motor is driven by and connected with the driving roller by a belt; and the right side of the supporting seat is fixedly provided with a controller. The inner surface of a third connecting plate is movably provided with a second grinding shaft, a first grinding shaft and a third grinding shaft in sequence from left to right, and the grinding shafts are driven by a group of second motors, so that the single-time grinding area can be increased, and the problem of low single-time grinding efficiency caused by only arranging one grinding head on the existing equipment is solved.

Owner:长兴鼎峰铸材科技股份有限公司

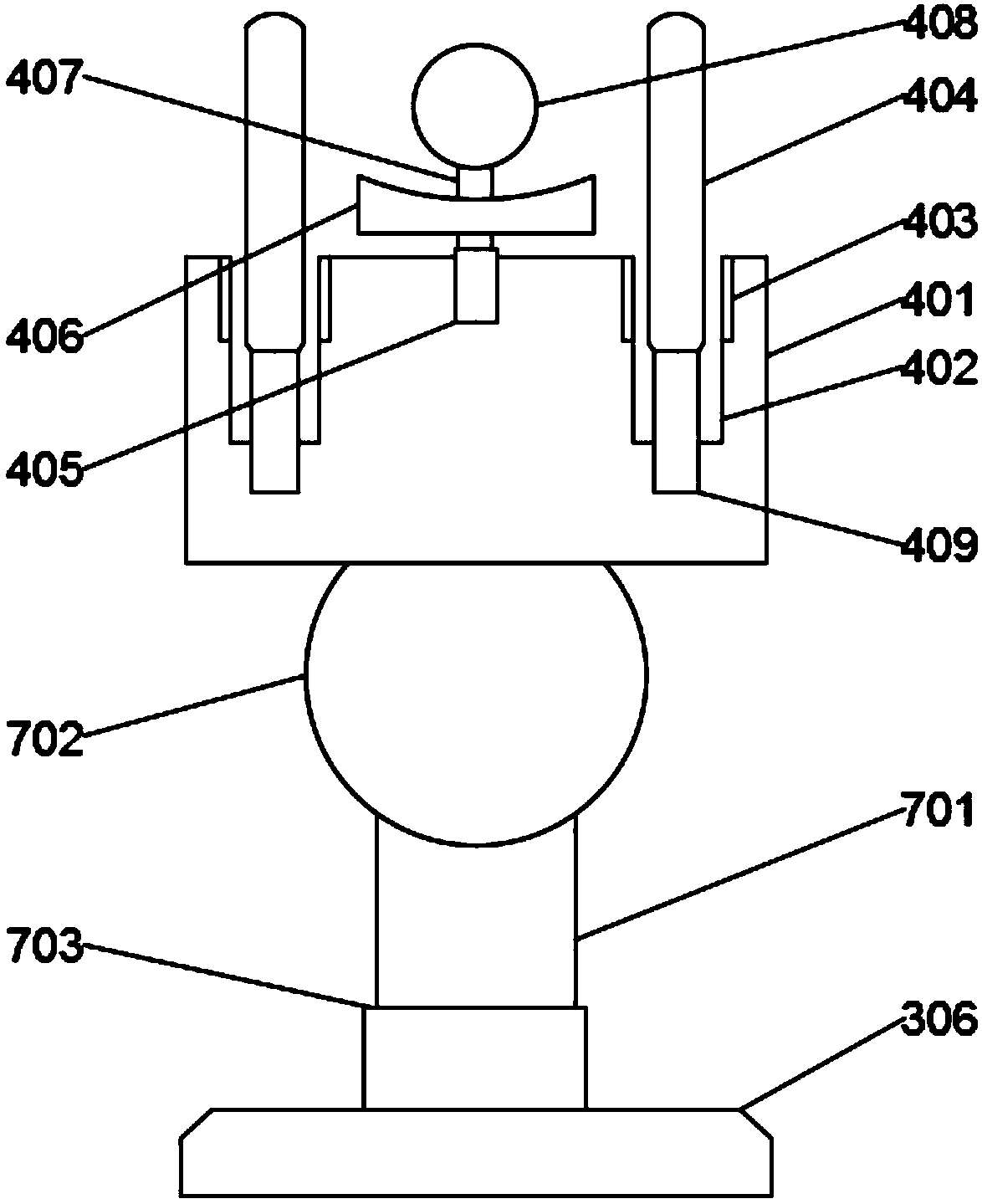

Optical lens grinding device

ActiveCN113427355AEasy to clamp and fixConvenient grinding workGrinding carriagesOptical surface grinding machinesOptic lensMachining

The invention is suitable for the field of grinding devices, and provides an optical lens grinding device. The optical lens grinding device comprises a machining table, a rack, a top plate and a grinding head and further comprises a lifting mechanism, a bearing mechanism and a transmission mechanism, the lifting mechanism is installed on the top plate, a rotating mechanism is installed on the lifting mechanism, and the grinding head is installed on the rotating mechanism. The bearing mechanism is installed on the machining table, and the bearing mechanism is used for clamping and fixing an optical lens to be machined. The transmission mechanism is installed between the top plate and the machining table, the rotating mechanism is connected with the bearing mechanism through the transmission mechanism, the transmission mechanism is used for controlling whether the bearing mechanism rotates or not, and when the transmission mechanism controls the bearing mechanism to rotate, the rotating directions of the bearing mechanism and the rotating mechanism are the same or opposite. The grinding head and the optical lens can be controlled to rotate in the same or opposite directions, and the grinding effect and efficiency are improved.

Owner:JIANGSU JIAYI BEIKE OPTICS TECH CO LTD

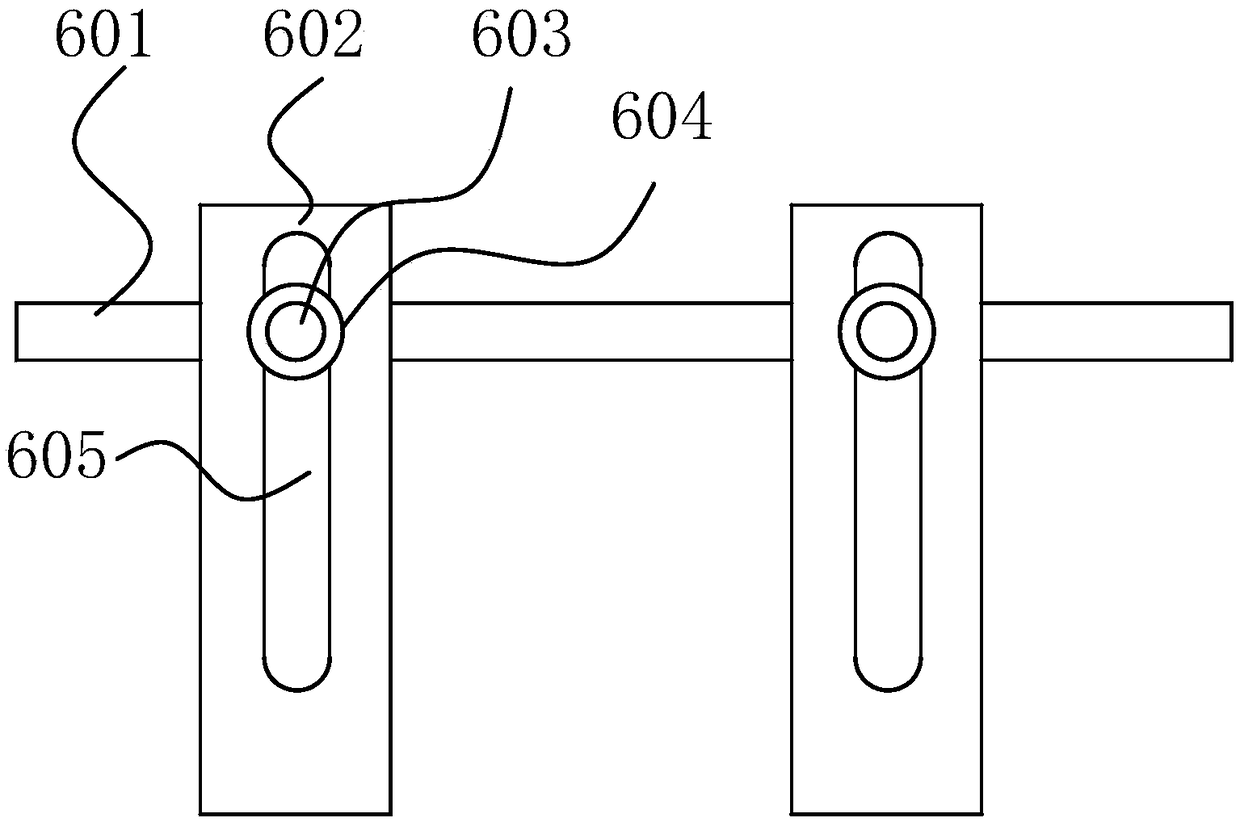

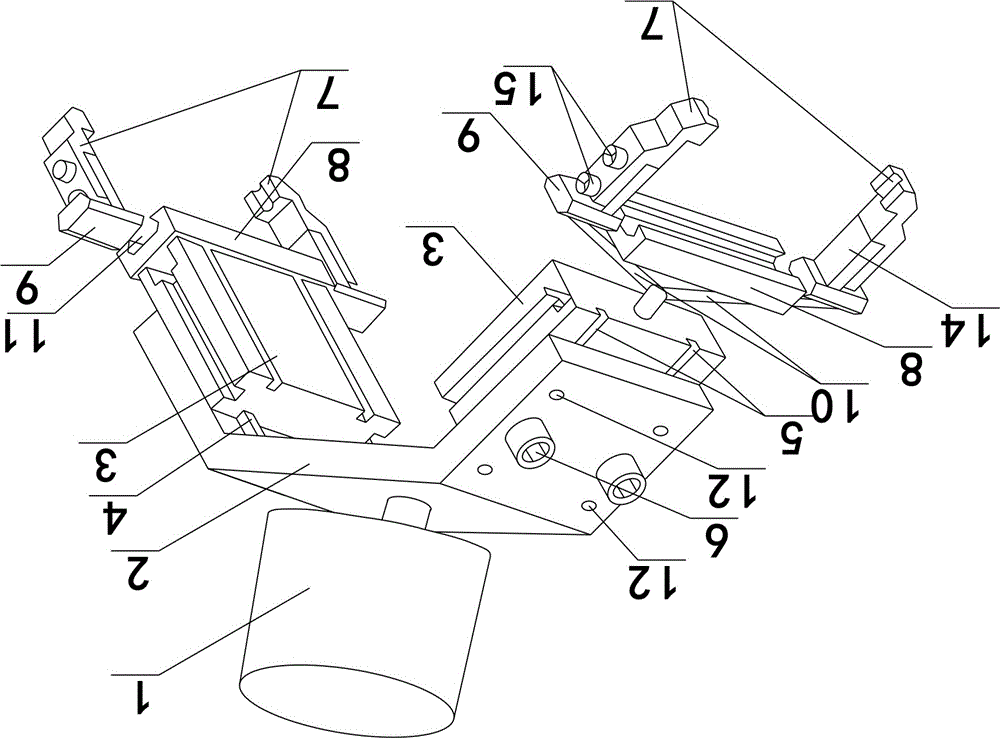

Grinding mechanism for sides of raw glass sheets

InactiveCN111805345AConvenient for side grinding needsMeet side grinding needsEdge grinding machinesGrinding drivesStructural engineeringGlass sheet

The invention discloses a grinding mechanism for sides of raw glass sheets, and relates to the technical field of grinding mechanisms. The grinding mechanism comprises a bottom frame and a mounting frame, wherein the end surfaces of the side plates of the bottom frame are provided with flanges, and the upper sides of the flanges are provided with slide rails; a cross bar of the mounting frame is provided with a slide groove, both ends of the slide groove are installed with rotating seats, one end of an installed screw rod is rotatably installed in a rotating seat, and the other end of the screw rod passes through the rotating seat and is in transmission connection to a power mechanism installed at the end of the cross bar; the screw rod is fitted with two sliding blocks, and the installedsliding blocks move along with the sliding groove; the lower ends of the sliding blocks are matched with a grinding mechanism; the upright of the mounting frame is provided with a clamp slot that is clamped on the side of the bottom frame, and a slideway is installed in the clamp slot to cooperate with the sliding rail. The grinding mechanism completes the grinding of the sides of the raw glass sheets installed on a conveying rack through the provided grinding mechanism, and at the same time adjusts the distance between the two grinding mechanisms through the power mechanism, which is convenient to meet the side grinding requirements of the raw glass sheets of different sizes.

Owner:安徽蓝博玻璃有限公司

Grinding device with clamping function for bearing machining

InactiveCN109129055AFast processSanding works fastRevolution surface grinding machinesGrinding work supportsEngineeringGrinding process

The invention discloses a grinding device with a clamping function for bearing machining. The grinding device comprises a workbench. The top of the workbench is fixedly connected with a grinding mechanism, a clamp is slidingly connected to the portion, located below the grinding mechanism, of the top of the workbench, and the bottom of the workbench is fixedly connected with a dust removal mechanism. The workbench comprises a tabletop. The two sides of the bottom of the tabletop are fixedly connected with landing legs, and the top of the tabletop is fixedly connected with a protective cover. Through the cooperative use of the workbench, the grinding mechanism, the clamp and the dust removal mechanism, a bearing can be turned over and moved in the bearing grinding process, it is better guaranteed that grinding work is rapidly carried out, the grinding efficiency is greatly improved, ground chippings can be adsorbed in the grinding process, the bearing does not need to be ground regularly, it is better guaranteed that the grinding work is rapidly carried out, and great convenience is brought to the grinding work.

Owner:LEIYANG XINDAWEI TECH

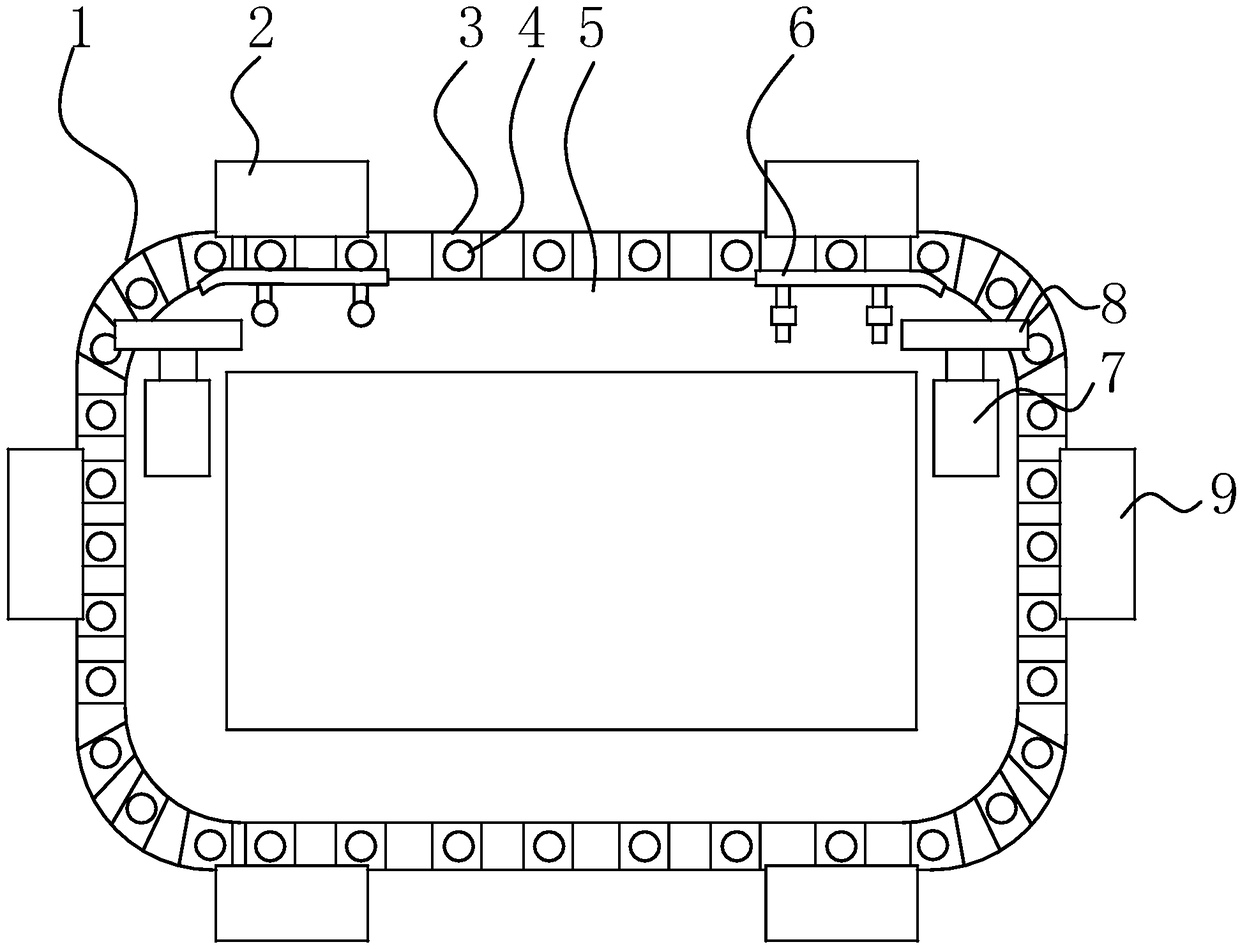

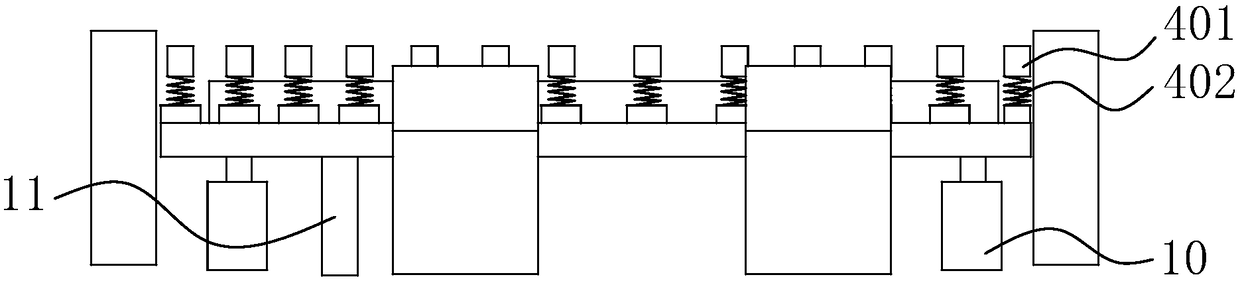

Automatic buffing and polishing device for lipstick tubes

ActiveCN108907946ASimple structureGrinding speed is fastEdge grinding machinesPolishing machinesElectric machineryEngineering

The invention discloses an automatic buffing and polishing device for lipstick tubes, which comprises a supporting plate and a chain, a transverse grinding machine and a longitudinal grinding machinewhich are arranged around the supporting plate, the supporting plate has a rectangular structure and the bottom part is provided with a supporting rod, the chain is connected by the second motor drivearranged at the bottom of the supporting plate and rotates around the supporting plate, a fixed block is arranged on the upper surface of the chain, a placing rack is arranged at the top of the fixedblock, the placing rack comprises a placing block and an elastic piece arranged between the placing block and the fixed block bracket, a transverse grinding machine is arranged on the outer side of the long side of the chain, a limiting mechanism is arranged on the inner side of the long side of the chain corresponding to the upper surface of the supporting plate, the outer side of the short sideof the chain is provided with a longitudinal grinding machine. The device has the advantages of simple structure, fast grinding speed, high efficiency, convenient operation and good buffing and polishing effect.

Owner:安徽裕佳铝塑科技有限公司

Grinding device for metal material processing

InactiveCN110774149AEasy clampingAvoid displacementGrinding carriagesGrinding machinesPolishingMetallic materials

The invention discloses a grinding device for metal material processing. The grinding device for metal material processing comprises a polishing sheet and a clamping plate. The top of the polishing sheet is connected with one end of a connecting shaft through a mounting plate. The other end of the connecting shaft penetrates through the top of the mounting frame and is rotatably connected with a motor shaft of the grinding motor. Vertically arranged sliding rods are connected to the two ends of the top of the mounting frame. The tops of the sliding rods penetrate through a top plate of a firstsupporting frame and are connected to the bottoms of connecting plates. The connecting plates are connected to two sides of a first sliding block correspondingly. The first sliding block is connectedto a first screw rod which is vertically arranged. The top end of the first screw rod is rotatably connected with a motor shaft of the rotating motor. The rotating motor is arranged on a top box of asecond supporting frame. A rotating shaft connected with the bottom end of the first screw rod is arranged in a bearing seat. A grinding motor connected with a grinding sheet is mounted on the mounting frame, the mounting frame slides through the sliding rods, the height of the grinding sheet is increased, and processing and grinding of metal workpieces with different heights are facilitated.

Owner:中山市宝元海精密五金制品有限公司

Sharpening device for pencil cutter

InactiveCN109227238AEasy to fixConvenient grinding workGrinding carriagesOther manufacturing equipments/toolsDrive shaftEngineering

The invention discloses a sharpening device for a pencil cutter. The device includes a machine frame and a sharpening assembly. The sharpening assembly includes a grinding motor, a grinding wheel, aninstallation platform, a pressing plate and bolts. The grinding motor is provided with a driving shaft, and the grinding wheel is mounted on the driving shaft. The upper surface of the installation platform is inclined, and the relatively high side of the inclined surface corresponds to the position of the grinding wheel. When the grinding motor moves, the grinding wheel moves along the relativelyhigh side of the inclined surface, the inclined surface is provided with several first screw holes matched with the bolts, the pressing plate is provided with several through holes corresponding to the first screw holes one to one, and the several bolts sequentially pass through the through holes and the first screw holes in a one-to-one corresponding mode. Compared with the prior art, the sharpening device is provided with the sharpening assembly which includes the motor, the installation platform and the pressing plate, the pressing plate can stably fix the cutter on the installation platform, the motor can well sharpen the cutter and thus the cutter sharpening work can be effectively achieved.

Owner:靖州县金心笔业有限责任公司

Grinding machine with tool clamping device

InactiveCN105666256AGrinding work freelyConvenient grinding workOther manufacturing equipments/toolsGrinding work supportsEngineeringMechanical engineering

The invention relates to the technical field of tool grinding, in particular to a grinding machine with a tool clamping device. The grinding machine with the tool clamping device comprises a base, a sliding rail, a sliding block, a grinding mechanism and the tool clamping device; the tool clamping device comprises two clamping portions, a rotating motor, an installing plate and two direct-driving air cylinders, the installing plate comprises a horizontal section located in the middle and inclined sections located on the two sides, the output end of the rotating motor is connected with the horizontal section of the installing plate, the direct-driving air cylinders are installed on the inclined sections located at the two ends of the installing plate respectively, the inner side surface of each inclined section of the installing plate is provided with two parallel sliding rails, the outer side surface of each direct-driving air cylinder is provided with two sliding grooves corresponding to the sliding rails, the sliding rails are clamped into the sliding grooves respectively, the direct-driving air cylinders are fixed on the inclined sections of the installing plate through screws, and the output end of each direct-driving air cylinder is connected with one clamping portion.

Owner:于秀洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com