Equipment for grinding surface of plate for manufacturing unmanned vehicle

A self-driving car, surface grinding technology, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reduced use effect of automobile panels, inconvenient recycling of dust, inconvenient fixing of automotive panels, etc., to achieve Improve the quality of use, improve the efficiency of mixing and purification, and improve the effect of purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

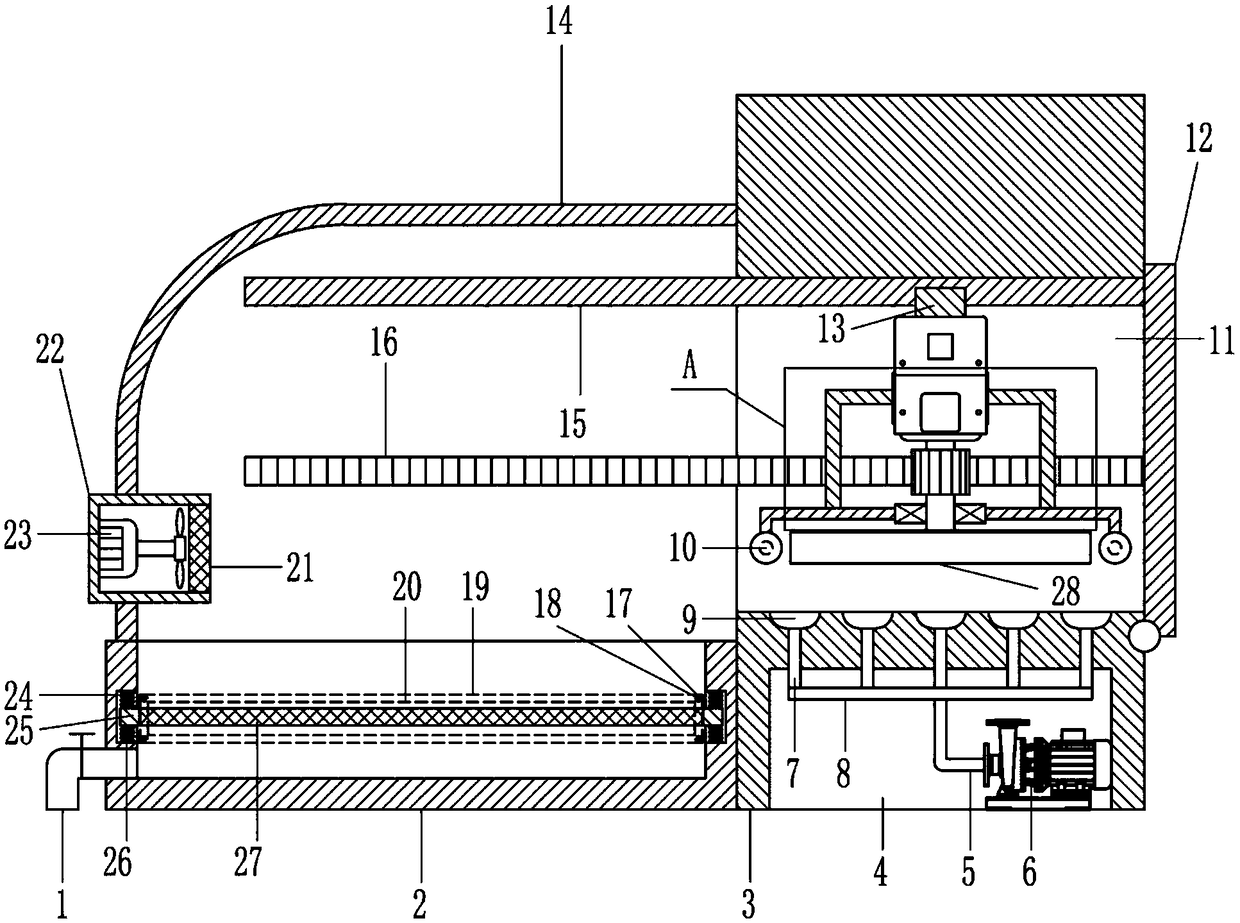

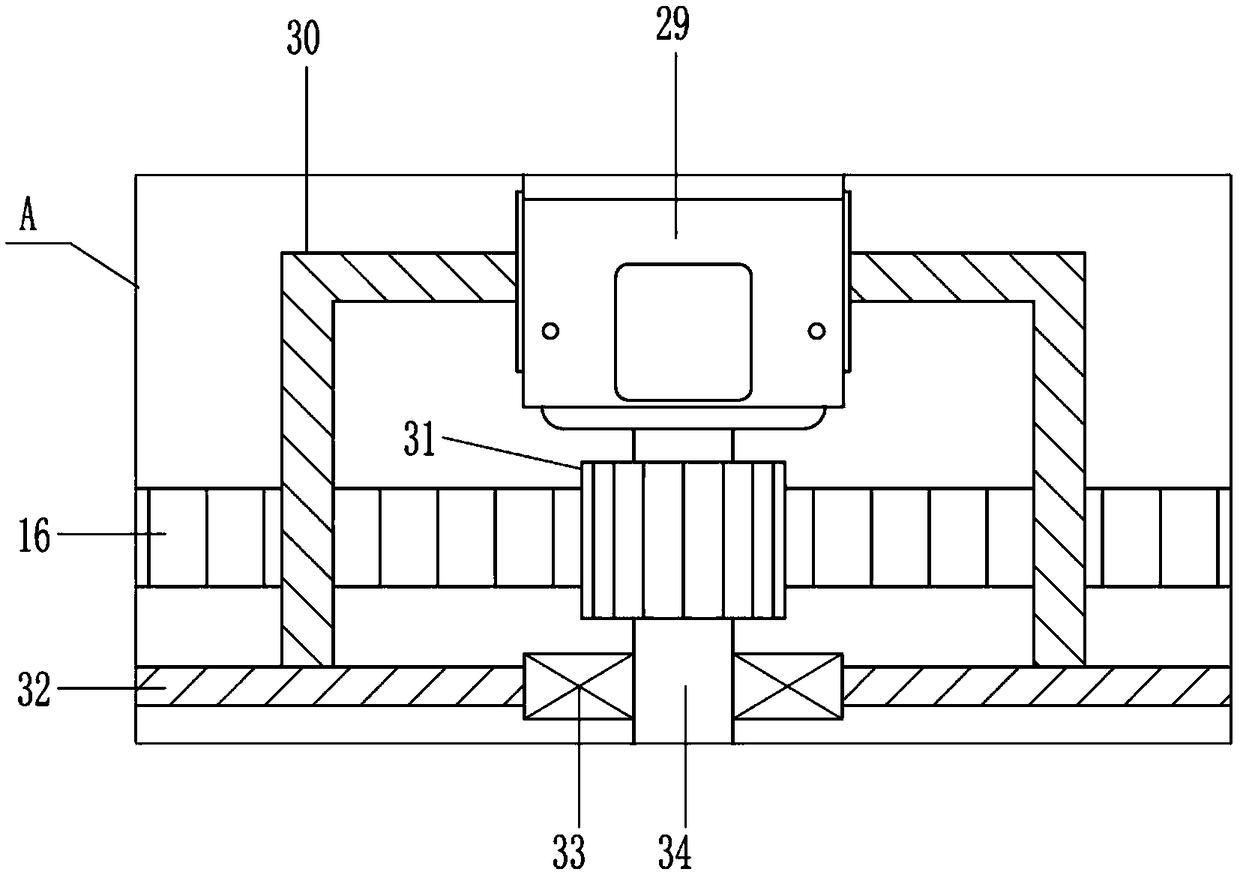

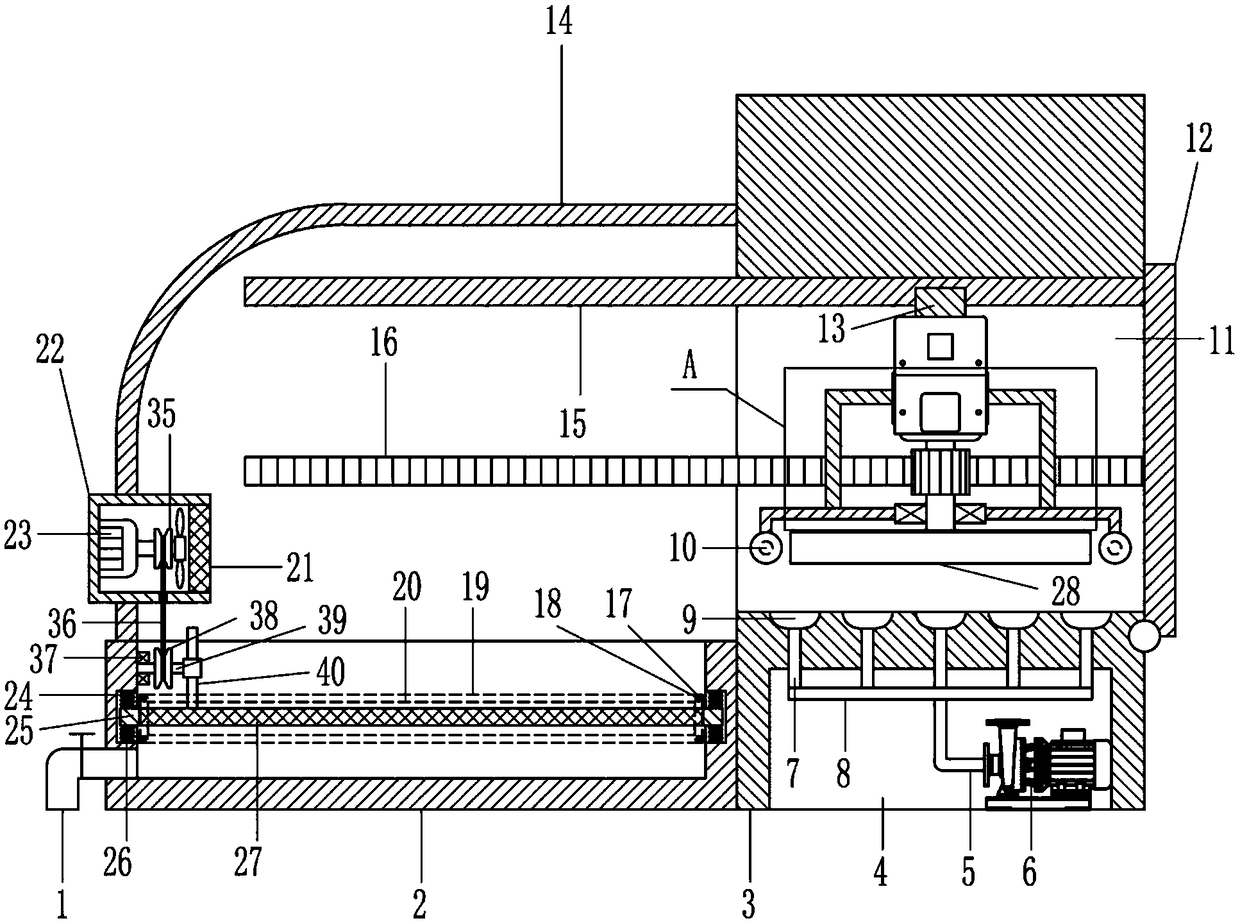

[0030] A plate surface grinding equipment for the manufacture of unmanned vehicles, such as Figure 1-8 As shown, it includes a faucet 1, a filter frame 2, a placement seat 3, a first air pipe 5, a vacuum generator 6, a second air pipe 7, an air distribution pipe 8, a vacuum suction cup 9, a cleaning roller 10, a cover plate 12, a first slide Block 13, sealing cover 14, slide rail 15, rack 16, butterfly bolt 17, sealing plate 19, screen plate 21, installation frame 22, dust extraction fan 23, second slider 25, first elastic member 26, filter Net 27, grinding block 28, driving motor 29, fixed frame 30, gear 31, mounting frame 32, the first bearing block 33 and the first rotating shaft 34; The first installation groove 4 is arranged at the bottom of the placement seat 3, and the middle part of the placement seat 3 is opened. There is a placement port 11, and the vacuum generator 6 is fixedly connected to the inner wall of the first installation groove 4; the first air pipe 5 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com