Grain processing device for semiconductor graphite wafer and operation method thereof

A processing device and semiconductor technology, which is used in the manufacture of semiconductor/solid state devices, machine tools suitable for grinding workpiece planes, grinding drive devices, etc. The problems such as the complex fixing method of the circle can reduce labor intensity, improve grinding efficiency, and increase the scope of clamping use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

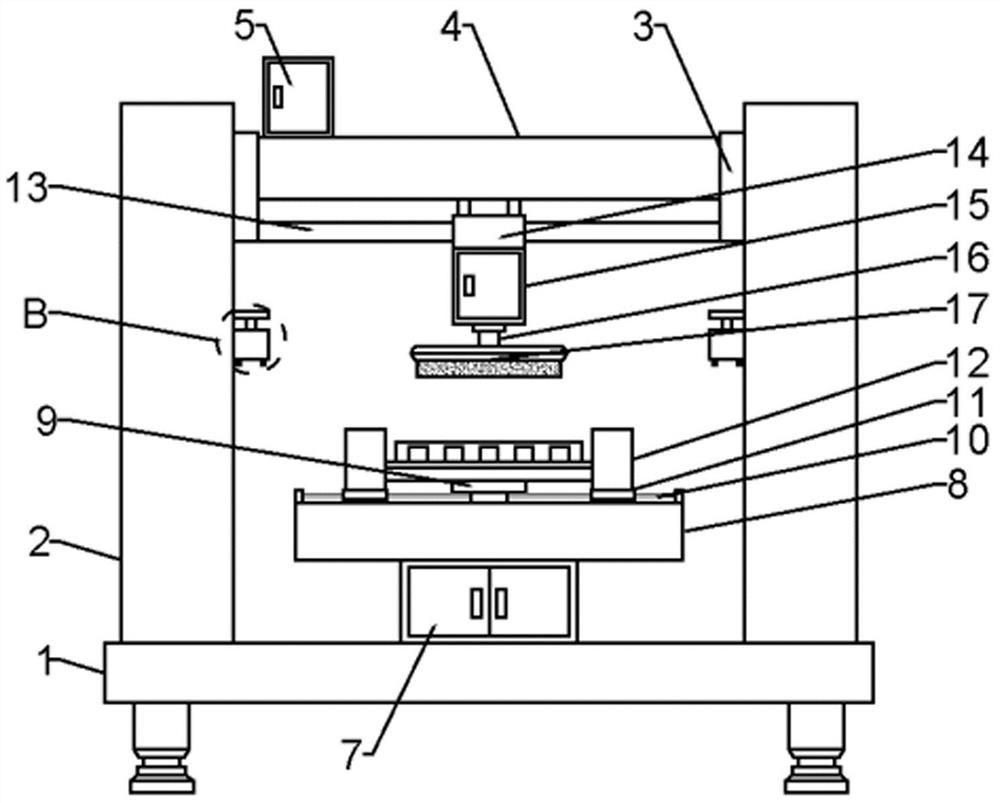

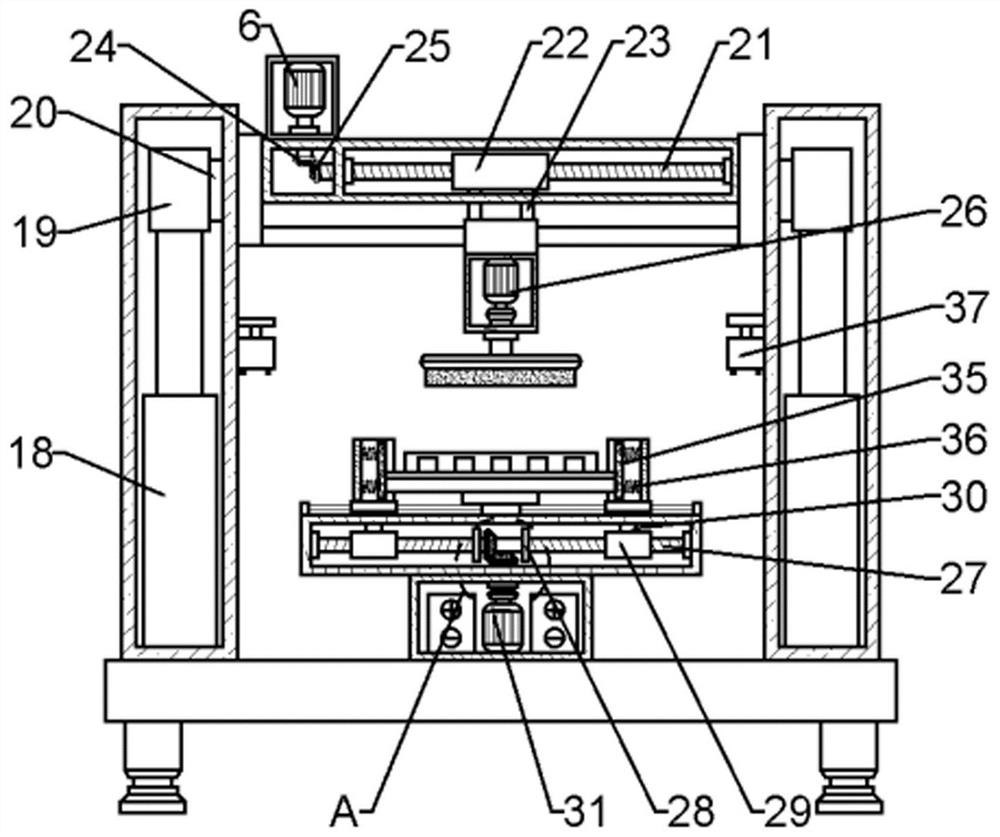

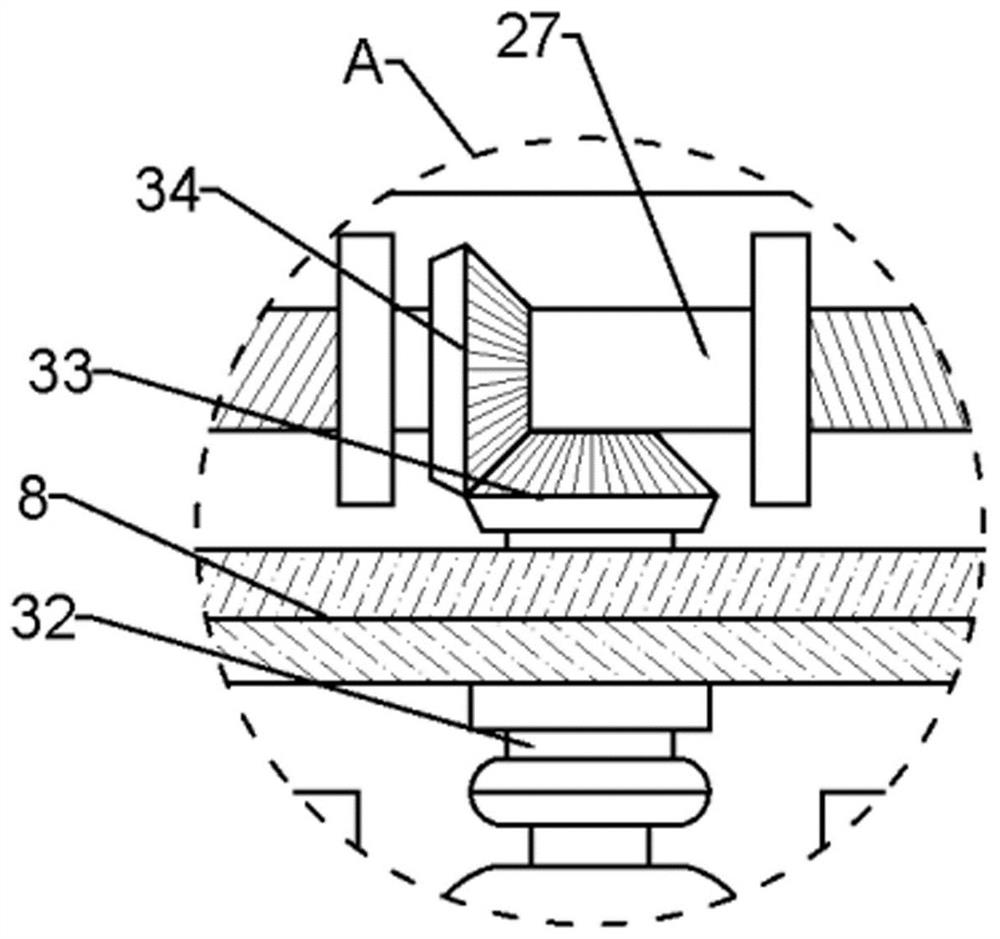

[0030] Example 1: see Figure 1-4 , a grain processing device for semiconductor graphite wafers, comprising a base 1, a column 2 is vertically fixed in the middle of both sides of the top surface of the base 1, and a column 2 is vertically fixed on the upper parts of the inner sides of the two columns 2. Be provided with movable plate 3 to the activity, be provided with crossbeam 4 horizontally on the top between two described movable plates 3, be fixedly provided with motor box 5 in the middle part of one end of the top surface of described crossbeam 4, in described motor box 5 The first motor 6 is vertically fixed inside, and the model of the first motor 6 is T63B4; a rectangular equipment box 7 is fixedly installed in the middle of the top surface of the base 1, and a horizontally fixed equipment box 7 is installed on the top surface of the equipment box 7. There is a rectangular bearing platform 8, a rectangular fixing block is fixed in the middle of the top surface of the...

Embodiment 2

[0036] Example 2: see Figure 5 , in the present embodiment, the present invention also proposes a method for operating a grain processing device for a semiconductor graphite wafer, comprising the following steps:

[0037] Step 1, at first the first motor 6, the electric push cylinder 18, the second motor 26 and the third motor 31 are respectively electrically connected to the storage battery through wires, and the wafer plate is placed on the top surface of the rubber pallet 9, and then according to The size of the wafer plate is adjusted to the distance between the curved splints on both sides;

[0038] Step 2, drive the driving bevel gear 33 at the top of the drive shaft 32 to rotate by controlling the third motor 31, drive the rotating rod 27 to rotate through the meshing transmission of the driving bevel gear 33 and the driven bevel gear 34, and rotate through the driving bevel gear 33 on the rod body of the rotating rod 27. The forward thread and the reverse thread driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com