A grinding and screening device for flour production and processing

A screening device and flour technology, applied in the fields of sieves, solid separation, chemical instruments and methods, etc., can solve the problems of high noise of the vibrating sieve plate, easy clogging of the sieve plate, inconvenient cleaning, etc., to reduce extrusion wear and improve the sieve. Efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed description is given in conjunction with specific embodiments and accompanying drawings.

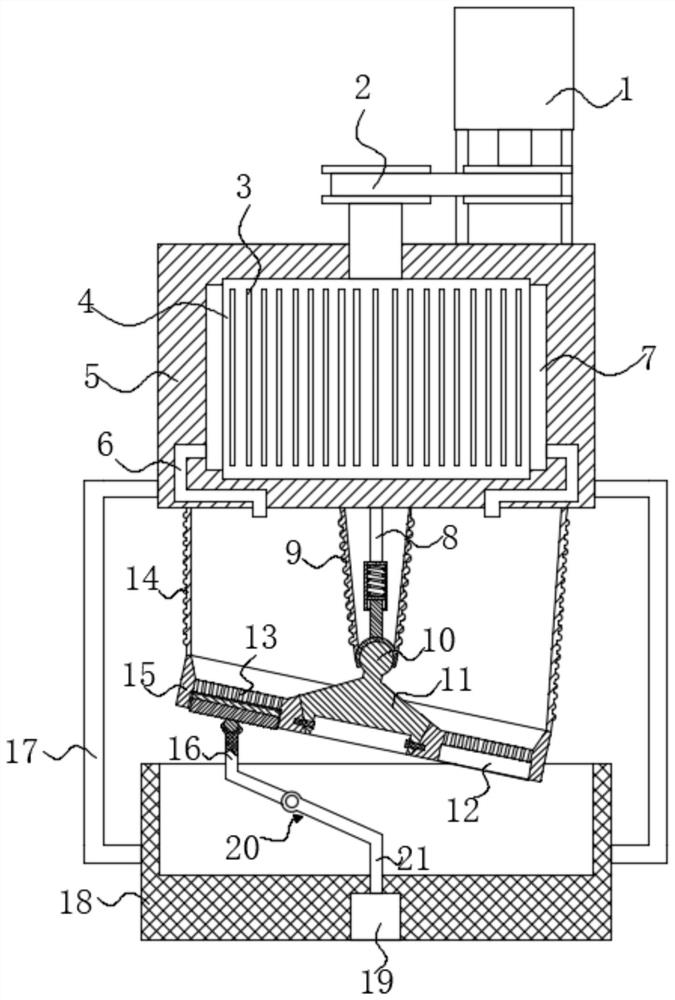

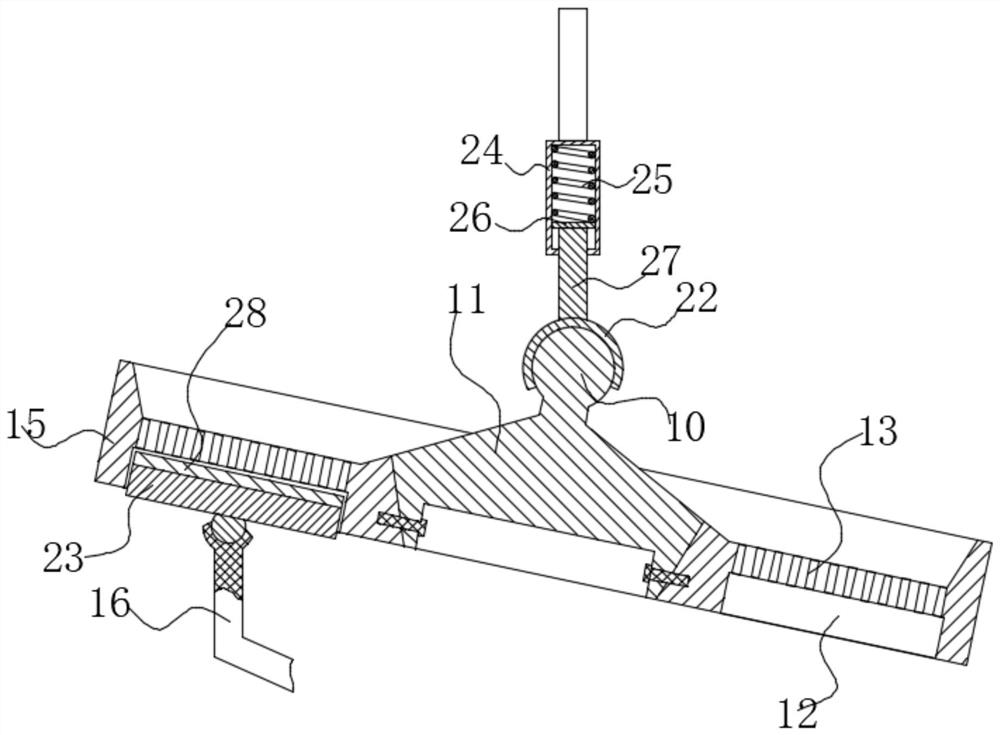

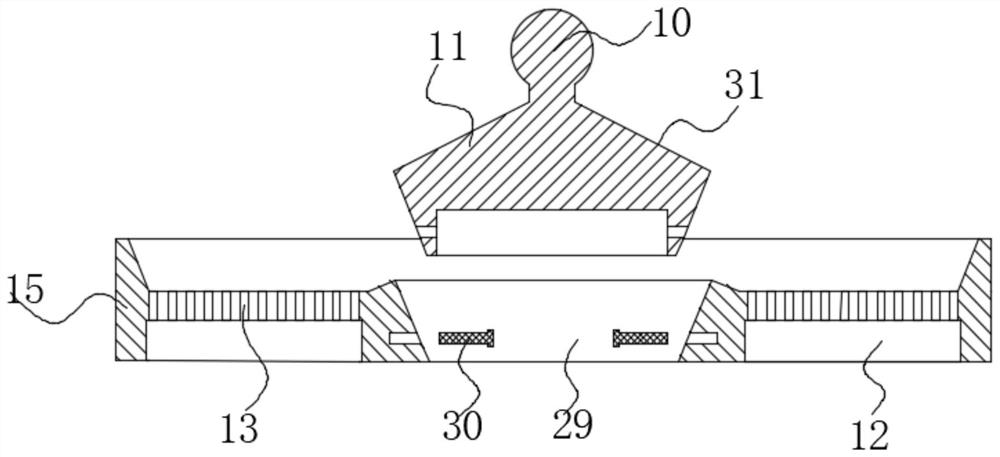

[0026] see figure 1 , In this embodiment, a grinding and screening device for flour production and processing includes a collecting box 18, a grinding box 5 and a screening box 15, the grinding box 5 is fixedly installed on the top of the collecting box 18 through a bracket 17, and the A grinding drum 4 is installed in the grinding box 5 along the vertical axis. A grinding cavity 7 is formed between the inner wall of the grinding box 5 and the grinding drum 4. The feeding pipe 6 is pierced through the bottom of the grinding box 5. Preferably, the feeding pipe 6 is embedded on the inner wall of the grinding box 5, and the top of the grinding box 5 is fixedly installed with a first A motor 1, the first motor 1 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com