A bending device for hatch cover processing

A bending device and hatch cover technology, applied in the field of hatch cover bending, can solve problems such as damage to the internal structure of the hatch cover, change of hatch cover toughness, and inability to realize functions, so as to improve the use value, protect the internal structure and Toughness, the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

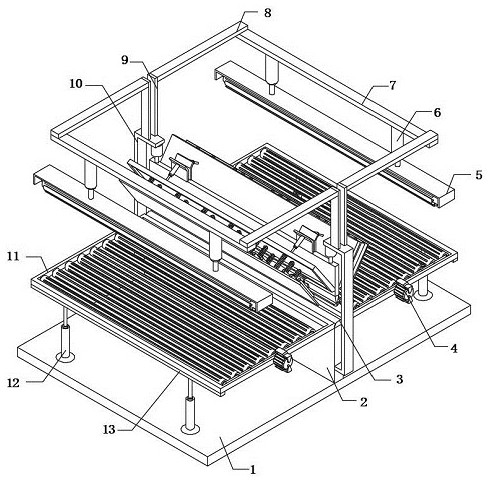

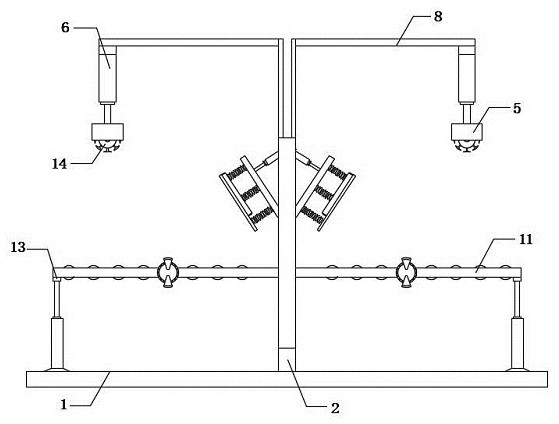

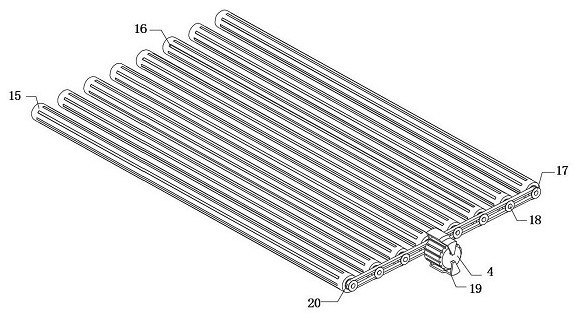

[0030] refer to Figure 1-4, a bending device for hatch cover processing, including a bending table 1 and an extrusion frame 11, the inner walls on both sides of the two extrusion frames 11 are connected with rotating shafts 18 at equal distances through bearings, and the outer walls of each rotating shaft 18 are fixed. A sliding bending roller 15 is connected, the outer wall of the sliding bending roller 15 is provided with installation holes equidistantly, and the inner wall of each installation hole is fixedly connected with a heat conduction rod 16, and the outer walls of a plurality of heat conduction rods 16 are fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com