Cutter grinding machine

A knife sharpening machine and sharpening stone technology, applied in the direction of grinding workpiece supports, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of manual hand-held kitchen knives, unsatisfactory effect, operator injury, etc. It is easy to observe the sharpening state and improve the safety effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

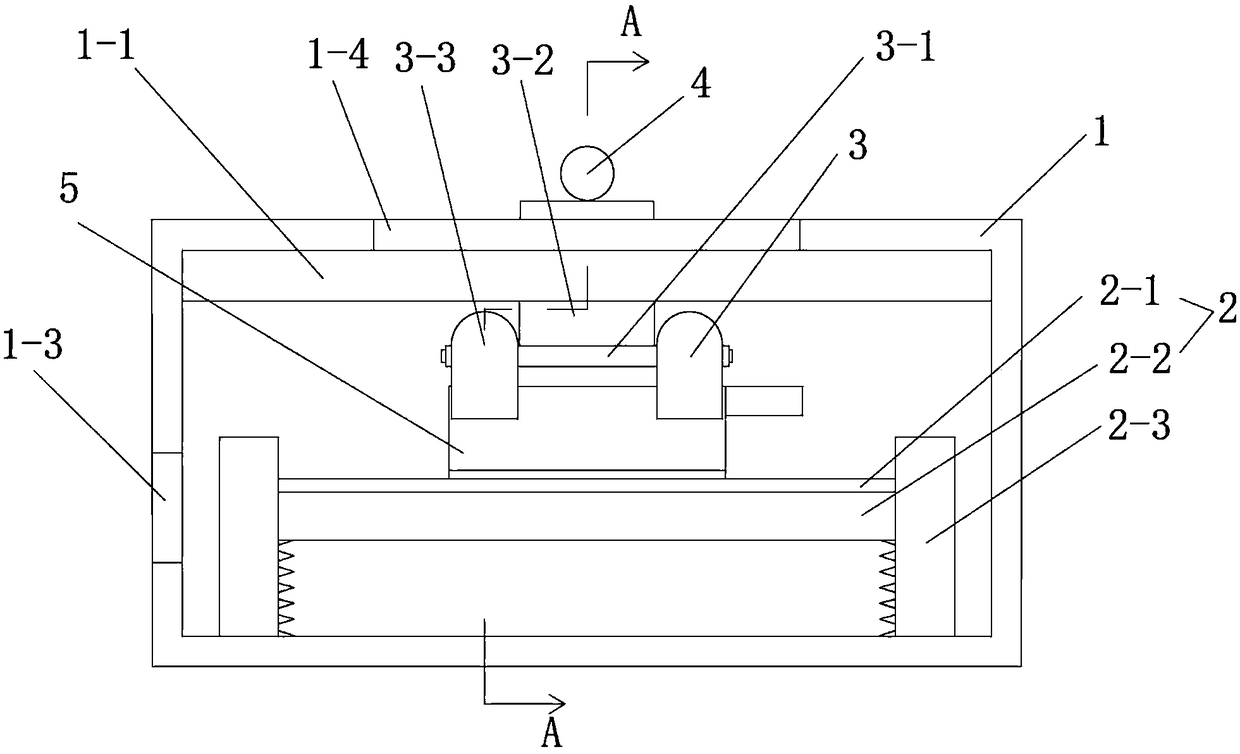

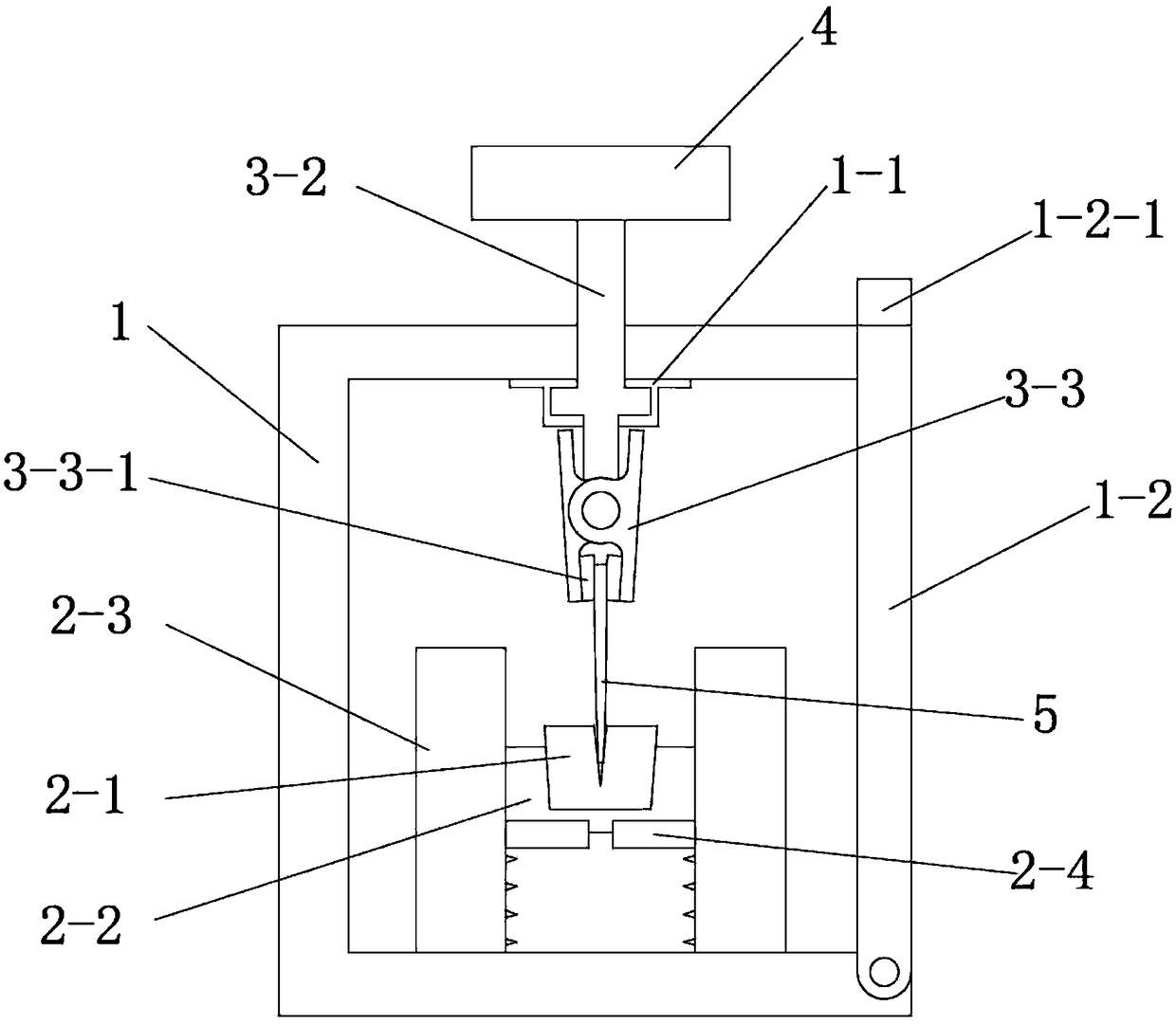

[0051] See Figure 1 to Figure 4 , The knife sharpener of this embodiment includes a chassis 1, a knife sharpening assembly 2, a clamping device 3 and a handle 4. One side of the case 1 is open, and a protective cover 1-2 is rotatably connected. The bottom of the protective cover 1-2 is rotatably connected with the bottom of the open side of the cabinet 1. The inner top of the protective cover 1-2 is provided with an iron plate. The top of the open side of the cabinet 1 is provided with a magnet corresponding to the position of the iron sheet on the protective cover 1-2. In order to open or close the protective cover 1-2 conveniently, a handle 1-2-1 is provided on the top of the protective cover 1-2. The knife sharpening assembly 2 and the clamping device 3 are slidably arranged on the top of the cabinet 1 and directly above the knife sharpening assembly 2 . The sliding direction of the clamping device 3 is consistent with the length direction of the sharpening assembly 2 ...

Embodiment 2

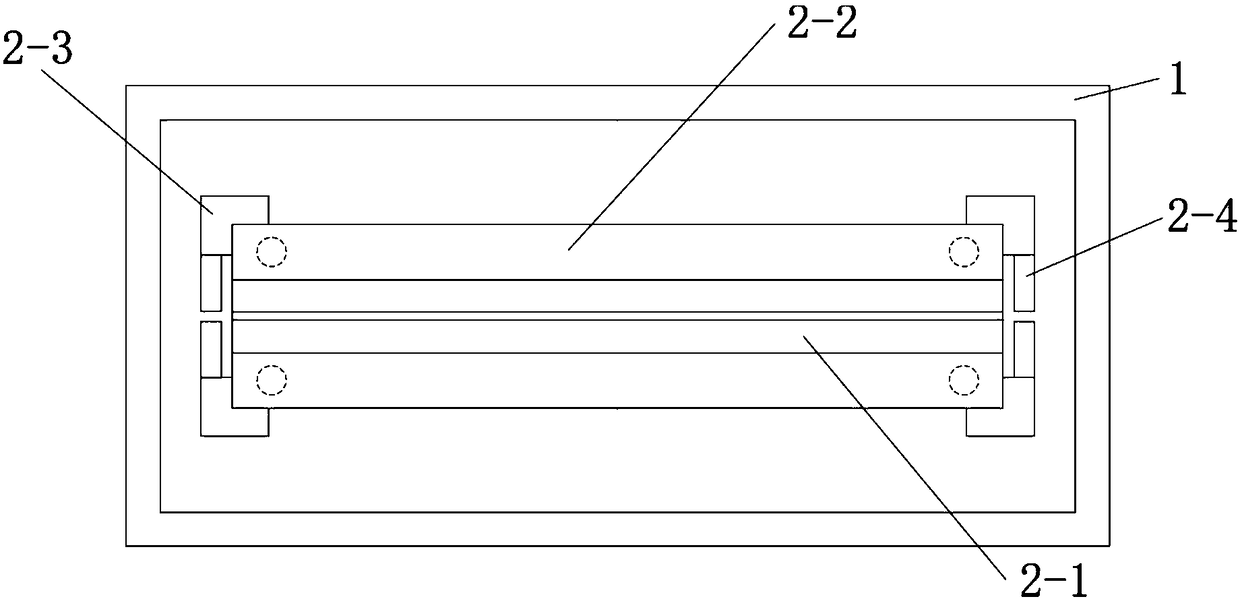

[0056] See Figure 5 , This embodiment is basically the same as Embodiment 1, except that the cross section of the guide post 2-3 is W-shaped. Compared with Embodiment 1, this embodiment adds two sliding surfaces, so that the sliding of the whetstone mounting base 2-2 is more stable.

[0057] The working principle of this embodiment: the present invention realizes the continuous grinding of the kitchen knife through the V-shaped groove on the whetstone and the spring between the bottom of the whetstone mounting seat 2-2 and the bottom of the cabinet 1, and the cutting edge Gradually thinning, the spring slowly bounces the whetstone 2-1, so that the cutting edge of the kitchen knife can be sharpened more and more sharply. First, press the whetstone mounting seat 2-2 until the spring is compressed to the maximum state, turn the limit stop 2-4 to the top of the whetstone mounting seat, release your hand, and under the action of the spring, the limit stop 2 -4 Restrict the upwar...

Embodiment 3

[0059] See Figure 6 , This embodiment is basically the same as Embodiment 1, except that the handle 1-2-1 is replaced by a handle groove 1-2-2 arranged on the top of the front end of the protective cover 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com