Maintaining device for mold

A mold and shell technology, applied in the field of mold maintenance devices, can solve the problems of unfixed mold position, low work efficiency, abrasive tool damage, etc., and achieve the effects of improving grinding and rust removal efficiency, fast and convenient cleaning, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

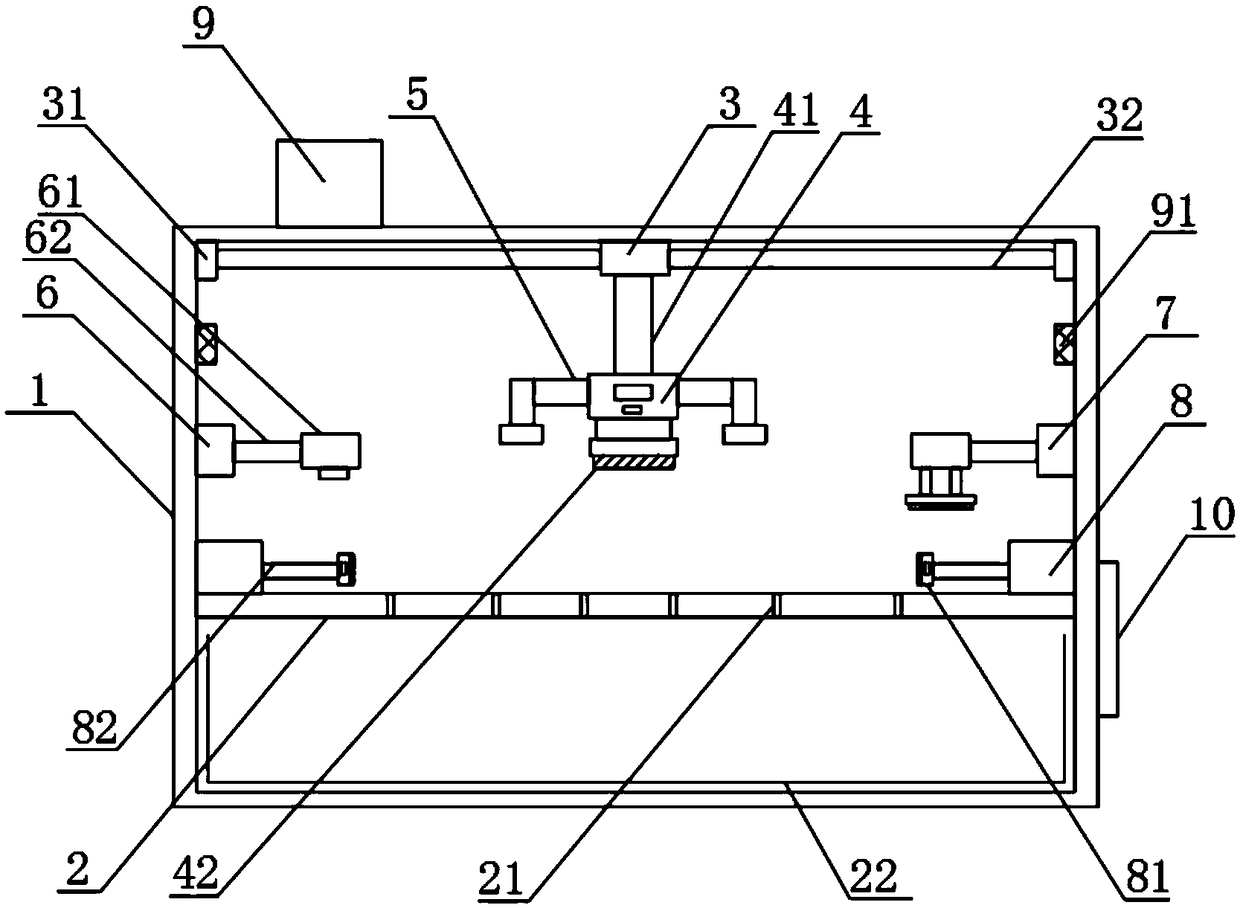

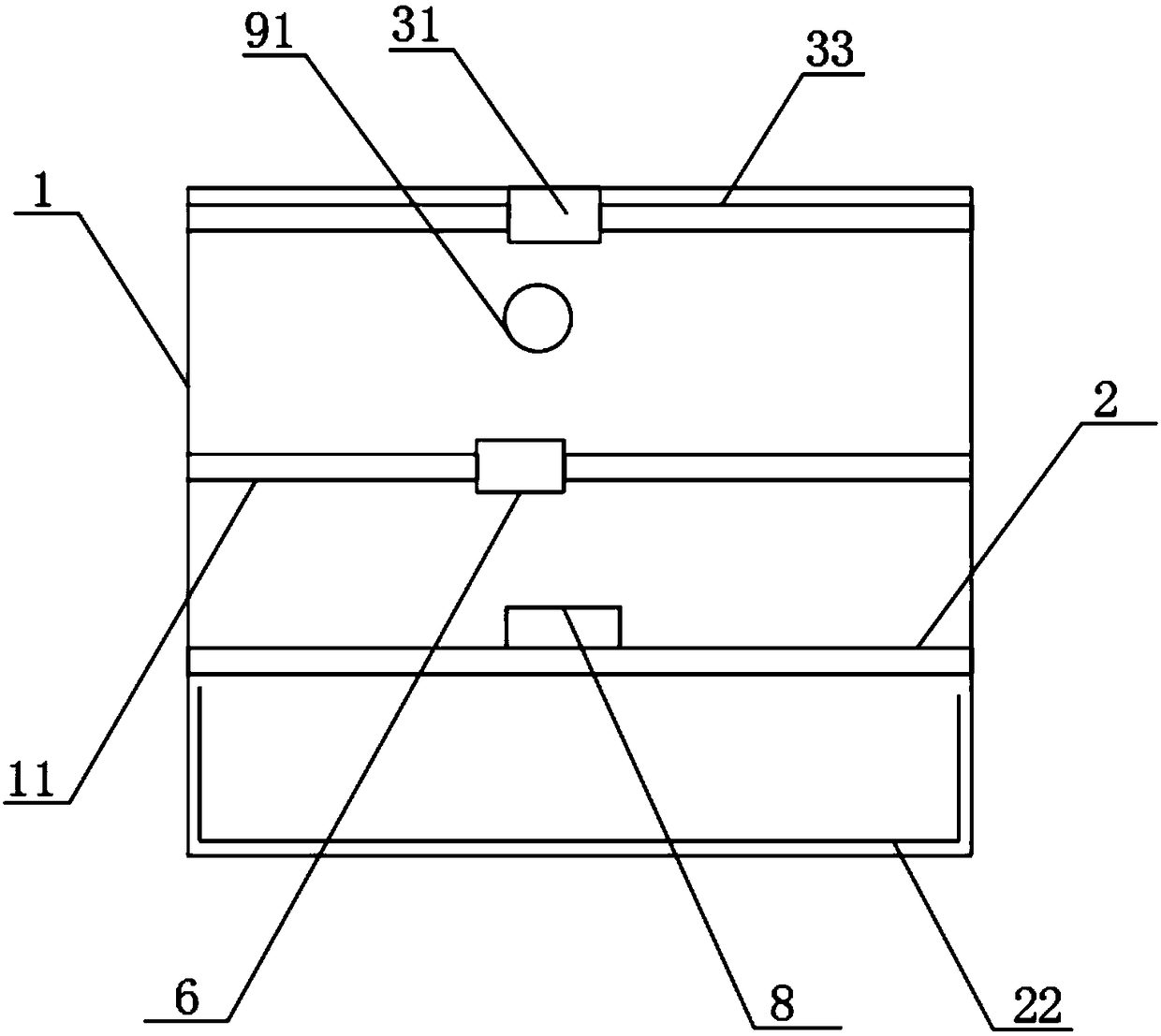

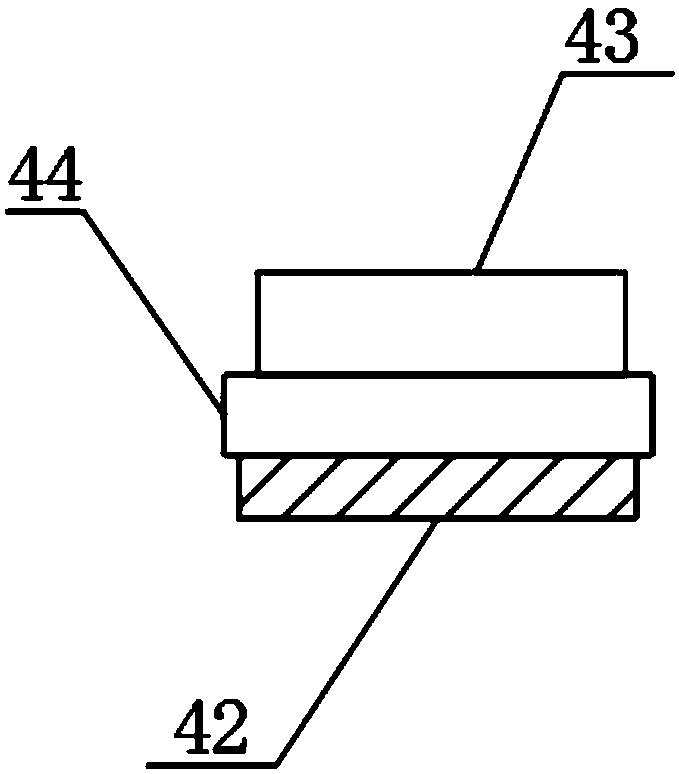

[0026] The present invention provides such as Figure 1-5 The maintenance device for a mold shown includes a housing 1, a working panel 2 is provided inside the housing 1, a first sliding block 3 is provided on the top of the inner wall of the housing 1, and a first sliding block 3 is provided on the bottom of the first sliding block 3. A lifting seat 4 is provided, dust blowing devices 5 are provided on both sides of the lifting seat 4, a side block 6 is provided on one side of the inner wall of the housing 1, and a smearing device 7 is provided on the other side of the inner wall of the housing 1, The top of the working panel 2 is provided with a fixing seat 8 , the side blocks 6 and the application device 7 are both arranged on the top of the fixing seat 8 , and the top of the housing 1 is provided with a water storage chamber 9 .

[0027] Both sides of the first sliding block 3 are provided with a second sliding block 31, the second sliding block 31 is arranged on both sid...

Embodiment 2

[0033]A pressure plate 81 is provided on one side of the fixed base 8, and a pressure pad is provided on the outside of the pressure plate 81. A sixth electric push rod 82 is provided between the fixed base 8 and the pressure plate 81, and the sixth electric push rod 52 pushes the pressure plate 51. The movement can fasten the position of the mold that needs to be maintained from the side to facilitate the polishing work on the top. The surface of the pressing plate 81 is provided with an infrared generator, and the surface of the lifting seat 4 is provided with an infrared receiver. The infrared generator Matching with the infrared receiver, the outer side of the housing 1 is provided with a touch screen 10, the surface of the lifting seat 4 is provided with a camera, and the front and rear sides of the side block 6 are provided with a seventh electric push rod 11, The seventh electric push rod 11 is arranged on the front side and the rear side of the fixed block 71, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com