Patents

Literature

31results about How to "Does not affect whiteness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

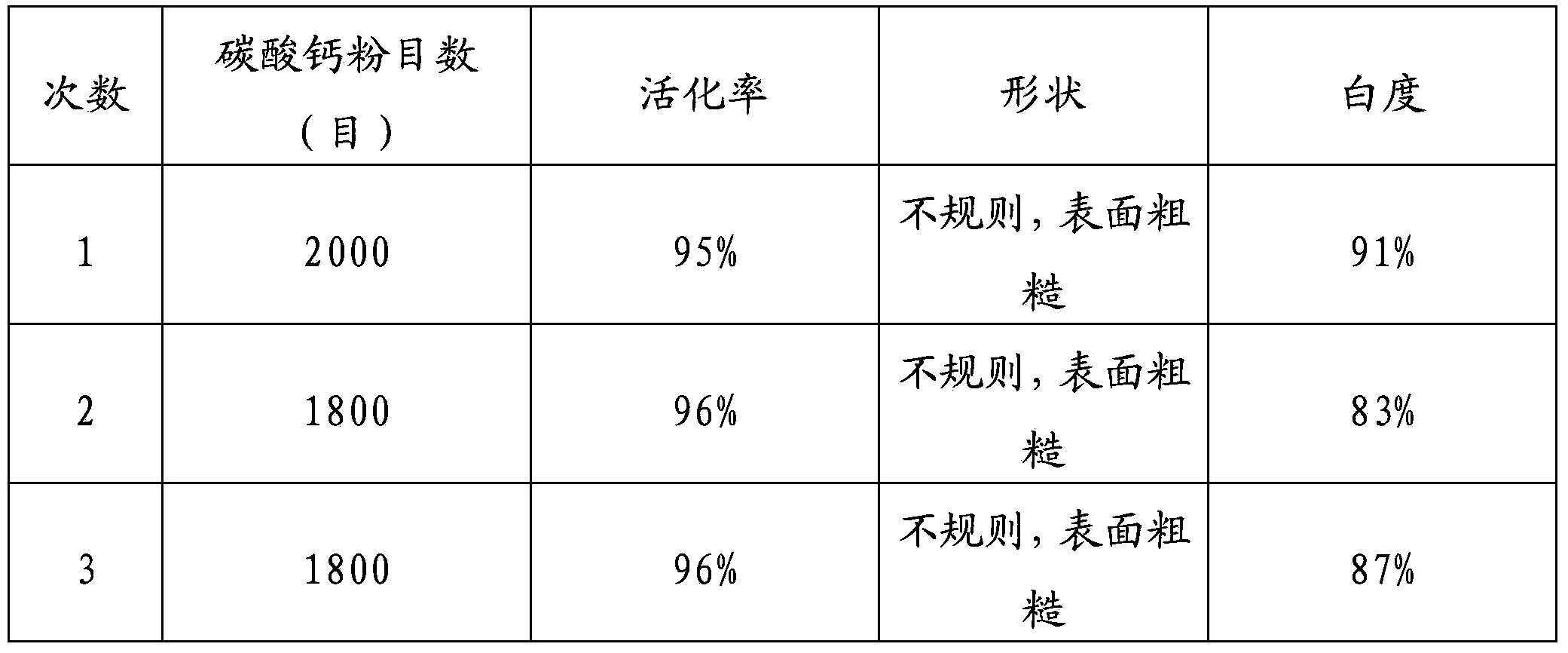

Preparation method of superfine modified ground limestone

ActiveCN103232732AConvenient grinding workImprove grinding effectPigment treatment with macromolecular organic compoundsPigment physical treatmentMaterials scienceSlurry

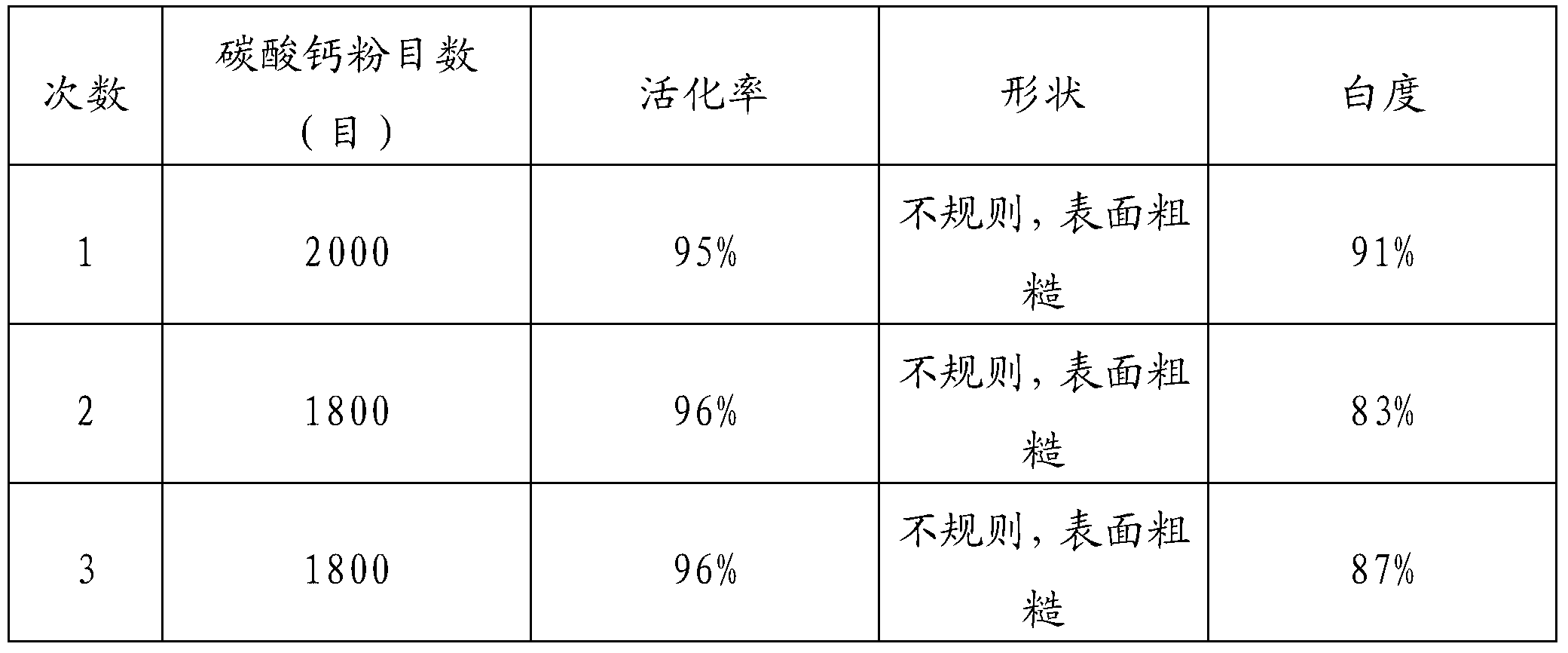

The invention relates to a preparation method of superfine modified ground limestone. The preparation method of the superfine modified ground limestone comprises the following steps of: (1) steeping slurry; (2) grinding in a four-level wet-method grinding manner; (3) drying: carrying out spray drying on the slurry by using a spray drying device; and (4) modifying: grinding and dispersing the collected ground limestone powder by a dry method at the grinding rate of 1460r / min, and adding modifiers in the grinding process so as to obtain the superfine modified ground limestone. By using the four-level wet-method grinding manner and a method of modifying subjected to drying, the problem of waste of modifiers during liquid modification is solved, and the activating rate and whiteness of the product are improved.

Owner:潍坊双冠新材料有限公司

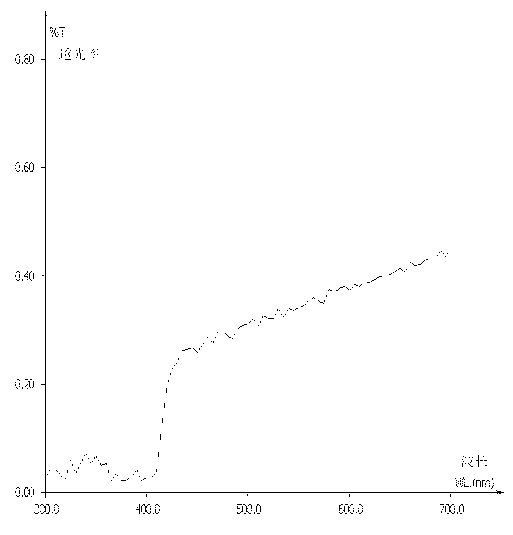

Modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of anti-ultraviolet finishing agent

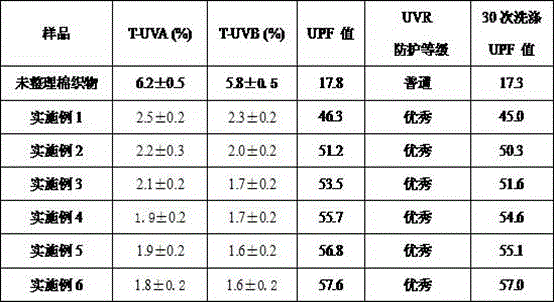

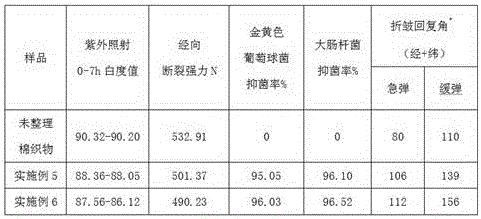

The invention provides a modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of the anti-ultraviolet finishing agent. The modified-chitosan-containing anti-ultraviolet finishing agent for the cotton fabric is a uniformly mixed solution of 3,4,5-trimethoxybenzoyl chitosan, a crosslinking agent, a penetrant and an acetic acid or lactic acid solution, wherein the crosslinking agent is organic polycarboxylic acid or amino-modified silicone oil emulsion; the penetrant is either JFC or peregal O. The anti-ultraviolet cotton fabric with anti-ultraviolet, anti-bacterial and anti-crease finishing functions is obtained through double-dip double-nip, water washing and drying, the anti-ultraviolet, anti-bacterial and anti-crease finishing functions are high in durability, the cotton fabric still maintains the original style of the fabric after finishing, the hand feel, the strength, the whiteness and the color of the cotton fabric are not affected, and the original human body affinity is maintained; the finishing agent is simple in composition and easy to prepare, and a finishing process is simple and environment-friendly.

Owner:EASTERN LIAONING UNIV

Process for printing QS quality safety sign on gold card paper

InactiveCN101670720AImprove ink absorptionImprove adhesionPattern printingOther printing apparatusSpot colorQuality safety

The process relates to a process for printing a QS quality safety sign on gold card paper, which comprises the following steps: 1, carrying out computer color separation on a QS sign pattern to be printed, and separately making an electronic file with all edges longer than the size of a white pattern; 2, making 3 films by using the file made in the step 1; 3, carrying out plate burning by using the films in the step 1 to make 3 corresponding printing plates; 4, installing the printing plates obtained in the step 3 on an offset press; 5, pouring a shell-lac alcoholic solution and water in a first machine set; pouring white ink and a fountain solution in a second machine set; and pouring spot blue ink and the fountain solution in a third machine set; 7, installing ultraviolet light tubes between the first machine set and the second machine set, between the second machine set and the third machine set and behind the third machine set; 8, printing shell-lac by the first machine set, printing the white ink by the second machine set, and printing the spot blue ink by the third machine set, and then obtaining a QS sign printing product. The process has the advantages of convenient printing, less process faults, flat and smooth ink layers and good handfeel.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation of a novel organic / inorganic composite sizing system

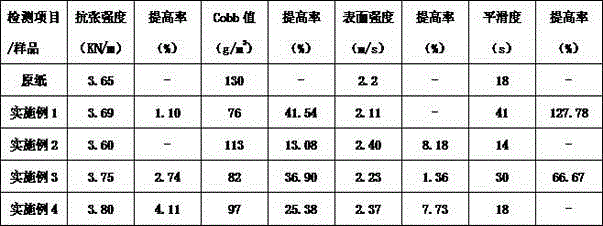

ActiveCN106283869ADoes not affect whitenessDoes not affect the degree of sizingWater-repelling agents additionReinforcing agents additionChemistrySurface strength

The invention discloses a novel surface sizing system--chitosan / silica sol double sizing system: it combines the degraded chitosan with silica sol to form a stable complex system of organic matter and inorganic matter. The mass ratio of sugar to silica sol is 2: 3 - 1: 9. Water-soluble chitosan is prepared by hydrogen peroxide oxidation degradation method. Silica sol is synthesized by the dissolving method of monatomic silicon. The new paper making agent formed by the compounding is applied to the surface sizing of cultural paper. it can obviously promote the water resistance on the paper surface, surface strength, the degree of internal bonding, galling speed and other properties, improving printing performance and meanwhile reducing the cost of sizing.

Owner:GUANGDONG PAPER IND RES INST

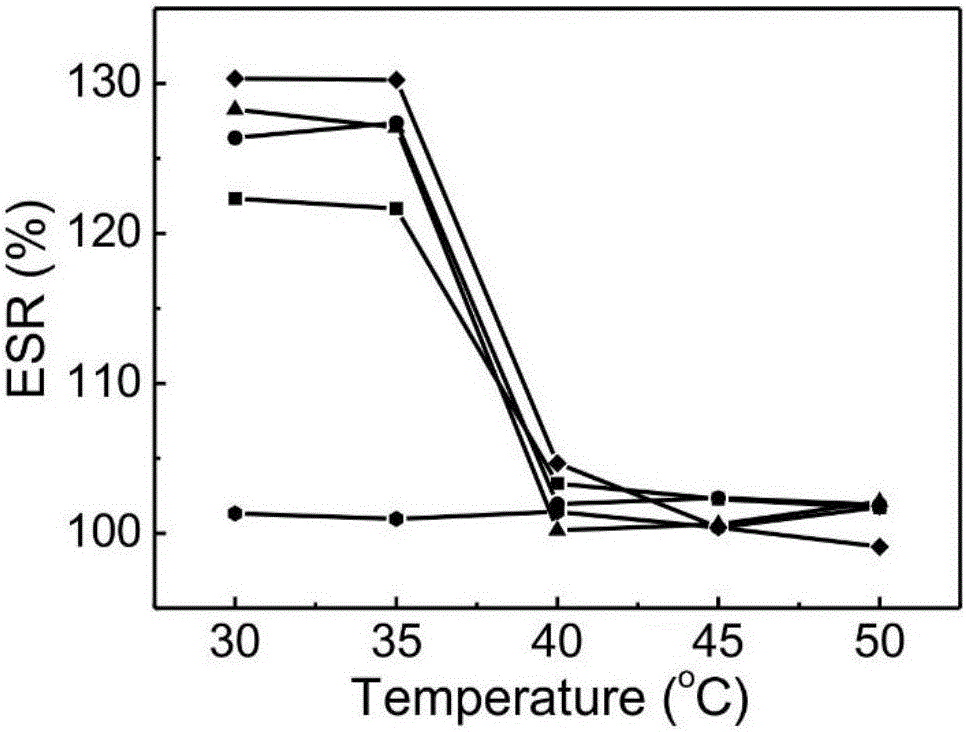

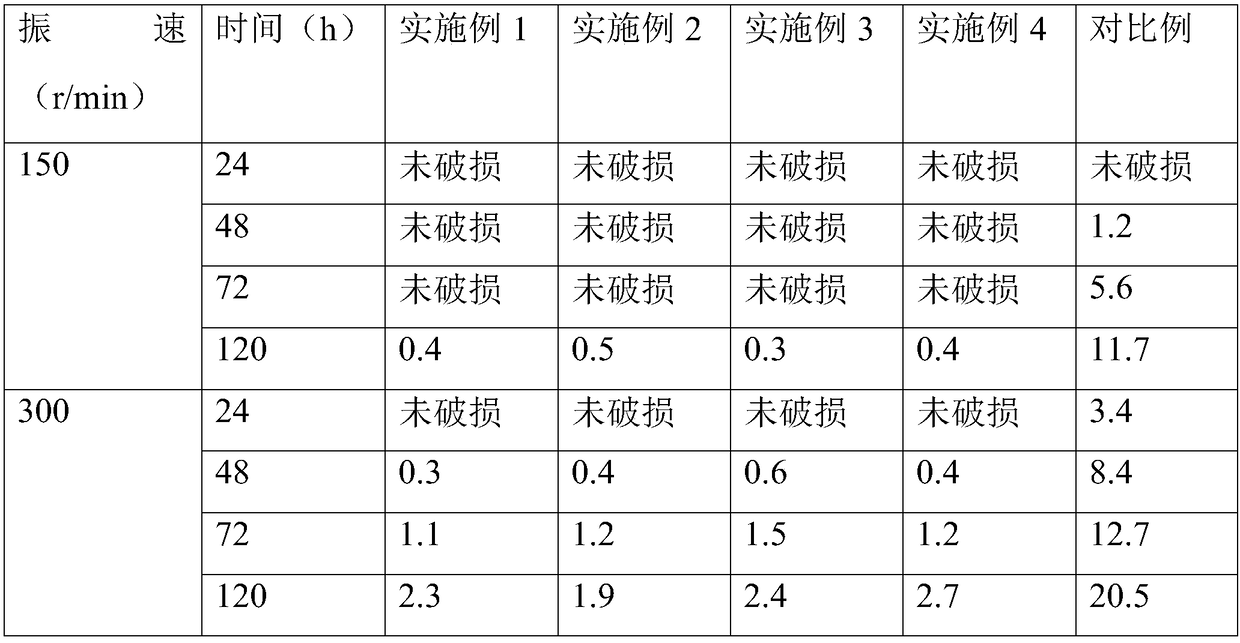

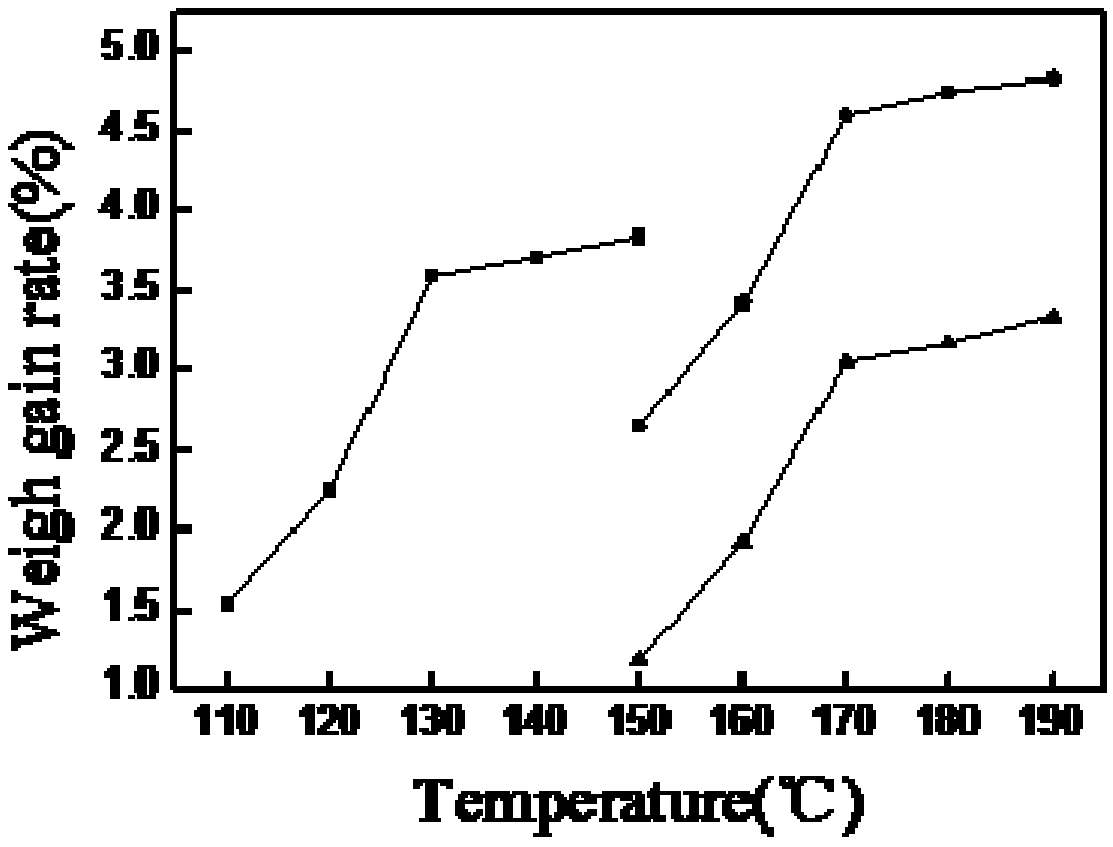

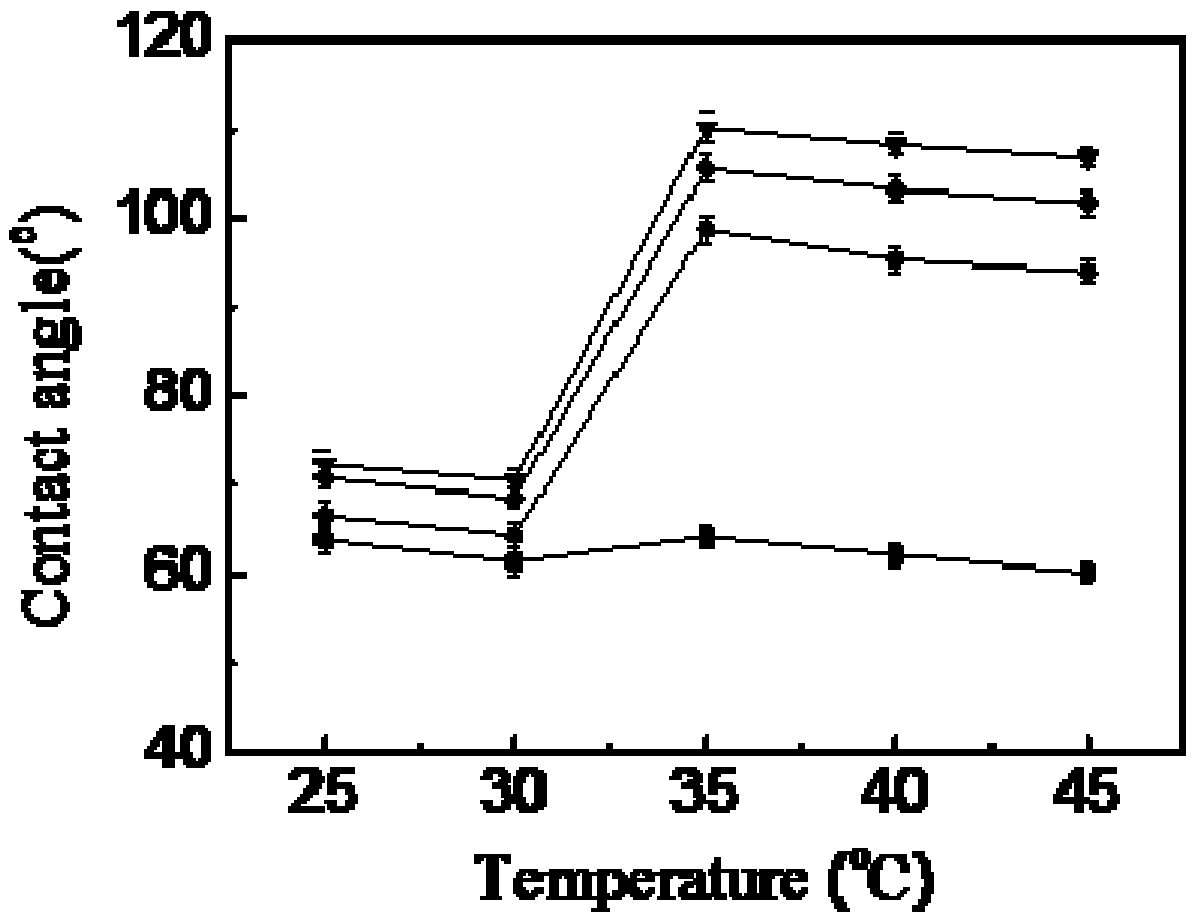

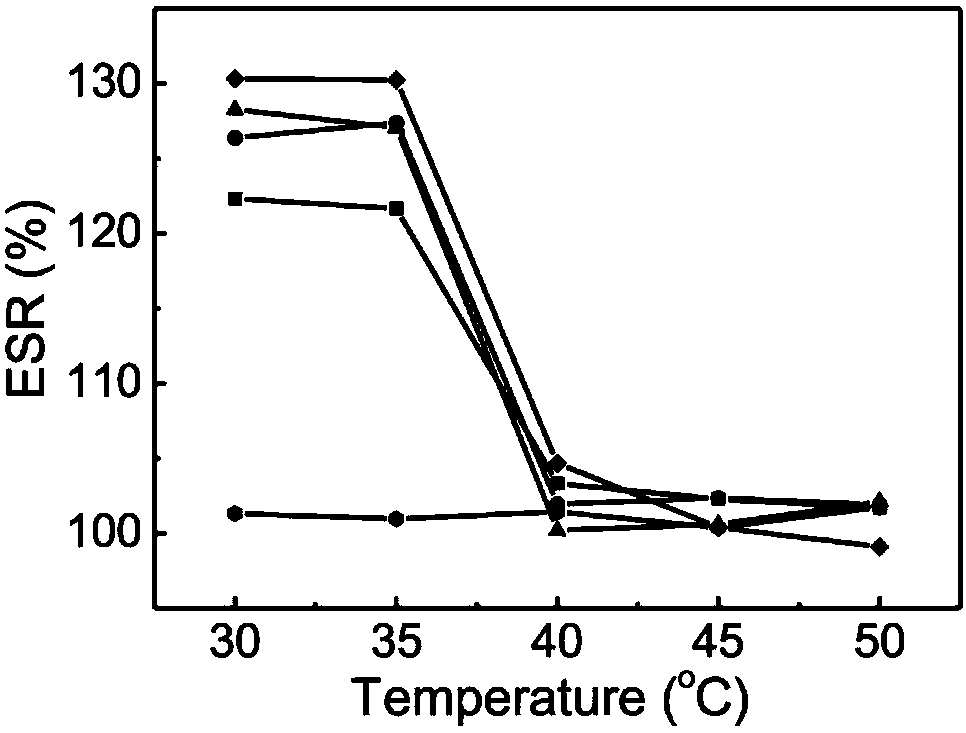

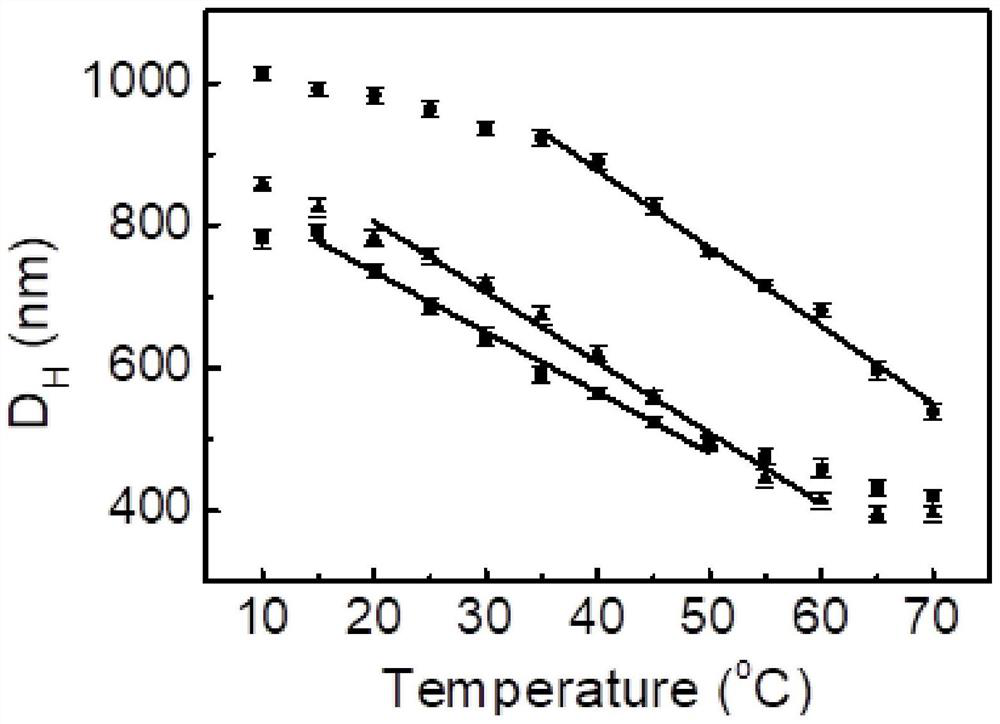

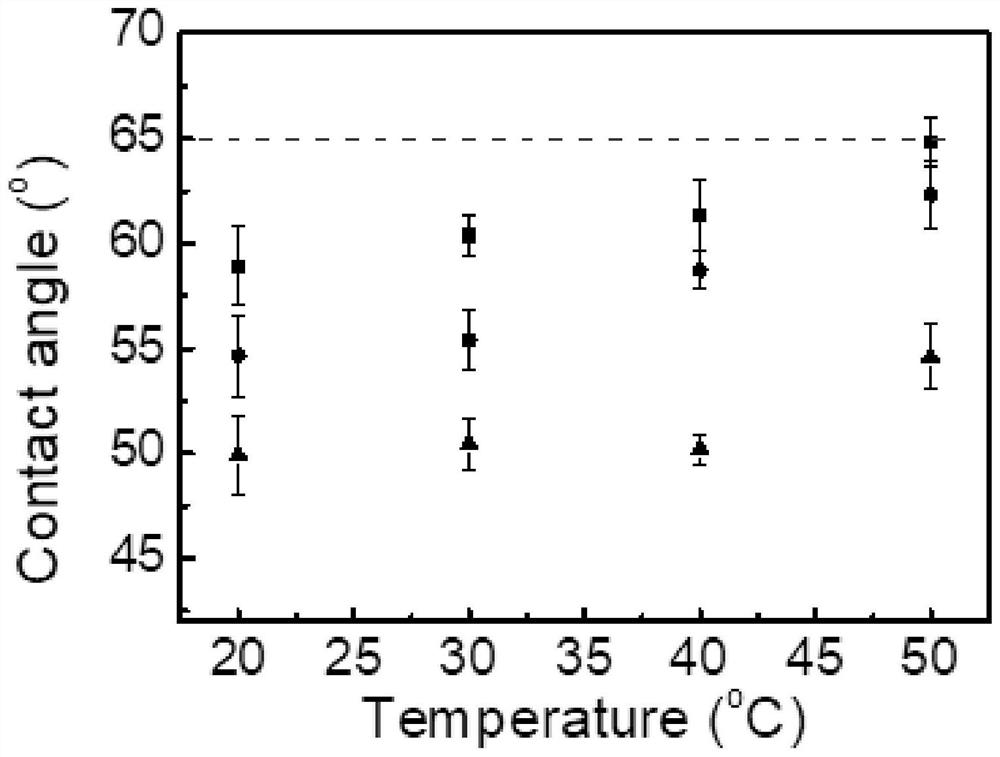

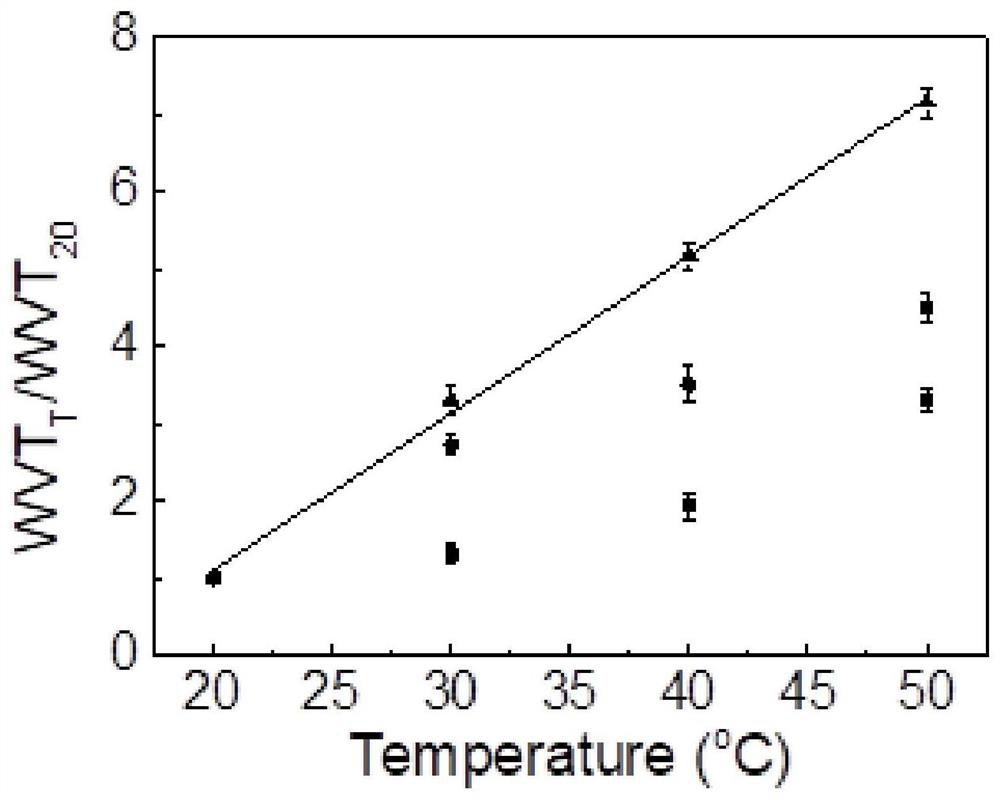

Method for realizing textile intelligent cleaning function through crosslinking temperature-sensitive copolymer

ActiveCN105803762ARealize intelligent cleaning functionRealize self-cleaning functionVegetal fibresAnimal fibresCooking & bakingSide chain

The invention discloses a method for realizing a textile intelligent cleaning function through a crosslinking temperature-sensitive copolymer. The method comprises the following steps of (1) using the temperature-sensitive copolymer, a crosslinking agent, a catalyst and a solvent to process a textile; (2) carrying out crosslinking reaction on the processed textile through heating and baking. According to the method for realizing thetextile intelligent cleaning function through the crosslinking temperature-sensitive copolymer provided by the invention, the cleaning efficiency of the textile during the washing process is improved, and the self-cleaning effect is achieved during the wearing process; the operation can be carried out conveniently without influencing the original whiteness and flexibility; a covalent bond is formed through reaction of a reactive functional group contained in an acrylate monomer with the reactive functional group at the tail end of a side chain in the temperature-sensitive copolymer and a reactive functional group on the surface of the textile with carboxyl contained in the crosslinking agent, and the temperature-sensitive copolymer is fixed on the surface of the textile, so that the modified textile has a function of hydrophily / hydrophobicity intelligent adjustment.

Owner:ZHEJIANG SCI-TECH UNIV

Preparing method of using marble wastes to recycle heavy calcium powder

ActiveCN106497143ASimple processEasy to operatePigment flushingCoatingsScrapEnvironmentally friendly

The invention relates to a preparing method of using marble wastes to recycle heavy calcium powder. The preparing method comprises the steps of material selecting, cleaning, airing, crushing, screening through vibration, ball-milling and grading. The preparing method is simple in technology and convenient to operate, achieves recycling and reuse of the marble wastes so as to turn waste into wealth, saves investment cost and mineral resources, and is very environmentally friendly.

Owner:SICHUAN YINGJING KAIQUAN INDAL

Textile stabilizer

InactiveCN103924438ADoes not affect whitenessDoes not affect the feelFibre treatmentBleaching apparatusStearic acidEthyl acetate

The invention discloses a textile stabilizer. The textile stabilizer comprises the following components by weight: 3-5 parts of sodium silicate, 1-3 parts of stearic acid, 2-6 parts of sodium hexametaphosphate, 6-8 parts of polyoxyethylene octyl benzyl alcohol, 3-6 parts of polyacrylamide, 3-5 parts of ethyl acetate, 10-20 parts of poly propylene glycol, 1-3 parts of magnesium peroxysulphate, 10-20 parts of ethanol and 300-500 parts of water. Compared with the prior art, the textile stabilizer has the following advantages: (1) the textile stabilizer has very significant effect on the stability of hydrogen peroxide, also has the effect of an assistant scouring agent; (2) the textile stabilizer is low in price, does not affect the whiteness and handle of fabrics, and may not produce silica scales; and (3) the textile stabilizer can be evenly dispersed in solutions to make the fabrics soft in hand feeling.

Owner:SUZHOU FANGRAN TEXTILE

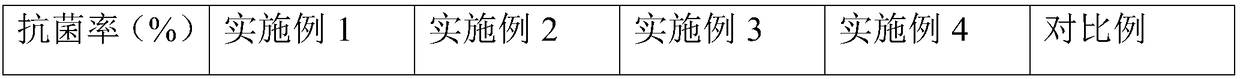

Polyhexamethylene biguanide hydrochloride compound microencapsulated antibacterial finishing agent and preparation method thereof

InactiveCN109371698AImprove antibacterial propertiesGood effectBiochemical fibre treatmentMicroballoon preparation4-isopropylphenolCopper

The invention relates to a polyhexamethylene biguanide hydrochloride compound microencapsulated antibacterial finishing agent and a preparation method thereof. The antibacterial finishing agent comprises a core material and a shell material; the core material comprises polyhexamethylene biguanide hydrochloride, nanometer copper ions, 3-methyl-4-isopropylphenol, a dispersant, an emulsifying agent and a stabilizer; and the shell material is a mixed biological adhesive material composed of a synthesized biological adhesive material and chitosan. The antibacterial finishing agent has high efficiency, wide spectrum and washing resistance to various fabrics and is high in safety, simple in preparation process and low in cost.

Owner:福州盛世凌云环保科技有限公司

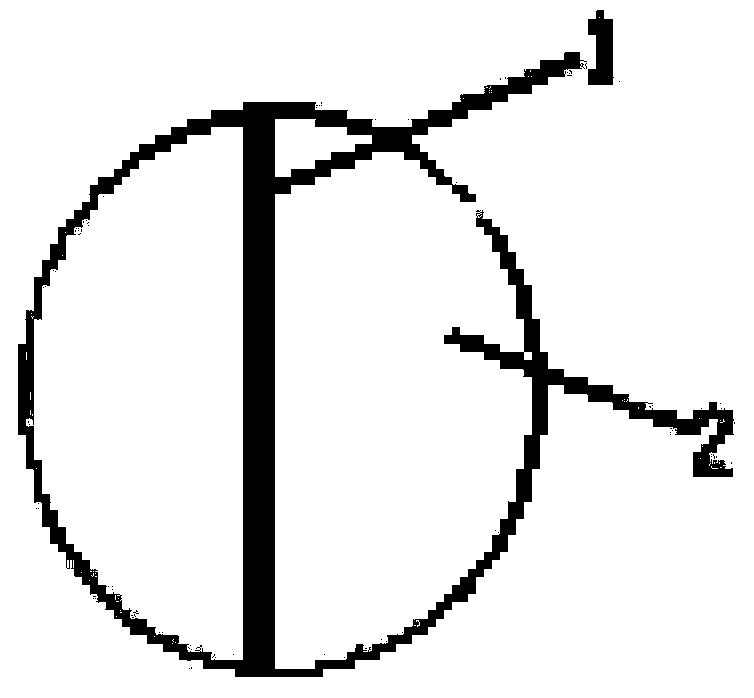

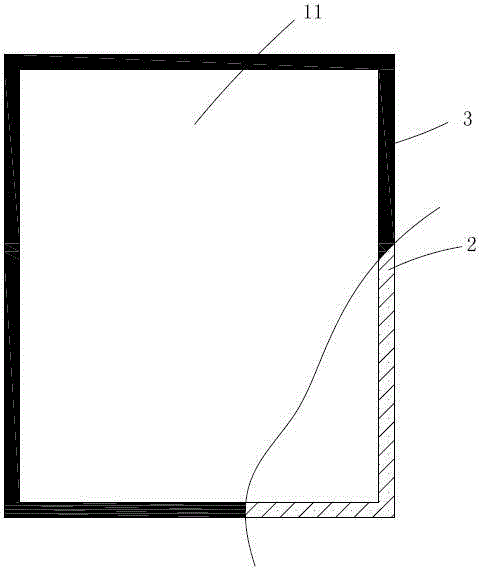

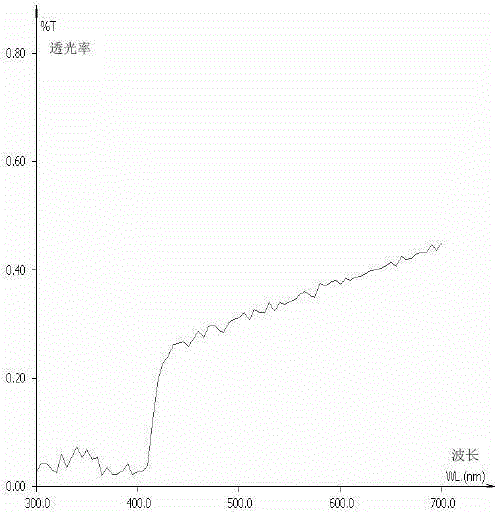

Mobile phone lens and printing method thereof

ActiveCN102756579AIncrease coverageDoes not affect whitenessOther printing apparatusComputer scienceMechanical engineering

The invention provides a printing method of a mobile phone lens. The printing method includes the steps: firstly, providing a mobile phone lens substrate and a film for displaying patterns to be printed; secondly, manufacturing a first screen and a second screen by the aid of the film; thirdly, printing frosted cream on the mobile phone lens substrate by the aid of the first screen to obtain the mobile phone lens substrate with a frosted surface; and fourthly, printing white ink on the mobile phone lens substrate with the frosted surface by the aid of the second screen. The invention further provides a mobile phone lens obtained by the printing method. The covering rate of the mobile phone lens manufactured by the printing method of the mobile phone lens is obviously increased, and whiteness of the white ink is unaffected.

Owner:BYD CO LTD

Method for reducing preparation cost and improving cleaning efficiency by increasing crosslinking efficiency

The invention discloses a method for reducing preparation cost and improving cleaning efficiency by increasing crosslinking efficiency, comprising the following steps: 1) treating a textile material with a mixed solution of a temperature sensitive copolymer, a crosslinking agent, a catalyst and a solvent; wherein the mixed solution comprises the following raw materials (by mass percent concentration): 0.1-50% of a temperature sensitive copolymer; 1-12% of a crosslinking agent; 0.1-12% of a catalyst, and the balance a solvent; 2) heating and baking the treated textile to carry out a cross-linking reaction. A cross-linked structured system composed of the fiber-crosslinking agent-temperature sensitive polymer is formed, and the temperature-sensitive polymer is fixed on the surface of the textile. The method is convenient to operate, original whiteness and flexibility of the textile will not influenced, and crosslinking efficiency and temperature sensitivity of the smart textile can be enhanced. And then, the cleaning effect of the smart cleaning textile is enhanced and the costs are reduced.

Owner:ZHEJIANG SCI-TECH UNIV

White cement grinding aid

InactiveCN110316991AImprove grinding efficiencyReduce energy consumptionCement grindingEthylene glycol

The invention discloses a white cement grinding aid. The white cement grinding aid comprises, by mass percentage, 5-30% of wollastonite powder, 21-30% of triethanolamine, 40-50% of ethylene glycol and6-20% of sodium oleate. The white cement grinding aid can increase white cement raw material grinding efficiency and lower energy consumption and can also effectively lower clinker fine powder surface energy, avoid particle aggregation and improve clinker fine powder fineness without affecting clinker whiteness.

Owner:杭州斯曼特建材科技有限公司

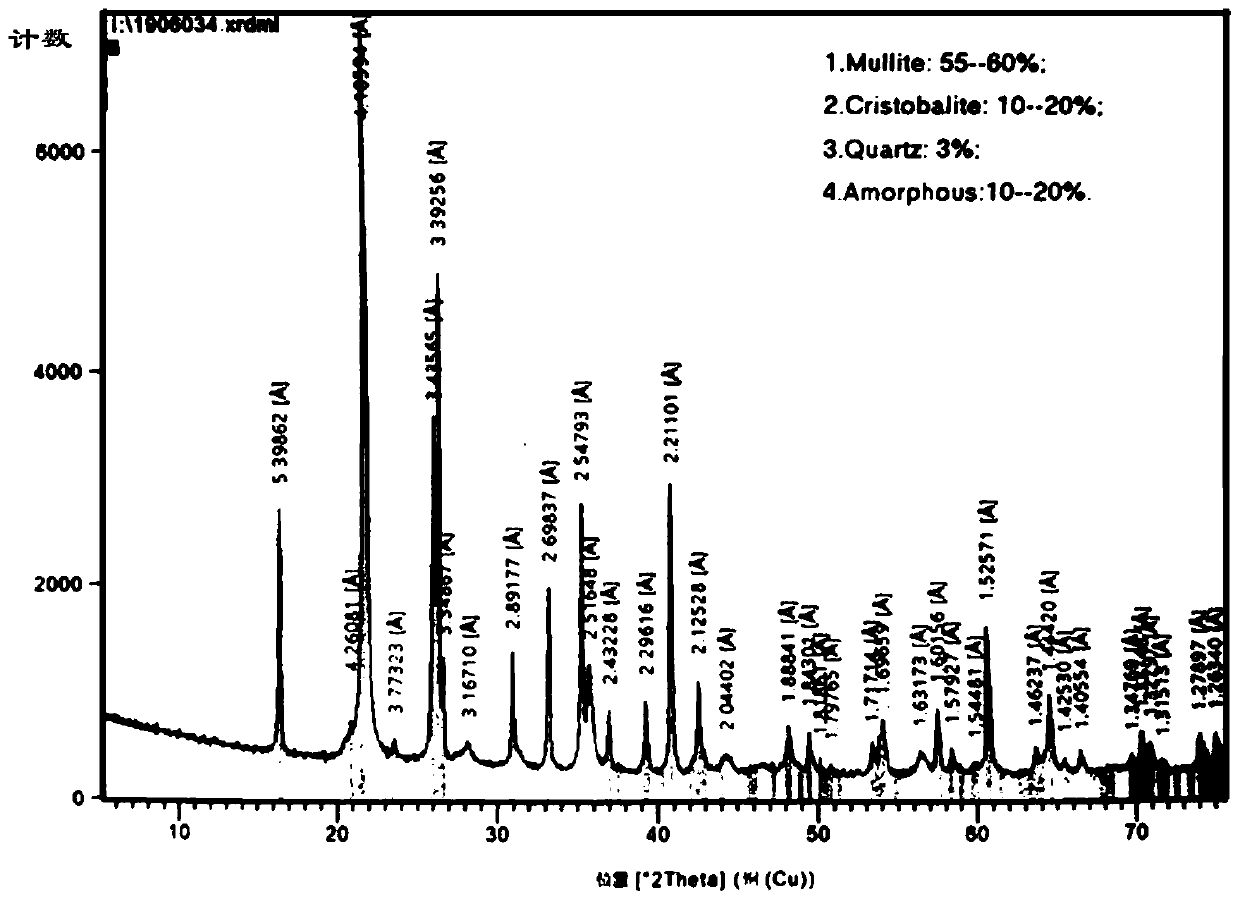

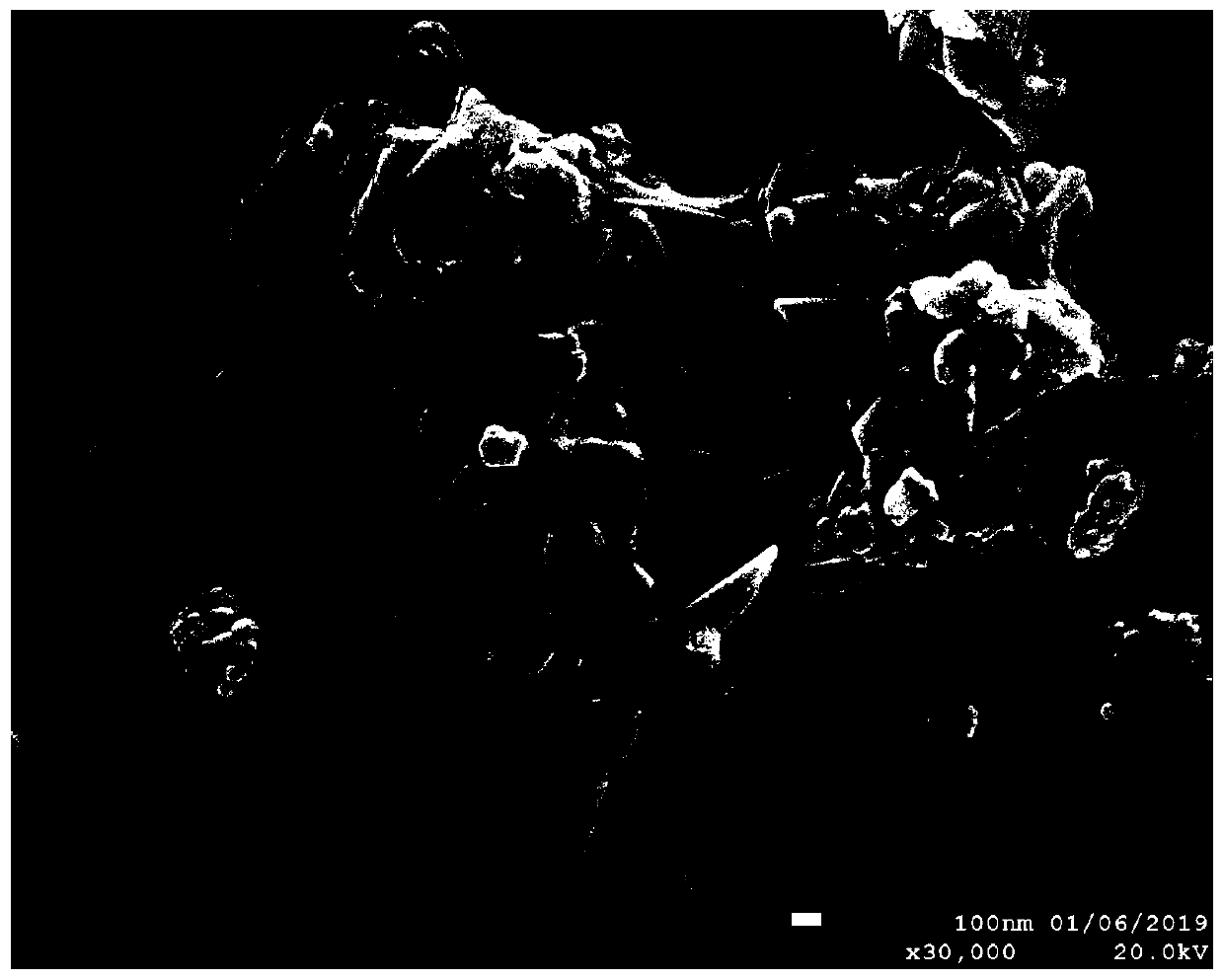

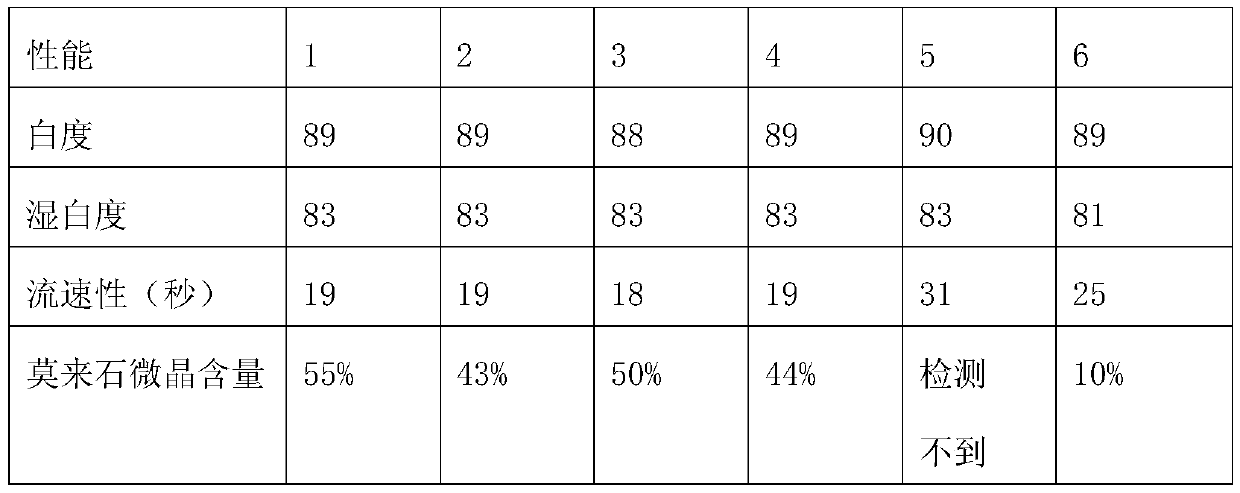

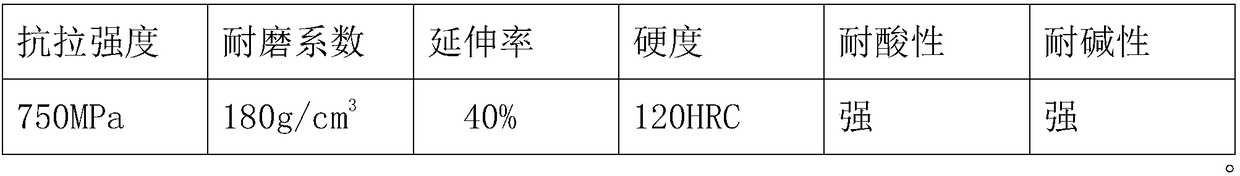

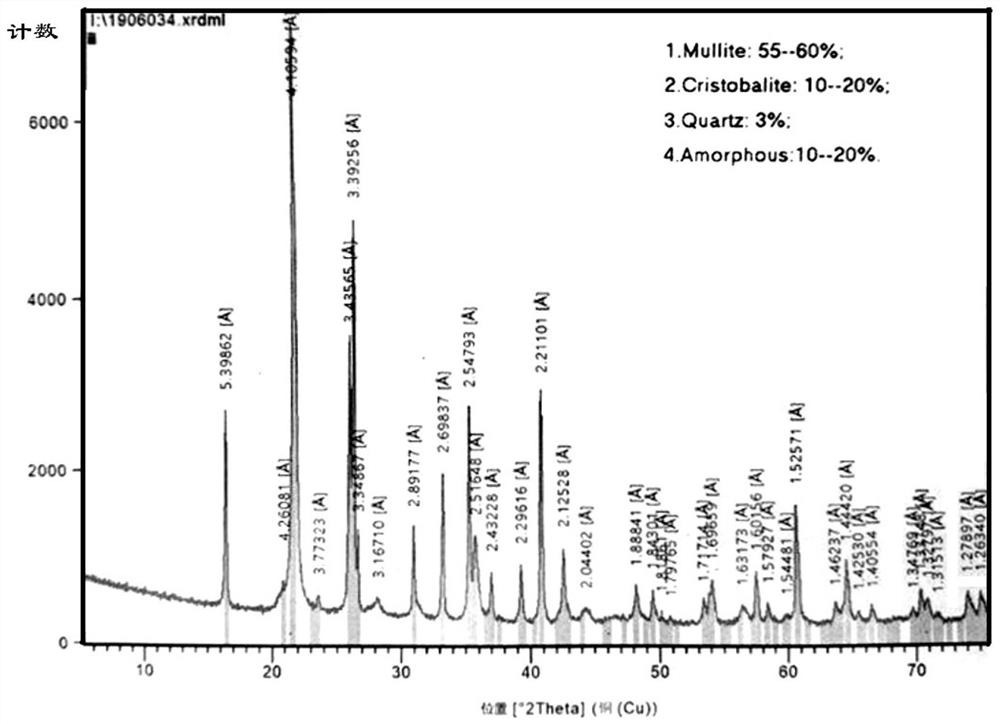

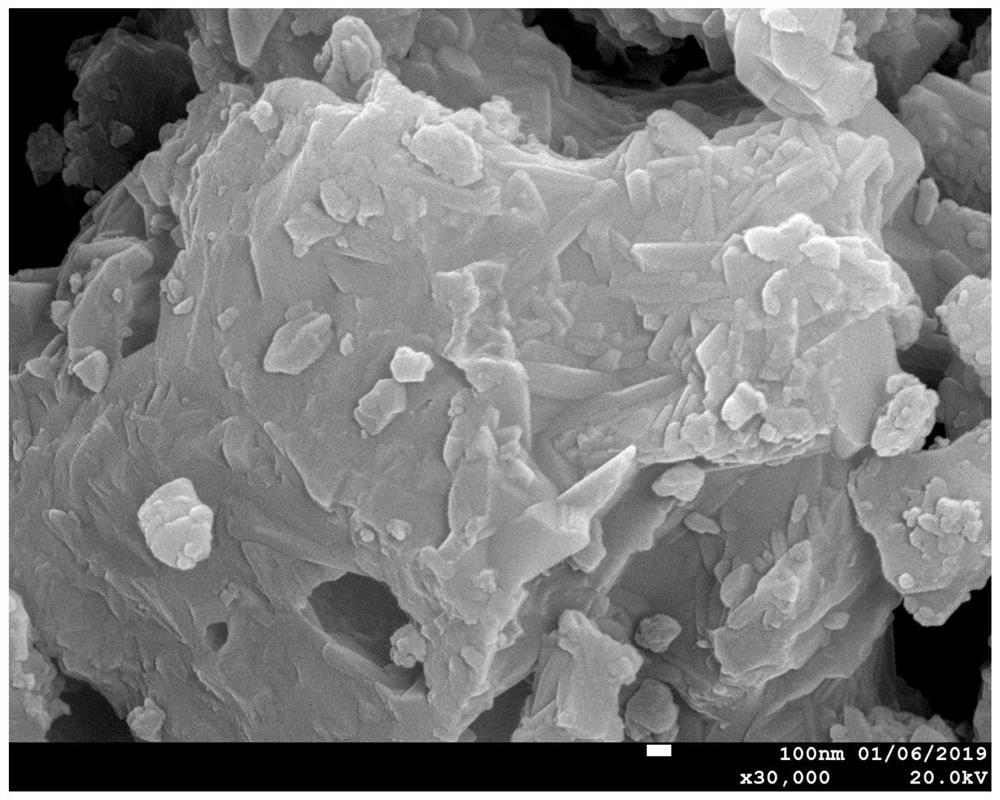

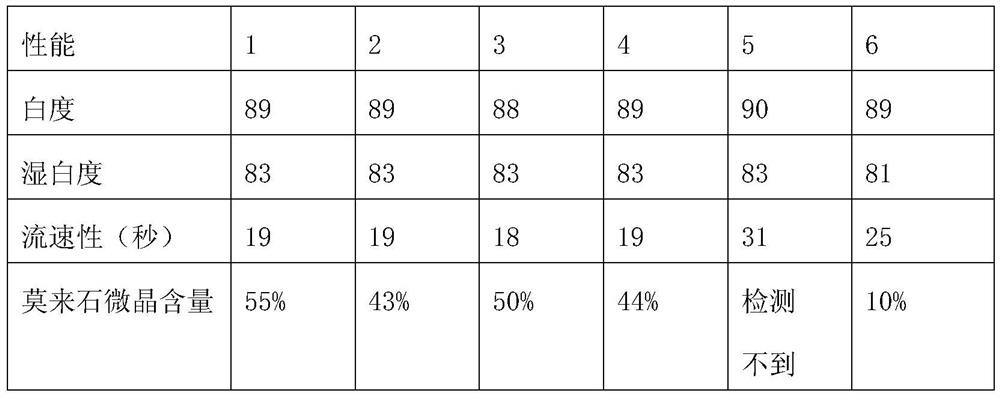

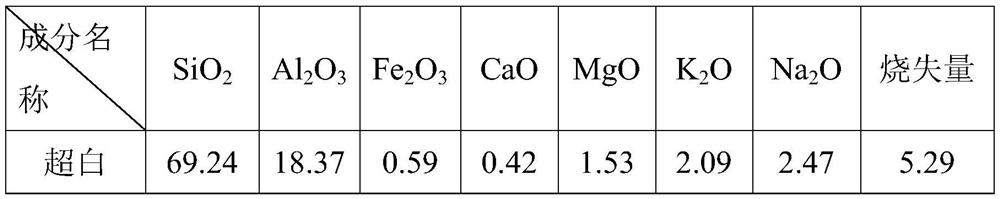

Production method of microcrystalline mullite type calcined kaolin, obtained product and application

ActiveCN111018488AImprove economic efficiencyFor air circulationCeramic materials productionClaywaresCoal gangueCeramic glaze

The invention discloses a production method of microcrystalline mullite type calcined kaolin, the prepared microcrystalline mullite type calcined kaolin and application of the microcrystalline mullitetype calcined kaolin. The method comprises the following steps: 1) taking high-iron coal gangue with Fe2O3 content of more than or equal to 0.4% as a raw material; adjusting to enable Al2O3 content in the raw materials to be greater than or equal to 30%; (2) crushing and grinding the raw materials obtained in the step (1) to 100 meshes or above to obtain a mixed powder, (3) adding water into themixed powder, uniformly mixing to prepare a wet material, carrying out ageing and mud extruding to prepare bricks, stacking the bricks on a kiln car, drying, and calcining the kiln car in a tunnel kiln at 800-1350 DEG C to obtain the microcrystalline mullite type calcined kaolin. The calcined kaolin product prepared by the production method of the microcrystalline mullite type calcined kaolin is high in whiteness, uniform in chemical components and stable in microstructure, contains a large amount of mullite microcrystals, and is a preferred raw material for ceramic glaze, high-quality clay bricks, light mullite bricks and ceramic fiber cotton.

Owner:山西超牌煅烧高岭土有限公司

Preparation method of superfine modified ground limestone

ActiveCN103232732BConvenient grinding workImprove grinding effectPigment treatment with macromolecular organic compoundsPigment physical treatmentPhysical chemistrySpray dried

The invention relates to a preparation method of superfine modified ground limestone. The preparation method of the superfine modified ground limestone comprises the following steps of: (1) steeping slurry; (2) grinding in a four-level wet-method grinding manner; (3) drying: carrying out spray drying on the slurry by using a spray drying device; and (4) modifying: grinding and dispersing the collected ground limestone powder by a dry method at the grinding rate of 1460r / min, and adding modifiers in the grinding process so as to obtain the superfine modified ground limestone. By using the four-level wet-method grinding manner and a method of modifying subjected to drying, the problem of waste of modifiers during liquid modification is solved, and the activating rate and whiteness of the product are improved.

Owner:潍坊双冠新材料有限公司

Preparation method of ceramic grinding body for gypsum grinding

The invention discloses a preparation method of a ceramic grinding body for gypsum grinding. The preparation method comprises the following steps of a, selecting the powder, using BaO (barium oxide),TiC (titanium carbide), Mo2C (molybdenum carbide), ZrO2 (zirconium dioxide), Cr2C3 (Chromium carbide) and TaC (tantalum carbide) as the raw materials, preparing acetic acid with concentration of 80% to 90% as a solvent, pouring into the raw materials, mixing with the raw materials, fully impregnating for 3 to 6h, mixing, and controlling the time within 0.5h, so as to obtain a grinding medium; b, drying the raw materials in step a, mixing with coke, selecting spheres, and fully grinding, wherein the ratio of spheres to material is 3:5, the rotation speed of sphere grinding is 300 to 450rpm, andthe duration of sphere grinding is 30 to 48h; c, screening the mixture after sphere grinding, wherein the sieve hole is 50 to 150 meshes; d, putting the screened mixture into a die, and pressing intothe blank at the pressure of 350 to 550MPa; e, heating the fetched blank, cooling the heated and formed blank, cutting after cooling, grinding and polishing. The prepared grinding body has higher hardness and longer service life.

Owner:FOSHAN HUAQIANG XIEXING CERAMIC CO LTD

Blanching method capable of improving strength of bamboo pulp fiber

The invention relates to the technical field of papermaking pulping, in particular to a blanching method capable of improving strength of bamboo pulp fiber. Damage to lignin and cellulose is reduced by reducing the blanching temperature of an EOP section and reducing the severity of a reaction, meanwhile, the temperature, pH value and the dosage of a chlorine dioxide blanching agent in the anterior and posterior blanching process of the EOP section are controlled for optimization of comprehensive reaction conditions, finally, whitening enzyme in the model of BUZYME3500, which is produced by the Bachmann Company, is selected for enzyme treatment of bamboo pulp, damage of the EOP section to bamboo pulp fiber can be reduced finally under the synergistic action, the strength of the bamboo pulpfiber is greatly improved, the whitening degree of the bamboo pulp cannot be affected, the whitening degree of the prepared bamboo pulp reaches 85-87 degrees, no yellowing phenomenon can be caused after stabilization, and the tearing strength and the fracture resistance of paper prepared from the bamboo pulp can be improved by 5% or above.

Owner:CHONGQING LEE & MAN PAPER MFG

Production method, obtained product and application of microcrystalline mullite-type calcined kaolin

ActiveCN111018488BPromote circulationIncrease effective spaceCeramic materials productionClaywaresTunnel kilnFiber

The invention discloses a production method of microcrystalline mullite-type calcined kaolin, the obtained microcrystalline mullite-type calcined kaolin and applications thereof. 1) Fe 2 O 3 ≥0.4% high-speed iron coal gangue as raw material, adjusted to make Al in the raw material 2 O 3 ≥30%, 2) crush the raw materials obtained in step 1), and grind them to more than 100 meshes to obtain a mixed powder, 3) add water to the mixed powder and mix evenly to make a wet material, age, squeeze the mud to make a brick, and put it in the The kiln car is dried, and after drying, the kiln car enters a tunnel kiln for calcination at 800-1350° C. to obtain the microcrystalline mullite-type calcined kaolin. The calcined kaolin product prepared by the production method of microcrystalline mullite type calcined kaolin of the present invention has high whiteness, uniform chemical composition, stable microstructure, and contains a large amount of mullite microcrystals. It is a ceramic glaze, high-quality clay brick, The raw material of choice for lightweight mullite bricks and ceramic fiber wool.

Owner:山西超牌煅烧高岭土有限公司

A method to achieve intelligent cleaning function of textiles by cross-linking temperature-sensitive copolymers

ActiveCN105803762BRealize intelligent cleaning functionRealize self-cleaning functionVegetal fibresAnimal fibresCross-linkSide chain

The invention discloses a method for realizing a textile intelligent cleaning function through a crosslinking temperature-sensitive copolymer. The method comprises the following steps of (1) using the temperature-sensitive copolymer, a crosslinking agent, a catalyst and a solvent to process a textile; (2) carrying out crosslinking reaction on the processed textile through heating and baking. According to the method for realizing thetextile intelligent cleaning function through the crosslinking temperature-sensitive copolymer provided by the invention, the cleaning efficiency of the textile during the washing process is improved, and the self-cleaning effect is achieved during the wearing process; the operation can be carried out conveniently without influencing the original whiteness and flexibility; a covalent bond is formed through reaction of a reactive functional group contained in an acrylate monomer with the reactive functional group at the tail end of a side chain in the temperature-sensitive copolymer and a reactive functional group on the surface of the textile with carboxyl contained in the crosslinking agent, and the temperature-sensitive copolymer is fixed on the surface of the textile, so that the modified textile has a function of hydrophily / hydrophobicity intelligent adjustment.

Owner:ZHEJIANG SCI-TECH UNIV

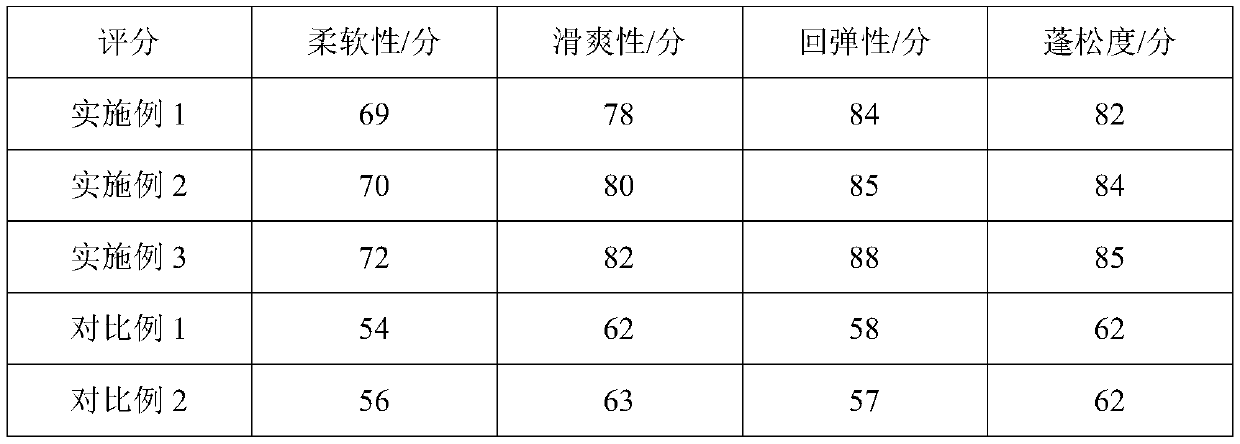

Softening agent special for paper softening and mould proofing and preparation method thereof

ActiveCN110777560AReduce mutual frictionGood flexibilityVegetable material additionPaper/cardboardCellulosePolymer science

The invention relates to the technical field of softening agents, in particular to a softening agent special for paper softening and mould proofing and a preparation method thereof. The softening agent is prepared from the following components in parts by weight: 5-10 parts of resin, 3-8 parts of cetyl dimethicone, 2-5 parts of nano zinc oxide, 2-5 parts of chitosan, 2-4 parts of hydroxyethyl cellulose, 3-5 parts of an aloe extract, 1-2 parts of a solvent, 1-2 parts of a pH regulator, 2-3 parts of liquid wax and 5-10 parts of water. The softening agent has the advantages of being good in handfeeling and water and mold proofing effect, high in stability and free of influences on paper whiteness.

Owner:多恩生物科技有限公司

Method for preparing environmental-friendly waterproof warp knitted fabric

InactiveCN107938312AImprove waterproof performanceDoes not affect wash fastnessWarp knittingVegetal fibresFiberSodium lactate

The invention discloses a method for preparing an environmental-friendly waterproof warp knitted fabric and belongs to the technical field of fabrics. The method comprises the following steps: mixingplant ash, nano carbon powder, sodium hydroxide and water, and boiling; putting a ramie fiber and a nano carbon dioxide accelerant fiber into the boiled mixture, and continuously boiling; taking out the boiled fiber, washing with clean water, naturally drying in the air, and blending so as to obtain yarns; uniformly mixing chitosan, stearoyl sodium lactate, n-butyl alcohol, dodecafluoroheptyl methacrylate, sodium dodecyl benzene sulfonate and absolute ethyl alcohol in a reactor; soaking the blended yarns into the uniformly mixed solution, and performing magnetic stirring; and taking out the yarns, naturally drying in the air, dying in a drying machine, and finally performing warp knitting, thereby obtaining a fabric. The method disclosed by the invention is simple and feasible, process parameters are also relatively easy to control, and in addition, on-batch production can be achieved; the warp knitted fabric is high in waterproof property and is relatively high in softness, and in addition, original washing fastness and whiteness of the knitted fabric are not affected.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

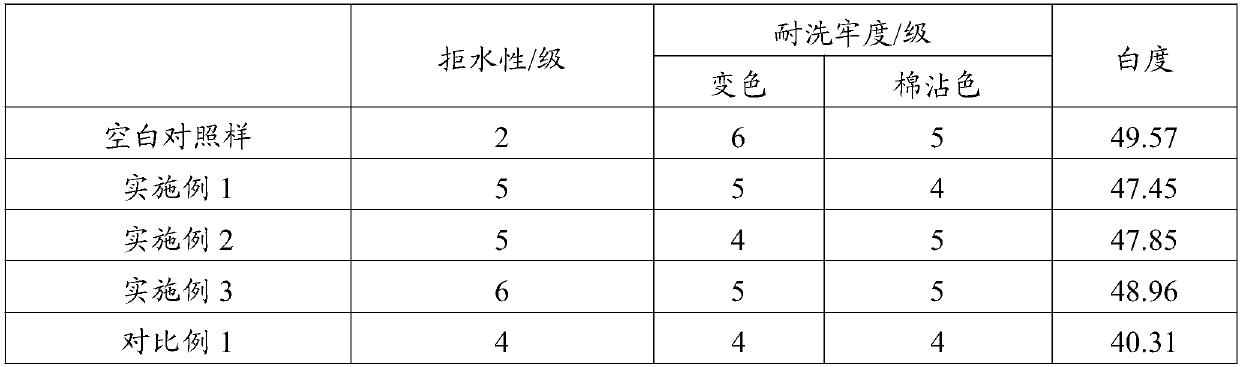

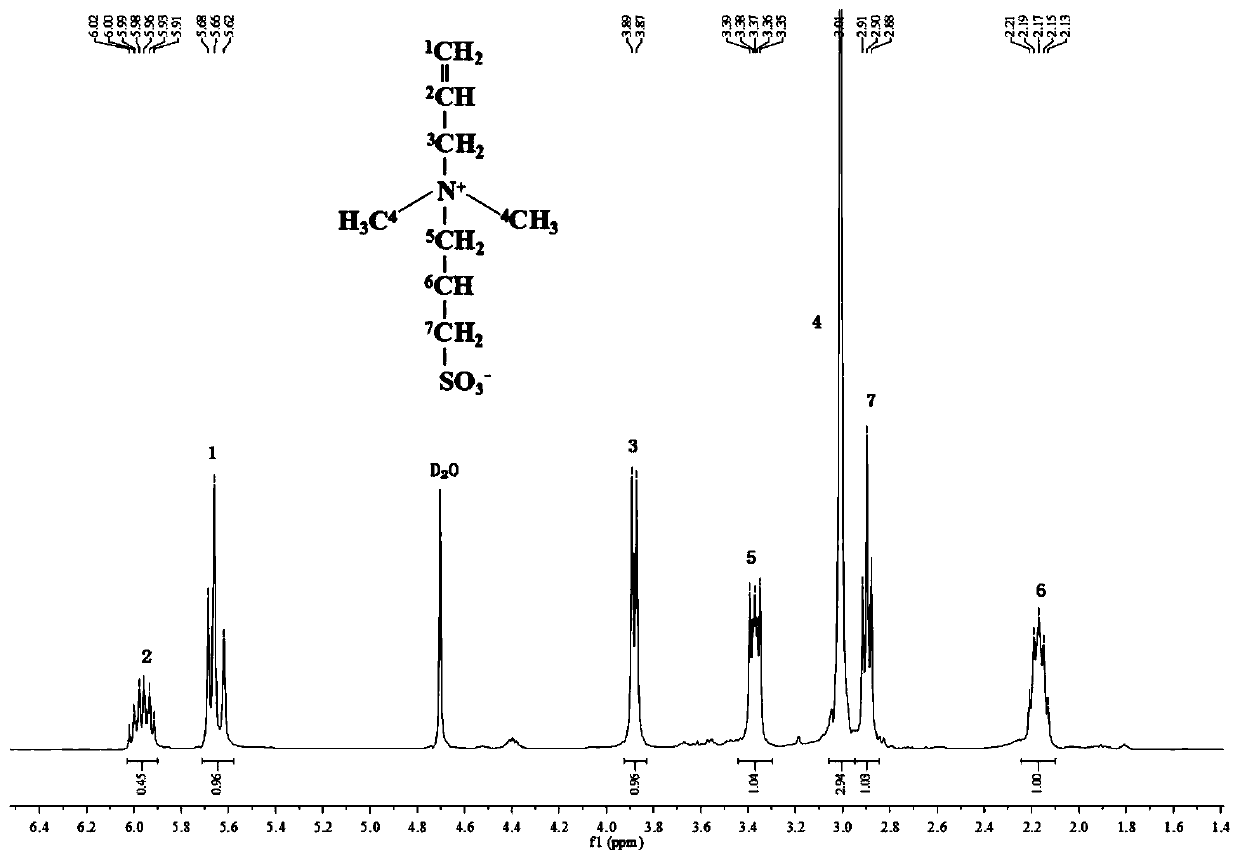

A kind of betaine type antibacterial finishing agent and preparation method thereof

ActiveCN108219065BImprove hydrophilicityImprove breathabilityBiochemical fibre treatmentSulfonic acids salts preparationBetaineOrganic synthesis

The invention discloses a betaine type antibacterial finishing agent and a preparation method thereof and belongs to the technical field of organic synthesis. A synthetic route of the betaine type antibacterial finishing agent comprises the following steps: firstly, taking olefin containing tertiary amine and a substance with a sulfonic acid or carboxylic acid group to react to generate an intermediate product betaine monomer; then taking the betaine monomer and maleic anhydride to be subjected to addition polymerization reaction to generate a betaine polymer, i.e., a target product. The antibacterial agent disclosed by the invention is green and environmentally friendly and can realize efficient and broad-spectrum antibacterial effects; meanwhile, the betaine type antibacterial finishingagent contains a reactive group, can be subjected to covalent reaction with the surface of a material and has a lasting antibacterial property. Moreover, a preparation technology of the antibacterialagent is simple and industrialization is easy to realize.

Owner:JIANGNAN UNIV

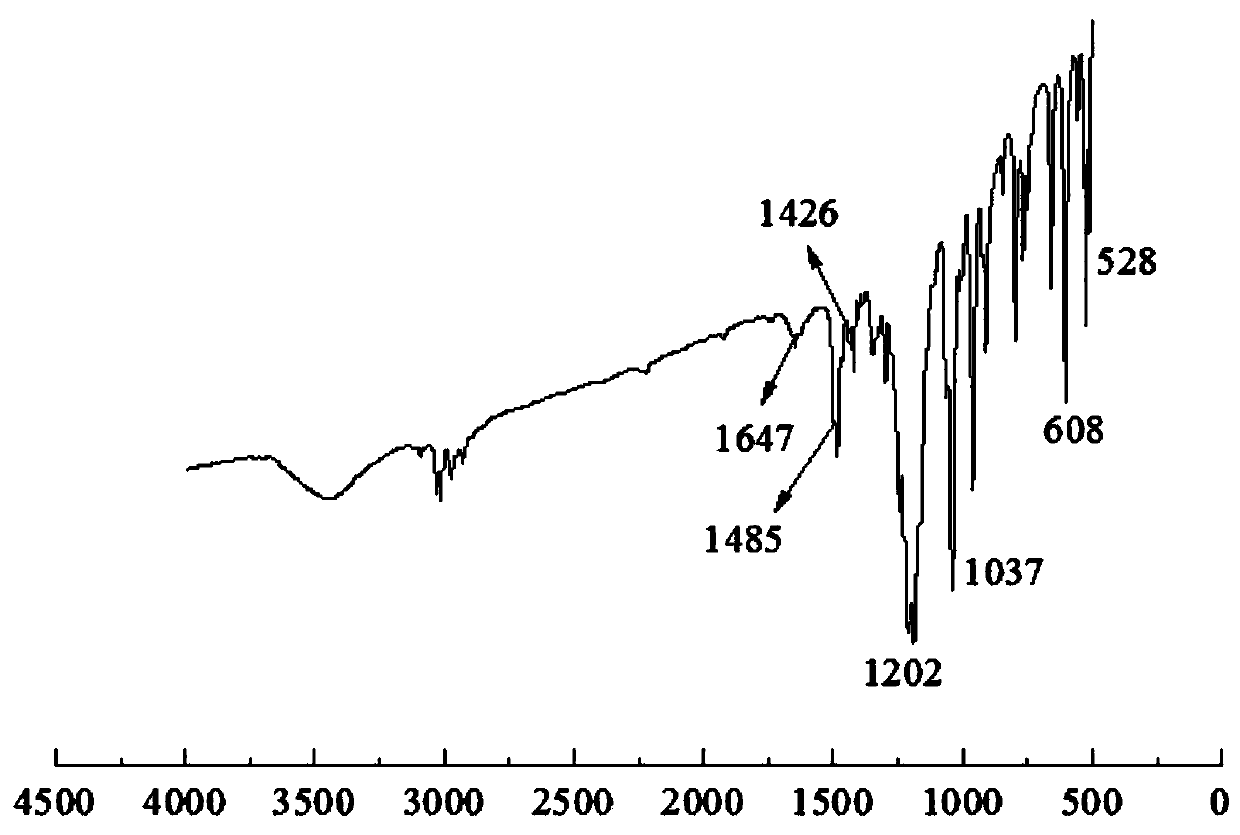

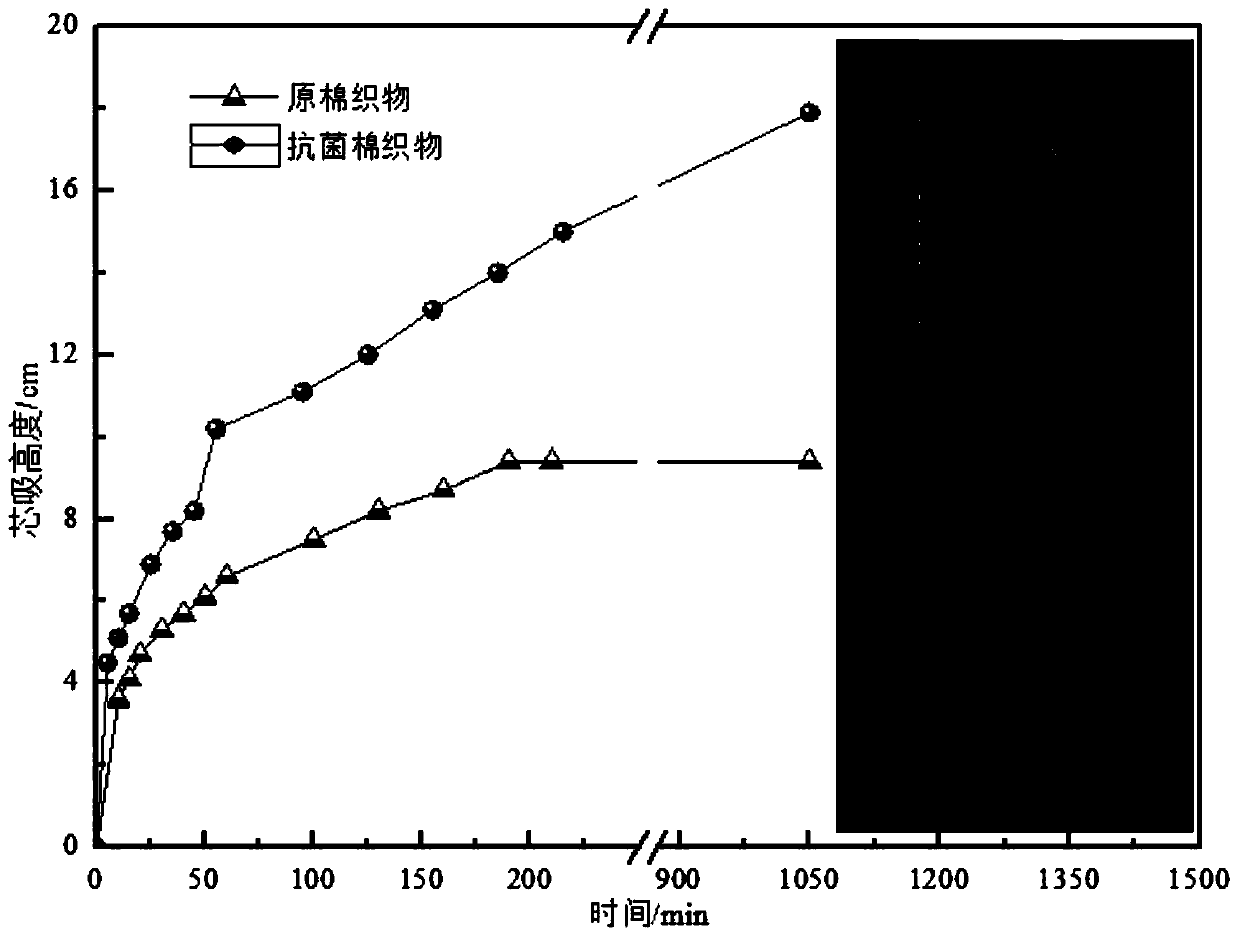

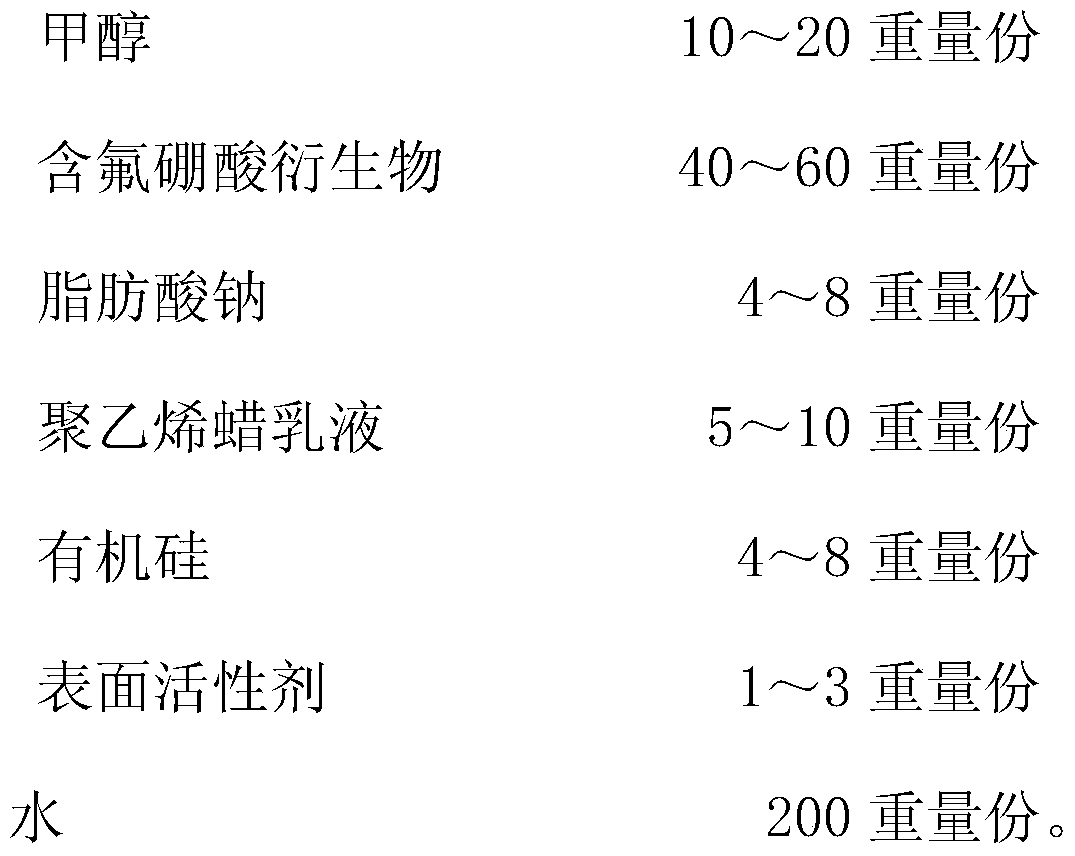

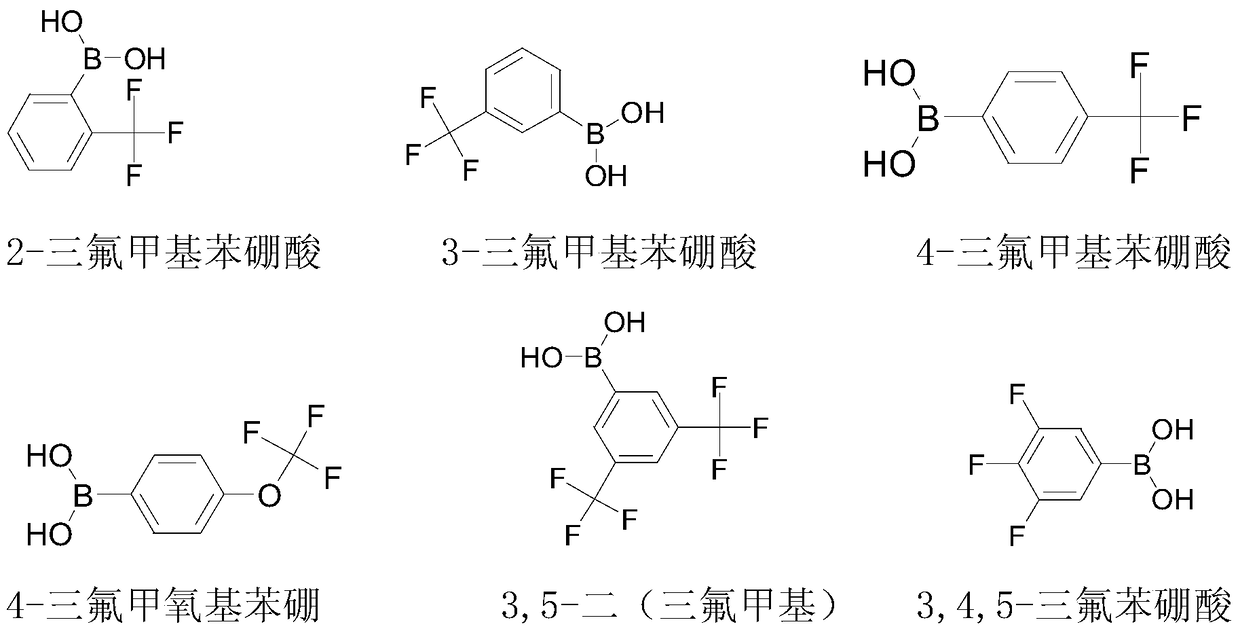

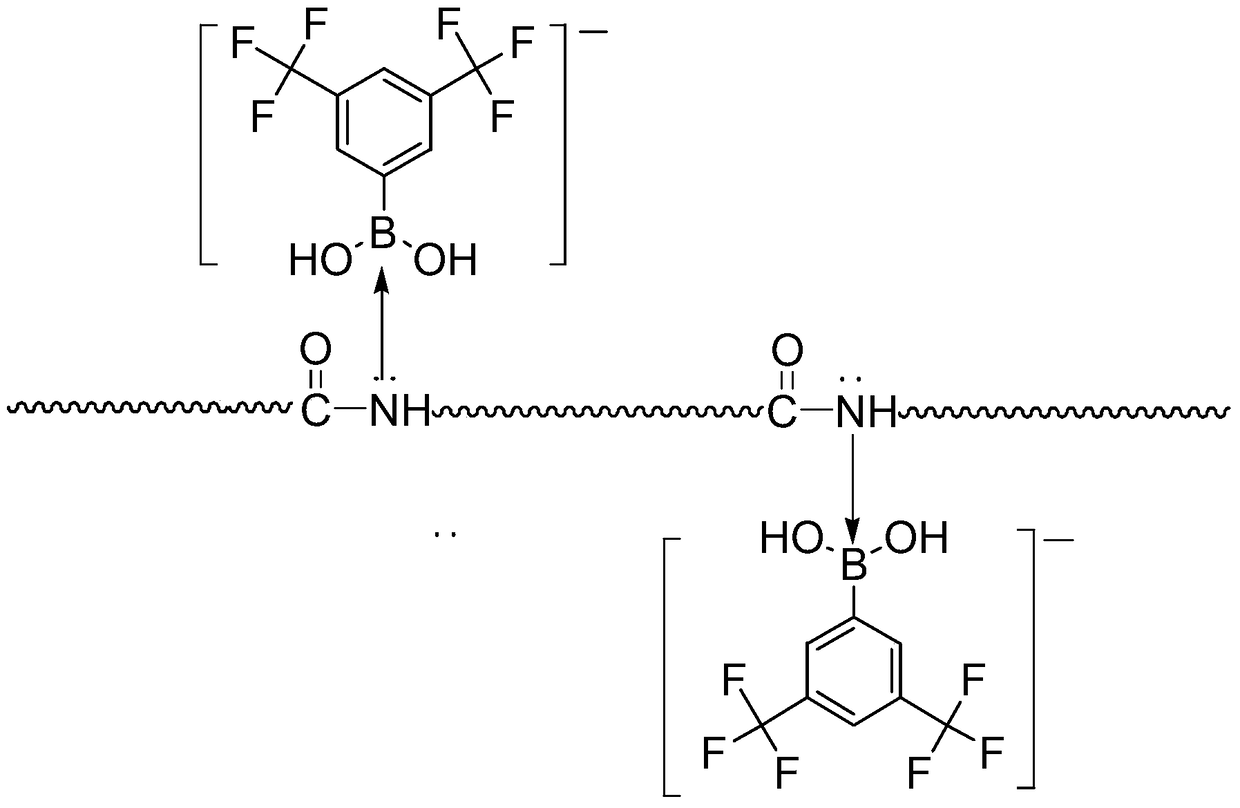

A kind of waterproof finishing agent and its application

InactiveCN105220473BImprove waterproof performanceDoes not affect wash fastnessFibre treatmentEmulsionBoronic acid

The invention discloses a waterproof finishing agent and a use thereof. The waterproof finishing agent comprises, by weight, 10-20 parts of methanol, 40-60 parts of a fluorine-containing boronic acid derivative, 4-8 parts of sodium aliphatate, 5-10 parts of polyethylene wax emulsion, 4-8 parts of an organosilicon, 1-3 parts of a surfactant and 200 parts of water. The fluorine-containing boronic acid derivative is one of 2-trifluoromethylphenylboronic acid, 3-trifluoromethylphenylboronic acid, 4-trifluoromethylphenylboronic acid, 4-trifluoromethoxyphenylboronic acid, 3, 5-bis(trifluoromethyl) derivative and 3, 4, 5-trifluorophenylboronic acid. The fluorine-containing boronic acid derivative is used as a main raw material of the waterproof finishing agent. Through a common double-padding-double-dipping production technology and coordination complexation, a fabric is treated by the waterproof finishing agent. The treated fabric has good waterproofness and retains original fastness to washing and whiteness so that the waterproof finishing agent has a practical application value and a wide application prospect in the field with self-cleaning requirements.

Owner:戴李宗

A method of recycling heavy calcium powder by using marble waste

ActiveCN106497143BAchieve recyclingAchieve reusePigment flushingCoatingsMineral SourcesMaterials science

The invention relates to a preparing method of using marble wastes to recycle heavy calcium powder. The preparing method comprises the steps of material selecting, cleaning, airing, crushing, screening through vibration, ball-milling and grading. The preparing method is simple in technology and convenient to operate, achieves recycling and reuse of the marble wastes so as to turn waste into wealth, saves investment cost and mineral resources, and is very environmentally friendly.

Owner:SICHUAN YINGJING KAIQUAN INDAL

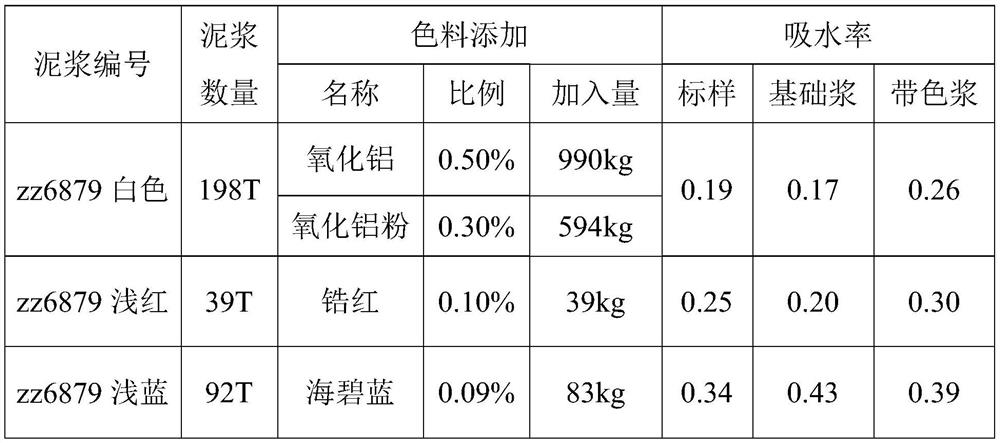

Temperature regulating slurry for reducing firing temperature of brindled brick, brindled brick and manufacturing method of brindled brick

The invention discloses a temperature regulating slurry for reducing the firing temperature of a brindled brick, the brindled brick and a manufacturing method of the brindled brick. The temperature regulating slurry comprises the following raw materials in percentage by mass: 48%-52% of talc particles; 18%-22% of magnesia; and 28%-32% of sodium humate. A mud raw material with high aluminum content, low magnesium content, low iron content and good plasticity is adopted in the temperature regulating slurry, so that the brindled brick is influenced by the added brindle particles and the firing temperature of the brindled brick is increased, the firing temperature of the brindled brick is effectively reduced by adding the temperature regulating slurry, so that the stability of the firing temperature of the brindled brick is maintained, the quality and color repeatability among different batches of brindled bricks is improved, the production continuity is ensured, and the production efficiency is improved; and while the firing temperature of the brindled brick is stabilized, the whiteness of the brindled brick is not influenced, and the strength of the brindled brick can be synchronously improved.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

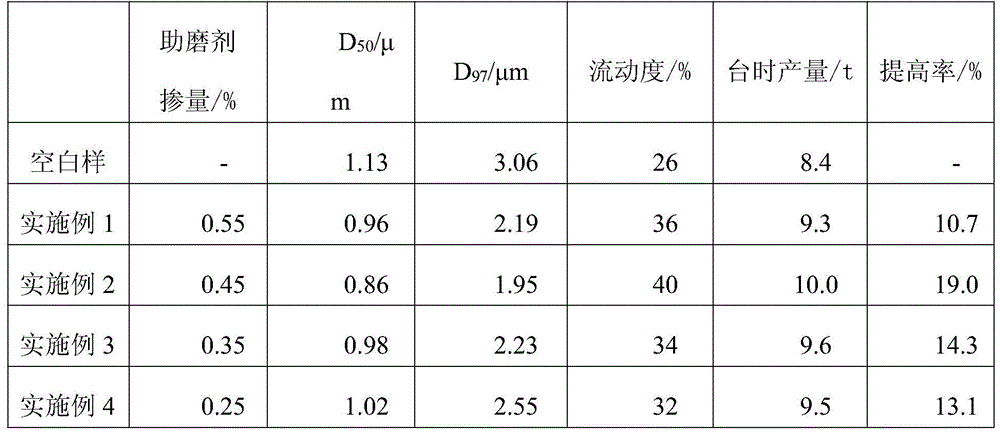

A powder grinding aid suitable for superfine kaolin powder

InactiveCN104449570BSufficient supplyEasy to processOther chemical processesPolyethylene glycolPyrophosphate

The invention relates to a powder grinding aid suitable for kaolin, particularly relates to a powder grinding aid suitable for kaolin ultrafine powder, and belongs to the technical field of grinding of kaolin ultrafine powder. The powder grinding aid is prepared from the following substances in parts by weight: 1-5 parts of polymeric alkylol amine, 1-10 parts of polyethylene glycol, 5-15 parts of polyacrylamide, 1-15 parts of sodium pyrophosphate and 20-50 parts of wollastonite in powder. The grinding aid disclosed by the invention is compounded by mineral raw materials and common chemical materials, so that the powder grinding aid is sufficient in raw material source, available, low in toxicity, non-volatile, simple to produce and process, and low in cost; a kaolin grinding production enterprise utilizes the powder grinding aid disclosed by the invention; and the operation is simple and convenient. According to the powder grinding aid disclosed by the invention, the grinding efficiency is improved; the energy consumption is reduced; the surface energy of the kaolin ultrafine powder can also be effectively lowered; particle aggregation is avoided; the fineness of the power grinding aid is improved; the liquidity of the powder grinding aid is improved; and the whiteness of kaolin is not affected.

Owner:SHENYANG JIANZHU UNIVERSITY

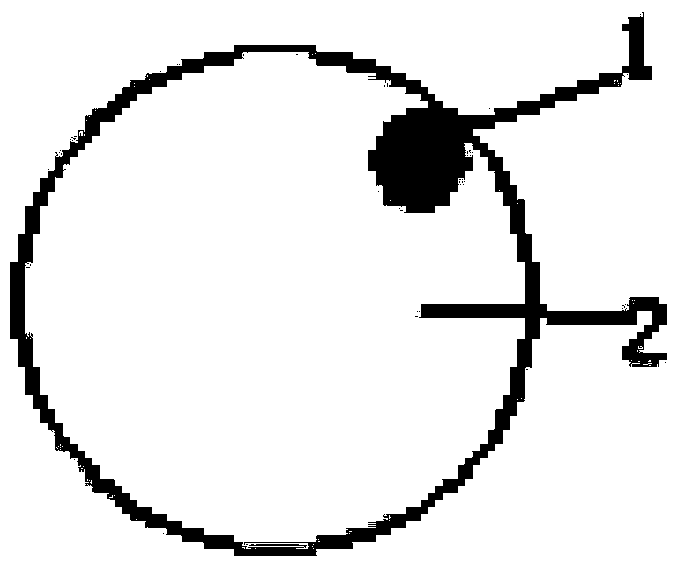

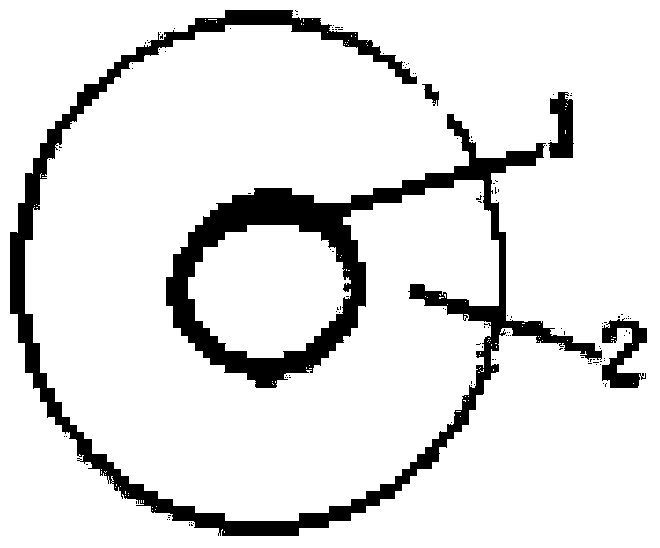

A kind of high-performance nylon-based dyeable conductive fiber and its preparation method

ActiveCN106757507BDoes not affect whitenessImprove conductivityElectroconductive/antistatic filament manufactureFilament forming substance formingFiberPolyamide

The invention relates to a high-performance polyamide-based dyeable conductive fiber and a preparation method thereof, belonging to the field of composite conductive fibers. The fiber provided by the invention employs a three-layer concentric circle structure which comprises three components, i.e., a highly-conductive medium carbon black component, a shielding composite substance component and a white conductive component in a mass ratio of 5-30%: 20-30%: 50-65%, wherein an inner layer, a middle layer and an outer layer are the highly-conductive medium carbon black component, the shielding composite substance component and the white conductive component respectively, or are the highly-conductive medium carbon black component, the white conductive component and the shielding composite substance component respectively. The fiber provided by the invention has improved conductivity and maintains original whiteness and dyeability. According to the invention, a metal oxide and a conductive intrinsic polymer are blended and granulated during preparation of white dyeable conductive master batch, so the characteristics of the two white conductive additive are integrated; and polyamide carrier resin is added to adjust a fusion index, so fluidity is improved, and the conductivity of the eventually prepared fiber is improved.

Owner:CTA HIGH TECH FIBER

Process for printing QS quality safety sign on gold card paper

InactiveCN101670720BGood ink absorptionImprove adhesionPattern printingOther printing apparatusColored whiteUltraviolet lights

The process relates to a process for printing a QS quality safety sign on gold card paper, which comprises the following steps: 1, carrying out computer color separation on a QS sign pattern to be printed, and separately making an electronic file with all edges longer than the size of a white pattern; 2, making 3 films by using the file made in the step 1; 3, carrying out plate burning by using the films in the step 1 to make 3 corresponding printing plates; 4, installing the printing plates obtained in the step 3 on an offset press; 5, pouring a shell-lac alcoholic solution and water in a first machine set; pouring white ink and a fountain solution in a second machine set; and pouring spot blue ink and the fountain solution in a third machine set; 7, installing ultraviolet light tubes between the first machine set and the second machine set, between the second machine set and the third machine set and behind the third machine set; 8, printing shell-lac by the first machine set, printing the white ink by the second machine set, and printing the spot blue ink by the third machine set, and then obtaining a QS sign printing product. The process has the advantages of convenient printing, less process faults, flat and smooth ink layers and good handfeel.

Owner:SHAANXI UNIV OF SCI & TECH

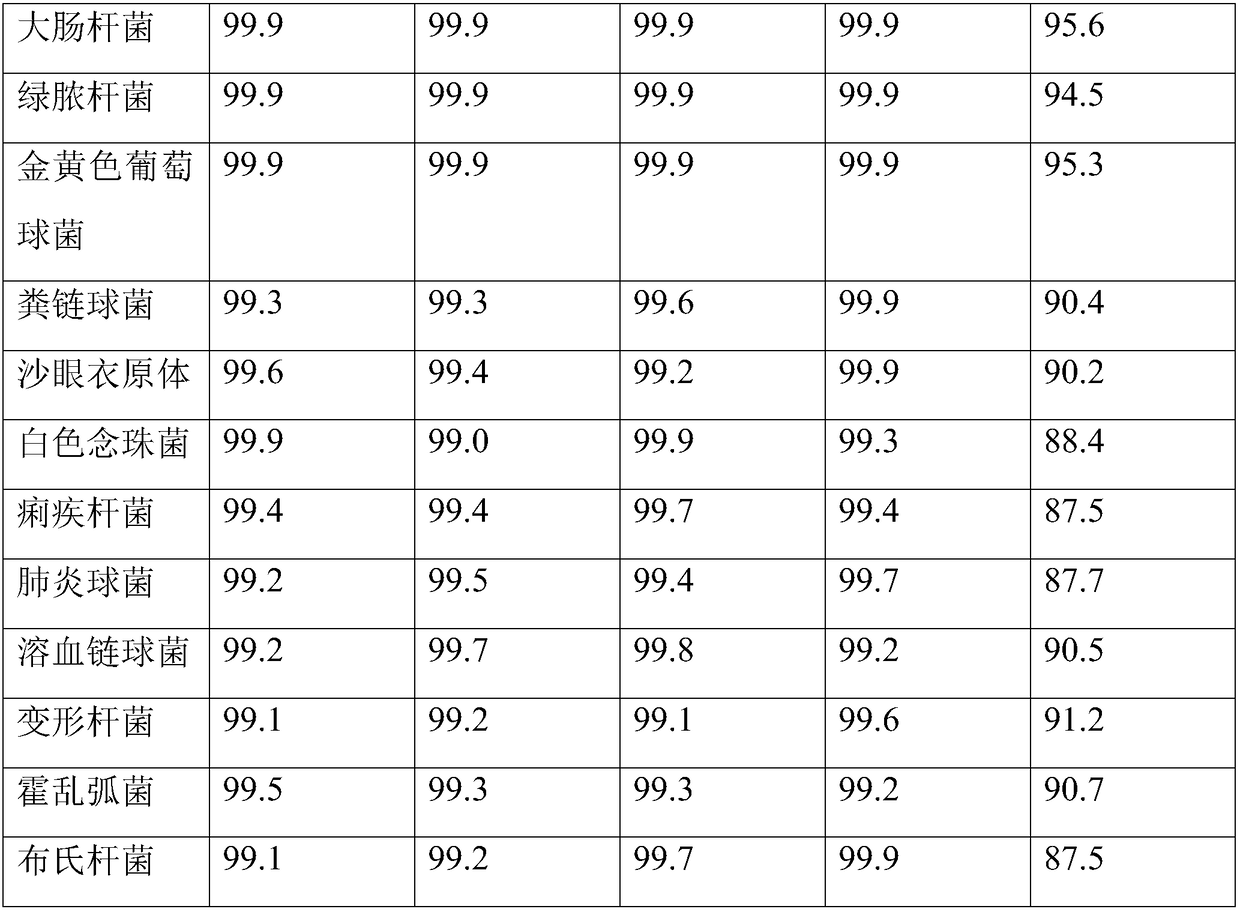

Packaging container

PendingCN113734624AImprove utilization and distribution uniformityReduce the amount of oxygen absorberBottlesPackaging milkChemistryOxygen absorption

The invention relates to a packaging product, in particular to a packaging container. The container wall of the packaging container comprises a light blocking layer and an oxygen absorption layer, the light blocking layer is prepared from polyethylene glycol terephthalate and a light blocking agent, and the oxygen absorption layer is prepared from the polyethylene glycol terephthalate and an oxygen absorption agent. According to the packaging container, the light blocking agent and the oxygen absorption agent are arranged in two layers, so that the using amount of the light blocking agent and the oxygen absorption agent can be remarkably reduced, the utilization rate and the distribution uniformity of the light blocking agent and the oxygen absorption agent can be improved, the purposes that the blocking property of the container wall to illumination and oxygen can be greatly improved while the using amount of an additive is reduce, and the oxygen permeation rate of the container is obviously reduced are achieved.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

A method for achieving linear regulation of comfort and anti-bacterial adhesion by cross-linking thermosensitive microgels on the surface of fabrics

ActiveCN110528282BAchieve comfortEasy to operateBiochemical fibre treatmentVegetal fibresPolymer scienceBacterial Adhesions

Owner:ZHEJIANG SCI-TECH UNIV

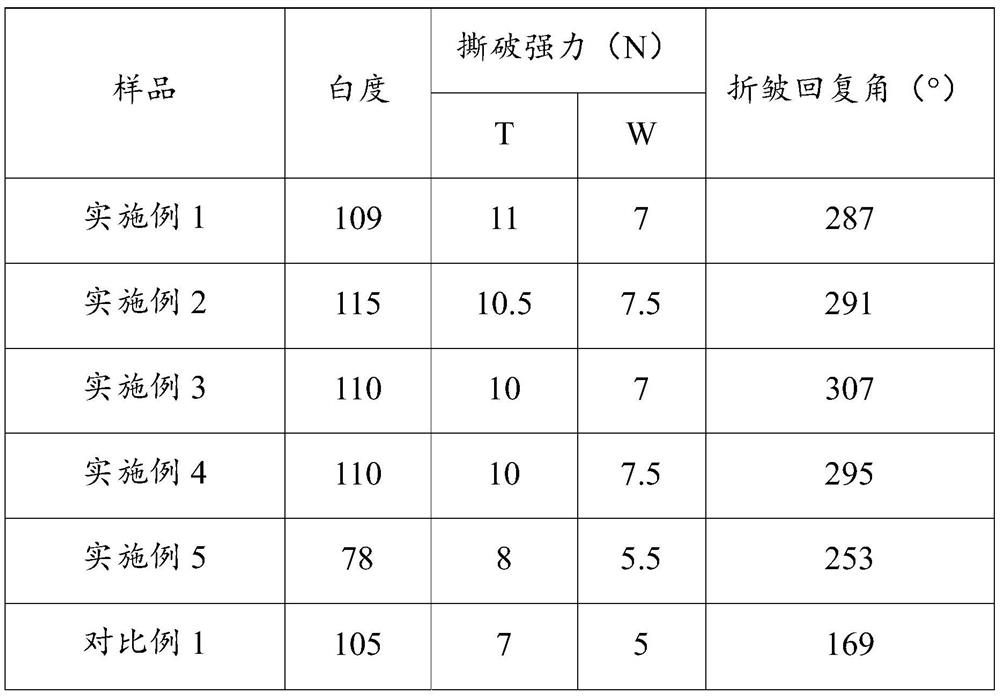

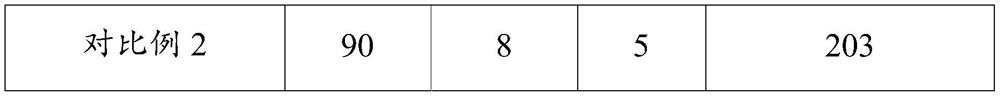

Ultralow molecular weight polyacrylic acid as well as preparation method and application thereof

PendingCN114716595ASimple stepsEasy to operateScale removal and water softeningWrinkle resistant fibresPolymer sciencePtru catalyst

The invention belongs to the technical field of polymer preparation, and particularly relates to ultralow molecular weight polyacrylic acid as well as a preparation method and application thereof. According to the preparation method of the ultralow-molecular-weight polyacrylic acid, the molecular weight of the product is directly controlled by using the polymerization inhibitor, and the ultralow-molecular-weight polyacrylic acid product is prepared by adding the initiator, the acrylic acid and the polymerization inhibitor into the reaction system in batches. The reaction process does not need to add a chain transfer agent, does not need a large amount of solvent and initiator, does not need a special device, does not need a noble metal catalyst, and is simple in steps, convenient to operate and easy to control. The applicant finds that the ultra-low molecular weight polyacrylic acid provided by the invention is adopted as the fabric finishing agent, a good non-ironing finishing effect is achieved, the whiteness is not influenced, the strength loss is small, and the crease recovery angle of the finished fabric can reach 280 degrees or above.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

A mobile phone lens and printing method thereof

ActiveCN102756579BIncrease coverageDoes not affect whitenessOther printing apparatusComputer scienceMechanical engineering

The invention provides a printing method of a mobile phone lens. The printing method includes the steps: firstly, providing a mobile phone lens substrate and a film for displaying patterns to be printed; secondly, manufacturing a first screen and a second screen by the aid of the film; thirdly, printing frosted cream on the mobile phone lens substrate by the aid of the first screen to obtain the mobile phone lens substrate with a frosted surface; and fourthly, printing white ink on the mobile phone lens substrate with the frosted surface by the aid of the second screen. The invention further provides a mobile phone lens obtained by the printing method. The covering rate of the mobile phone lens manufactured by the printing method of the mobile phone lens is obviously increased, and whiteness of the white ink is unaffected.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com