A kind of waterproof finishing agent and its application

A water-repellent finishing and surfactant technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of limited application, affecting the washing fastness and whiteness of textiles, etc., achieve broad application prospects, and the treatment method is simple and easy , The effect of easy process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

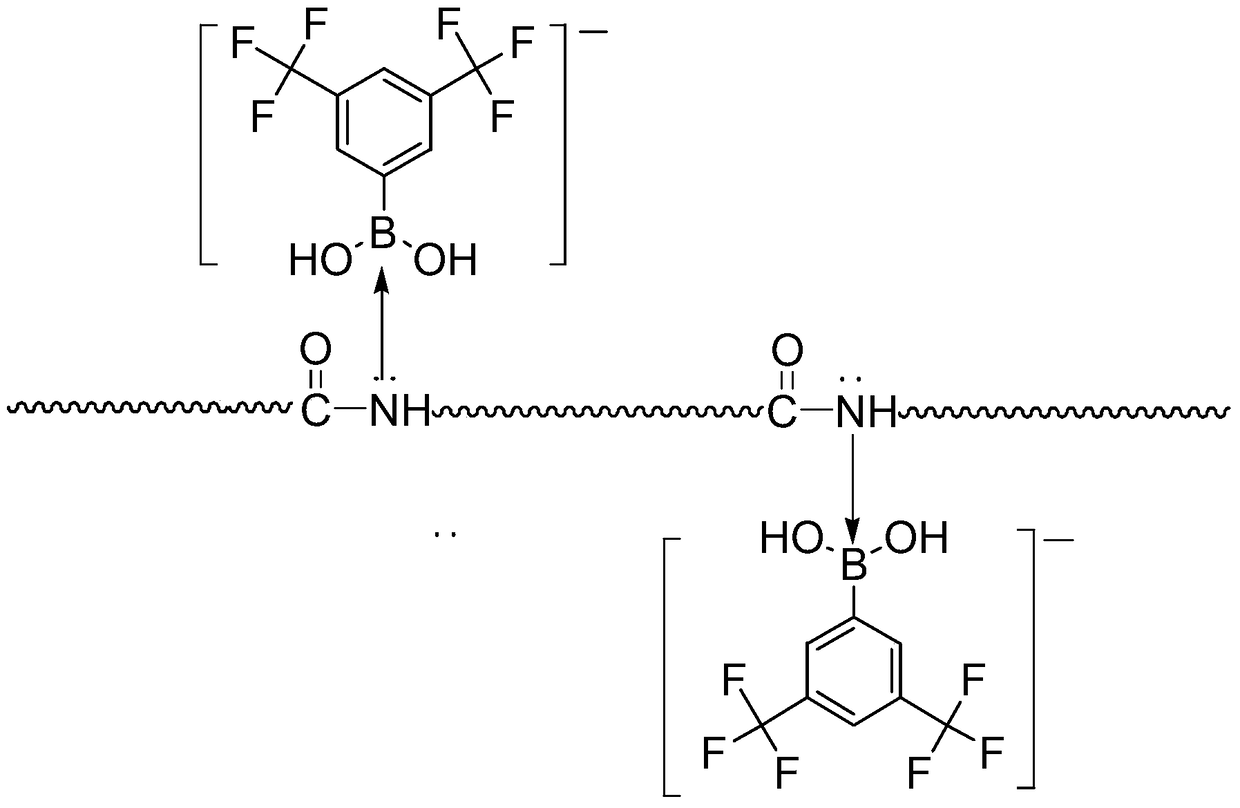

Method used

Image

Examples

Embodiment 1

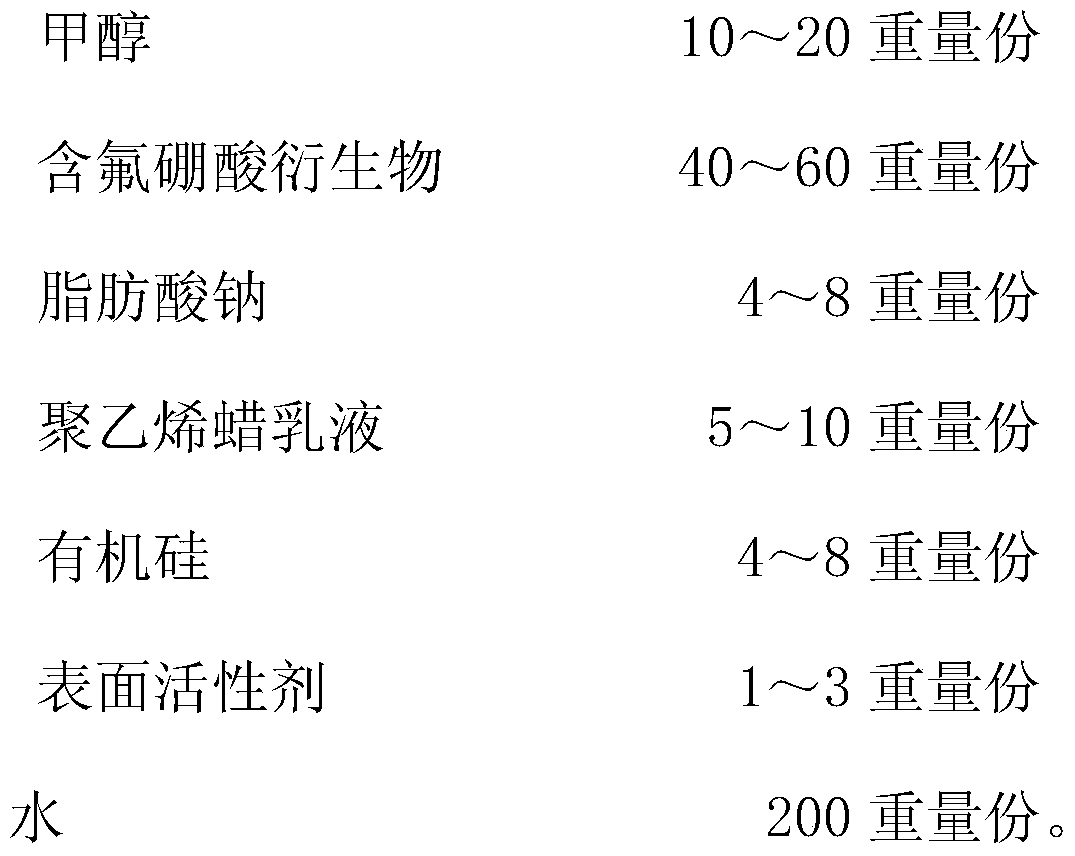

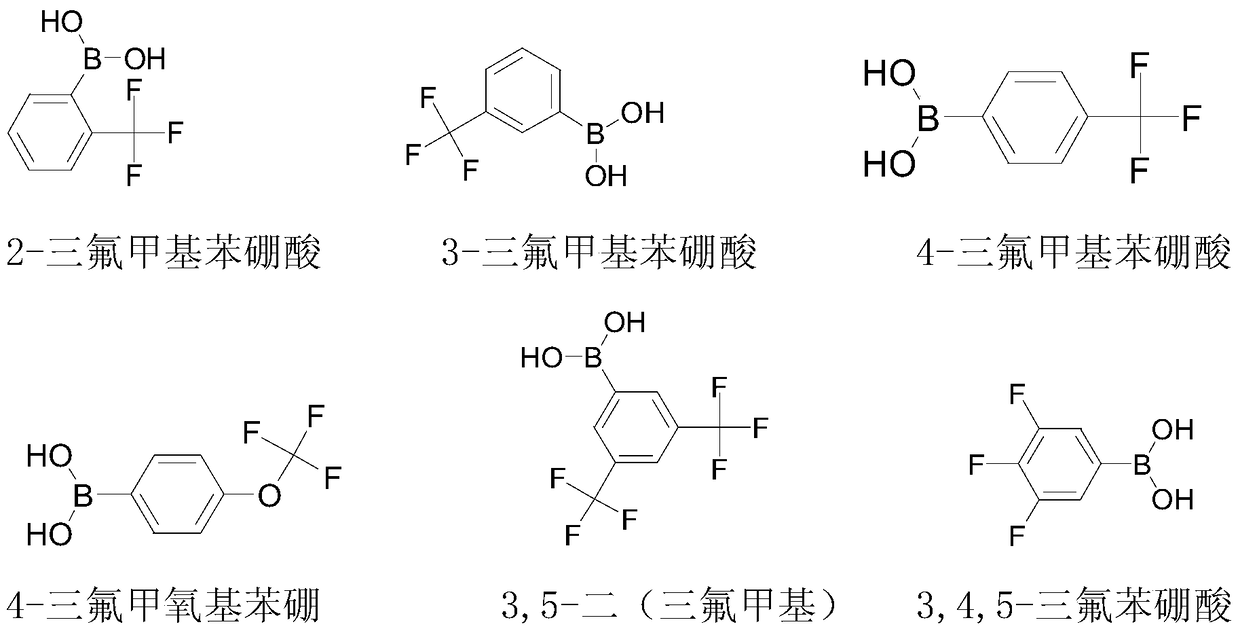

[0036] 1) 40 parts by weight of 3,5-bis(trifluoromethyl), 10 parts by weight of methanol, 5 parts by weight of sodium fatty acid, 8 parts by weight of polyethylene wax emulsion (particle size of 150nm), 5 parts by weight of silicone, 2 parts by weight of fatty alcohol polyoxyethylene ether, mixing the components, adding 200 parts by weight of water, stirring for 15 minutes, then ultrasonicating for 15 minutes, and standing to obtain a waterproof finishing agent;

[0037] 2) Adjust the finishing agent with acetic acid to obtain a finishing agent with a pH of 5.0, put the textile into a water-repellent finishing agent with a bath ratio of 1:40 and a temperature of 35°C for 15 minutes, then soak and shake for 15 minutes. , first pre-baked at 85°C for 15 minutes, then baked at 165°C for 10 minutes, ultrasonically washed 5 times and then dried to obtain high water-repellent fabrics. Sampling was carried out to test the waterproof performance of the finished textiles. The test resul...

Embodiment 2

[0041] 1) 60 parts by weight of 3,5-bis(trifluoromethyl), 10 parts by weight of methanol, 5 parts by weight of sodium fatty acid, 8 parts by weight of polyethylene wax emulsion (particle size of 150nm), 5 parts by weight of organic silicon, 2 parts by weight of fatty alcohol polyoxyethylene ether, mix the components, add 200 parts by weight of water, stir for 15 minutes, then ultrasonic for 15 minutes, and stand still to obtain a waterproof finishing agent;

[0042] 2) Adjust the finishing agent with acetic acid to obtain a finishing agent with a pH of 5.0, put the textile into a water-repellent finishing agent with a bath ratio of 1:40 and a temperature of 35°C for 15 minutes, then soak and shake for 15 minutes. , first pre-baked at 85°C for 15 minutes, then baked at 165°C for 10 minutes, ultrasonically washed 5 times and then dried to obtain high water-repellent fabrics. Sampling was carried out to test the waterproof performance of the finished textiles. The test results ar...

Embodiment 3

[0046] 1) According to the ratio of 40 parts by weight of 4-trifluoromethylphenylboronic acid, 10 parts by weight of methanol, 5 parts by weight of sodium fatty acid, 8 parts by weight of polyethylene wax emulsion (particle size is 150nm), 5 parts by weight of organic silicon, fatty alcohol poly 2 parts by weight of oxyethylene ether, mix the components, add 200 parts by weight of water, stir for 15 minutes, then sonicate for 15 minutes, and stand to obtain a waterproof finishing agent;

[0047] 2) Adjust the finishing agent with acetic acid to obtain a finishing agent with a pH of 5.0, put the textile into a water-repellent finishing agent with a bath ratio of 1:40 and a temperature of 35°C for 15 minutes, then soak and shake for 15 minutes. , first pre-baked at 85°C for 15 minutes, then baked at 165°C for 10 minutes, ultrasonically washed 5 times and then dried to obtain high water-repellent fabrics. Sampling was carried out to test the waterproof performance of the finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com