Method for preparing environmental-friendly waterproof warp knitted fabric

A warp knitted fabric, environmentally friendly technology, applied in the field of textiles, can solve problems such as poor air permeability, and achieve the effects of high softness, easy process parameters, and simple and easy methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

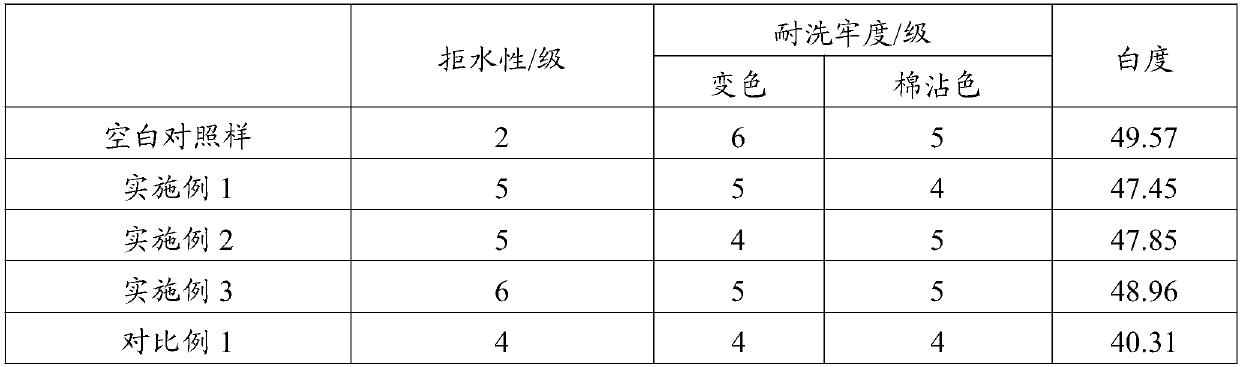

Examples

Embodiment 1

[0022] A preparation method of environment-friendly waterproof warp-knitted fabric, said preparation method comprising the following steps:

[0023] Step 1. Get 13 parts by mass of plant ash, 2 parts by mass of nano-carbon powder, 0.1 parts by mass of sodium hydroxide and 100 parts by mass of water and boil after mixing, the particle diameter of the nano-carbon powder is 20-40nm;

[0024] Step 2. Take by weighing 20 parts by mass of ramie fiber and 10 parts by mass of nanometer carbon dioxide catalyst fiber and put it into the boiled mixture, continue cooking for 2h;

[0025] Step 3. Take out the cooked fiber, wash it with water, dry it naturally, and then blend it into yarn;

[0026] Step 4. Take by weighing 4 parts by mass of chitosan, 1 part by mass of sodium stearoyl lactylate, 0.5 parts by mass of n-butanol, 2.2 parts by mass of dodecafluoroheptyl methacrylate, 1 part by mass of sodium dodecylbenzenesulfonate Add 20 parts by mass of absolute ethanol into the reactor and ...

Embodiment 2

[0030] A preparation method of environment-friendly waterproof warp-knitted fabric, said preparation method comprising the following steps:

[0031] Step 1. Get 15 mass parts plant ash, 4 mass parts nano carbon powder, 0.5 mass parts sodium hydroxide and 120 mass parts water and boil after mixing, the particle diameter of described nano carbon powder is 20-40nm;

[0032] Step 2. Take by weighing 35 parts by mass of ramie fiber and 15 parts by mass of nanometer carbon dioxide catalyst fiber and put it into the boiled mixture, continue cooking for 4h;

[0033] Step 3. Take out the cooked fiber, wash it with water, dry it naturally, and then blend it into yarn;

[0034] Step 4. Take by weighing 6 parts by mass of chitosan, 2 parts by mass of sodium stearoyl lactylate, 1.5 parts by mass of n-butanol, 3.5 parts by mass of dodecafluoroheptyl methacrylate, 1.5 parts by mass of sodium dodecylbenzenesulfonate and 35 parts by mass of absolute ethanol were added into the reactor and mix...

Embodiment 3

[0038] A preparation method of environment-friendly waterproof warp-knitted fabric, said preparation method comprising the following steps:

[0039] Step 1. Get 14 mass parts plant ash, 3 mass parts nano carbon powder, 0.3 mass parts sodium hydroxide and 110 mass parts water and boil after mixing, the particle diameter of described nano carbon powder is 20-40nm;

[0040] Step 2. Take by weighing 30 parts by mass of ramie fiber and 12 parts by mass of nanometer carbon dioxide catalyst fiber and put it into the boiled mixture, continue cooking for 3h;

[0041] Step 3. Take out the cooked fiber, wash it with water, dry it naturally, and then blend it into yarn;

[0042] Step 4. Take by weighing 5 parts by mass of chitosan, 1.5 parts by mass of sodium stearoyl lactylate, 1 part by mass of n-butanol, 3 parts by mass of dodecafluoroheptyl methacrylate, and 1 part by mass of sodium dodecylbenzenesulfonate Add 28 parts by mass of absolute ethanol into the reactor and mix evenly, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com