Preparation method of superfine modified ground limestone

A technology for the preparation of heavy calcium carbonate, which is applied in the fields of dyeing physical treatment, dyeing low-molecular organic compound treatment, and fibrous fillers. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

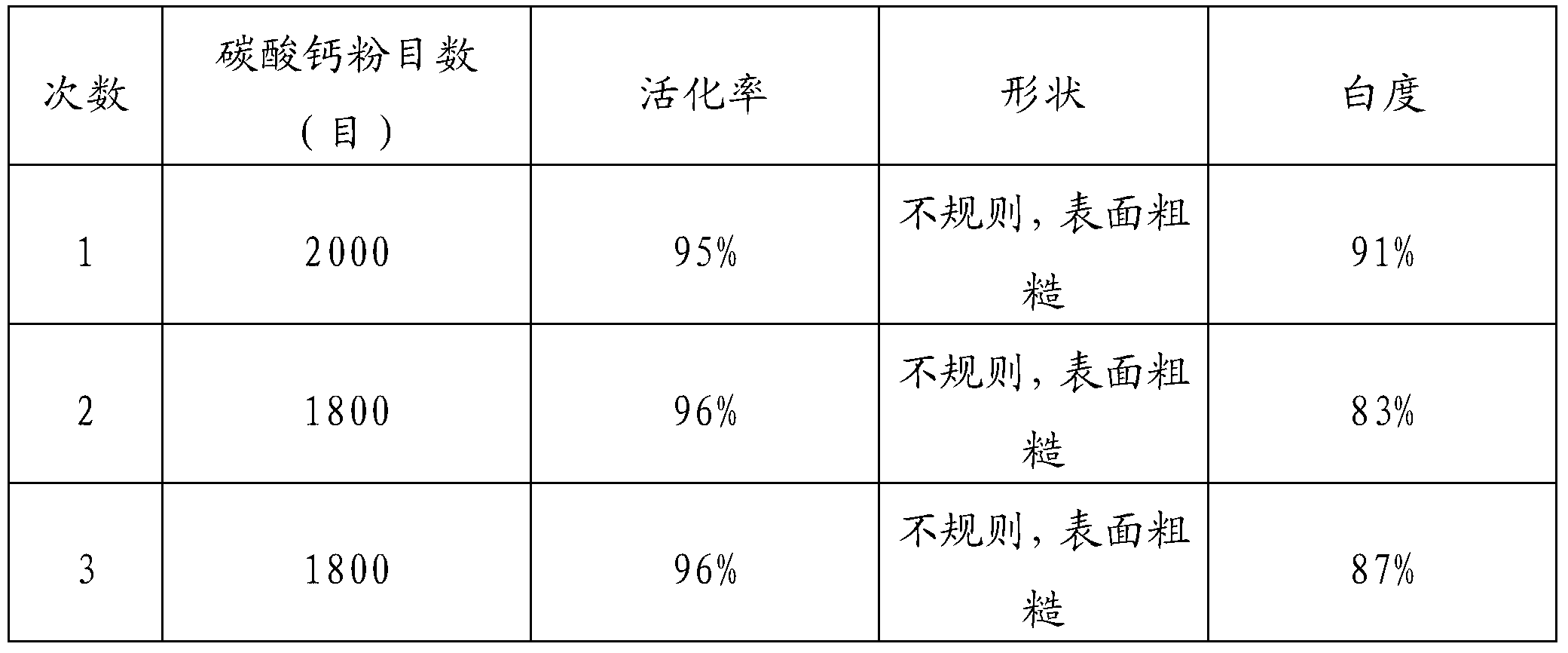

Embodiment 1

[0027] A preparation process for superfine modified ground calcium carbonate, comprising the steps of:

[0028] (1) bubble paste

[0029] Fully mix stone powder, water, and sodium polyacrylate, including 69kg of stone powder, 26kg of water, 7kg of dispersant, and 30 minutes of soaking time;

[0030] (2) grinding

[0031] A four-stage wet grinding method is adopted. In the first-stage grinding, the flow rate of the slurry is 6t / h, and 0.4kg of sodium polyacrylate is added during the grinding process. The grinding temperature is 20°C and the grinding time is 60min; the second-level grinding In the process, the flow rate of the slurry is 6t / h, and 0.4kg of sodium polyacrylate is added during the grinding process, the grinding temperature is 30°C, and the grinding time is 60min; in the third-stage grinding, the flow rate of the slurry is 6t / h, and Add 0.4kg of sodium polyacrylate during the grinding process, the grinding temperature is 30°C, and the grinding time is 60min; in th...

Embodiment 2

[0038] A kind of preparation technology of superfine modified ground calcium carbonate, comprises the steps:

[0039] (1) bubble paste

[0040] Fully mix stone powder, water, and sodium polyacrylate, including 74kg of stone powder, 31kg of water, 13kg of dispersant, and 30 minutes of soaking time;

[0041] (2) grinding

[0042] A four-stage wet grinding method is adopted. In the first-stage grinding, the flow rate of the slurry is 6t / h, and 0.4kg of sodium polyacrylate is added during the grinding process. The grinding temperature is 20°C and the grinding time is 60min; the second-level grinding In the process, the flow rate of the slurry is 6t / h, and 0.4kg of sodium polyacrylate is added during the grinding process, the grinding temperature is 30°C, and the grinding time is 60min; in the third-stage grinding, the flow rate of the slurry is 6t / h, and Add 0.4kg of sodium polyacrylate during the grinding process, the grinding temperature is 30°C, and the grinding time is 60min...

Embodiment 3

[0049] A kind of preparation technology of superfine modified ground calcium carbonate, comprises the steps:

[0050] (1) bubble paste

[0051] Fully mix stone powder, water, and sodium polyacrylate, including 72kg of stone powder, 29kg of water, 10kg of dispersant, and 30 minutes of soaking time;

[0052] (2) grinding

[0053] A four-stage wet grinding method is adopted. In the first-stage grinding, the flow rate of the slurry is 6t / h, and 0.4kg of sodium polyacrylate is added during the grinding process. The grinding temperature is 20°C and the grinding time is 60min; the second-level grinding In the process, the flow rate of the slurry is 6t / h, and 0.4kg of sodium polyacrylate is added during the grinding process, the grinding temperature is 30°C, and the grinding time is 60min; in the third-stage grinding, the flow rate of the slurry is 6t / h, and Add 0.4kg of sodium polyacrylate during the grinding process, the grinding temperature is 30°C, and the grinding time is 60min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com