Softening agent special for paper softening and mould proofing and preparation method thereof

A softener and softening technology, applied in the field of softeners, can solve the problems of inability to improve the paper's anti-mildew, whiteness, paper whiteness, shading and other properties, and achieve high uniformity, good bacteriostatic effect, and significant softness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

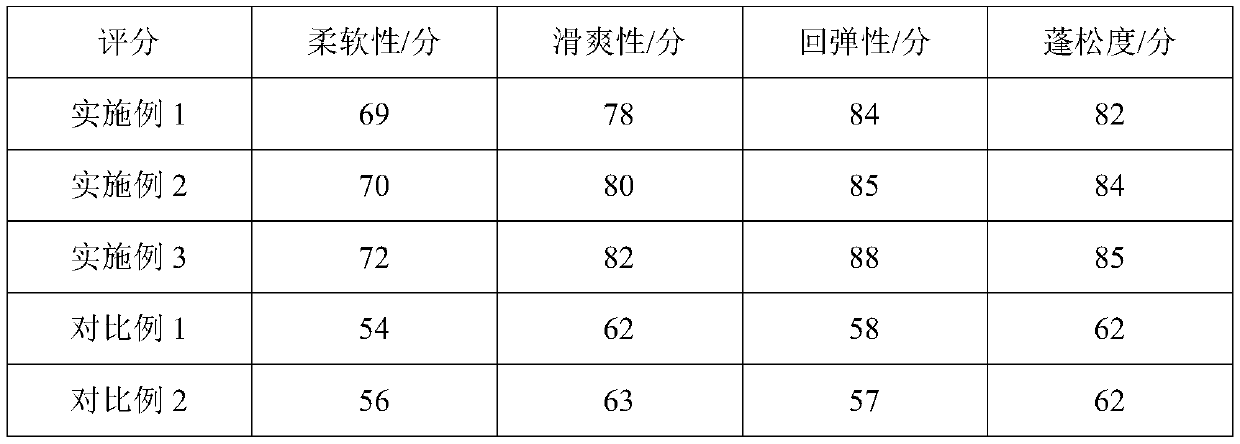

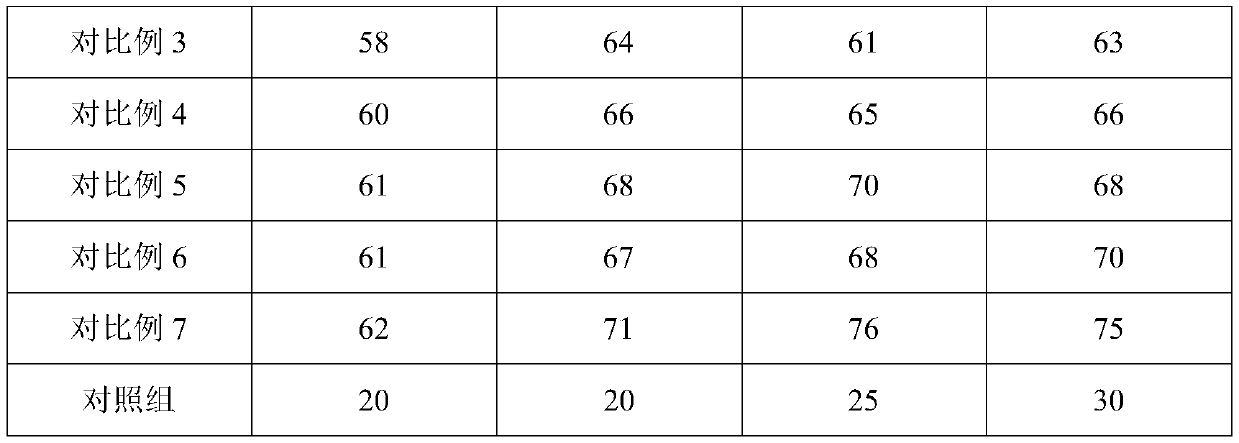

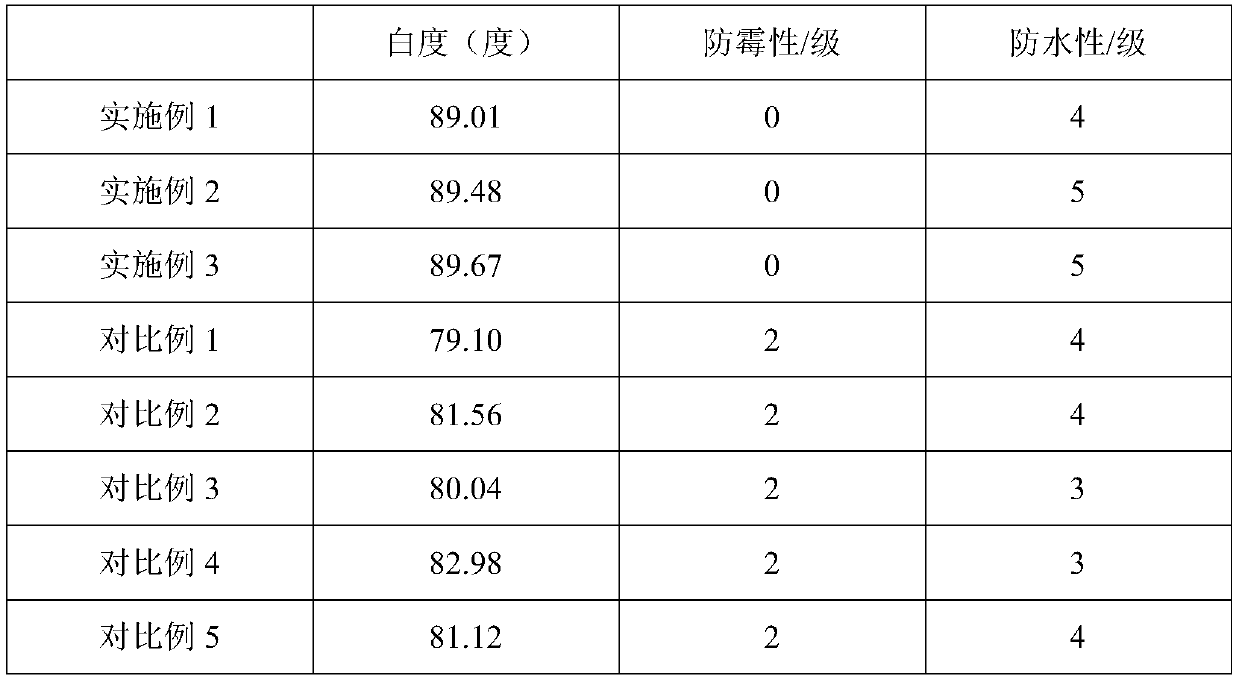

Examples

Embodiment 1

[0057] A special softener for paper softness and mildew resistance, comprising the following components in parts by weight: 5 parts of polyethylene, 8 parts of cetyl siloxane, 5 parts of nano-zinc oxide, 5 parts of chitosan, 4 parts of hydroxyethyl Cellulose, 5 parts aloe vera extract, 2 parts isopropyl alcohol, 1 part sorbic acid, 3 parts liquid wax, and 10 parts water.

[0058] The preparation method of the aloe extract comprises the following steps: drying and pulverizing the aloe, adding 5 times the amount of 75% ethanol, ultrasonically extracting for 1 hour, with an ultrasonic power of 100w, and filtering, the filtrate is sequentially extracted with ethyl acetate and petroleum ether, and the petroleum ether The extract is concentrated, dried, and obtained.

[0059] The preparation method of softening agent comprises the steps:

[0060] (1) Chitosan, hydroxyethyl cellulose, water, and sorbic acid are mixed to obtain solution 1;

[0061] (2) Add resin, cetyl siloxane and ...

Embodiment 2

[0064] A special softener for paper softness and mildew resistance, comprising the following components in parts by weight: 10 parts of polyurethane, 3 parts of cetyl siloxane, 2 parts of nano-zinc oxide, 2 parts of chitosan, and 2 parts of hydroxyethyl fiber 3 parts Aloe Vera Extract, 1 part Propylene Glycol, 2 parts Citric Acid, 2 parts Liquid Wax and 5 parts Water.

[0065] The preparation method of the aloe extract comprises the following steps: drying and pulverizing the aloe, adding 8 times the amount of 95% ethanol, ultrasonically extracting for 2 hours, with an ultrasonic power of 300w, and filtering, and the filtrate is sequentially extracted with ethyl acetate and petroleum ether, and the petroleum ether The extract is concentrated, dried, and obtained.

[0066] The preparation method of softening agent comprises the steps:

[0067] (1) Chitosan, hydroxyethyl cellulose, water, and citric acid are mixed to obtain solution 1;

[0068] (2) Add resin, cetyl siloxane an...

Embodiment 3

[0071] A special softener for paper softness and mildew resistance, comprising the following components in parts by weight: 8 parts of resin, 5 parts of cetyl siloxane, 3 parts of nano-zinc oxide, 4 parts of chitosan, and 3 parts of hydroxyethyl fiber element, 4 parts of aloe extract, 1.5 parts of surfactant, 1.5 parts of solvent, 1.5 parts of sodium bicarbonate, 2.5 parts of liquid wax and 8 parts of water. The resin is a mixture of polyethylene and polyurethane with a mass ratio of 2:1; the solvent is a mixed solvent of isopropanol and butylene glycol with a mass ratio of 1:1.

[0072] The preparation method of the aloe extract comprises the following steps: drying and pulverizing the aloe, adding 7 times the amount of 85% ethanol, ultrasonically extracting for 1.5 hours, with an ultrasonic power of 200w, and filtering, and the filtrate is sequentially extracted with ethyl acetate and petroleum ether, and the petroleum The ether extract was concentrated and dried to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com