Sewage treatment method of magnetic three-phase Fenton reactor and equipment thereof

A kind of sewage treatment equipment and Fenton reaction technology, which is applied in the field of sewage treatment equipment and magnetic three-phase Fenton reactor sewage treatment, can solve the problem of large demand for acid-base chemicals, high energy consumption of Fenton reactor, and catalyst catalysis. Low efficiency and other problems, to achieve the effect of easy storage and transportation, not easy to deteriorate, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

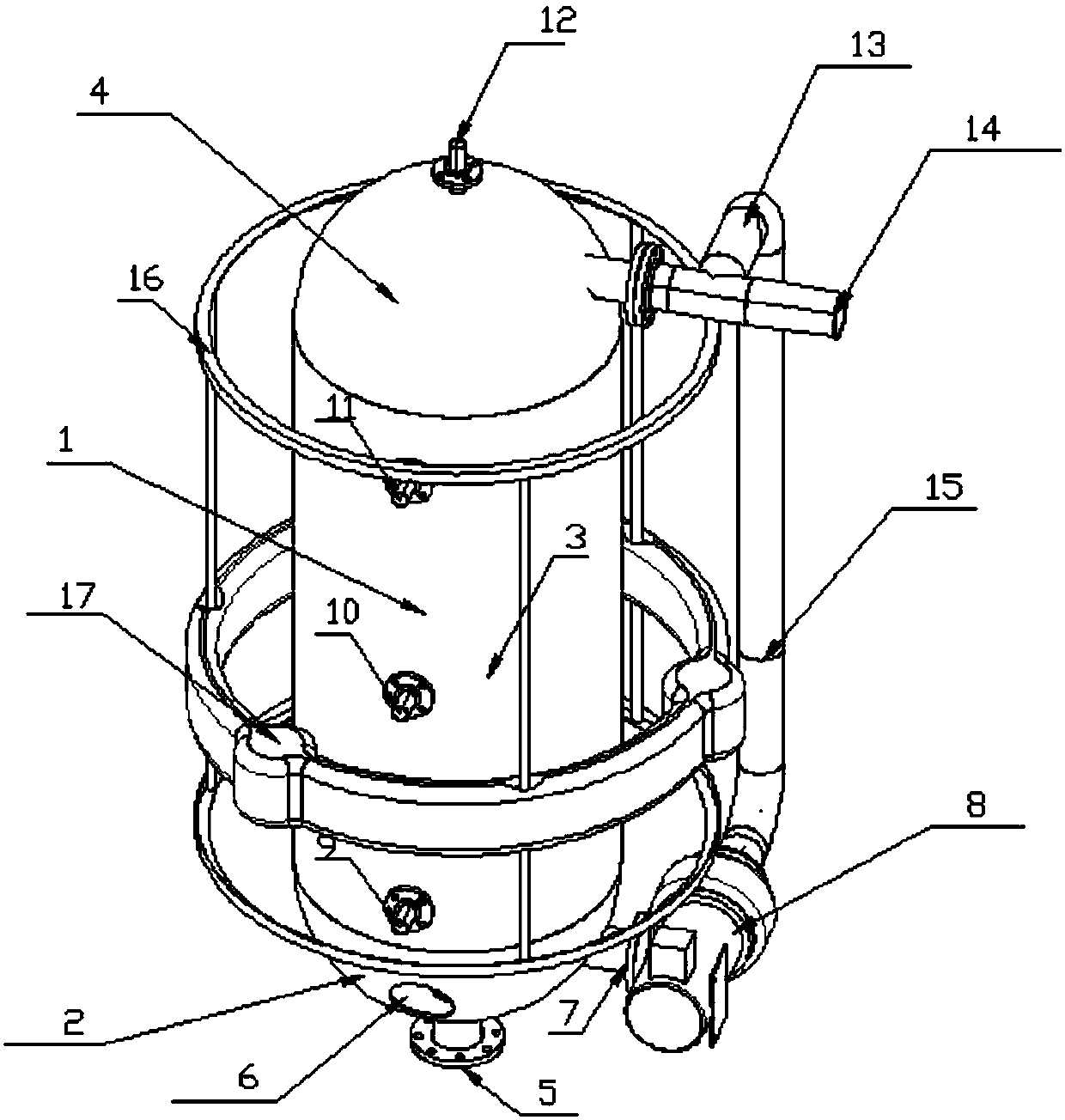

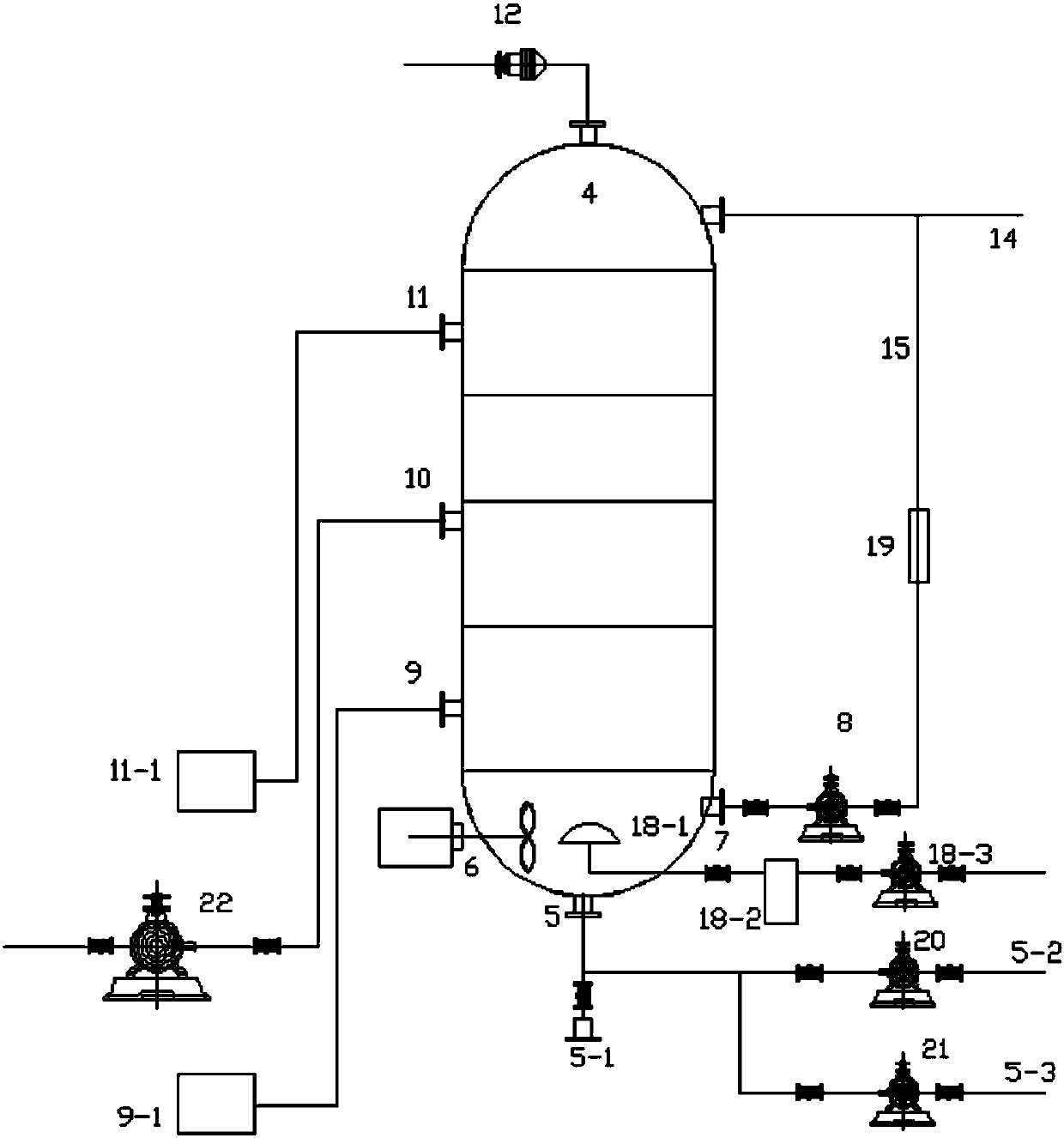

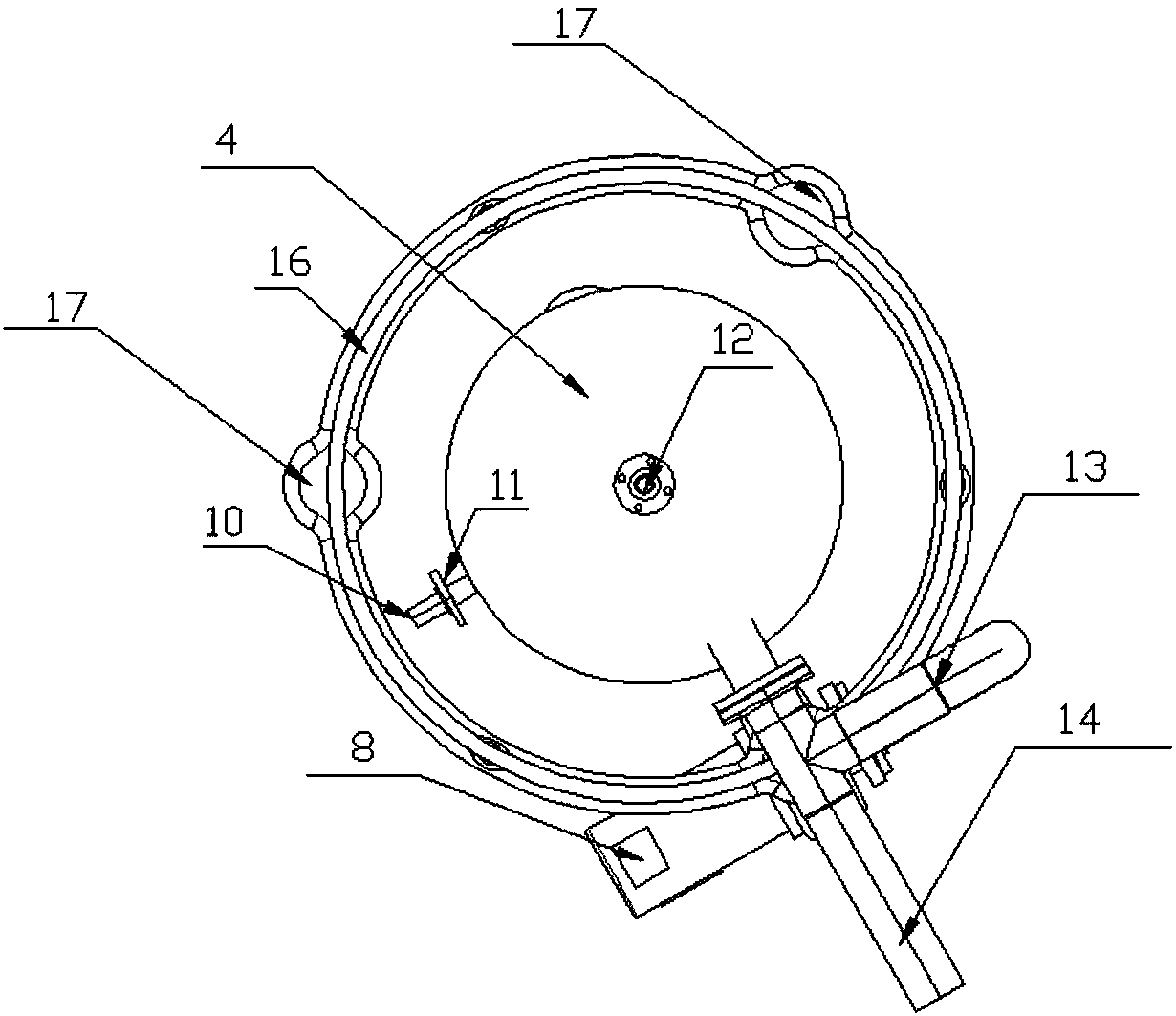

[0038] A kind of sewage treatment method of magnetic three-phase Fenton reactor, its step is:

[0039] (A) Sewage enters the bottom of the reactor from the water inlet, and the oxidant enters the bottom of the reactor through the flow meter by the first dosing pump, and the second dosing pump is a sulfuric acid dosing pump; the agitator arranged at the bottom of the reactor , Under the hydraulic action of the aeration system and the reflux pump, the sewage and oxidant entering the bottom of the reactor enter the reaction zone after being fully mixed; providing a good pre-mixing effect for the Fenton reaction.

[0040] (B) After the solution is mixed, it enters the Fenton reaction zone after uniform water distribution in the water inlet zone for Fenton reaction. In the reaction zone of the Fenton catalyst, the pH of the zone is controlled at 1.5 or 2 or 3 or 4 or 4.5, which meets the reaction acidic environment requirement of the Fenton reaction. Sulfuric acid is added to the ...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is that the flow rate of the reflux pump is 1-10 times of the influent flow rate, and the sewage returned to the reactor dilutes the raw water, increases the load on the reactor, and makes the use of Fenton's reagent The efficiency is improved, and the iron-based catalyst is composed of iron: carbon: copper = 70-90:6-10:4-10, which can be used more fully. Other steps and parameters are the same as in Example 1. Taking flax wastewater as an example, the COD removal rate reaches about 70%, while the chromaticity is reduced to 1-5 times.

[0045] Other implementation steps are the same as in Example 1.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is that the dosage of hydrogen peroxide is selected to be 100-1000ml / L according to different influent water quality. For example, for printing and dyeing wastewater, the dosage of hydrogen peroxide is 800ml / L; for methyl orange wastewater, the dosage of hydrogen peroxide is 300mg / L. The hydrogen peroxide enters the Fenton reaction zone after being mixed with the sewage in the dosing pipeline, and after contacting with the Fenton catalyst, a heterogeneous Fenton reaction occurs inside the Fenton reaction zone to degrade the sewage. In 30 minutes, the COD removal rate of printing and dyeing wastewater can reach 80%; the COD removal rate of methyl orange can reach 90%.

[0048] Other implementation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com