Powder alloy smithing float grease seal ring with upper and lower double-layer and method of producing the same

A floating oil seal and powder alloy technology, applied in the field of mechanical seals, can solve the problems of high processing hardness, waste, burns and seizures, etc., achieve high wear resistance and fatigue resistance, increase service life, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

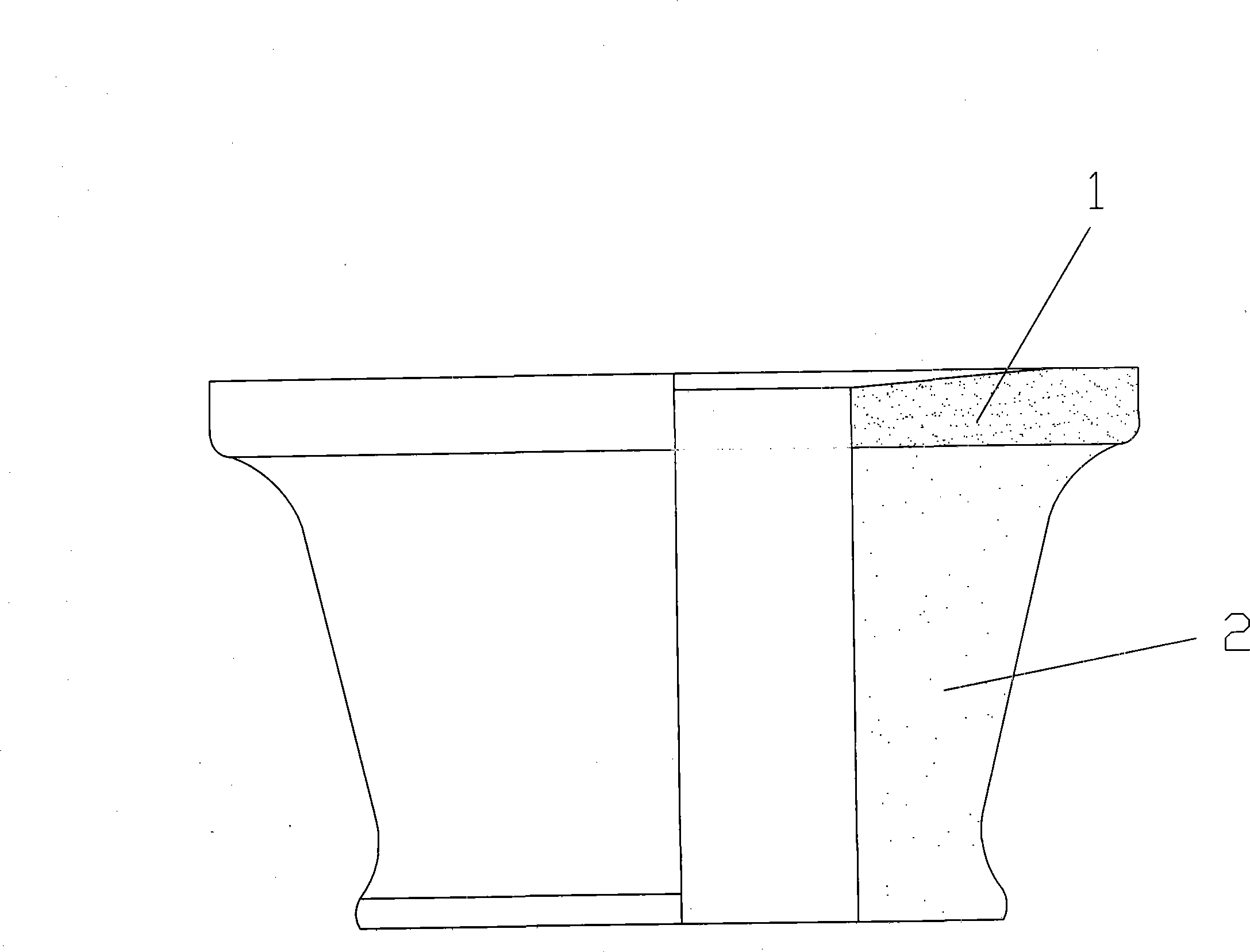

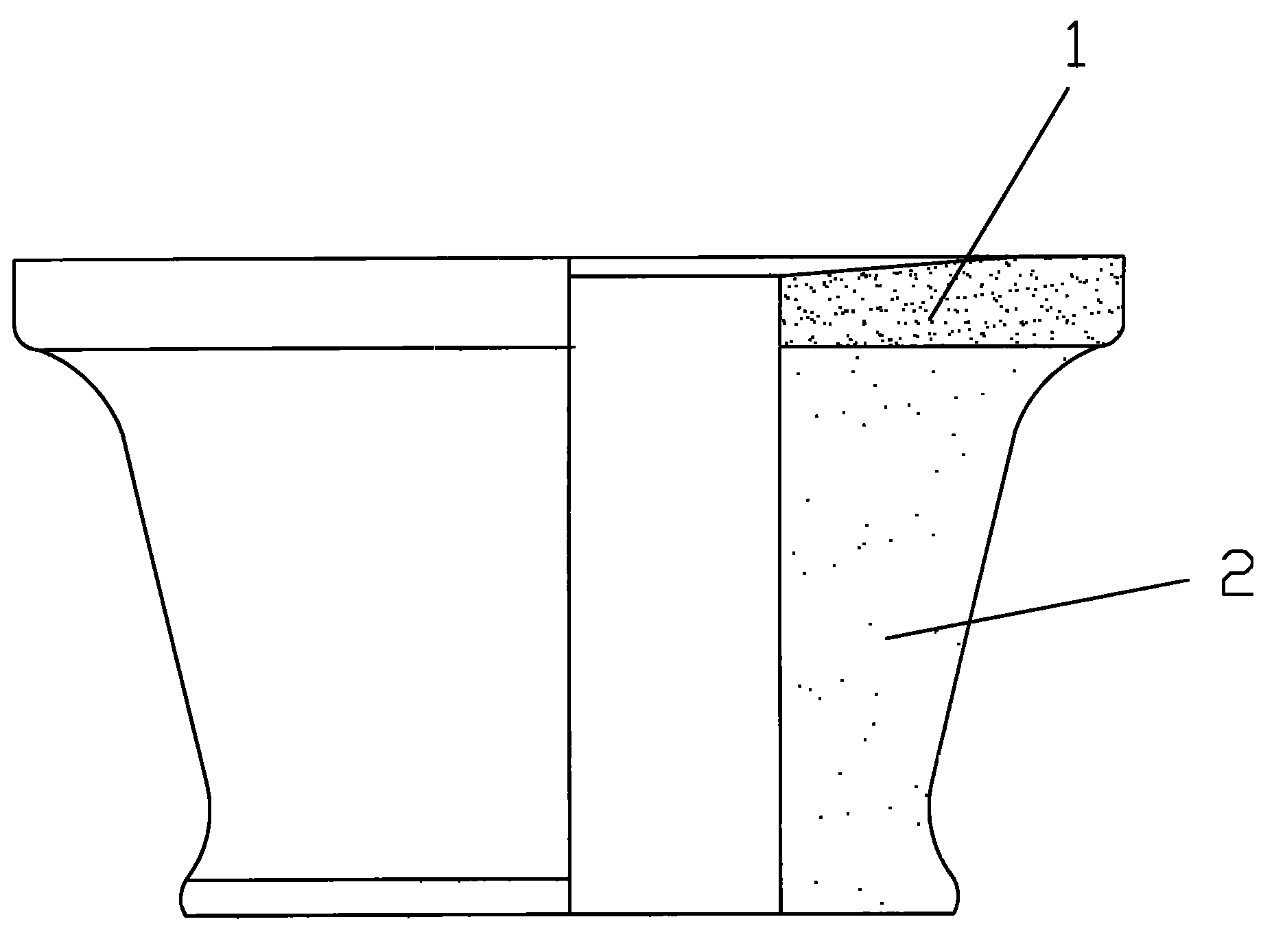

[0020] see figure 1 , an upper and lower double-layer powder alloy forged floating oil seal ring, the outer diameter of the floating oil seal ring is Φ58~Φ394mm, including an upper layer 1 and a lower layer 2, the upper layer 1 is made of rare alloy powder material, and the height of the upper layer is 2~3.5mm, its chemical composition and weight percentage are: Cu: 0.5~3%, C: 0.5~1%, Cr: 0.5~2%, MoS 2 : 0.5-1.5%, the rest is iron; the lower layer 2 is made of common iron powder, and its chemical composition and weight percentage are respectively: Cu: 0.5-3%, C: 0.5-1%, and the rest is iron; The upper layer 1 and the lower layer 2 are pressed and sintered at high temperature to form an integral floating oil seal ring. The upper and lower double-layer powder alloy forged floating oil seals significantly reduce the material cost compared with the alloy material us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com