Polyhexamethylene biguanide hydrochloride compound microencapsulated antibacterial finishing agent and preparation method thereof

A technology of polyhexamidine hydrochloride and antibacterial finishing agent is applied in the field of microcapsule antibacterial finishing agent compounded with polyhexabiguanide hydrochloride and its preparation field, which can solve the problems of poor washing resistance, poor broad-spectrum and the like, To achieve good washing resistance, improve washing fastness, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

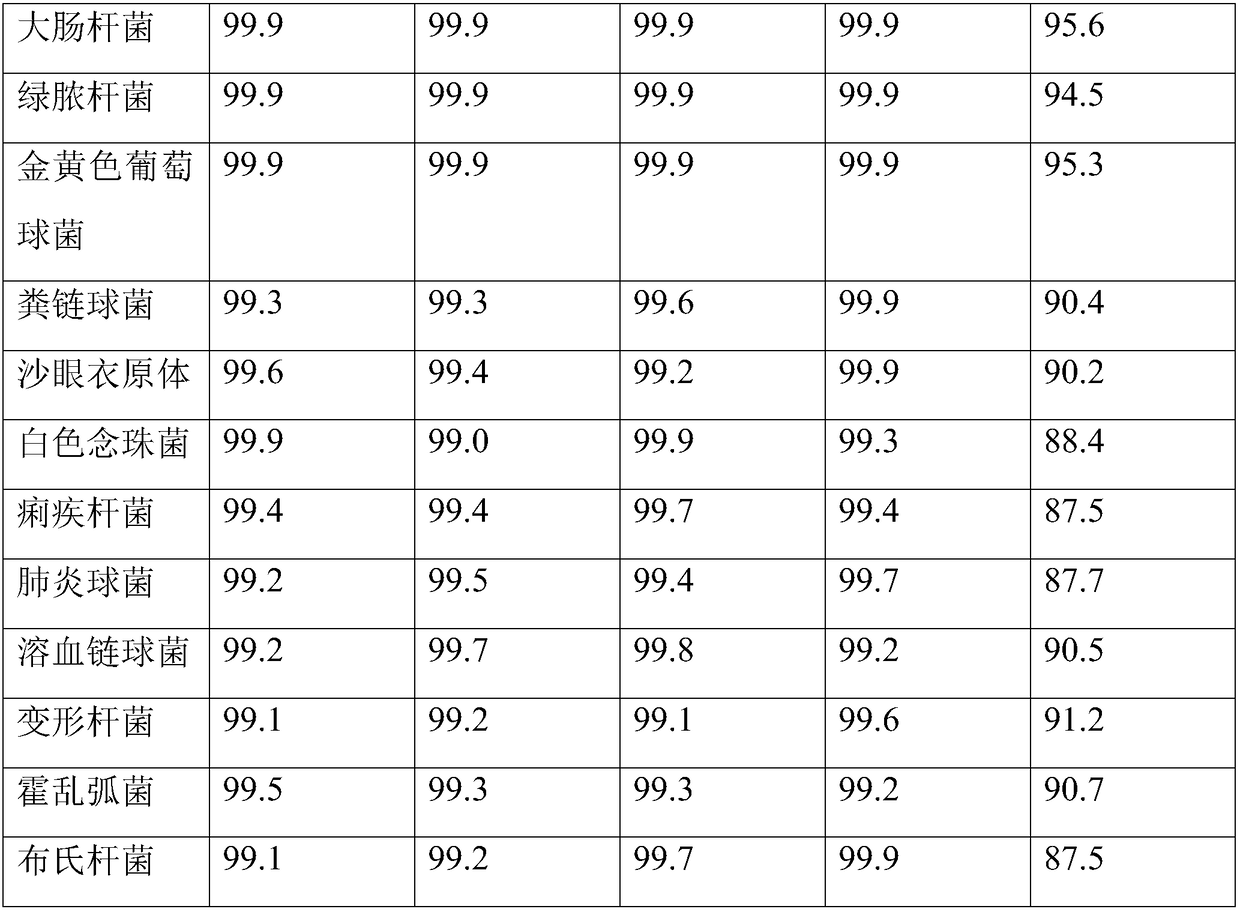

Embodiment 1

[0043] (1) Preparation of the core material: under the stirring condition of a high-speed shear emulsifier, add 0.5 part of polyhexabiguanide hydrochloride, 1 part of nano-copper ion, 1 part of 3-methyl-4-isopropylphenol to the water 5 parts, 5 parts of vinylbisstearamide, 2 parts of polysorbate 80, 4 parts of polyvinyl alcohol, after stirring for 20-30 minutes, reduce the stirring speed to obtain the core material, and set aside;

[0044] (2) preparation of shell material: 30 parts of polycarbophil and 15 parts of chitosan are dissolved in citric acid solution, add PVP ethanol solution, obtain shell material after fully dissolving, for subsequent use;

[0045] (3) Preparation of microcapsules: at 50°C, add the core material obtained in step (1) dropwise to the shell material obtained in step (2), stir evenly while adding dropwise, fully mix, and then The temperature was naturally lowered to 20°C, and finally a microcapsule antibacterial finishing agent compounded with polyhex...

Embodiment 2

[0047] (1) Preparation of the core material: under the stirring condition of a high-speed shear emulsifier, 3 parts of polyhexabiguanide hydrochloride, 2 parts of nano-copper ions, 3 parts of 3-methyl-4-isopropylphenol were added to the water part, 8 parts of glyceryl tristearate, 5 parts of sorbitan laurel, 7 parts of hydroxymethylcellulose, after stirring for 20-30 minutes, reduce the stirring speed to obtain the core material, and set aside;

[0048] (2) preparation of shell material: 50 parts of polycarbophil and 20 parts of chitosan are dissolved in citric acid solution, add PVP ethanol solution, obtain shell material after fully dissolving, standby;

[0049] (3) Preparation of microcapsules: at 60°C, add the core material obtained in step (1) dropwise to the shell material obtained in step (2), stir evenly while adding dropwise, fully mix, and then The temperature was naturally lowered to 20°C, and finally a microcapsule antibacterial finishing agent compounded with poly...

Embodiment 3

[0051] (1) Preparation of the core material: under the stirring condition of a high-speed shear emulsifier, add 1 part of polyhexabiguanide hydrochloride, 5 parts of nano-copper ions, 2 parts of 3-methyl-4-isopropylphenol to water 5 parts, 5 parts of dioctyl sodium sulfosuccinate, 10 parts of sorbitan oleate, 5 parts of hydroxymethyl cellulose, after stirring for 20-30 minutes, reduce the stirring speed to obtain the core material, and set aside;

[0052] (2) Preparation of shell material: 40 parts of carbomer and 30 parts of chitosan are dissolved in citric acid solution, PVP ethanol solution is added, fully dissolved to obtain shell material, and set aside;

[0053] (3) Preparation of microcapsules: at 60°C, add the core material obtained in step (1) dropwise to the shell material obtained in step (2), stir evenly while adding dropwise, fully mix, and then The temperature was naturally lowered to 25°C, and finally a microcapsule antibacterial finishing agent compounded with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com