A mobile phone lens and printing method thereof

A printing method and lens technology, applied in printing, printing devices, etc., can solve the problems of poor coverage of white ink and achieve the effect of improving the coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

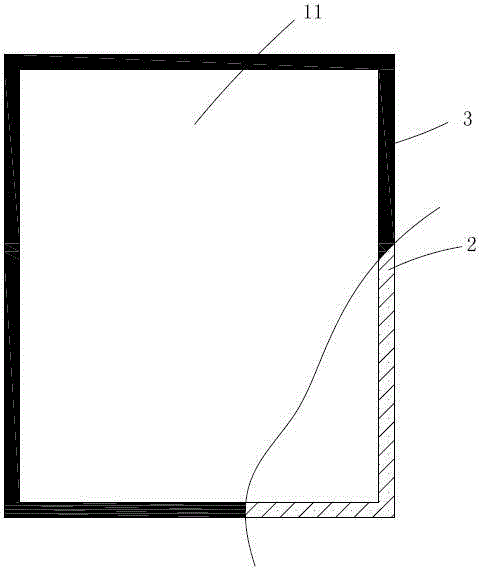

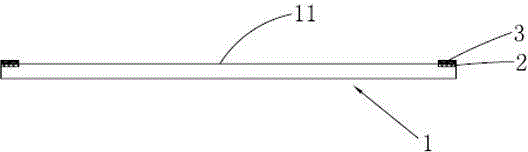

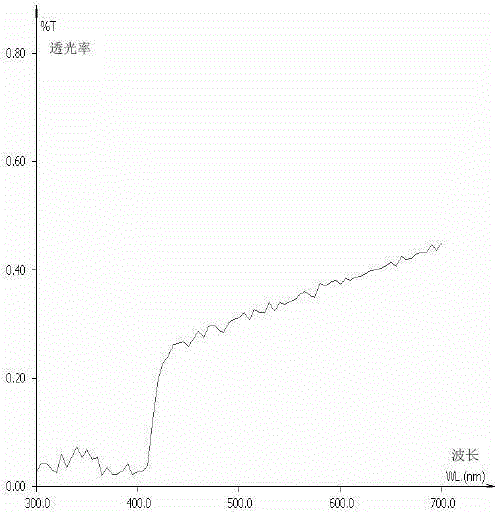

Examples

Embodiment 1

[0049] This embodiment is used to illustrate the operation steps and the obtained effects of the printing method of the present invention;

[0050] 1. Use a camera to take a display frame pattern of an ordinary mobile phone and input it into the computer. The display frame pattern includes a display area pattern and a frame pattern, and the typesetting work is done to achieve an aesthetic effect;

[0051] 2. Output the typesetting display frame pattern to the film through the computer;

[0052] 3. Use this film to make two screens with different meshes and materials that meet the requirements. Among them, the first screen is made of monofilament polyester screen with a mesh of 150 mesh, and the second screen is made of a mesh with a mesh of 150. Made of 380 mesh ordinary polyester screen;

[0053] 4. At room temperature (20°C), use the first screen printing (using a scraper at 75°C) on the surface of the mobile phone lens substrate to be printed with a layer of frosting paste...

Embodiment 2

[0075] This embodiment is used to illustrate the operation steps and the obtained effects of the printing method of the present invention;

[0076] 1. Take a picture of the display frame pattern of an ordinary mobile phone and input it into the computer. The display frame pattern includes a display area pattern and a frame pattern, and the typesetting work is done to achieve an aesthetic effect;

[0077] 2. Output the typesetting display frame pattern to the film through the computer;

[0078] 3. Use this film to make two screens with different meshes and materials that meet the requirements. Among them, the first screen is made of monofilament polyester screen with a mesh of 120 mesh, and the second screen is made of a mesh of 120 mesh. Made of 180 mesh ordinary polyester screen;

[0079] 4. At room temperature (25°C), use the first screen printing (using a 90-degree scraper) on the surface of the mobile phone lens substrate to be printed with a layer of frosting paste produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com