Packaging container

A packaging container and light-blocking layer technology, which is applied in the field of packaging products, can solve the problems of large changes in acidity, taste, and viscosity of dairy products, high cost of color masterbatch and oxygen absorbing agent, and uneven distribution of bottle materials. Achieve the effects of improving utilization rate and distribution uniformity, reducing oxygen permeability and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

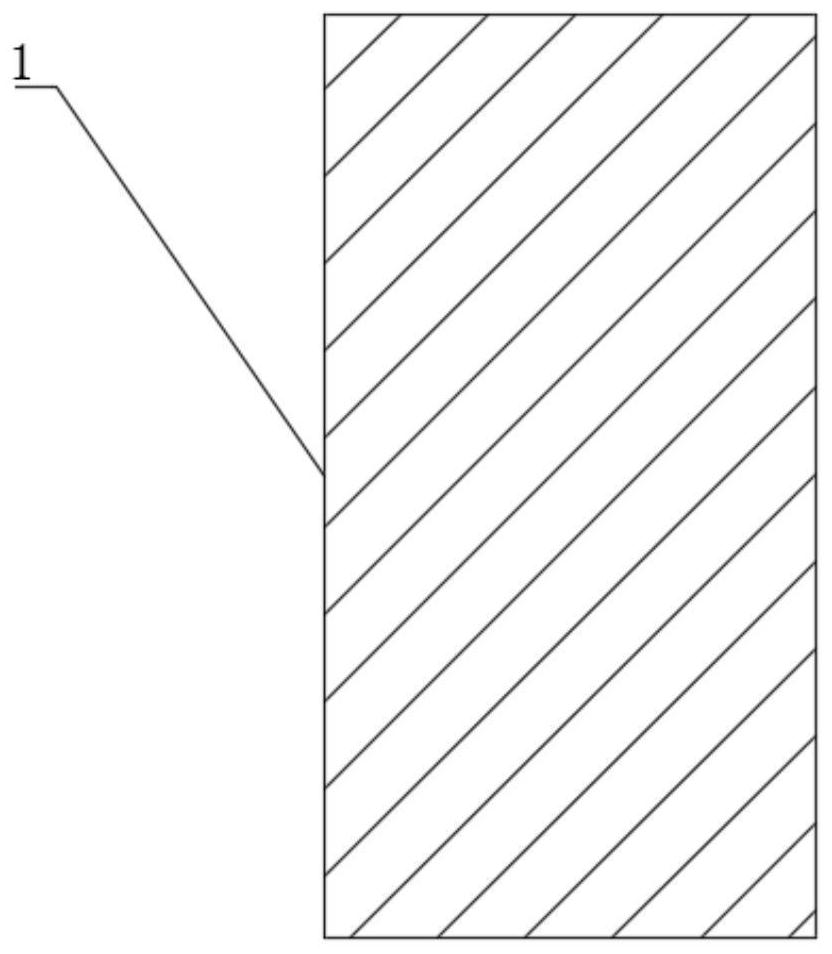

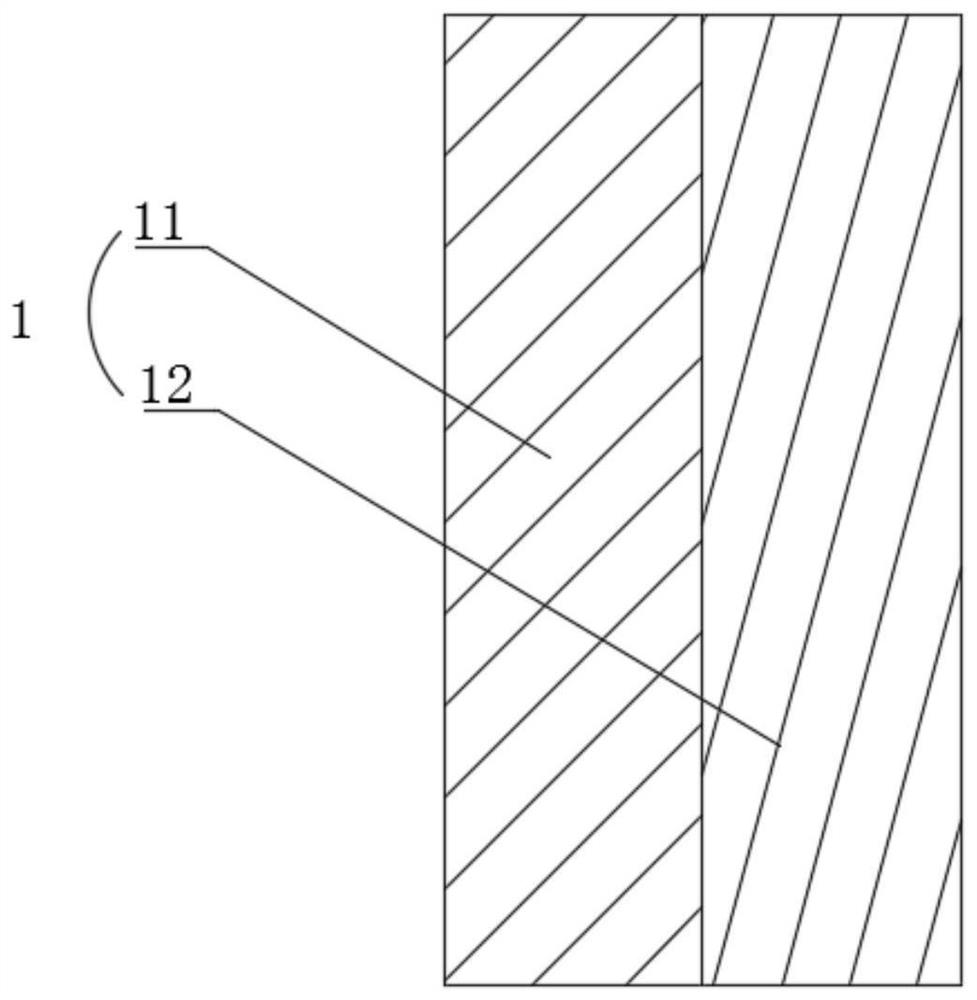

[0040] This embodiment provides a packaging bottle, the bottle wall has a two-layer structure, arranged according to layer A / layer B, wherein layer A is the light-blocking layer of the outer layer, and layer B is the oxygen-absorbing layer of the inner layer. The raw material formula of packing bottle is as follows:

[0041] Layer A is made of raw materials with the following weight: polyethylene terephthalate 15.456, blue-gray masterbatch Lactra SX 1.344g.

[0042] Layer B is made of the following raw materials: polyethylene terephthalate 3.818g, black color oil 0.004g, oxygen absorber amosorb 4020E 0.378g.

Embodiment 2

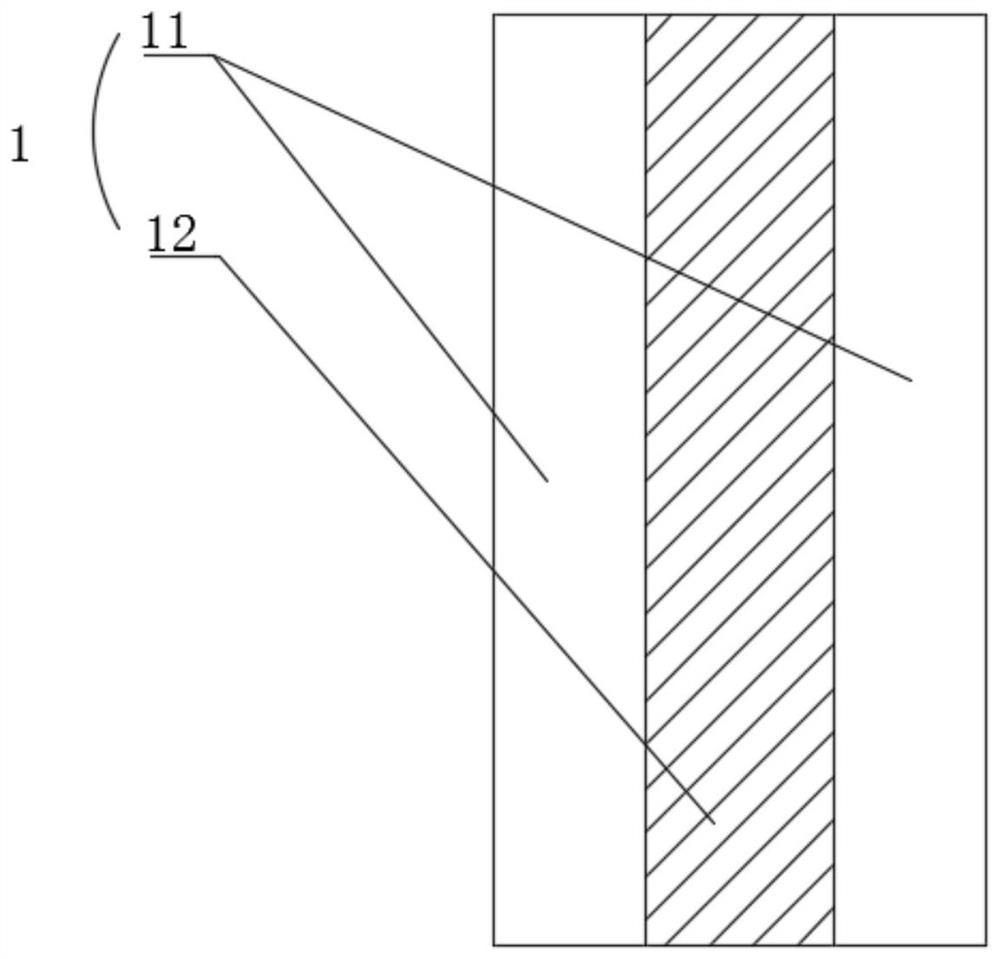

[0044] This embodiment provides a packaging bottle, the packaging bottle is produced by a double-channel injection molding process, the bottle wall is a two-layer structure, arranged according to the A layer / B layer, wherein the A layer is the light blocking layer of the outer layer, and the B layer is the outer light blocking layer. Inner oxygen absorbing layer. The raw material formula of packing bottle is as follows:

[0045] Layer A is made of the following raw materials: polyethylene terephthalate 13.524g, blue-gray masterbatch Lactra SX 1.176g.

[0046] Layer B is made of the following raw materials: polyethylene terephthalate 5.337g, black color oil 0.018g, oxygen absorber amosorb 4020E 0.945g.

Embodiment 3

[0048] This embodiment provides a packaging bottle, the packaging bottle is produced by a double-channel injection molding process, the bottle wall is a two-layer structure, arranged according to the A layer / B layer, wherein the A layer is the light blocking layer of the outer layer, and the B layer is the outer light blocking layer. Inner oxygen absorbing layer. The raw material formula of packing bottle is as follows:

[0049] Layer A is made of the following raw materials: polyethylene terephthalate 17.388g, blue-gray masterbatch Lactra SX 1.512g.

[0050] Layer B is made of the following raw materials by weight: polyethylene terephthalate 1.89g, black color oil 0.01g, oxygen absorber amosorb 4020E 0.105g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com