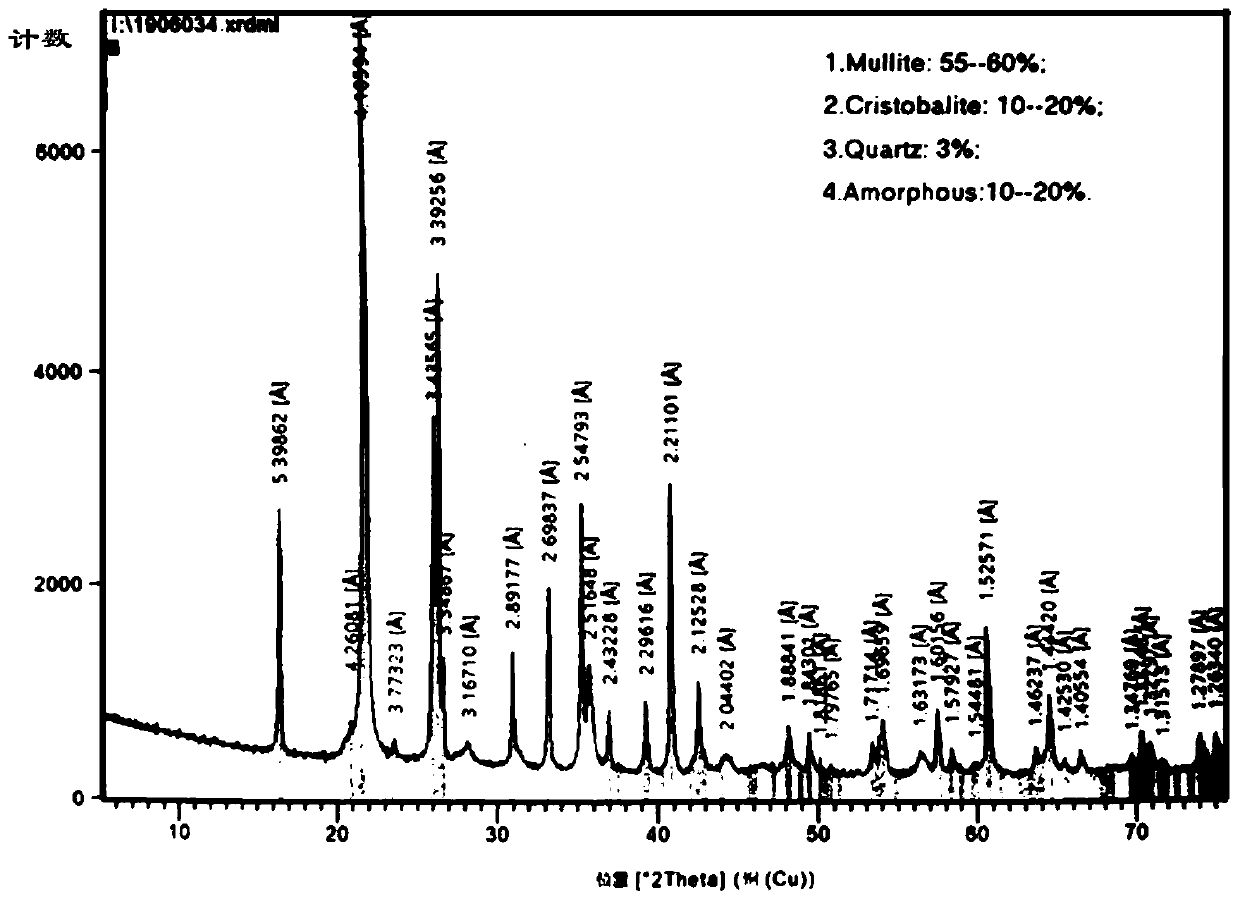

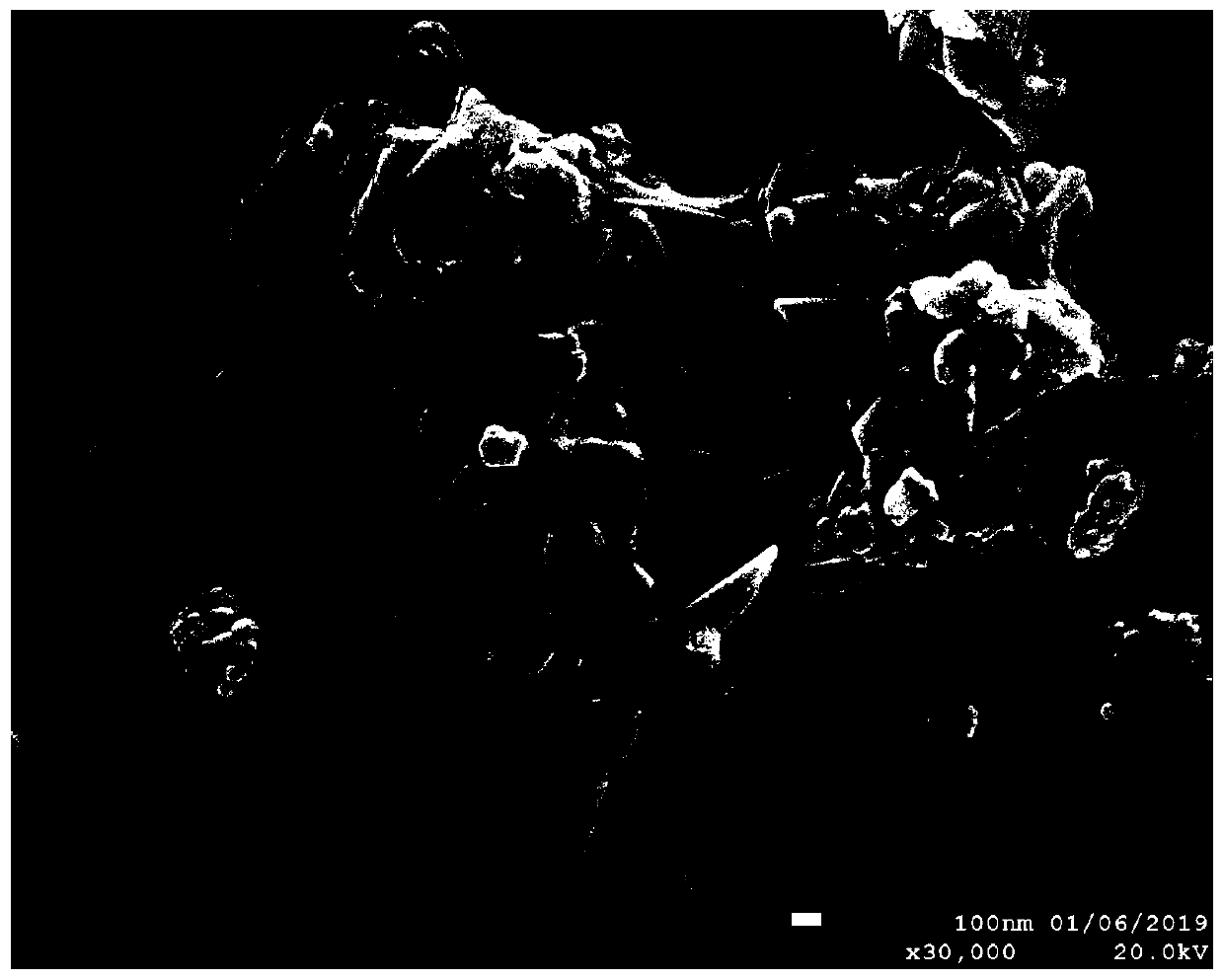

Production method of microcrystalline mullite type calcined kaolin, obtained product and application

A technology of calcined kaolin and microcrystalline mullite, which is applied in the production field of microcrystalline mullite type calcined kaolin and microcrystalline mullite type calcined kaolin, which can solve the problems of poor quality, limited application and high whiteness of calcined kaolin Calcined kaolin cannot use high-speed iron raw materials to achieve the effects of facilitating air circulation, improving economic benefits, and increasing effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

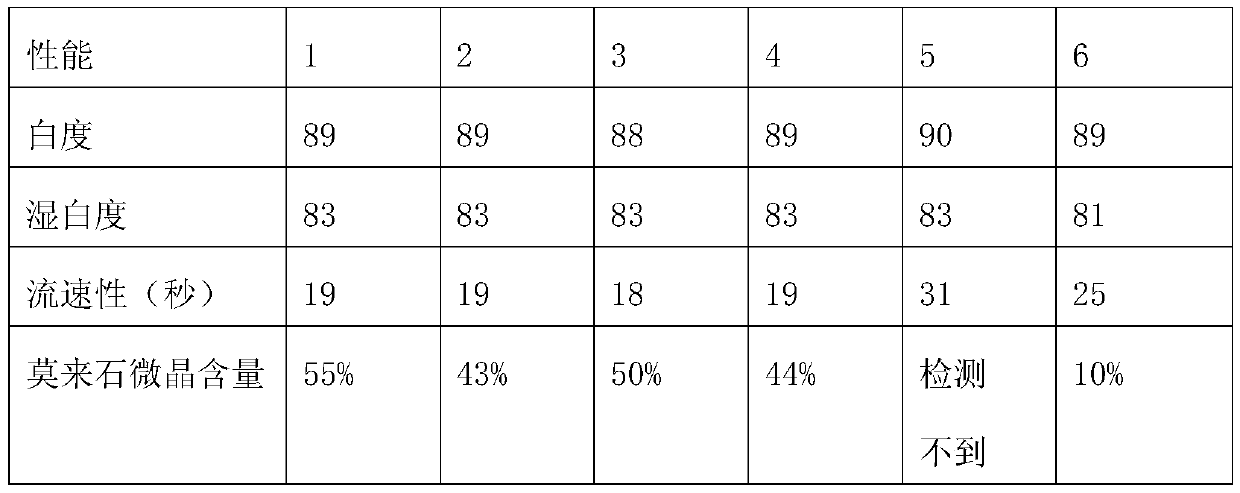

Examples

Embodiment 1

[0046] The composition of high-iron gangue raw materials (content is calculated after calcination, the same below) is shown in Table 1:

[0047] SiO 2

Al 2 O 3

Fe 2 O 3

TiO 2

other 54.1%43.2%0.8%1.1%0.8%

[0048] 1) From Table 1, it can be seen that Al in the raw material 2 O 3 More than 30%, Fe 2 O 3 More than 0.4%, no need to add aluminum regulator,

[0049] 2) Crush the raw material obtained in step 1) and grind to 100 mesh to obtain a mixed powder,

[0050] 3) Add the mixed powder to water and mix it evenly to make a wet material. The weight ratio of the mixed powder to water is 75:25, and the moisture content of the wet material is 25%. The wet material is aged for 8 hours and squeezed to make it. After the bricks are stacked on the kiln car, they are dried until the moisture content is less than 5%. After drying, the kiln car enters the tunnel kiln for calcination. In the tunnel kiln, the oxidizing atmosphere is below 1100°C, and the reducing atmosphere is above 1100°C...

Embodiment 2

[0052] The composition of high-speed iron coal gangue raw materials is shown in Table 2:

[0053] SiO 2

Al 2 O 3

Fe 2 O 3

TiO 2

other 70.1%27.2%0.7%1.3%0.7%

[0054] 1) It can be seen from Table 2 that Al in the raw material 2 O 3 Less than 30%, Fe 2 O 3 More than 0.4%, add bauxite to adjust Al 2 O 3 Content to 32%,

[0055] 2) Crush the raw material obtained in step 1) and grind to 150 mesh to obtain a mixed powder,

[0056] 3) Add the mixed powder to water and mix it evenly to make a wet material. The weight ratio of the mixed powder to water is 90:10, and the moisture content of the wet material is 10%. The wet material is aged for 4 hours and then made by squeezing mud. After the bricks are stacked on the kiln car, they are dried until the moisture content is less than 5%. After drying, the kiln car enters the tunnel kiln for calcination. In the tunnel kiln, the oxidizing atmosphere is below 1100°C, and the reducing atmosphere is above 1100°C. The tunnel kiln includes th...

Embodiment 3

[0058] The composition of high-speed iron coal gangue raw materials is shown in Table 3 below:

[0059] SiO 2

Al 2 O 3

Fe 2 O 3

TiO 2

other 68.828.5%1.0%0.9%0.8%

[0060] 1) It can be seen from Table 3 that Al in the raw material 2 O 3 Less than 30%, Fe 2 O 3 More than 0.4%, add aluminum powder to adjust Al 2 O 3 Content to 38%,

[0061] 2) Crush the raw material obtained in step 1) and grind to 150 mesh to obtain a mixed powder,

[0062] 3) Add the mixed powder to water and mix evenly to make a wet material. The weight ratio of the mixed powder to water is 80:20, and the moisture content of the wet material is 20%. The wet material is aged for 2 hours and then made by squeezing mud. After the bricks are stacked on the kiln car, they are dried until the moisture content is less than 5%. After drying, the kiln car enters the tunnel kiln for calcination. In the tunnel kiln, the oxidizing atmosphere is below 1100°C, and the reducing atmosphere is above 1100°C. The tunnel kiln i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com