Patents

Literature

39results about How to "Effective clamping and positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

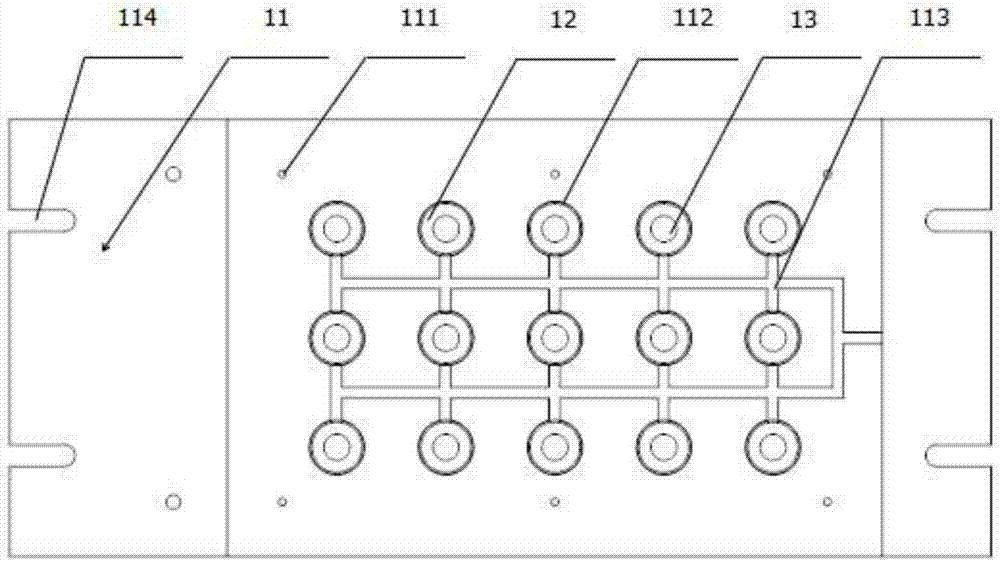

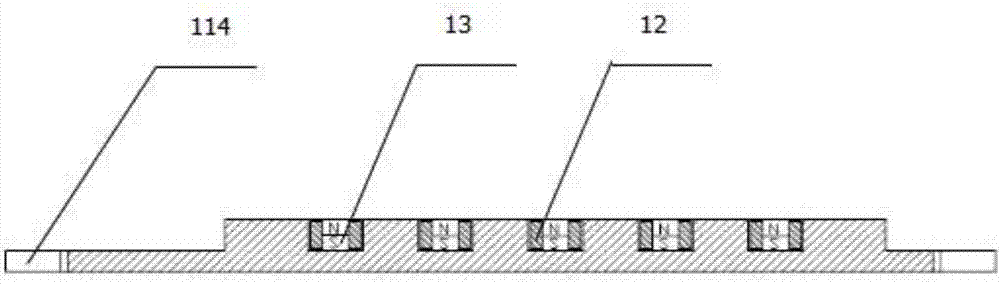

Novel functional flexible clamp and application method thereof

ActiveCN107322347AVersatileEnergy savingPositioning apparatusMaintainance and safety accessoriesPhysicsMagneto

Owner:HEBEI UNIV OF TECH

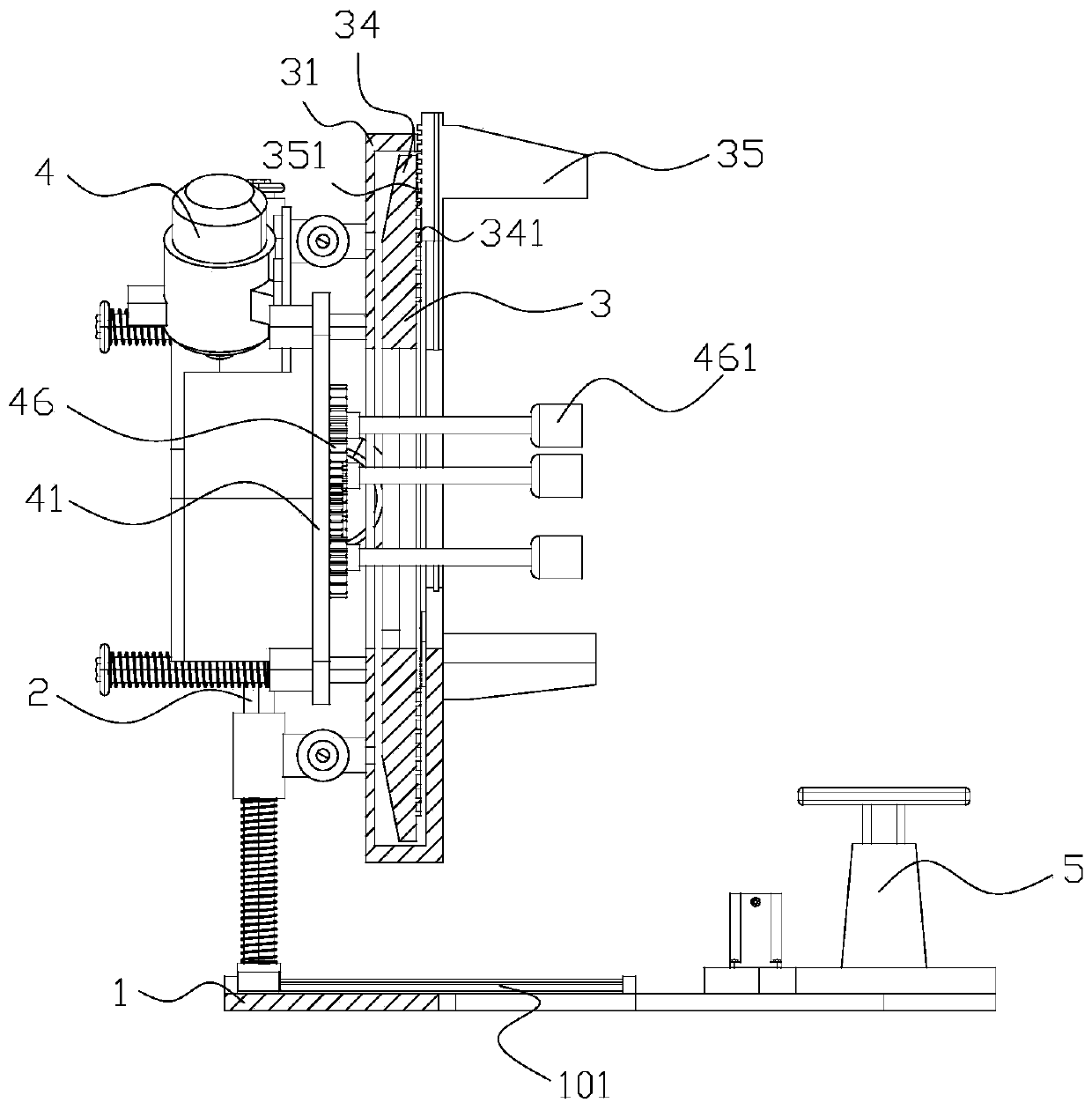

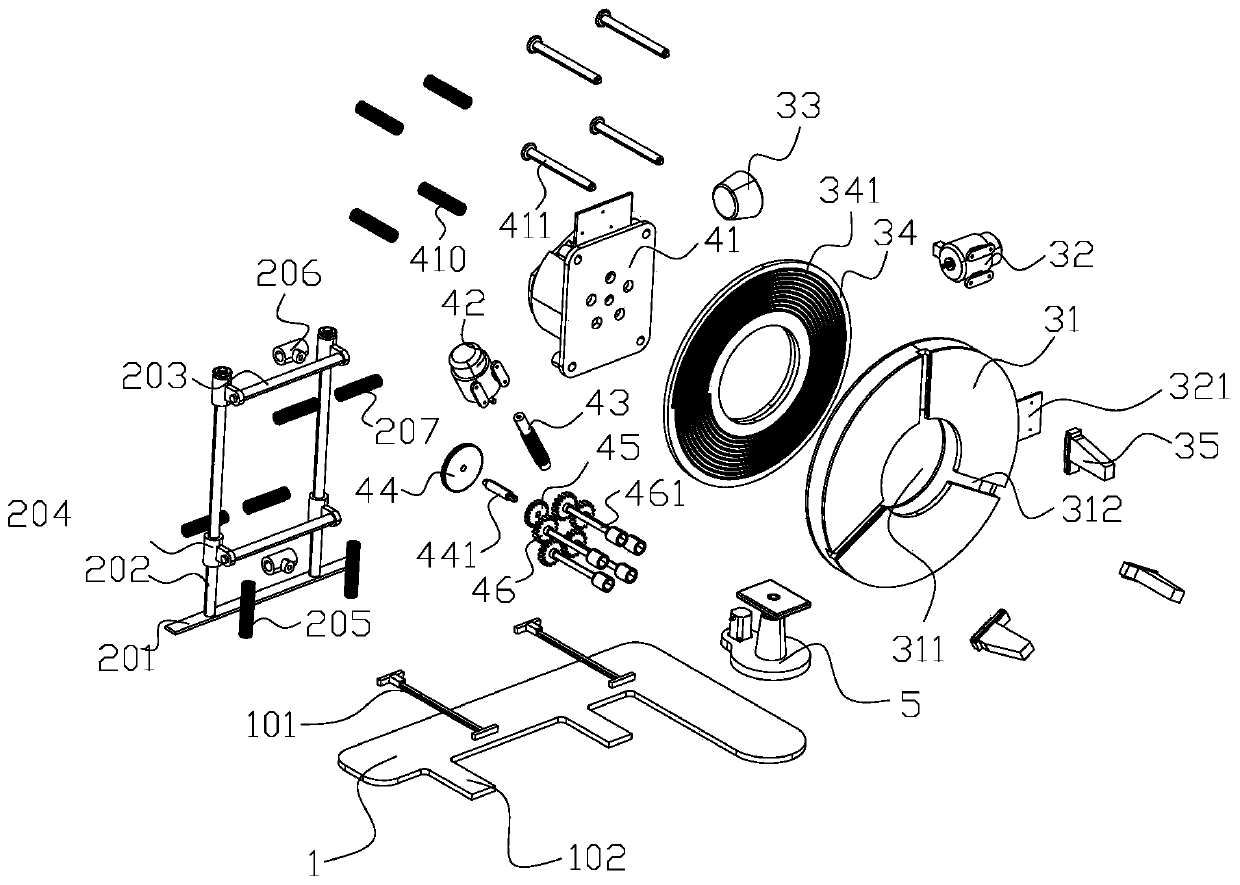

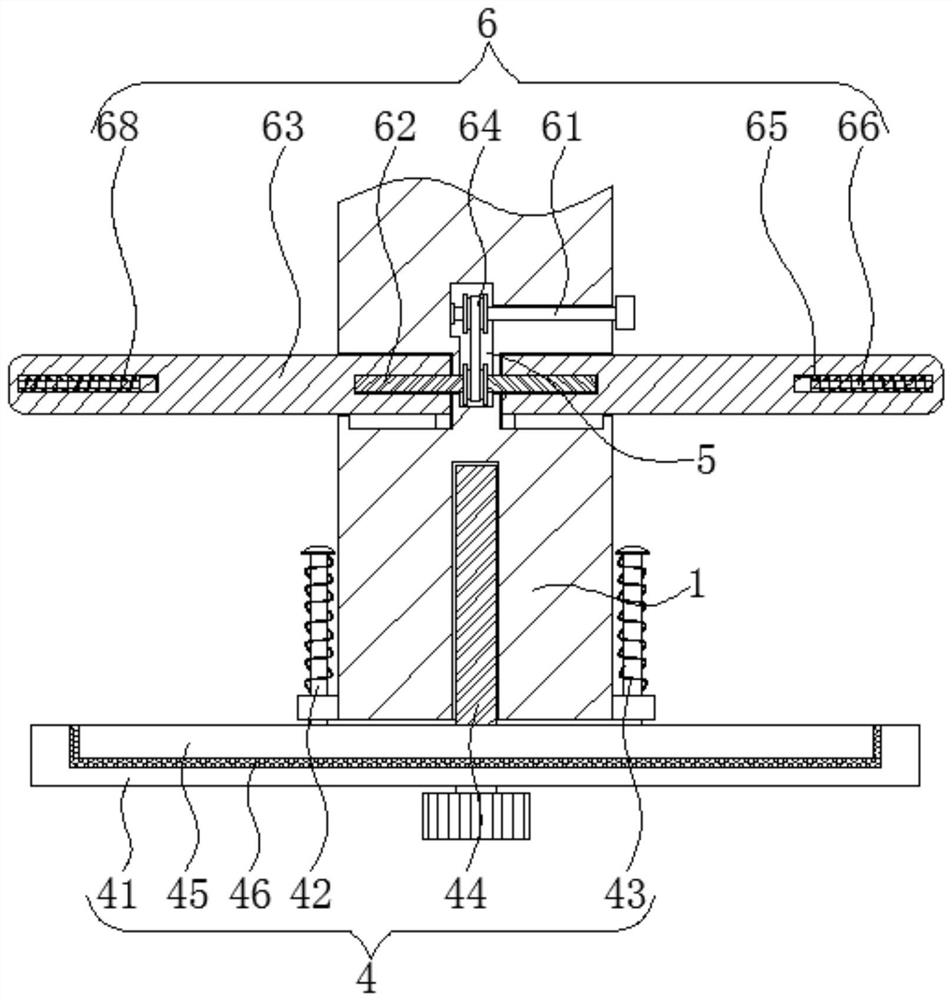

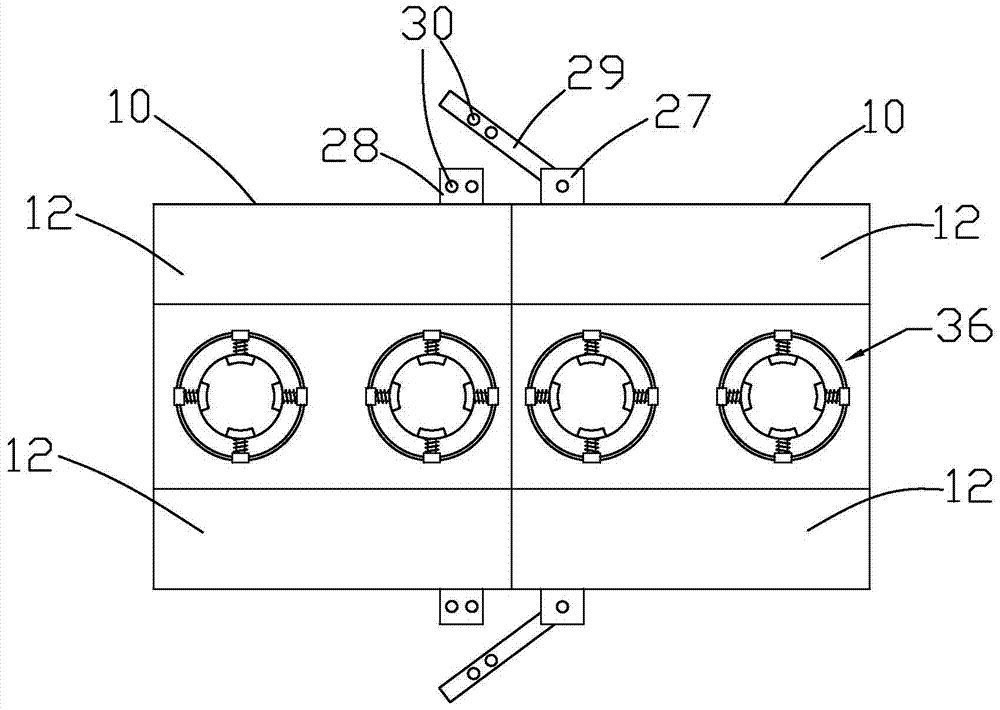

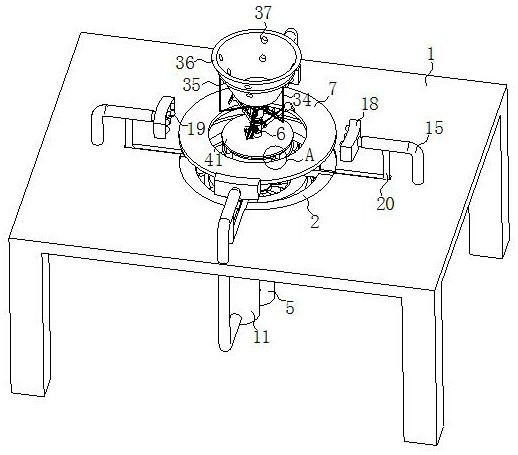

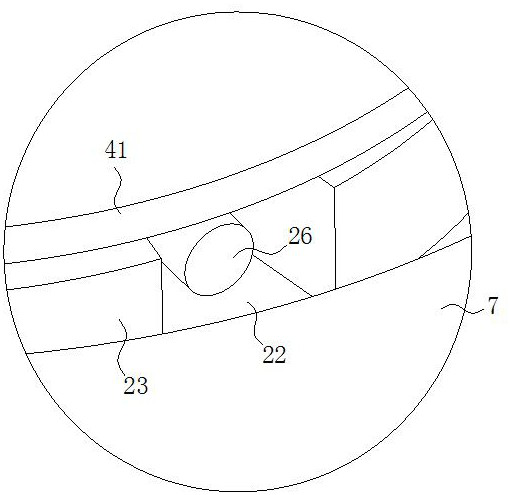

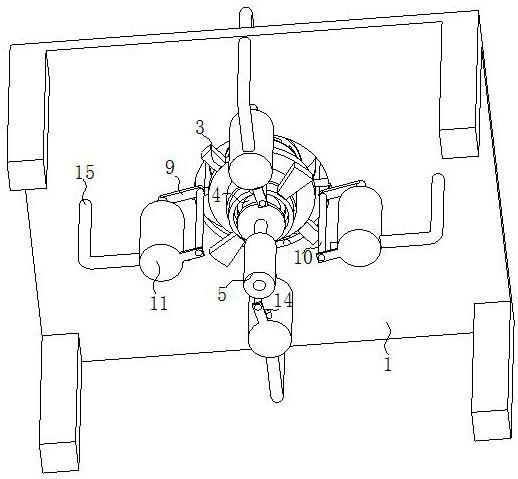

Automobile tire assembling and disassembling tool

InactiveCN110217047AEffective clamping and positioningImprove stabilityWheel mounting apparatusTyre repairingJackscrewElectric machinery

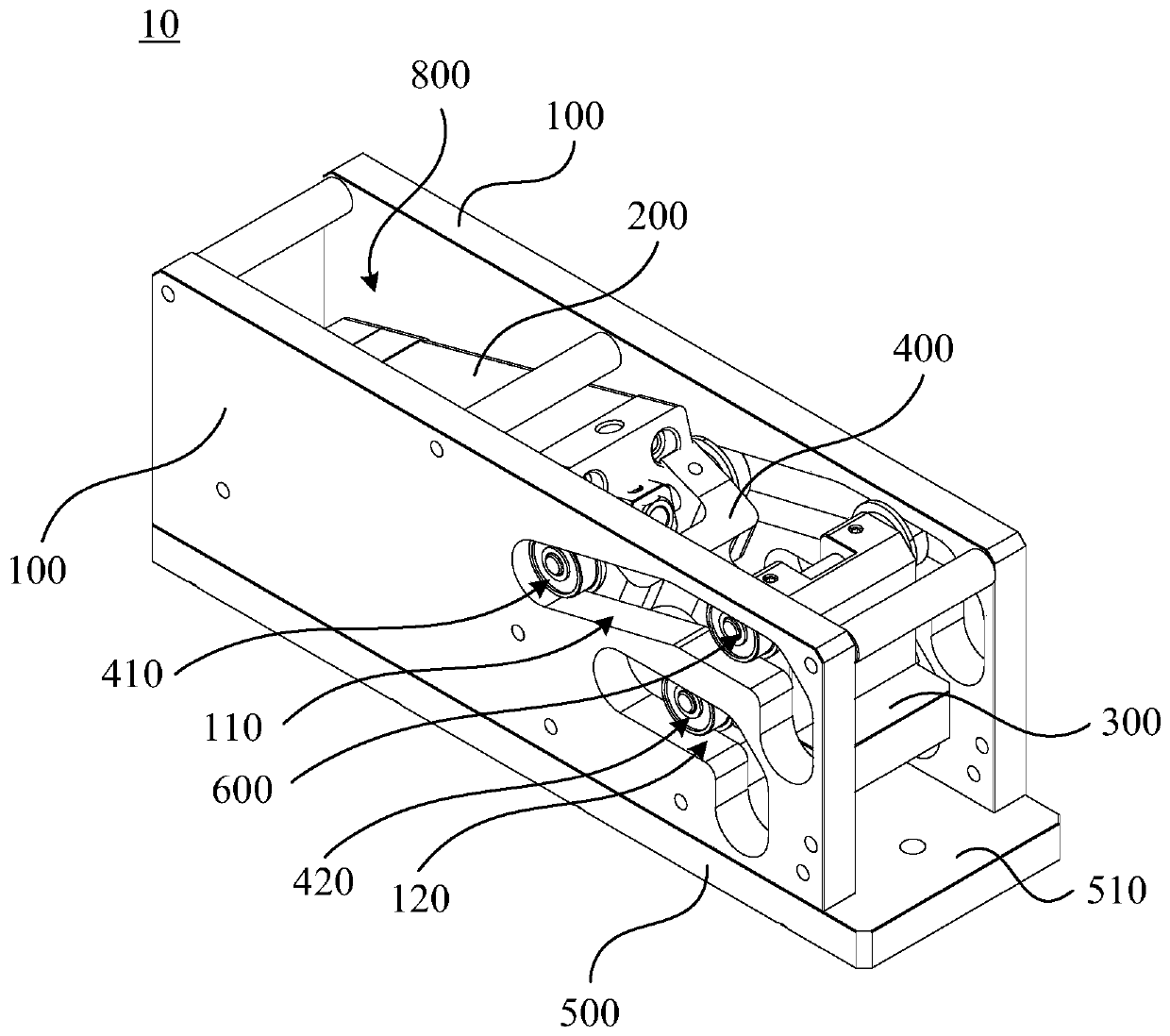

The invention relates to the field of automobile parts. An automobile tire assembling and disassembling tool comprises a frame, a moving frame, a wheel clamping component, a bolt assembling and disassembling component and a jack component; the moving frame is arranged on the frame through a slide rail; the wheel clamping component comprises a chuck, a clamping motor, a driving conical gear, a driven conical gear and multiple clamping jaws; clamping jaw grooves are formed in the chuck; the chuck is connected with the moving frame; the clamping motor is arranged on the chuck; the driving conicalgear is connected with the clamping motor; the driven conical gear is arranged in the chuck; the driven conical gear is engaged with the driving conical gear; a clamping thread is arranged on the driven conical gear; the clamping jaws are arranged in the clamping jaw grooves; a threaded groove is clamped on each clamping jaw; the threaded groove is matched with the clamping thread; the bolt assembling and disassembling component is used for assembling and disassembling bolts on wheels; and the jack component is used for jacking an automobile. The automobile tire assembling and disassembling tool has the beneficial effects that the stability of the wheel assembling and disassembling process is improved, the operation is convenient and fast, and meanwhile, the assembling and disassembling efficiency is enhanced.

Owner:杨道财

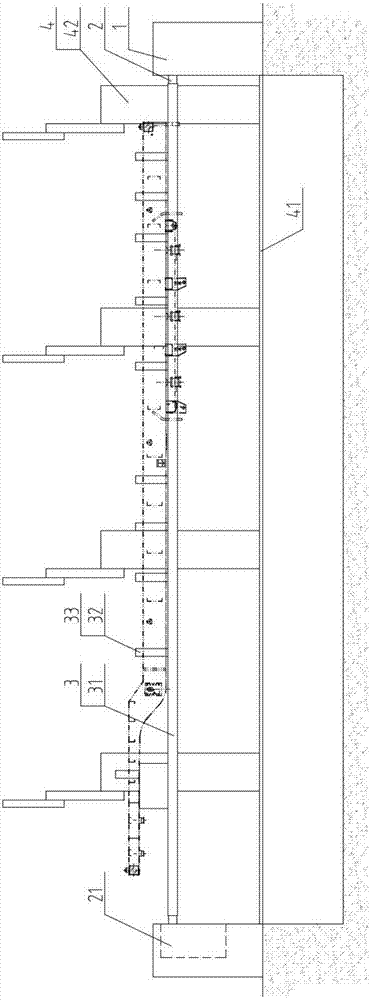

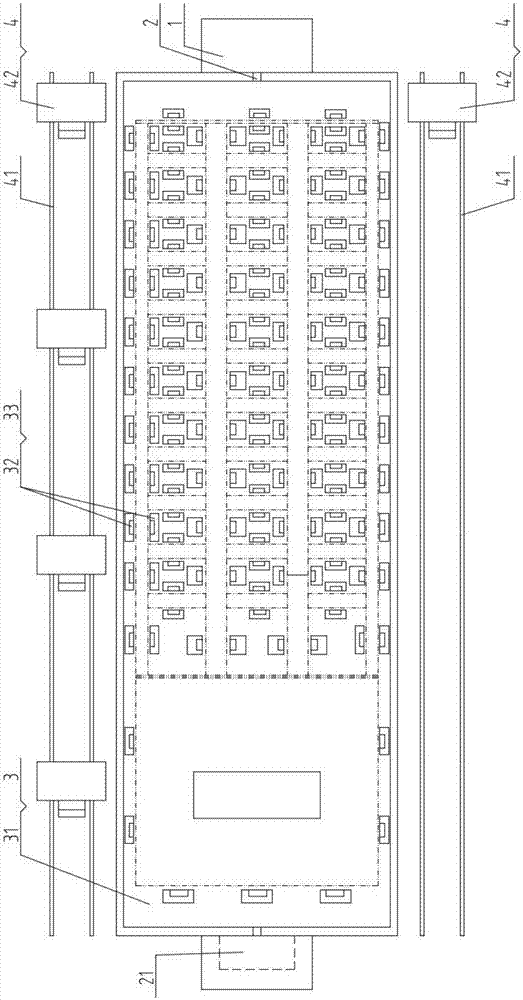

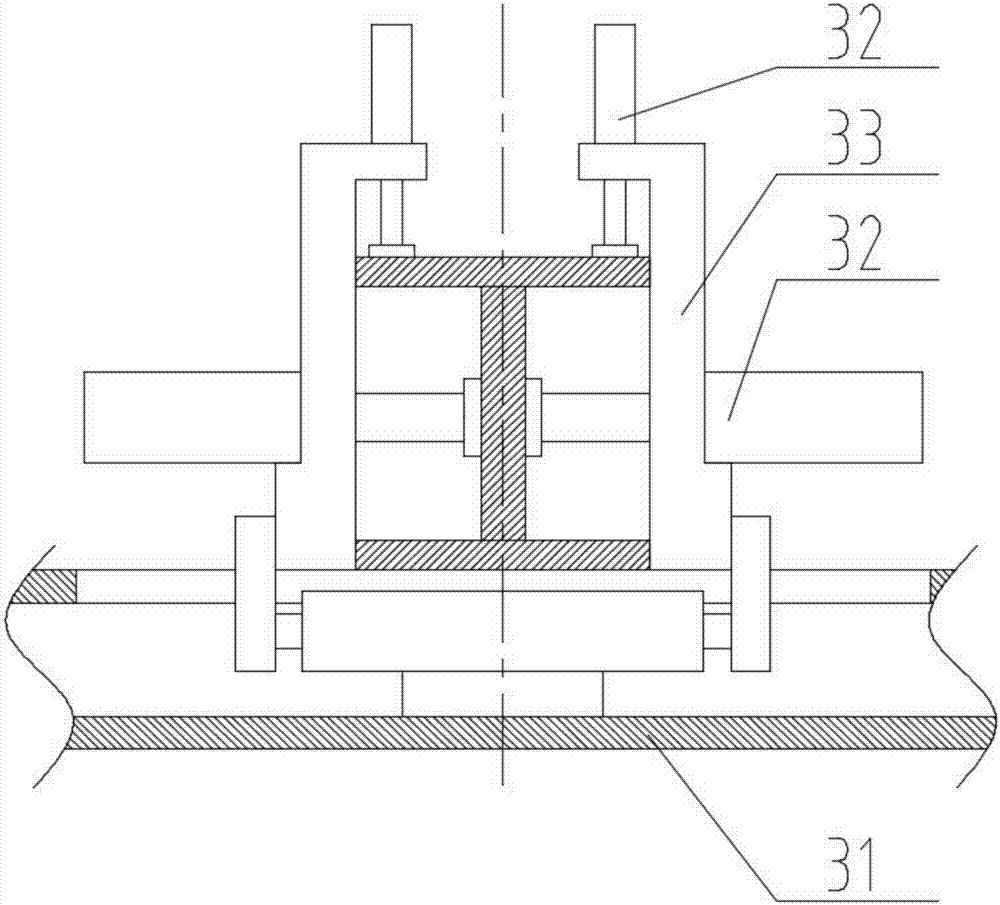

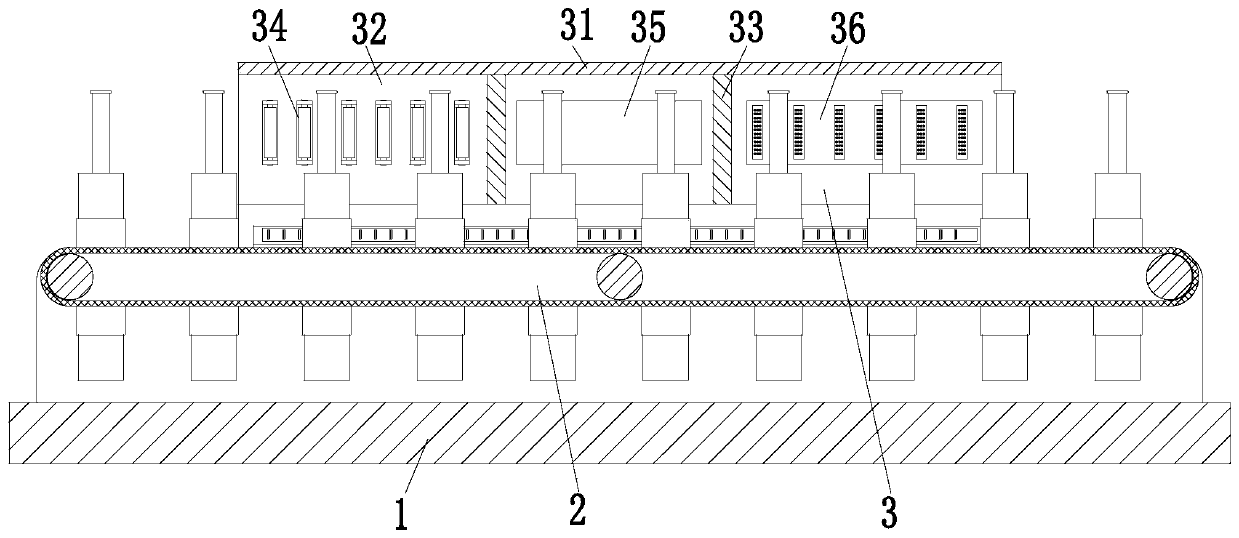

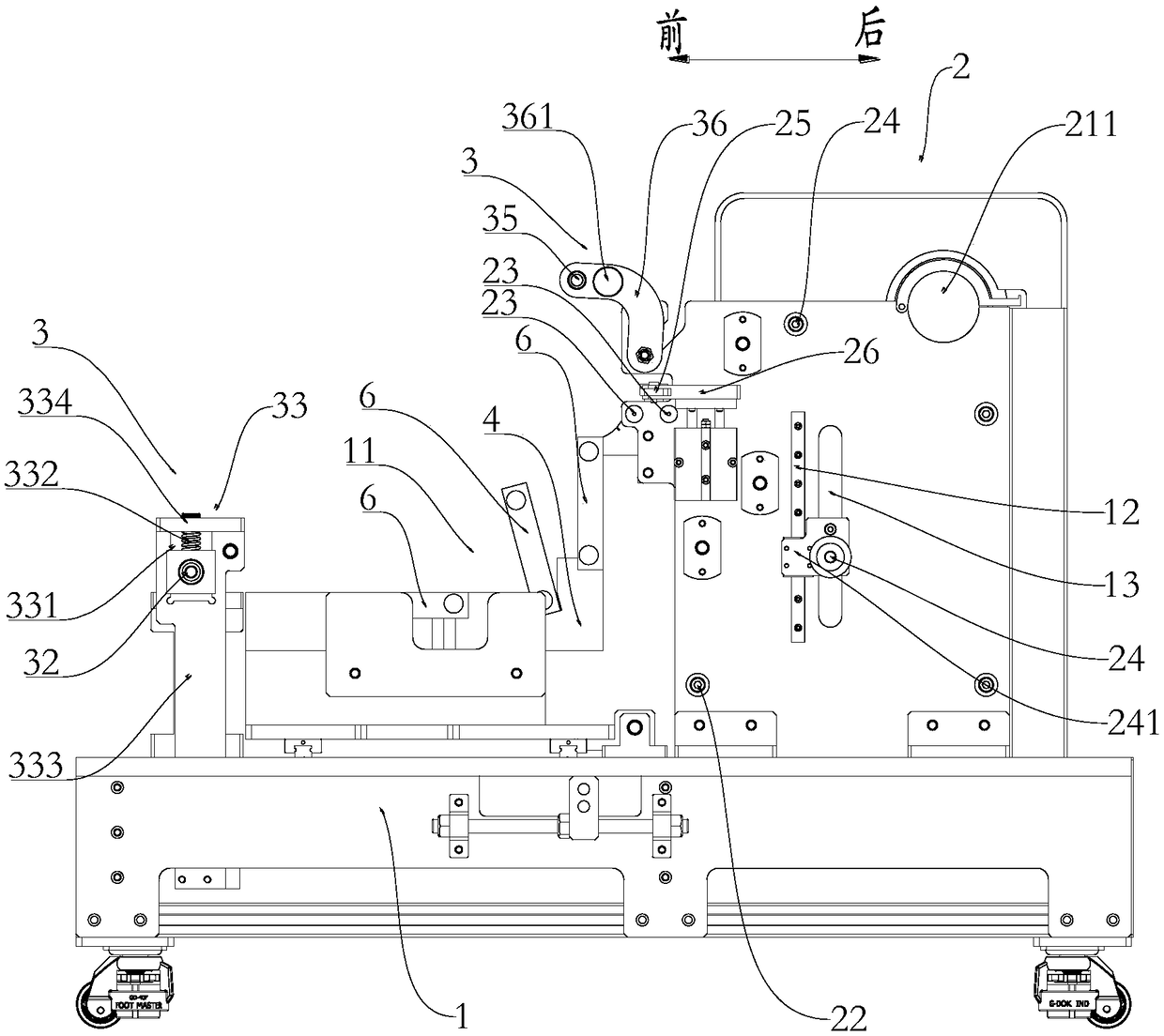

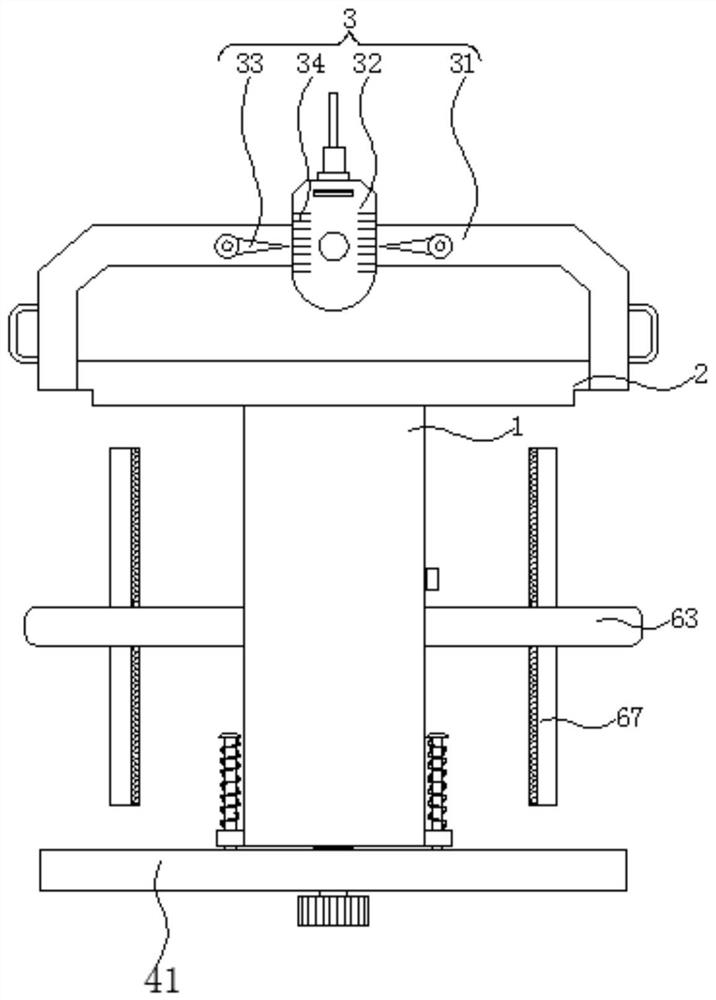

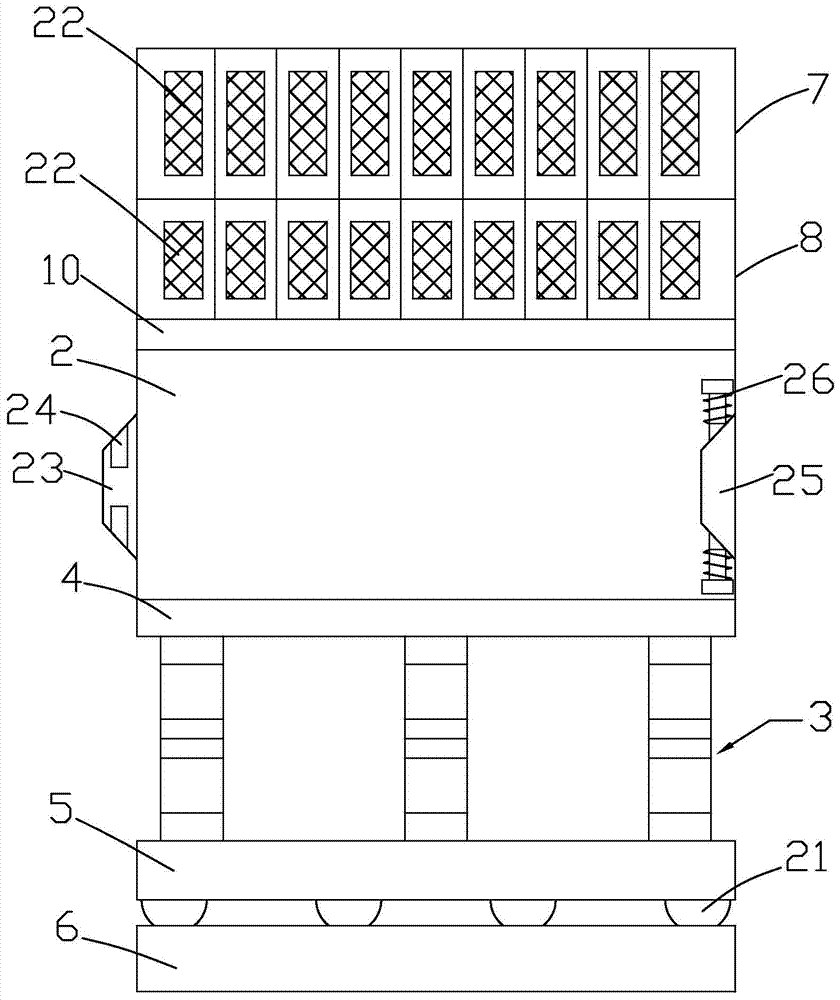

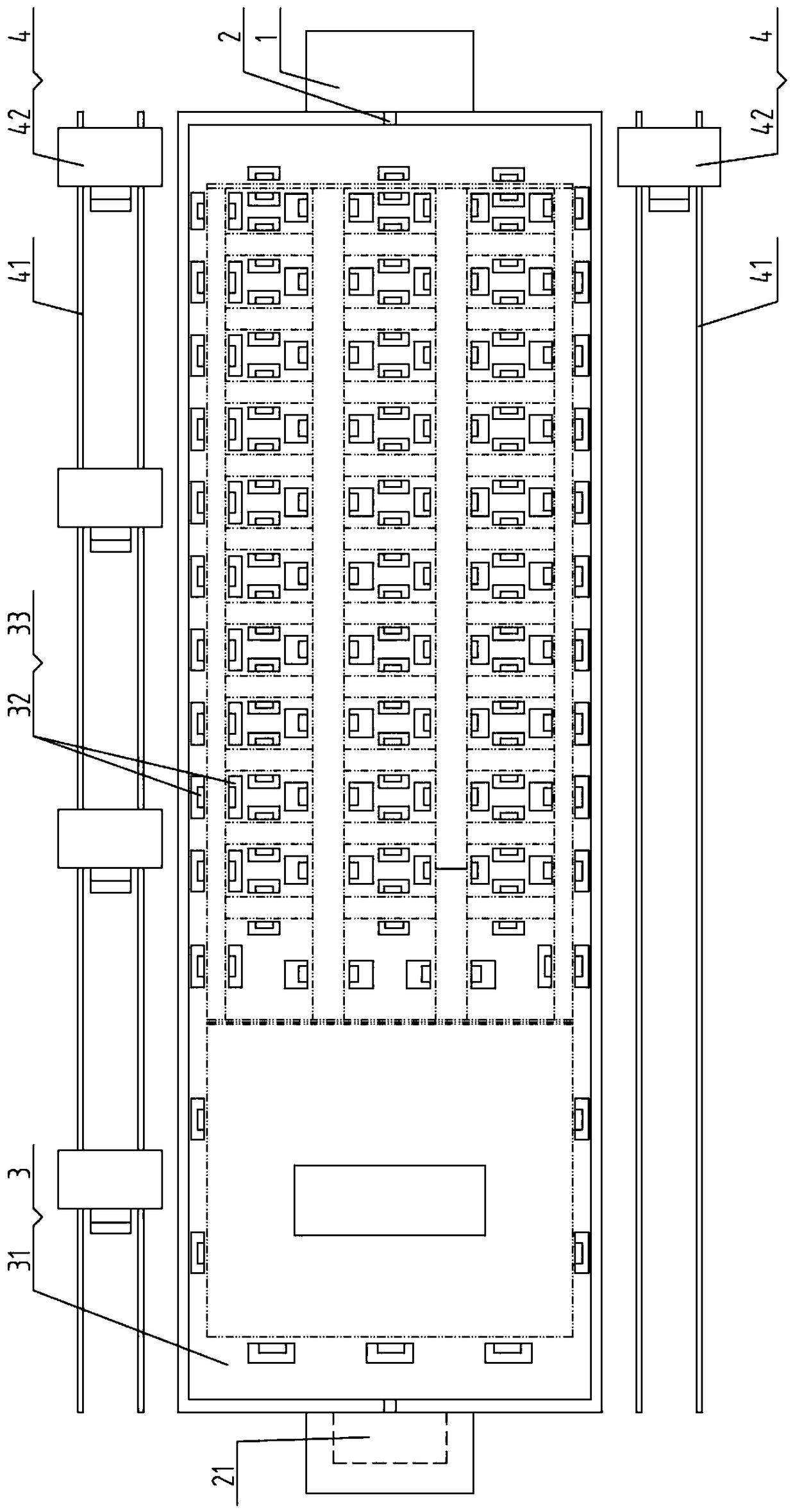

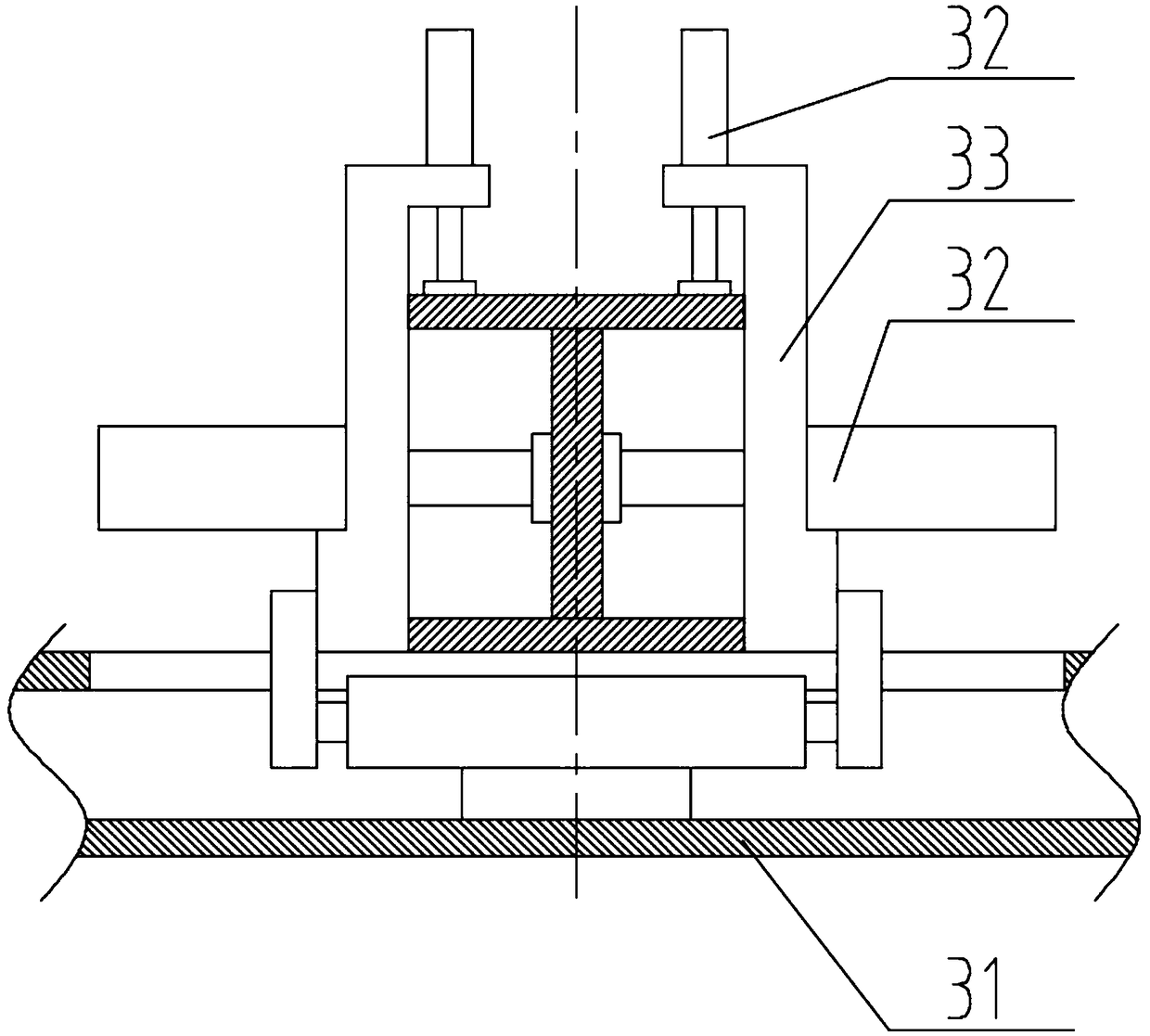

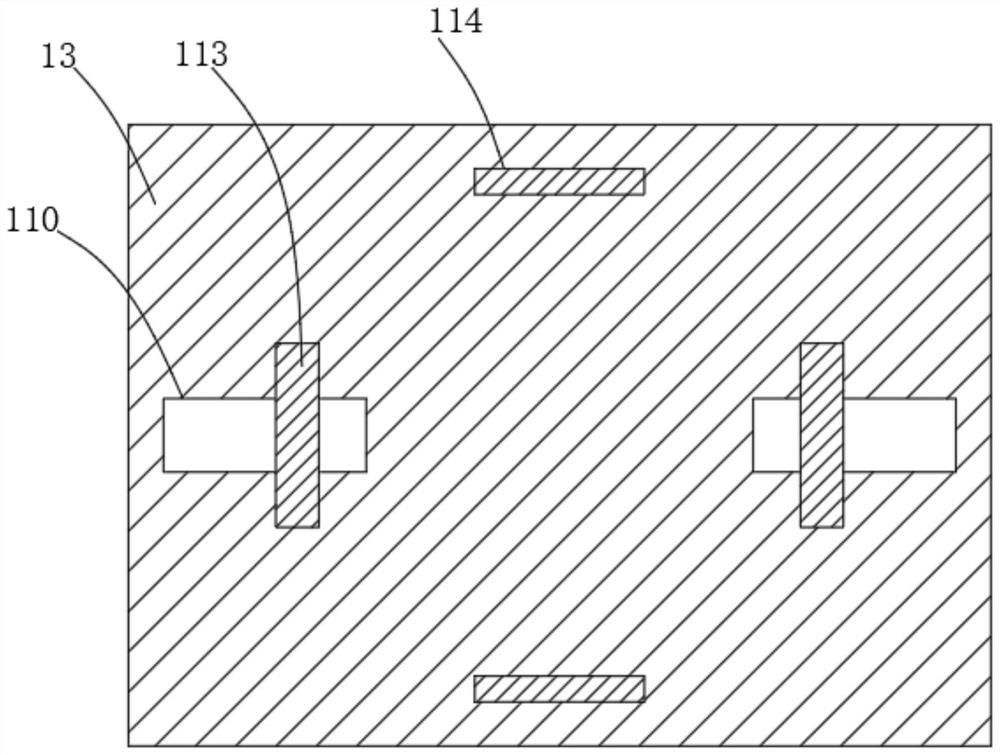

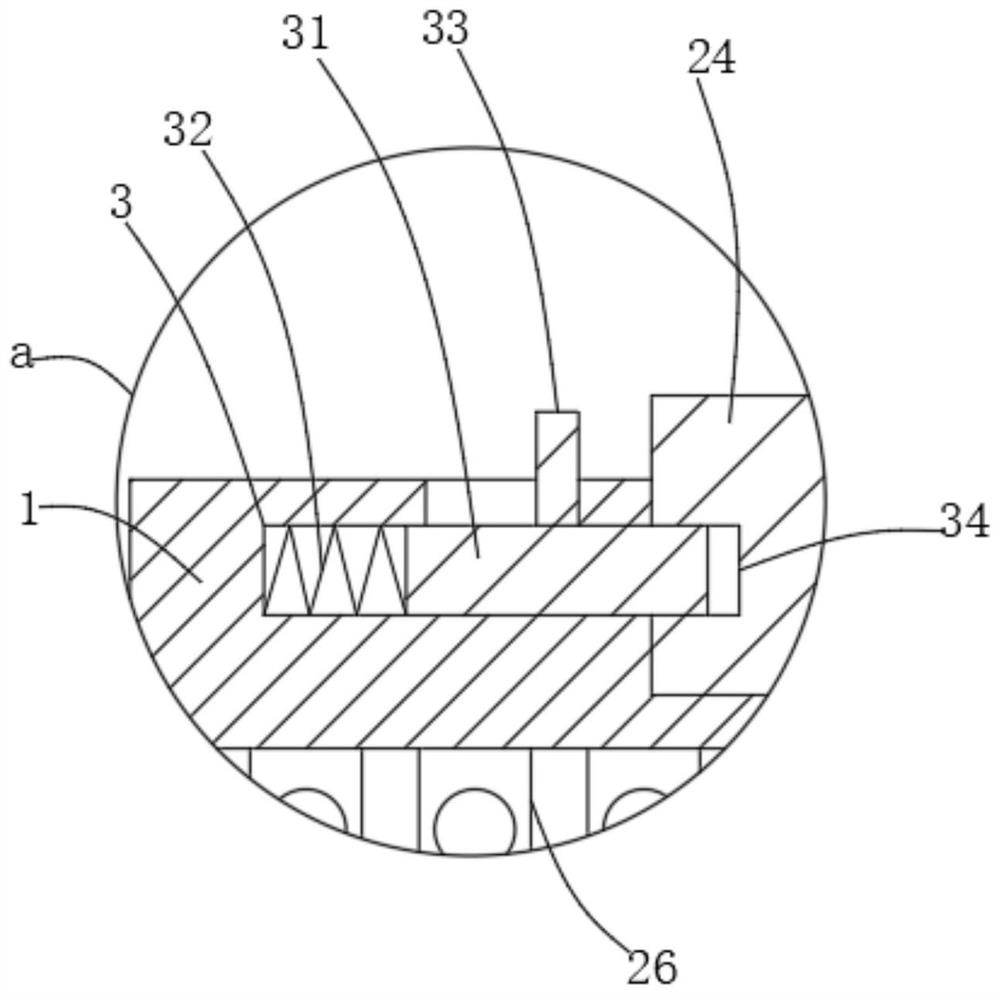

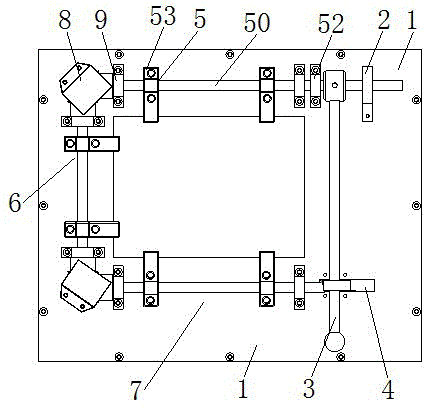

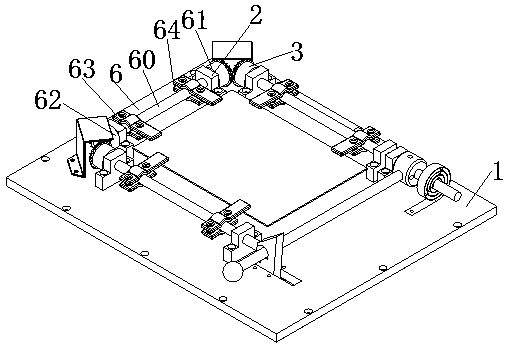

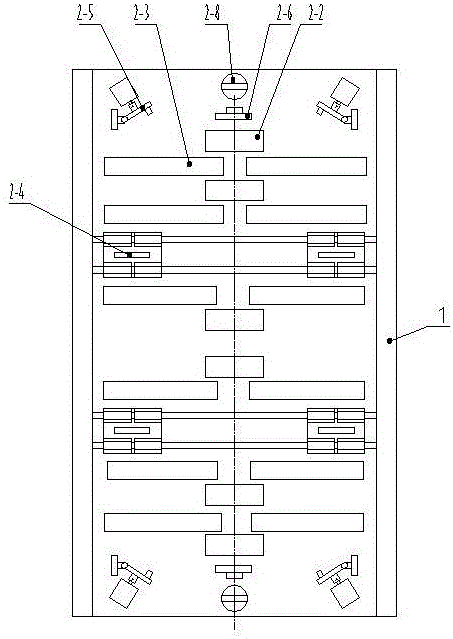

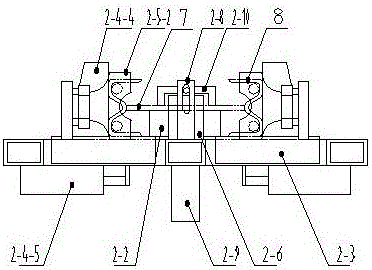

Panel positioning components of trailer frame assembly splicing welding system

ActiveCN107160079AReduce institutional settingsEasy to set upWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses panel positioning components of a trailer frame assembly splicing welding system. The number of the panel positioning components is multiple, and the multiple panel positioning components are arranged on the upper surface of a workpiece supporting plate (31), and the panel positioning components comprise compression devices (32) and positioning devices (33); each compression device comprises a supporting base fixedly installed on the workpiece supporting plate, a stretchable control mechanism installed on the supporting base and a pressing head installed on the stretchable control mechanism, the compression directions of each compression device at least comprise the horizontal direction and the vertical direction, the compression devices are symmetrically arranged with respect to a positioned panel, and the pressing heads are oppositely arranged; and each positioning device comprises a large beam positioning mechanism, a transverse beam positioning mechanism and an edge beam positioning mechanism. By means of the panel positioning components of the trailer frame assembly splicing welding system, overall and quick splicing and welding of a trailer can be achieved, and the splicing and welding efficiency is high.

Owner:江苏富华交通运输设备股份有限公司

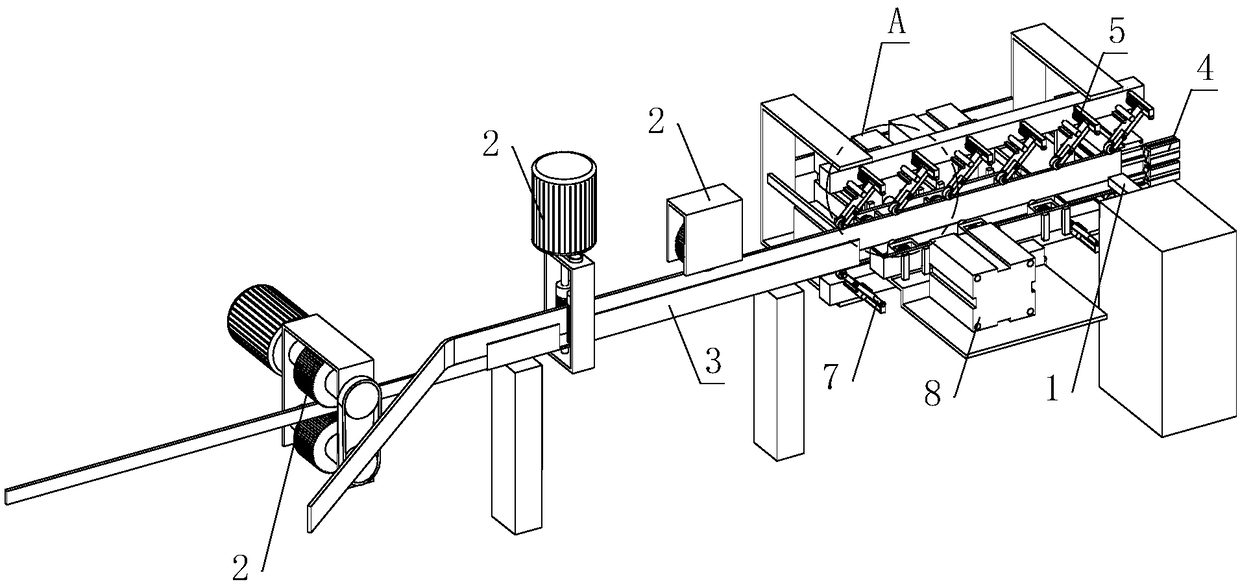

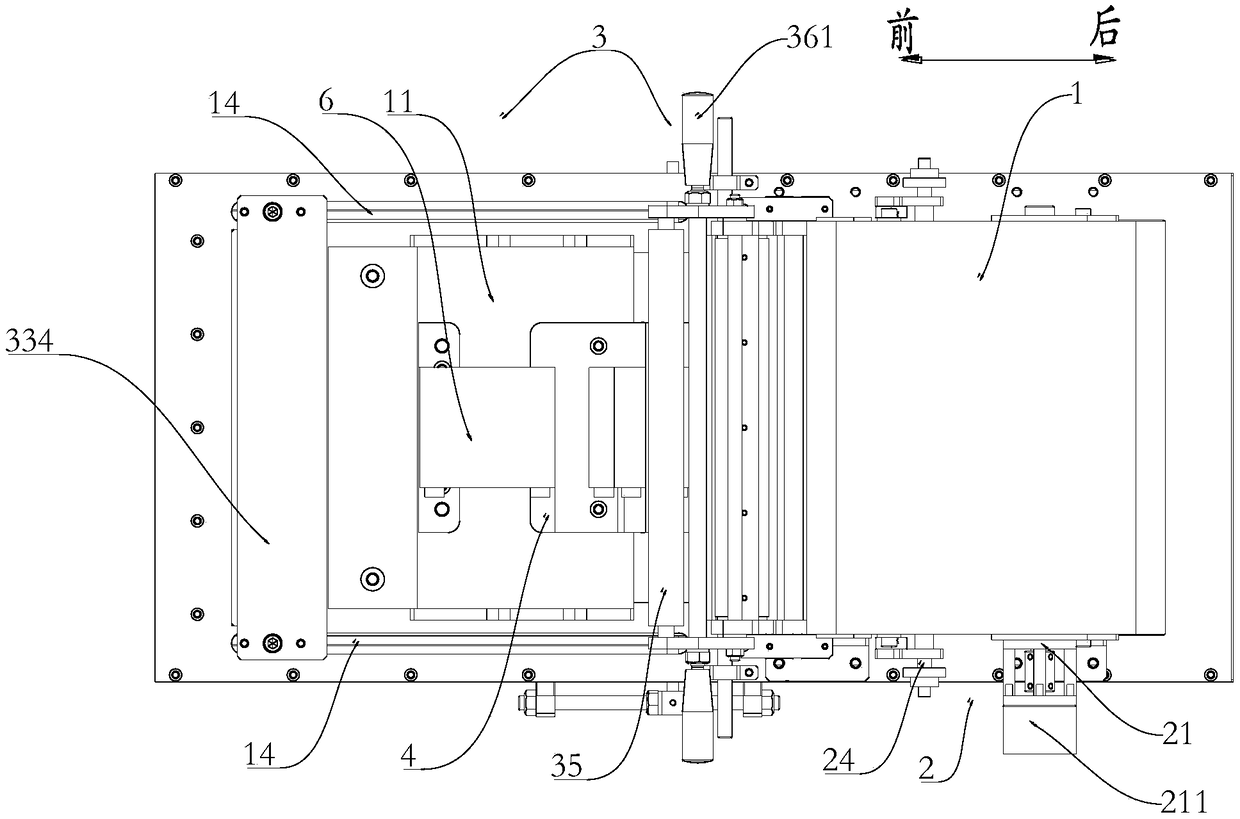

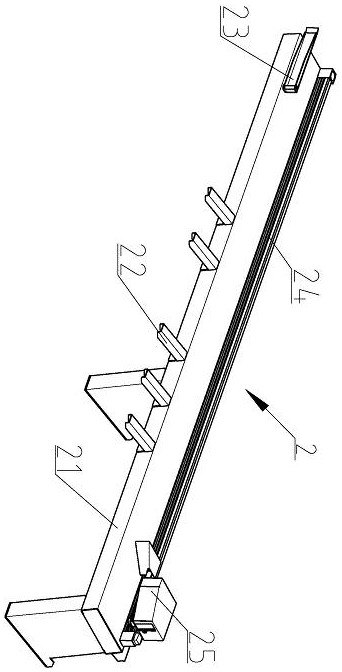

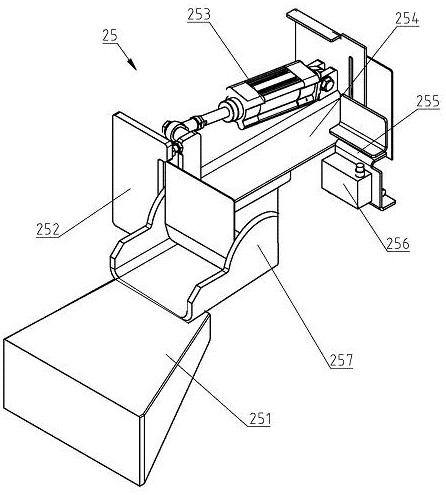

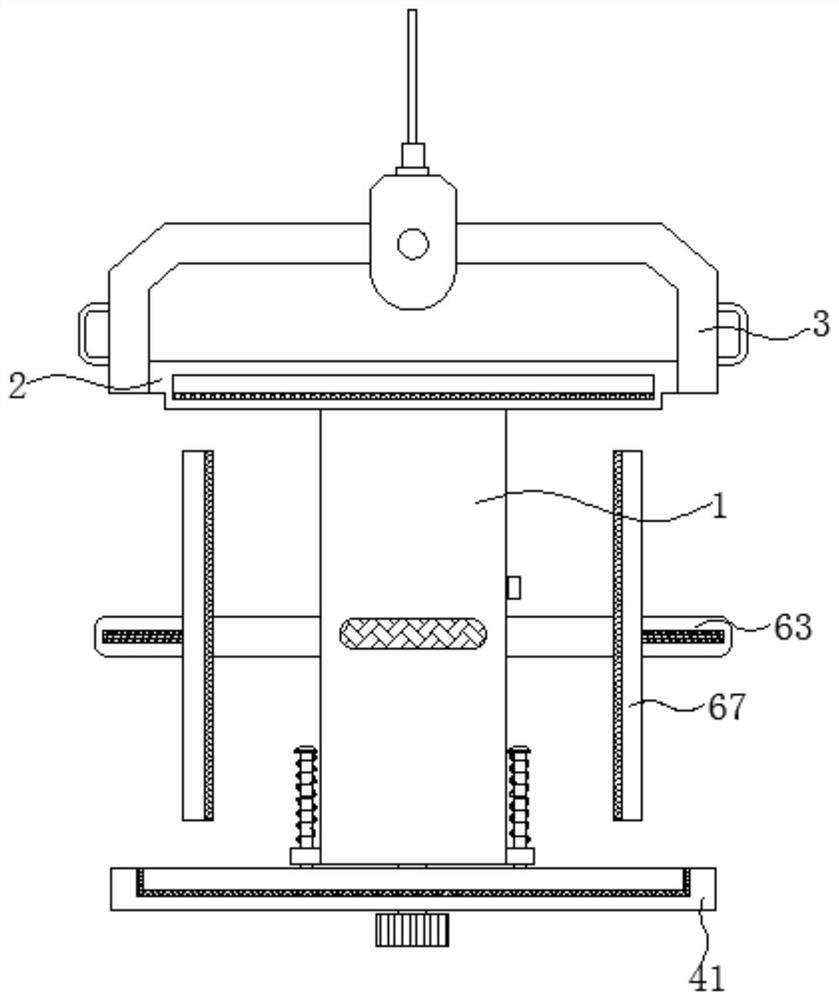

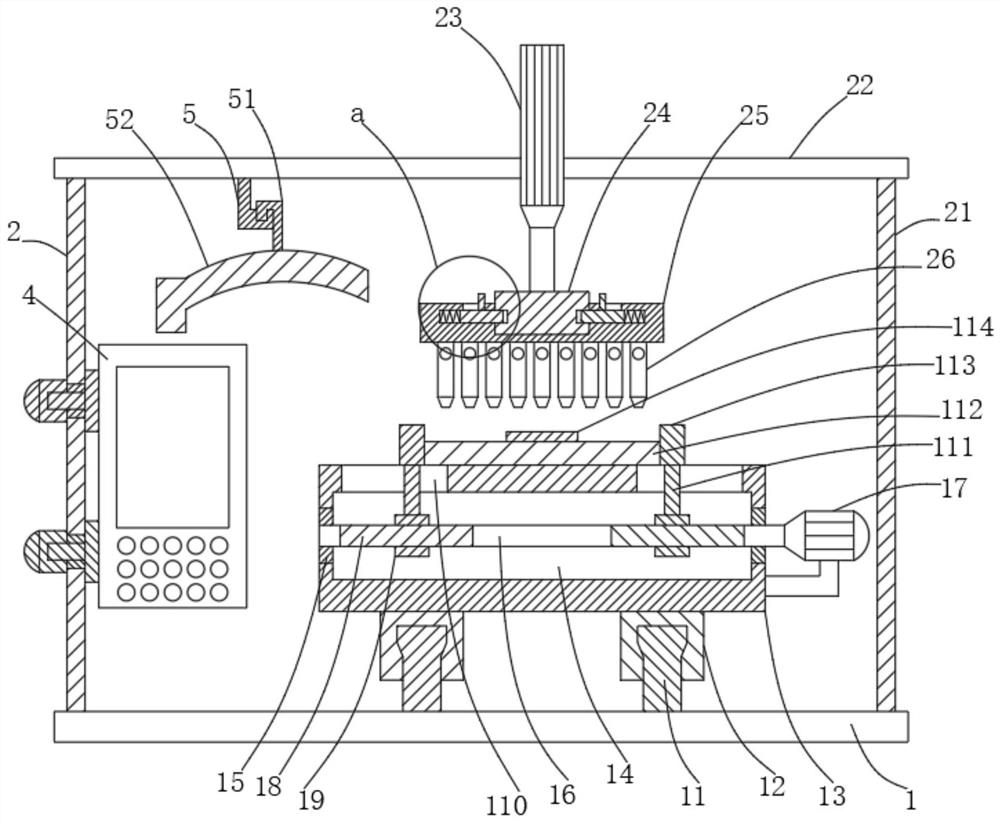

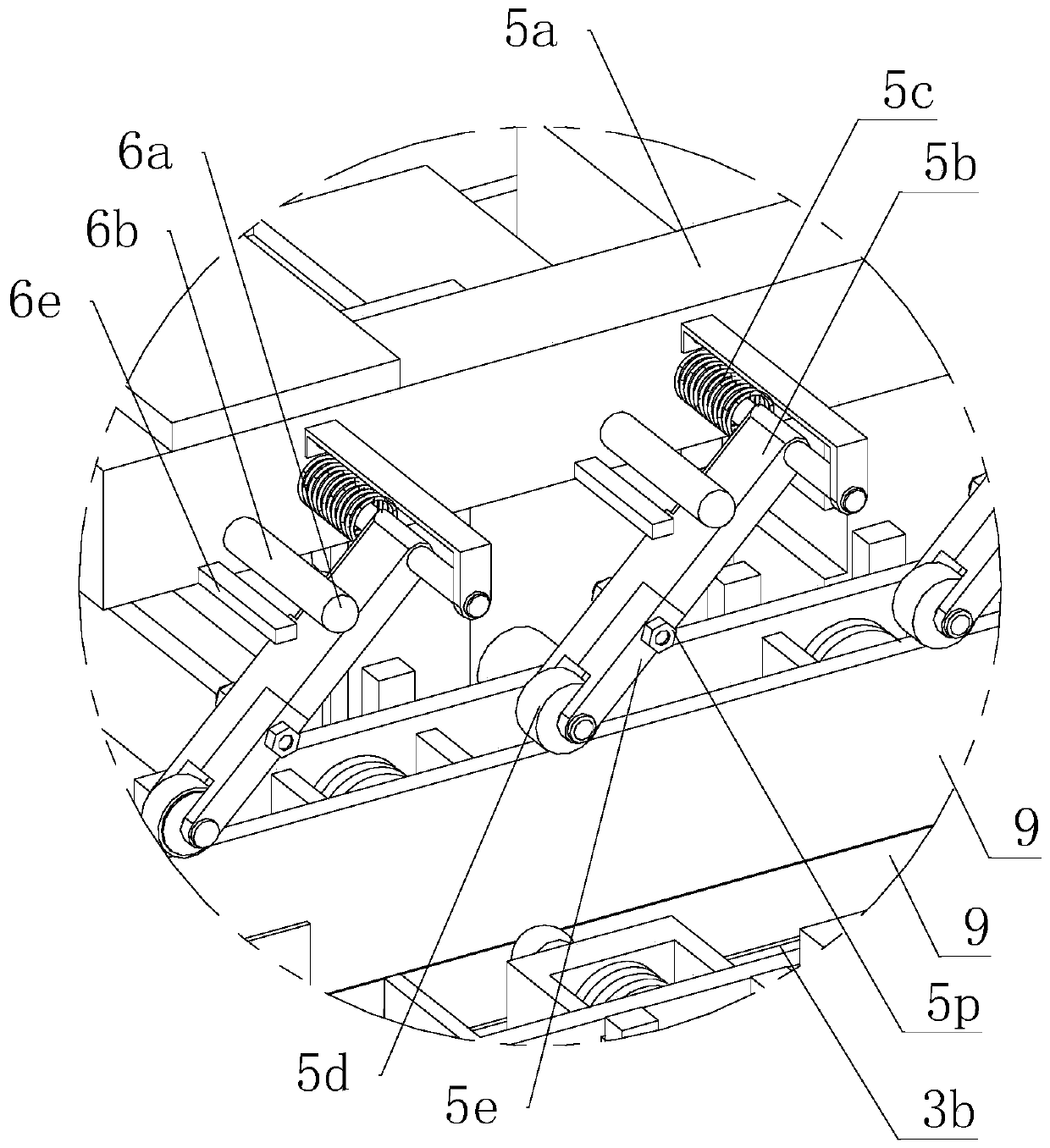

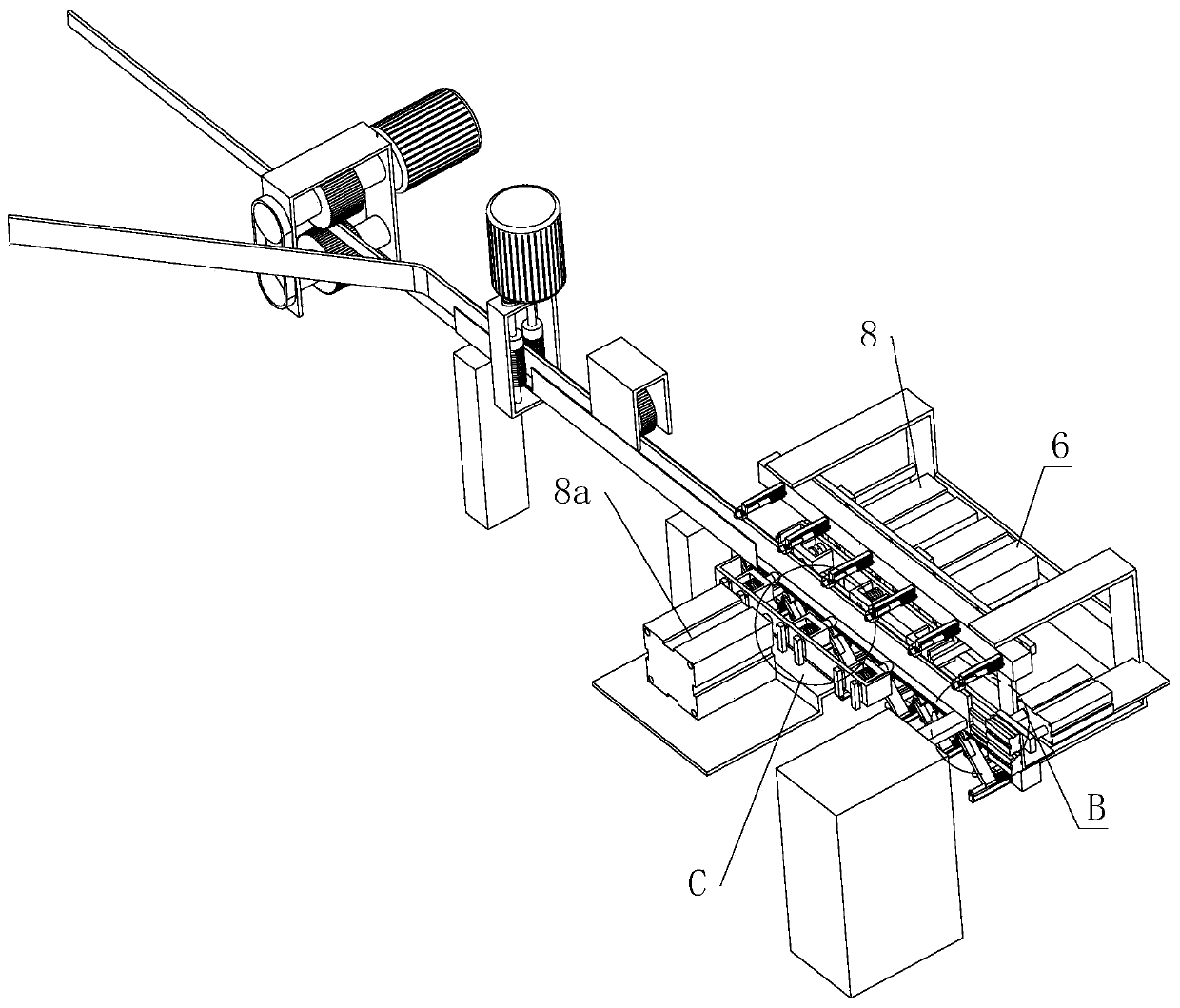

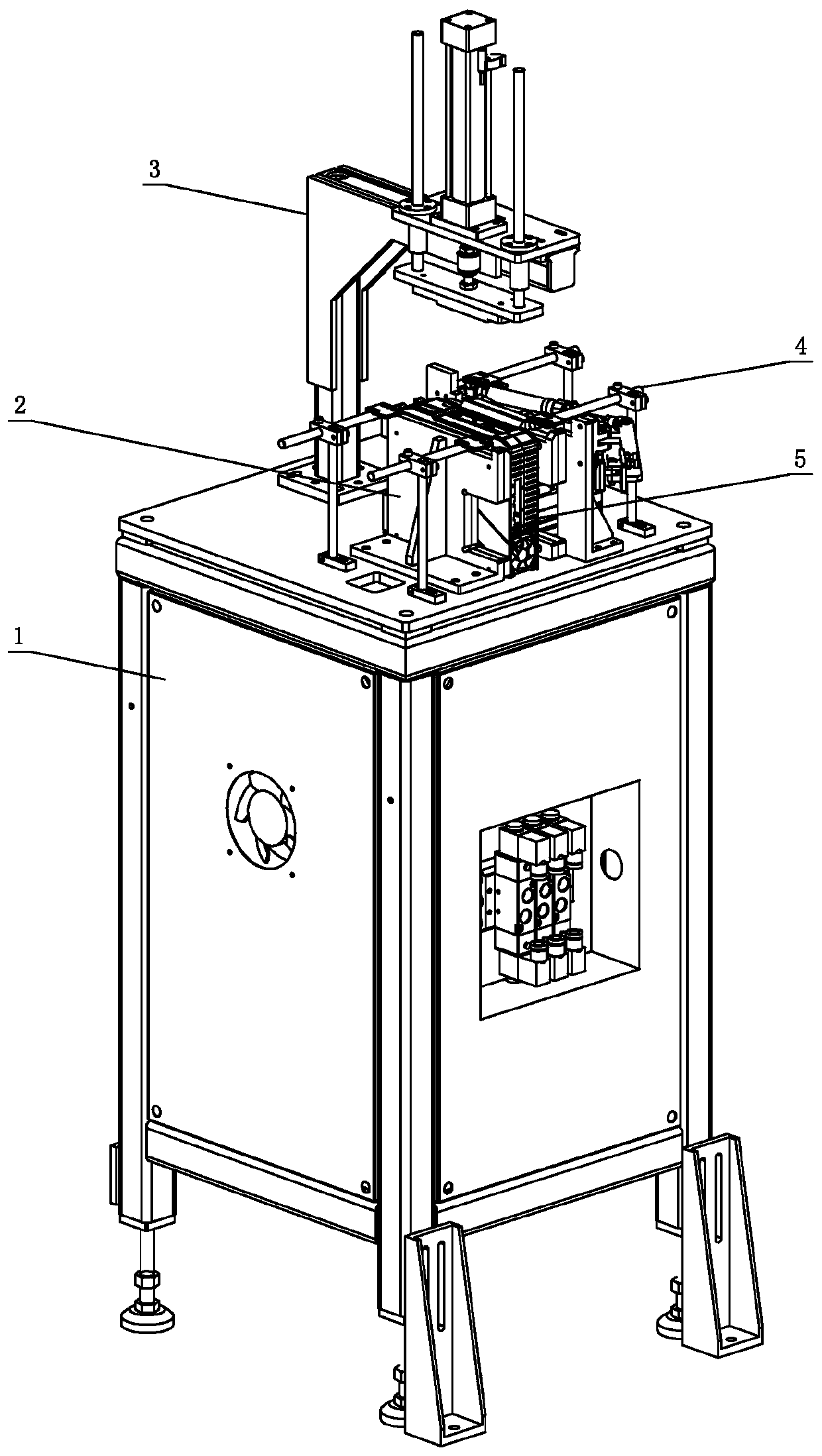

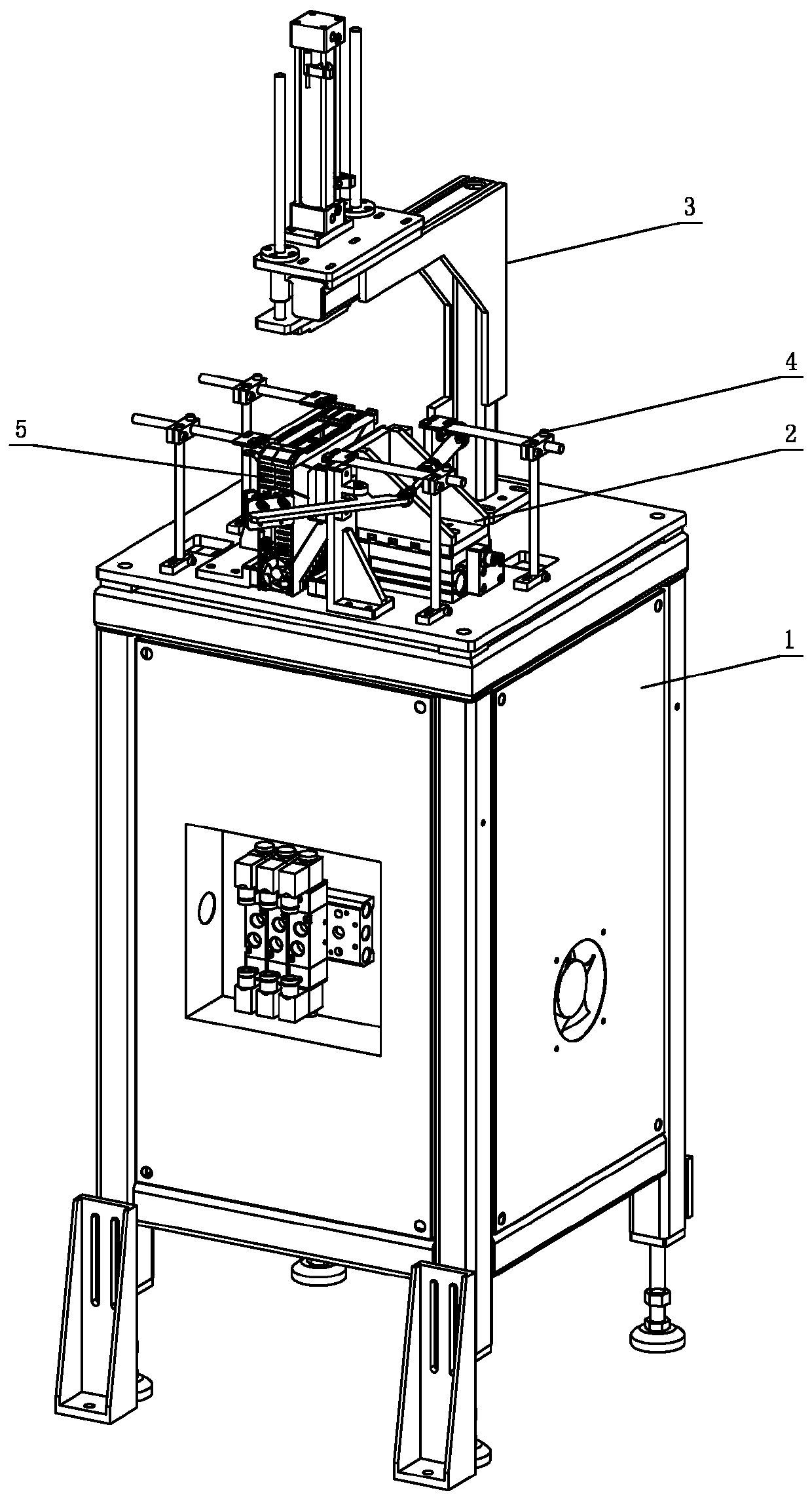

Welding equipment and welding method for bimetallic band saw strips

ActiveCN109175703AGuaranteed mobilityEffective clamping and positioningWelding/cutting auxillary devicesAuxillary welding devicesElectrical connectionEngineering

The invention relates to the field of bimetallic saw strip machining, in particular to welding equipment and welding method for bimetallic band saw strips. The welding equipment comprises a laser generator, a base material supplying slide rail, a pre-welding position alignment device, a main controller, an upper fixture device and a lower fixture device, wherein the upper fixture device and the lower fixture device are symmetrically arranged up and down, the laser generator is arranged at the downstream end of the base material supplying slide rail, the upper fixture device and the lower fixture device are located above and below the base material supplying slide rail correspondingly, the back side of the base material supplying slide rail is provided with a power device, the front side and the back side of the base material supplying slide rail are each provided with one clamping device, and the pre-welding position alignment device can be movably arranged at the end portion of the downstream end of the base material supplying slide rail through an avoidance air cylinder and is further in electrical connection with the main controller. By means of the welding equipment and weldingmethod for the bimetallic band saw strips, two pre-welding base materials can be effectively clamped and positioned, and then the welding quality is improved, in addition, a rubber shaft sleeve and arubber sleeve which are in direct contact with the base materials can both be detachably arranged, and the fixture maintenance cost is greatly lowered.

Owner:PUTIAN HENGDA MACHINERY & ELECTRICITY IND

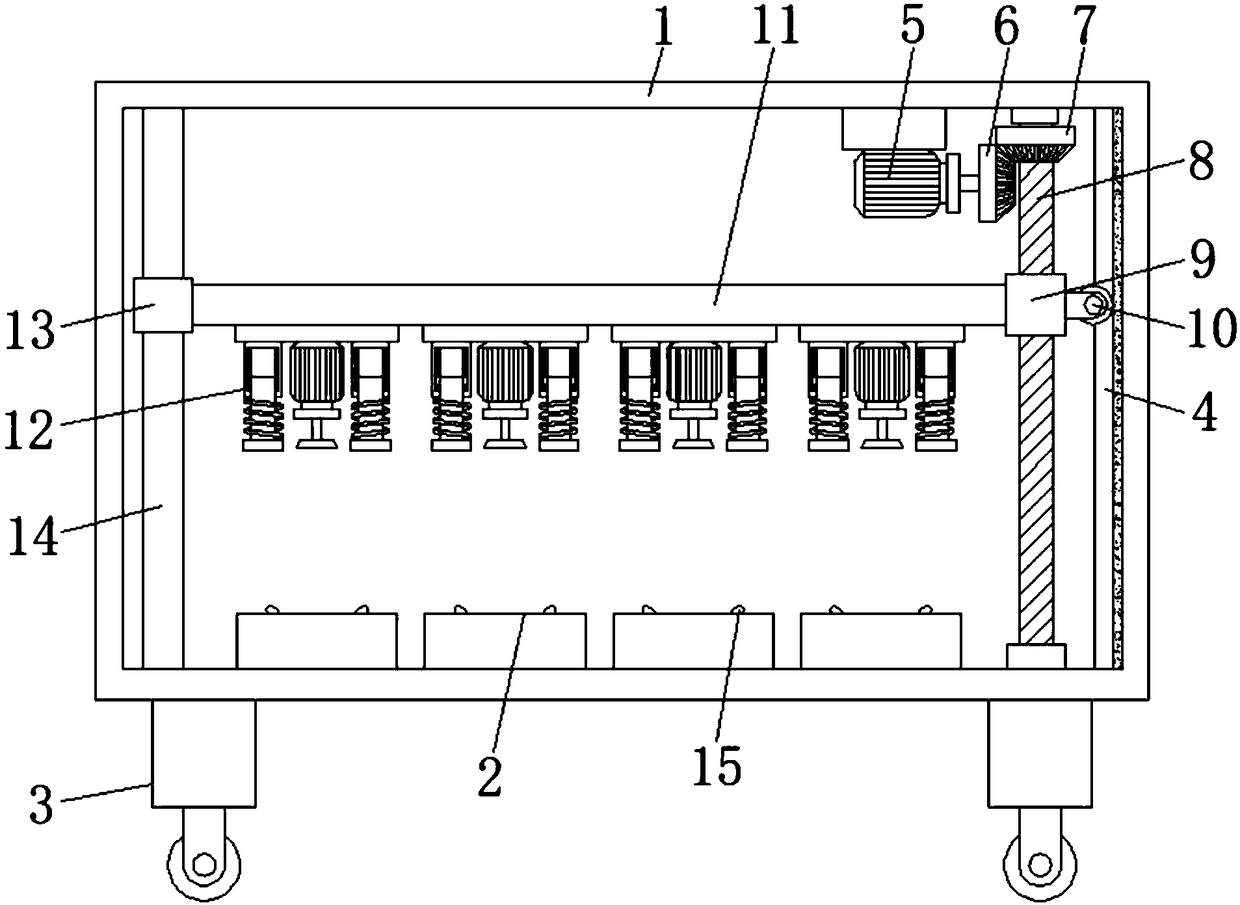

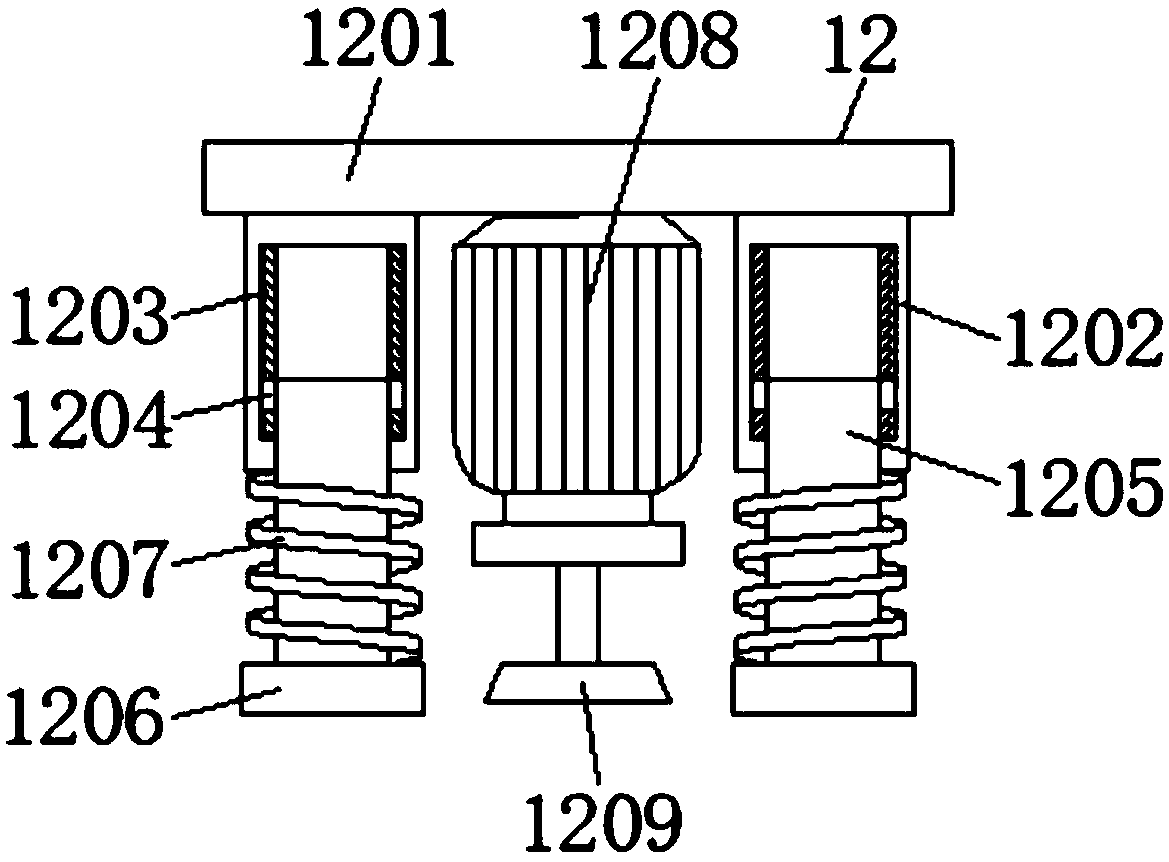

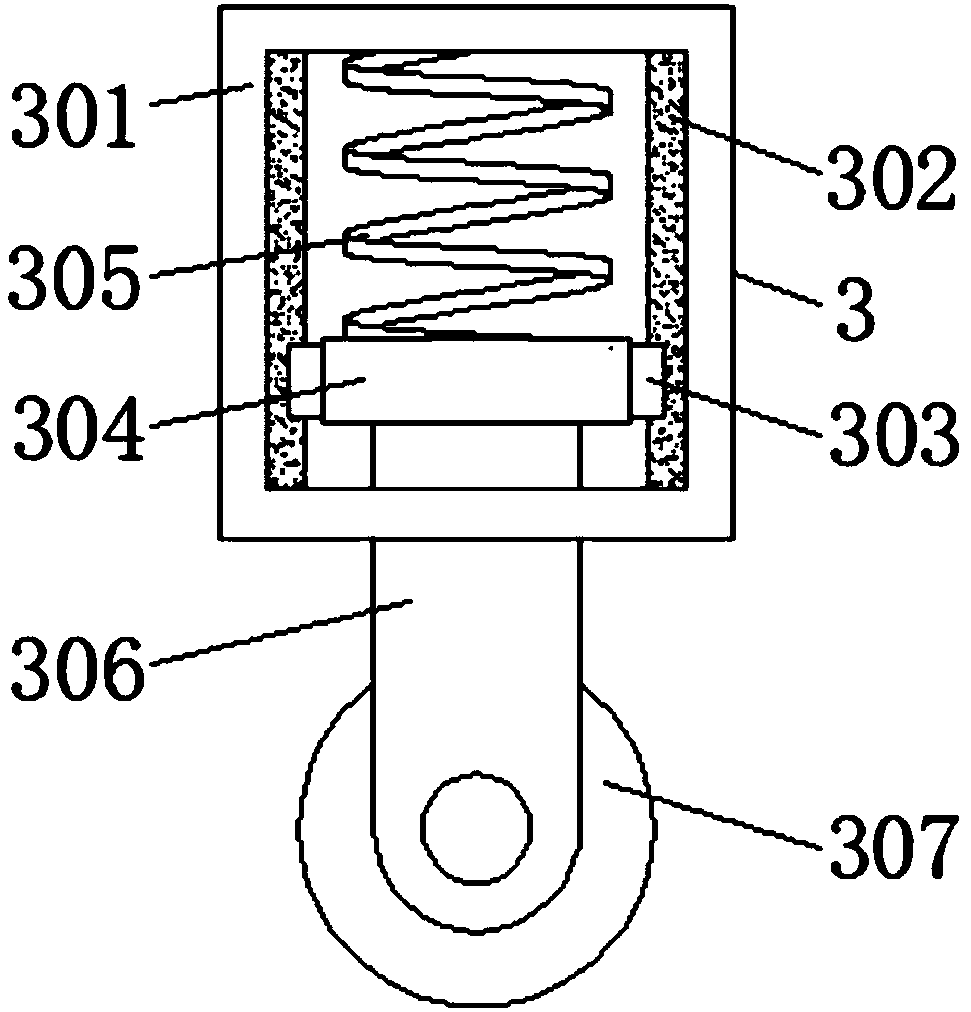

Watch glass grinding equipment for photovoltaic solar panel

ActiveCN108527044AEffective clamping and positioningConvenient grinding workGrinding carriagesGrinding drivesWatch glassDrive shaft

The invention relates to the technical field of manufacturing of photovoltaic products and discloses watch glass grinding equipment for a photovoltaic solar panel. The watch glass grinding equipment comprises an equipment body; four clamping devices which are arranged at an equal interval are fixedly installed at the inner bottom wall of the equipment body; the four corners of the bottom of the equipment body are each fixedly provided with a moving device; the right side of the inner wall of the equipment body is fixedly connected with a guide rail; the inner top wall of the equipment body isfixedly connected with a first motor through a fixing block; an output shaft of the first motor is fixedly connected with a first bevel gear through a transmission shaft; the right side of the first bevel gear is engaged with a second bevel gear; an inner ring of the second bevel gear is connected with a threaded rod in a sleeving manner; and the top end and the bottom end of the threaded rod areboth movably connected with the inner top wall and the inner bottom wall of the equipment body through bearing seats. The watch glass grinding equipment disclosed by the invention solves the problemsthat the existing glass grinding machine is low in work efficiency, the shake generated in grinding affects the grinding quality and transportation is inconvenient, and achieves the effects of high machining efficiency, good machining quality and convenient operation.

Owner:SHAOXING UNIVERSITY

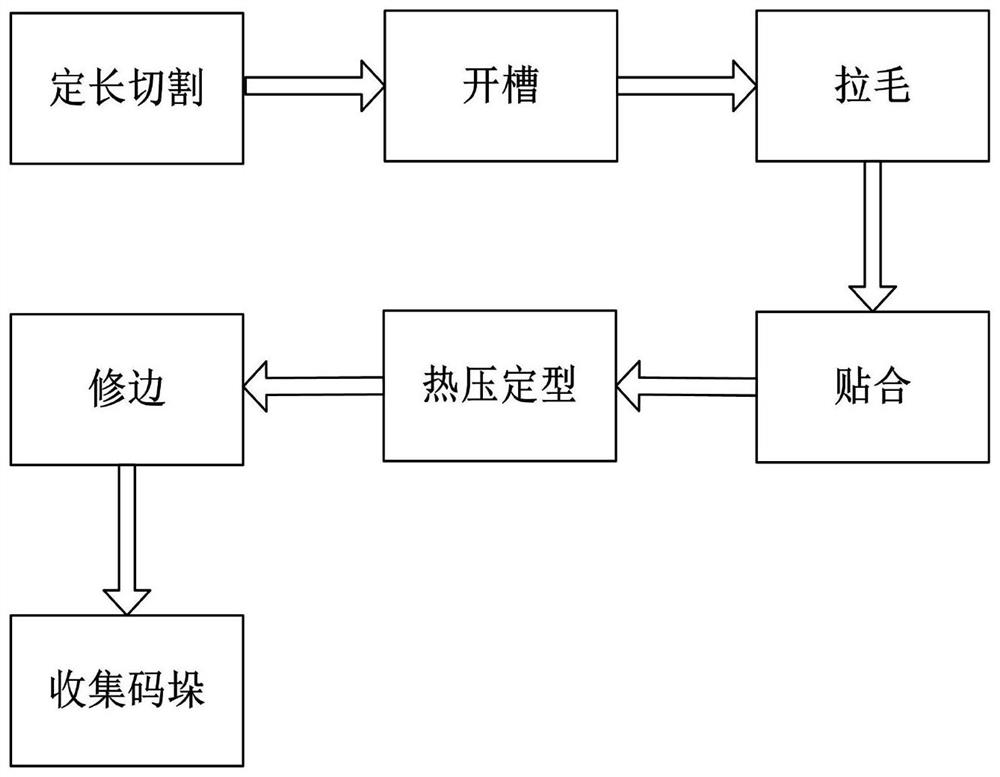

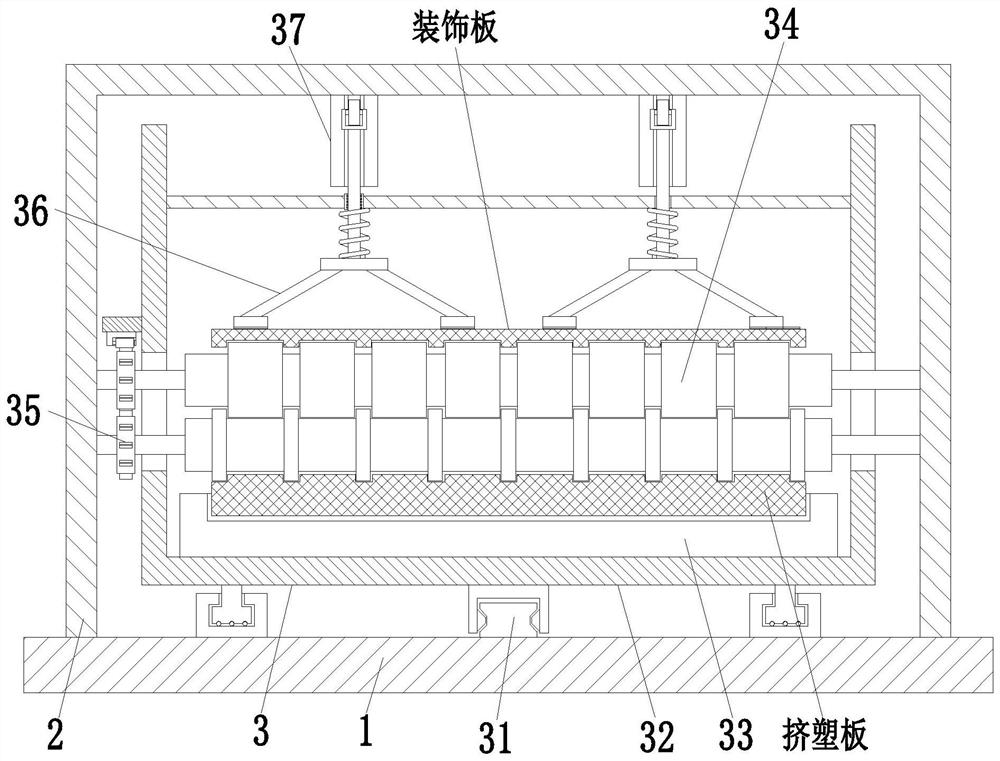

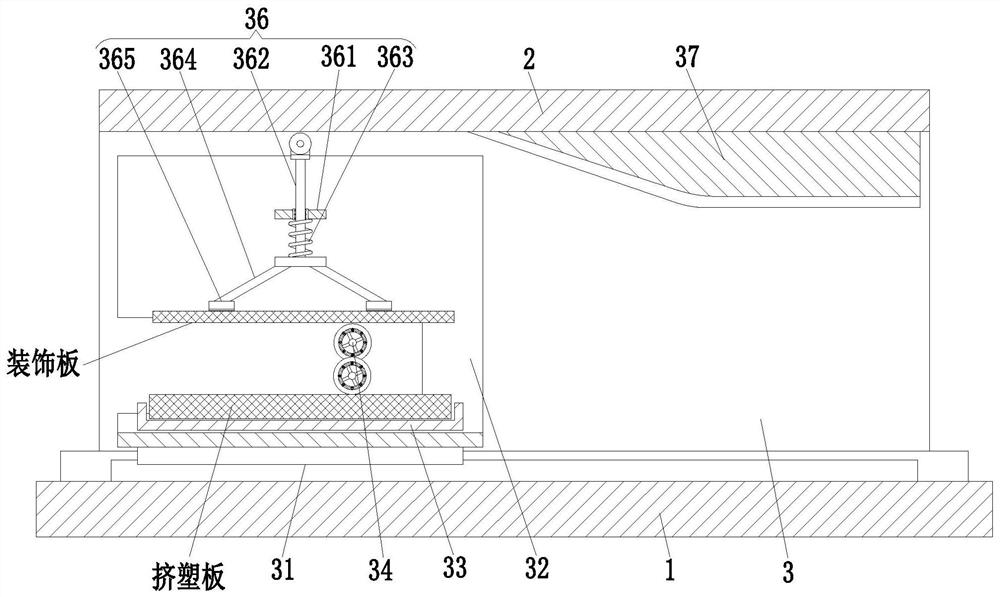

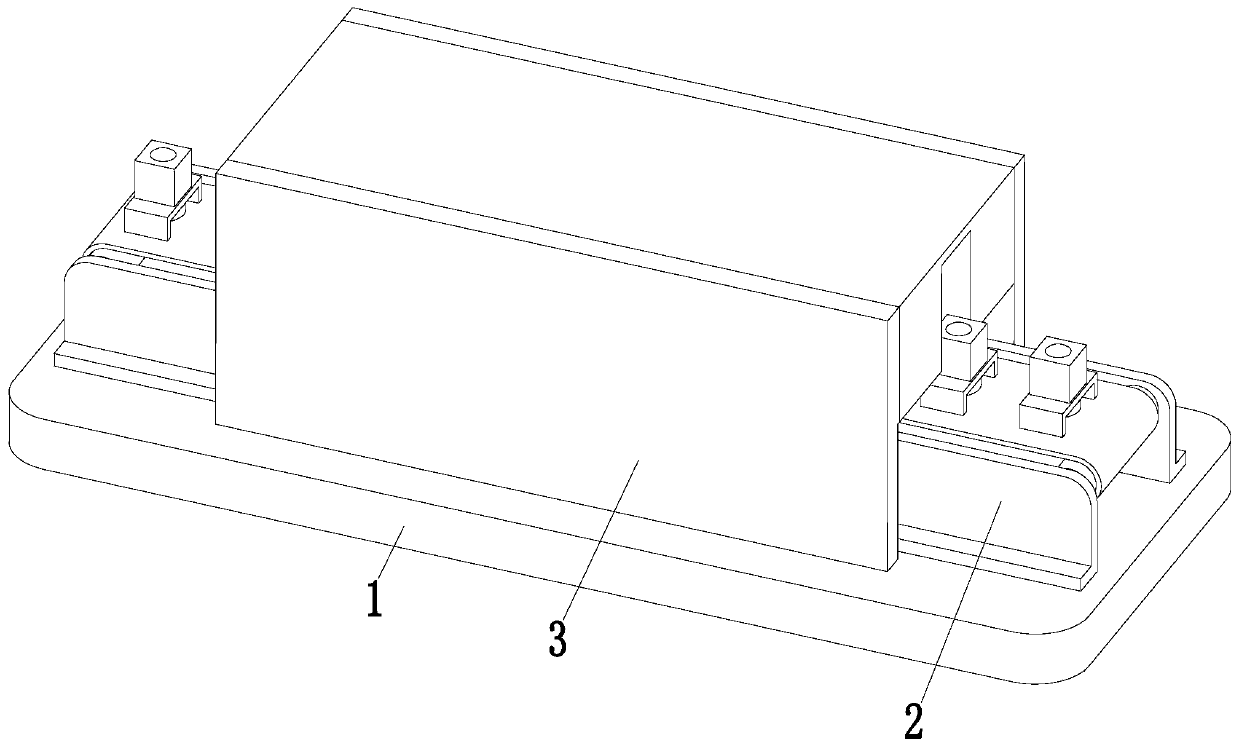

Processing and forming method for decorative extruded sheet

ActiveCN111941858AImprove gluing effectImprove adhesionLiquid surface applicatorsFlat articlesMechanical engineeringMaterials science

The invention relates to a processing and forming method for a decorative extruded sheet. The decorative extruded sheet comprises a bottom plate, a fixing frame and a forming device; the fixing frameis installed at the upper end of the bottom plate; the section of the fixing frame is of a U-shaped structure; the forming device is arranged inside the fixing frame; and the forming device is installed on the bottom plate. The processing and forming method provided by the invention can solve the problems that when an existing device is used for gluing the surface of an extruded sheet, the gluingeffect is good, coating is uneven, and many areas which are not glued usually exist on the surface of the extruded sheet, so the follow-up bonding effect of the extruded sheet is poor, and glue failure is prone to occurring; moreover, when the existing device is used for bonding the decorative extruded sheet, poor positioning effect and inaccurate positioning of the extruded sheet are caused, so the follow-up bonding effect of the extruded sheet is poor; deviation easily occurs; and follow-up use of the decorative extruded sheet is not facilitated.

Owner:济宁市爱科新型材料有限公司

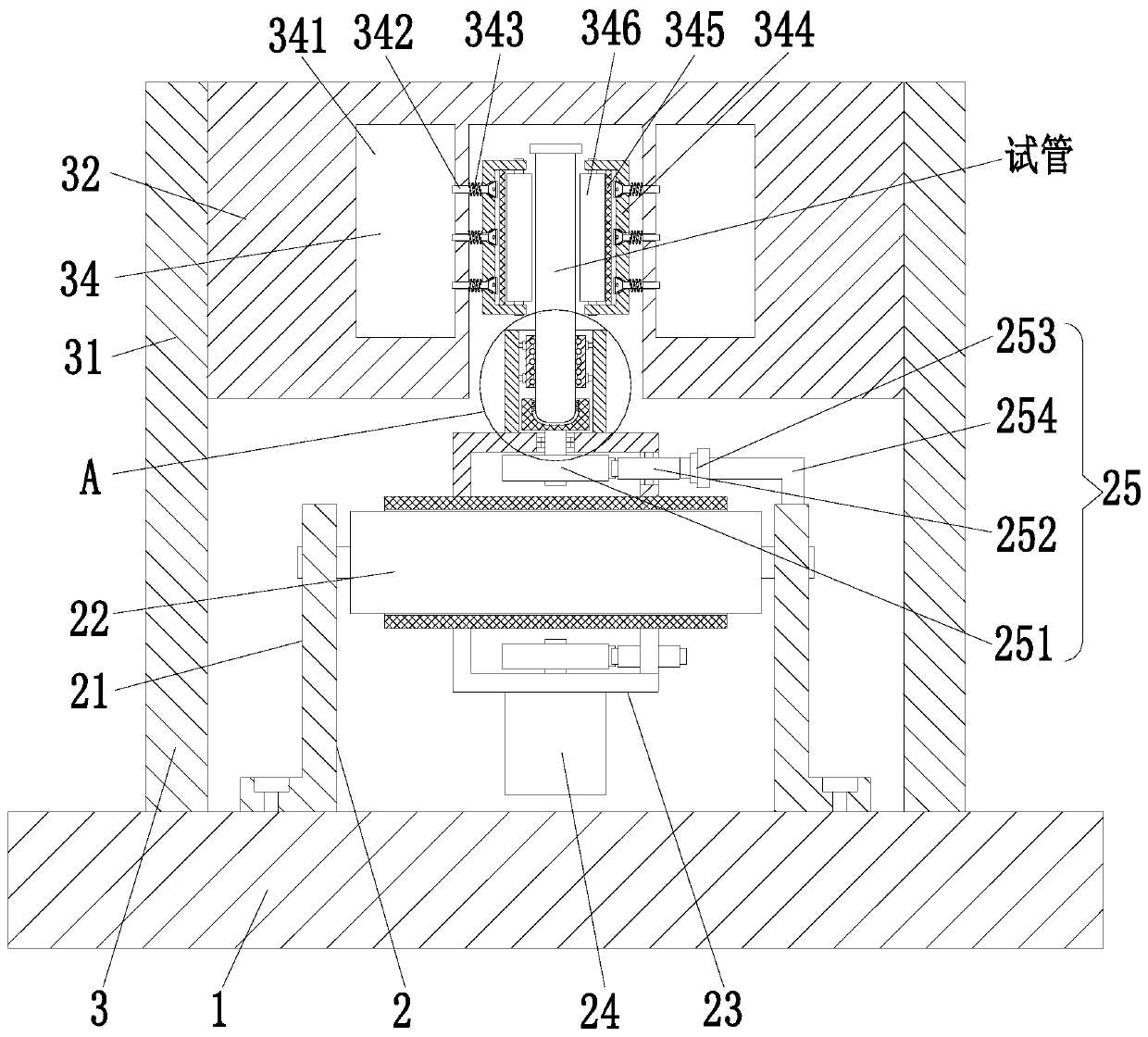

Quick removing device for temporarily-attached labels of glass test tubes

ActiveCN111318530AEffective clamping and positioningAvoid tiltingHollow article cleaningEngineeringStructural engineering

The invention relates to a quick removing device for temporarily-attached labels of glass test tubes. The quick removing device for the temporarily-attached labels of the glass test tubes comprises abottom plate, a conveying device and a removing device, the conveying device is installed in the middle of the upper end of the bottom plate, the removing device is arranged above the conveying device, and the lower end of the removing device is installed on the bottom plate. According to the quick removing device for the temporarily-attached labels of the glass test tubes, the problems that whenthe labels on the outer sides of the test tubes are removed through existing equipment, a direct scrubbing mode is generally adopted, but the label removing effect is poor, an adhesive layer is proneto being generated to be adhered to the outer walls of the test tubes, and the subsequent label adhering effect is influenced through the mode, when the existing equipment applies an adhesive removingagent to the outer sides of the test tubes, the applying effect is poor, applying is not uniform, the adhesive removing agent cannot fully dissolve the labels, and the removing effect of the labels on the outer sides of the test tubes is poor are solved.

Owner:FUYANG NORMAL UNIVERSITY

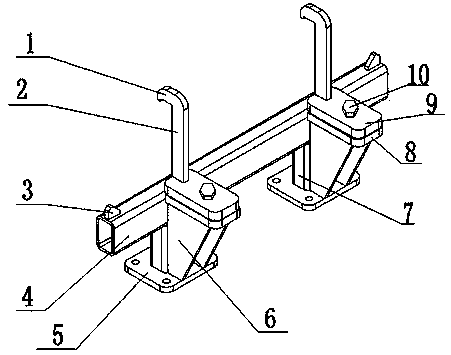

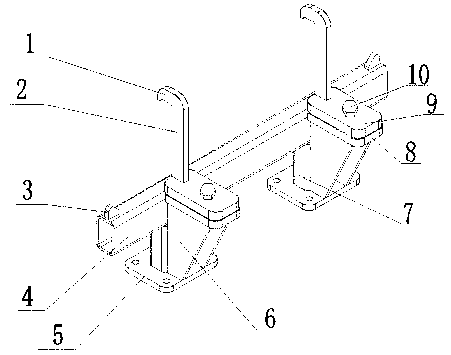

Clamping and positioning method for rear frame welding

InactiveCN104191131AEffective clamping and positioningGood effectWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses a clamping and positioning method for rear frame welding. The method includes the following steps that first, an installing plate is fixed to a fixing frame of a turn-over frame, and a rear frame is placed on the upper end face of a connecting plate; second, the rear frame is positioned and clamped by a clamping plate through a clamping structure, the other end of the rear frame is fixed and fastened to a fixing disk on the fixing frame, and therefore the fixing frame can be turned over freely, and in other words, the rear frame can be welded conveniently. Due to the clamping and positioning method for rear frame welding, the rear frame can be effectively clamped and positioned, the effect is good, and safety performance and practicability are high.

Owner:CHENGDU RONGDE CONSTR LABOR

Clamping and positioning device for welding machining of rear frame

InactiveCN103231194AEffective clamping and positioningGood effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

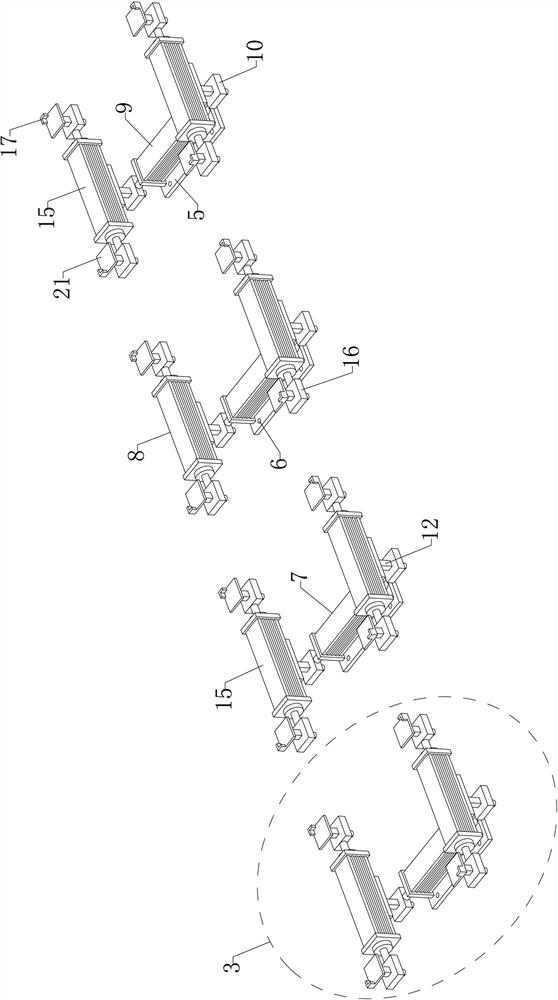

The invention discloses a clamping and positioning device for welding machining of a rear frame. The clamping and positioning device comprises mounting plates (5) and a connecting plate (4), wherein the mounting plates (5) and the connecting plate (4) are connected through support plates (7), fixed plates (8) are connected with the vertical side face of the connecting plate (4), positioning plates (9) are connected with the upper end surfaces of the fixed plates (8) through bolts (10), clamping plates (2) are connected with the positioning plates (9), and the upper parts of the clamping plates (2) are bent to form hook-shaped clamping structures (1). According to the clamping and positioning device disclosed by the invention, the rear frame can be effective clamped and positioned, the effects are good, and the security and the practicability are high.

Owner:CHENGDU HAILINGDA MACHINERY

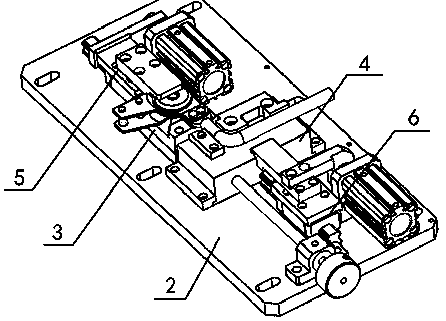

Semi-automatic laminator and laminating method

PendingCN109378516AFinish quicklyQuick changeAssembling battery machinesFinal product manufactureSemi automaticEngineering

The invention relates to a semi-automatic laminator and a laminating method. The semi-automatic laminator comprises a rack, a film feeding device and a film pressing device, wherein the film feeding device and the film pressing device are detachably arranged on the rack; a coating area used for mounting jigs and fixtures is reserved on the rack between the film pressing device and the film feedingdevice; and according to the film feeding device, packaging films are forwards transported to the upper side of the coating area and fixedly pressed on outer side walls of articles positioned in thejigs and fixtures by virtue of the film pressing device. According to the semi-automatic laminator disclosed by the invention, laminating and packaging of to-be-packaged articles can be rapidly and accurately completed, and due to the arrangement of the coating area, the jigs and fixtures of various models can be rapidly replaced. For example, if the to-be-packaged articles are batteries, the jigsand fixtures for batteries of various models can be rapidly replaced in the coating area.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

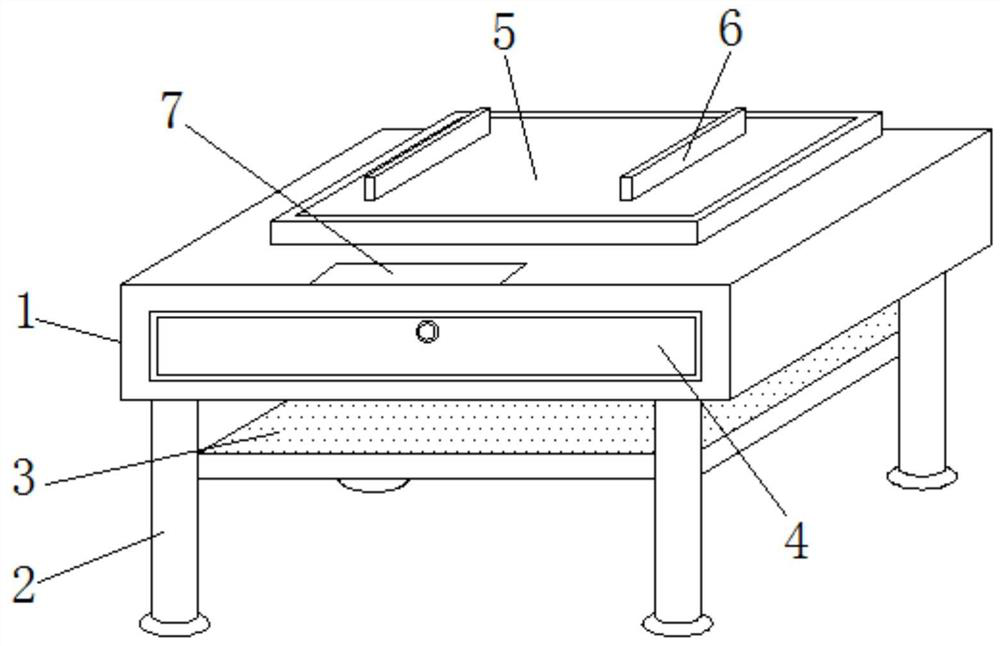

Multifunctional positioning mold of non-standard parts

ActiveCN109866053ASolve precise positioningSolve the problem of inconvenient positioningPositioning apparatusMetal-working holdersMechanical engineeringMultiple function

The invention discloses a multifunctional positioning mold of non-standard parts. The problem that the non-standard parts like non-standard clamp bodies cannot be precisely positioned is solved. The multifunctional positioning mold of the non-standard parts comprises a base, a clamp bearing base, a pipe bearing base, a clamp positioning assembly, and a pipe positioning assembly are arranged on thebase, all structural parts of the non-standard parts are effectively clamped and positioned, the mold can be special for auxiliary production of the non-standard clamp bodies, the problem that the non-standard parts are not convenient to position is solved, and the whole mold is compact in structural fit, high in stability and high in specificity.

Owner:南京联科镀膜包装材料有限公司

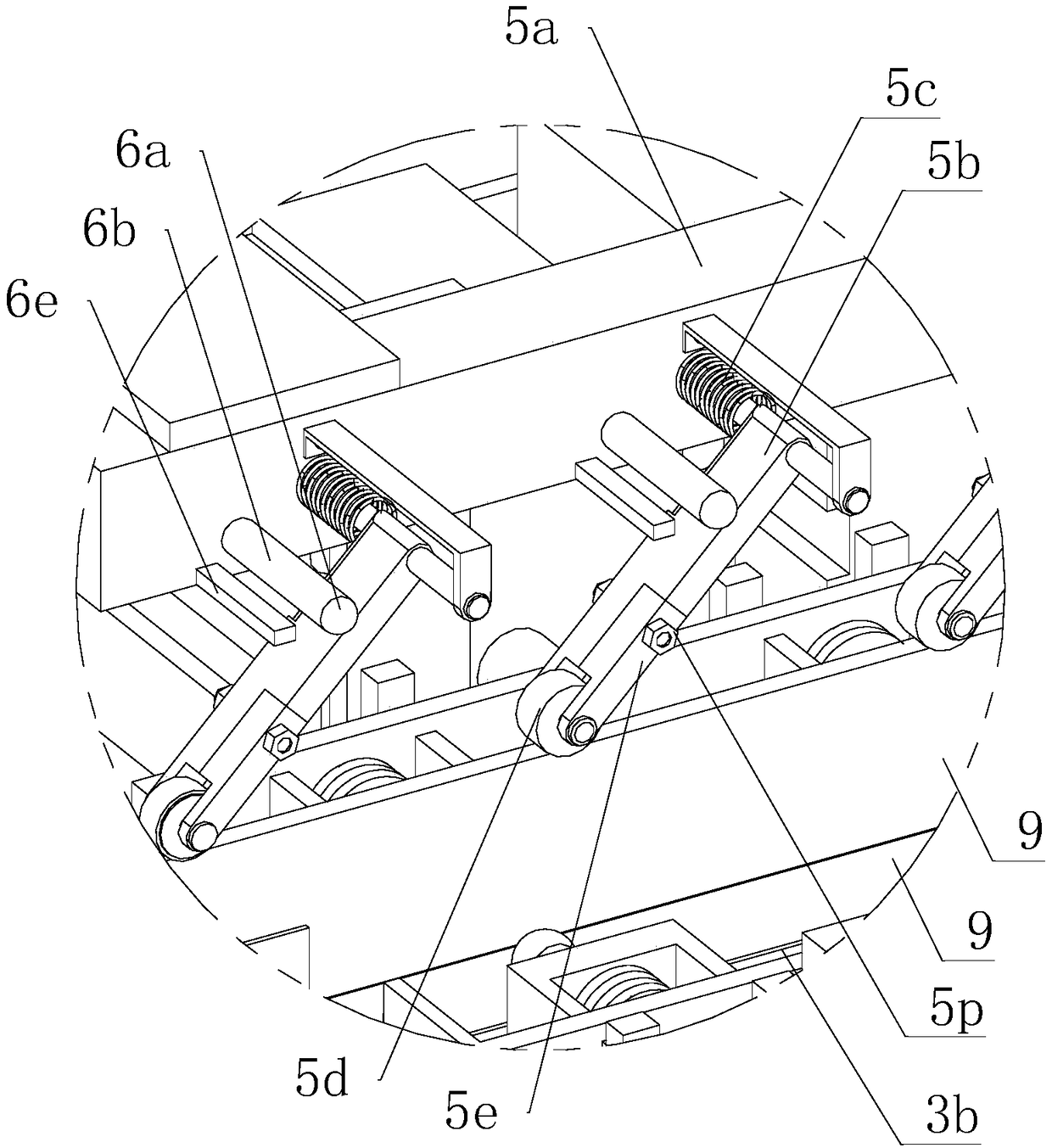

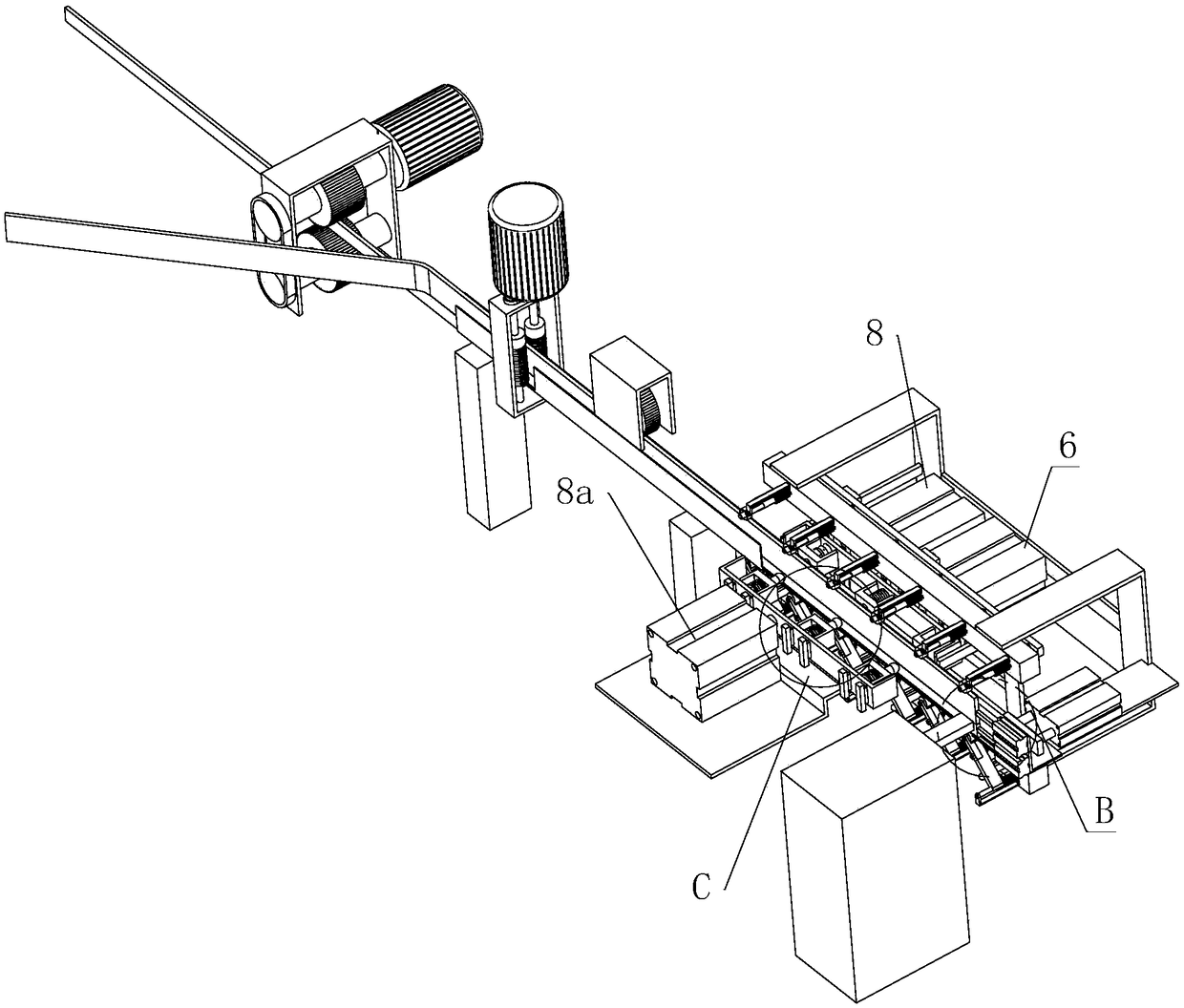

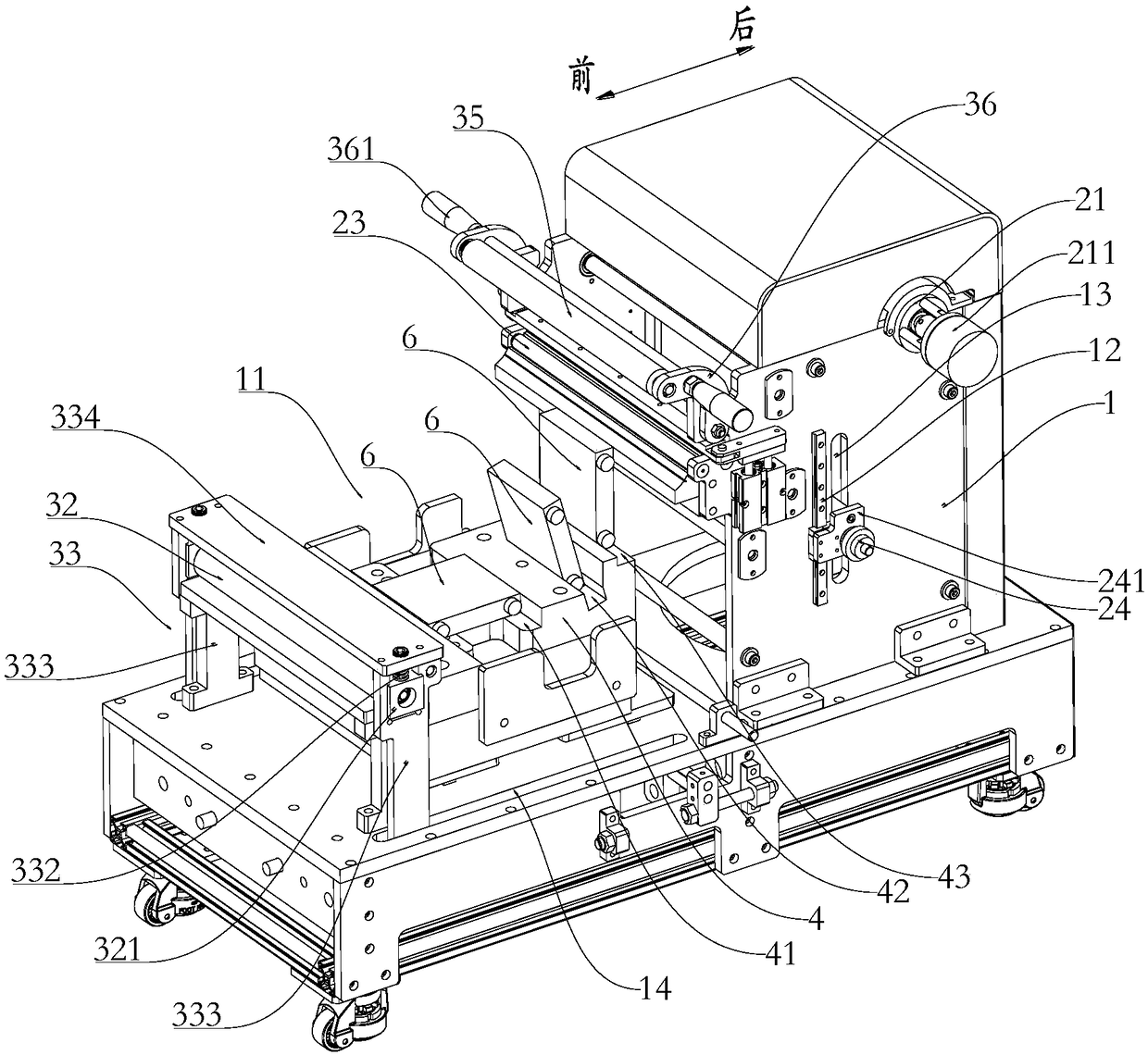

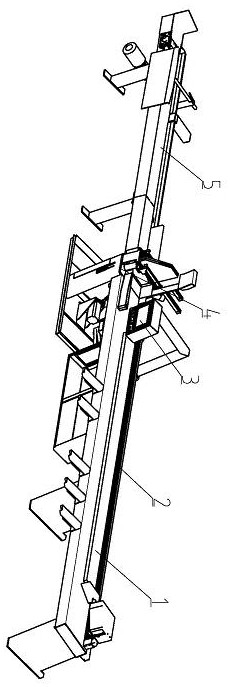

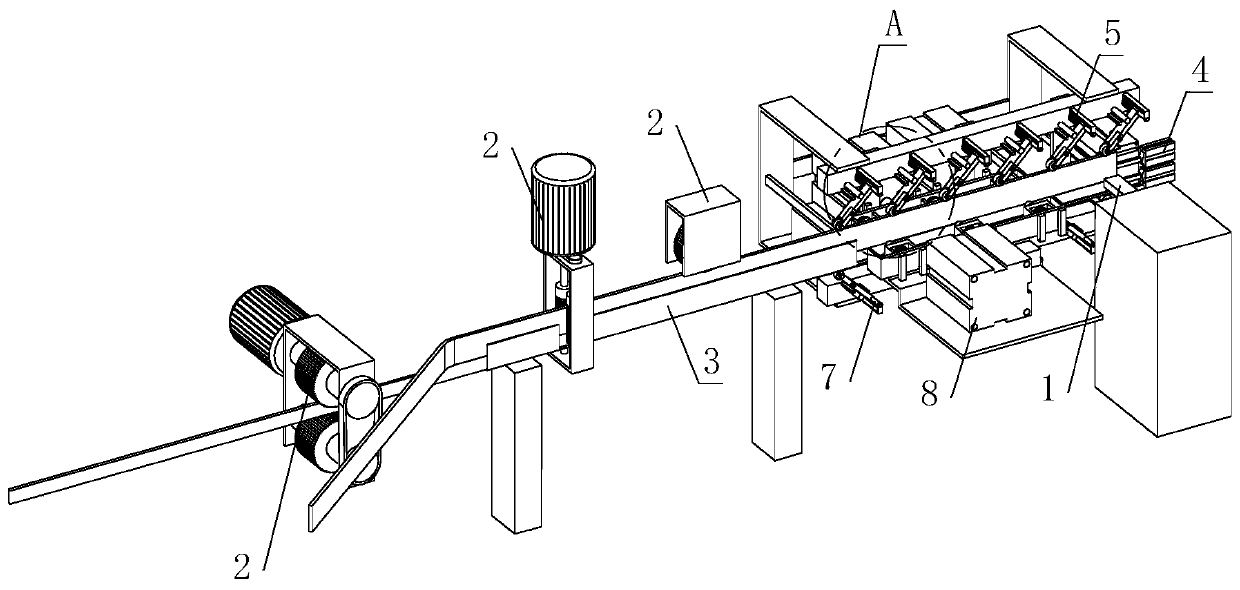

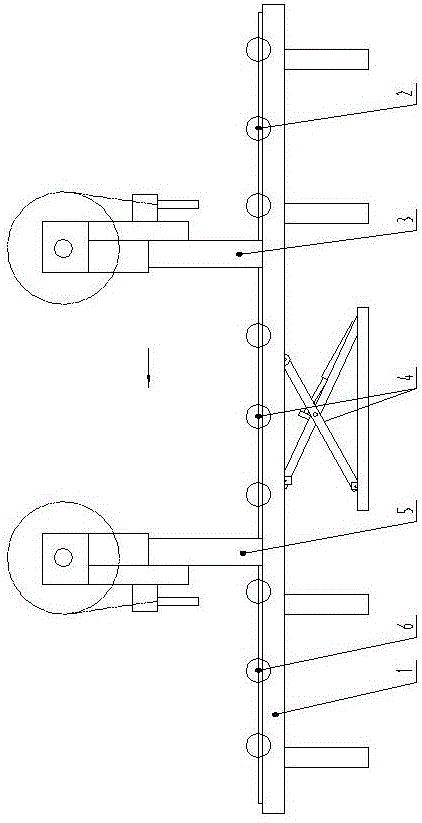

Push rod type optimizing and accurate cutting-off saw

InactiveCN112356155AEffective clamping and positioningAccurate truncated sawingFeeding devicesGripping devicesCircular sawElectric machinery

The invention discloses a push rod type optimizing and accurate cutting-off saw. The push rod type optimizing and accurate cutting-off saw comprises a material pushing machine, a sawing machine and asawed material sorting machine which are sequentially arranged from front to back along a timber sawing path, according to the material pushing machine, the sawing machine and the sawed material sorting machine, the material pushing machine comprises a material pushing machine frame, an accurate pusher is movably arranged on the material pushing machine frame through a material pushing electric cylinder, a timber side pressing device is further arranged on the material pushing machine frame, a sawing workbench and a main motor are arranged on a sawing machine machine frame, a left clamping assembly and a right clamping assembly are arranged above the sawing workbench, a vertical pressing assembly is arranged between the left clamping assembly and the right clamping assembly, a swing cutting assembly is further installed on the sawing machine machine frame, the main motor drives a circular saw web through the swing cutting assembly, the sawed material sorting machine comprises a sortingmachine frame, a sorting conveying belt is arranged on the sorting machine frame in a stretch-draw mode, and a plurality of sorting air cylinders and sorting baffles are further arranged on the sorting machine frame. By means of the transverse cutting-off saw, sliding-free accurate pushing of timber can be achieved, and effective clamping and positioning and accurate cutting and sawing can be carried out on the wood.

Owner:JIANGSU JIANGJIA MACHINERY

Correcting device for building curtain wall construction

InactiveCN111894292AEffective clamping and positioningPlay a positioning roleWallsBuilding material handlingMechanical engineeringArchitectural engineering

The invention provides a correcting device for building curtain wall construction. The correction device for building curtain wall construction comprises a main body plate and a top plate; and the topplate is fixedly connected to the top of the main body plate. According to the correcting device for building curtain wall construction, a bottom plate structure is arranged to mainly play a role inpositioning a curtain wall in the vertical direction, and finally the distance between a bottom plate and the top plate can be adjusted by rotating an adjusting shaft; and through the arrangement of apositioning structure, the curtain wall can be positioned in the horizontal direction, when the width of the curtain wall is larger than the maximum clamping range of two positioning plates, the distance between the two positioning plates can be adjusted by rotating a rotating rod, through the cooperation of the positioning structure and the bottom plate structure, the curtain wall can be effectively positioned and clamped in the vertical direction and the horizontal direction at the same time, the correction device can be adaptively adjusted according to the size of the curtain wall and canposition curtain walls of different sizes, and therefore different use requirements of people are met.

Owner:安徽方舟建筑安装有限公司

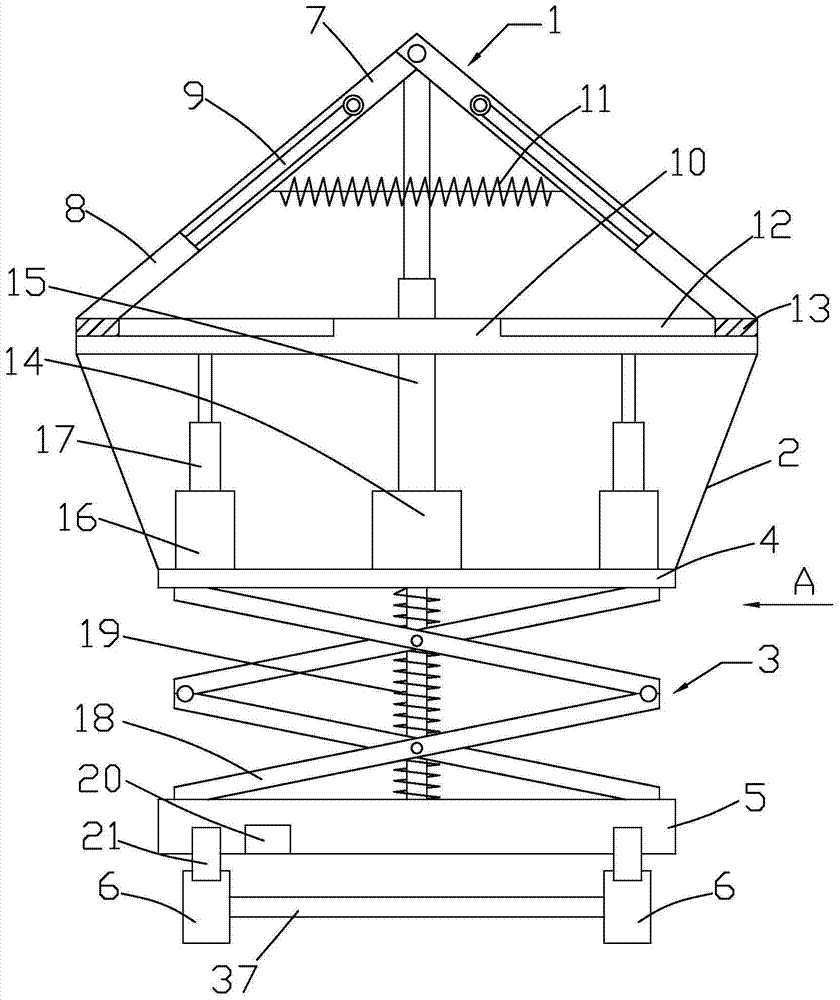

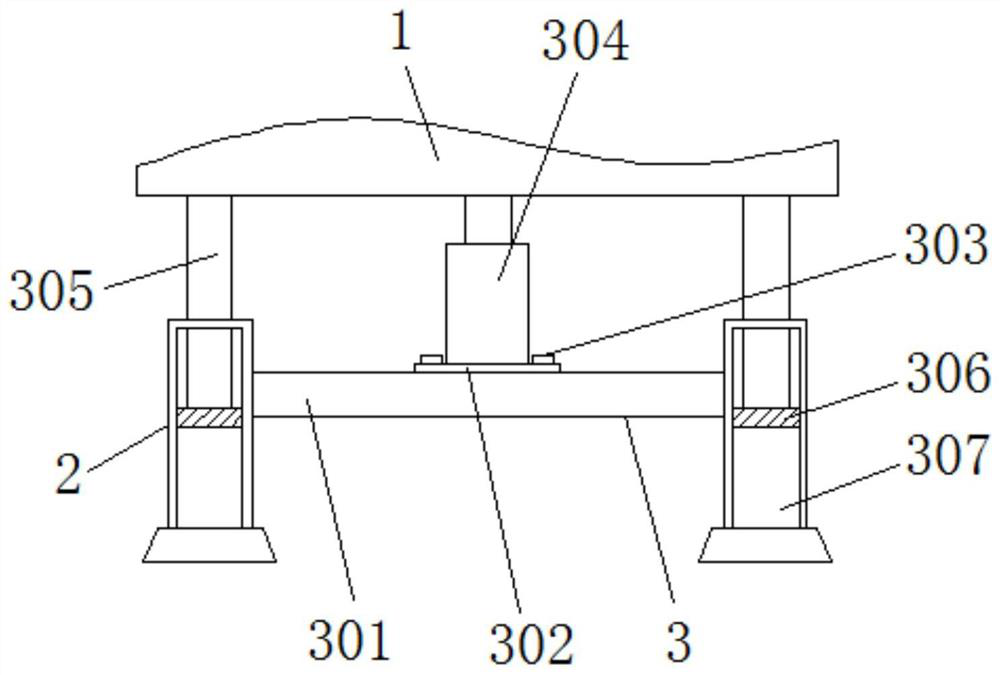

A jacking device and construction method for repairing the roof of a large-span ancient building

InactiveCN105672482BHigh strengthFit tightlyBuilding repairsHydraulic cylinderArchitectural engineering

The invention discloses a large-span historic building roof surface repair jacking device and a construction method. The large-span historic building roof surface repair jacking device comprises a roof adhering mechanism, jacking mechanisms and a guide moving mechanism; the roof adhering mechanism comprises beams, first positioning plates and second positioning plates; each jacking mechanism comprises an upper jacking plate, a lower supporting plate and a jacking frame; a positioning mechanism is arranged on each through groove; adjacent two beams are connected with each other through a clamping mechanism; a protective cover is arranged between each beam and the upper jacking plate; the adjacent two protective covers are connected with each other through a buckling mechanism; a first hydraulic cylinder and a second hydraulic cylinder are arranged in each protective cover; the guide moving mechanism comprises two positioning guide rails and guide wheels are which are arranged parallel to each other; each lower supporting plate is limited to the corresponding positioning guide rail through the corresponding guide wheel. According to the large-span historic building roof surface repair jacking device and the construction method, the strength and stability of an overall roof surface are improved by performing a jacking construction method on a roof without influencing a wall body of the original historic building; meanwhile, the safety of construction personnel in construction is improved; the construction quality is guaranteed.

Owner:浙江鑫直建筑有限公司

A photovoltaic solar panel surface glass grinding equipment

ActiveCN108527044BEffective clamping and positioningConvenient grinding workGrinding carriagesGrinding drivesWatch glassDrive shaft

The invention relates to the technical field of photovoltaic product manufacturing, and discloses a photovoltaic solar panel surface glass grinding equipment, which includes a device body, and four equidistantly arranged clamping devices are fixedly installed on the inner bottom wall of the device body. The moving devices are fixedly installed at the four corners, the right side of the inner wall of the equipment body is fixedly connected with the guide rail, the inner top wall of the equipment body is fixedly connected with the first motor through the fixed block, and the output shaft of the first motor is fixedly connected with the transmission shaft There is a first bevel gear, and the right side of the first bevel gear meshes with a second bevel gear. The inner ring of the second bevel gear is fixedly sleeved with a threaded rod. The top wall and the inner bottom wall are flexibly connected. The invention solves the problems of low working efficiency of the existing glass grinding machine, the vibration during grinding affects the quality of the grinding, and the problems of inconvenient transportation, and achieves the effects of high processing efficiency, good processing quality and convenient operation.

Owner:SHAOXING UNIVERSITY

Special fixture for machining groove on small pressure bar

InactiveCN102896523AEffective clamping and positioningEasy to processPositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a special fixture for machining a groove on a small pressure bar. The ends of the pressure bar are positioned by a first positioning bar and a second positioning bar of the fixture, and a shank of the pressure bar is positioned by a V-shaped block and a pressure plate of the fixture. The special fixture is simple in structure and convenient to operate. The small pressure bar is effectively positioned and clamped by the special fixture so as to facilitate machining.

Owner:SUZHOU RIHE SEWING EQUIP

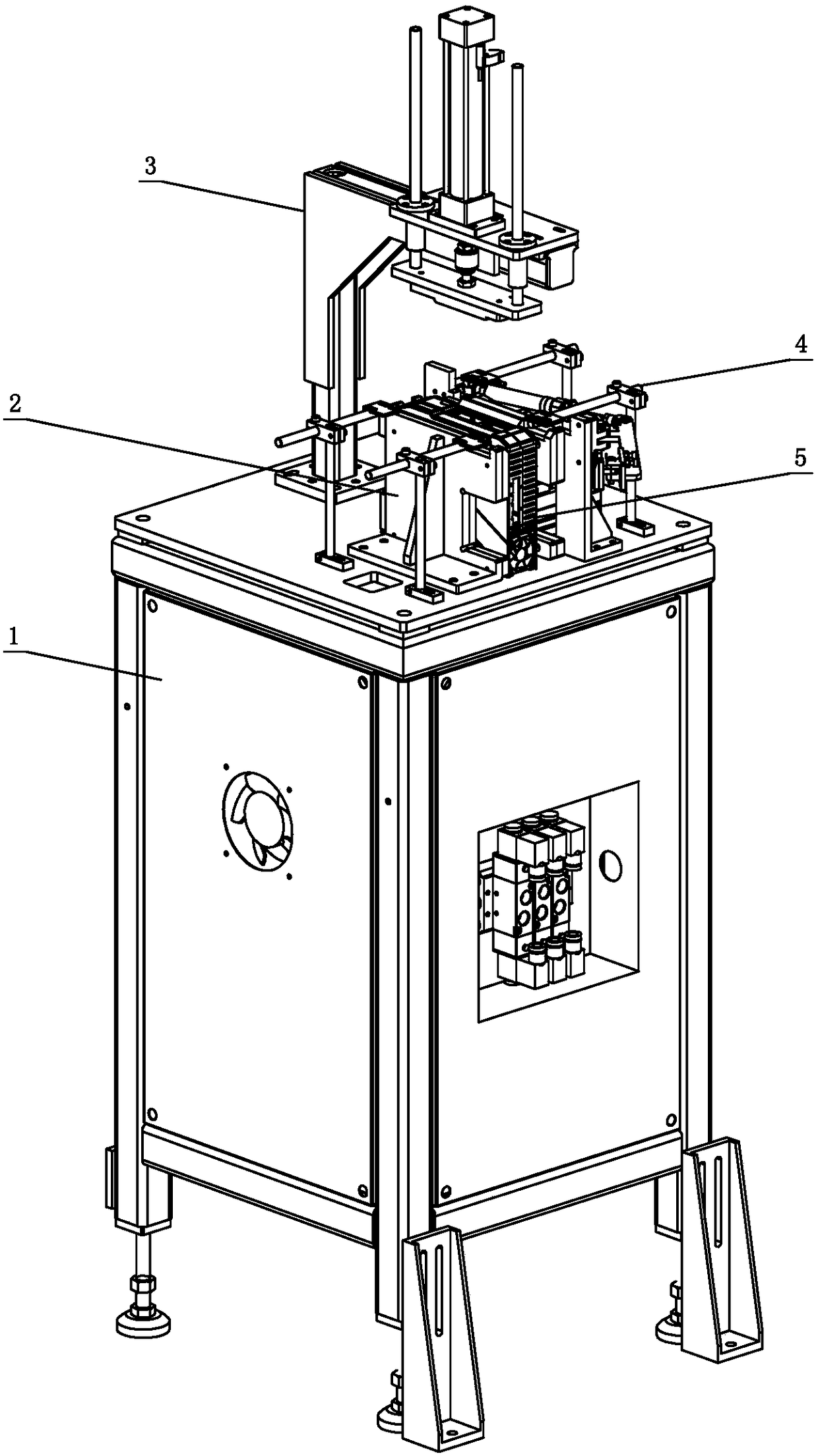

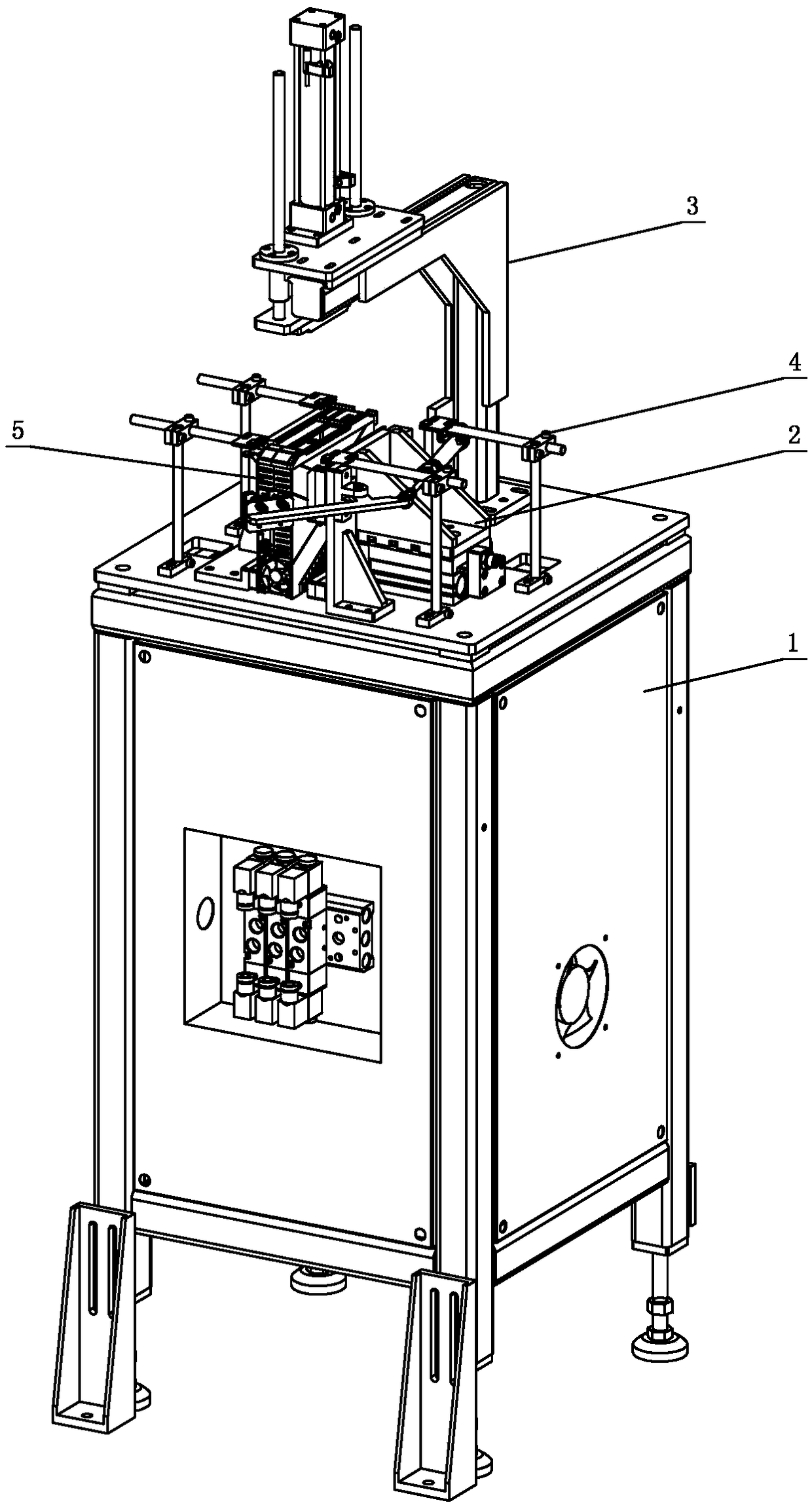

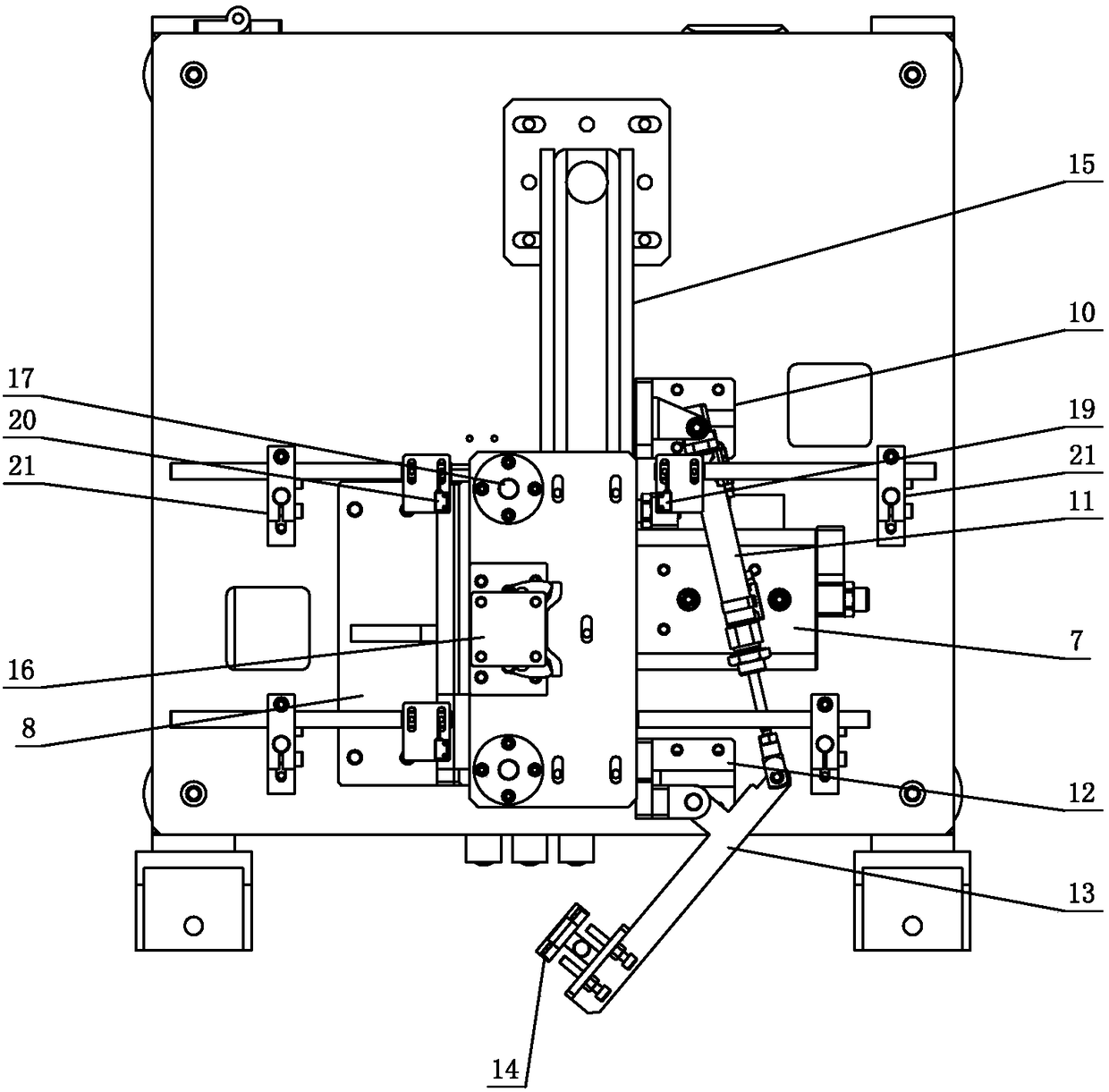

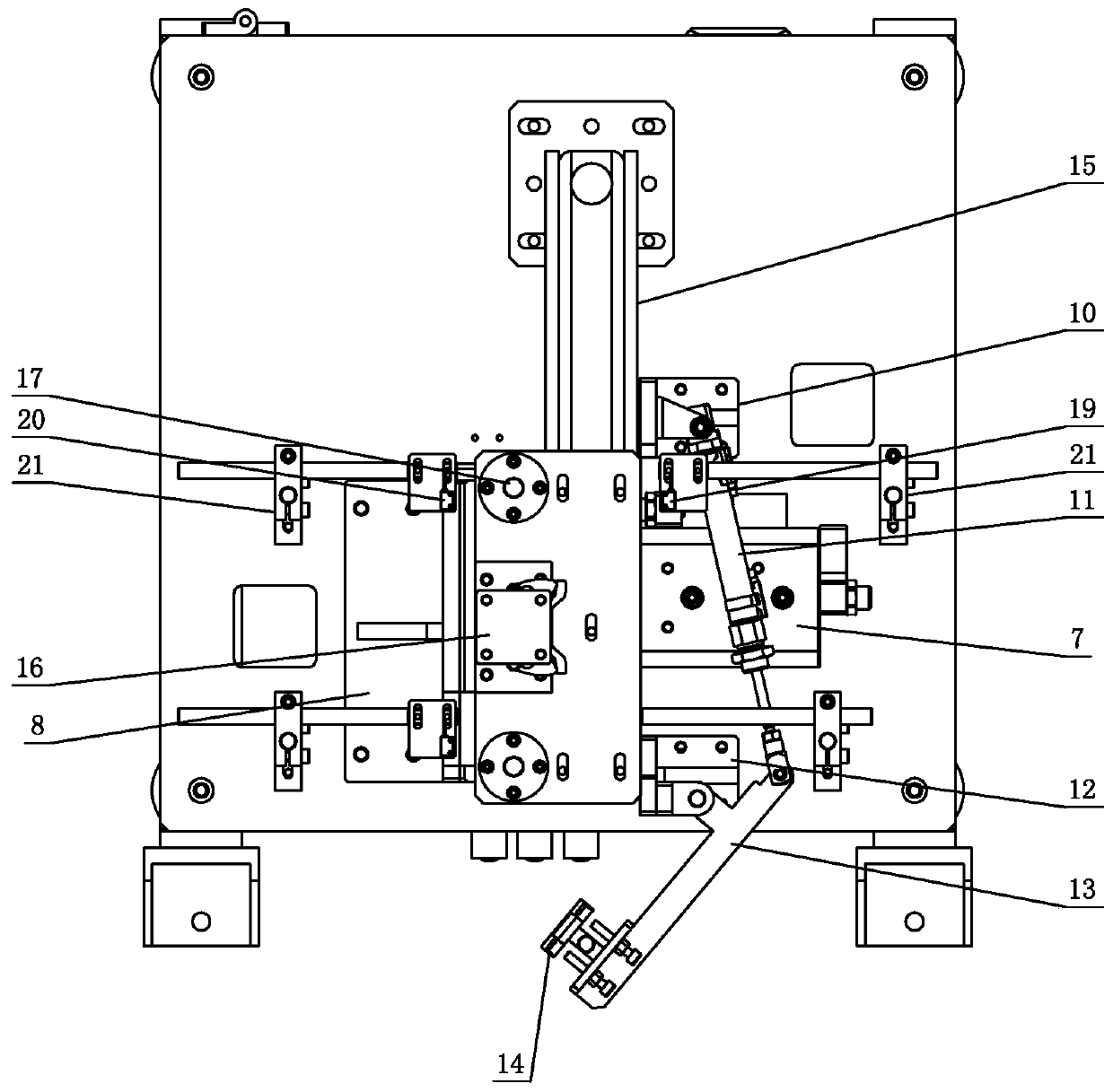

Upper cover plastic shell press-fitting device for assembling drivers

ActiveCN108161830AImprove work efficiencyGood quality of workMetal-working hand toolsWork in processEngineering

The invention provides an upper cover plastic shell press-fitting device for assembling drivers. The upper cover plastic shell press-fitting device comprises a press-fitting working platform. A locating datum mechanism and a pressing mechanism are arranged on the working platform. The locating datum mechanism comprises a side pressing locating assembly and an end pressing locating assembly which do not interfere with each other. The side pressing locating assembly comprises a side pressing cylinder, a first side pressing plate and a second side pressing plate. The side pressing cylinder drivesthe first side pressing plate and the second side pressing plate to get close to each other or away from each other so as to clamp the side face of a semifinished driver. The end pressing locating assembly comprises an end pressing cylinder and an end pressing plate. The end pressing cylinder at least drives the end pressing plate to locate and press one end face of the semifinished driver. The pressing mechanism comprises a pressing cylinder and a press-fitting tool. A rod body of the pressing cylinder is connected with and drives the press-fitting tool to rise and drop relative to the press-fitting working platform to conduct press-fitting on an upper cover plastic shell and the semifinished driver. The upper cover plastic shell press-fitting device can guarantee accurate and efficientpress-fitting assembly of the upper cover plastic shell and the semifinished driver and is reliable in performance and capable of reducing the labor intensity of workers and lowering the labor cost.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Painting device for artware processing and using method

PendingCN111958561AEffective clamping and positioningAvoid pinchingWork holdersWork benchesEngineeringWorkbench

The invention discloses a painting device for artware processing. The painting device comprises a workbench, supporting columns are installed at the bottom end of the workbench, a height adjusting mechanism is connected between the supporting columns and the workbench, and a drawing and closing classification mechanism is installed inside the workbench. According to the painting device, when a worker needs to paint artware, the artware needs to be fixed to the painting device, a first hand-screwing nut is unscrewed firstly, then a screwing head is screwed, a threaded rod starts to rotate, andtherefore two clamping blocks are driven to start to move oppositely through second sliding blocks, and the artware can be effectively clamped and positioned, wherein elastic cushions are installed onthe inner sides of the clamping blocks to prevent the artware from being damaged by clamping; and after clamping and positioning are conducted, the first hand-screwing nut is screwed and fixed, and when the user needs to conduct face changing and color brushing, second hand-screwing nuts can be screwed so that the user can rotate a positioning table to a proper position.

Owner:义乌市鹏锦饰品有限公司

Plate positioning part of a trailer frame assembly assembly welding system

ActiveCN107160079BRapid positioningFast solderingWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameCompression device

The invention discloses panel positioning components of a trailer frame assembly splicing welding system. The number of the panel positioning components is multiple, and the multiple panel positioning components are arranged on the upper surface of a workpiece supporting plate (31), and the panel positioning components comprise compression devices (32) and positioning devices (33); each compression device comprises a supporting base fixedly installed on the workpiece supporting plate, a stretchable control mechanism installed on the supporting base and a pressing head installed on the stretchable control mechanism, the compression directions of each compression device at least comprise the horizontal direction and the vertical direction, the compression devices are symmetrically arranged with respect to a positioned panel, and the pressing heads are oppositely arranged; and each positioning device comprises a large beam positioning mechanism, a transverse beam positioning mechanism and an edge beam positioning mechanism. By means of the panel positioning components of the trailer frame assembly splicing welding system, overall and quick splicing and welding of a trailer can be achieved, and the splicing and welding efficiency is high.

Owner:江苏富华交通运输设备股份有限公司

Multi-angle machining type robot speed reducer shell machining equipment

PendingCN113183015AHigh degree of automationCollinearGrinding carriagesPolishing machinesElectric machineRobotic arm

The invention discloses multi-angle machining type robot speed reducer shell machining equipment in the technical field of mechanical arms, which comprises a mounting table, a stepped ring groove is arranged in the center of the upper end face of the mounting table, a fixed ring is arranged in the center of the mounting table, the fixed ring is fixedly arranged on the lower end face of the mounting table, a collecting mechanism is fixedly arranged in the fixed ring, a motor is arranged at the lower end of the collecting mechanism, and an electric push rod is fixedly arranged at the lower end of the motor; an output shaft of the motor vertically penetrates through the collecting mechanism and is slidably arranged with the collecting mechanism, a polishing mechanism is arranged at the upper end of the collecting mechanism, a sweeping mechanism is arranged at the upper end of the polishing mechanism, a sealing mechanism is arranged at the upper end of the sweeping mechanism, and the polishing mechanism, the sweeping mechanism and the sealing mechanism are all fixedly arranged on the output shaft; and a plurality of clamping mechanisms are uniformly arranged at the outer end of the circumference of the polishing mechanism at equal angles. Through the arrangement, the problem that when existing equipment is used for grinding and polishing the inner wall of a shell, due to the complex structure, and when shells of different sizes are polished, a plurality of parts need to be replaced can be solved.

Owner:昂越(上海)机械有限公司

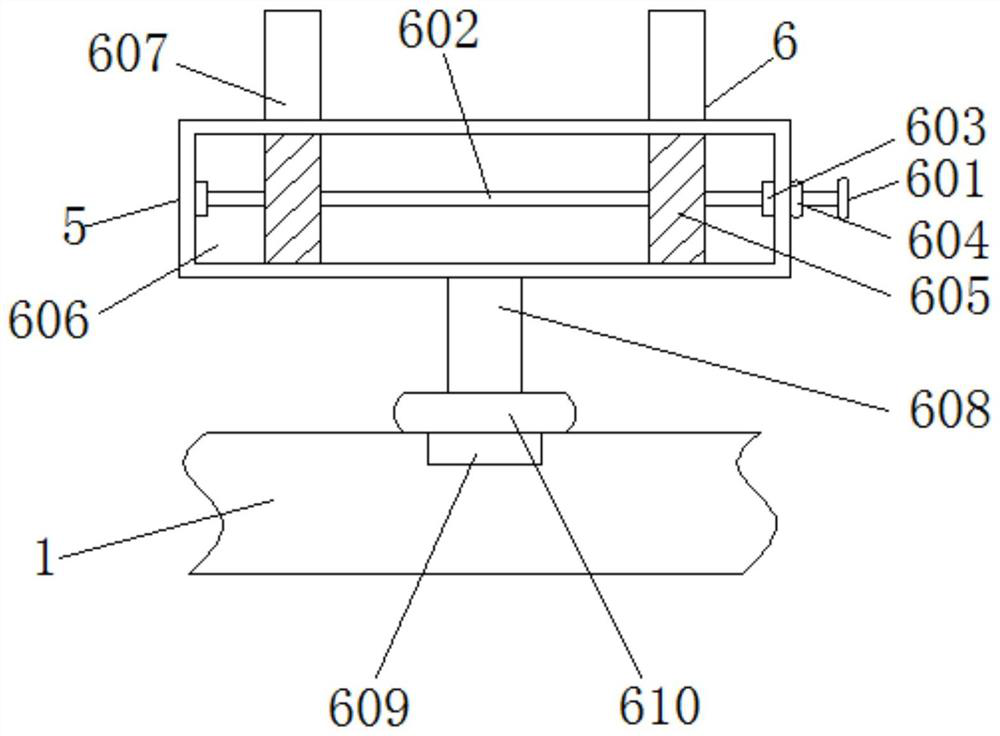

Universal programming test equipment for integrated circuit

PendingCN114325327AEffective clamping and positioningEasy to install and disassembleElectronic circuit testingMeasurement instrument housingCouplingElectric machinery

The invention discloses universal programming test equipment for an integrated circuit, and the equipment comprises a table board, guide rails are fixed on the table board, guide rail pairs are slidably arranged on the guide rails, a supporting table is fixed on the two guide rail pairs, an inner cavity is formed in the supporting table, shaft sleeves are fixed on the two sides of the inner wall of the inner cavity, supporting shafts are rotatably arranged in the shaft sleeves, and a motor is fixed on the supporting table. A rotating shaft of the motor is fixed to the supporting shaft through a coupler, a threaded protrusion is arranged on the supporting shaft, a threaded sleeve is arranged on the threaded protrusion in a threaded mode, a limiting rod is fixed to the threaded sleeve, a limiting hole is formed in the inner wall of the inner cavity, the limiting rod and the limiting hole are arranged in a sliding mode, a movable clamping plate is fixed to the limiting rod, and a positioning plate is fixed to the supporting table. A circuit board is clamped between the movable clamping plate and the positioning plate. The circuit board can be effectively clamped and positioned through opposite movement of the movable clamping plate in cooperation with the positioning plate, and the circuit board can slide back and forth in cooperation with relative sliding of the guide rail pair and the guide rail so that the circuit board can be in contact test with a test pen.

Owner:SUZHOU XINHUARUI ELECTRONICS

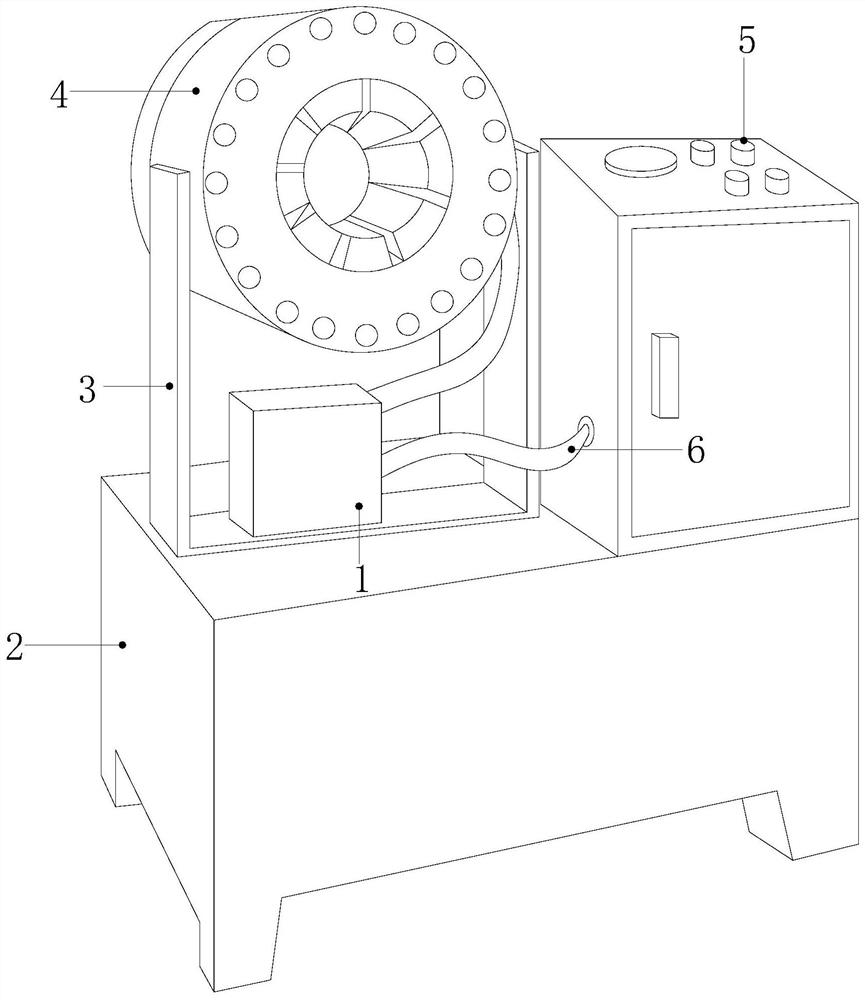

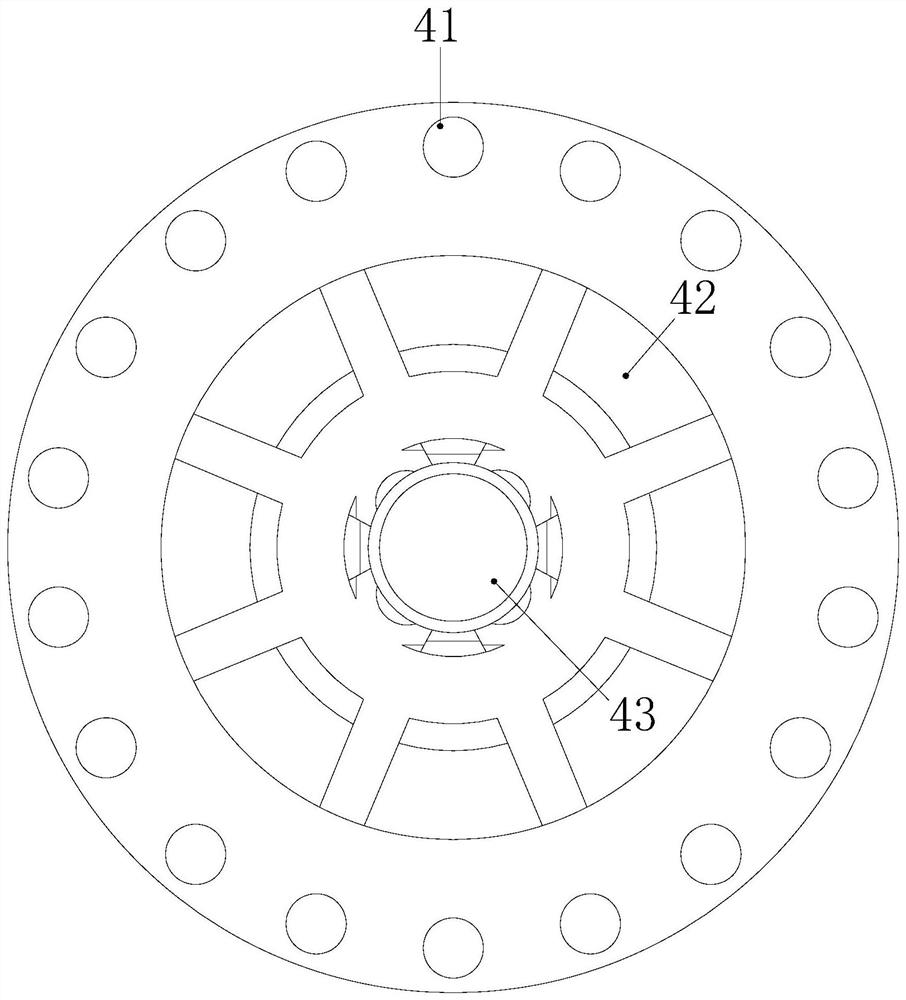

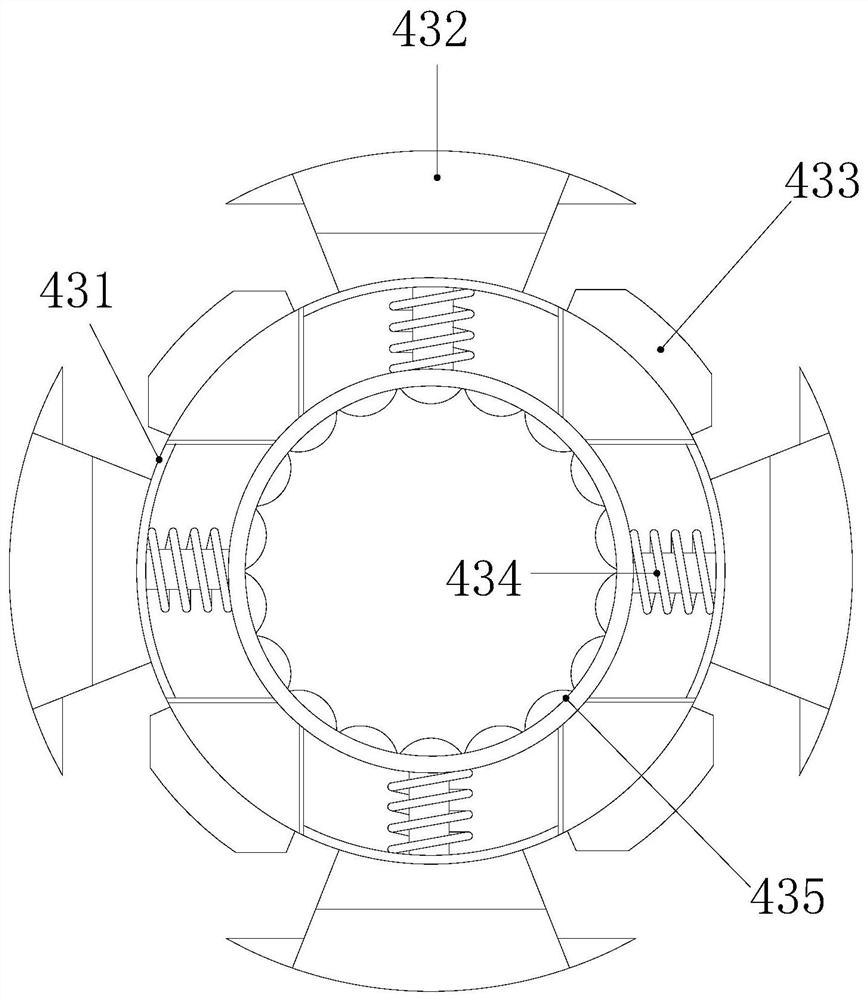

Stable pipe exchanging and adjusting necking machine

PendingCN113020465AUniform deliveryEffective clamping and positioningMetal-working feeding devicesPositioning devicesClassical mechanicsEngineering

The invention discloses a stable pipe exchanging and adjusting necking machine which structurally comprises a power box, a machine body, a supporting frame, a clamping device and a control box. When the stable pipe exchanging and adjusting necking machine is used, a sleeve is necked, the sleeve is installed on a connector and is clamped and limited through mutual cooperation of a plurality of supporting and jacking pieces, and the sleeve is not prone to displacement in the necking process. A compression plate and a bearing block are extruded through inward convergence of buckling and pressing blocks, the compression plate, the bearing block and the buckling and pressing blocks can be matched to conduct necking and pressing treatment on the sleeve, necking treatment is effectively conducted on the sleeve, and the necking precision and the necking effect of the sleeve are improved.

Owner:四川慧海杨帆贸易有限公司

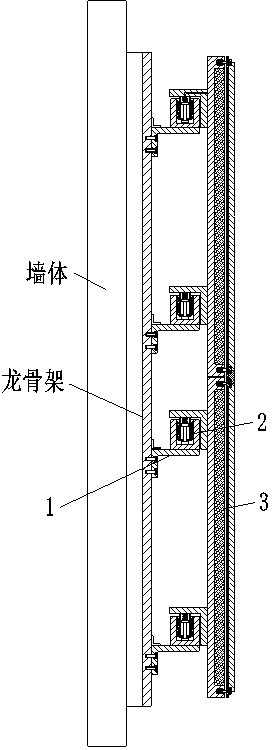

A kind of environment-friendly building exterior wall decorative plate and its installation method

ActiveCN111719793BEffective clamping and positioningImprove the installation effectCovering/liningsBuilding insulationsFixed frameArchitectural engineering

The invention relates to an environment-friendly building exterior wall decorative plate and its installation method, comprising a fixing frame, a positioning device and a plate body, the fixing frame is installed on the keel frame through screws, the fixing frame has an L-shaped structure, and the upper end of the fixing frame A reinforcing plate is installed between the keel frame, and the number of fixing frames is two. A positioning device is installed on the fixing frames, and a plate body is installed between the right ends of the positioning frames. The present invention can solve the problem of poor installation effect, inconvenient installation and disassembly of the existing exterior wall decoration boards, large gaps between the installed boards, and rainwater easily seeping into the boards, affecting the subsequent use of the boards In addition, when the existing decorative panels for exterior walls are used, the use effect of the panels is poor, the protective performance is low, the decorative layer of the panels is prone to breakage, and the broken panels are prone to fall off, which affects the safety of use and other problems.

Owner:深圳市中筑营造建设工程有限公司

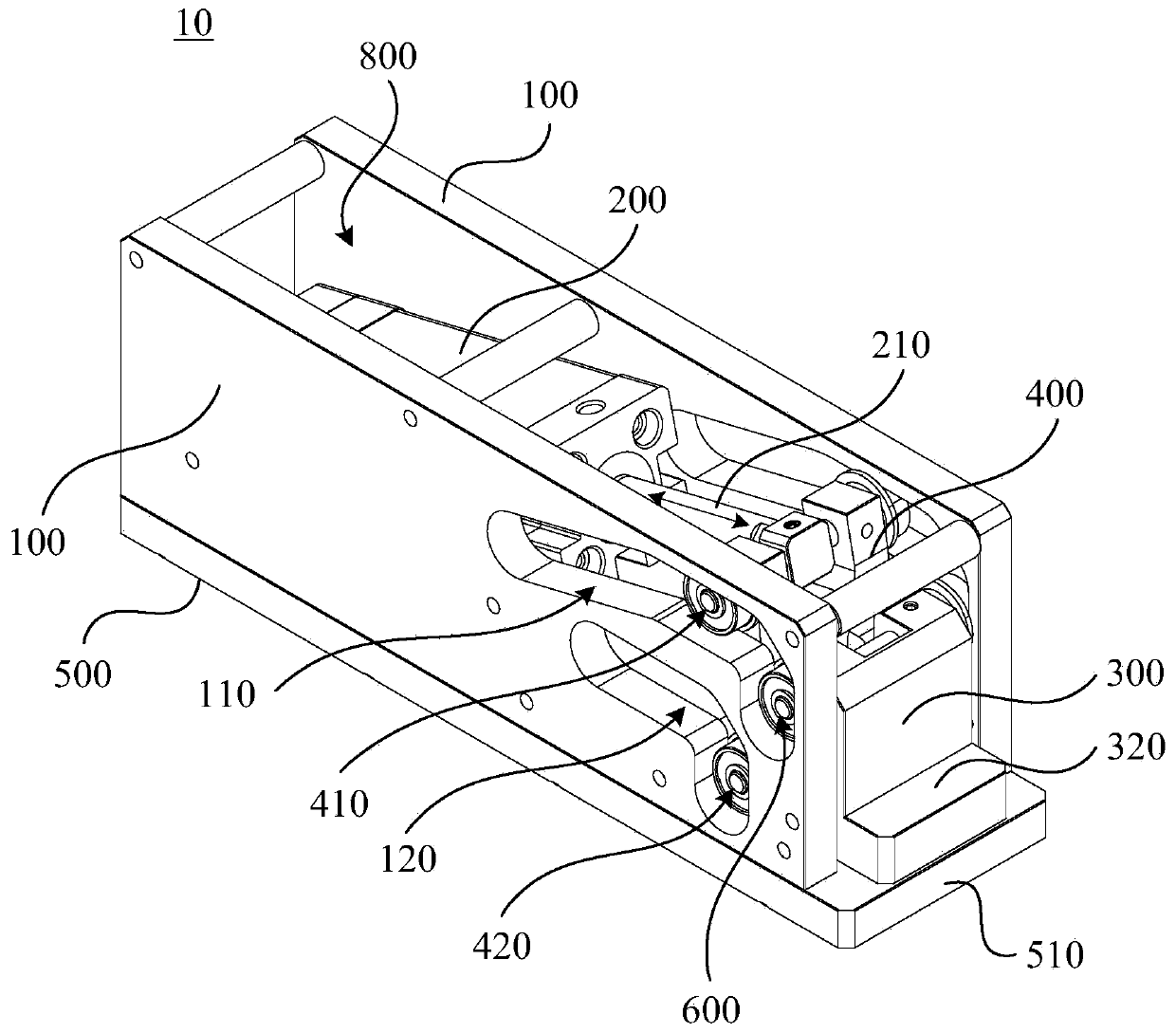

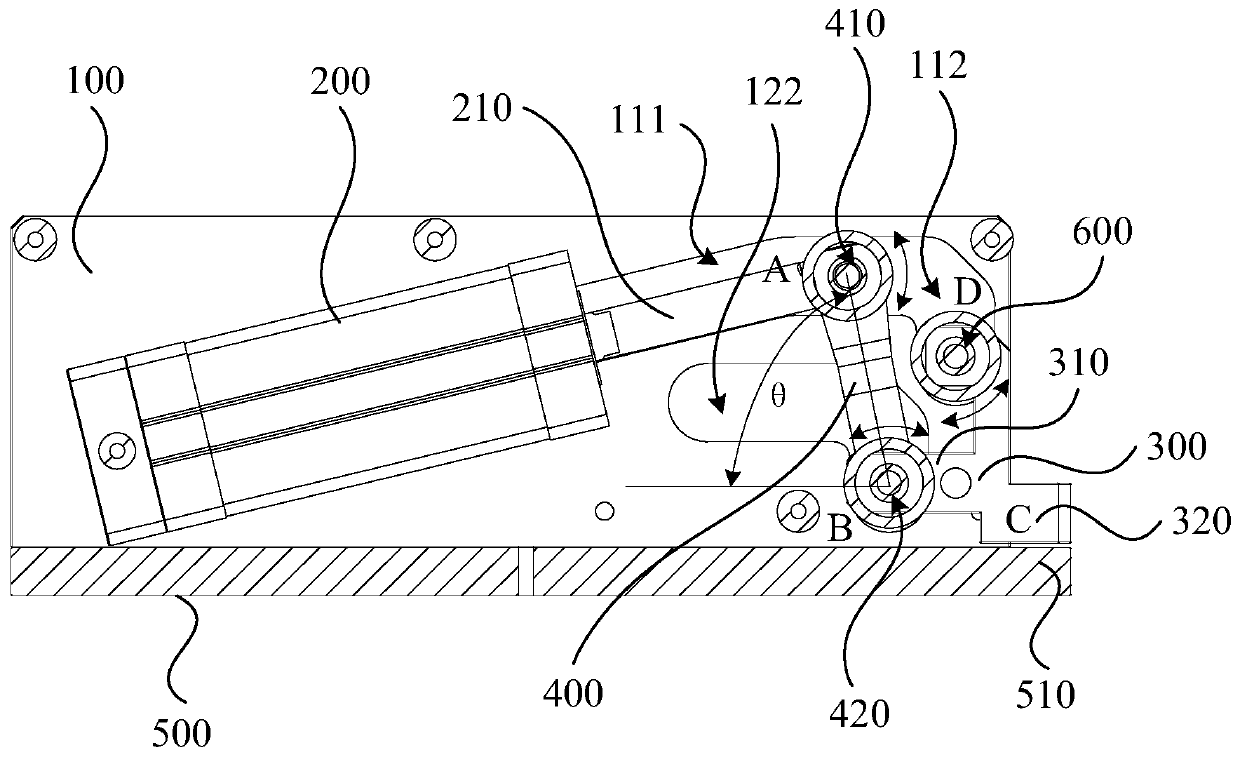

Exposure machine and clamping device for circuit board

PendingCN110244522AEffective clamping and positioningReliable positioning and clampingPhotomechanical exposure apparatusMicrolithography exposure apparatusProduction qualityElectrical and Electronics engineering

The invention discloses an exposure machine and a clamping device for a circuit board. The clamping device for the circuit board comprises a support member which is provided with a first guiding channel and a second guiding channel, a telescopic member provided with a telescopic end, a clamping member which includes a connecting end and a clamping end opposite to the connecting end, and a first transmission member, wherein one end of the first transmission member is rotatingly connected to the telescopic end and cooperates to form a first rotating structure, the other end of the first transmission member is rotatingly connected to the connecting end and cooperates to form a second rotating structure, the first rotating structure can reciprocate along the length direction of the first guiding channel, and the second rotating structure can reciprocate along the length direction of the second guiding channel. The clamping device of the circuit board does not affect the exposure quality of the circuit board, thus, the exposure quality of the exposure machine using the clamping device for the circuit board is high, and the production quality of the circuit board can be effectively guaranteed.

Owner:ZHONGSHAN AISCENT TECH

Electronic information engineering component integrated packaging operation system

InactiveCN113284827AEfficient packaging operationsEffective clamping and positioningSemiconductor/solid-state device manufacturingRobot handControl engineering

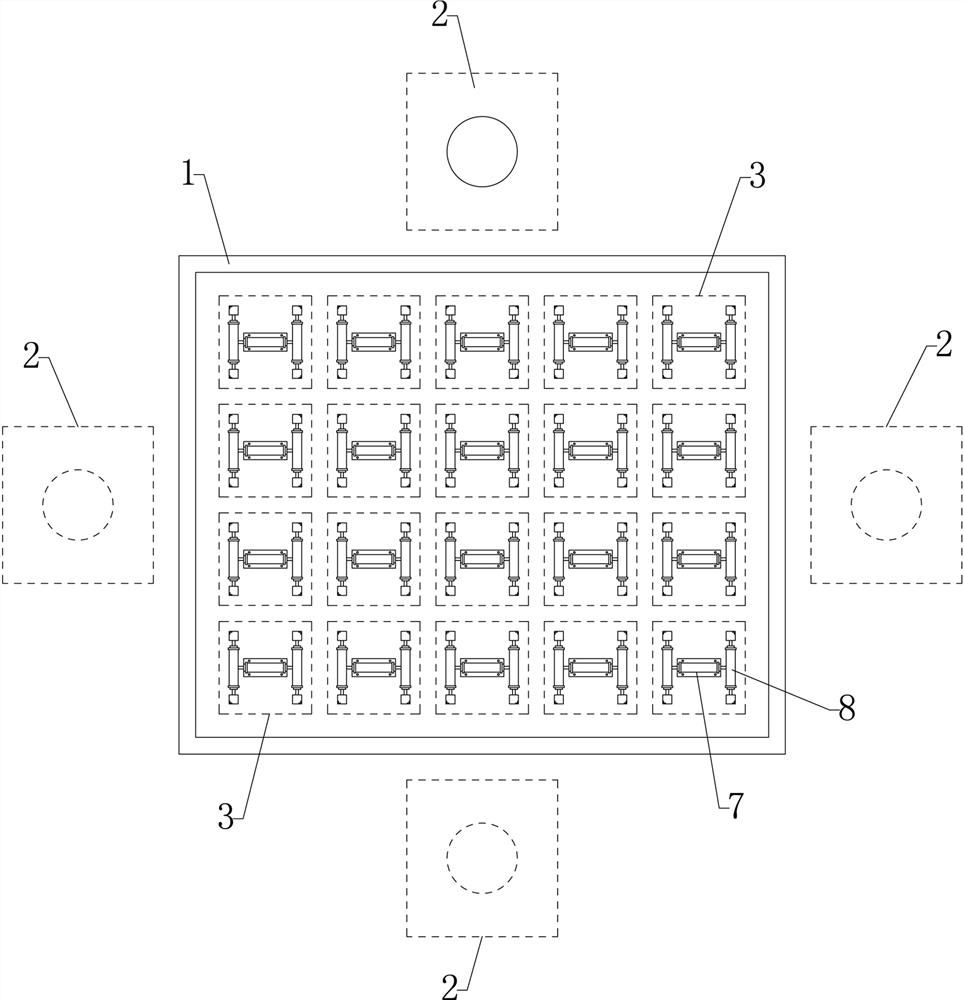

The invention relates to the technical field of component packaging, in particular to an electronic information engineering component integrated packaging operation system which comprises an operation platform, automatic packaging manipulators are installed on the ground in the outer sides of all edges of the operation platform respectively, and all the automatic packaging manipulators are controlled by an external control terminal. A plurality of component locking and fixing devices are installed in the operation platform at intervals in an array mode, actions of the component locking and fixing devices are mutually independent, and the component locking and fixing devices can be used for locking and fixing components of different sizes. Each component locking and fixing device is mounted on the operation platform in a detachable fixing manner. According to the system, an integrated structure is adopted, a plurality of component locking and fixing devices are integrally installed on the operation platform, efficient packaging of components can be achieved, and corresponding packaging of all the components can be achieved by controlling all the automatic packaging manipulators in the operation process.

Owner:杨丽

A kind of welding equipment and welding method of bimetallic band saw blade

ActiveCN109175703BGuaranteed mobilityEffective clamping and positioningWelding/cutting auxillary devicesAuxillary welding devicesElectrical connectionStructural engineering

The invention relates to the field of bimetallic saw strip machining, in particular to welding equipment and welding method for bimetallic band saw strips. The welding equipment comprises a laser generator, a base material supplying slide rail, a pre-welding position alignment device, a main controller, an upper fixture device and a lower fixture device, wherein the upper fixture device and the lower fixture device are symmetrically arranged up and down, the laser generator is arranged at the downstream end of the base material supplying slide rail, the upper fixture device and the lower fixture device are located above and below the base material supplying slide rail correspondingly, the back side of the base material supplying slide rail is provided with a power device, the front side and the back side of the base material supplying slide rail are each provided with one clamping device, and the pre-welding position alignment device can be movably arranged at the end portion of the downstream end of the base material supplying slide rail through an avoidance air cylinder and is further in electrical connection with the main controller. By means of the welding equipment and weldingmethod for the bimetallic band saw strips, two pre-welding base materials can be effectively clamped and positioned, and then the welding quality is improved, in addition, a rubber shaft sleeve and arubber sleeve which are in direct contact with the base materials can both be detachably arranged, and the fixture maintenance cost is greatly lowered.

Owner:PUTIAN HENGDA MACHINERY & ELECTRICITY IND

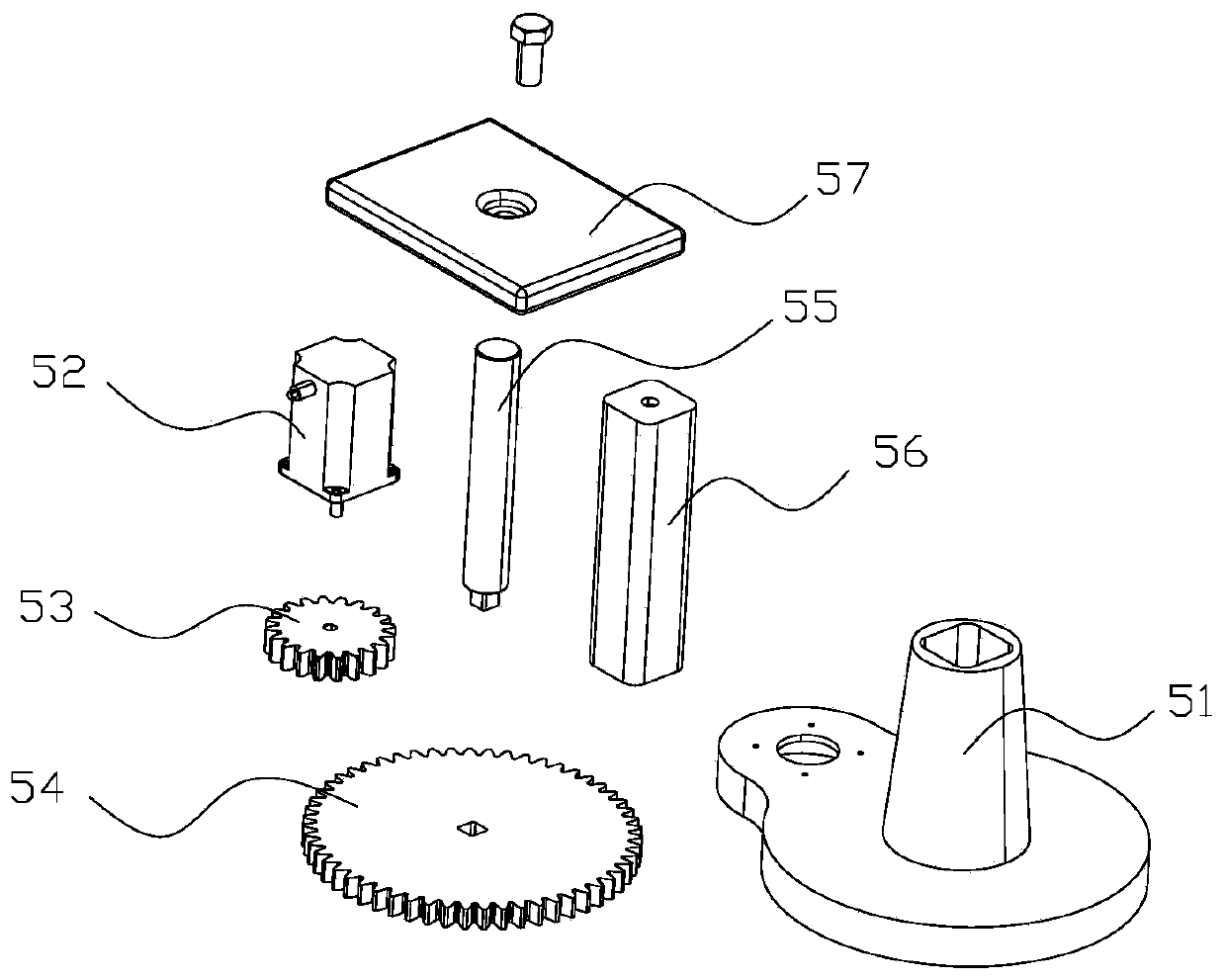

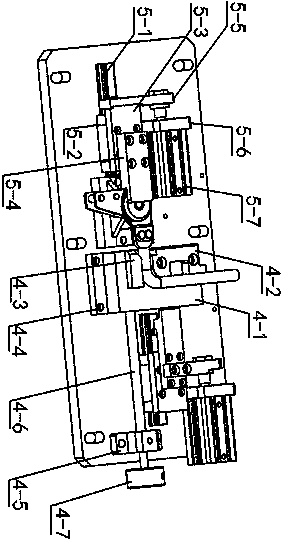

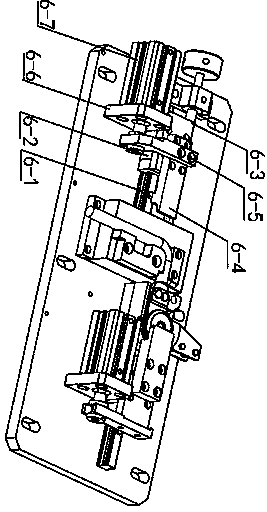

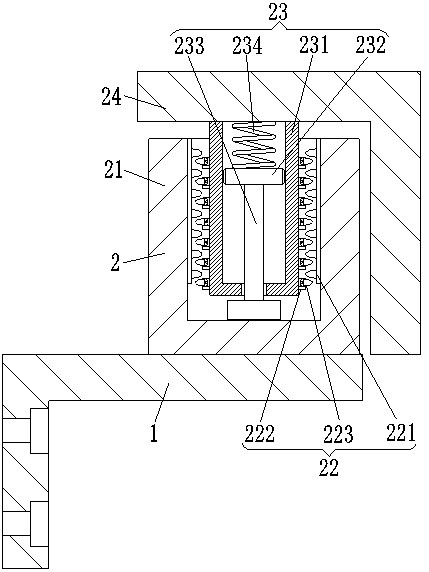

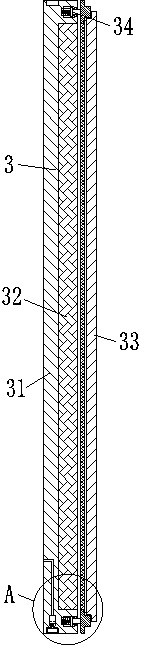

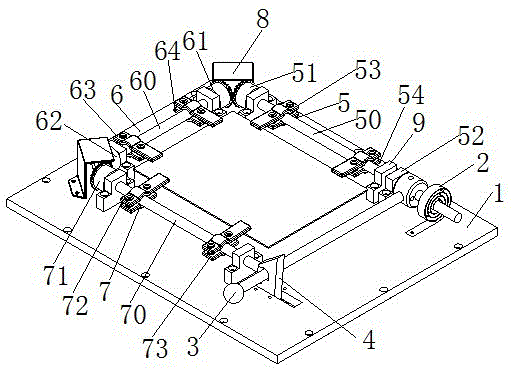

Tri-axial linkage type large circuit board test fixture

InactiveCN104166023ASimple structureEasy inspection and maintenanceMeasurement instrument housingSelf lockingTest fixture

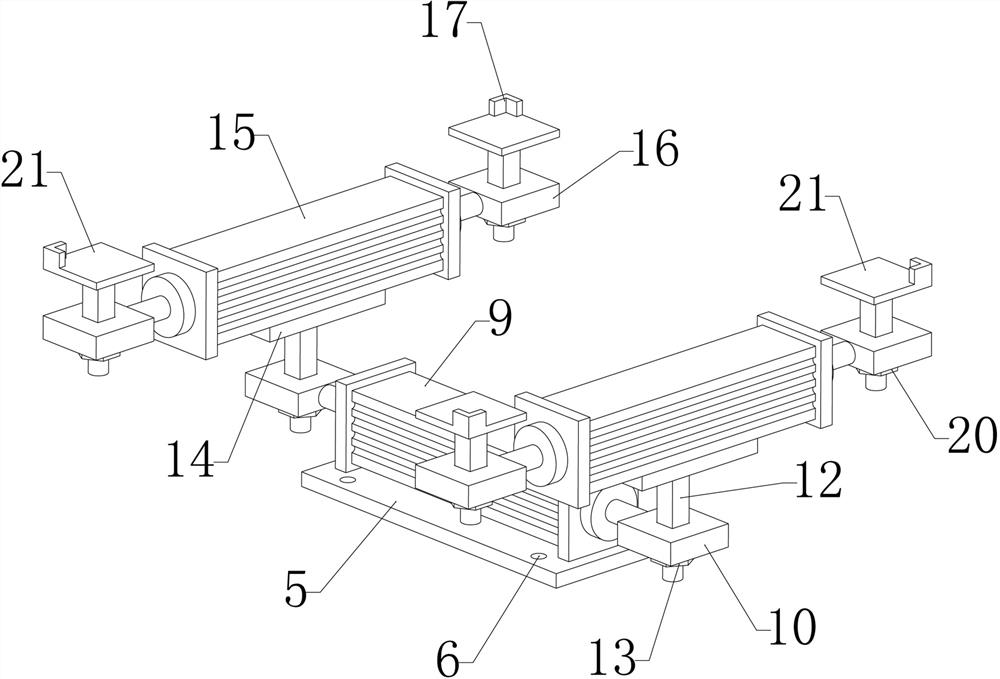

The invention discloses a tri-axial linkage type large circuit board test fixture. The tri-axial linkage type large circuit board test fixture comprises a universal bottom plate, a press fitting spring roll strip, an opening hand lever, a self-locking hook, a first rotary shaft set, a second rotary shaft set, a third rotary shaft set and bevel gear protection cover pieces, wherein the first rotary shaft set, the second rotary shaft set and the third rotary shaft set are sequentially connected in a meshing and perpendicular intersection mode; the bevel gear protection cover pieces are arranged at the meshing positions respectively; the first rotary shaft set, the second rotary shaft set and the third rotary shaft set are all installed on the universal bottom plate through rotary shaft seats; the opening hand lever is arranged at the non-meshing end of the first rotary shaft set; the press fitting spring roll strip is arranged on the first rotary shaft set close to the right side of the opening hand lever; the end of the outer ring of the press fitting spring roll strip is fixed to the universal bottom plate; the self-locking hook locking the opening hand lever is arranged on the opening hand lever close to the non-meshing position of the third rotary shaft set. In this way, the tri-axial linkage type large circuit board test fixture is simple and practical in structure, convenient to detect and maintain, and capable of effectively clamping and positioning a large circuit board.

Owner:苏州市吴中区胥口广博模具加工厂

Second rotating shaft group of three-axis linked large circuit board testing fixture

InactiveCN104198773AEffective clamping and positioningSimple structureMeasurement instrument housingEngineeringBevel gear

The invention discloses a second rotating shaft group of a three-axis linked large circuit board testing fixture. The second rotating shaft group of the three-axis linked large circuit board testing fixture comprises a second rotating shaft, a front second rotating shaft bevel gear, a back second rotating shaft bevel gear, upper second rotating shaft pressing pieces and lower second rotating shaft pressing pieces; the two ends of the second rotating shaft are mounted on a universal base plate by use of rotating shaft seats; the front second rotating shaft bevel gear and the back second rotating shaft bevel gear are mounted on the two end portions of the second rotating shaft, respectively; the back second rotating shaft bevel gear is engaged with a first rotating shaft bevel gear; two upper second rotating shaft pressing pieces are arranged between the two rotating shaft seats of the second rotating shaft, and the corresponding lower second rotating shaft pressing pieces are arranged on the lower parts of the upper second rotating shaft pressing pieces; the upper second rotating shaft pressing pieces and the lower second rotating shaft pressing pieces are locked to the second rotating shaft by use of screws. In this way, the second rotating shaft group of the three-axis linked large circuit board testing fixture is simple and practical in structure, convenient to detect and repair, and capable of effectively clamping and positioning a large-scale circuit board.

Owner:苏州市吴中区胥口广博模具加工厂

Top cover plastic case pressing equipment for assembling the driver

ActiveCN108161830BEffective generationImprove assembly qualityMetal-working hand toolsWork in processMechanical engineering

The invention provides an upper cover plastic shell press-fitting device for assembling drivers. The upper cover plastic shell press-fitting device comprises a press-fitting working platform. A locating datum mechanism and a pressing mechanism are arranged on the working platform. The locating datum mechanism comprises a side pressing locating assembly and an end pressing locating assembly which do not interfere with each other. The side pressing locating assembly comprises a side pressing cylinder, a first side pressing plate and a second side pressing plate. The side pressing cylinder drivesthe first side pressing plate and the second side pressing plate to get close to each other or away from each other so as to clamp the side face of a semifinished driver. The end pressing locating assembly comprises an end pressing cylinder and an end pressing plate. The end pressing cylinder at least drives the end pressing plate to locate and press one end face of the semifinished driver. The pressing mechanism comprises a pressing cylinder and a press-fitting tool. A rod body of the pressing cylinder is connected with and drives the press-fitting tool to rise and drop relative to the press-fitting working platform to conduct press-fitting on an upper cover plastic shell and the semifinished driver. The upper cover plastic shell press-fitting device can guarantee accurate and efficientpress-fitting assembly of the upper cover plastic shell and the semifinished driver and is reliable in performance and capable of reducing the labor intensity of workers and lowering the labor cost.

Owner:GUANGDONG LXD ROBOTICS CO LTD

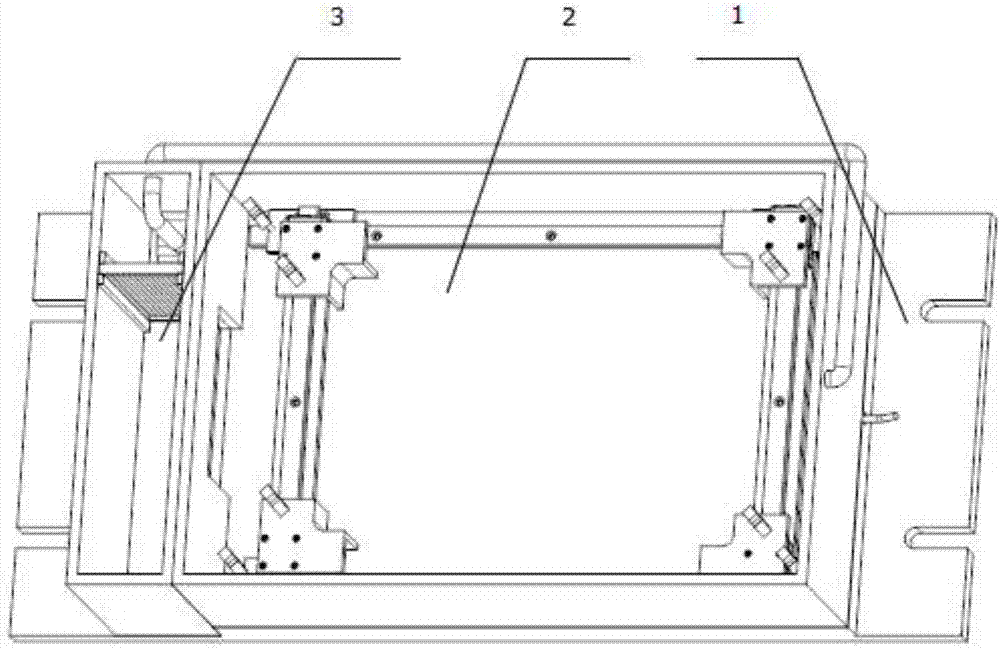

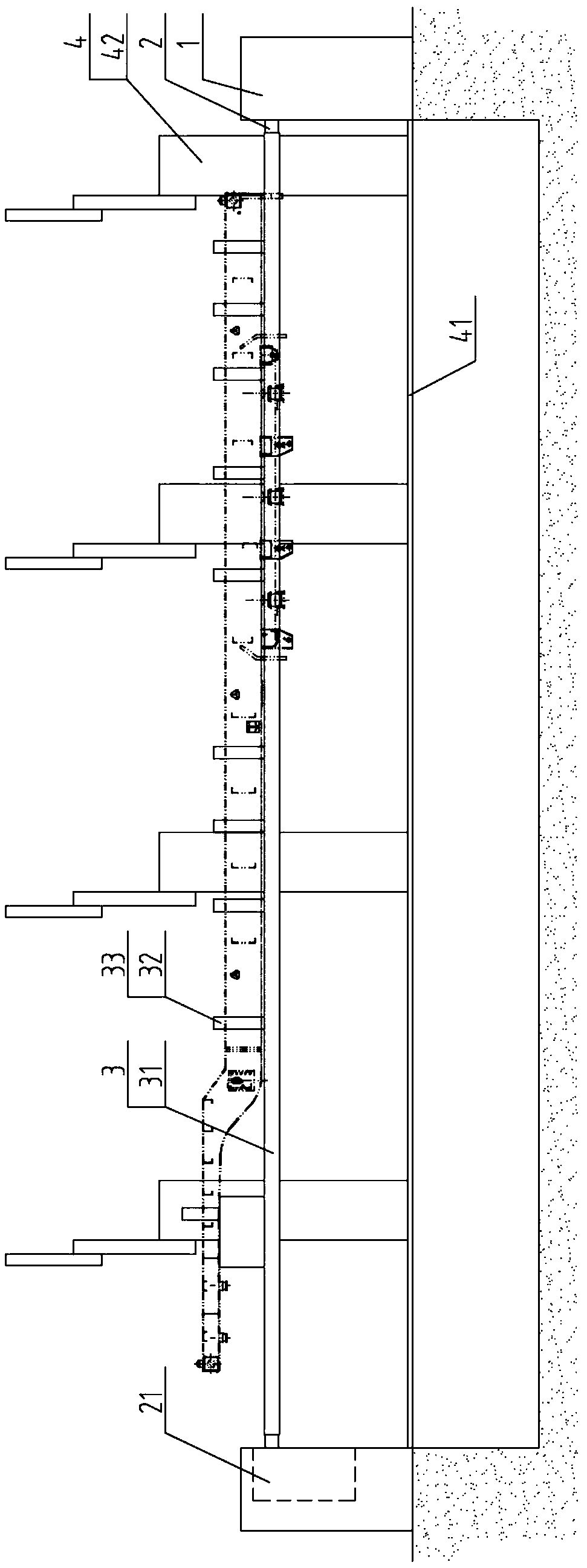

Special automatic assembly welding machine for middle slot

ActiveCN105436758BFully automatedQuick positioning clampingWelding/cutting auxillary devicesAuxillary welding devicesWork performanceUltimate tensile strength

The invention belongs to the technical field of machining of a middle trough of a scraper conveyor, and particularly relates to a specialized automatic assembly welding machine tool for the middle trough. The specialized automatic assembly welding machine tool comprises a rack, wherein a front clamping location device, an automatic welding device I, a lifting turnover device, an automatic welding device II and a rear clamping location device are sequentially arranged on the upper edge of the rack in a middle trough machining moving direction; the front clamping location device comprises one column of middle plate supporting rollers, two columns of middle trough supporting rollers, a trough ledge side face clamping location mechanism, an overturn type trough ledge end ditch clamping location mechanism, a middle plate front and back clamping location mechanism and a middle plate top pressing mechanism; and the automatic welding device I / II comprise welding supports arranged along the two sides of the rack, welding guns, wire feeders, welding wire winding drums, welding support longitudinal moving mechanisms, welding gun and wire feeder lifting moving mechanisms, welding gun and wire feeder transverse moving mechanisms and welding wire winding drum lifting supporting mechanisms. The specialized automatic assembly welding machine tool can improve working performance and welding quality and reduces labor intensity of workers.

Owner:郑州市嵩阳煤机制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com