Clamping and positioning method for rear frame welding

A technology of clamping and positioning, rear frame, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as poor clamping and positioning, achieve good effect, high safety and practicability, and effective clamping The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

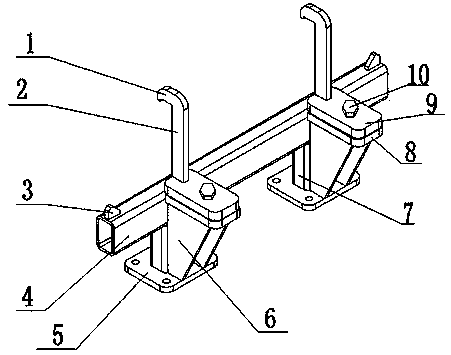

[0014] Such as figure 1 A clamping and positioning method for rear frame welding processing shown includes the following steps: (A) fixing the mounting plate on the turning frame fixing frame, and placing the rear frame on the end surface of the connecting plate; (B) clamping the plate The rear frame is positioned and clamped by the clamping structure, and the other end of the rear frame is fixed and locked with the fixed plate on the fixed frame, so that the fixed frame can be turned over arbitrarily, and the rear frame can be welded conveniently; the above steps Among them, the mounting plate 5 and the connecting plate 4 are connected by a support plate 7, the vertical side of the connecting plate 4 is connected with a fixed plate 8, the upper end surface of the fixed plate 8 is connected with a positioning plate 9 through a bolt 10, and the positioning plate 9 is connected The clamping plate 2, the upper part of the clamping plate 2 is bent to form a hook-shaped clamping st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com