Cloth cutting device for clothing manufacture

A cutting device and fabric technology, applied in the field of fabric cutting, can solve the problem of high cost, achieve the effect of solving passivation problem, promoting grinding work, and improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

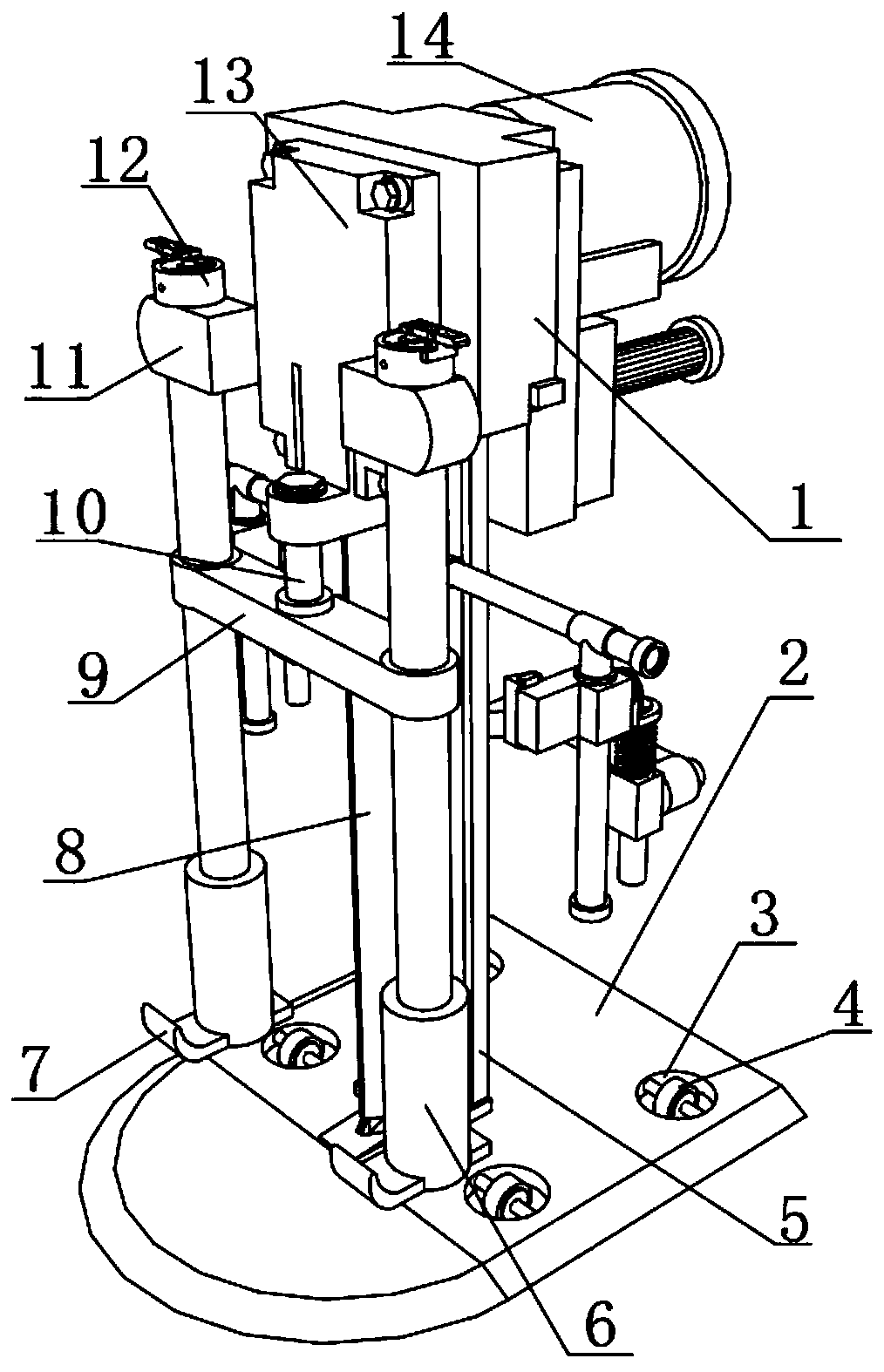

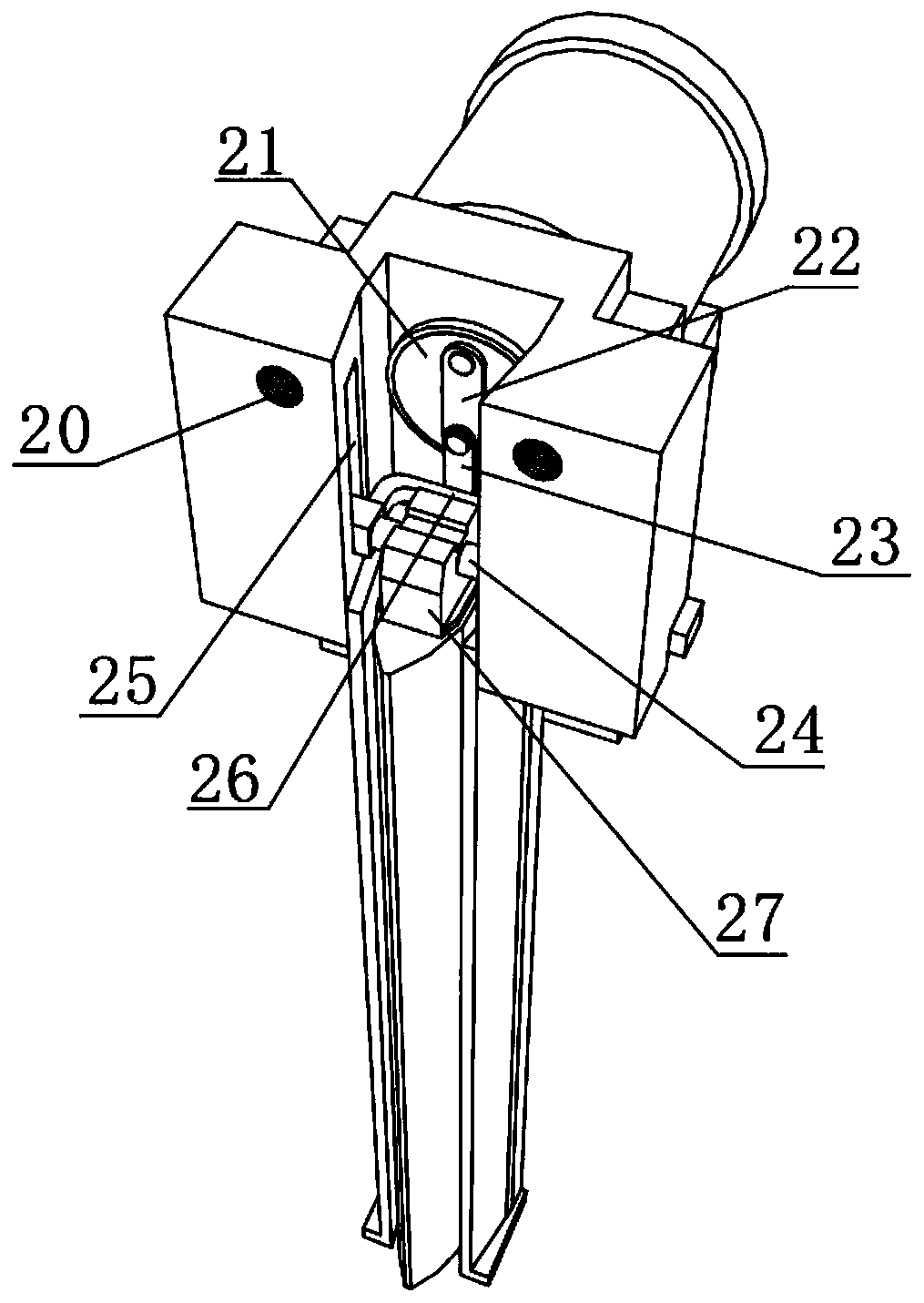

[0034] A cloth cutting device for clothing, such as figure 1 with image 3As shown, it includes a frame 1 and a cutting low plate 2, the bottom outer wall of the frame 1 is fixed with a knife rest 5 by bolts, and the bottom outer wall of the knife rest 5 is welded on the top outer wall of the cutting low plate 2; the cutting low plate 2 top outer wall is opened There are four installation holes 3, and the inner walls of each installation hole 3 are provided with rollers 4. The inner walls on both sides of the frame 1 are provided with chute 25, and the inner walls on both sides of the two chute 25 are slidably connected with the same first One slider, the outer walls of the opposite sides of the two first sliders are welded with mounting shafts 24, and the peripheral outer walls of the mounting shafts 24 are sleeved with fixing seats 27; The outer wall at the back of the first slider is welded with a U-shaped connecting frame 26, and the outer wall at the back of the U-shaped...

Embodiment 2

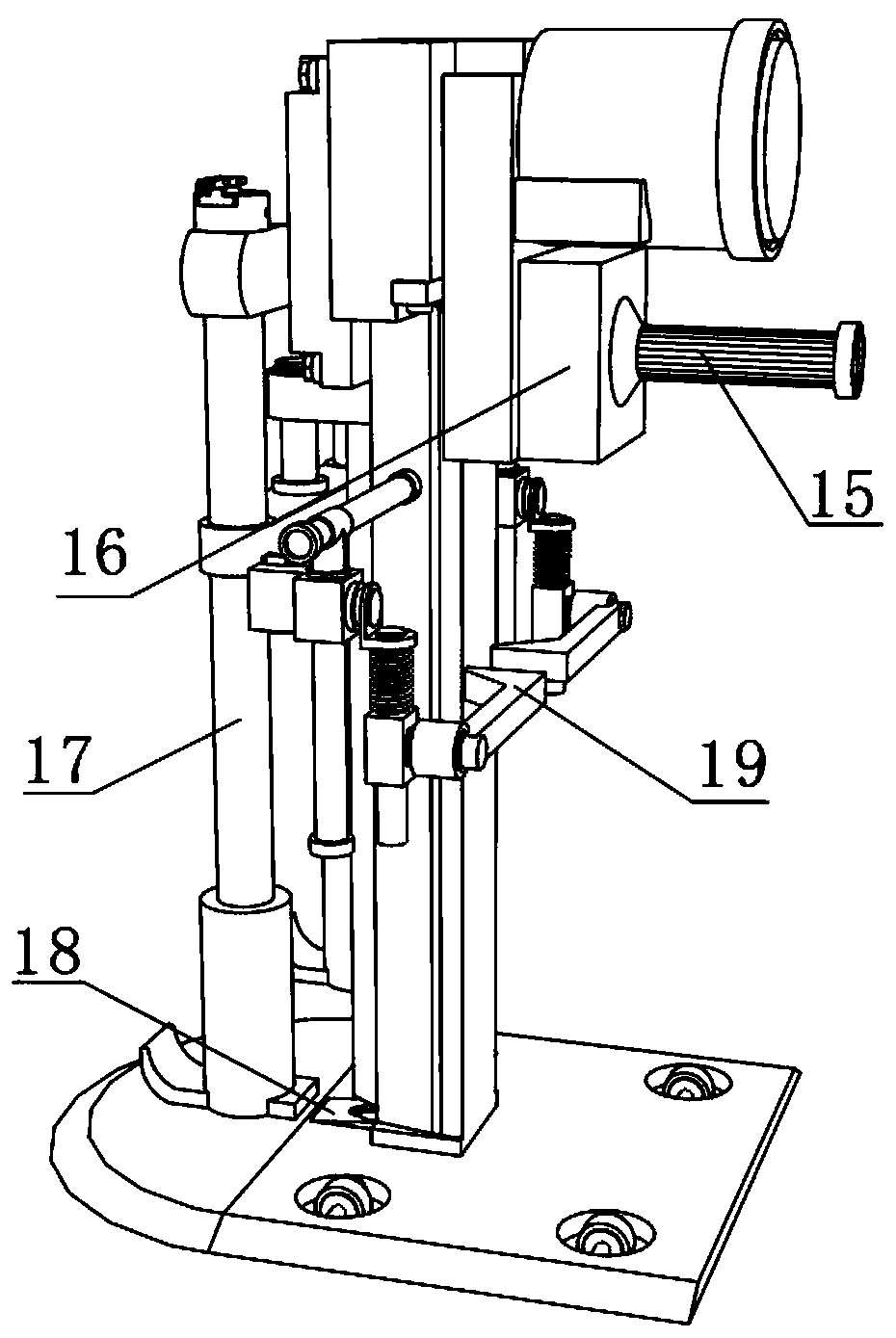

[0040] A cloth cutting device for clothing, such as figure 2 with Figure 5 As shown, in order to solve the passivation problem that occurs after the cutting knife 8 is used for a long time; this embodiment makes the following improvements on the basis of embodiment 1: the outer walls of the opposite sides of the two supports 19 are provided with a cutting unit, and the cutting The unit includes a telescopic spring 35, an L-shaped connector 36, a three-way pipe 37, a frosted block 38, a first slide bar 39, a connecting block 40, a second slide bar 41, a constant speed motor 42, a sleeve 43 and a third slide bar 44, one side of the outer wall of the constant speed motor 42 is fixed on one end of the bracket 19 by bolts, and the output end of the constant speed motor 42 is fixed with a sleeve 43 through the rotating rod, and the inner wall of the circumference of the sleeve 43 is plugged with a third slider. Rod 44, and the outer wall of the top circumference of the third slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com