Patents

Literature

77results about How to "Easy to squeeze and fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

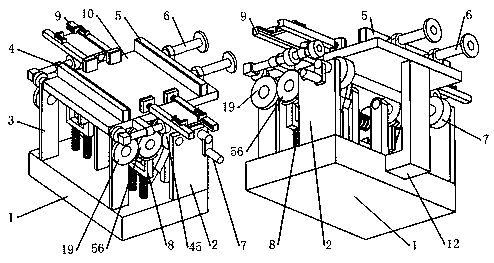

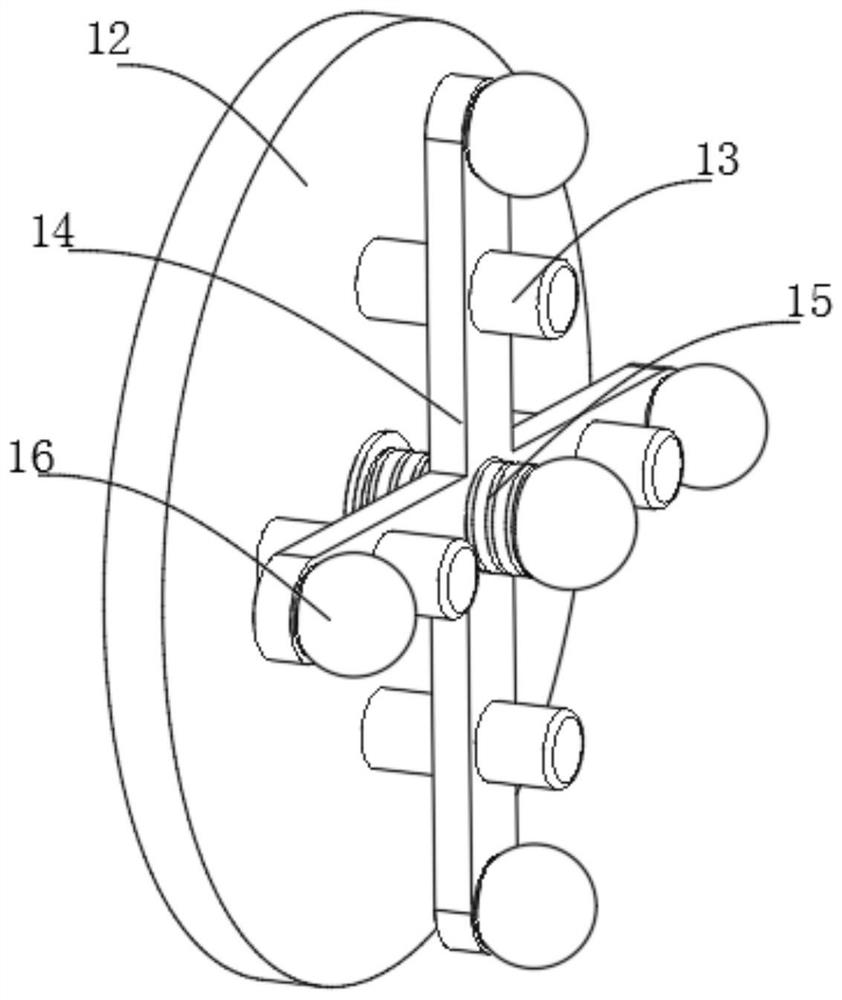

Tubular type bus duct locking apparatus

InactiveCN107732826AThe installation structure is stableEasy to installTotally enclosed bus-bar installationsEngineeringExtrusion

The invention discloses a tubular type bus duct locking apparatus. The tubular type bus duct locking apparatus comprises a base; two mounting bolts which are symmetrical left and right are fixedly connected with the top of the base; multiple limiting springs which are symmetrical left and right are fixedly connected with the bottom of the base; one ends, far from the base, of the limiting springsare fixedly connected with U-shaped plates; and the front surface of each U-shaped plate is movably connected with a bolt which runs through the corresponding U-shaped plate. By virtue of setting of driving gears, driven gears, extrusion rods and arc-shaped plates, the tubular type bus duct can be mounted and fixed; by virtue of the setting of the arc-shaped plates, installation and fixation can be more fitted, and a more stable and firmer effect can be achieved; and the tubular type bus duct is mounted and fixed through meshed connection of the gears, so that the installation structures can be more steady and firmer, and an effect of convenience in mounting and detaching is achieved, thereby further ensuring that an operator can quickly mount and detach the bus duct.

Owner:江苏大浪电气集团有限公司

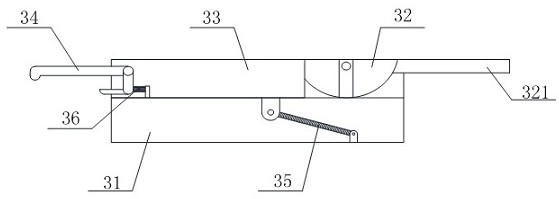

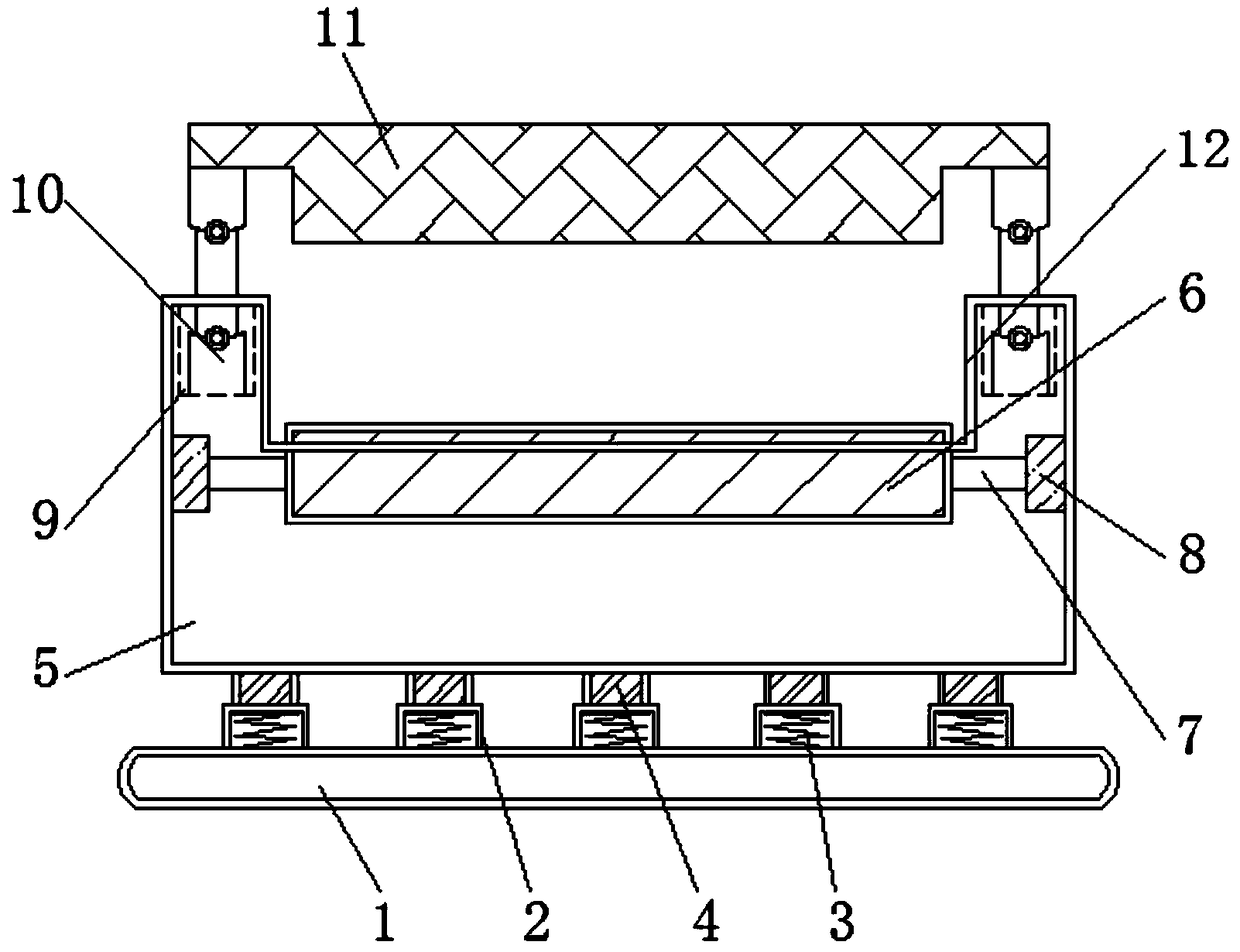

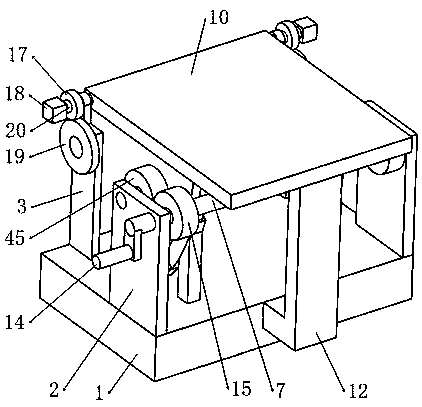

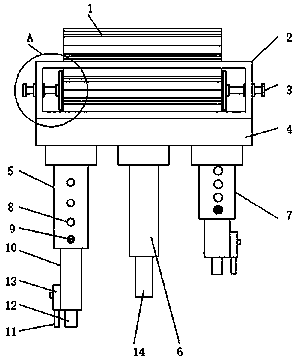

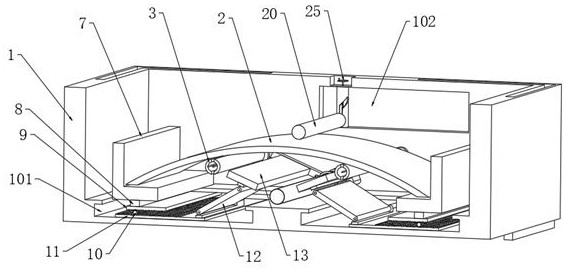

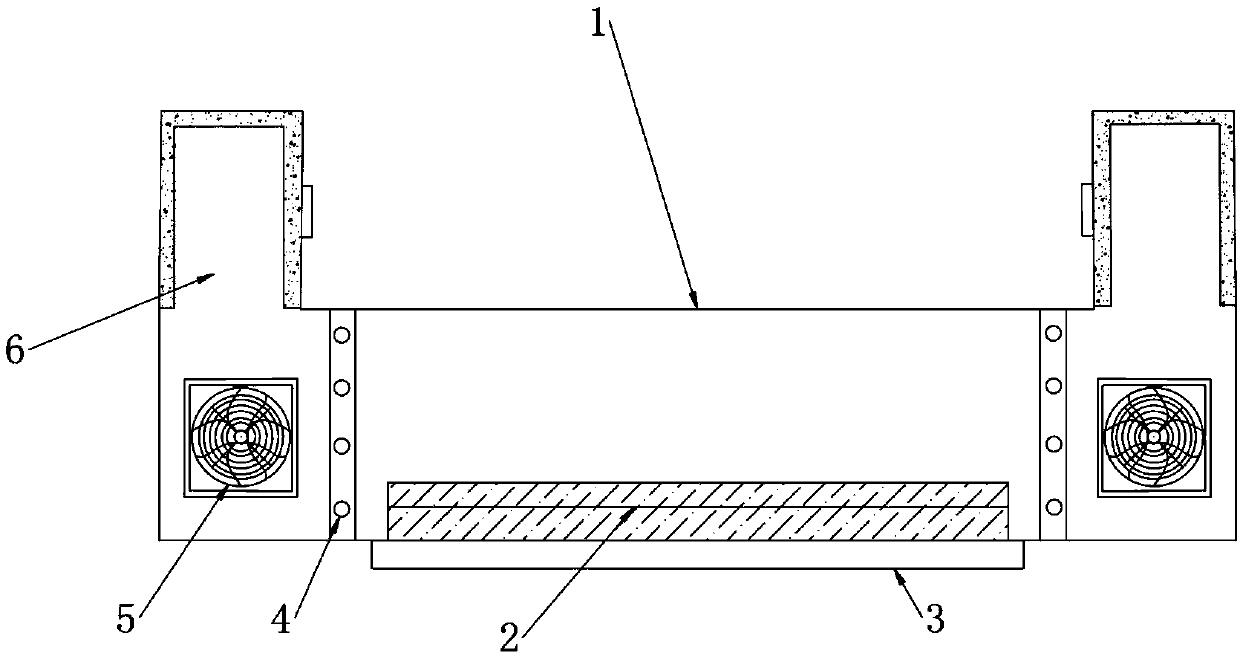

Cloth cutting device for clothing manufacture

ActiveCN110685144APlay a cutting roleLow costGrinding carriagesGrinding drivesStructural engineeringKnife holder

The invention discloses a cloth cutting device for clothing manufacture and relates to the technical field of cloth cutting, aiming to solve the problem that conventional bench type cutting devices are not adaptable to mass cutting of cloth. The cloth cutting device comprises a rack and a lower cutting plate; a blade carrier is arranged on the outer wall of the bottom of the rack, and the outer wall of the bottom of the blade carrier is welded to the outer wall of the top of the lower cutting plate; four mount holes are formed on the outer wall of the top of the lower cutting plate, and four rollers are respectively arranged inside the four mount holes; slide slots are respectively formed on the inner walls of two sides of the rack, two first sliders are slidably connected to the inner walls of two sides of the two slide slots respectively, the two first sliders are the same, mounting shafts are welded to outer walls of opposite sides of the two first sliders respectively, and holderssleeve the outer peripheral walls of the mounting shafts respectively; a cutting blade is fastened to the outer wall of the bottom of the holder, a U-shaped connecting frame is welded to the outer walls of backs of the two first sliders, and a second connecting plate is rotationally connected to the outer wall of the back of the U-shaped connecting frame. In application of the cloth cutting device, squeezing and fixing to single-layer or multi-layer cloth are facilitated, and accordingly, the cutting quality of the cutting blade is improved.

Owner:湖南浚林服饰有限公司

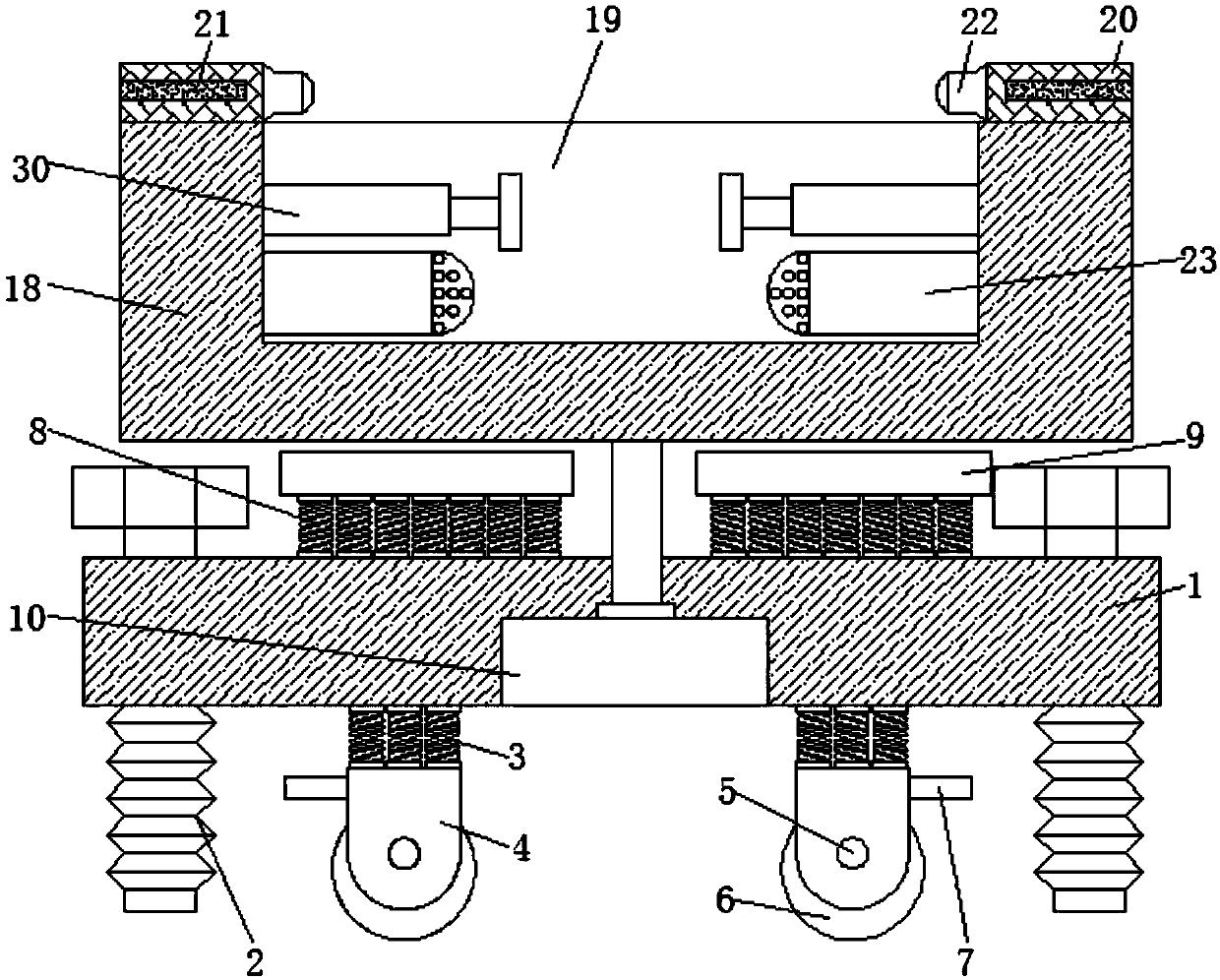

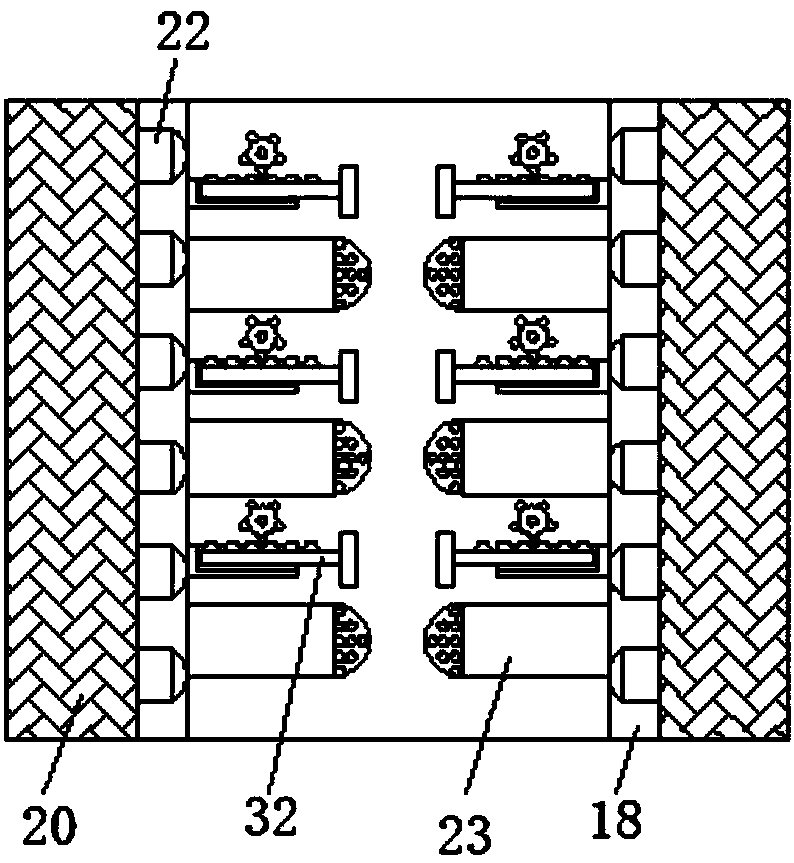

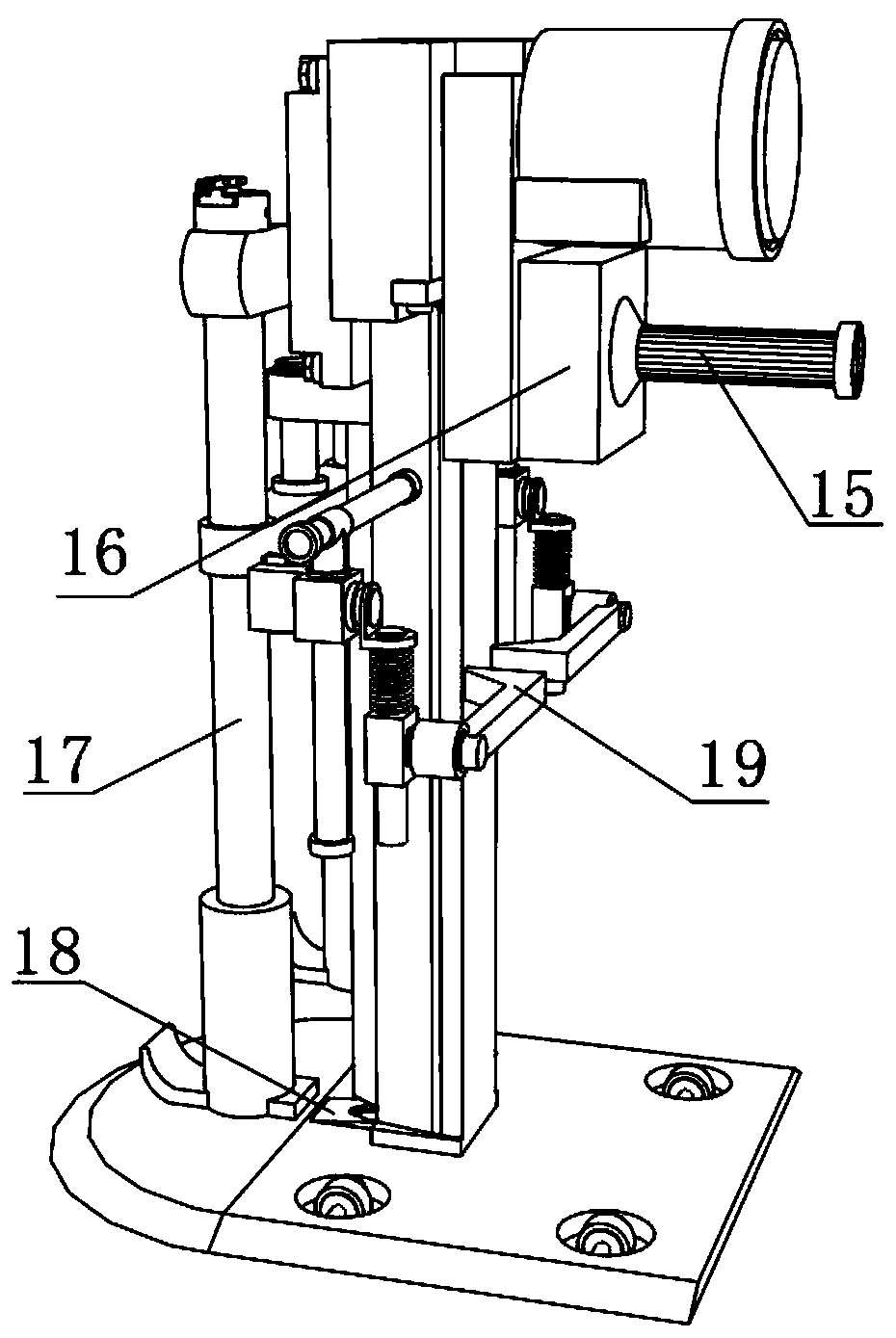

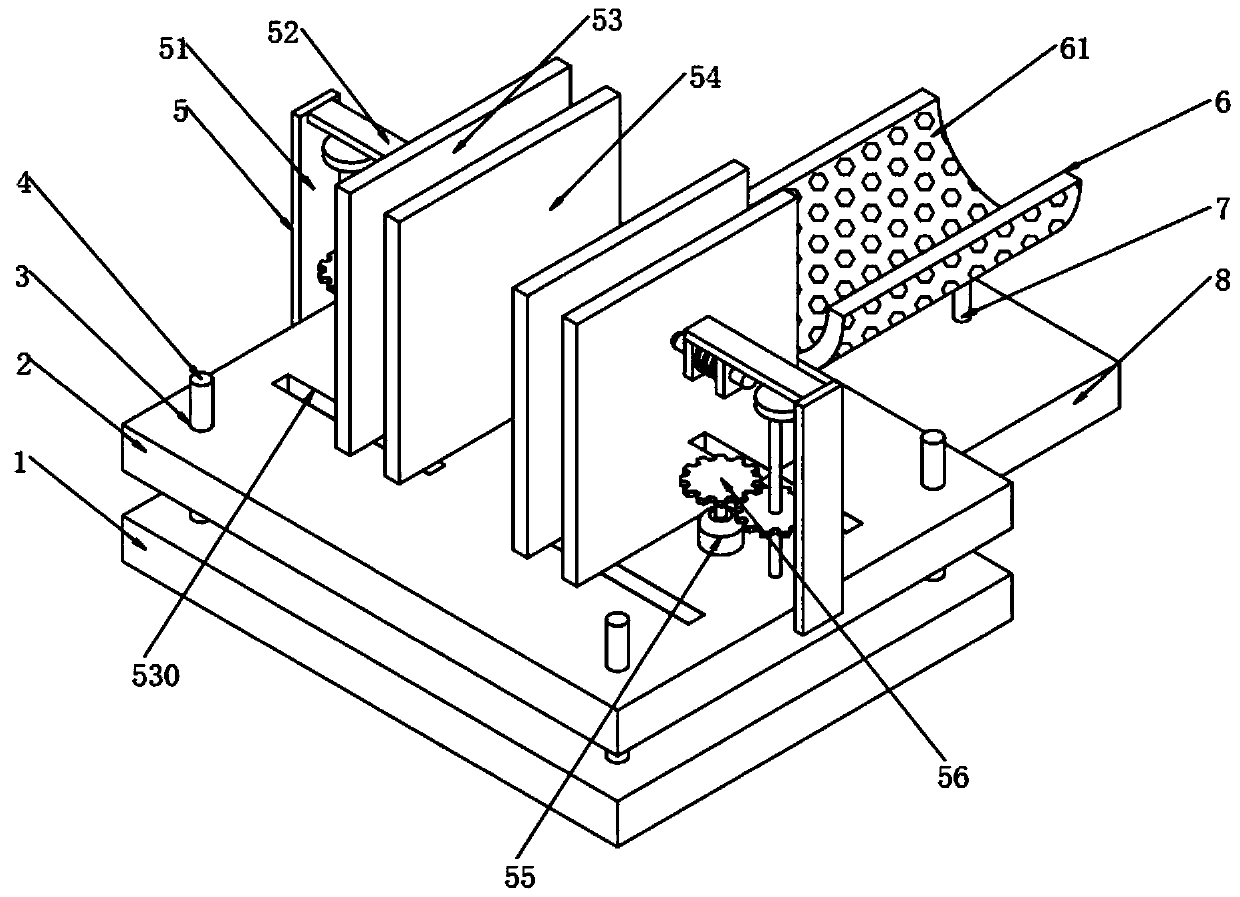

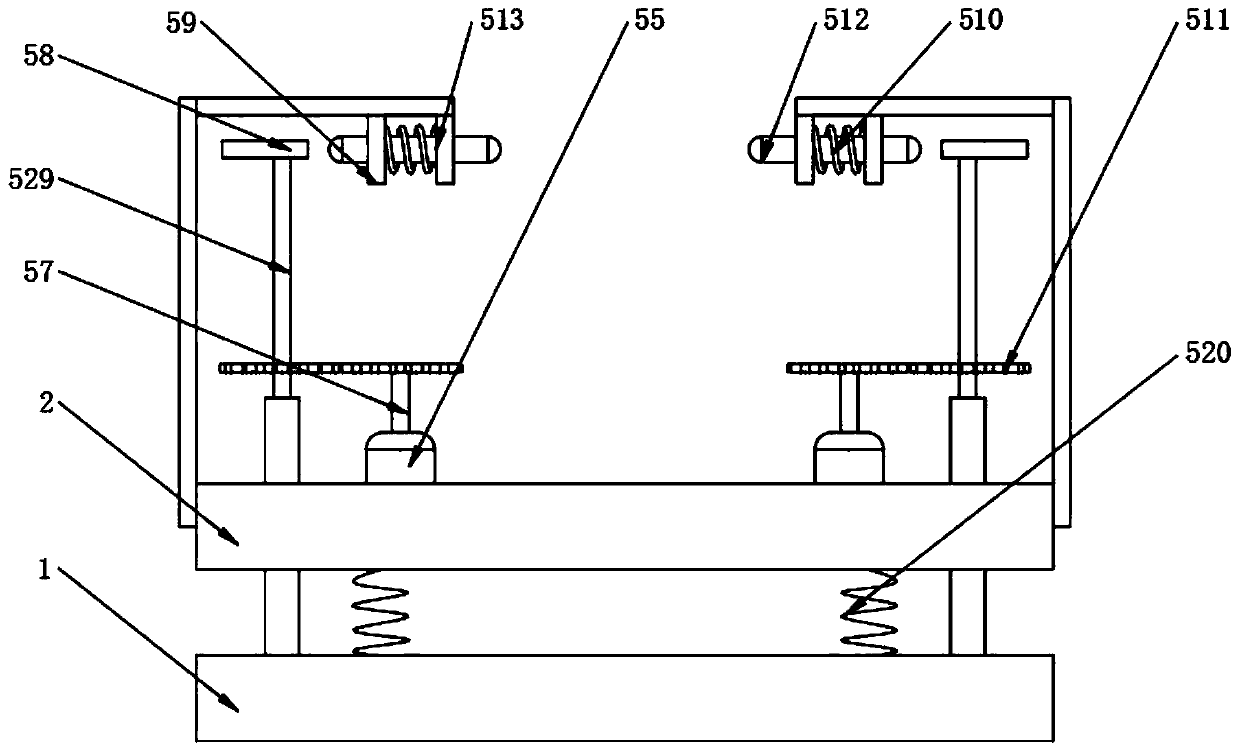

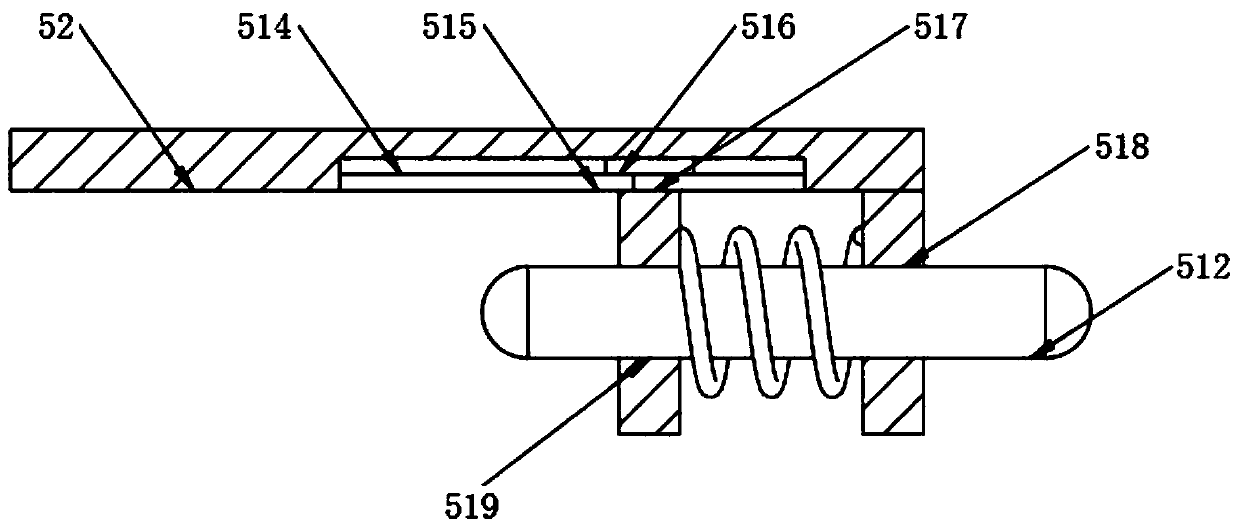

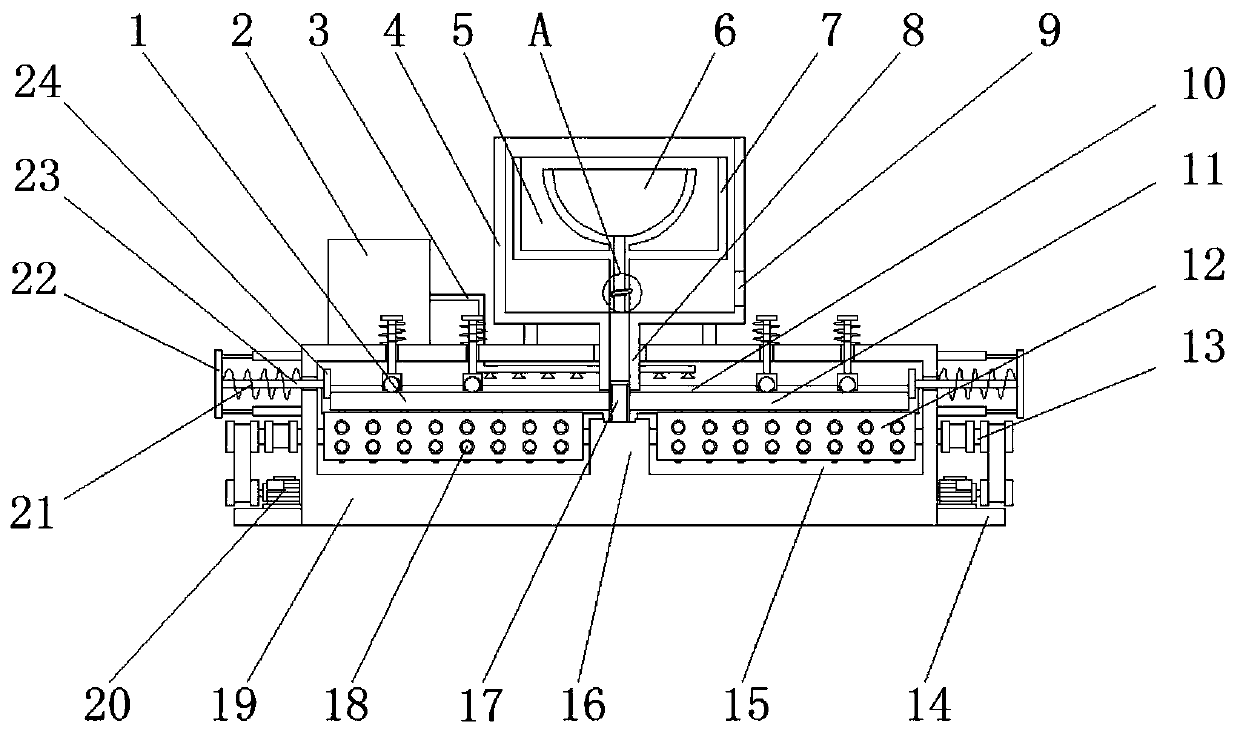

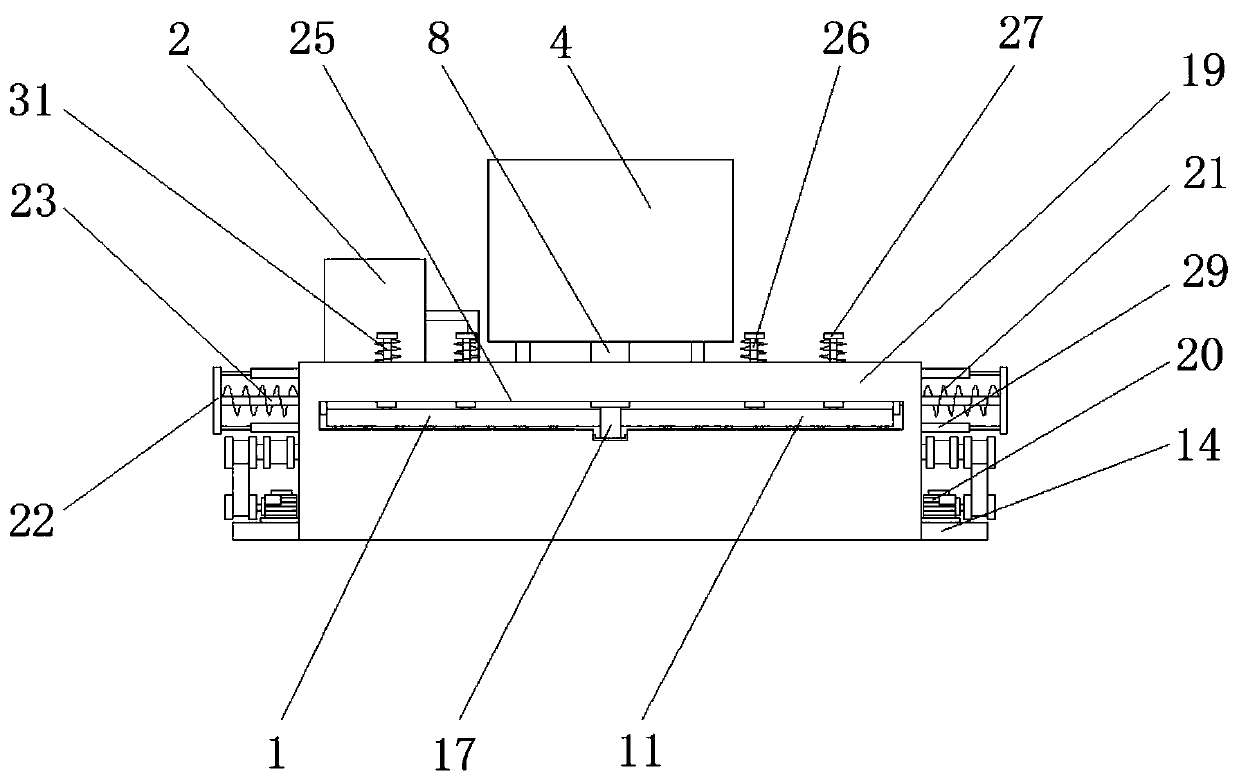

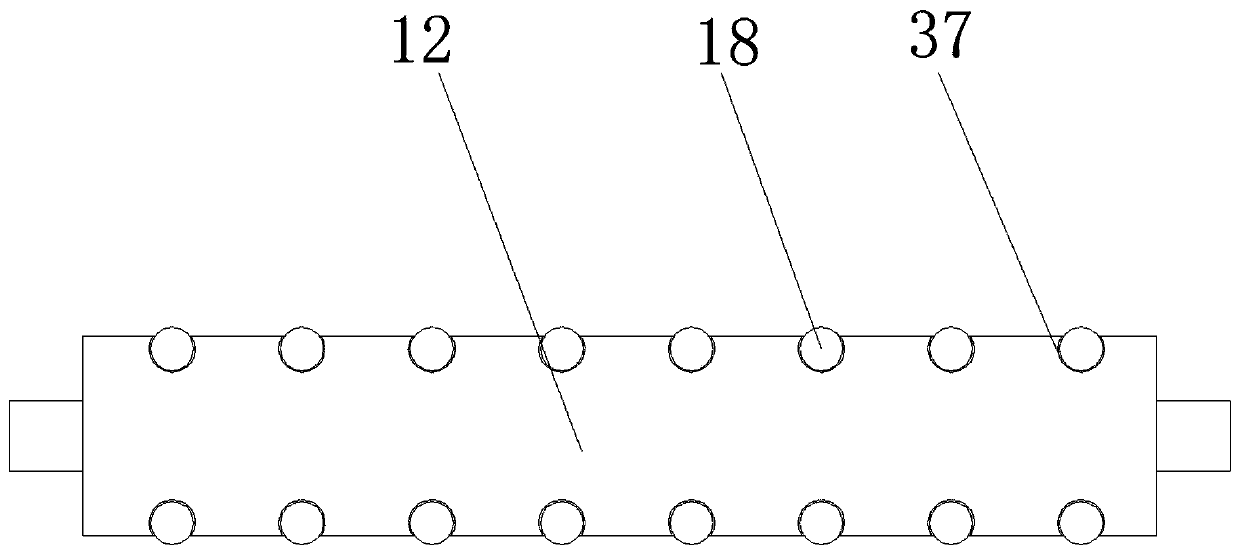

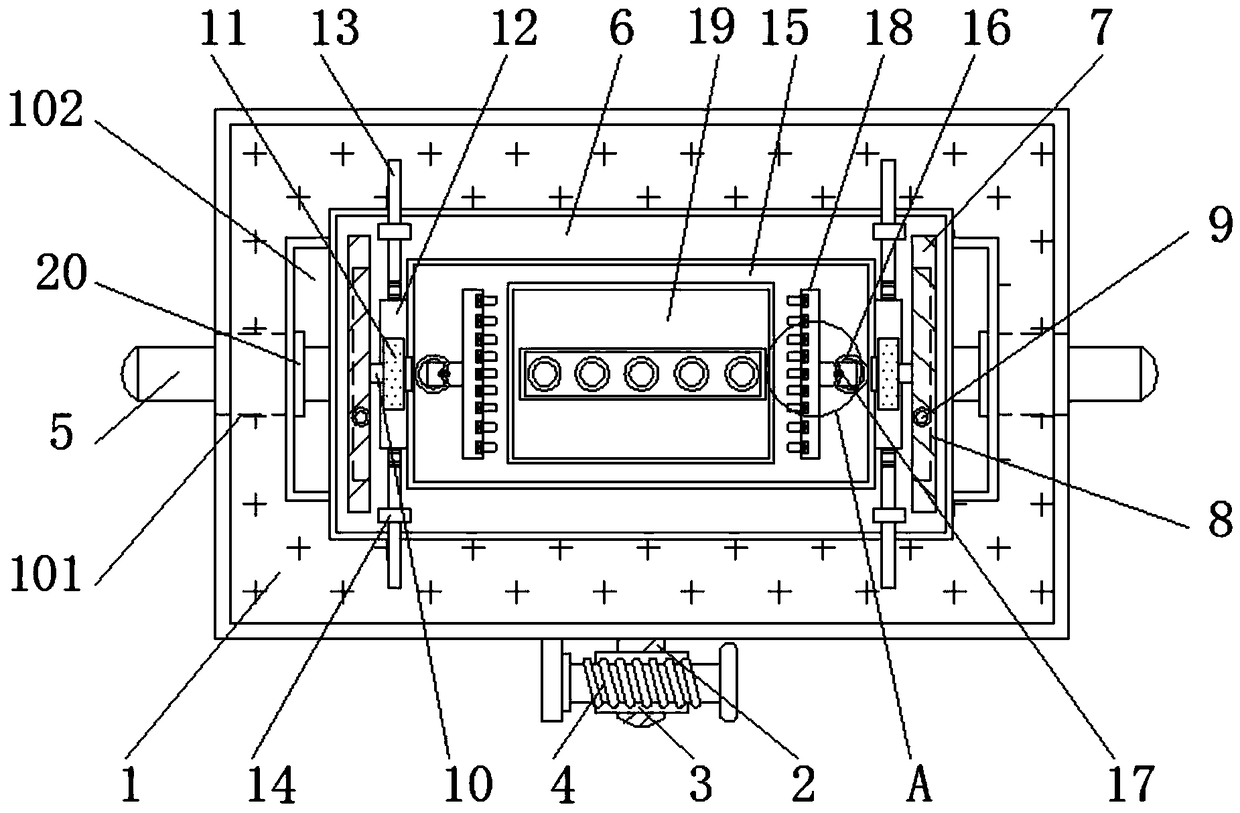

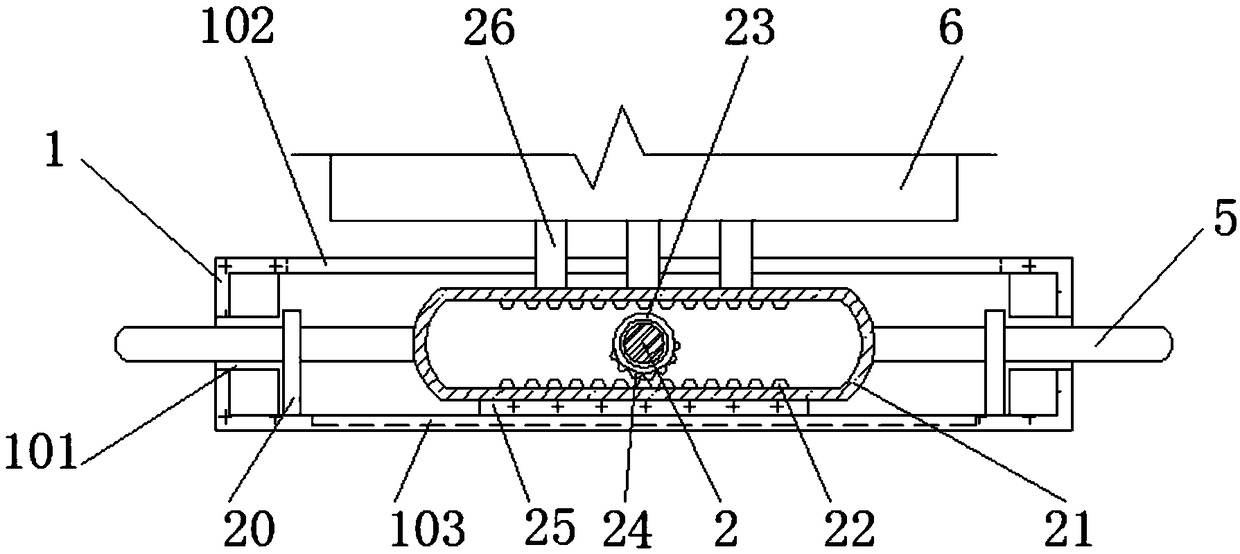

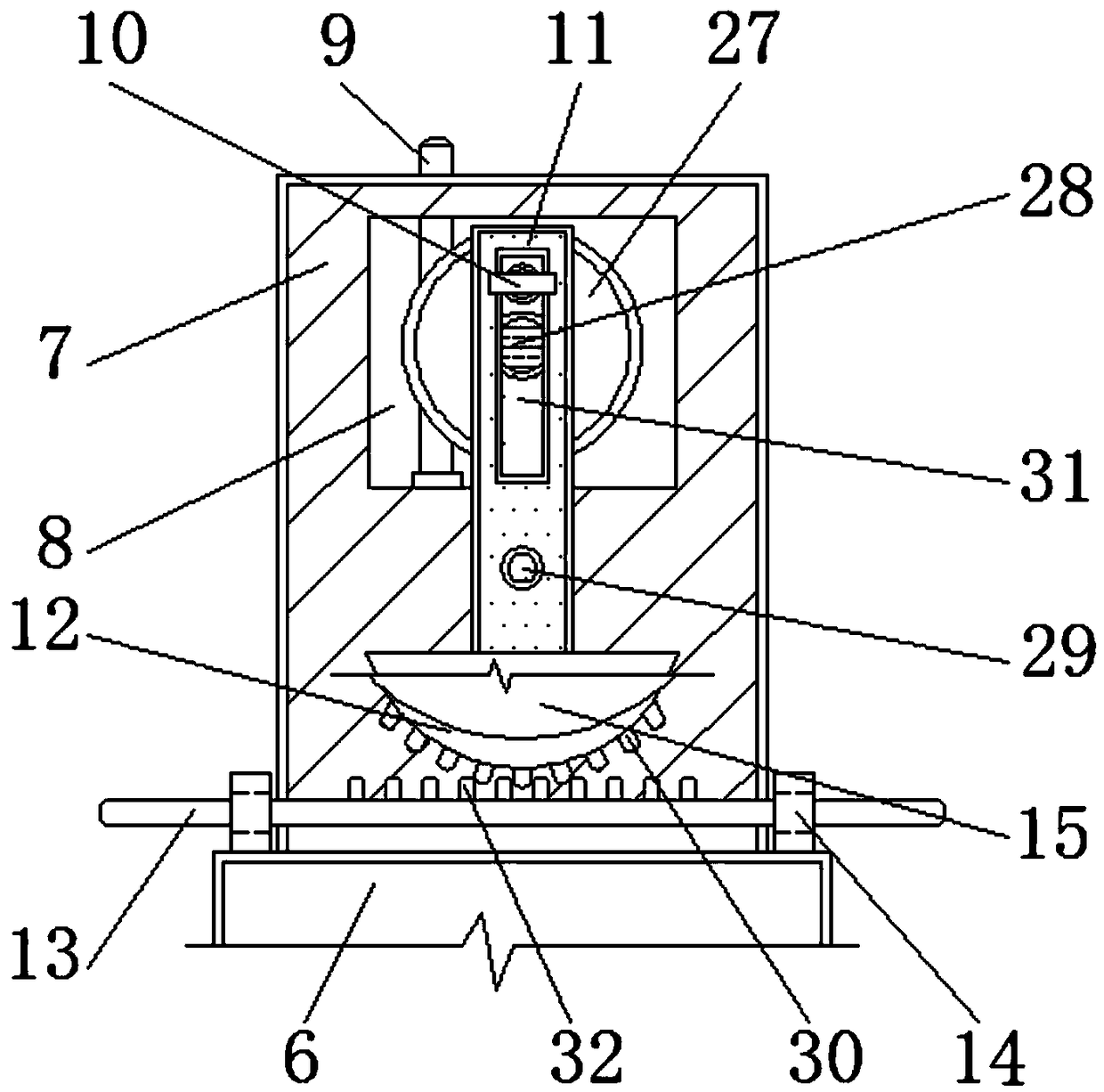

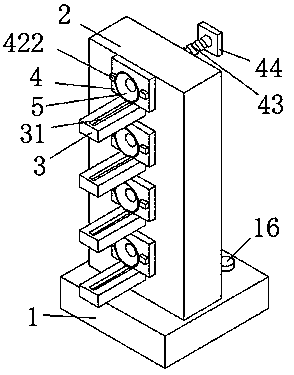

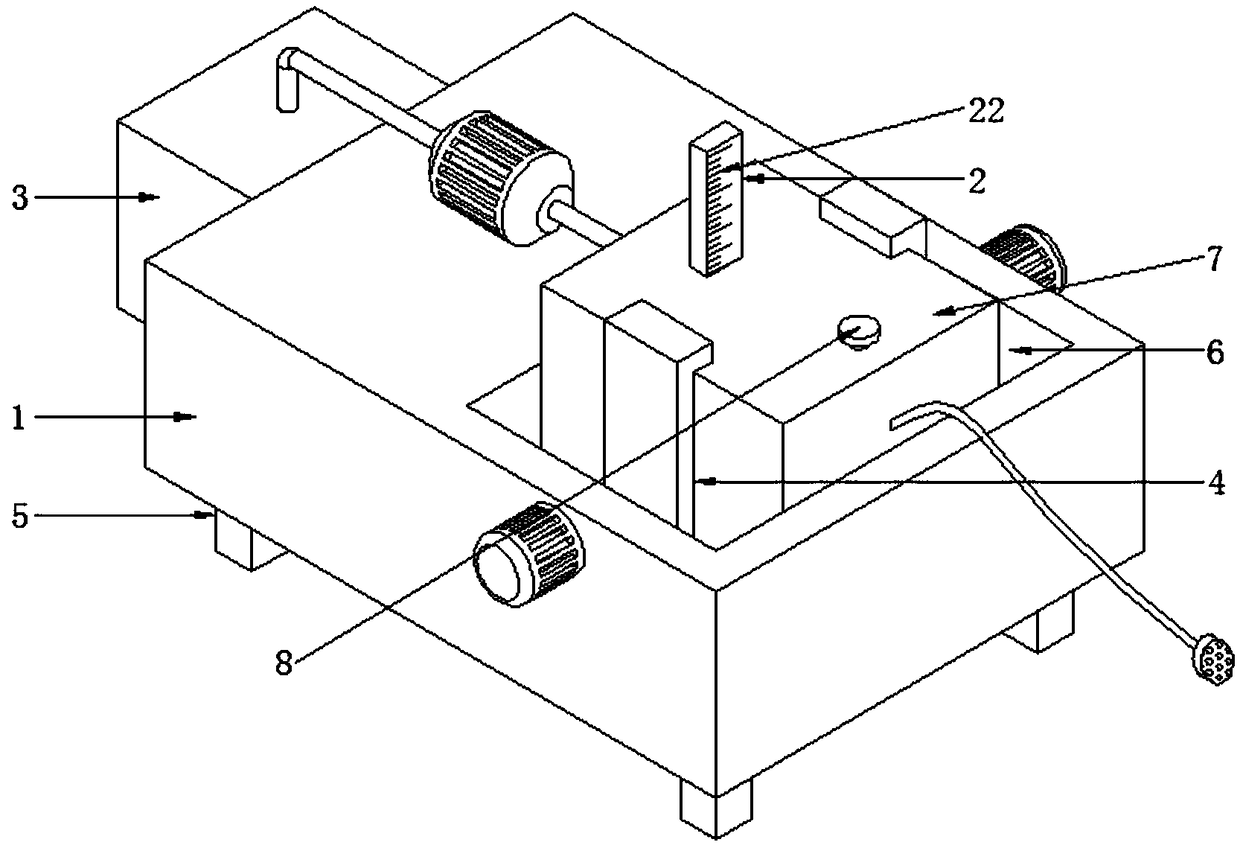

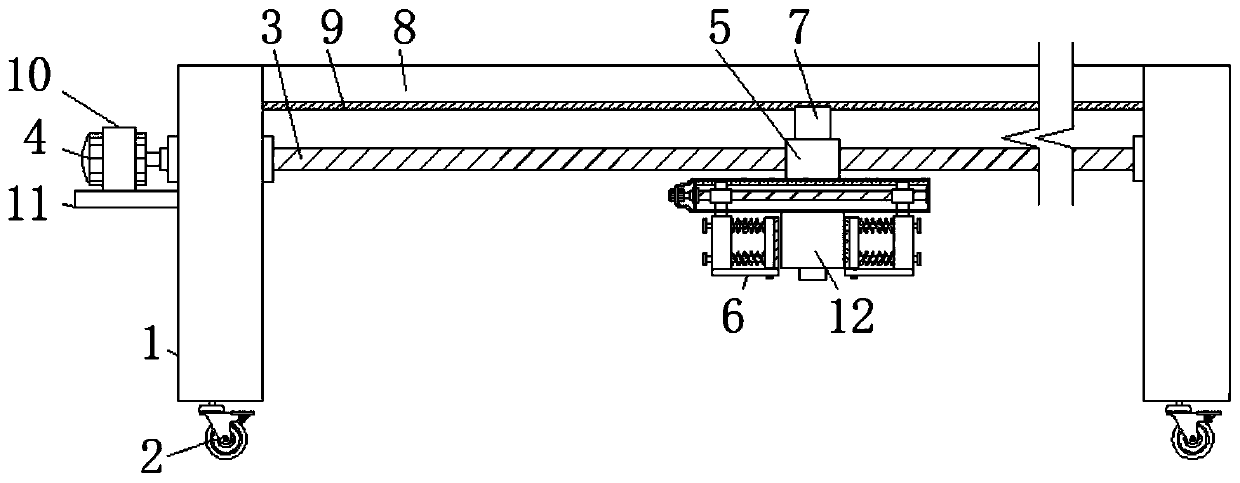

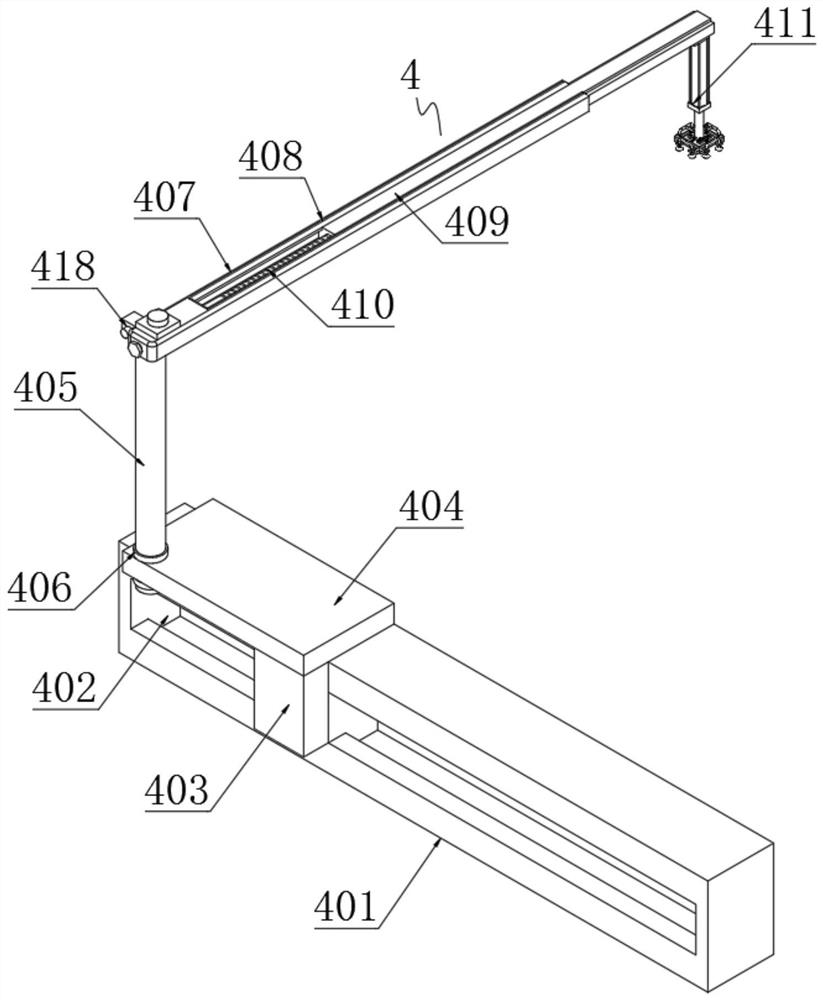

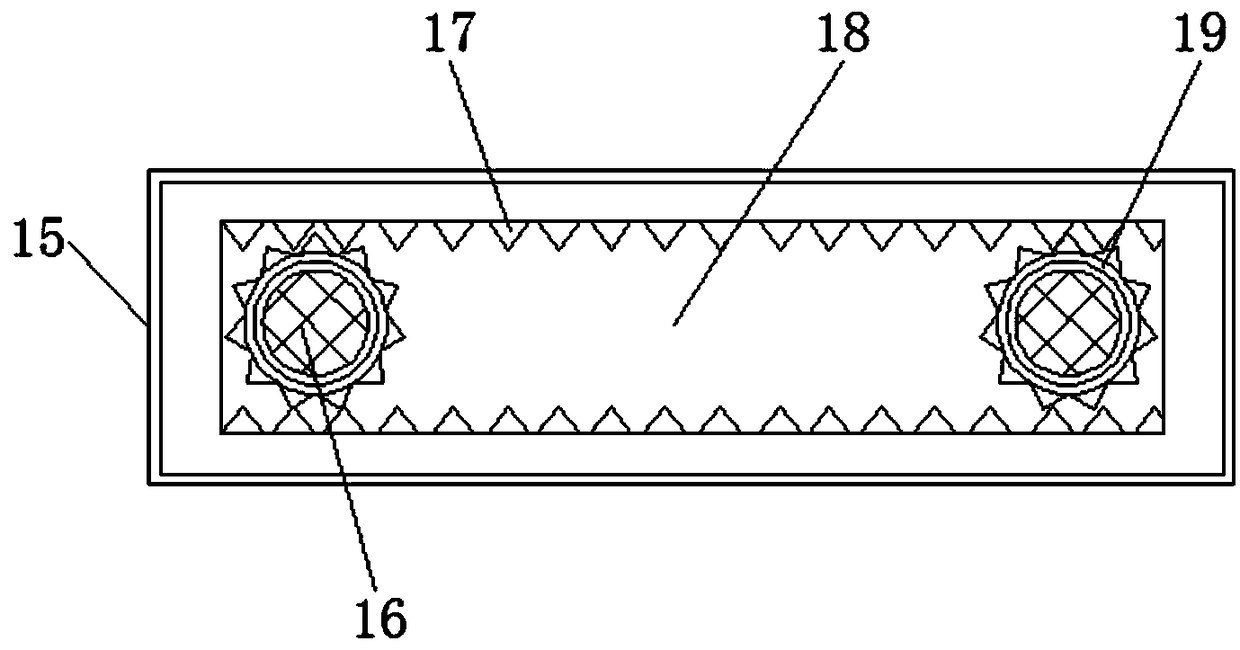

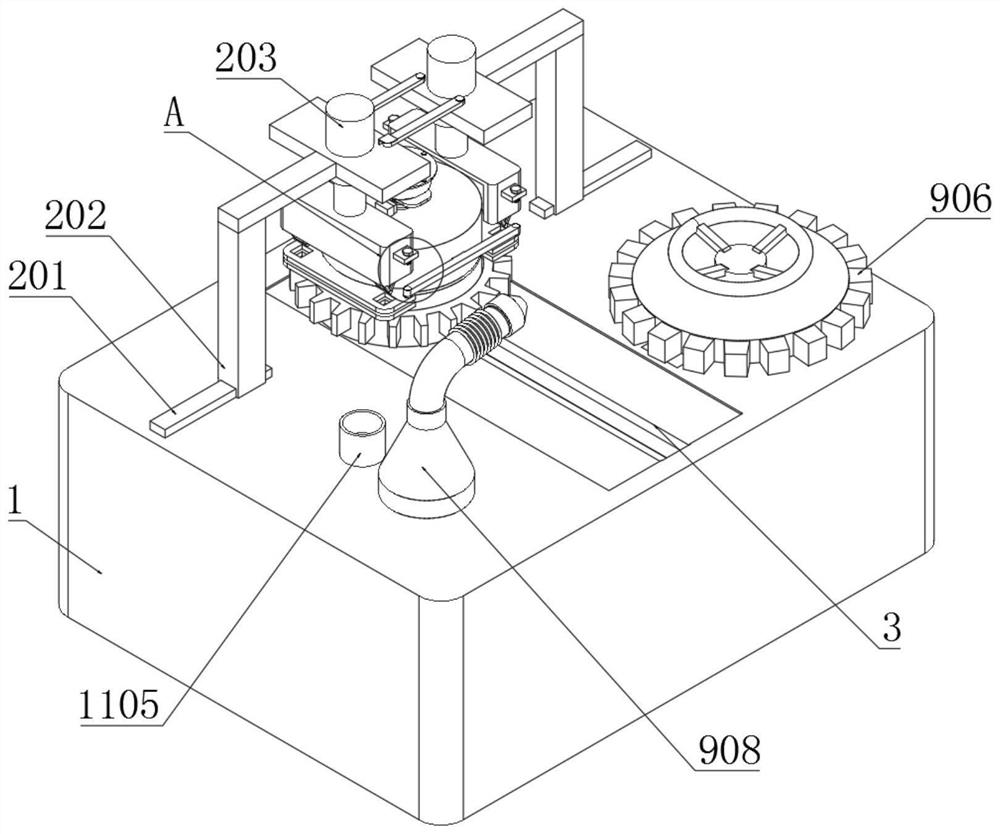

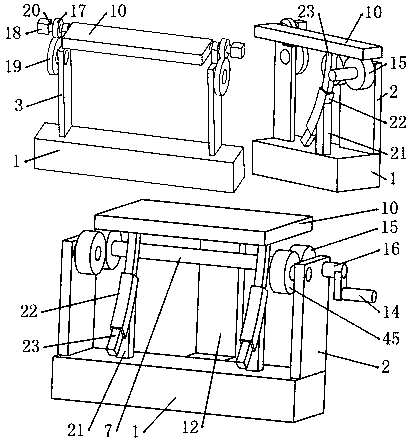

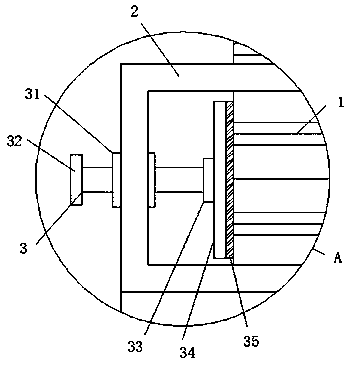

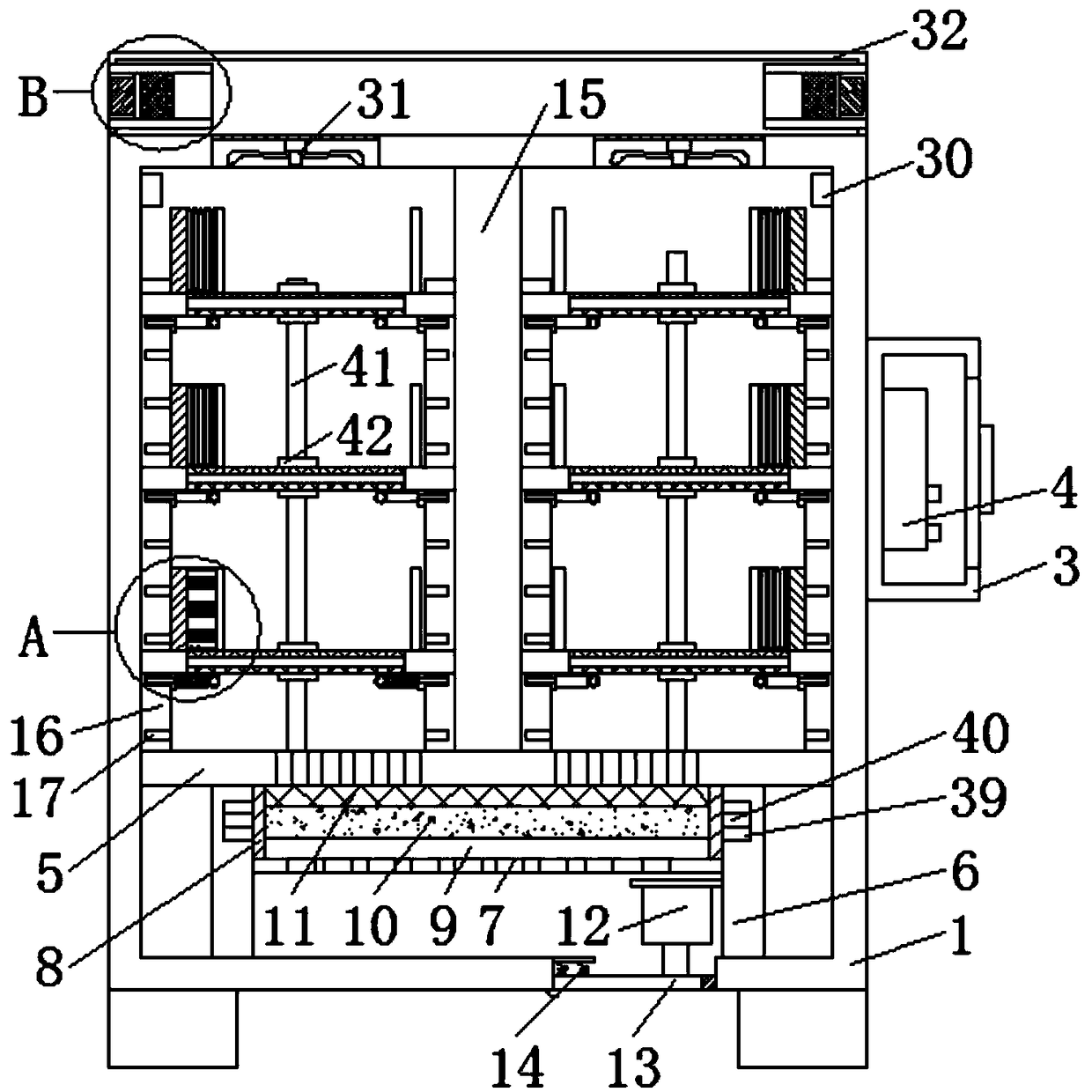

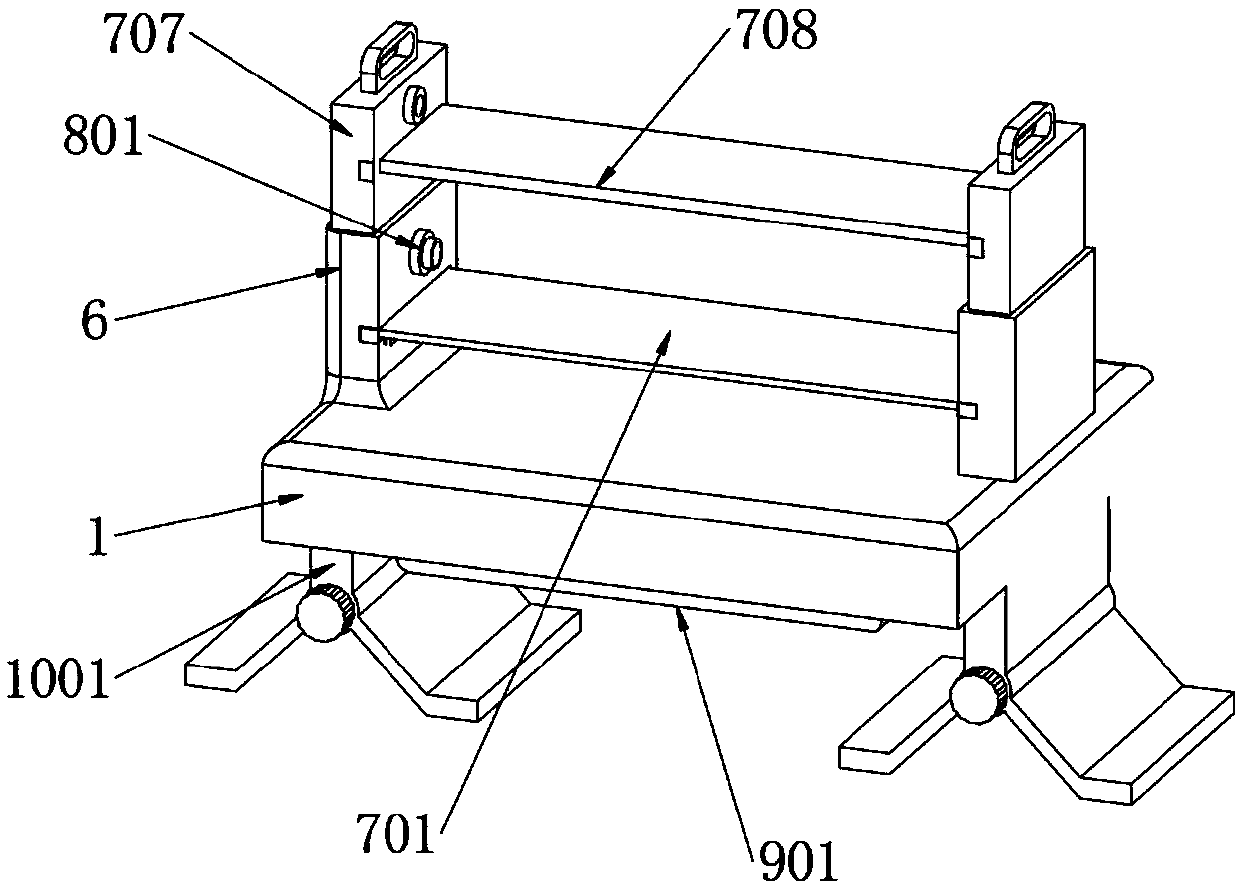

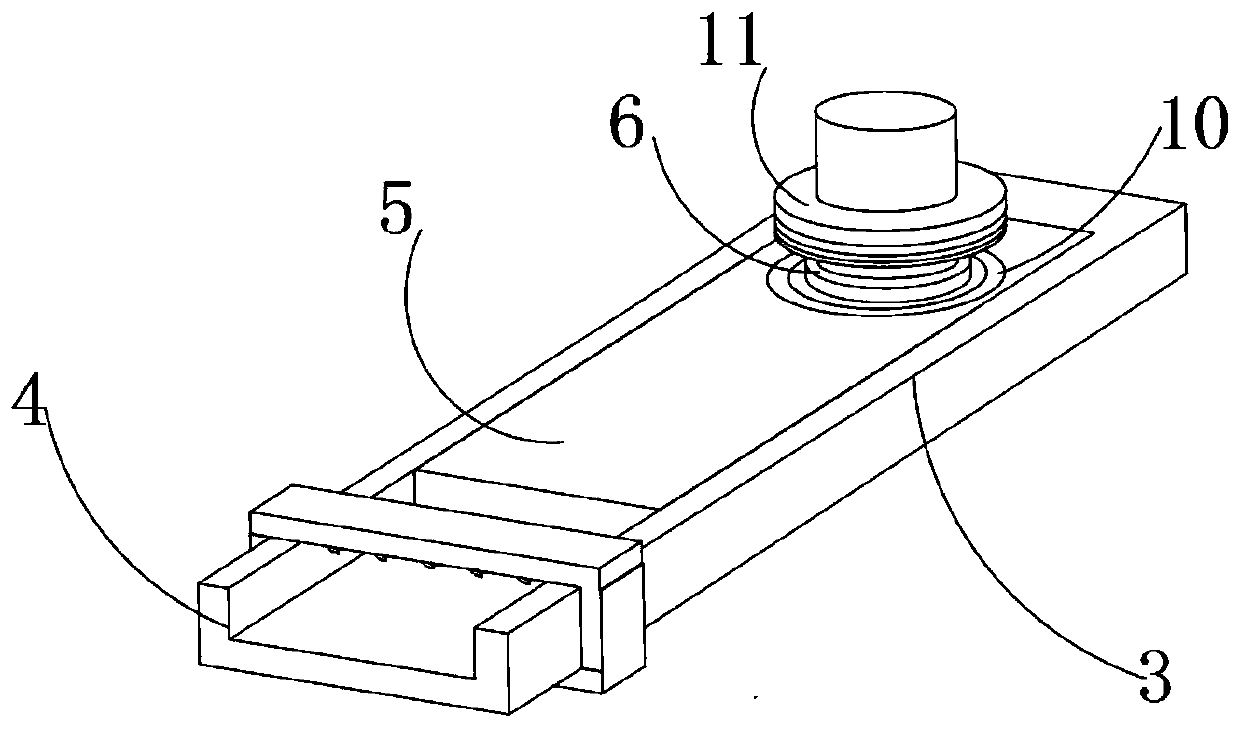

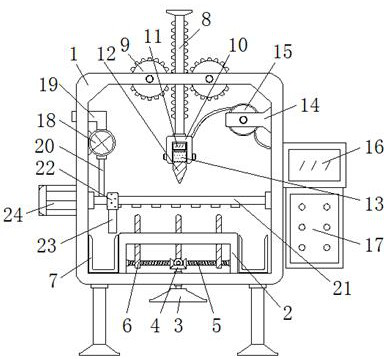

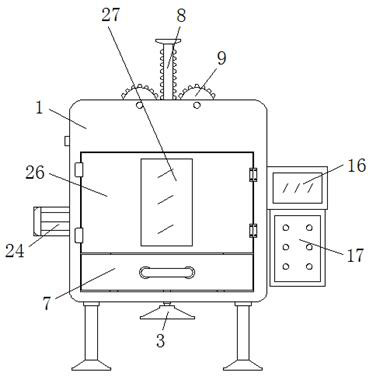

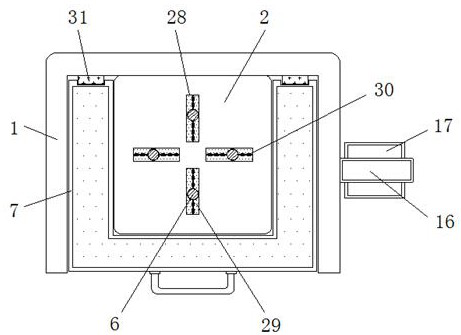

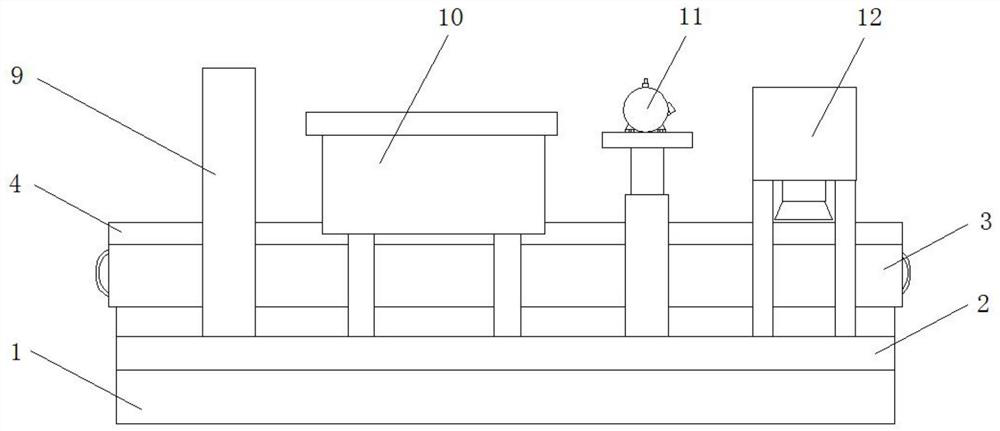

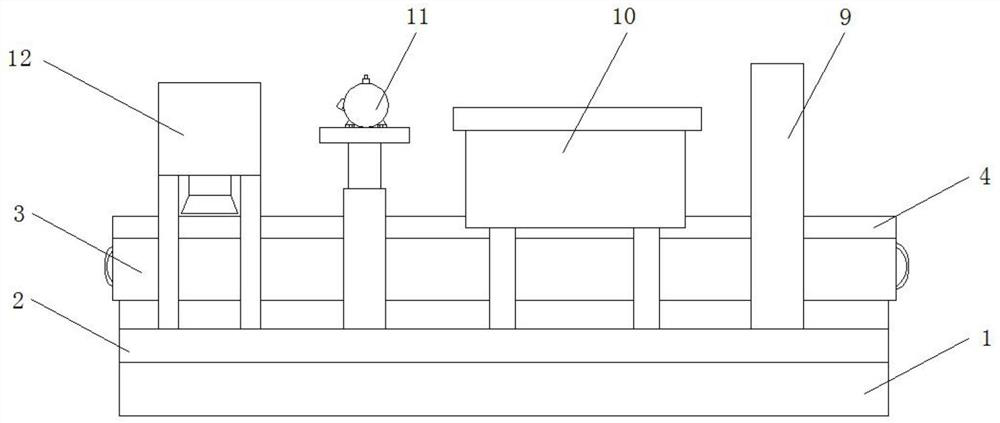

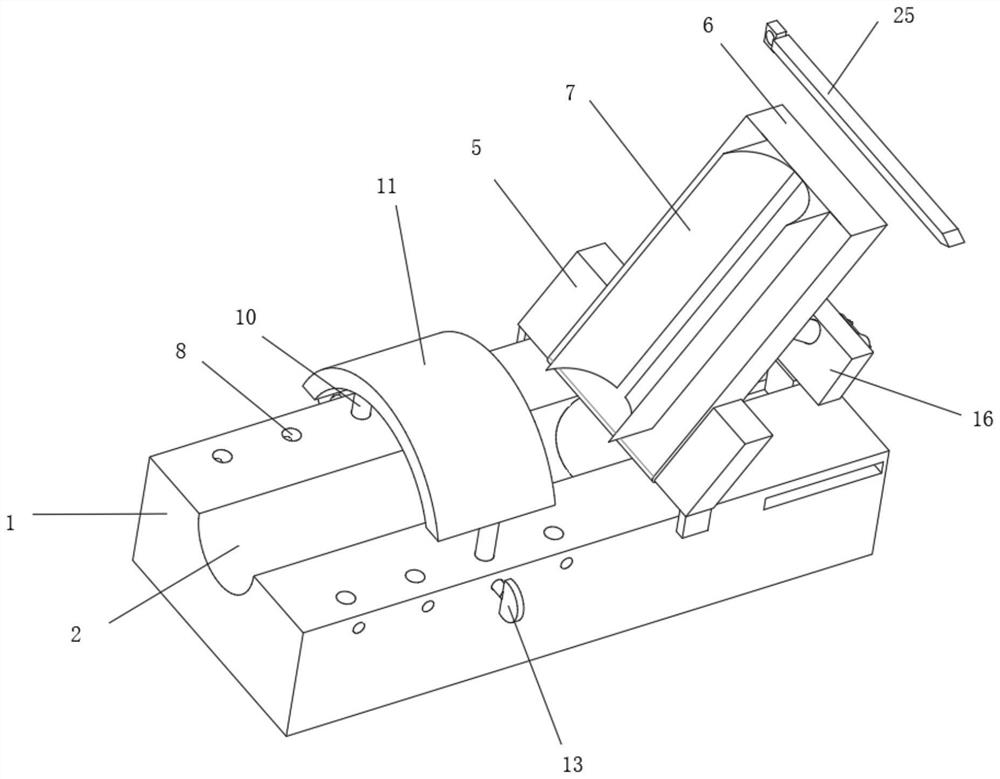

Vertical type automatic wall brick pasting device for construction operation

ActiveCN108179866AEasy to squeeze and fixRealize automatic tilingBuilding constructionsBrickArchitectural engineering

The invention discloses a vertical type automatic wall brick pasting device for construction operation. The device comprises a strip-shaped bearing base, wherein the upper surface of the strip-shapedbearing base is provided with a vertical type automatic wall brick pasting mechanism, and the lower surface of the strip-shaped bearing base is provided with a travel mechanism. The device has the beneficial effects that wall bricks are rotated, adsorbed and pasted through control, so that automatic brick pasting can be realized, the labor intensity can be alleviated, the work efficiency is increased, and the pasted bricks can be extruded and fixed by adjusting a horizontal rolling cylinder.

Owner:安徽坦程建设有限公司 +1

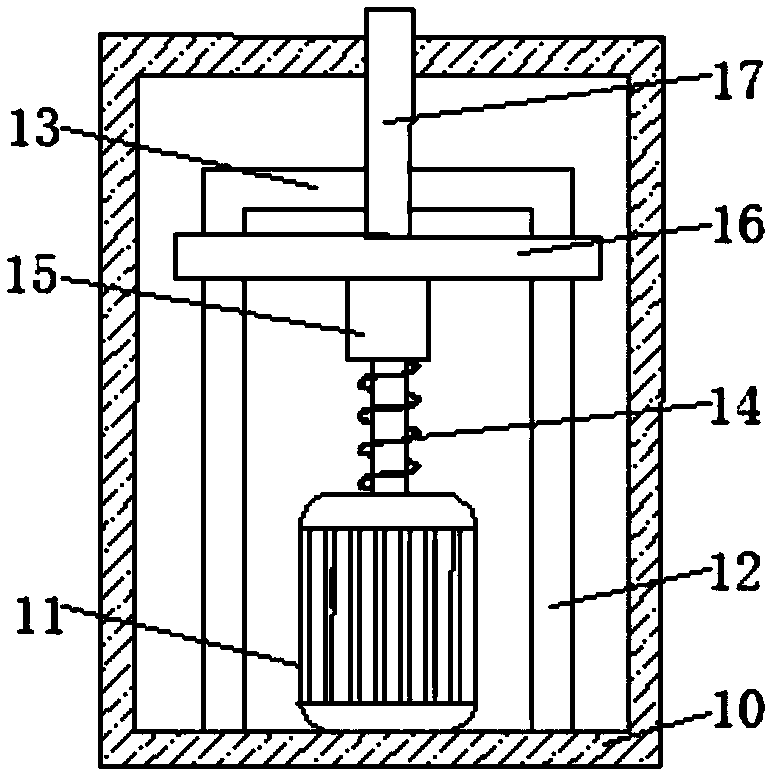

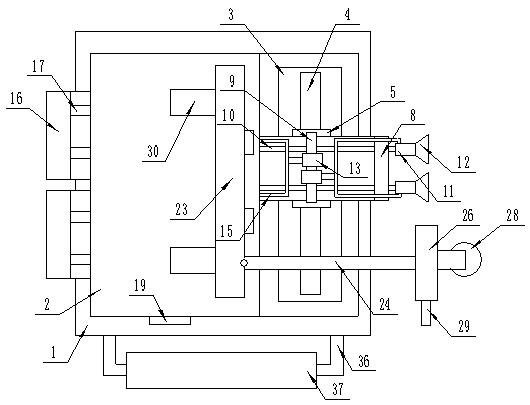

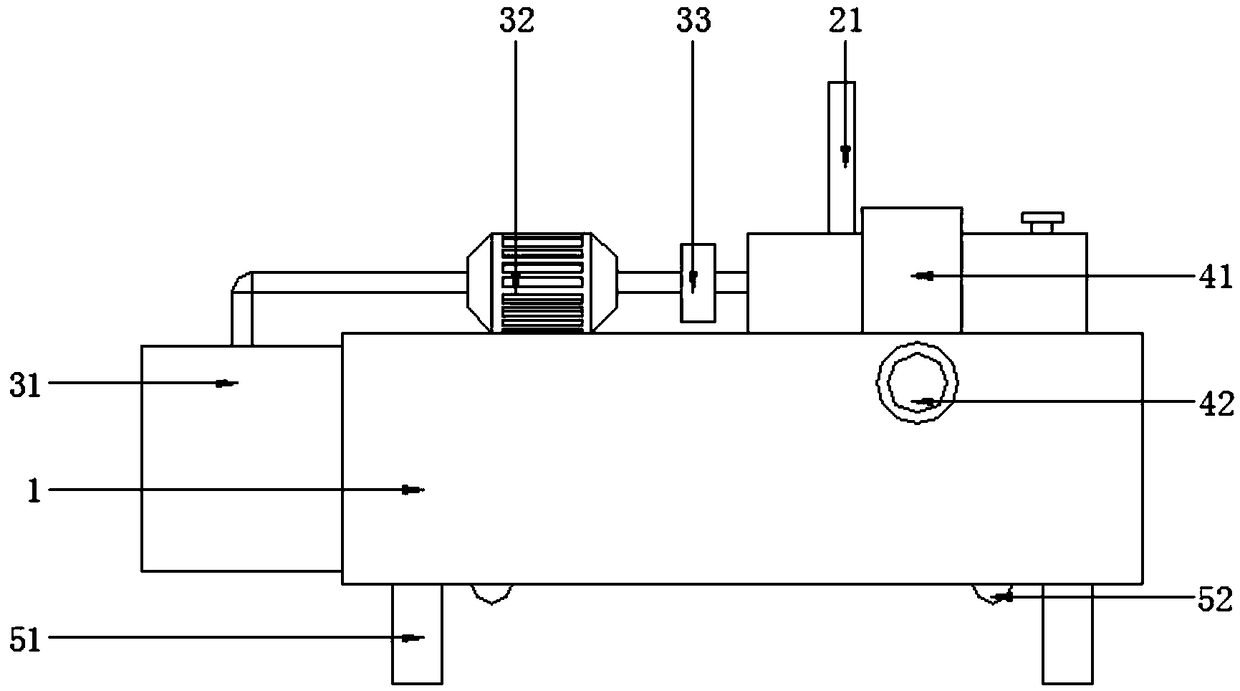

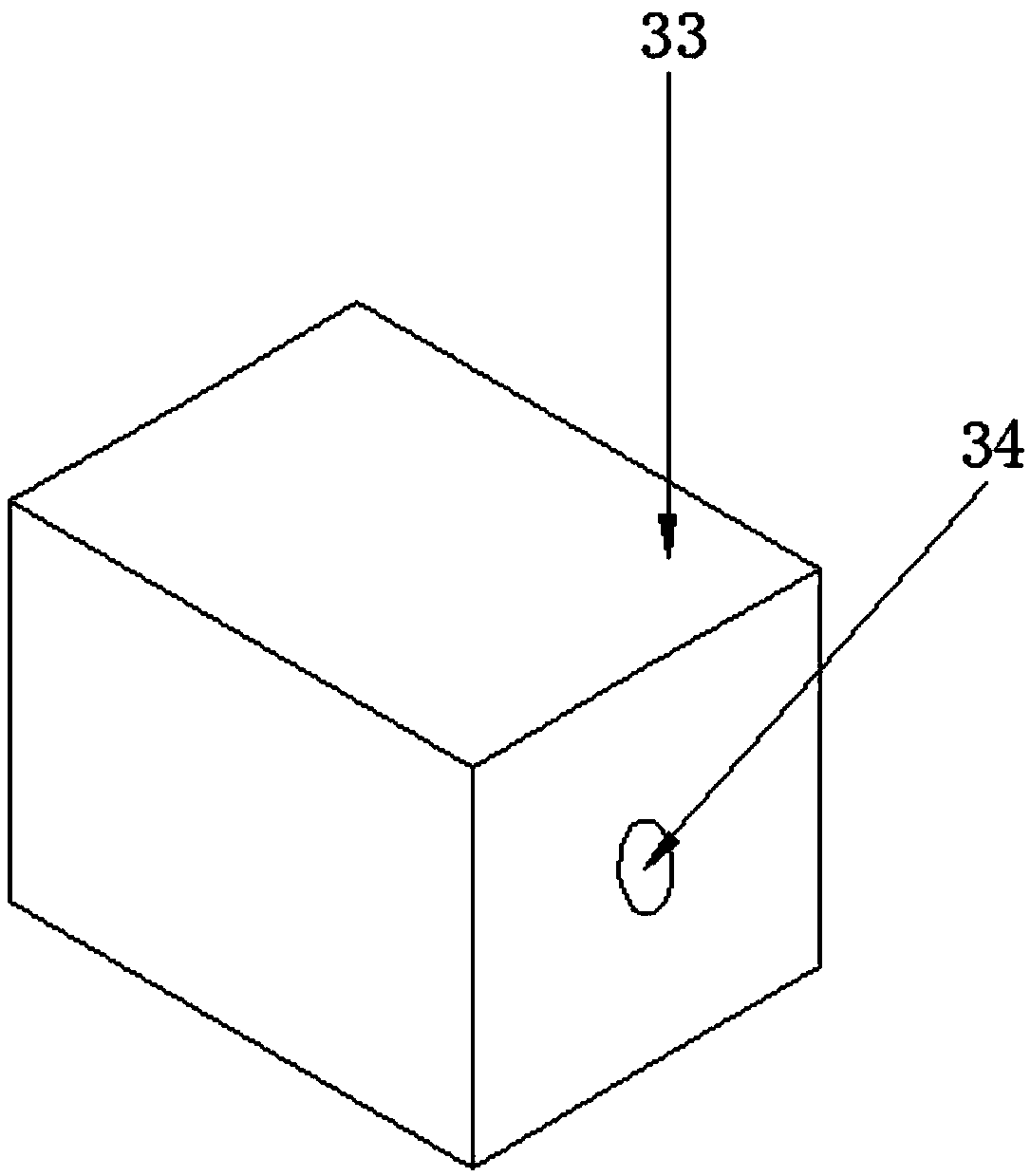

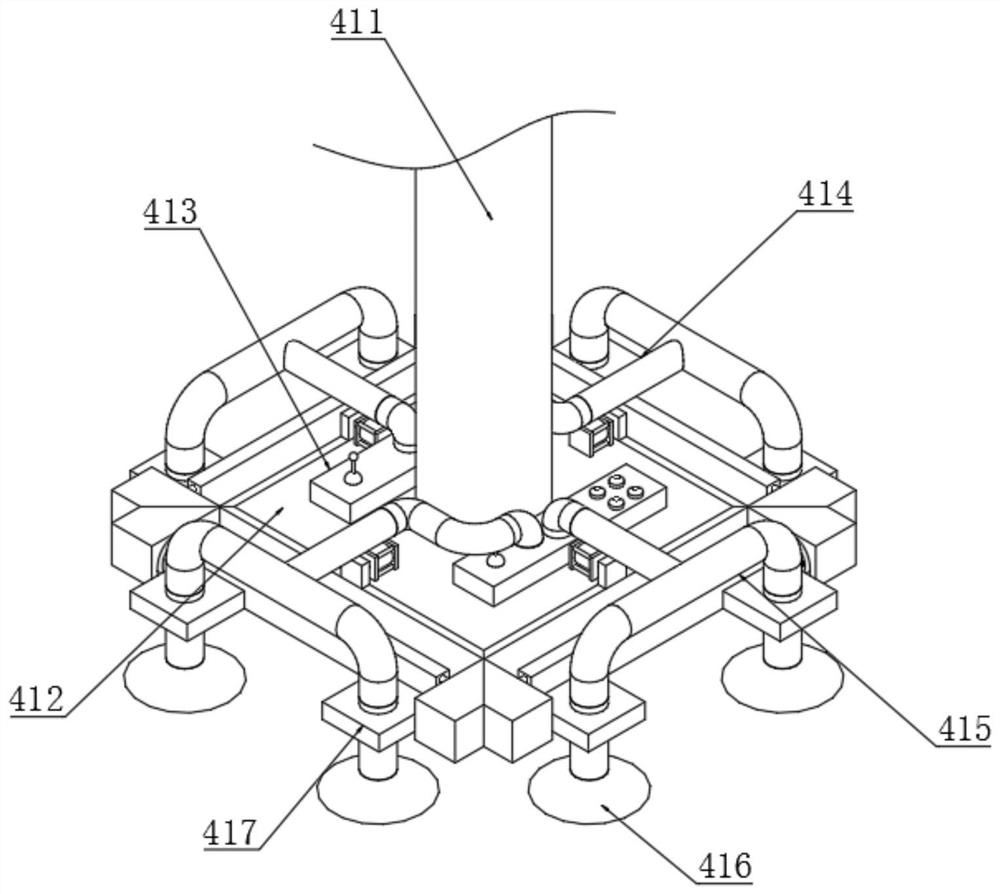

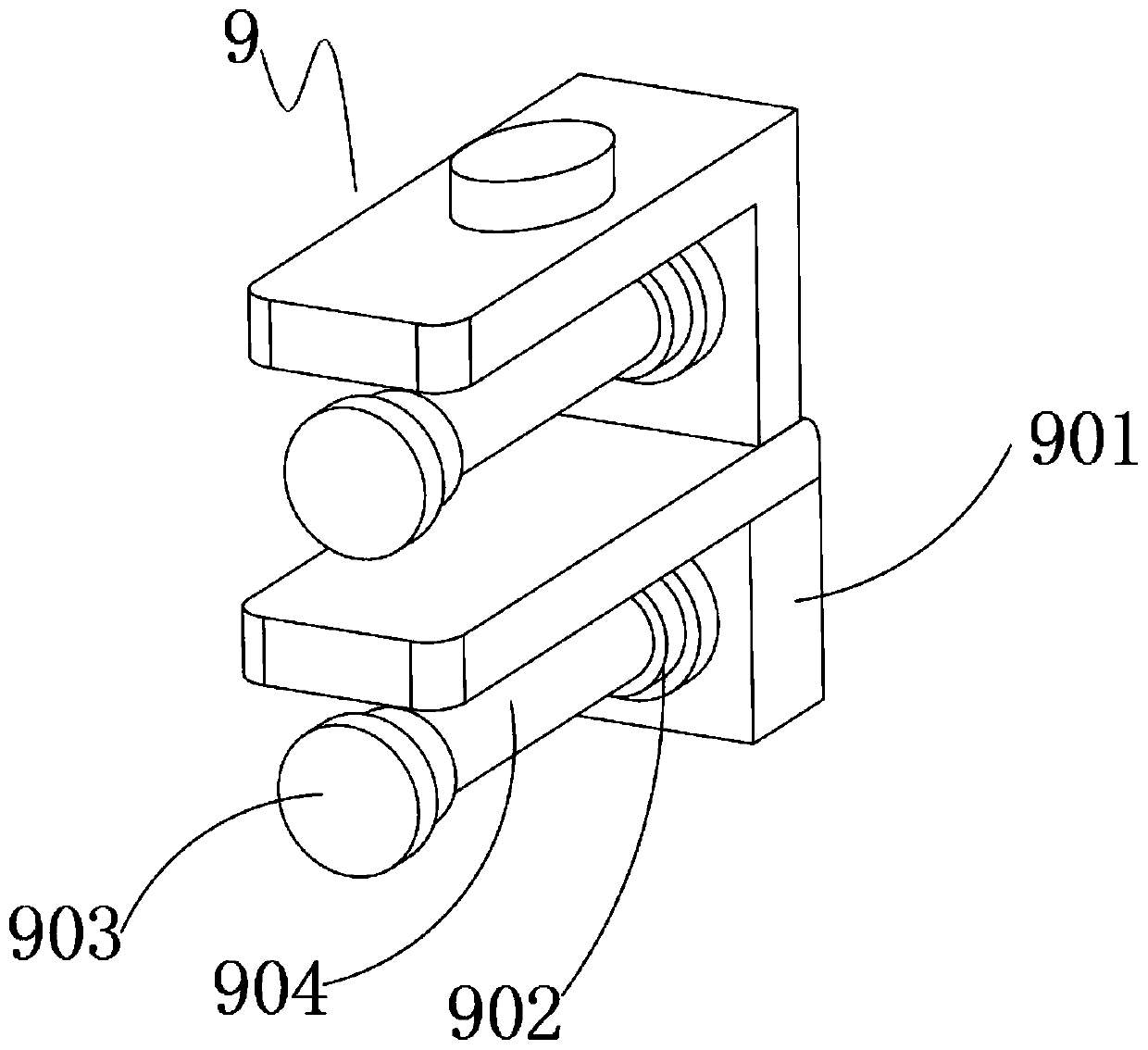

Noise elimination and reduction device of diesel engine

ActiveCN110425037AReduce the temperatureReduce impact forceExhaust apparatusNon-rotating vibration suppressionVibration amplitudeArchitectural engineering

The invention discloses a noise elimination and reduction device of a diesel engine. The noise elimination and reduction device comprises a lower base, an upper base, fixed holes, fixed rods, an extrusion assembly, a cooling assembly, a lifting assembly and a fixed plate, wherein the fixed rods are fixedly welded to the periphery of the top of the lower base; the fixed holes are formed in the periphery of the top of the upper base, and the fixed holes penetrate to the bottom of the upper base; the upper base sleeves the fixed rods through the fixed holes; the upper base is provided with the extrusion assembly; and one side of the lower base is provided with the fixed plate. According to the noise elimination and reduction device, the diesel engine can be convenient to extrude and fix, andthe distance between an extrusion plate a and an extrusion plate b is adjusted conveniently, so that the extrusion tightness is adjusted, the vibration amplitude of the diesel engine is reduced, the stability is improved, and the noise reduction and elimination are achieved conveniently; the temperature of an exhaust pipe can be reduced, and the impact force between molecules is reduced, so that the noise reduction and elimination are achieved conveniently; and the height of a semicircular storage plate can be adjusted conveniently, and the exhaust pipe can be placed conveniently.

Owner:广东宇豪新材料科技有限公司

Steel-aluminum joint welding device

InactiveCN110253165AEasy to weldFor lateral movementWelding/cutting auxillary devicesAuxillary welding devicesAlloyEngineering

The invention discloses a steel-aluminum joint welding device. The steel-aluminum joint welding device comprises a protective base, a heating base, conveying rollers, mounting grooves and a shell. The shell is internally provided with the mounting grooves. A feed port is arranged on one side of the sell at the mounting grooves. According to the steel-aluminum joint welding device, a thin copper plate is arranged between a steel plate and an aluminum alloy plate; the aluminum alloy plate and the steel plate make contact with a material guide tube through the thin copper plate; on the one hand, the steel plate and the thin copper plate are isolated through limiting of the thin copper plate, and the situation that the steel plate and the aluminum alloy plate make contact with each other and have a reaction in the heating process and the welding quality is affected by brittle compounds generated from the reaction is avoided; and on the other hand, the thin copper plate achieves the heat conduction effect and conducts heat generated from a heating barrel to the welding ends of the aluminum alloy plate and the steel plate through a delivery tube, a material guide tube and the thin copper plate in sequence to achieve the preheating effect on the steel plate and the aluminum alloy plate. The influence of bubbles generated from uneven heating in the welding process on the welding quality is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

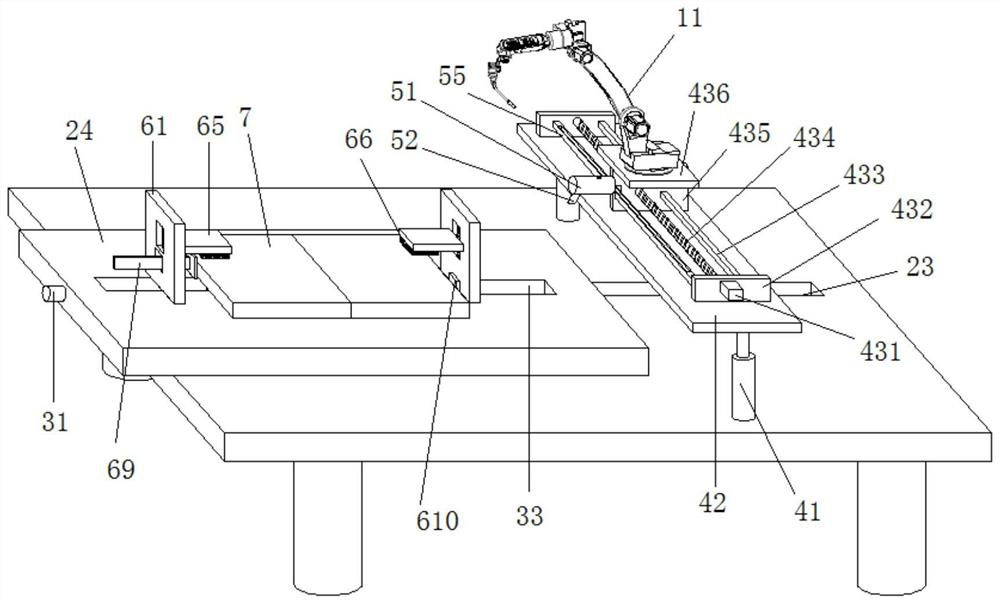

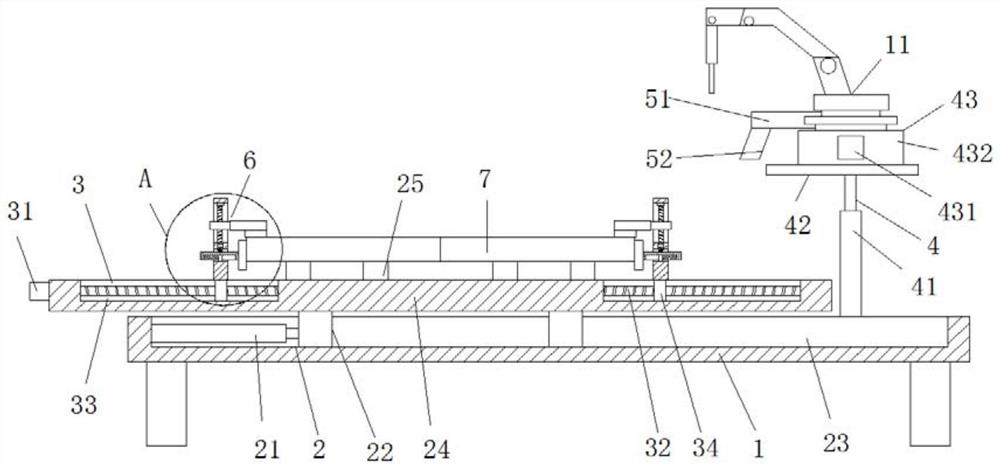

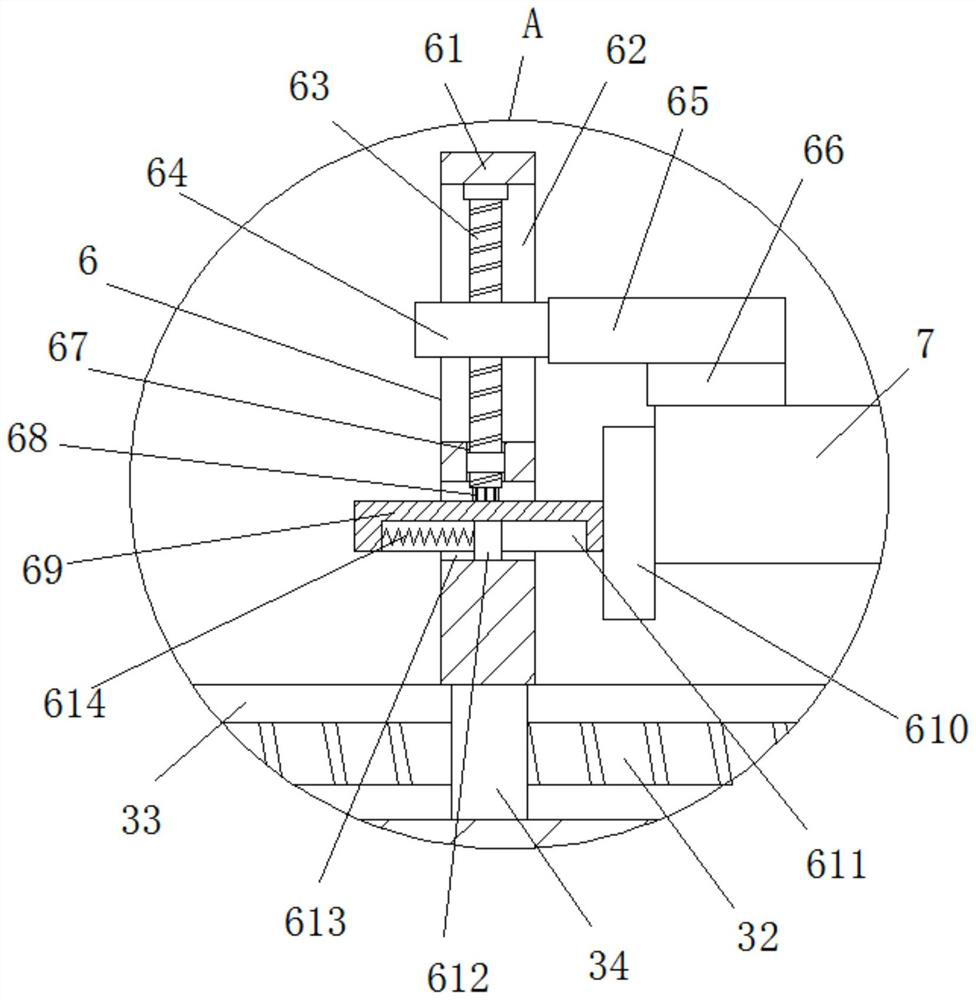

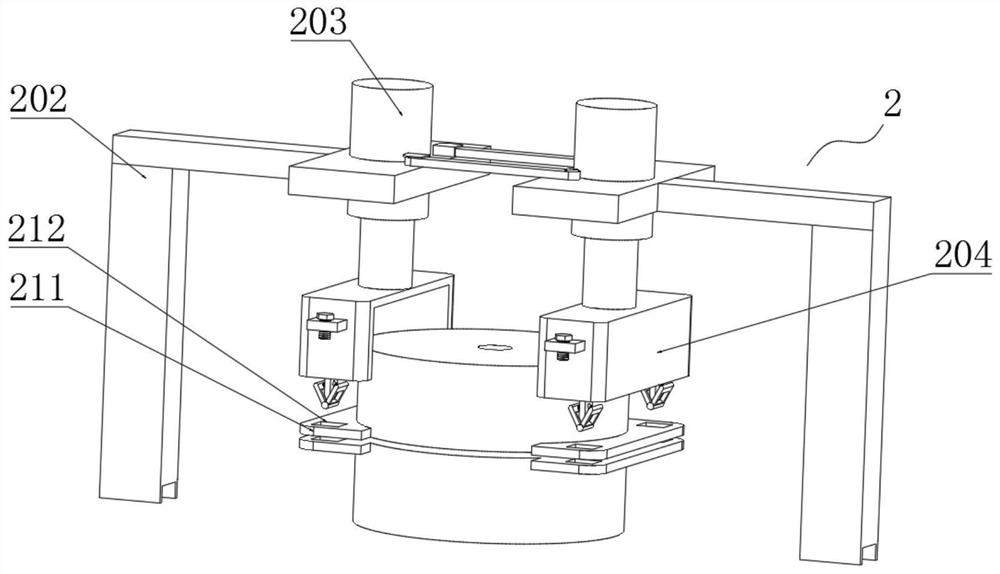

Welding robot for plate butt joint

InactiveCN113996975AAvoid liftingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention belongs to the technical field of plate welding, particularly relates to a welding robot for plate butt joint, and provides the following scheme aiming at the problems that it is inconvenient for an existing welding robot to fix plates during welding and welding seams cannot be timely cooled during welding. The welding robot comprises a working plate and a welding robot body, a horizontal adjusting mechanism is mounted on the working plate, a placing plate is connected to the horizontal adjusting mechanism, a closing mechanism is mounted at the top of the placing plate, two fixing mechanisms are connected to the closing mechanism, a plurality of supporting rods are mounted at the top of the placing plate, two plates are placed at the tops of the supporting rods, and the fixing mechanisms abut against the corresponding plates. A lifting supporting mechanism is installed on the top of the working plate, and the welding robot is installed on the lifting supporting mechanism. The welding robot is convenient to operate, top pressing and fixing are conveniently conducted while a plate is extruded and fixed, the plate fixing effect is improved, and a welding seam can be cooled in time during welding.

Owner:嘉兴浮升科技有限公司

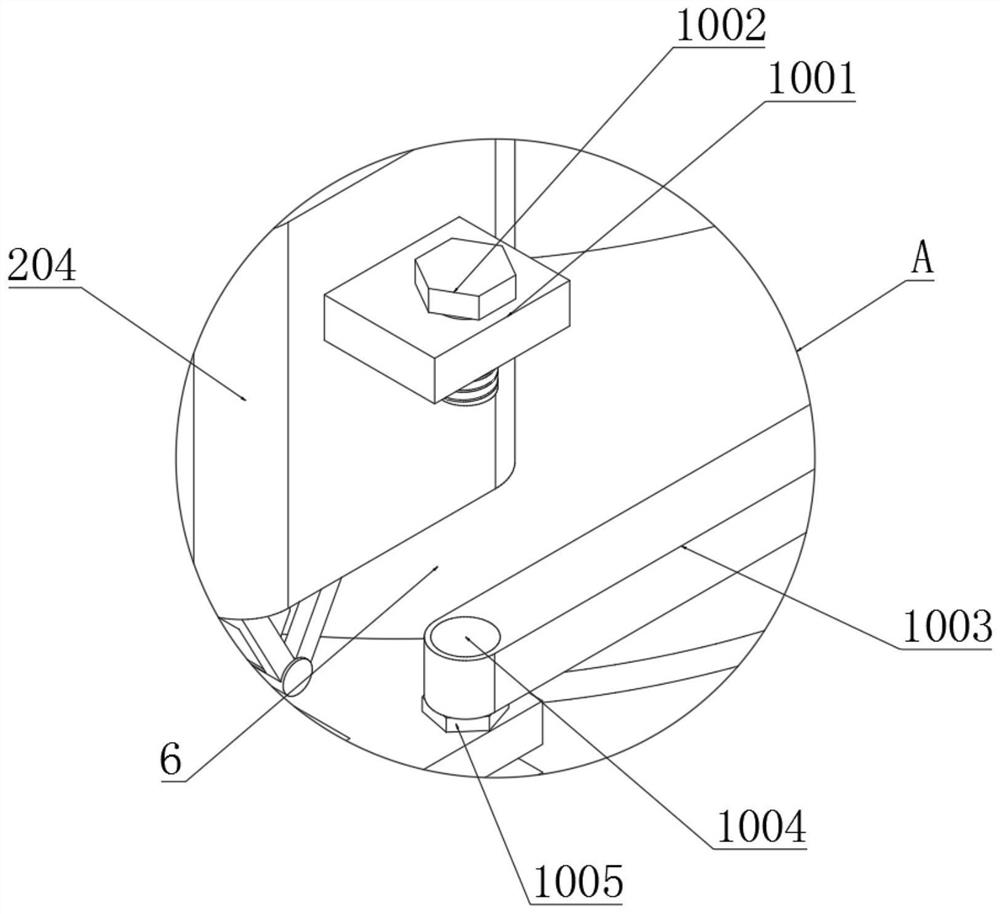

Water pump housing processing jig for facilitating use in multiple machining processes

InactiveCN109290900AHeight adjustableSmooth rotationGrinding machinesGrinding work supportsEngineeringMachining process

The invention discloses a water pump housing processing jig for facilitating use in multiple machining processes. The water pump housing processing jig comprises a jig base and a moving plate, whereina fixed rod is arranged inside the jig base; a first worm wheel is arranged outside the fixed rod; the outside of the first worm wheel is fixedly provided with a first worm rod; moving rods are arranged on the left and right sides of the jig base; and second fixing blocks are arranged outside the moving rods. The water pump housing processing jig for facilitating use in multiple machining processes is provided with a placement plate, and a first vertical rod and a second vertical rod with the inside being of a hollow structure are connected through threads so as to facilitate adjustment of the height of the placement plate; and meanwhile, the bottom of the second vertical rod and an inclined plate are in bearing connection so as to facilitate the rotation of the placement plate, so that two pressing plates fix the different positions of a water pump housing well, a water pump is well-processed for grinding, drilling, painting and the like, and the use range of the jig is extended.

Owner:邓兴明

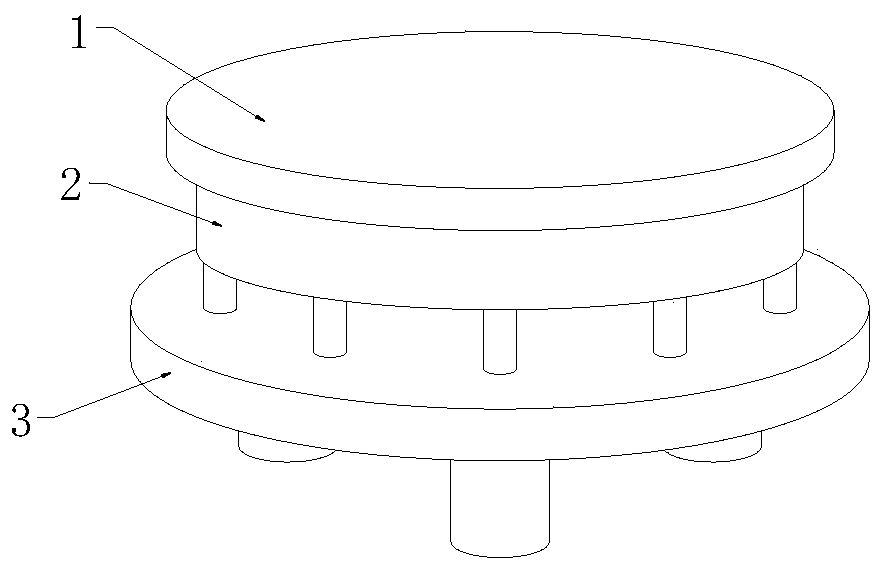

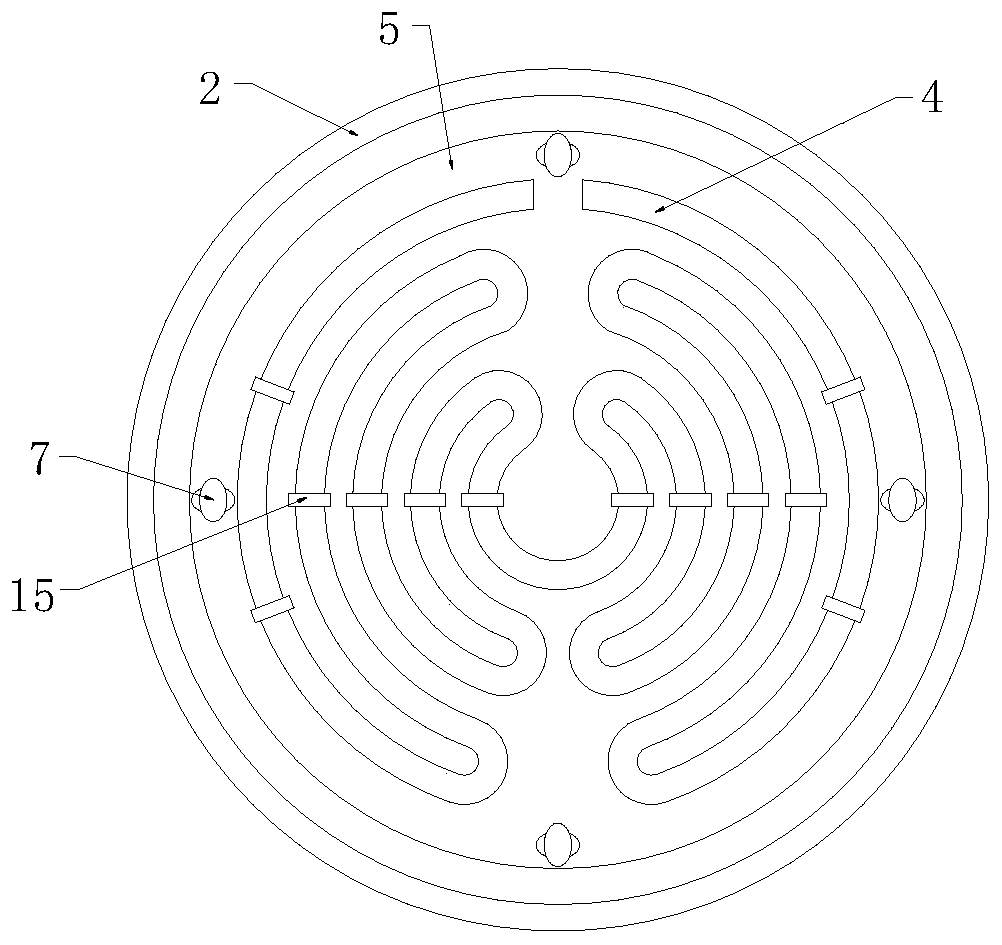

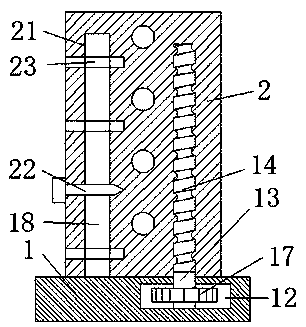

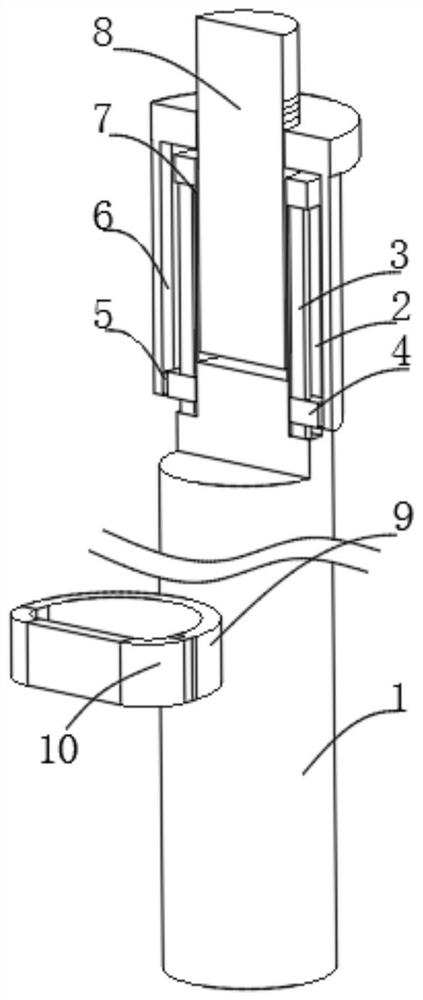

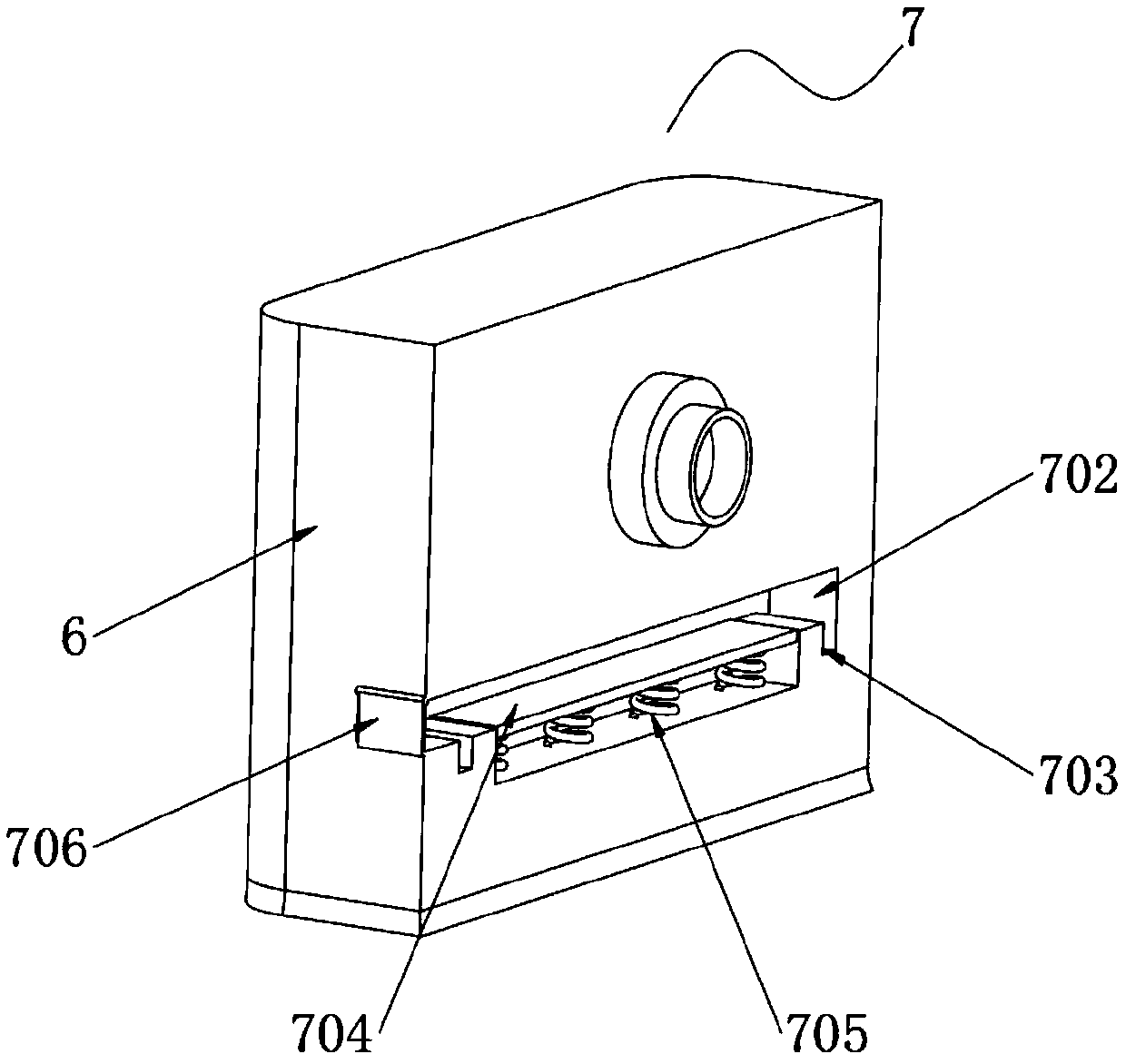

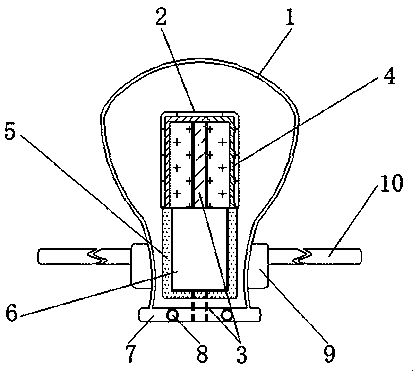

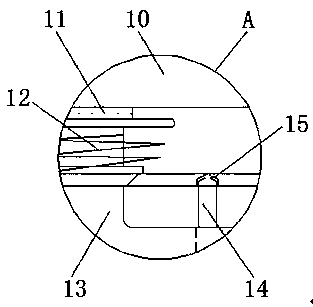

MOCVD heater source convenient for installing heating sheet and use method thereof

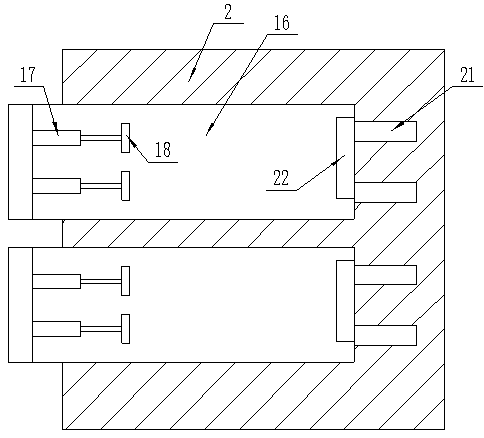

ActiveCN110656372ASolve the service lifeEasy to squeeze and fixPolycrystalline material growthFrom chemically reactive gasesPhysicsOrganic chemicals

The invention discloses an MOCVD (Metal Organic Chemical Vapor Deposition) heater source convenient for mounting a heating sheet and a use method thereof. The heater source comprises an end cover, a cylinder, a supporting frame, a heating sheet body, a disc, an elliptical rod, an elliptical block, a circular groove, a first reset coil spring, a rotating pin, a first magnetic block, a second magnetic block, a bearing, a first fixing rod, a rotating plate, a first spring, a pressing plate, a second fixing rod, a T-shaped rod, a second spring, a limiting block, a first storage groove, a magneticsquare, a fixed pin, a second reset coil spring, a bolt, a nut, a second storage groove, a second limiting groove, a third spring and a clamping block. According to the invention, the disc is installed inside the cylinder, so that the elliptic rod is installed inside an elliptic hole on the disc, and the elliptic block is reversely rotated, so that the rotating pin rotates to drive the first magnetic block and the second magnetic block to be separated; under the action of an elastic force of the first reset coil spring, the elliptic block rotates to restore the original position to be attachedwith the disc, thereby completing the disc installation; the bolt moves to extrude the clamping block, the clamping block is extruded to move, the clamping block moves into the inside of the second limiting groove, and the end cover is further installed on the cylinder.

Owner:江苏实为半导体科技有限公司

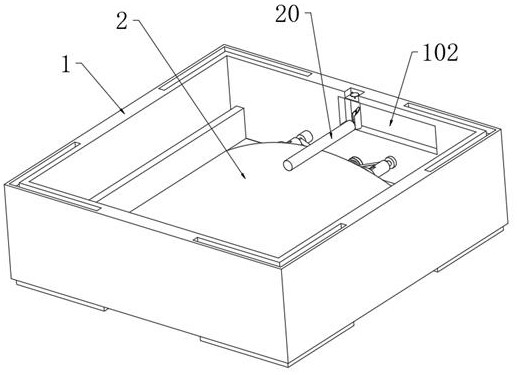

Wall brick attaching auxiliary fixing device for building construction

The invention discloses a wall brick attaching auxiliary fixing device for building construction. The wall brick attaching auxiliary fixing device comprises a base. A movable plate is movably connected to the upper surface of the base. Object carrying plates are arranged on the side wall of the movable plate at equal intervals and are horizontally and fixedly connected to the side wall of the movable plate. The upper surfaces of the object carrying plates are connected with moving plates in a sliding mode. Suction discs are fixedly connected to the side walls, away from a fixing plate, of themoving plates. By means of the wall brick attaching auxiliary fixing device, attached wall bricks can be effectively pressed and fixed, and meanwhile, wall bricks with different heights can be extruded and fixed, unevenness caused by the increased stressing difference between the wall bricks can be avoided, and convenience is brought to a worker.

Owner:中旭装饰工程有限公司

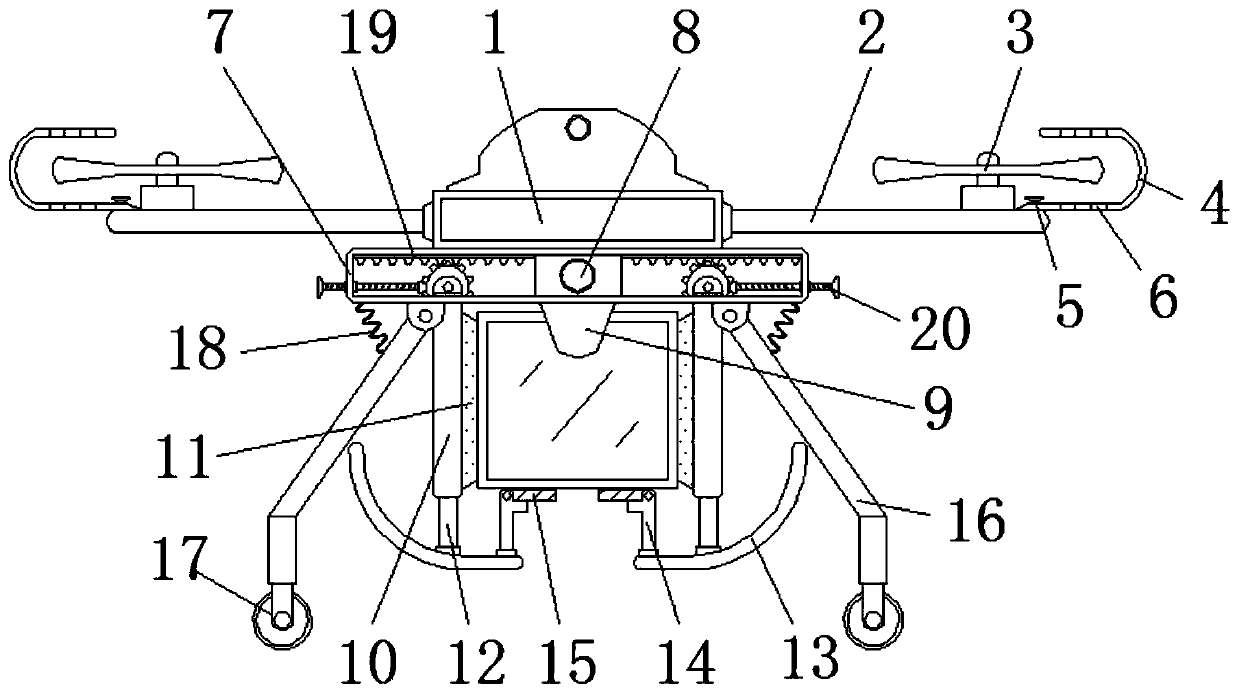

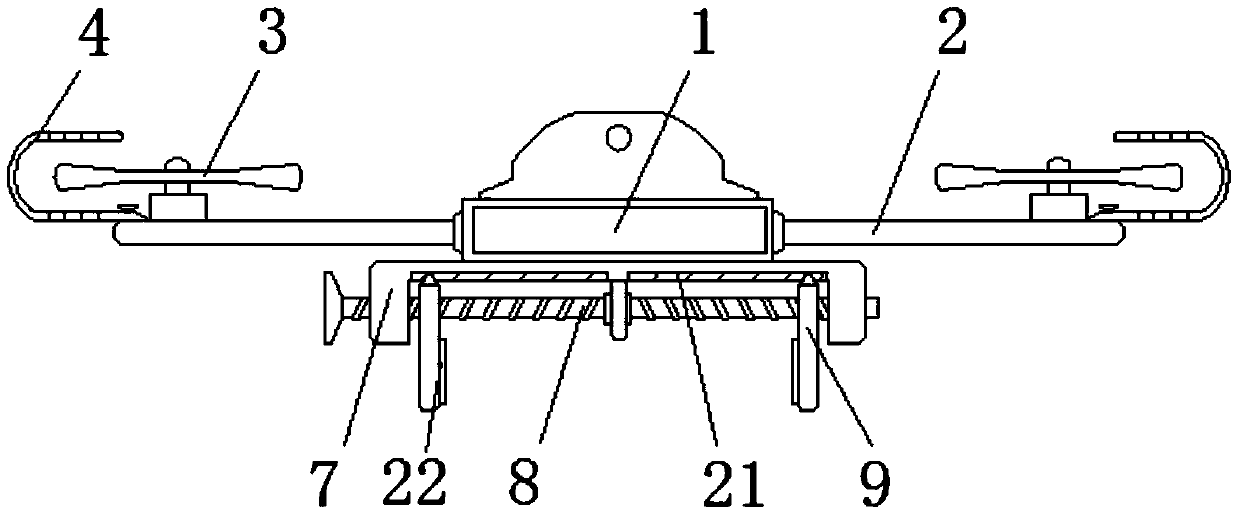

Logistics distribution unmanned aerial vehicle

ActiveCN110979704AEffectively fixedEffective protectionAlighting gearAircraft indicatorsGear wheelUncrewed vehicle

The invention discloses a logistics distribution unmanned aerial vehicle, which comprises an unmanned aerial vehicle body, wings, a mounting plate and a second open slot, wherein supporting rods are fixedly mounted on the side surfaces of the unmanned aerial vehicle body; the wings are mounted above the outer end parts of the supporting rods; a protection plate is connected above the outer end part of each supporting rod through fastening bolts; the mounting plate is fixedly bonded to the middle of the lower part of the unmanned aerial vehicle body; the middle part of the mounting plate is connected with a connecting lead screw; a sliding rod is connected below the mounting plate; a sliding groove is formed in the middle of the upper part of the inner side of the mounting plate; the secondopen slot is formed in the middle of the lower surface of the mounting plate; first open slots are formed in the left end and the right end of the lower surface of the mounting plate; a connecting gear is rotationally connected above the sliding rod; and fixed clamping blocks are fixed to the left side and the right side of the surface of the sliding rod. According to the logistics distribution unmanned aerial vehicle, objects can be effectively fixed, the wings can be effectively protected, the resistance generated by airflow during object transportation can be reduced at the same time, andelectric energy is saved.

Owner:陕西蓝天上航空俱乐部有限公司

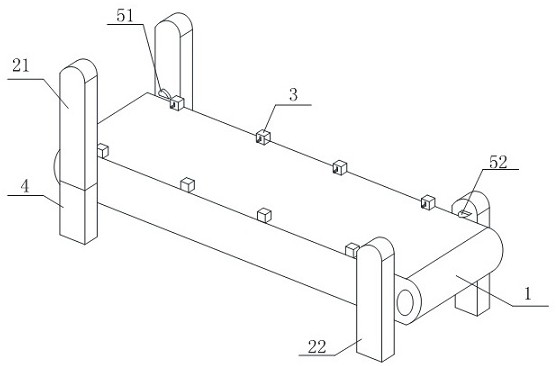

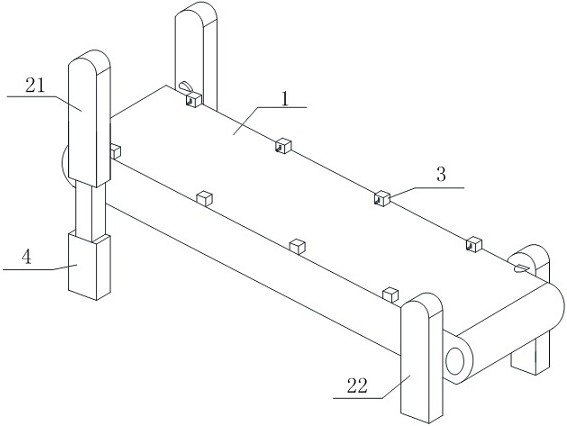

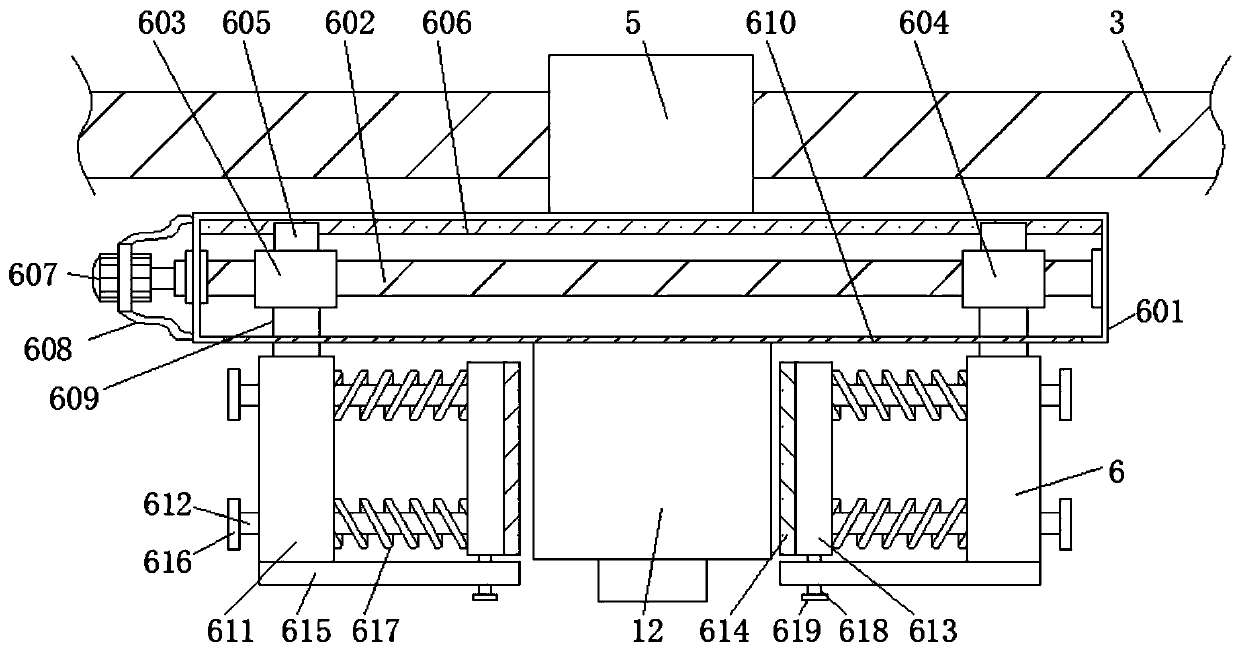

Conveying device for decorative plates

ActiveCN112340361AFor efficient deliveryRealize rotary conveyingConveyorsSupporting framesDrive wheelStructural engineering

The invention belongs to the technical field of conveying, and provides a conveying device for decorative plates. The conveying device comprises a conveying belt, a supporting device and a clamping device. The supporting device comprises an upper supporting device body and a lower supporting device body, and the lower supporting device body comprises a lower supporting plate and a compaction blocklocated on the lower supporting plate. The conveying belt sleeves a driving wheel and a driven wheel, and the driving wheel is connected with a driving part. The clamping device comprises a base, aneccentric part, a sliding block, an extrusion part and a reset part, the two ends of the reset part are correspondingly connected with the sliding block and the base, the eccentric part is connected with the base through a vertical plate, the eccentric part comprises an arc-shaped section and a right-angle section, and an accommodating space is formed in the sliding block. The extrusion part comprises an upper extrusion rod, a vertical rod and a lower extrusion rod, the upper extrusion rod is connected with the lower extrusion rod through the vertical rod, and an elastic piece is installed between the lower end of the vertical rod and the sliding block. According to the conveying device for the decorative plates, rectangular decorative plates can be effectively conveyed, potential safety hazards are reduced while the conveying efficiency is improved, and meanwhile, inclined conveying can be achieved at different angles.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

Pesticide spraying device convenient to fix for planting of citruses

InactiveCN108739749AEasy to observe the amount of entryEasy to control ratio matchingInsect catchers and killersEngineeringClean water

The invention discloses a pesticide spraying device convenient to fix for planting of citruses. The device includes a fixing platform, a liquid level observation assembly, a water inlet assembly, a fixing assembly, a movement support assembly, a fixing groove, a pesticide box and a feeding port; the fixing groove is formed in one side of the top of the fixing platform, the pesticide box is placedin the fixing groove, the liquid level observation assembly is installed in the pesticide box, the fixing assembly is mounted on the fixing platform, and the water inlet assembly is mounted on one side of the fixing platform; the liquid level observation assembly includes a fixing plate, a scale bar, a floating plate and multiple liquid drain holes. The floating plate is positioned in the pesticide box, the liquid drain holes are formed in the top of the floating plate at equal intervals, and the fixing plate is mounted at the center of the top of the floating plate. The feeding amount of liquid is observed conveniently, and proportional matching of pesticide and water is controlled conveniently. Flow velocity of clean water is reduced conveniently, and the water inflow is controlled better; by adjusting the position of an L-shaped clamping plate, the pesticide box is extruded and fixed conveniently.

Owner:ZHONGSHAN JIAYUAN ECOLOGICAL AGRI CO LTD

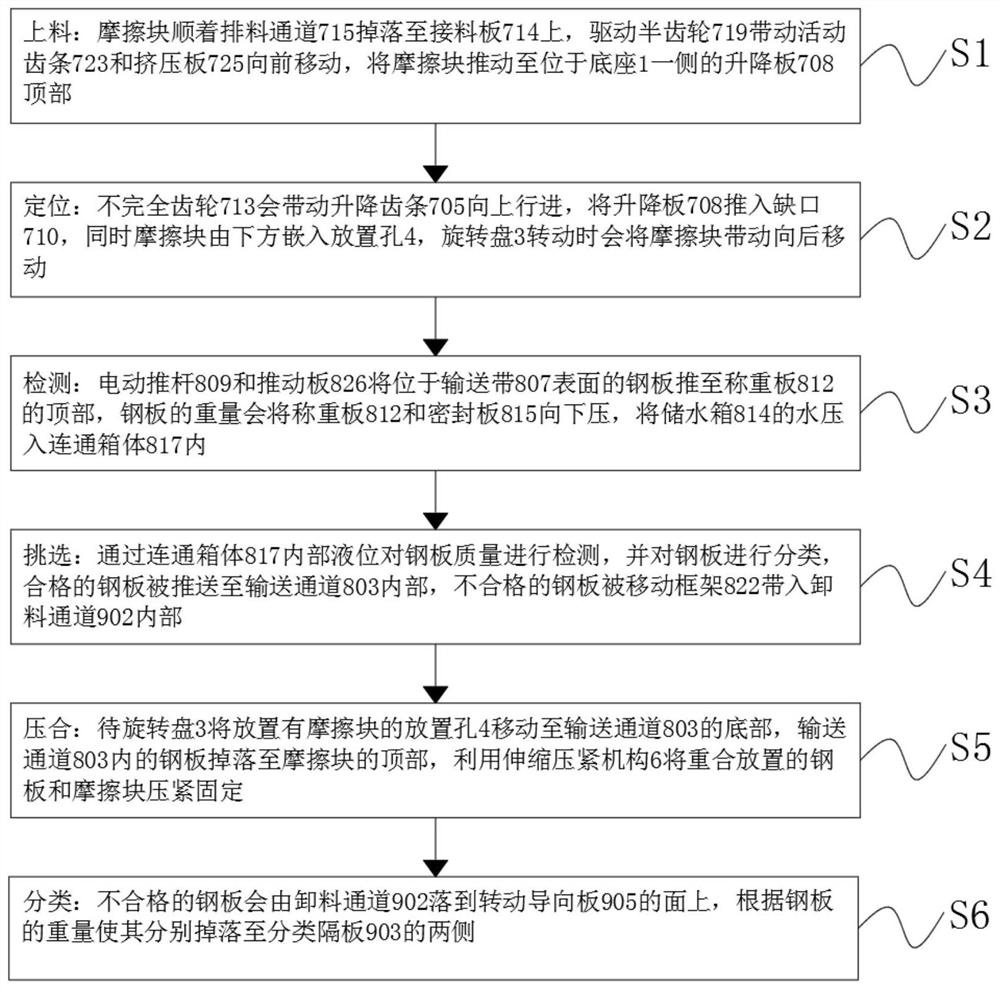

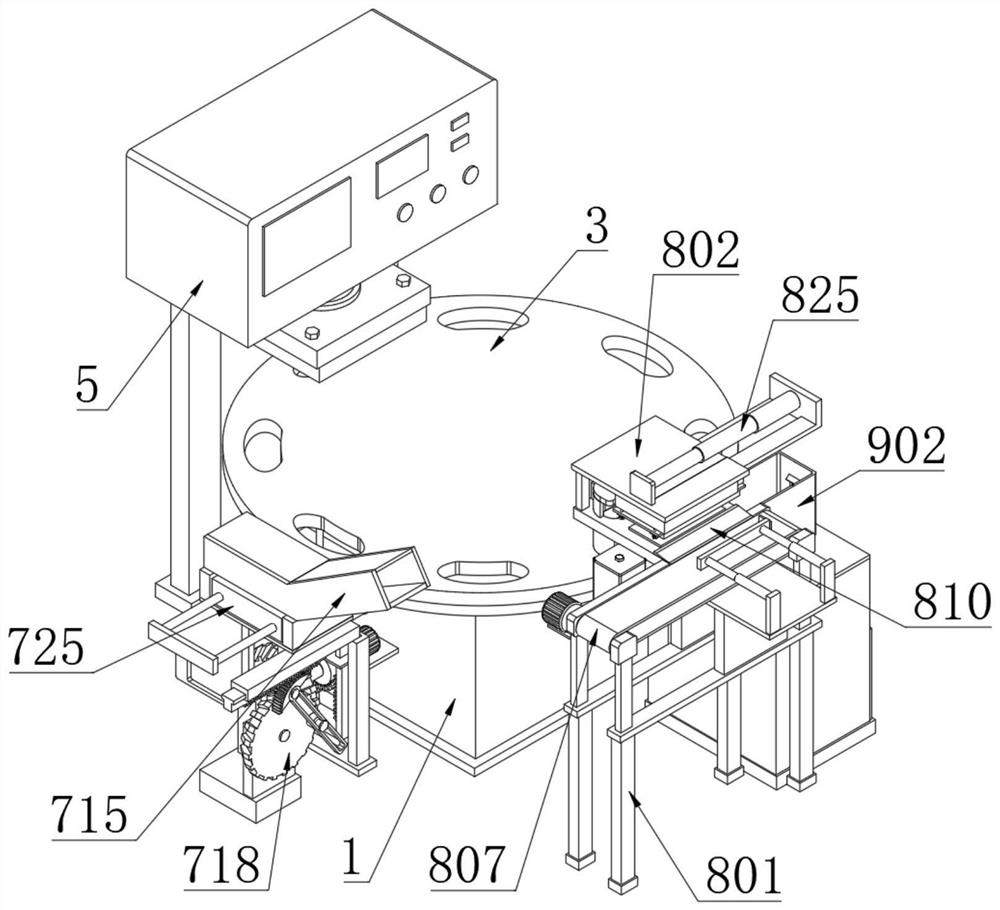

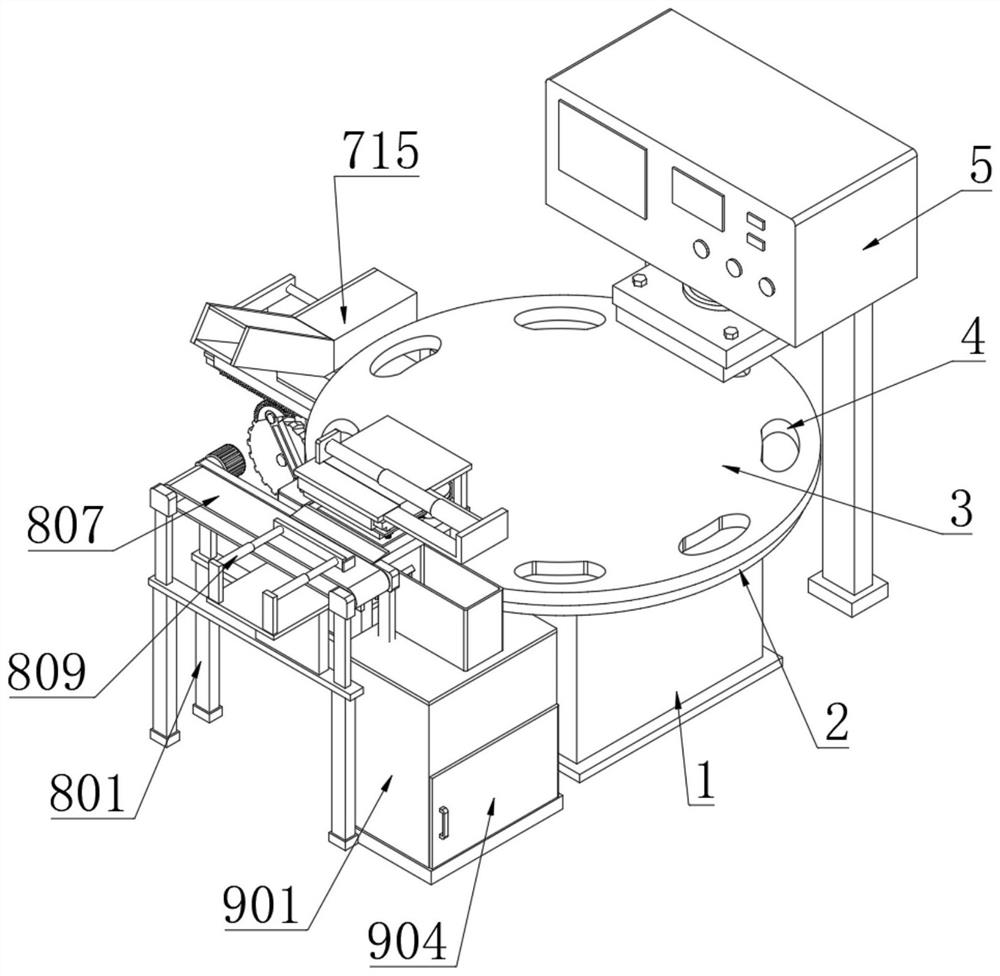

Preparation method of automobile brake pad

ActiveCN113385910AScientific and reasonable structureEasy to useSortingMetal working apparatusGear driveGear wheel

The invention discloses a preparation method of an automobile brake pad. The method comprises the steps that feeding is conducted, specifically, friction blocks fall onto a material receiving plate along a discharging channel, a driving half gear drives a movable gear rack and an extrusion plate to move forwards, and the friction blocks are pushed to the top of a lifting plate located at one side of a base; and positioning is conducted, specifically, an incomplete gear can drive a lifting gear rack to move upwards, the lifting plate is pushed into a notch, meanwhile,the friction blocks are embedded into containing holes from the lower portions, and when a rotating disc rotates, the friction blocks are driven to move backwards. The friction blocks used for preparing of the brake pad are discharged to the material receiving plate from the discharging channel in sequence, a driving bevel gear and a driven bevel gear are driven by a driving motor to rotate, a swing rod can be driven to rotate when a positioning column rotates, then the driving half gear rotates in a reciprocating manner, the effect of driving the movable gear rack and a support is achieved, the extrusion plate moves forwards and backwards, and the arranged friction blocks are sequentially pushed and placed on the surface of the lifting plate.

Owner:青岛方冠摩擦材料有限公司 +1

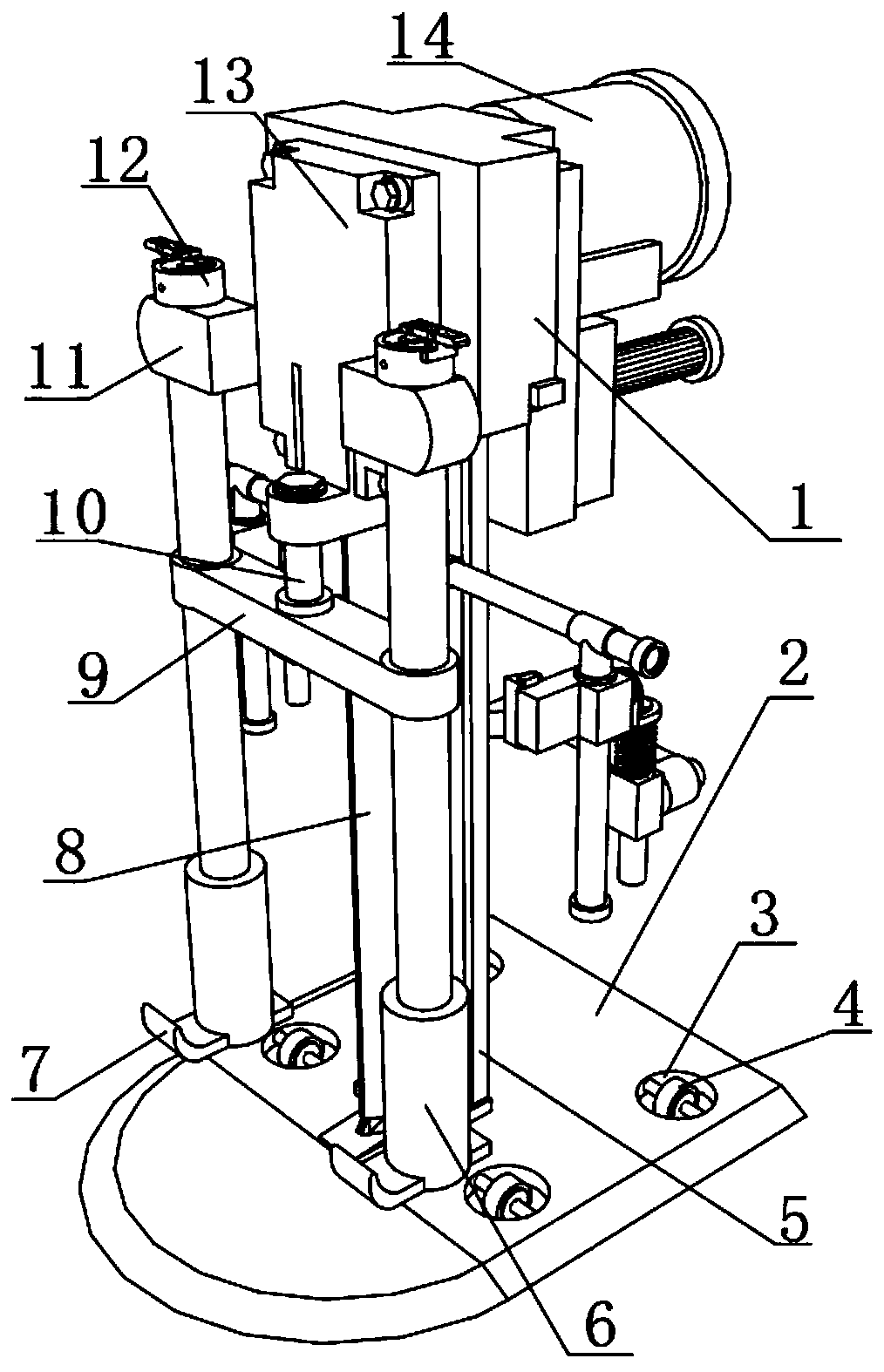

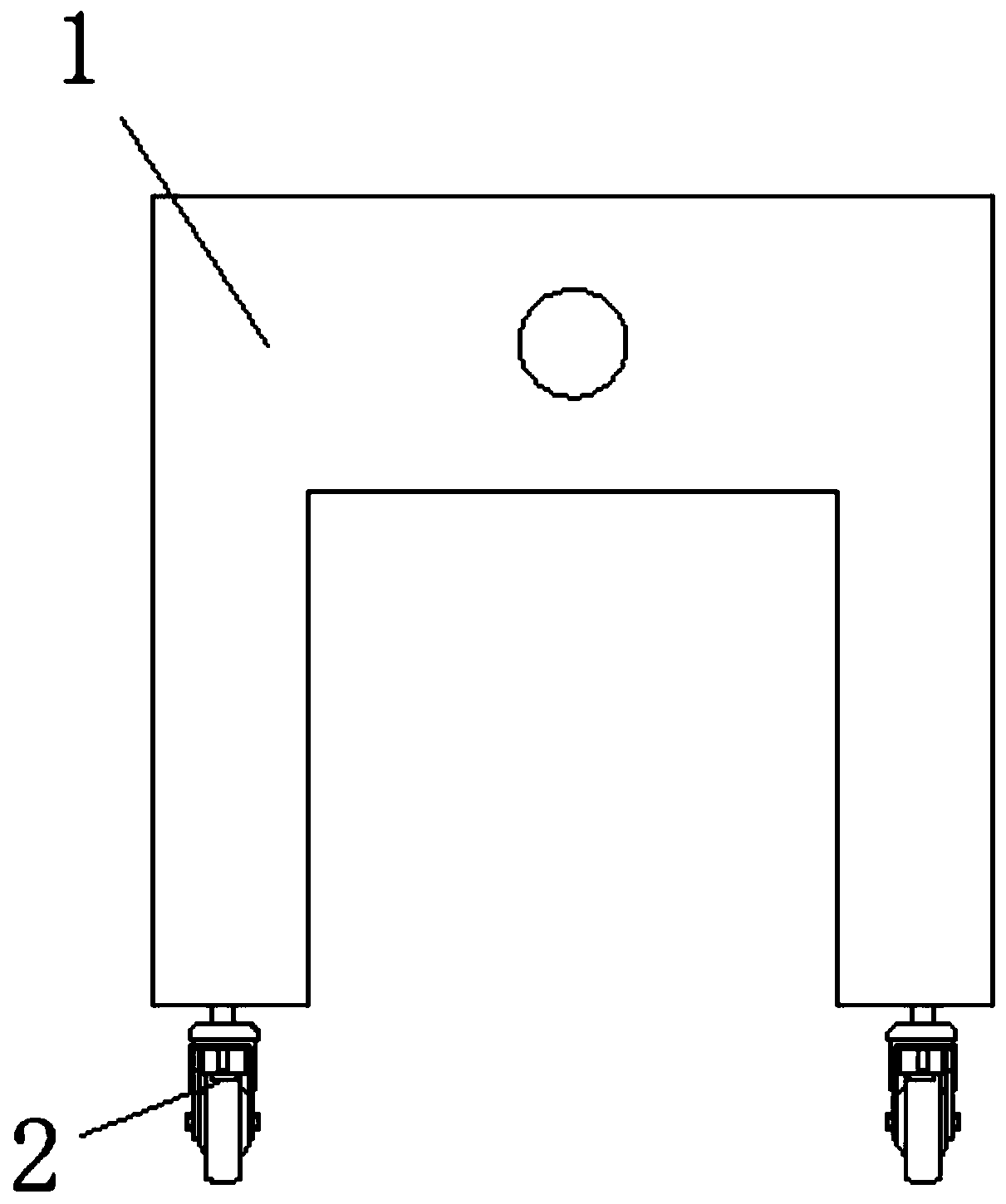

Wind power blade flaw detector capable of automatic detection

InactiveCN110261089AImprove flaw detection efficiencyReduce pull strengthMachine part testingElectricityMotor drive

The invention relates to a wind power blade flaw detector capable of automatic detection, and relates to the technical field of wind power blade flaw detection. The detector comprises a bracing frame, universal wheels are fixedly connected to the bottom of the bracing frame, a first threaded rod penetrates the side surface of the bracing frame and is movably connected with the bracing frame via a bearing, a rotating motor is fixedly connected to the left side of the first threaded rod, a first threaded bushing is in threaded connection to the external surface of the first threaded rod, a limiting mechanism is fixedly connected to the first thread bush, and a flaw detector body is arranged on the limiting mechanism. The bracing frame is erected on a blade, the rotating motor drives the first threaded rod to rotate so that the flaw detector body detects flaw of the blade, the detector can detect the flaw of the blade needless of being held, the blade flaw detection efficiency is improved, the tensile intensity of blade flaw detection is reduced, and the precision of blade flaw detection is increased due to constant height of the detector body and the blade.

Owner:杭州戬威科技有限公司

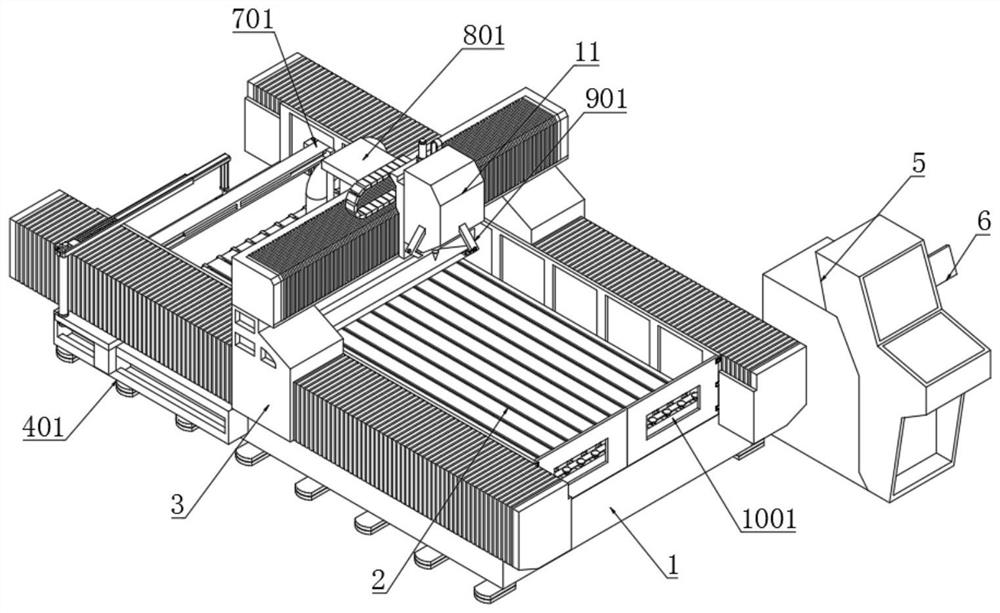

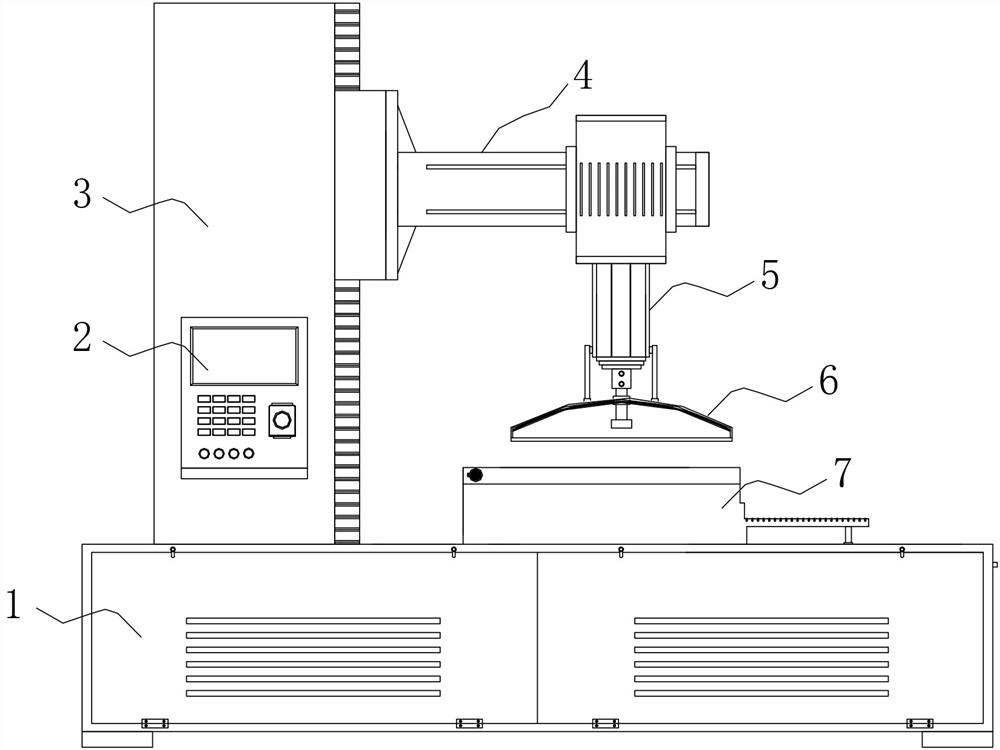

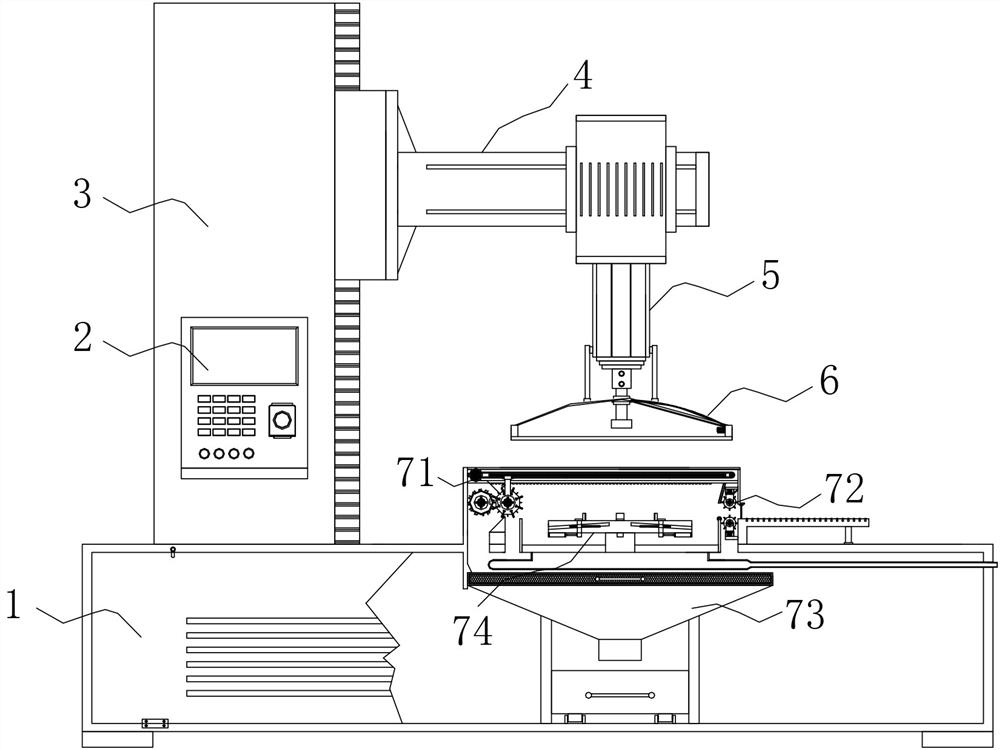

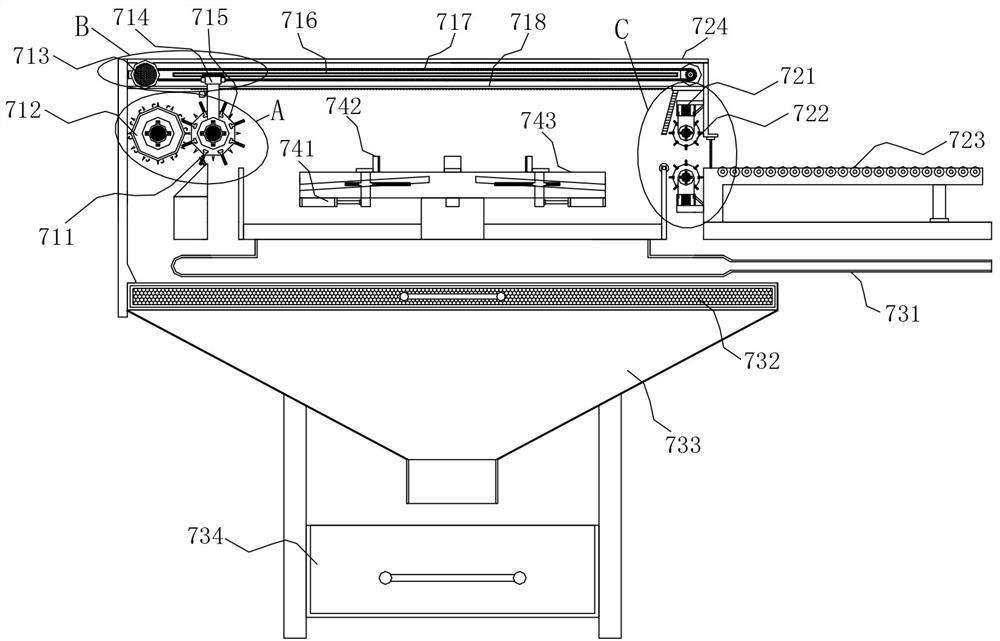

Convenient machine tool for aluminum alloy plate machining

ActiveCN111774908AScientific and reasonable structureEasy to useAutomatic control devicesMeasurement/indication equipmentsAir pumpEngineering

The invention discloses a convenient machine tool for aluminum alloy plate machining. The convenient machine tool comprises a machine base. The middle portion of the top end of the machine base is slidably connected with a workbench. The top of the outer surface of the machine base is movably connected with a portal frame. The middle portion of one end of the portal frame is movably connected witha spindle box. A movable taking mechanism is fixedly mounted on one side of the bottom of the front side of the machine base. Through a fixed plate, a master connecting plate, a stand column and a locating ring, a sliding block can slide and rotate conveniently, and the moving and rotating difficulty of the stand column is reduced. The convenient machine tool is provided with a driven sliding groove, a sliding bar and a main lead screw. The sliding bar can move conveniently, and the moving difficulty of the sliding bar is reduced. The convenient machine tool can adsorb aluminum alloy plates in different parts of the interior of the machine base. Meanwhile, through a lifting cylinder, a slave connecting plate, an air pump, suction pipes, connecting pipes, vacuum suckers, fixed blocks and control switches, the aluminum alloy plates inside the machine base can be taken conveniently, and the taking difficulty of the aluminum alloy plates inside the machine base is reduced.

Owner:哈尔滨东轻金属材料加工有限公司

Sheet printing device

Owner:江西金泰源陶瓷有限公司

Mechanical casting pouring system

ActiveCN112276061AScientific and reasonable structureEasy to useFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention discloses a mechanical casting pouring system. A second electric sliding rail is installed in the middle of the top end of a workbench; a sliding block is slidably connected to the outerend of the second electric sliding rail; a containing barrel is rotatably connected to the top end of the sliding block; a lower die is placed in the containing barrel; an upper die is connected to the top end of the lower die in a clamped mode; a pouring hole is formed in the middle of the top end of the upper die; and a pouring mechanism is clamped inside the pouring hole. The mechanical casting pouring system provided by the invention is scientific and reasonable in structure and safe and convenient to use; a pouring mechanism is arranged, and when a conveying pipe is slowly pulled out through the pouring mechanism and a scraper blade, a solution left on the outer surface of the conveying pipe can be conveniently scraped into the dies again, so that pouring liquid is prevented from flowing out; and in addition, the pouring liquid flowing out of the side of a threaded guide piece can be conveniently collected and guided through a collecting barrel, so that the pouring liquid slowlyflows into the dies through the collecting barrel, and large fluctuation of the pouring liquid in the dies is avoided.

Owner:广东金志利科技股份有限公司

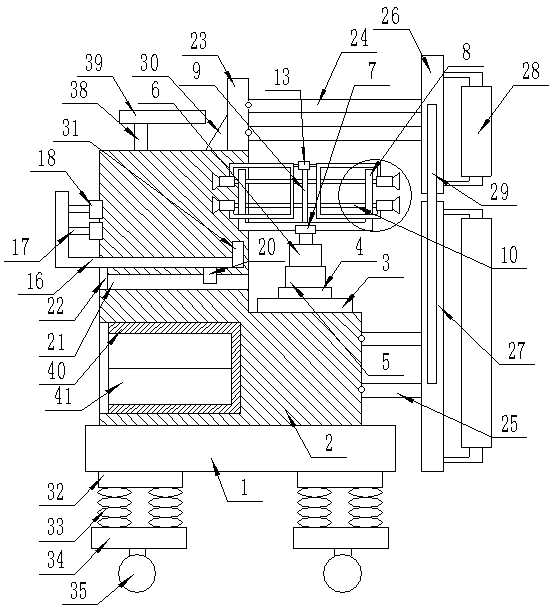

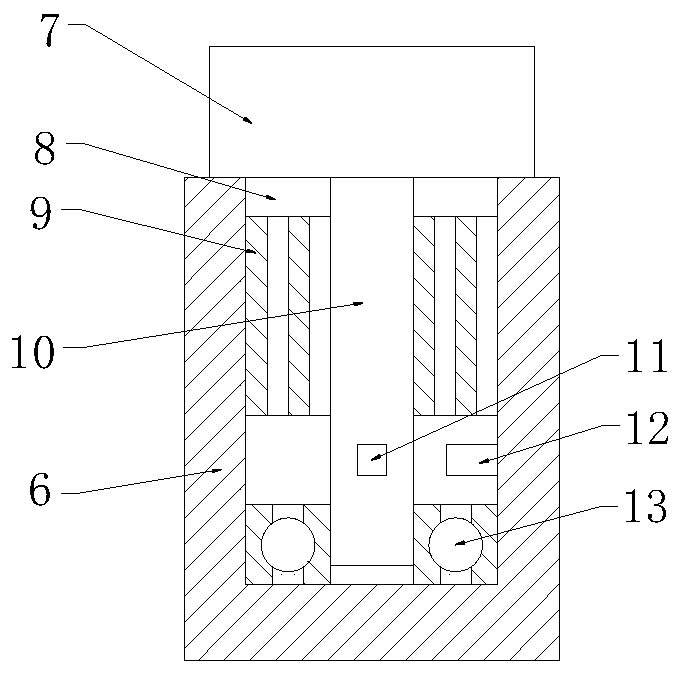

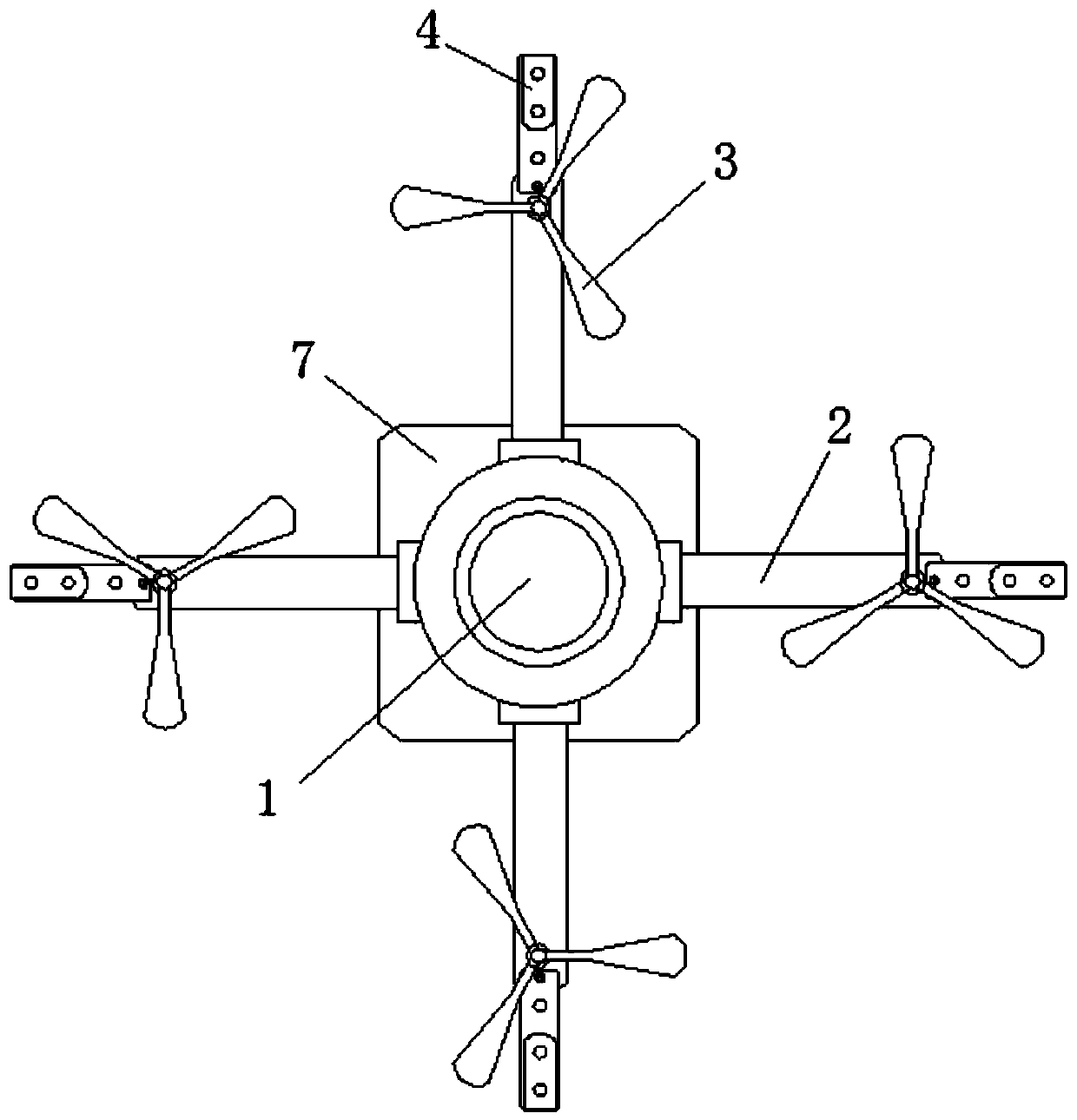

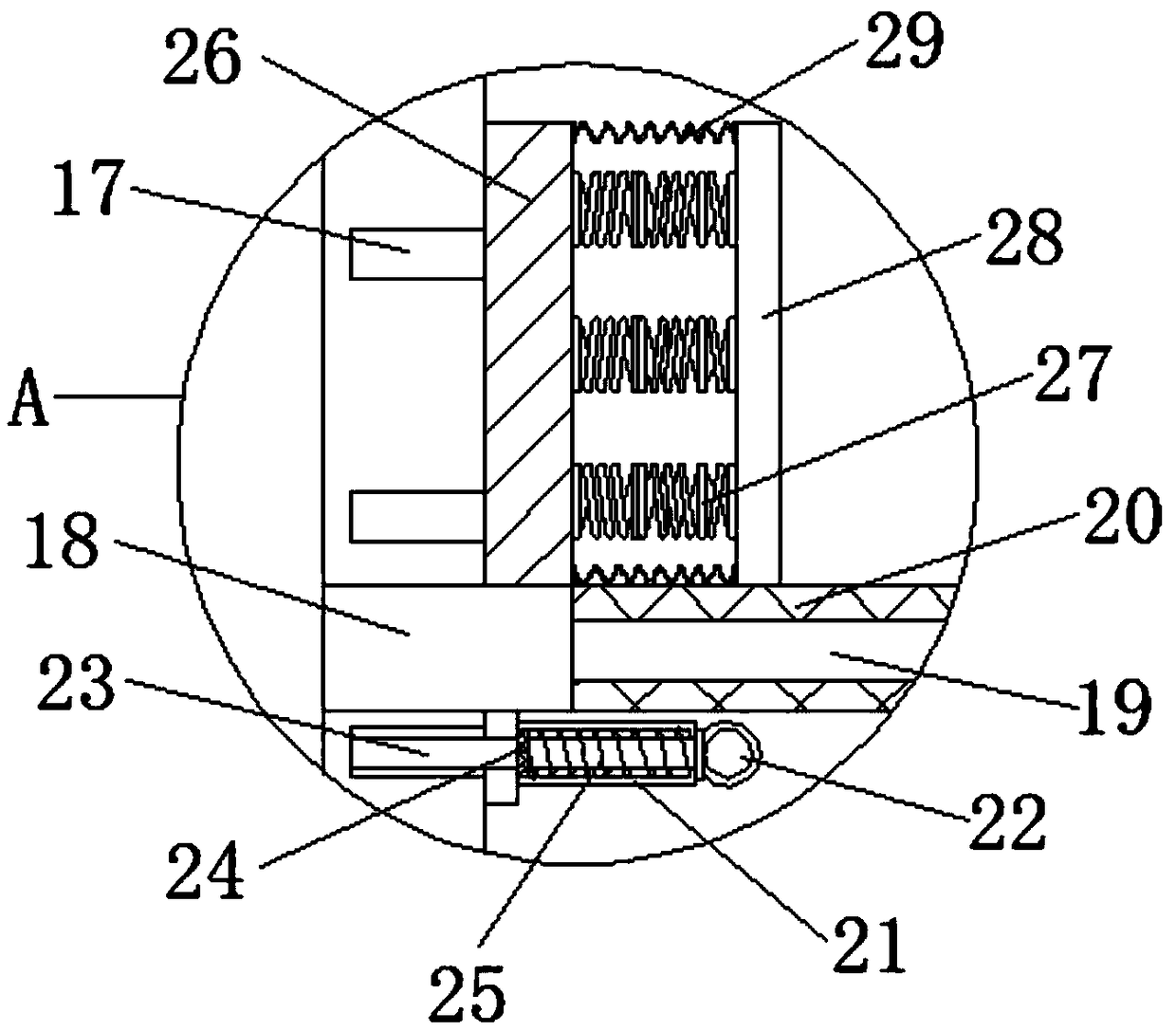

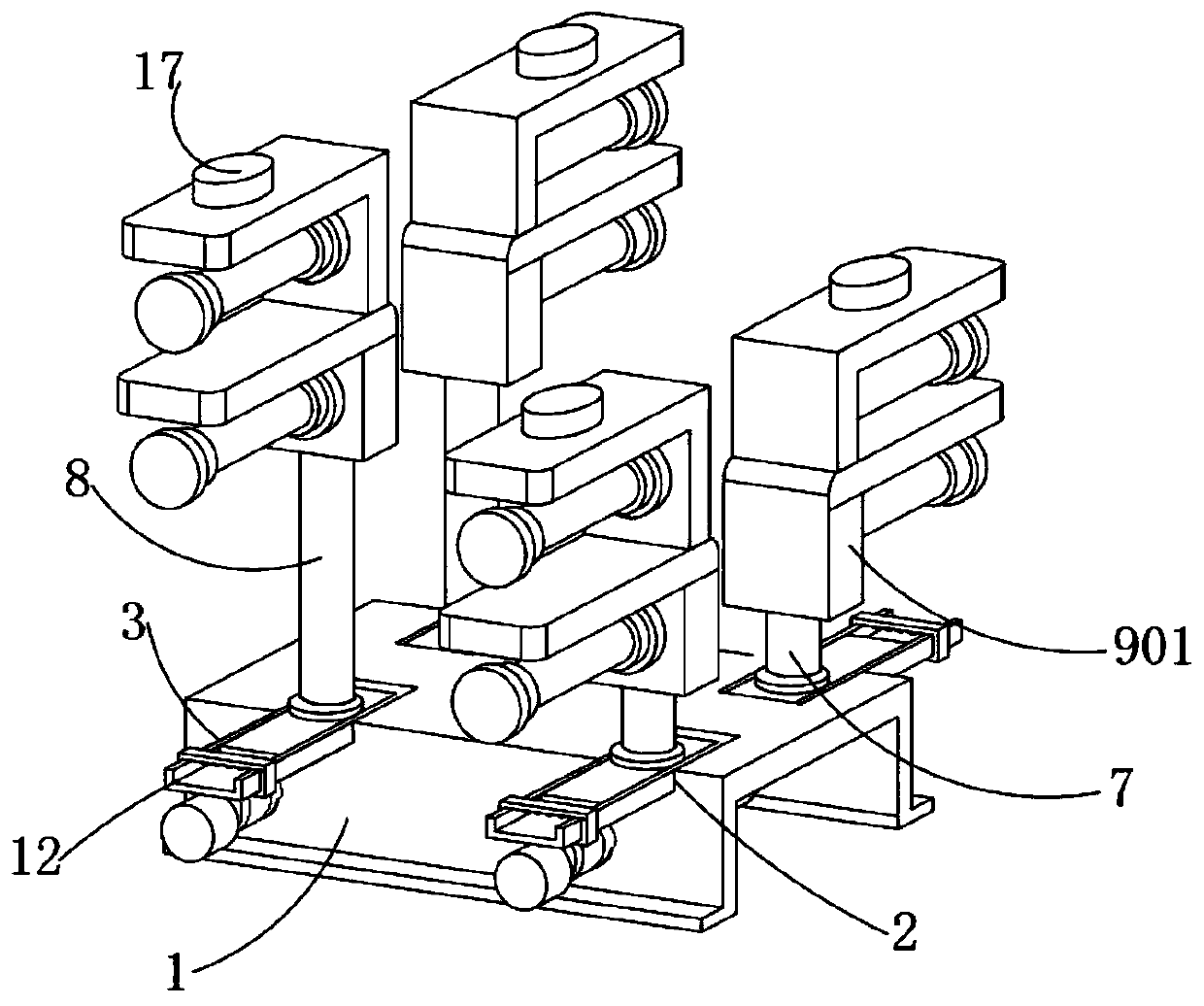

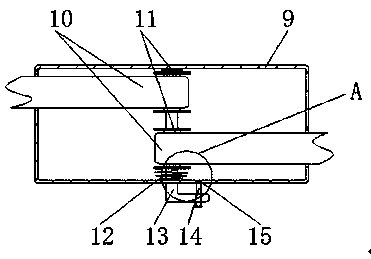

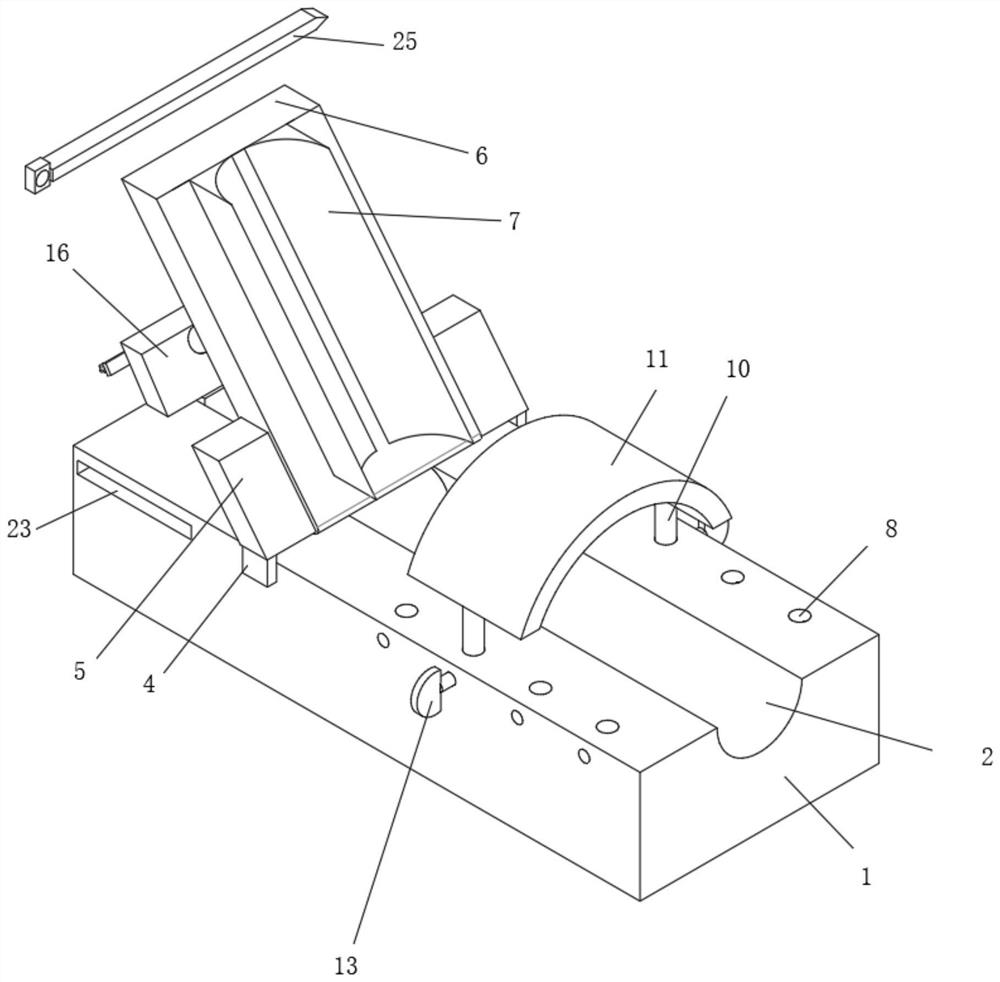

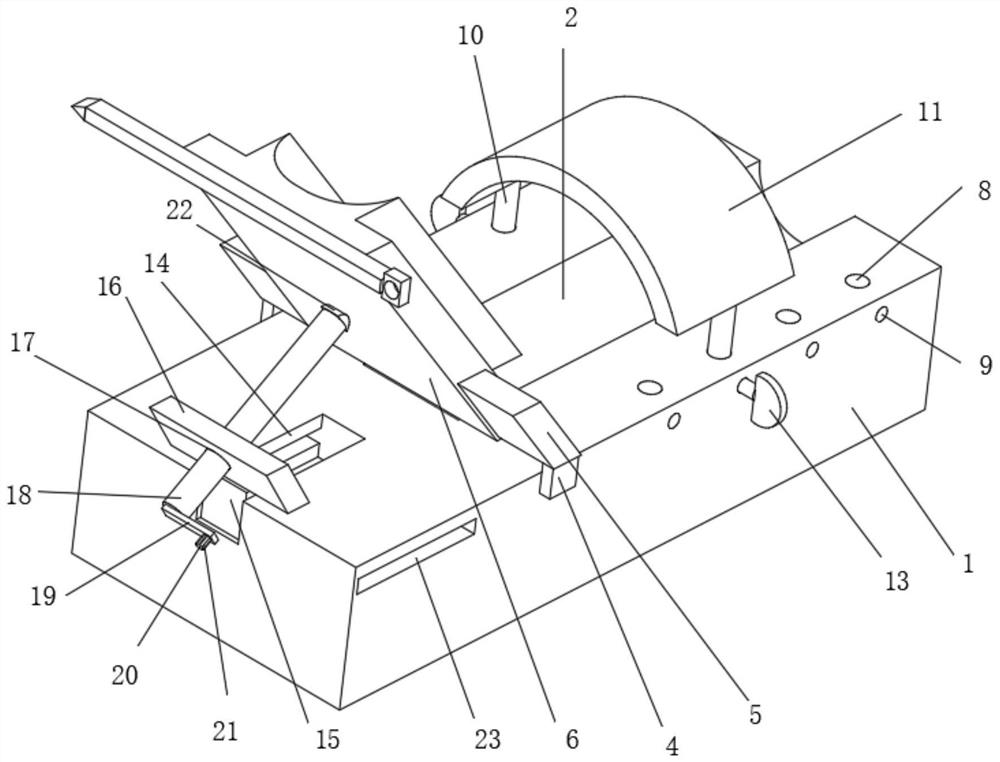

Adjustable die holder for machining workpieces

PendingCN110202054AEasy to squeeze and fixSimplifies the process of adjusting multiple screws and nutsShaping toolsMetal-working feeding devicesEngineeringExtrusion

The invention belongs to the field of die processing, and particularly relates to an adjustable die holder for processing workpieces. The adjustable die holder comprises an A support, an adjusting mechanism, a B support, a driving mechanism, an extruding mechanism, a moving mechanism and the like; the swing of the die holder can be distinguished from the extruding of the extruding mechanism through the design that a connecting rod presses down or not, so that the adjusting mechanism has two different output adjusting modes; the effect of maintaining the extruding mechanism to extrude the workpieces is achieved through the matching design of unidirectional teeth on a arc strip and a D gear; and in addition, due to the design of the extruding mechanism, a baffle, a extruding plate and the moving mechanism, the workpieces with different widths can be well extruded and fixed so as not to move during processing. Compared with the prior art, swing adjustment of the die holder and the extrusion fixing of the workpieces can be operated very conveniently, the process of complex adjustment of a plurality of screws and nuts in the prior art is greatly simplified, and the processing efficiencyof the workpieces is greatly improved.

Owner:HANGZHOU DIANZI UNIV

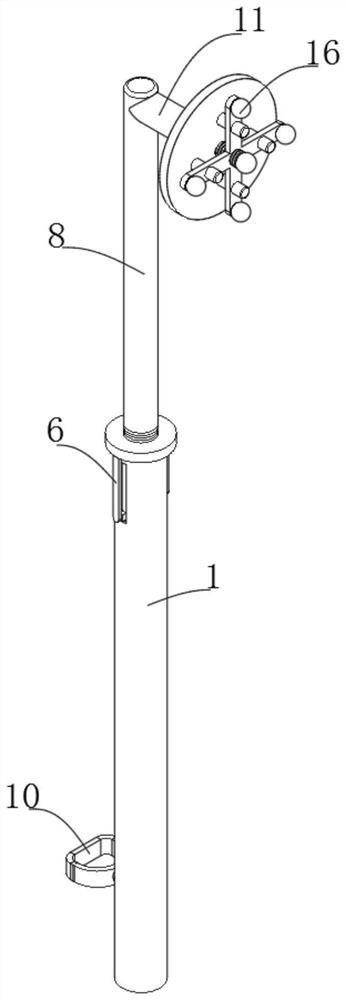

Portable face brick hollowing detection equipment for engineering supervision

InactiveCN112557507AEasy to placeEasy to installAnalysing solids using sonic/ultrasonic/infrasonic wavesConstruction engineeringScrew thread

The invention discloses portable face brick hollowing detection equipment for engineering supervision. Sliding grooves are symmetrically formed in the top of the outer end of a supporting rod, guide rods are fixedly connected into the sliding grooves, sliding blocks are slidably connected to the outer ends of the guide rods, and rotating shafts are rotatably connected to the outer ends of the sliding blocks; and the outer end of each rotating shaft is fixedly connected with a supporting frame, and the top of the supporting rod is provided with a threaded groove. According to the structure, when connection needs to be disassembled, a connecting rod is screwed out, and the connecting rod is left in the supporting frames; and through cooperation of the sliding blocks and the rotating shafts,after the connecting rod is moved upwards by a certain distance, the supporting frames are rotated conveniently, and a connecting frame is folded to the outer end of the supporting rod; meanwhile, theconnecting rod is conveniently placed through a placing frame; and one end of the edge part of the connecting rod is conveniently extruded and fixed due to the action of an elastic belt, so that theconnecting rod is conveniently folded, the occupied area is reduced, and the detection equipment is conveniently carried.

Owner:安徽家思特涂料有限责任公司

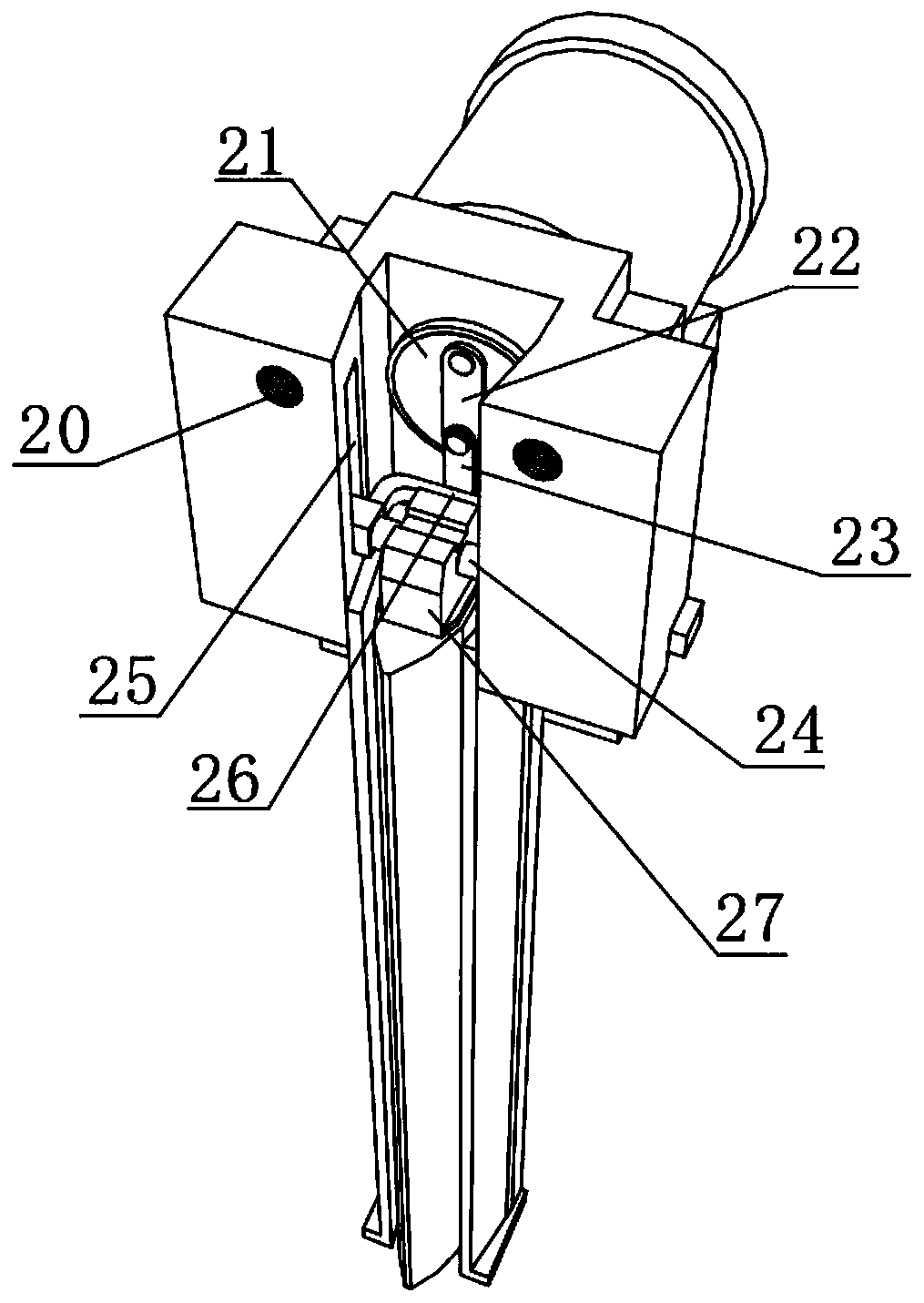

Firmly-fixed water suction pump

InactiveCN107676252AEasy to fixEasy to squeeze and fixPositive displacement pump componentsLiquid fuel engine componentsEngineeringPlunger

The invention relates to the technical field of water suction pumps and discloses a firmly-fixed water suction pump. The firmly-fixed water suction pump comprises a water suction pump body. The bottomof the water suction pump body is fixedly connected to the bottom of the inner wall of a fixing sleeve. The side faces of the fixing sleeve are movably connected with fixing devices. The bottom of the fixing sleeve is fixedly connected with a supporting plate. The two sides of the bottom of the supporting plate are fixedly connected with a first fixing support and a second fixing support correspondingly. The outer surface of the first fixing support is provided with fixing holes, the bottom inside the first fixing support is movably connected with an expansion link, the top of the expansion link is connected with the fixing holes through fixing pins in a clamped manner, and the bottom of the expansion link is fixedly connected with a first insertion rod. The firmly-fixed water suction pump is fixed to a slope through the first insertion rod on the bottom of the first fixing support and the second fixing support, the supporting plate can be in a horizontal state, the water suction pumpis extruded and fixed through the fixing devices, the water suction pump body is conveniently fixed, and the water suction pump body conveniently works on the slope.

Owner:JOHNSTON FLOW TECH WUXI CO LTD

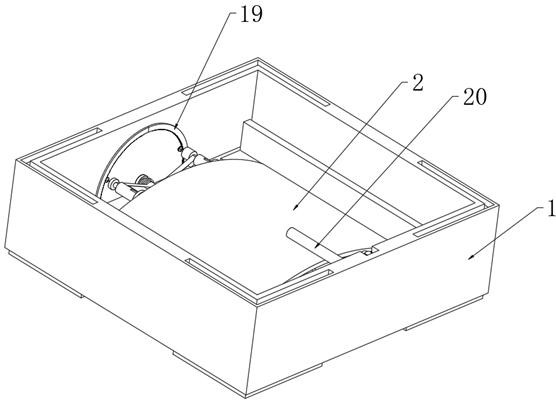

Transportation device for non-planar glass processing

ActiveCN114701859AUniform supportEven by forceConveyorsCharge manipulationMechanical engineeringIndustrial engineering

The invention relates to the field of glass transportation devices, in particular to a transportation device for non-planar glass processing. Comprising a loading frame and curved glass placed in the loading frame. A circumferential clamping mechanism is arranged in the loading frame, the circumferential clamping mechanism comprises a bearing roller assembly arranged below the curved glass and a group of clamping plate assemblies linked with the bearing roller assembly, and the circumferential clamping mechanism further comprises a front-back limiting assembly mounted on a bearing roller; by arranging the loading frame, the symmetrically arranged bearing rollers, the clamping plates which are linked with the bearing rollers and are arranged on the two sides of the curved glass, and the limiting rings which are arranged on the bearing rollers, are linked with the bearing rollers and are used for clamping the front end and the rear end of the curved glass, the curved glass is uniformly supported, so that the curved glass is uniformly stressed and is not easy to deform; meanwhile, the curved glass is circumferentially clamped, so that the curved glass has good stability, in addition, the circumferential clamping mechanism is triggered by the dead weight of the curved glass, the curved glass is convenient to assemble and disassemble, and the use is convenient.

Owner:徐州旭东玻璃有限公司

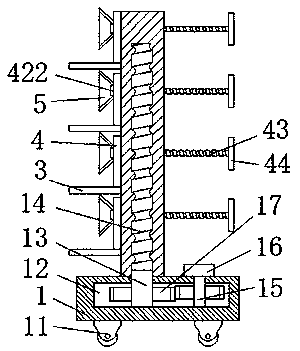

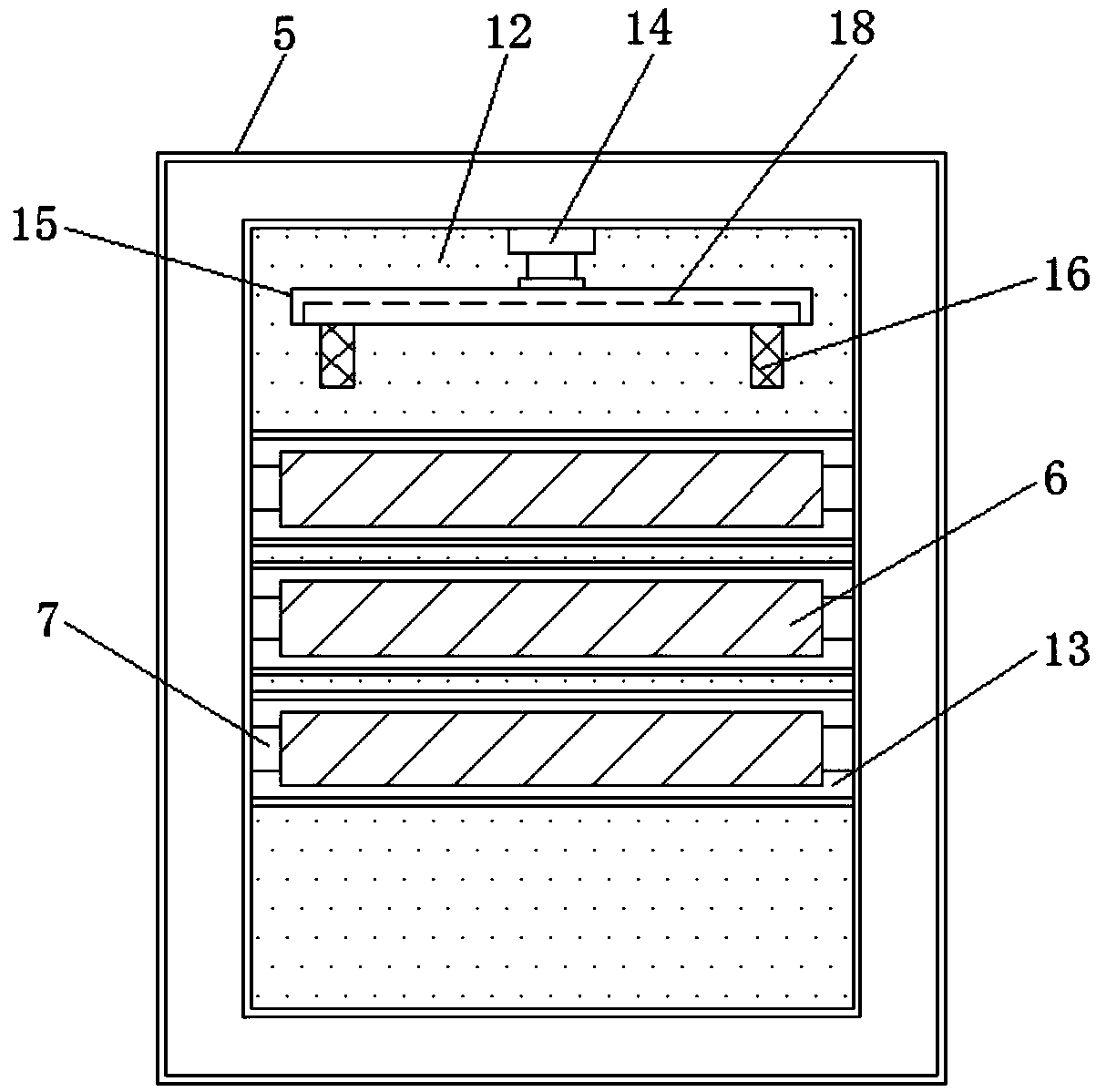

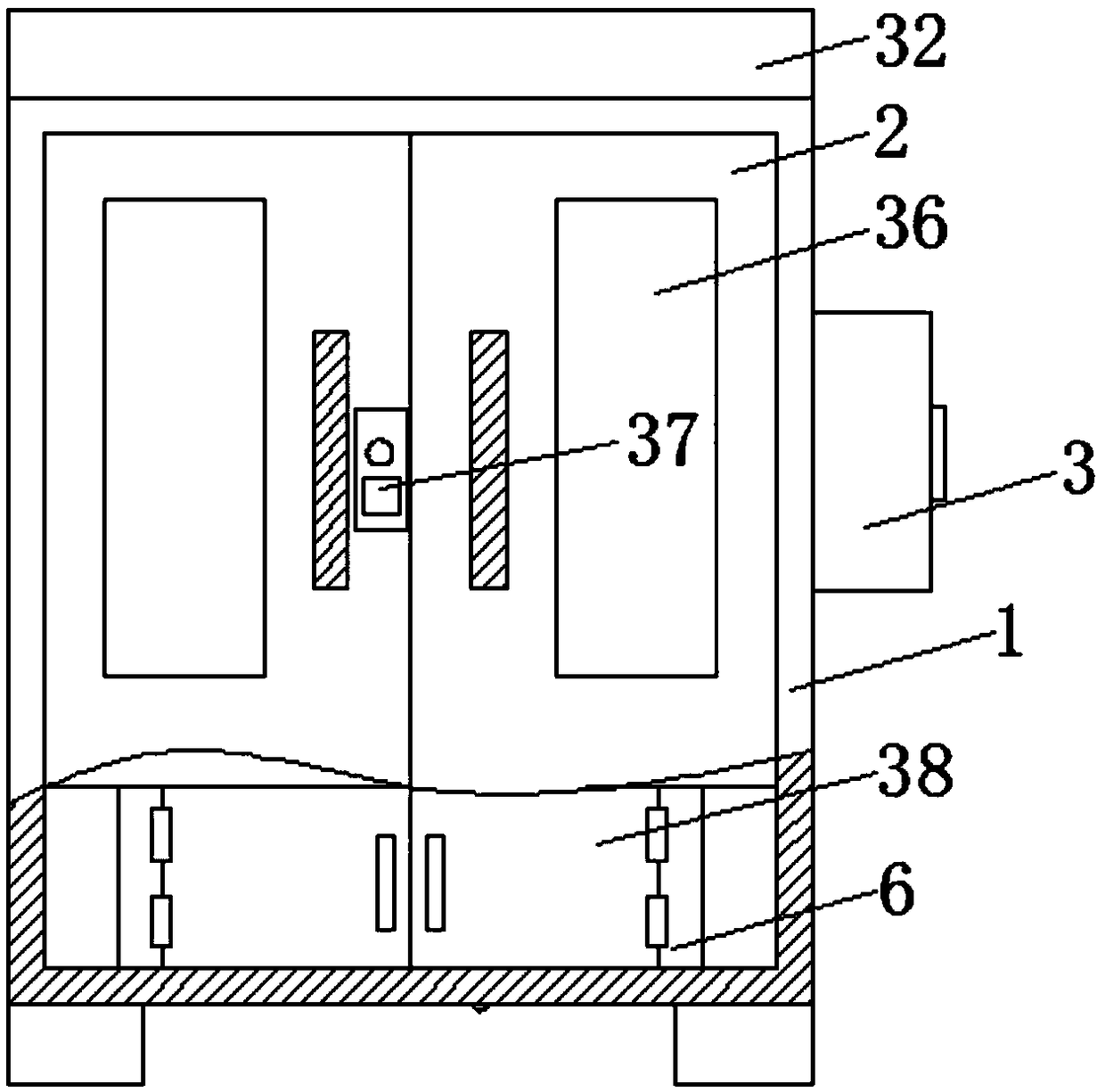

Hospital file managing device

InactiveCN109363376AImprove filtering effectEasy to squeeze and fixBook cabinetsFurniture partsEngineeringFile management

The invention relates to the technical field of file management, in particular to a hospital file managing device which comprises a cabinet body. Cabinet doors are symmetrically formed outside the cabinet body. A device box is arranged outside the cabinet body. A PLC is arranged in an inner cavity of the device body. A first partition plate is arranged in an inner cavity of the cabinet body. Through holes are formed in the upper end of the first partition plate at equal intervals. A box body is arranged at the lower end of the first partition plate. A second partition plate is connected with the inner cavity of the box body. Through holes are formed in the upper end of the second partition plate at equal intervals. An installation frame is arranged at the upper end of the second partitionplate. A dustproof net, a quick lime layer and drying cotton are sequentially arranged on the inner side of the installation frame from bottom to top. The hospital file managing device is reasonable in structural design, high in practicability and convenient to use and can conveniently dehumidify air in the file managing device and effectively protect files, and the distance of the partition plates inside the file managing device can be conveniently adjusted to fix file covers.

Owner:侯凯

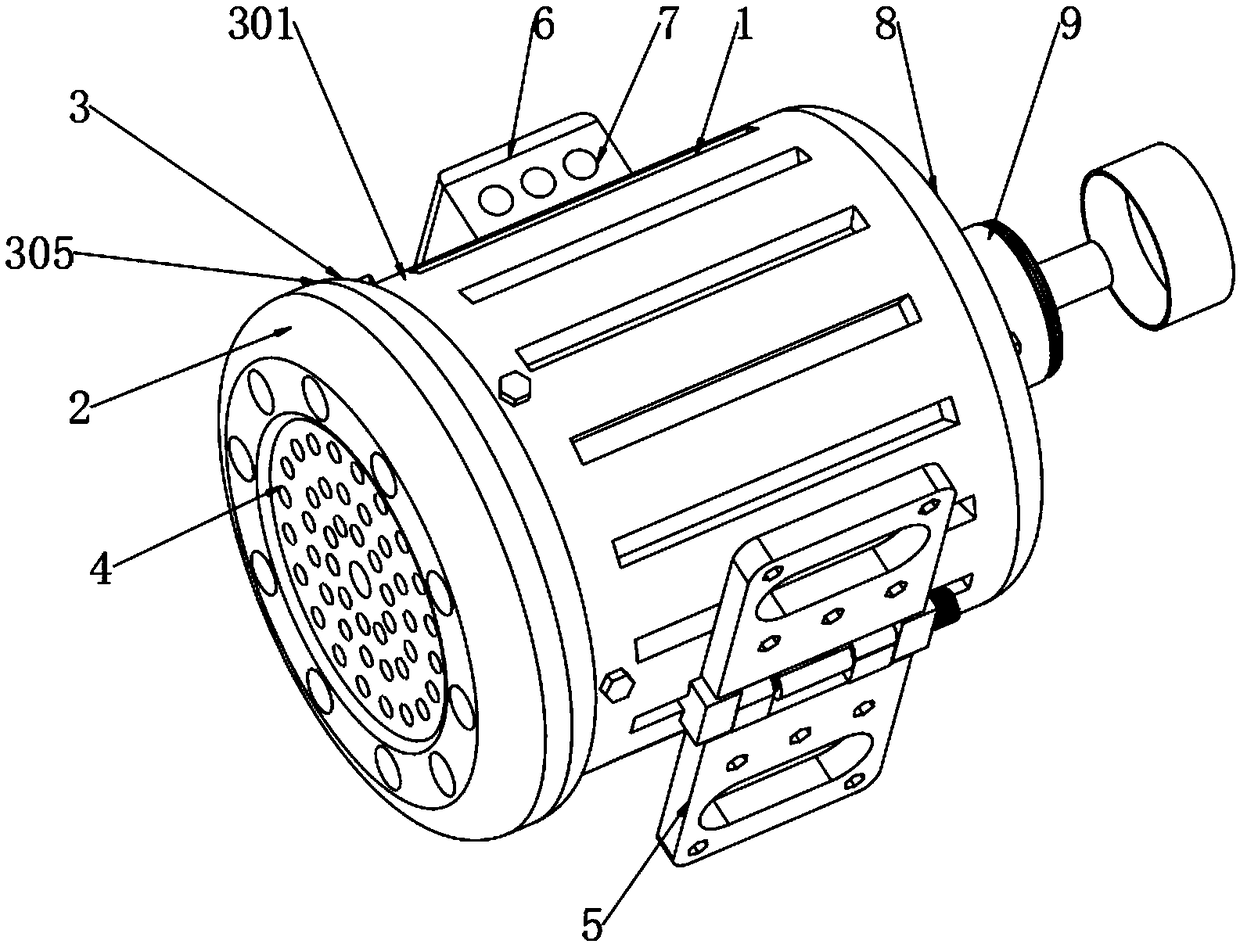

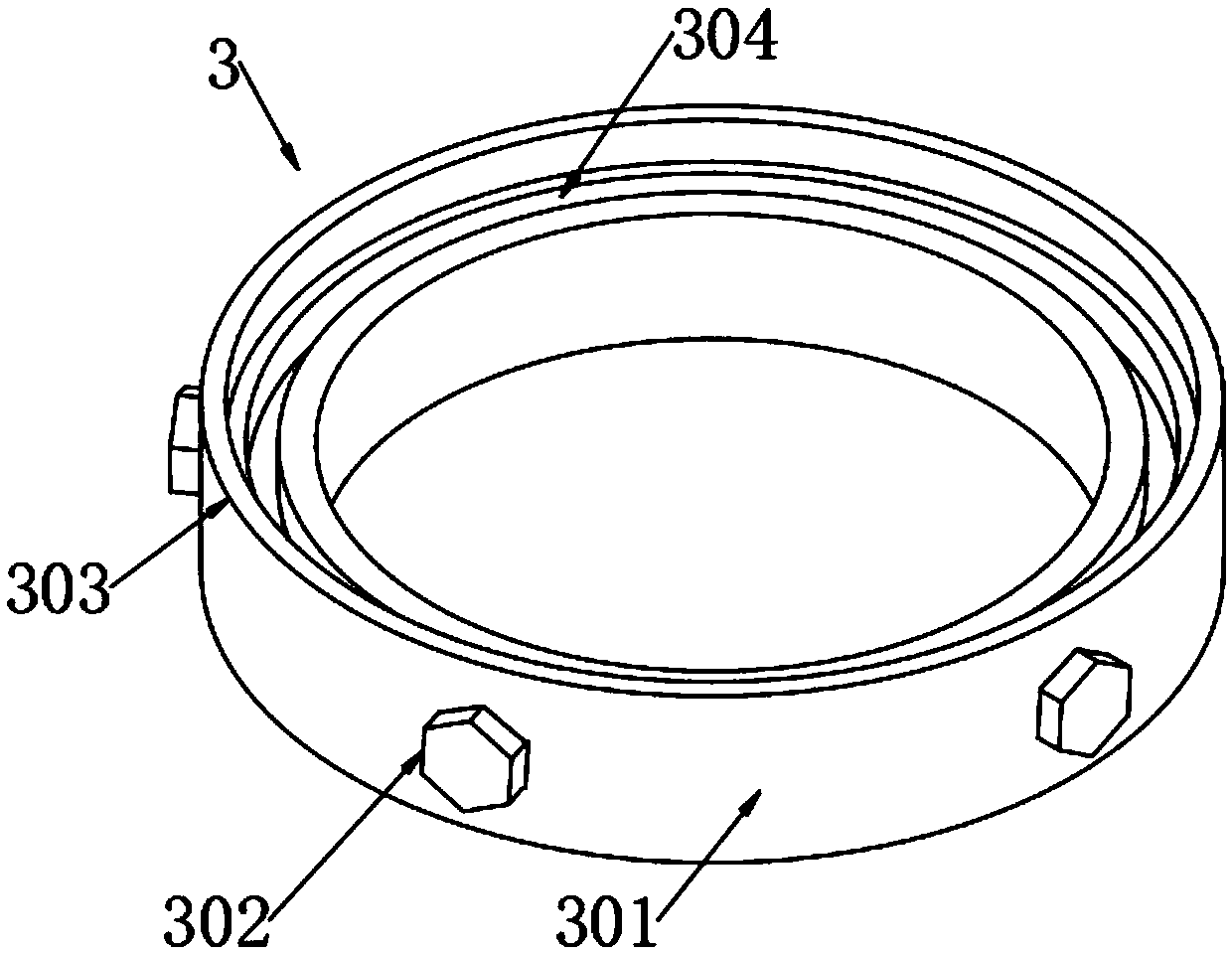

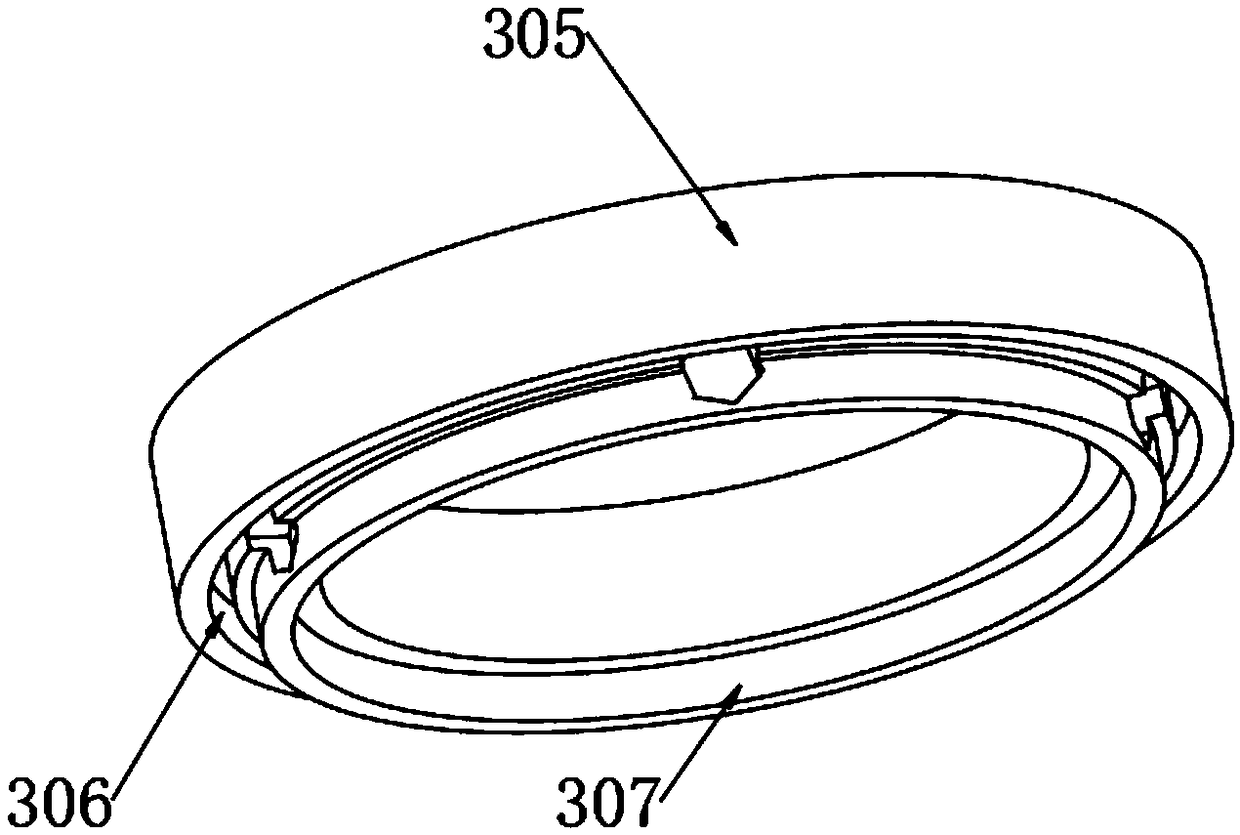

Dustproof and heat dissipation type portable motor

InactiveCN108900028AScientific and reasonable structureEasy to useCooling/ventillation arrangementSupports/enclosures/casingsEngineering

The invention discloses a dustproof and heat dissipation type portable motor. The dustproof and heat dissipation type portable motor comprises a motor shell, wherein a heat dissipation assembly is mounted at the lower end of the motor shell; a fixing assembly is mounted at one side of the motor shell. The dustproof and heat dissipation type portable motor is scientific and reasonable in structureand safe and convenient to use; the heat dissipation assembly is arranged and gas is convenient to circularly flow in the motor under the action of an air inlet hole, a ventilation channel, an air outlet plate and a heat dissipation hole, so that the heat dissipation effect of the device is improved and the problems that the hole is formed in the outer side of the device to carry out heat dissipation so that rainwater enters the device from the hole are avoided; meanwhile, the ventilation channel is arranged so that the inner part of the motor is not in direct contact with the external environment and the damp-proof and dustproof effect of the device is increased; the fixing assembly is arranged, and a first fixed plate and a second fixed plate are convenient to combine under the action ofa fixed block, a fixed shaft, a first rotary shaft and a second rotary shaft; the motor is convenient to carry and transport by utilizing the effect of a carrying groove, and various functions of carrying and fixing are realized; the motor is more convenient to use.

Owner:天津风云顶知识产权服务有限公司

Modularized cooling capacity sharing device

InactiveCN109595876AScientific and reasonable structureEasy to useMachines using electric/magnetic effectsRefrigeration devicesModularityEngineering

The invention discloses a modularized cooling capacity sharing device. The modularized cooling capacity sharing device comprises a shell, a semiconductor refrigeration sheet cold end is mounted on oneside of the shell, and a fixed sharing assembly is mounted on one side of the semiconductor refrigeration sheet cold end. The modularized cooling capacity sharing device is scientific and reasonablein structure and safe and convenient to use, a semiconductor refrigeration sheet is arranged, through the role of the semiconductor refrigeration sheet cold end and the semiconductor refrigeration sheet hot end, the purpose of refrigeration is achieved, then the use of a ventilation plate, an air exhaust fan and a first cold air shared channel, the transmission of the cold air is accelerated, thecold air generated by the semiconductor refrigeration sheet is transmitted and led to the first cold air sharing channel for use, the refrigeration time is reduced, the refrigeration cost is reduced,the use range is wider, the fixed sharing assembly is arranged, through role of a first mounting plate, a connecting groove and a limiting groove, the installation and disassembly of the first mounting plate are facilitated, a cold air blowing module, a refrigeration module and a plurality of modules are conveniently fixed simultaneously, and the work efficiency is improved.

Owner:余跃

Anti-blocking feeding mechanism for textile elasticizer

ActiveCN110607585AScientific and reasonable structureEasy to useTextiles and paperEngineeringSupport plane

The invention discloses an anti-blocking feeding mechanism for a textile elasticizer. The anti-blocking feeding mechanism comprises a support frame, and grooves are formed in four corners of the top end of the support frame; a fixing plate is welded on the inner wall of each groove, and a sliding groove is formed in the top end of each fixing plate; a sliding block is connected in each sliding groove in a sliding manner, and a bearing is embedded in the edge of the top end of each sliding block; a first supporting rod is nested inside each of the two bearings; the anti-blocking feeding mechanism is scientific and reasonable in structure and is safe and convenient to use, the grooves, the fixing plates, the sliding grooves and the sliding blocks facilitate moving of the first support rods and second support rods so that the tightness of a textile material can thus be adjusted during feeding, and the material is prevented from loosening and falling off during feeding; an L-shaped connecting plate, a rotating shaft and a guide channel facilitate guiding of the textile material, and therefore, it is prevented that when the textile material is fed into the elasticizer for elasticizing operation, the textile material is entangled, which causes the textile material being blocked on the elasticizer.

Owner:长兴剑华纺织有限公司

Infusion tube fixing glove convenient to wear

The invention discloses an infusion tube fixing glove convenient to wear. The infusion tube fixing glove convenient to wear comprises a glove main body, a first magic tape and a fixed frame; an outercover body is arranged above the glove main body; a through groove is formed in the upper surface of the glove main body; a second magic tape is fixed to the outer side of the through groove; the glove main body is fixed to the bottom end of the second magic tape; the first magic tape is fixed to the inner side surface of the outer cover body; a protecting cover is arranged in the middle of the inner side surface of the outer cover body; the glove main body is mounted above the fixed frame; and fixing straps are arranged on the left side and the right side of the fixed frame. A fixing rod anda winding plate are mounted on the infusion tube fixing glove convenient to wear, the fixing rod and the winding plate rotate to conveniently wind and store the fixing straps, and the whole infusion tube fixing glove is well placed; and meanwhile, through force accumulation of a torsion spring, the fixing rod automatically rotates in the reversed direction, and therefore, the fixing straps are conveniently pulled out for use, and the operation of a user is facilitated.

Owner:李蕾

Environment-friendly building material brick hardness detection device capable of timely cleaning wastes

InactiveCN112485103AImprove stabilityImprove cleaning effectInvestigating material hardnessElectric machineryBuilding material

The invention discloses an environment-friendly building material brick hardness detection device capable of timely cleaning wastes. The environment-friendly building material brick hardness detectiondevice comprises a detection box, a pressure sensor, a data display device, a data processing device and an air pump, a placement table is fixedly installed on the lower portion of the interior of the detection box, and a rotating wheel rod is rotatably connected to the lower portion of the detection box; and a first lead screw is arranged in the placement table, a material collecting frame is arranged at the lower part of the inner side of the detection box, a movable rod is connected to the upper portion of the detection box, rotating gears are arranged on the left side and the right side of the movable rod, and second forward and reverse motors are fixedly installed at the rear ends of the rotating gears. According to the environment-friendly building material brick hardness detectiondevice capable of cleaning waste in time, a bevel gear drives the first lead screw to rotate, the first lead screw is in threaded connection with limiting rods conveniently, the four limiting rods onthe surface of the placement table can move inwards conveniently, bricks of different sizes can be extruded and fixed conveniently, and the brick detection stability is improved.

Owner:陕西中科文鼎信息科技有限公司

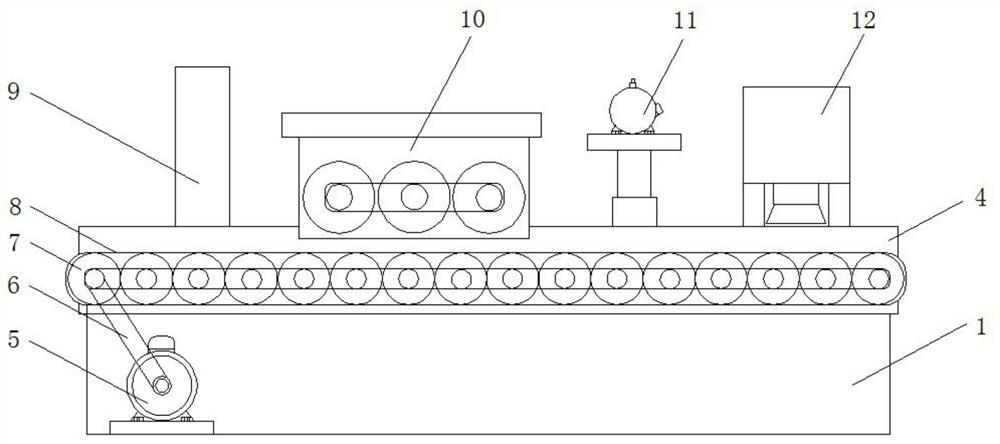

Sponge mattress processing integrated device

PendingCN113414801AEasy to replaceAdjust cutting heightCleaning using toolsCleaning using gasesMattress dustElectric machinery

The invention discloses a sponge mattress processing integrated device. The sponge mattress processing integrated device comprises a machine body, a first motor, a mattress cutting mechanism and a mattress overturning mechanism, connecting frames are arranged on the two sides of the machine body, a machine frame is arranged above the machine body, meanwhile, protective fences are arranged on the two sides of the machine frame, the first motor is arranged in the machine body, the first motor is connected to a conveying roller in a rotating mode through a belt transmission structure, meanwhile, a conveying belt is arranged on the outer side of the conveying roller, the mattress cutting mechanism is arranged above the conveying belt, a mattress cleaning mechanism is arranged on one side of the mattress cutting mechanism, the mattress overturning mechanism is arranged on one side of the mattress cleaning mechanism, and a mattress dust removal mechanism is arranged on the other side of the mattress overturning mechanism. According to the sponge mattress processing integrated device, the mattress cutting mechanism and the mattress overturning mechanism are arranged, the mattress cutting mechanism can conveniently cut a sponge mattress, the mattress overturning mechanism can conveniently overturn sponge, manual overturning is not needed, and the sponge mattress processing efficiency is greatly improved.

Owner:盐城酷艺家居有限公司

Automatic grinding machine tool with cleaning and recycling mechanism and using method of automatic grinding machine tool

InactiveCN113601360AReduce power supplyReduce cost consumptionGrinding carriagesGrinding drivesProcess engineeringEnergy cost

The invention relates to an automatic grinding machine tool with a cleaning and recycling mechanism and a using method of the automatic grinding machine tool. According to the automatic grinding machine tool with the cleaning and recycling mechanism and the using method of the automatic grinding machine tool, through a grinding base station assembly and a cleaning mechanism, a processing mechanism, a recycling mechanism, an adaptive tool and a protective cover assembly of the grinding base station assembly, impurities on the surface of a workpiece can be pretreated when the workpiece is subjected to grinding machining; and the probability of unnecessary abrasion caused by impurities in the subsequent grinding process is reduced, the grinding quality of the workpiece is effectively guaranteed, generated flying dust and irritant smoke can be sucked away in time in the machining period, the environment-friendly production and machining concept is better met, generated grinding chips, grinding wires difficult to clean and the like can be conveniently cleaned after machining, the time, manpower and energy cost invested for cleaning grinding wires in a traditional mode is effectively reduced, grinding fluid and grinding chips can be conveniently separated, and follow-up recycling is more convenient.

Owner:湖南致用科技有限公司

Pediatric blood drawing nursing device

PendingCN114027837AEasy to draw bloodPreventing failed blood drawsDiagnostic recording/measuringSensorsPhysical medicine and rehabilitationNursing care

The invention relates to the technical field of medical apparatus and instruments, and discloses a pediatric blood drawing nursing device which comprises a mounting seat, a placement groove is formed in the side face of the mounting seat, and the placement groove is a half-circle-shaped groove. According to the invention, the upper arm of an arm is placed in a placing groove, the forearm of the arm is placed between two groups of stop blocks, the position of a second connecting block is adjusted through a supporting device, and the second connecting block drives a first connecting block to rotate by taking a first rotating block as an axis, so that the angle of the second connecting block is rotated to the most comfortable angle; an auxiliary fixing device is used for pressing the upper arm of a partition wall so as to be fixed, the locking device is used for positioning the auxiliary fixing device so that the auxiliary fixing device can be fixed, and the whole arm is fixed through the method so as to facilitate blood drawing. In the process, the situation that blood drawing fails due to the fact that the arms move randomly is prevented, and the practicability of the special device is enhanced.

Owner:马瑞红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com