Automatic grinding machine tool with cleaning and recycling mechanism and using method of automatic grinding machine tool

A recovery mechanism and grinding technology, which is applied to the parts of grinding machine tools, grinding frame, grinding bed, etc., can solve the problems such as inability to clean, and achieve the goal of reducing cost consumption, reducing power supply, and reducing friction damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

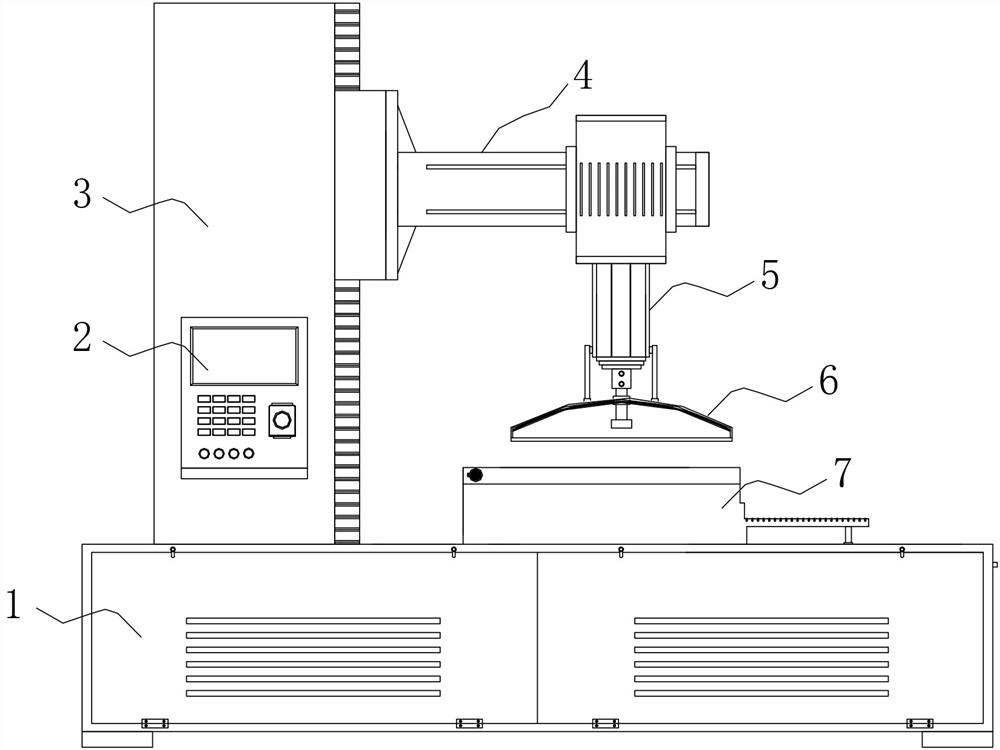

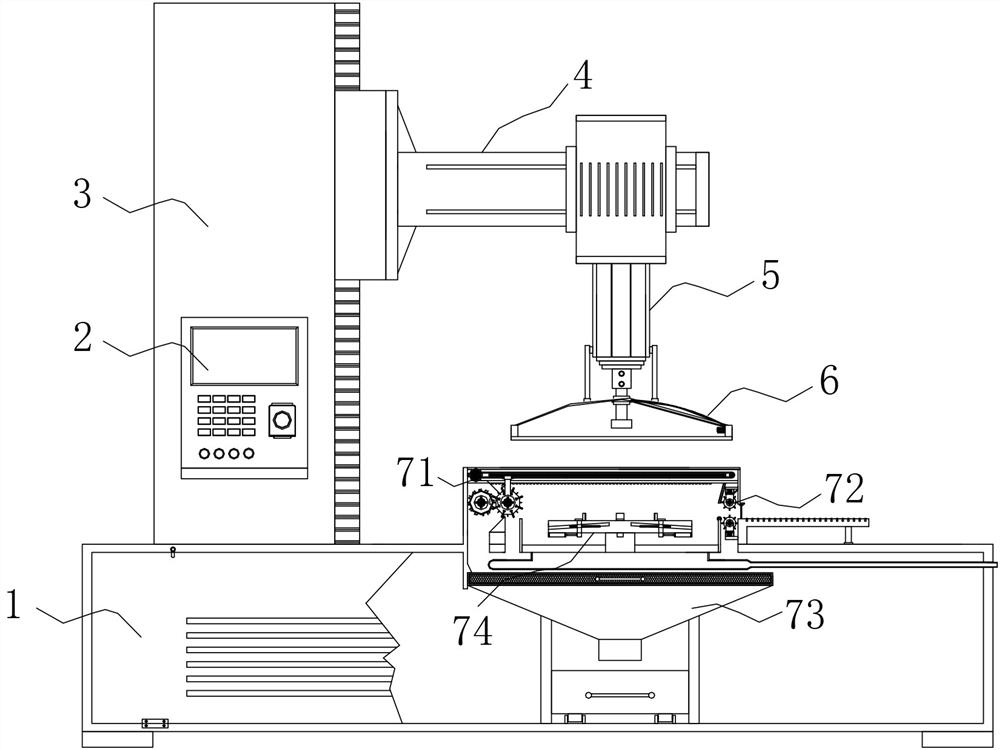

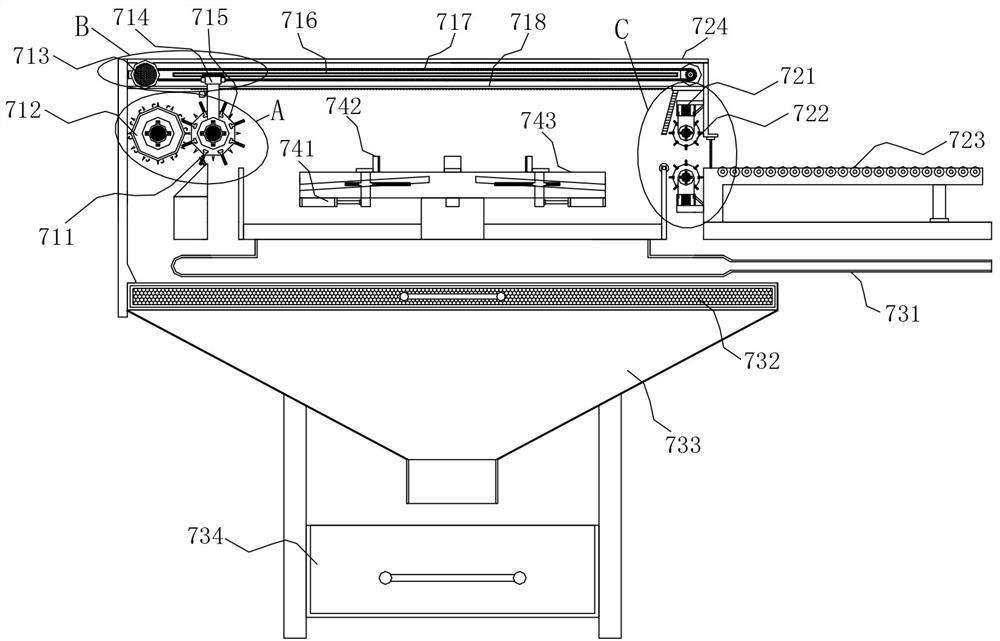

[0053] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 As shown, this embodiment proposes an automatic grinding machine tool with a cleaning and recovery mechanism, including a base 1, and a hydraulic vertical cabinet 3 is fixedly installed on one side of the upper end of the base 1, which can be used to provide power for lifting and lowering of cutter heads and grinding tools, ensuring overall operation The other side of the upper end of the base 1 is fixedly installed with a grinding abutment assembly 7 for processing the workpiece, which can be used to improve the processing effect on the workpiece. Therefore, this structure is designed to assist, and the outer surface of the front end of the hydraulic vertical cabinet 3 is fixed. The main console 2 used to control the machine tool is installed...

Embodiment 2

[0057] The scheme in embodiment 1 is further introduced below in combination with specific working methods, see the following description for details:

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 10 , Figure 12 and Figure 17 As shown, as a preferred embodiment, on the basis of the above method, further, the mobile support assembly includes rotating hangers 714 arranged at both ends of the cleaning drum 715, which is conducive to ensuring the stability of its operation structure, and a set of hangers 714 The interior is provided with the acceleration gear set 7141 that accelerates the rotation of the cleaning cylinder 715, which can make the rotation speed of the cleaning cylinder 715 faster and improve the cleaning effect. The grinding blade 7151 will only protrude when returning to a specific position, and the outer surfaces of the acceleration gear set 7141 and the deceleration gear set 714...

Embodiment 3

[0067] The schemes in Embodiment 1 and Embodiment 2 are further introduced below in conjunction with specific working methods, see the following description for details:

[0068] A method for using an automatic grinding machine tool with a cleaning and recovery mechanism, comprising the following steps:

[0069] Step 1, pretreatment stage: the workpiece is moved through the feeding table 723, and then passed between two groups of cleaning cylinder brushes 722, so as to clean the surface simply, and the spring kit 721 can make the workpiece pass through Cleaning the barrel brush 722 can maintain an effective clamping effect; Step 2, fixing stage: place the workpiece on the surface of the tooling seat 743, the small model can be settled and fixed by the top column 744, and the large model can be supported by the cylinder 741 on the top plate 742 to squeeze and fix, and at the same time, those special-shaped workpieces can be fixed through the auxiliary hole 745; Step 3, grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com