Portable face brick hollowing detection equipment for engineering supervision

A technology for hollowing out bricks and testing equipment, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Detect problems such as convenient installation and fixation of equipment to achieve the effect of reducing floor space and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

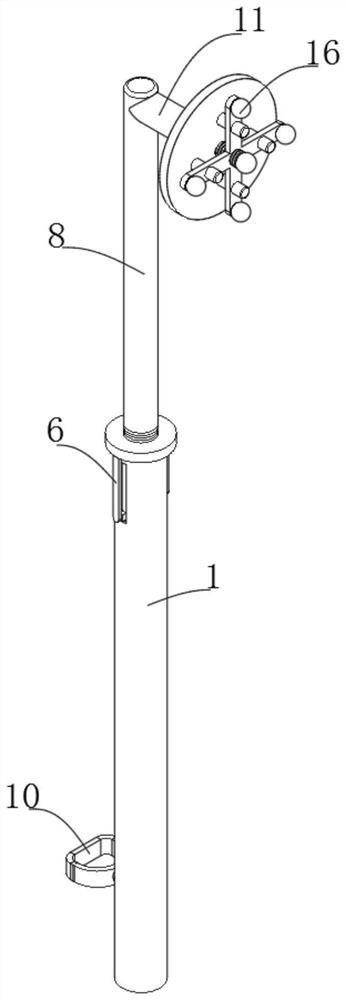

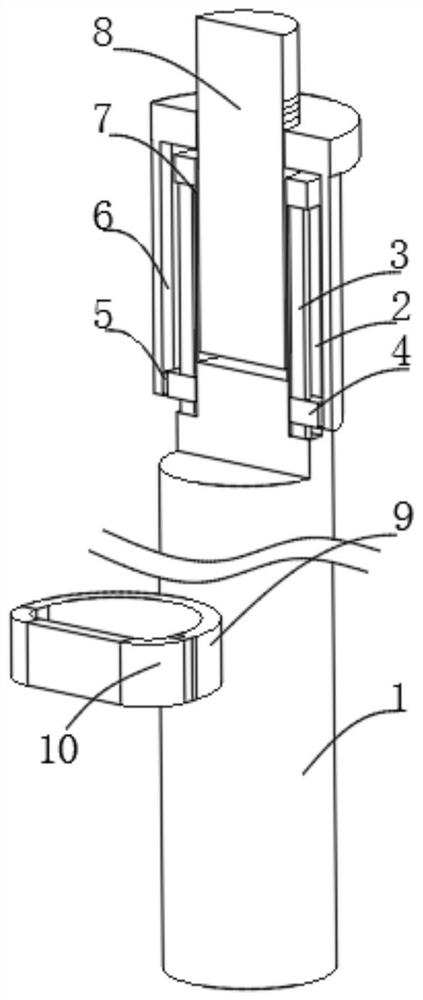

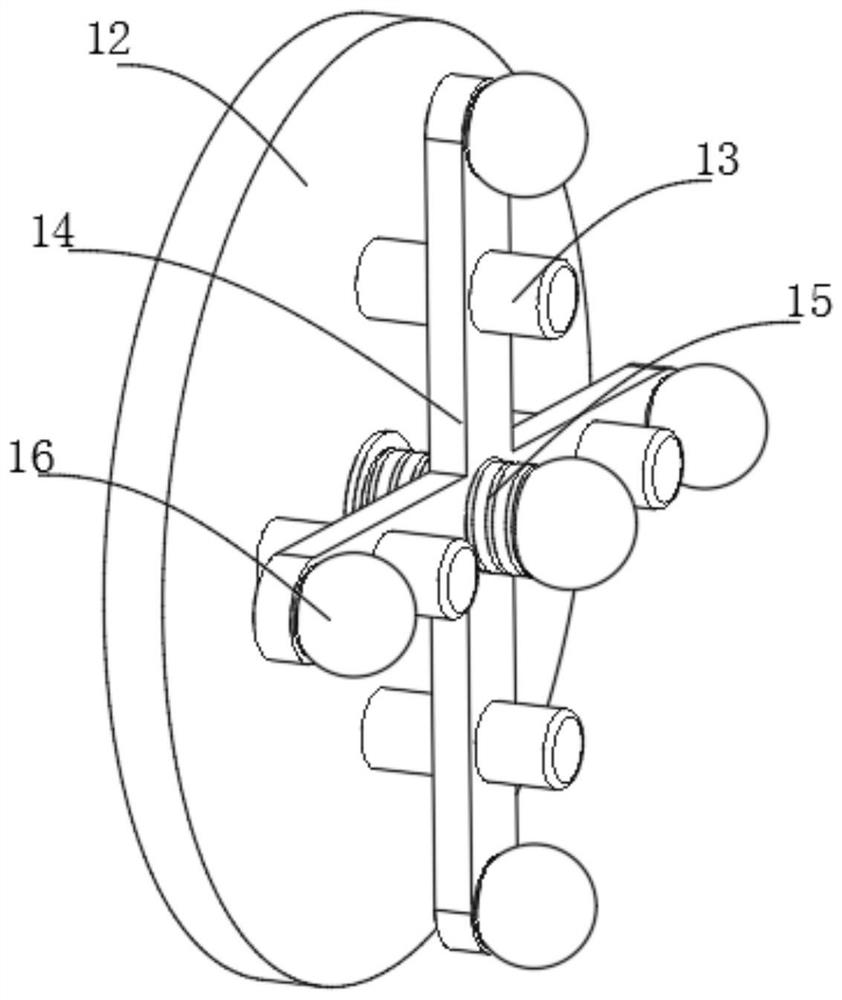

[0025] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a portable brick hollowing detection device for engineering supervision, including a support rod 1, a chute 2 is symmetrically opened at the top position of the outer end of the support rod 1, and the chute 2 is fixedly connected inside There is a guide rod 3, the outer end of the guide rod 3 is slidably connected with a slider 4, the outer end of the slider 4 is rotatably connected with a rotating shaft 5, the outer end of the rotating shaft 5 is fixedly connected with a support frame 6, and the top of the support rod 1 is provided with a thread groove 7, and the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com