Round tube inner wall grinding device for mechanical manufacturing

A technology for machine manufacturing and round pipes, which is applied to the field of grinding devices for the inner wall of round pipes for machine manufacturing, can solve the problems of increased work strength, poor fit, inconvenient grinding work, etc., so as to reduce work strength, improve fit, and avoid jamming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

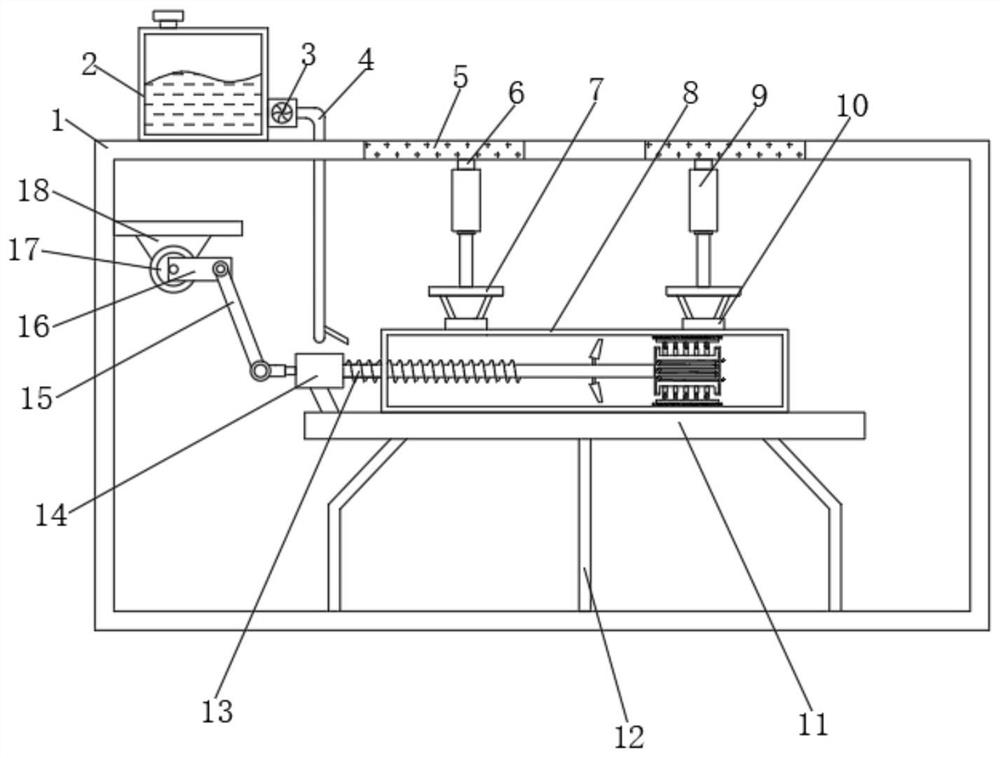

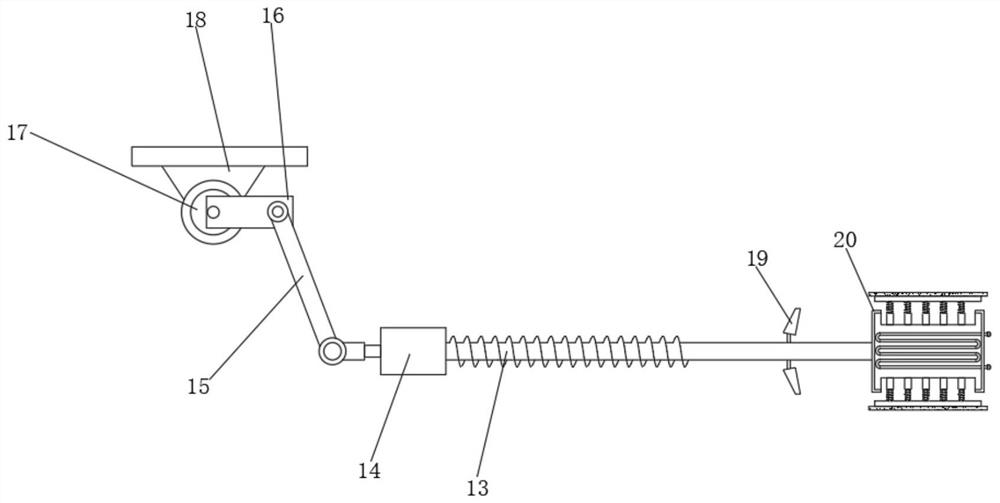

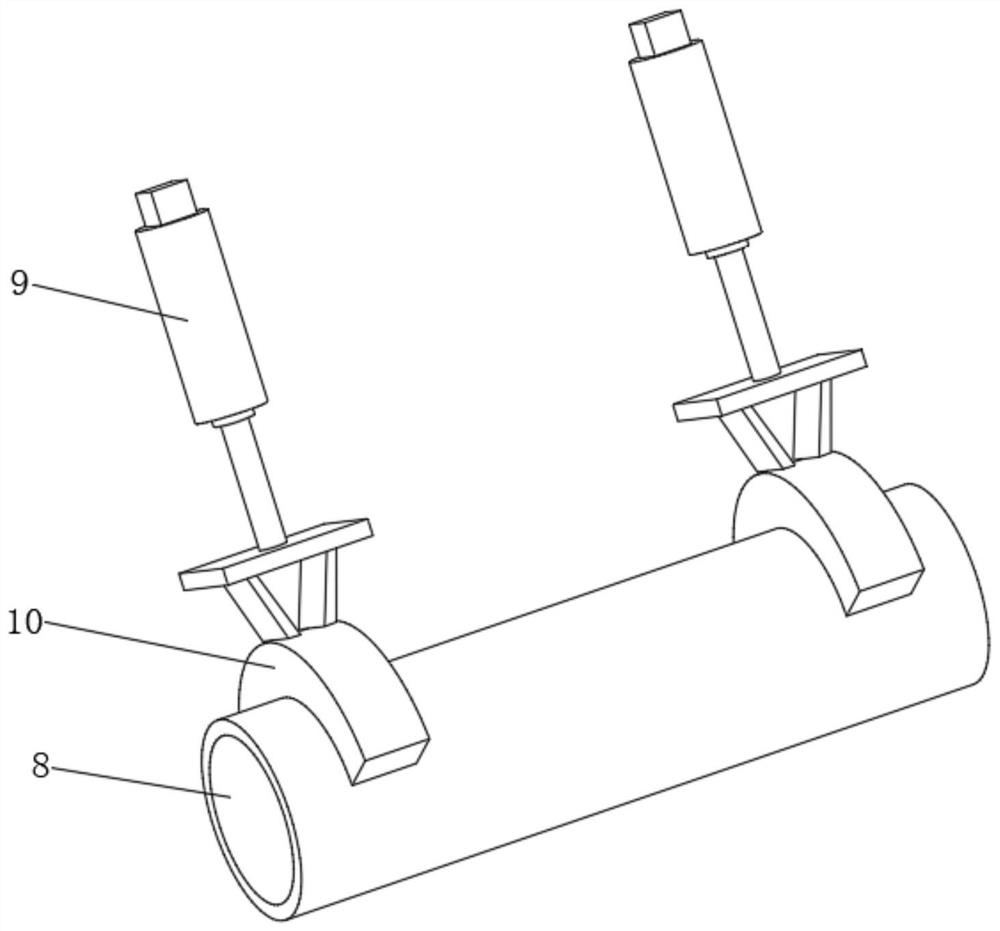

[0028] refer to Figure 1-4 , a circular tube inner wall grinding device for mechanical manufacturing, comprising a box body 1, the bottom inner wall of the box body 1 is connected with a support leg 12 by bolts, and the top outer wall of the support leg 12 is connected with a workbench 11 by bolts, and the workbench 11 A cylinder 8 is placed on the top outer wall of the box body 1, and a support plate is connected to one side of the inner wall of the box body 1 by bolts, and the bottom outer wall of the support plate is connected to a fixing seat 18 by bolts, and the bottom outer wall of the fixing seat 18 is connected to a motor 17 by bolts, And the output shaft outer wall of motor 17 is socketed with crank 16, and one side outer wall of crank 16 is connected with connecting rod 15 by rotating shaft, and one end outer wall of connecting rod 15 is connected with fixed rod 27 by rotating shaft, and one side outer wall of fixed rod 27 rotates Connected with threaded rod 13, one...

Embodiment 2

[0032] refer to Figure 5, a circular pipe inner wall grinding device for mechanical manufacturing. Compared with Embodiment 1, the inner walls of both sides of the fixed column 20 are provided with air inlet slots 28, and the cross section of the air inlet slots 28 is funnel-shaped. A cooling channel 29 is opened inside the column 20 , and the cooling channel 29 is divided into equidistant broken lines, and one end of the air inlet slot 28 is connected to the cooling channel 29 .

[0033] Working principle: When people need to polish the inner wall of the cylinder 8, they can place it on the workbench 11, and then people start the electric push rod 9, and the electric push rod 9 drives the clamping ring 10 down to tighten the cylinder 8. When the cylinder body 8 is fixed by the clamping ring 10, people start the motor 17, and the motor 17 drives the crank 16 to rotate, and the crank 16 is connected to the connecting rod 15 through a hinge, so that the connecting rod 15 can dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com