Plank grinding device with double-sided grinding

A wood-panel, double-sided technology, which is applied to grinding drive devices, grinding/polishing safety devices, and grinding slides, etc., can solve the problems of inconvenient grinding work, low grinding efficiency, slow grinding speed, etc., and improve grinding efficiency. , Prevent dust pollution, improve the effect of grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

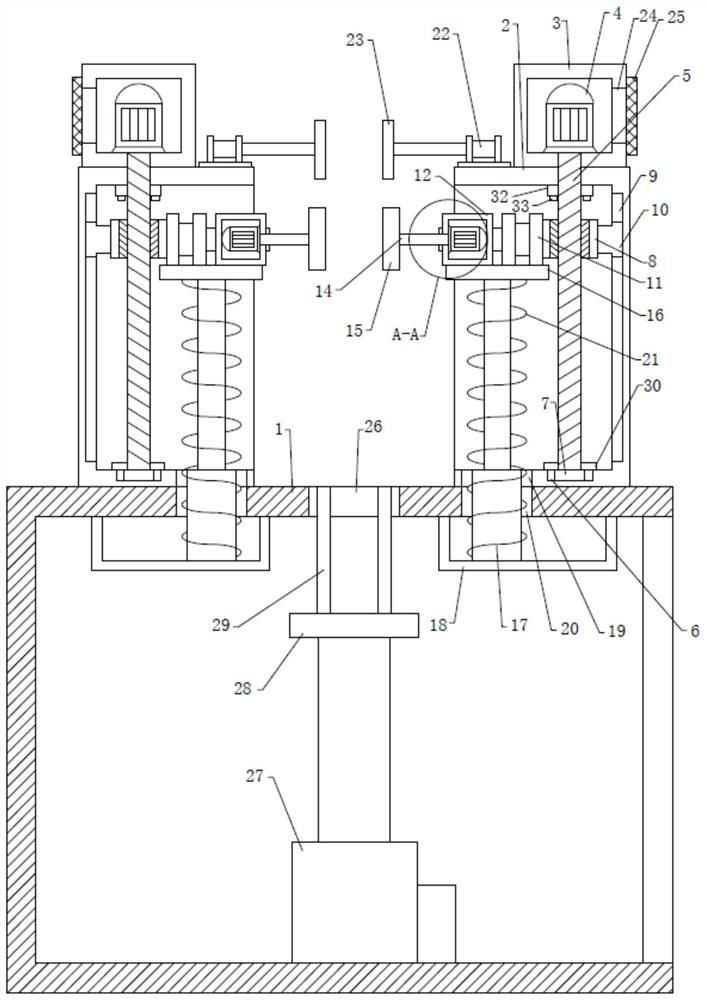

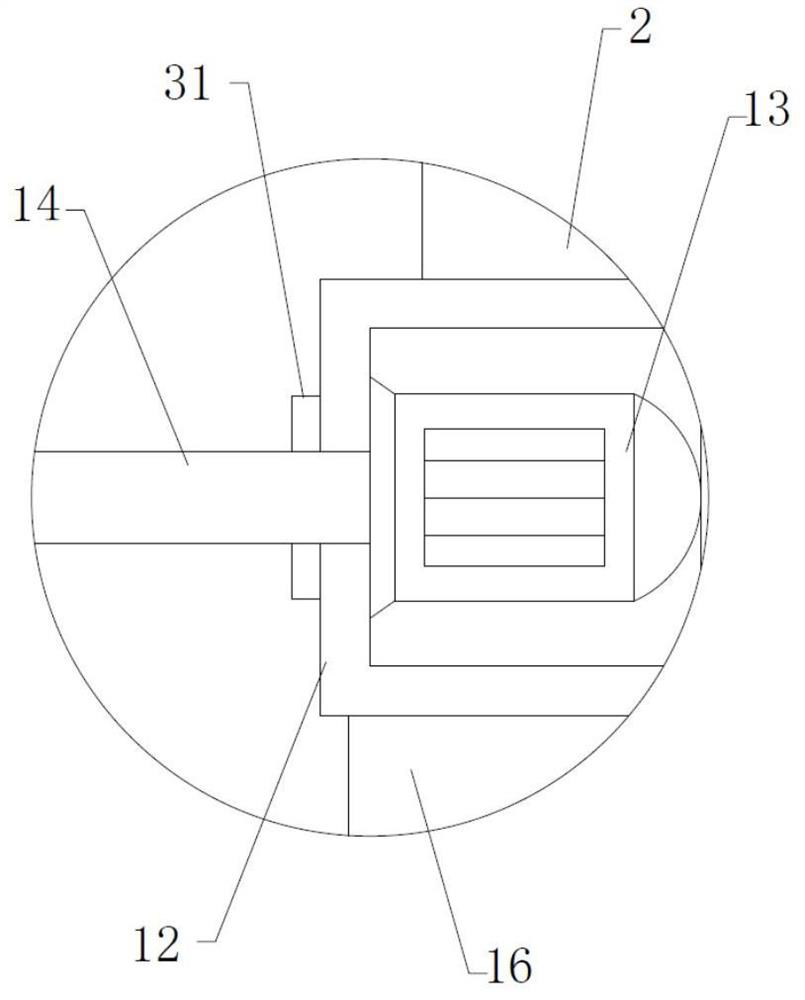

[0018]Put the plank between the two clamping plates 23, then start the second cylinder 22, the second cylinder 22 drives the clamping plate 23 to clamp the plank, then start the two grinding motors 13, the grinding motor 13 drives the grinding shaft 14 to rotate , the grinding shaft 14 drives the grinding head 15 to rotate, and the two grinding heads 15 polish the two sides of the plank respectively, and then starts the driving motor 4, and the driving motor 4 drives the threaded shaft 5 to rotate, and the bottom end of the threaded shaft 5 rotates with the rolling bearing 7 , because the threaded shaft 5 is threadedly connected with the threaded block 8, and the threaded block 8 is limited by the chute 9 and the slider 10, the threaded block 8 moves up and down on the surface of the threaded shaft 5, and the up and down movement of the threaded block 8 drives The first cylinder 11 moves up and down, because the bottom of the first cylinder 11 is fixed on the fixed plate 16, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com