Platform supporting device for automatic elevator mounting equipment

An automatic installation and support device technology, applied in the direction of lifting devices, etc., can solve the problems of shaking of the working platform, increase of construction difficulty, increase of construction error, etc., achieve consistent tension force, good positioning and locking effect, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

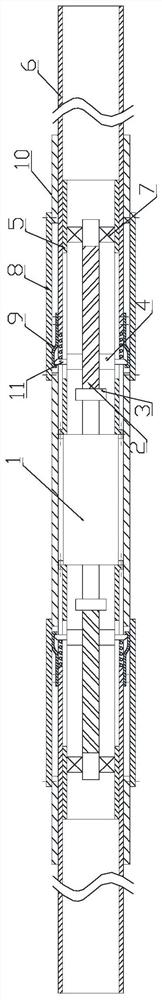

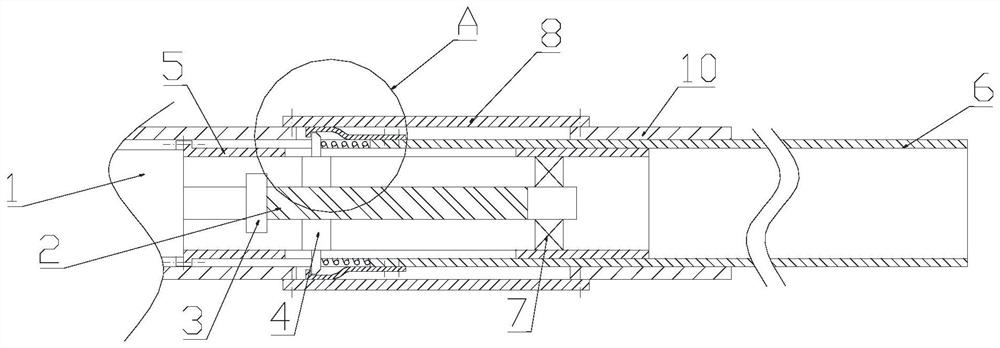

[0025] see Figure 1-Figure 3 The platform support device for elevator automation installation equipment of the present invention includes a support rod 6 arranged on the frame 10 of the working platform and a support and Lock the drive mechanism.

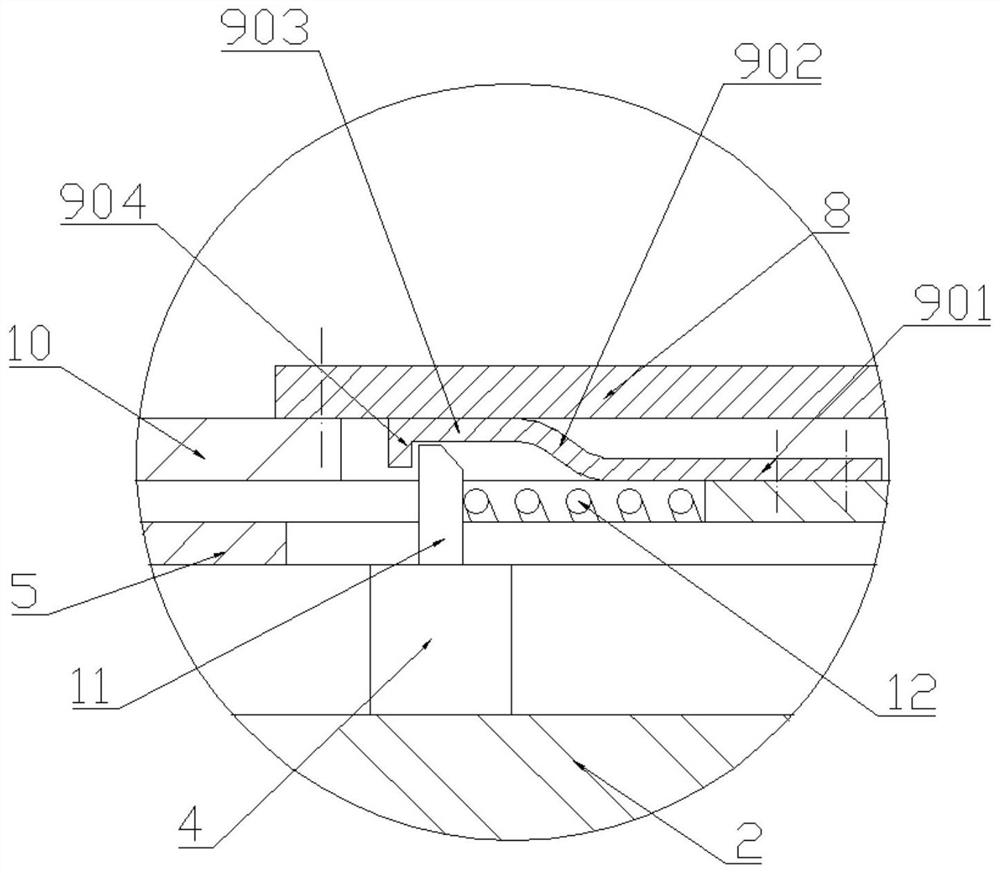

[0026] see Figure 1-Figure 3 , the supporting and locking driving mechanism includes a driving member 11 and a linear driving mechanism for driving the driving member 11 to perform a linear motion, wherein the supporting rods 6 are in two groups and are respectively located on both sides of the frame 10 The driving parts 11 are two groups, and the two groups of driving parts 11 are respectively connected with the two groups of support rods 6 through springs 12, one end of the spring 12 acts on the driving parts 11, and the other end acts on the On the support rods 6; each group of support rods 6 is provided with a locking member 9, and the frame 10 is provided with a groove for avoiding the locking member 9, and the groove is al...

Embodiment 2

[0038] see Figure 4 , The difference between this embodiment and Embodiment 1 is that there are two frames 10, and the two frames 10 are used to guide the support rods 6 on both sides respectively. This has the advantage that the frames 10 can be saved. materials, thereby saving costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com