Patents

Literature

34results about How to "Guarantee docking quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

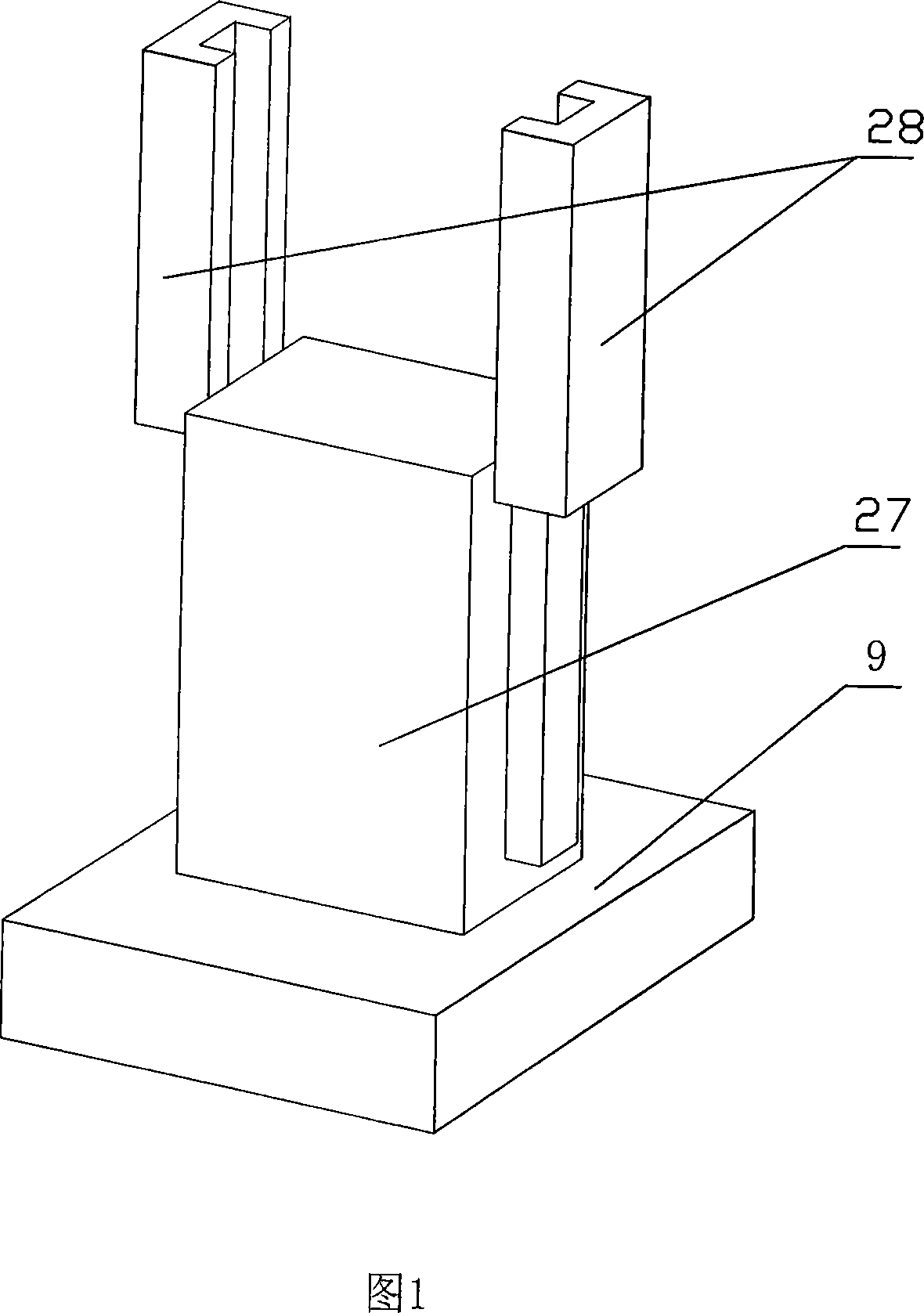

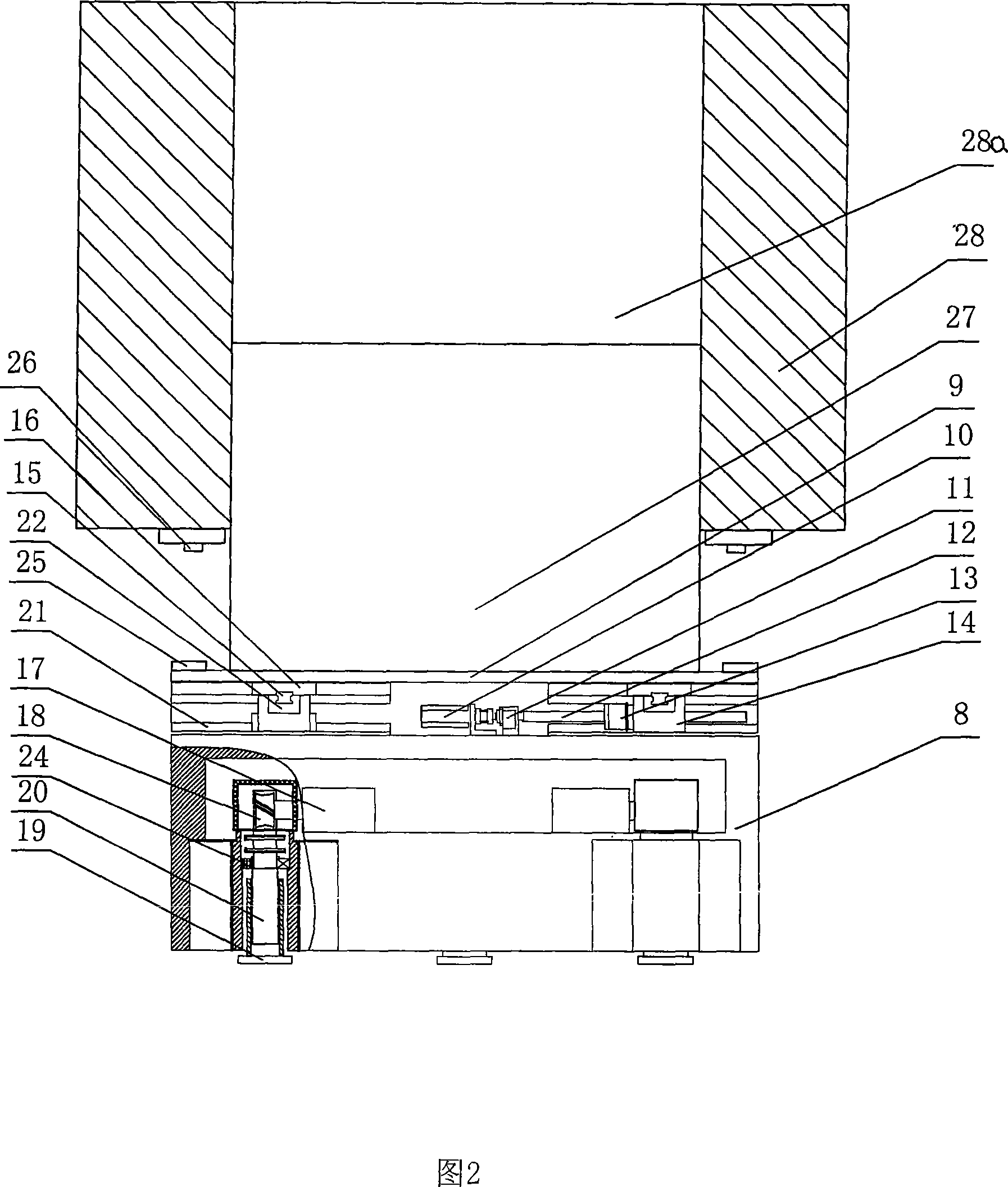

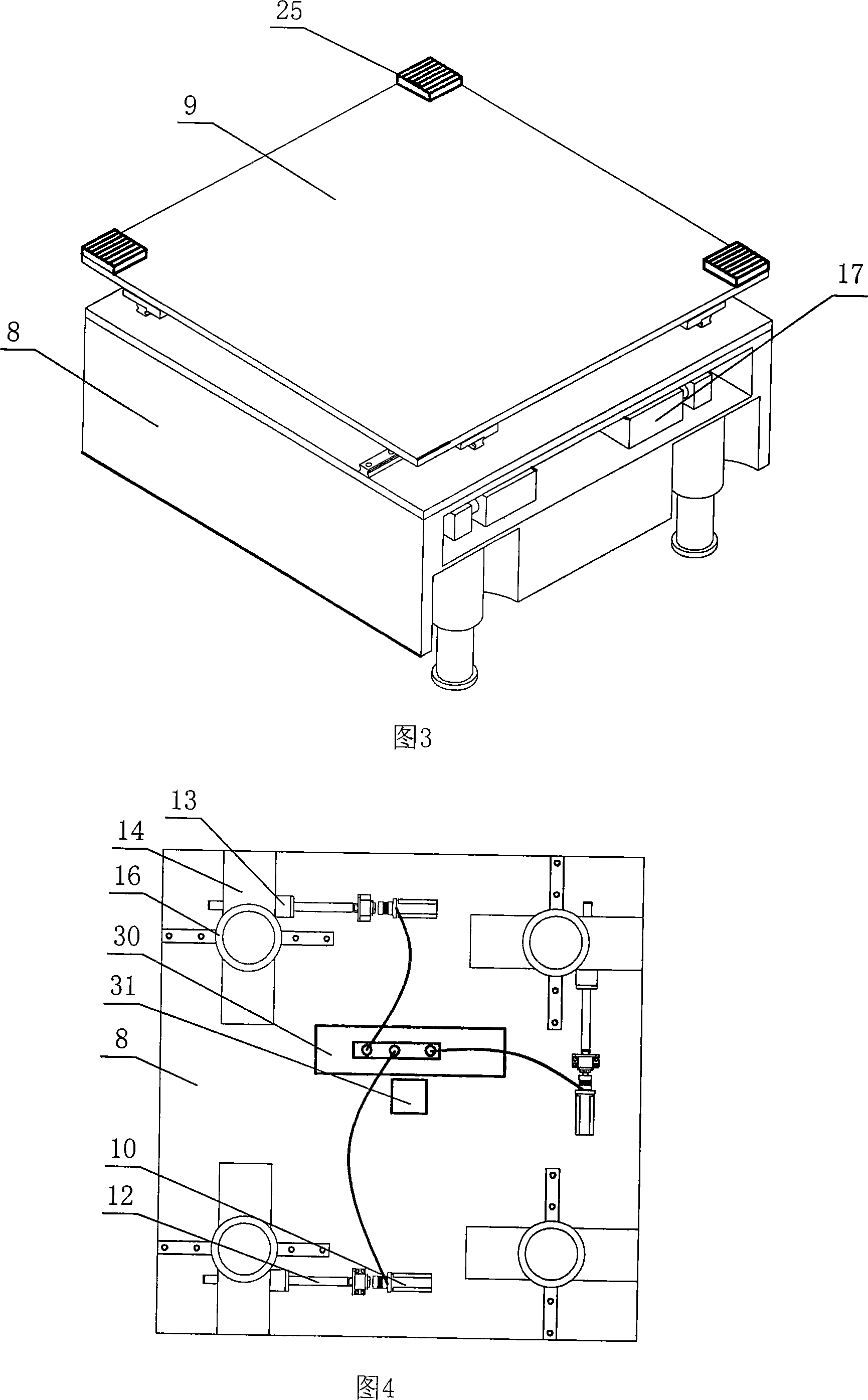

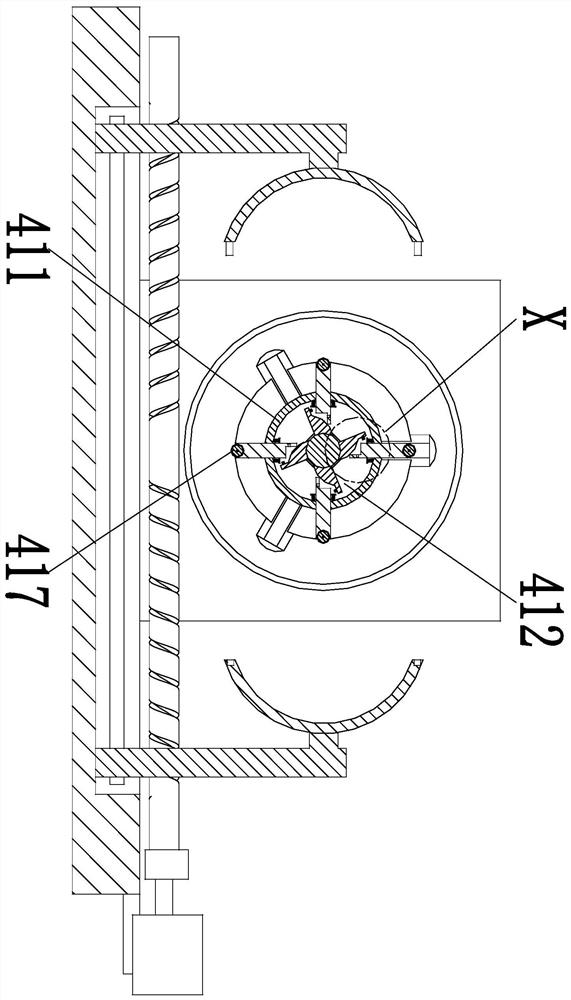

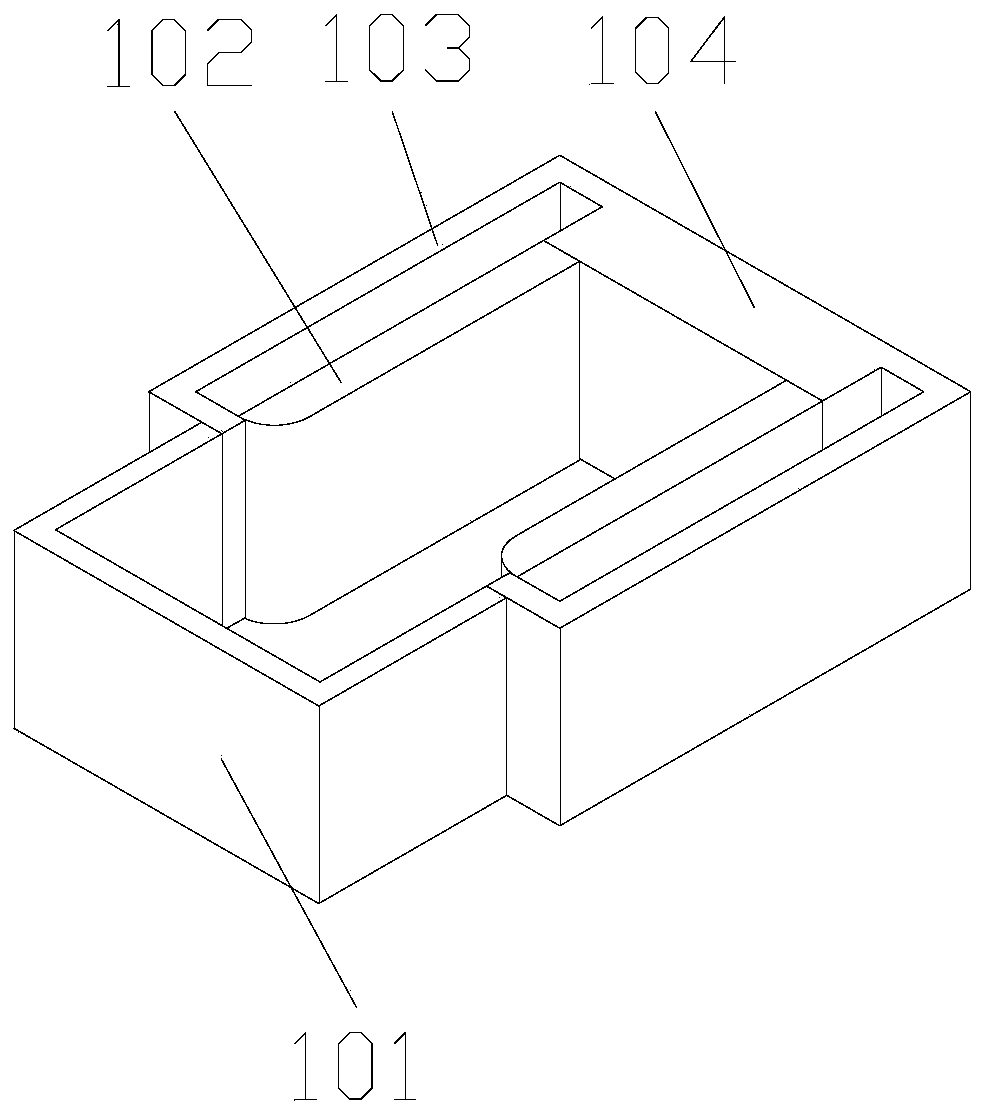

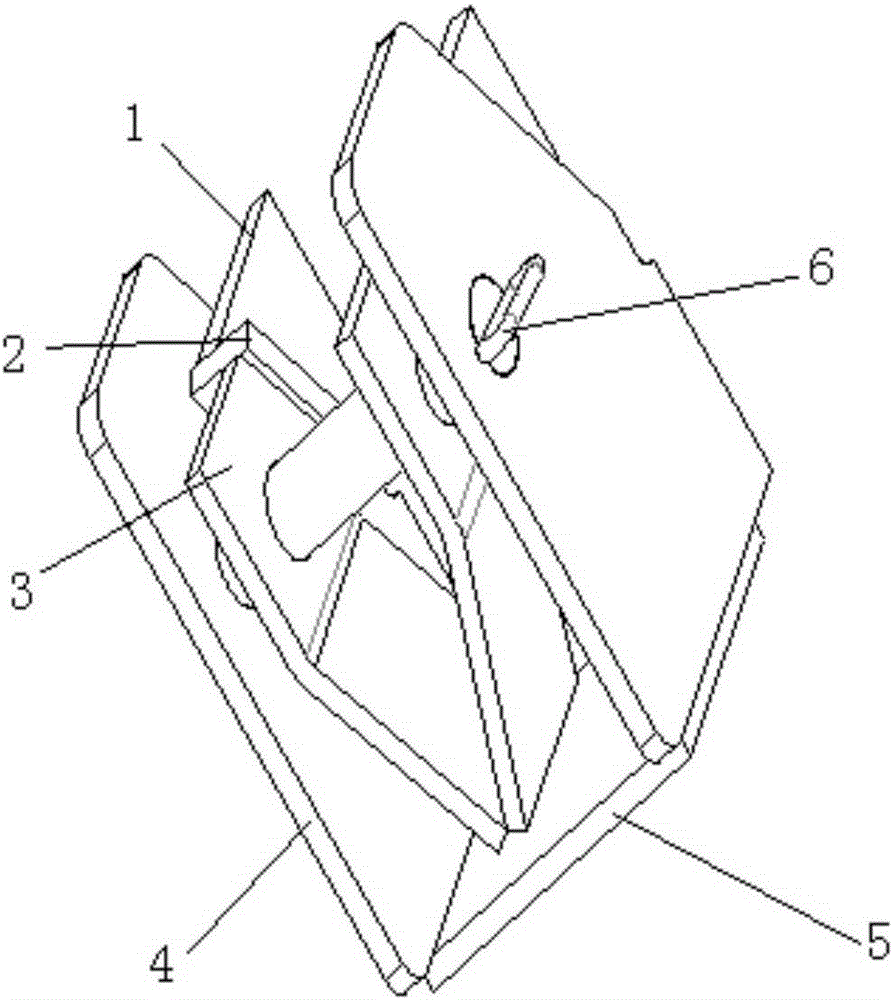

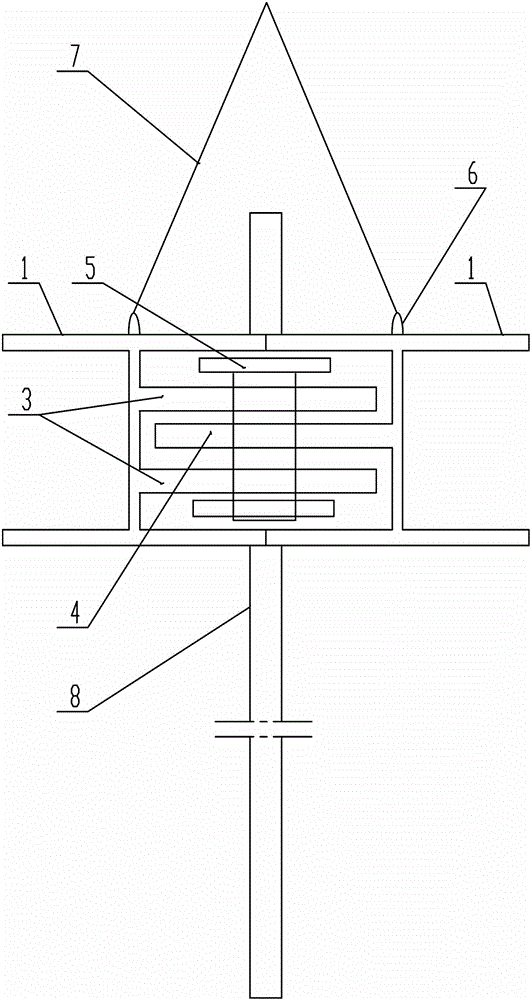

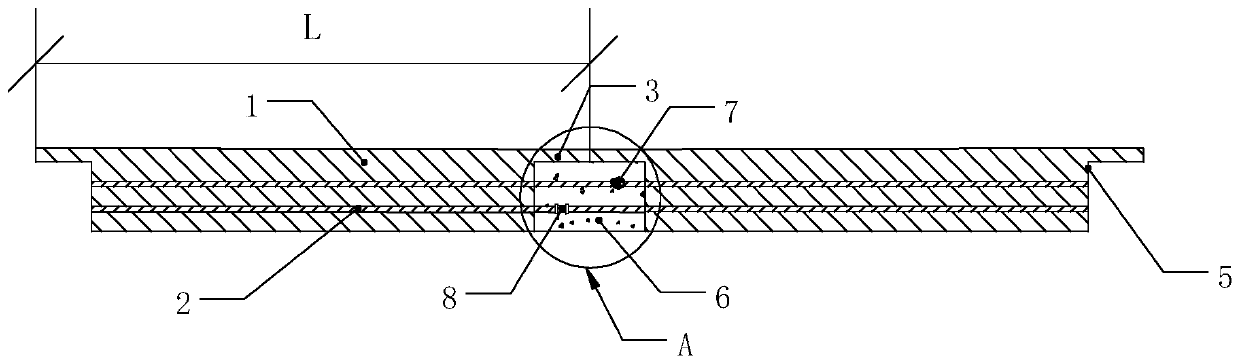

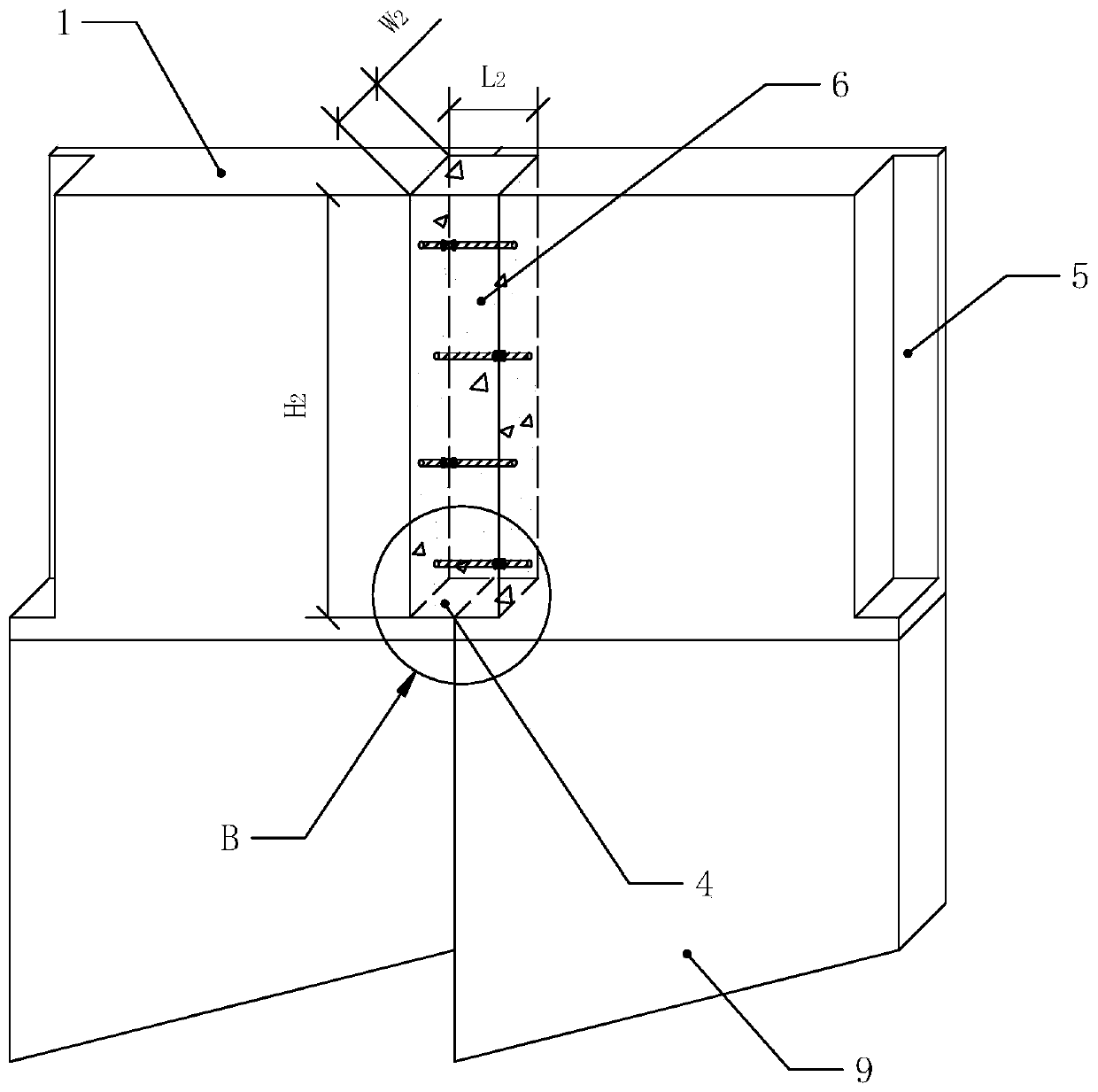

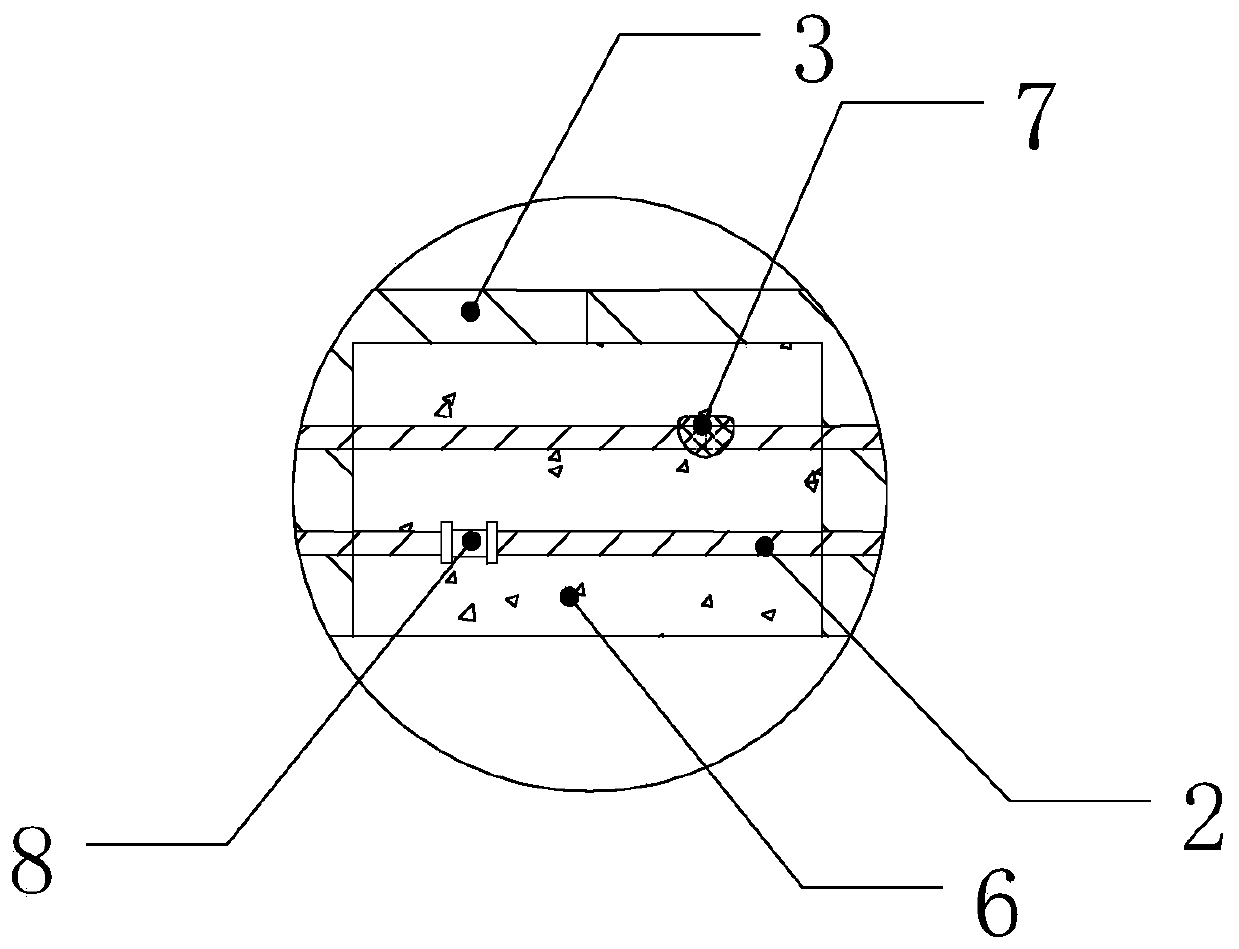

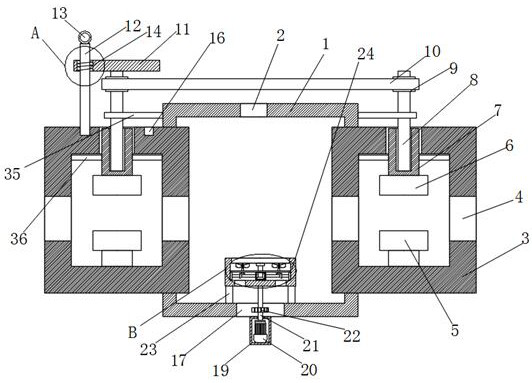

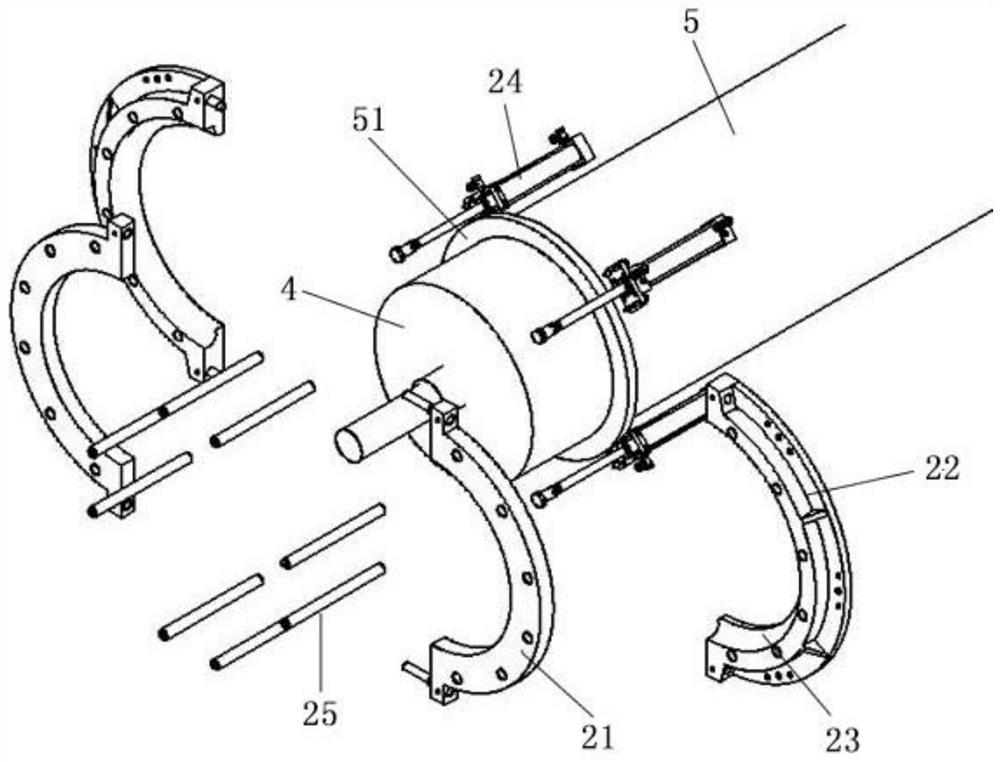

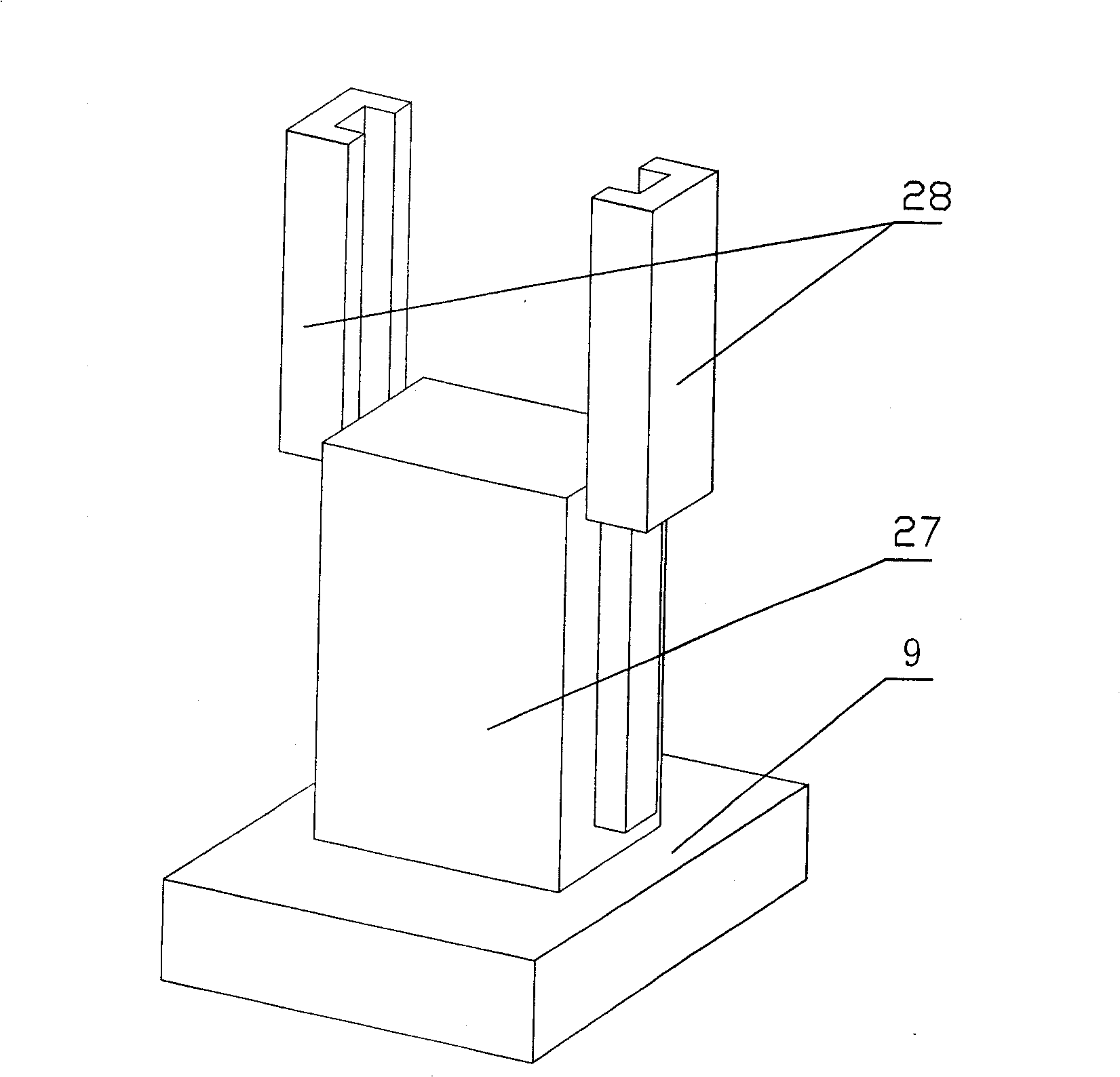

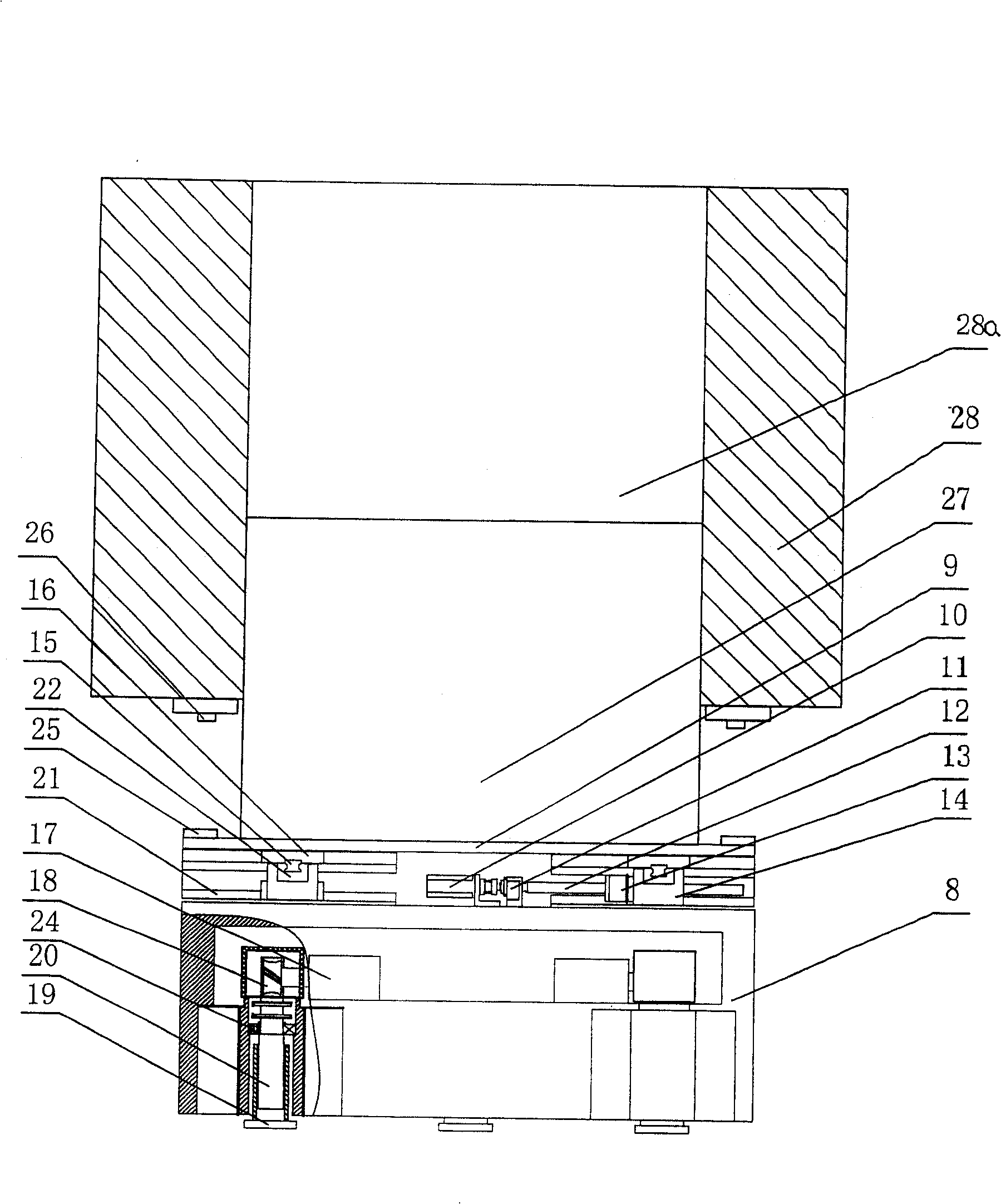

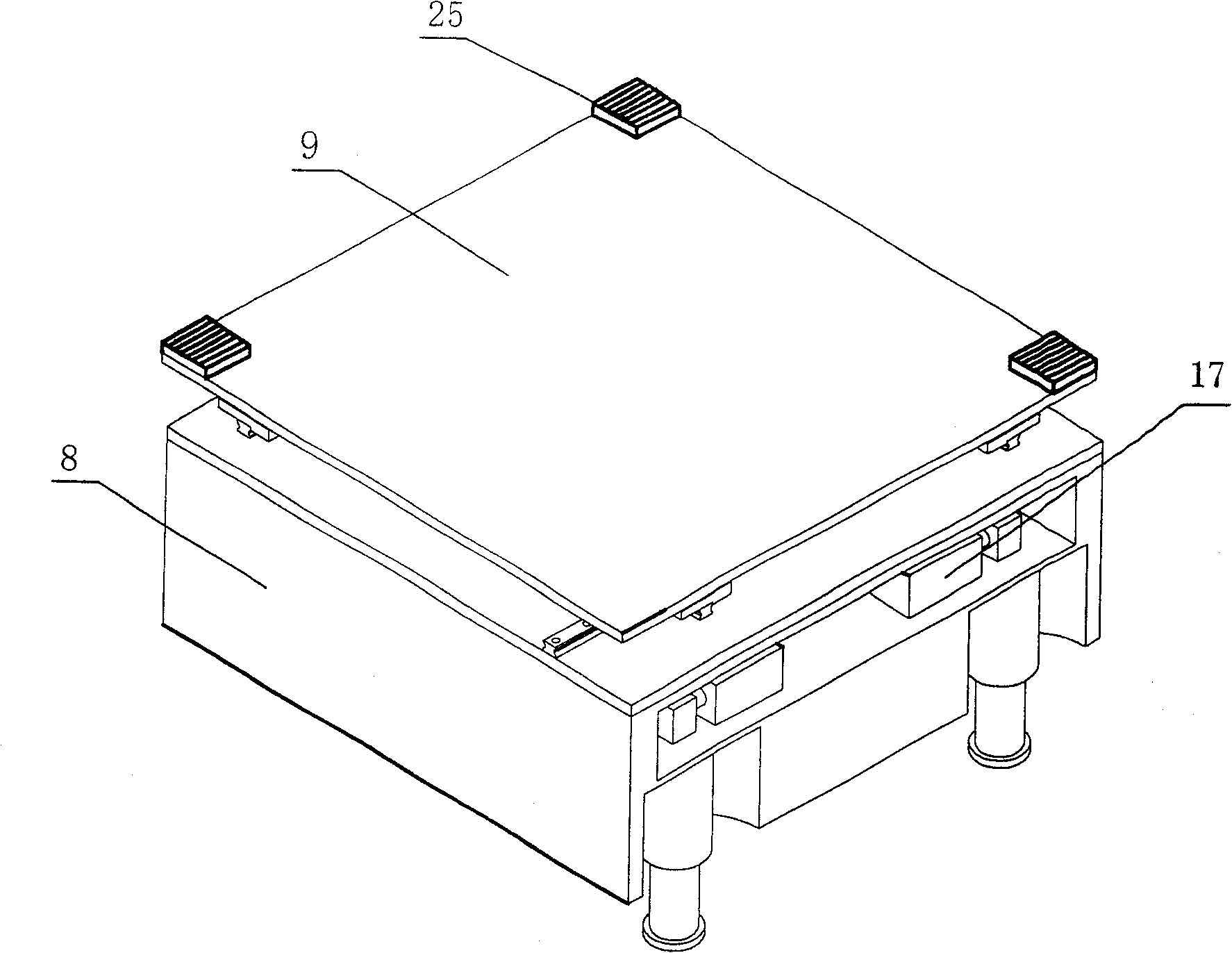

Self control type multi- degree of freedom buttjunction platform

InactiveCN101081507ASo as not to damageWith adaptive functionWork benchesAdaptive controlButt jointControl system

The present invention discloses one kind of butt-jointing platform with several freedom degrees, and the butt-jointing platform is one self-regulating mechanical butt-jointing platform with adaptive control system. The self-regulating mechanical butt-jointing platform includes one support platform, one work platform and three planar regulating mechanisms in the same structure. It features that three planar regulating mechanisms and one servo mechanism set between the support platform and the work platform are distributed to form one square, and that three vertical regulating mechanisms in the same structure on the support platform are distributed to form one triangle. The present invention features the self adapting function including measuring the butt-jointing position and angle between the butt-jointed body and the butt-jointed cavity and regulating the position and angle automatically to ensure high butt-jointing quality and effect.

Owner:CHONGQING UNIV

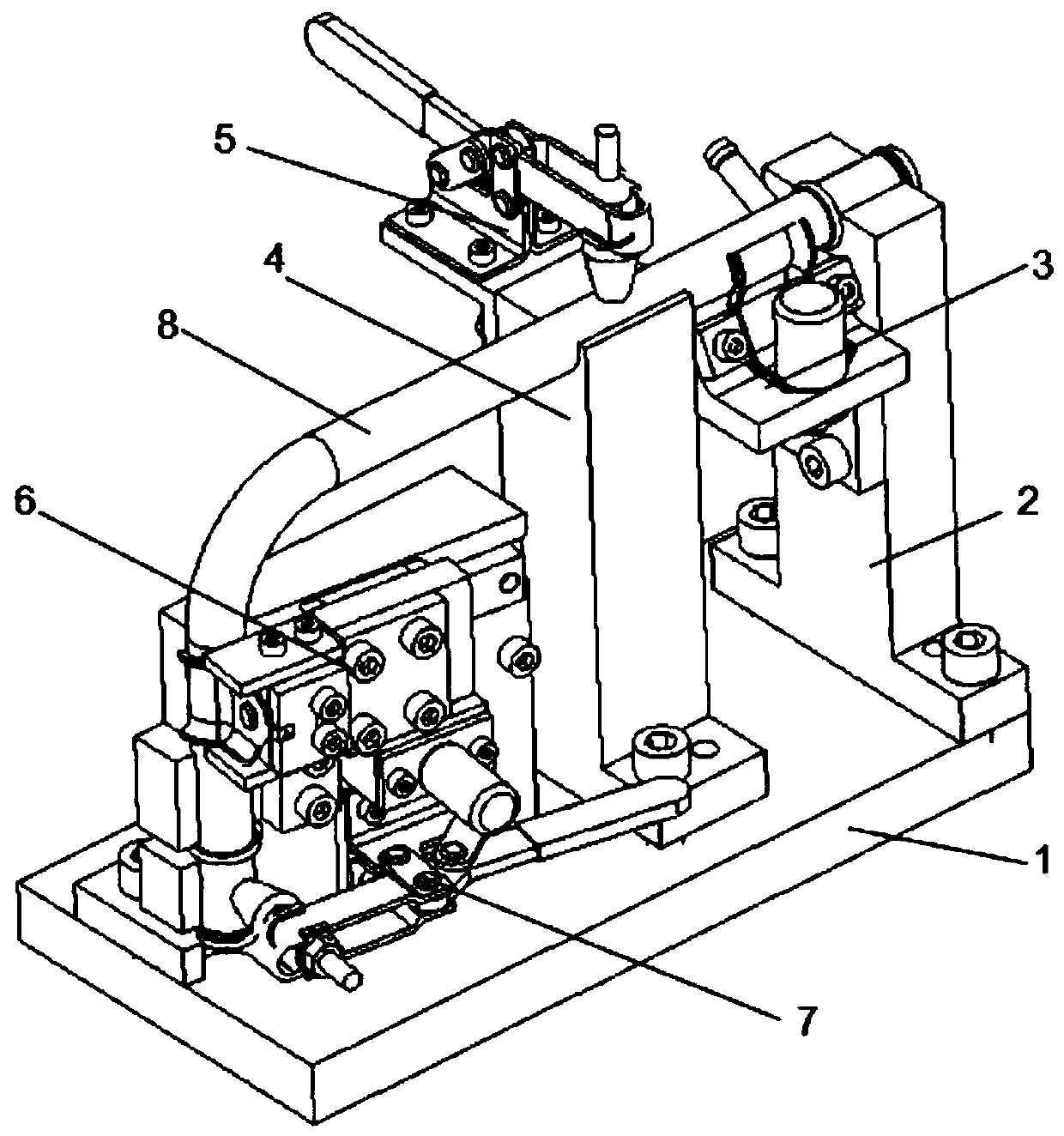

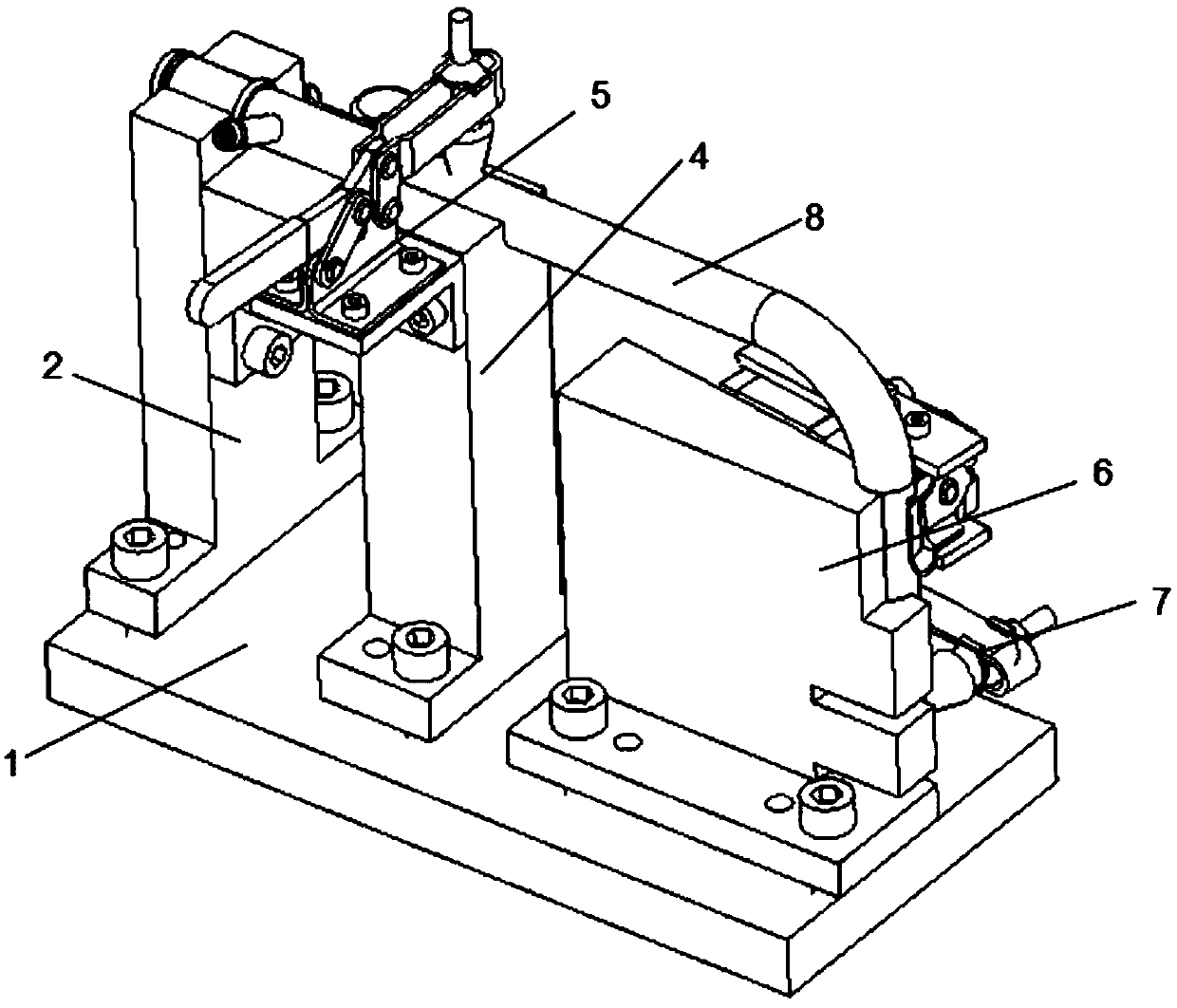

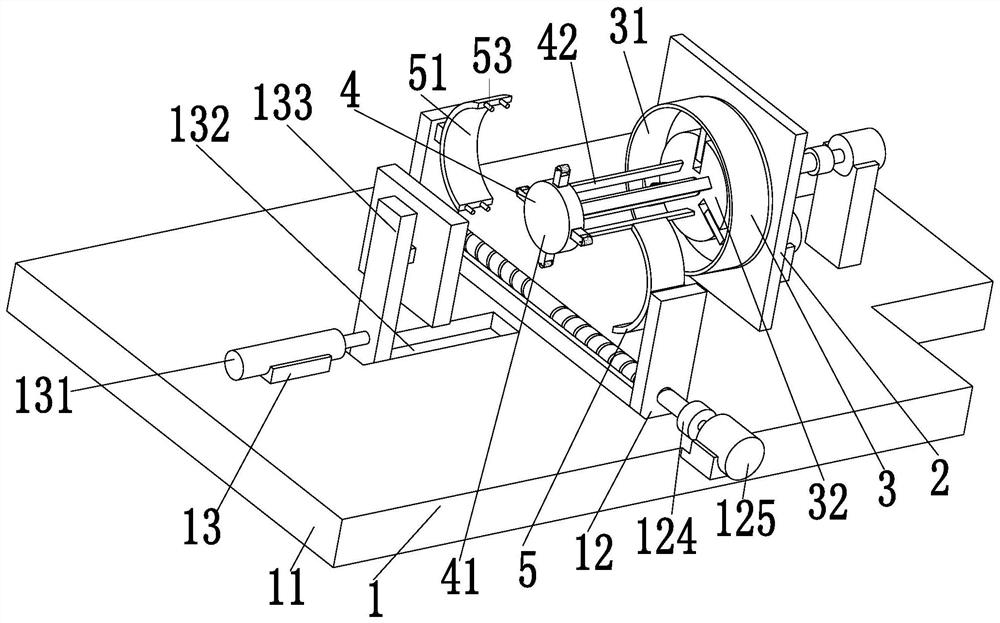

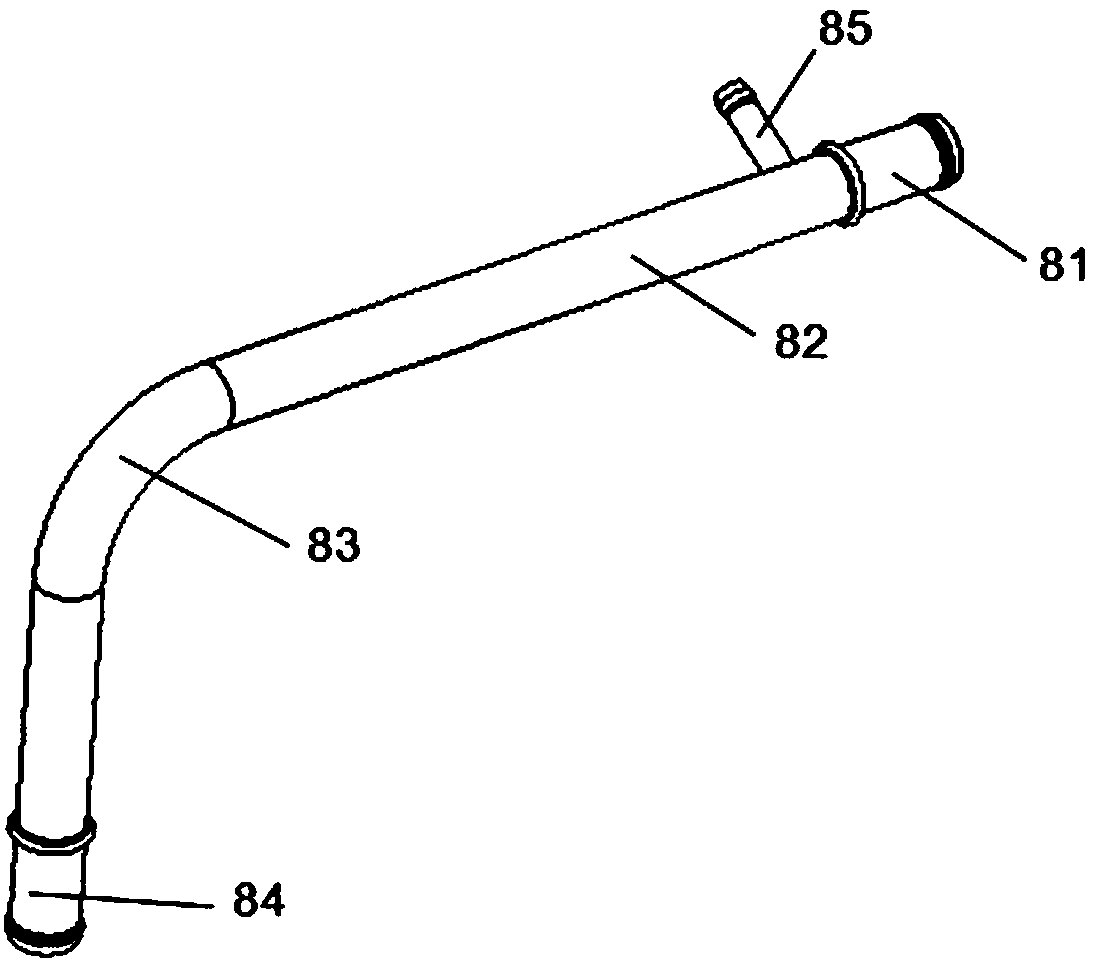

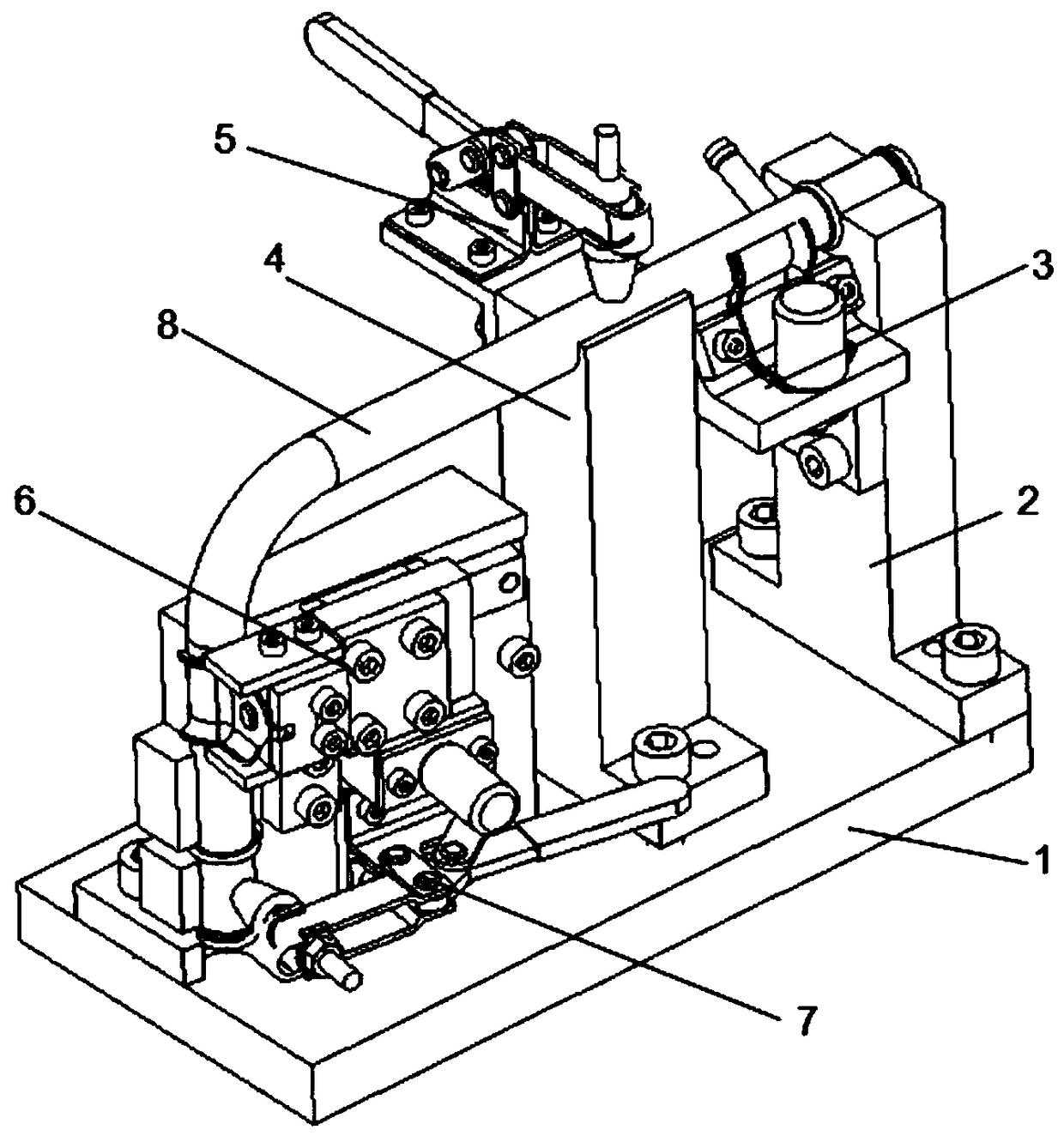

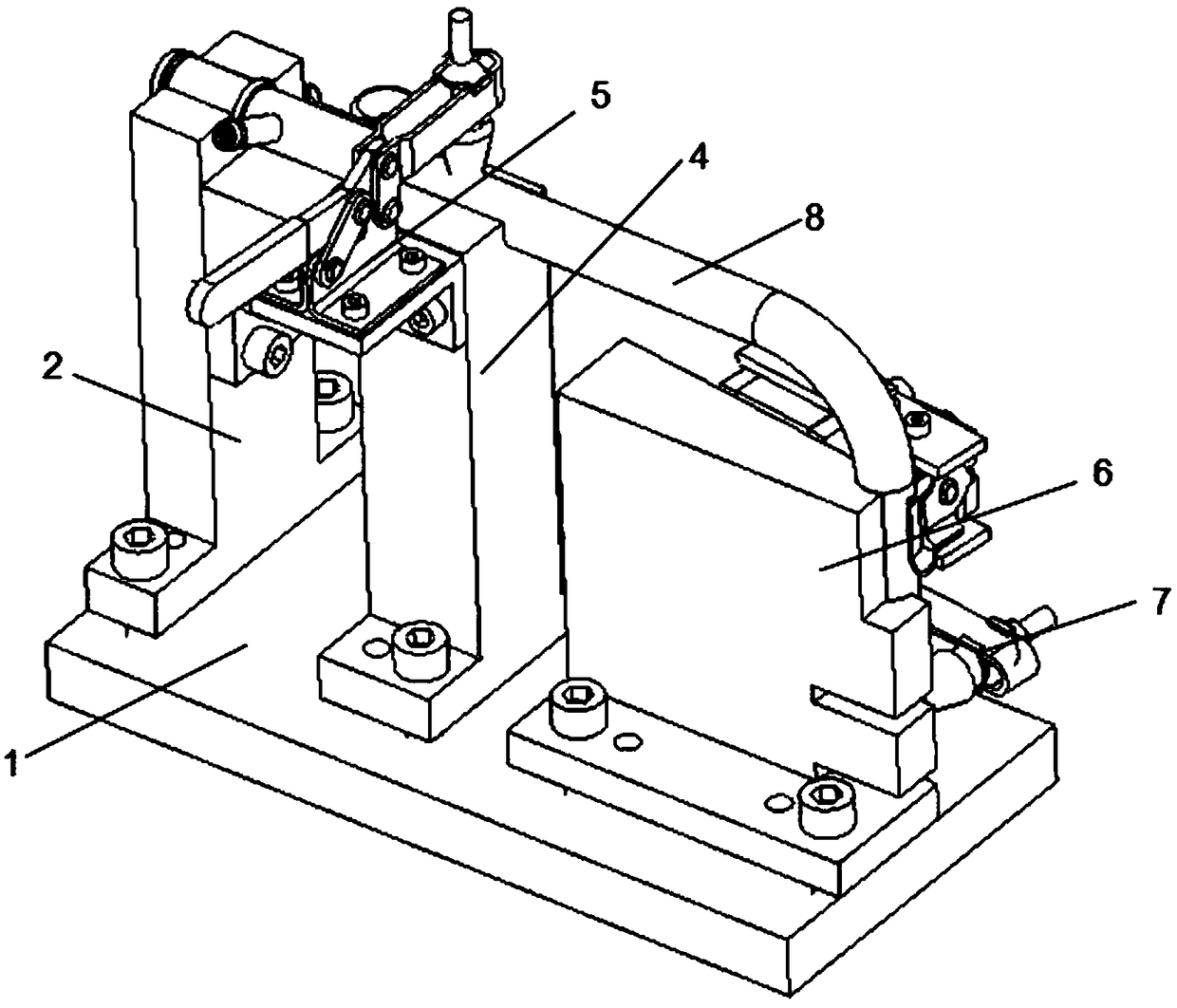

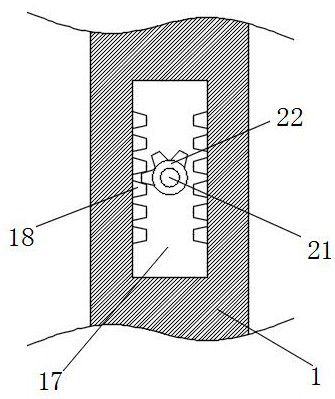

Bent pipe welding, positioning and locking device

ActiveCN107617847AImprove efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingEngineering

The invention provides a bent pipe welding, positioning and locking device. The device comprises a base; a first support base, a second support base and a bent pipe positioning mechanism are mounted on the base in sequence from right to left side by side; a branch pipe positioning mechanism is mounted between the first support base and the second support base; a first locking fixture is mounted onthe second support base; the bent pipe positioning mechanism is mounted on the left side of the second support base; and a second locking fixture is fixed on the side wall of the bent pipe positioning mechanism, and is positioned below a positioning and locking block. The bent pipe welding, positioning and locking device can realize quick positioning and butt joint of pipe fittings with differentshapes and guarantee the butt joint quality through presetting the first support base, the second support base, the first locking fixture, the bent pipe positioning mechanism and the second locking fixture; the branch pipe positioning mechanism can guarantee welding angles of a branch pipe with a first pipe tube and a second pipe tube to meet requirements; and the first locking fixture and the second locking fixture can realize quick locking of a straight pipe and the second pipe tube.

Owner:GUANGDONG JUNCHI TECH HLDG

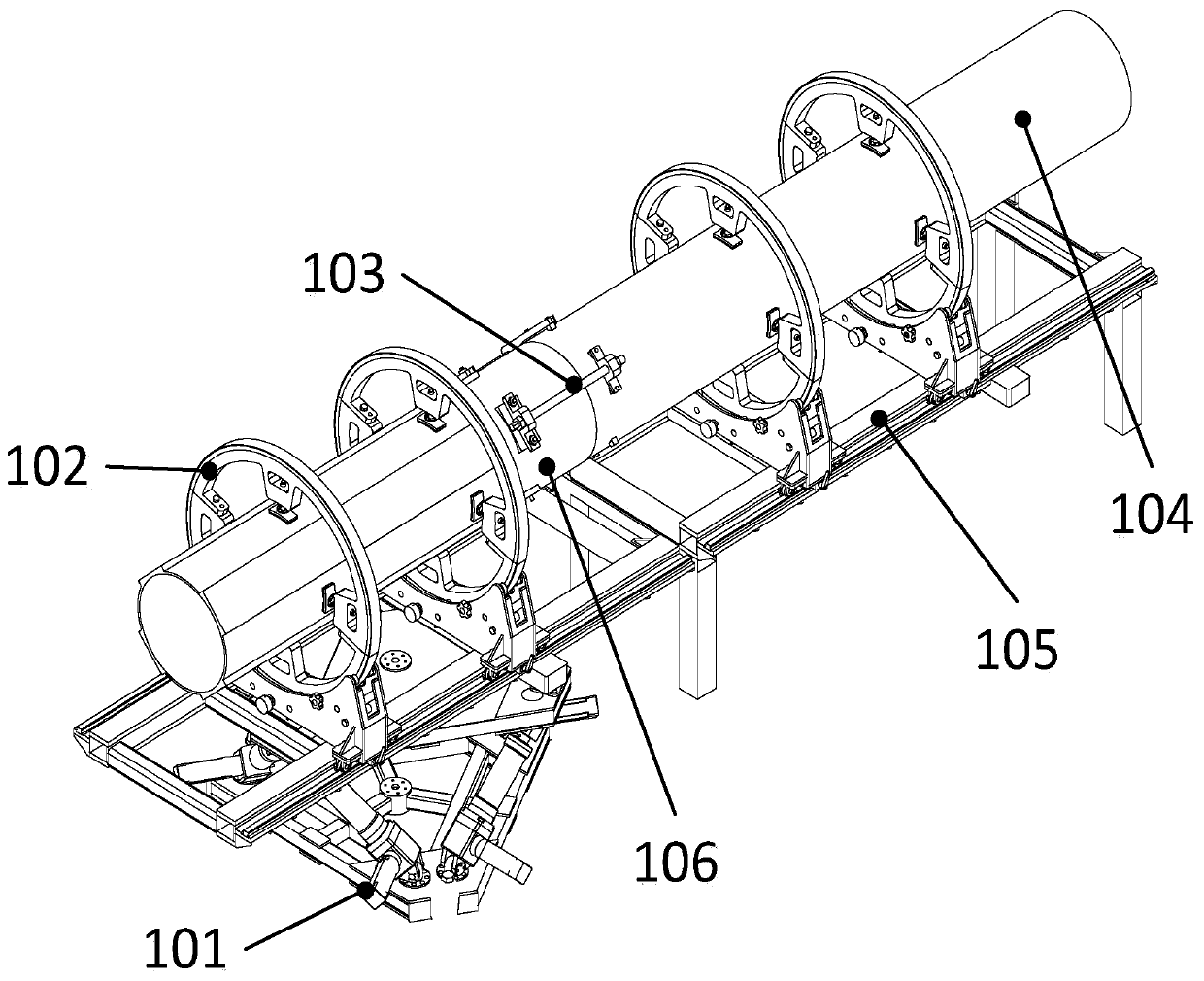

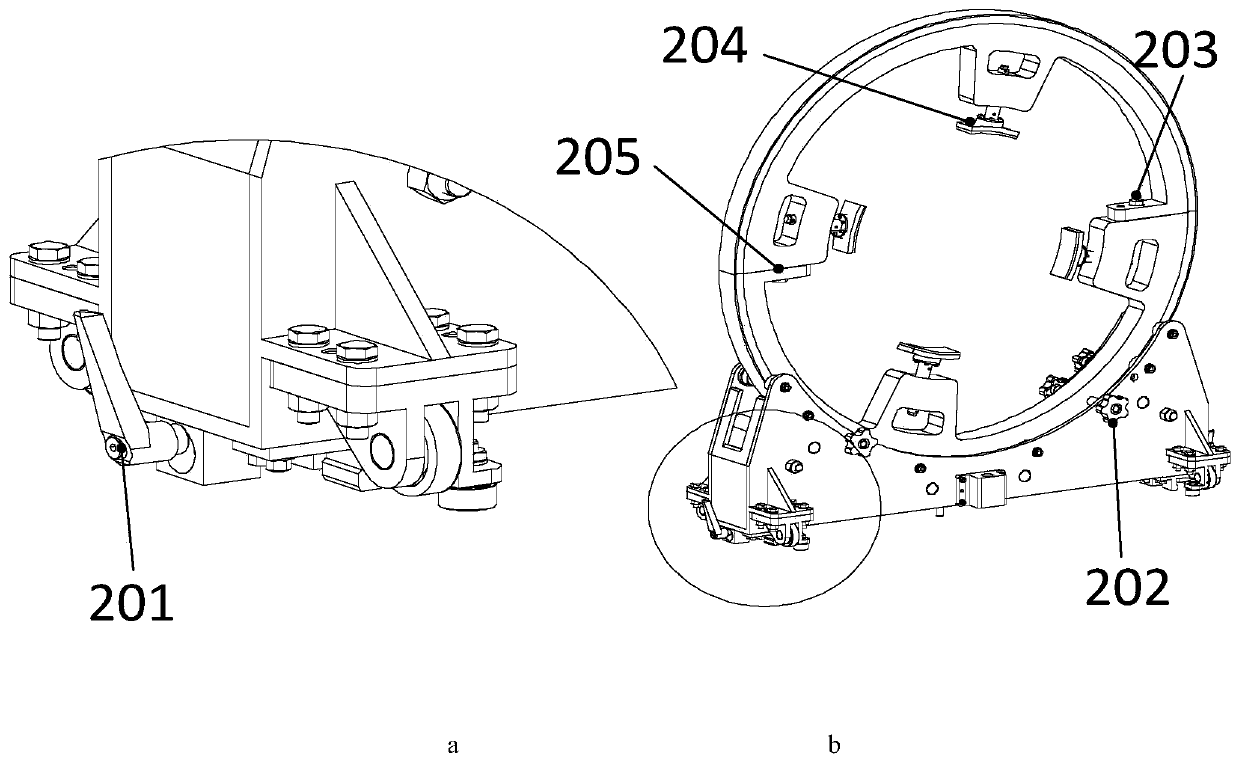

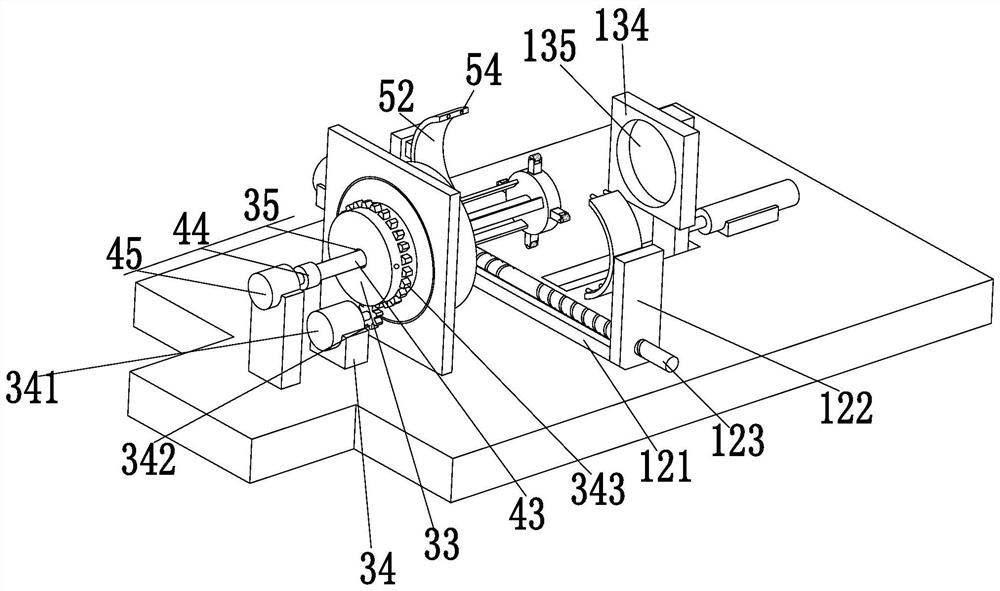

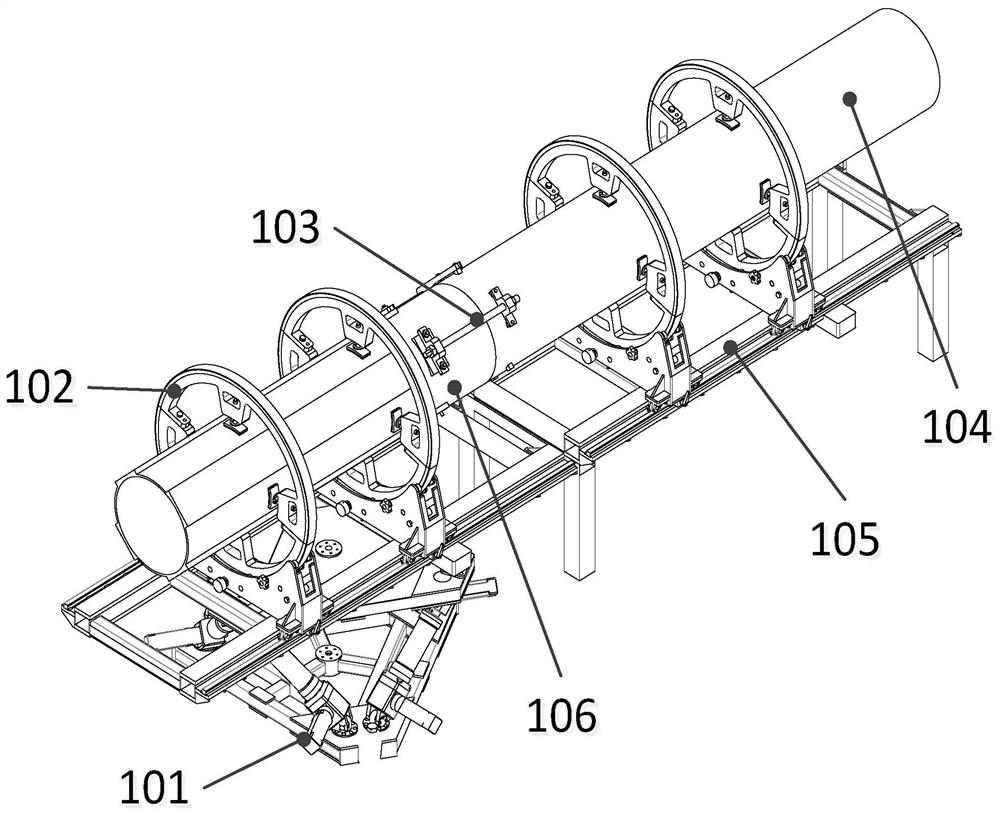

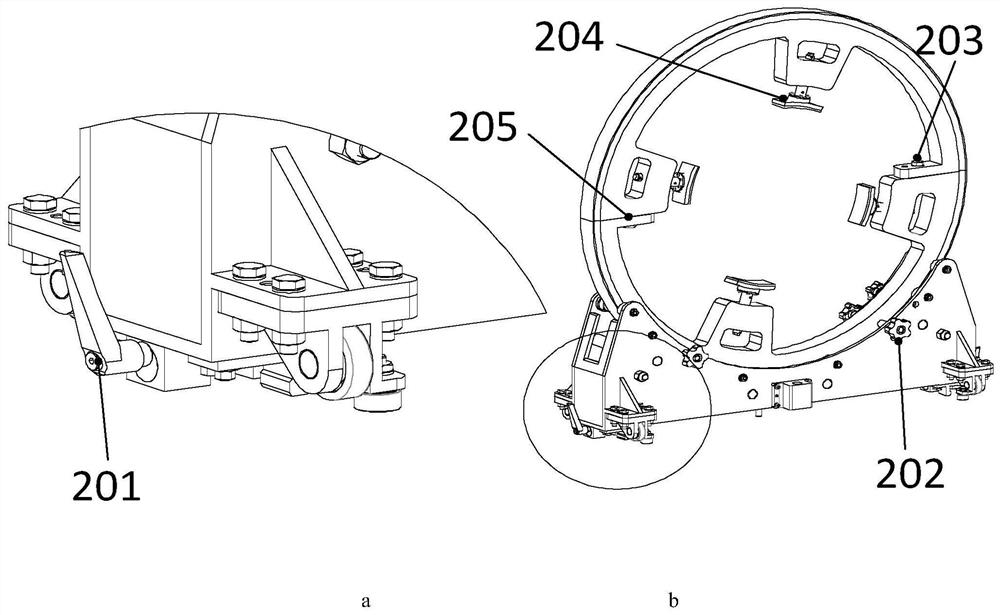

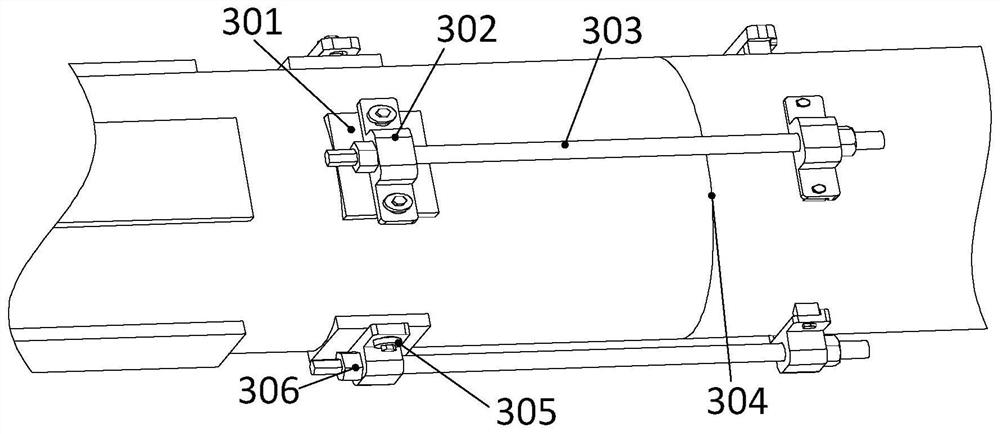

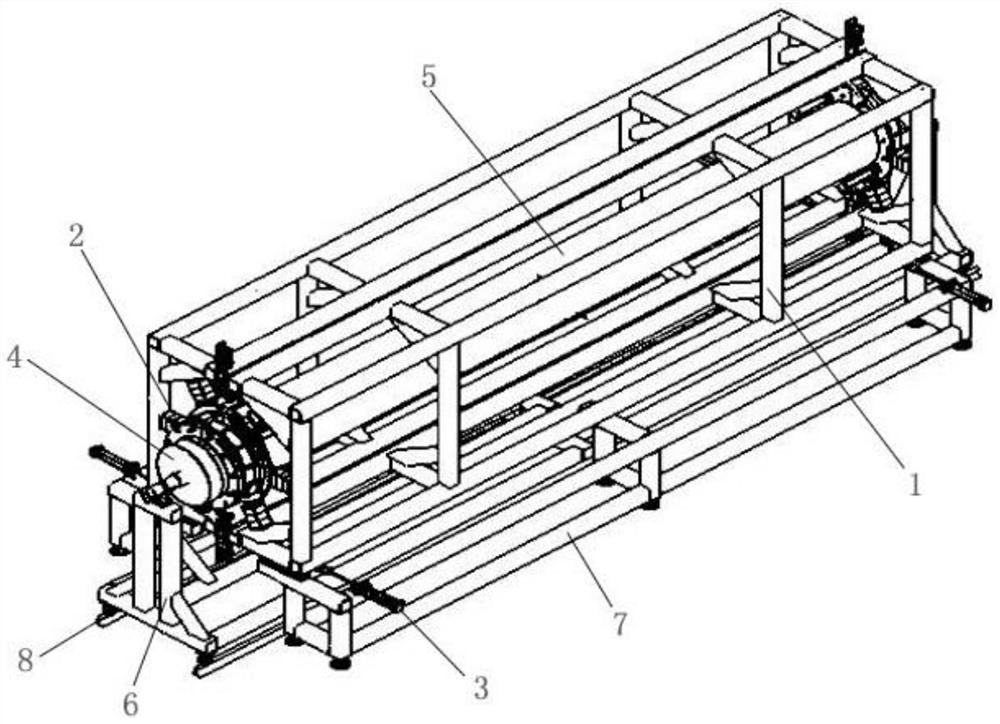

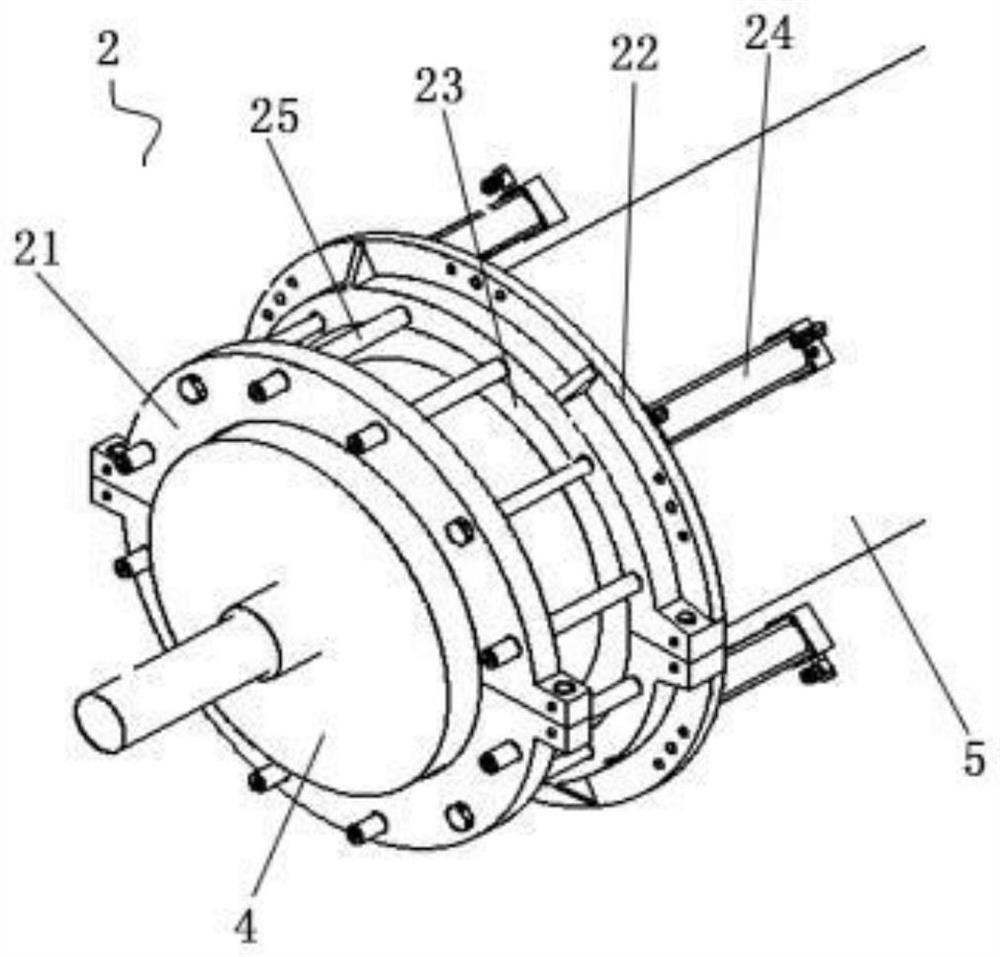

Cabin section rapid pose adjusting and tensioning device based on six-axis platform

The invention discloses a cabin section rapid pose adjusting and tensioning device based on a six-axis platform, and belongs to the field of missile cabin section butt joint, and the problem that thebutt joint cabin section is subjected to coaxiality adjustment and tension force application is solved. The cabin section rapid pose adjusting and tensioning device comprises a rotary clamping ring module and a tensioning module, the rotary clamping ring module is used for fixing the connection cabin section and adjusting the posture; and tensioning force is evenly exerted on the tensioning modulein the circumferential direction of the cabin section, and accurate and efficient butt joint of the cabin sections is completed. The cabin section rapid pose adjusting and tensioning device is suitable for the rapid and safe butt joint process between the guided missile cabin sections which are connected in a sleeved mode.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

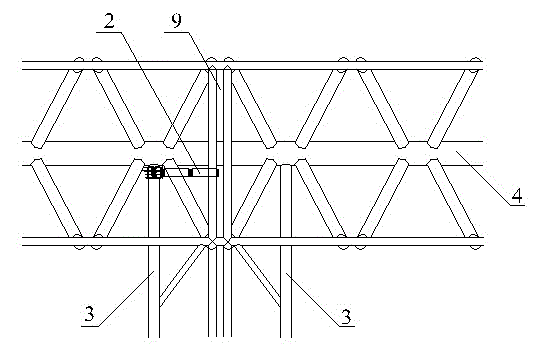

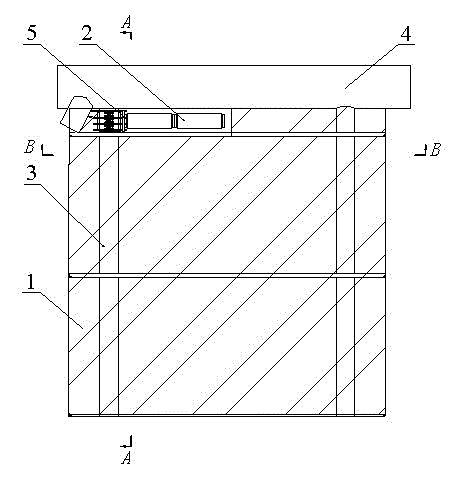

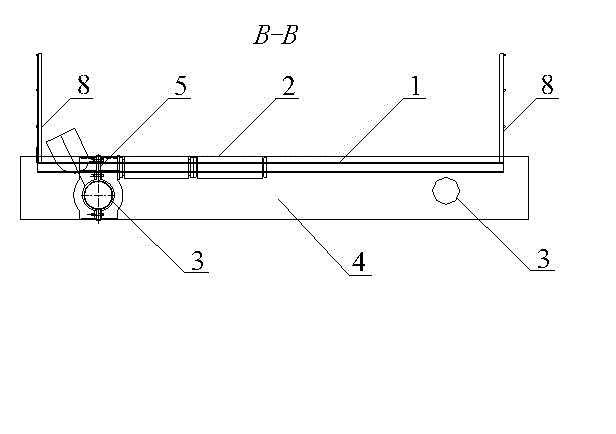

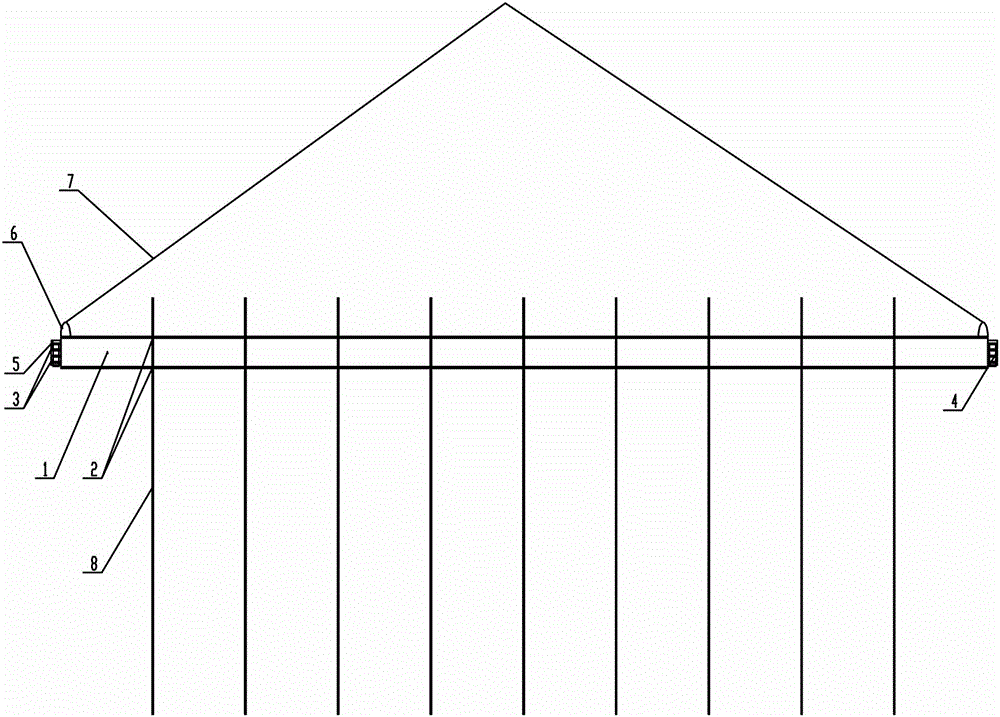

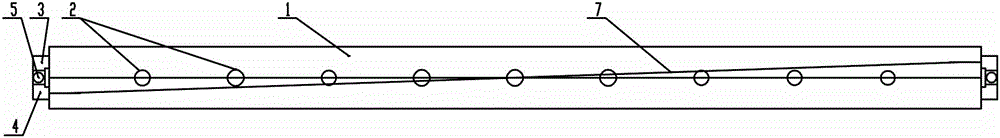

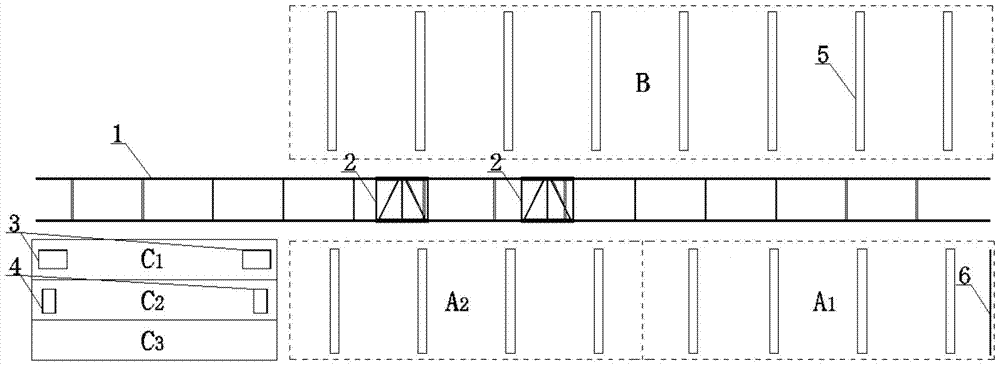

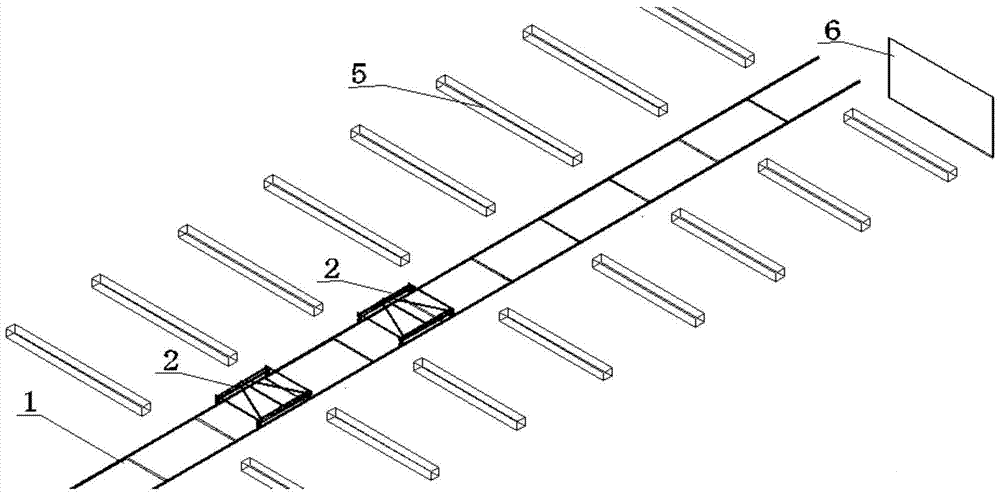

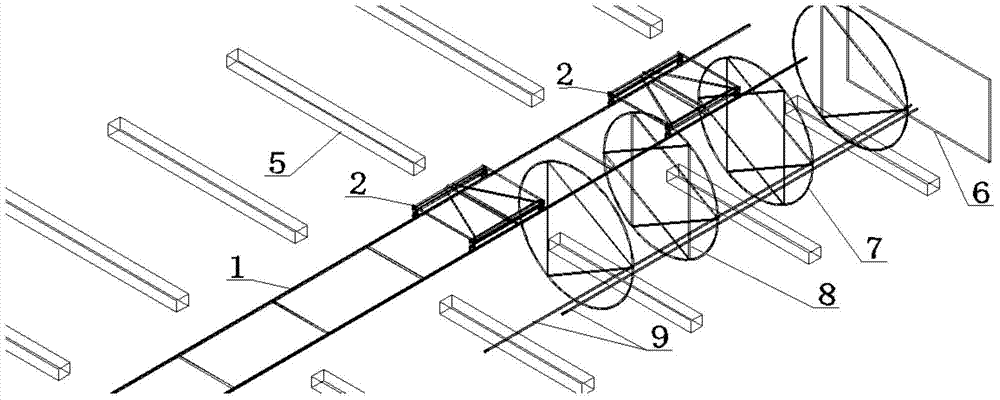

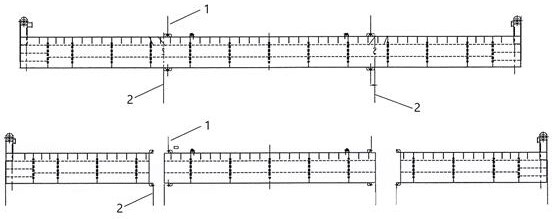

Integral pushing erection method for truss girders

ActiveCN102747691AGuarantee docking qualityReduce the difficulty of aerial assemblyBridge erection/assemblySteel tubePier

The invention relates to an integral pushing erection method for truss girders. The method comprises the following steps: splicing the truss girders, and enabling the two spliced truss girders (a left girder and a right girder) to be connected through a horizontal connecting steel pipe so that the integrated truss girders are formed; installing continuous-action jacks, installing a working platform between the two truss girders, and enabling two sides of the working platform to be respectively provided with one continuous-action jack; installing steel strands, enabling at least one steel strand to penetrate through the inside of the continuous-action jack of each side, enabling one ends of the steel strands to be anchored on bridge piers in front of the truss girders, and enabling the other ends of the steel strands to droop naturally; pushing and horizontally moving the truss girders, enabling the truss girders to pass across the bridge piers; and enabling horizontal jacks to be further installed at the tops of the bridge piers so that horizontal movement of the truss girders can be achieved. By the integral pushing erection method for the truss girders, the inverted triangular truss girders can be integrally pulled in place, the assembly difficulty is reduced, safety and efficiency are improved, the horizontal movement alignment is accurate, and butt joint quality of the truss girders is guaranteed.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

Corrugated packaging carton manufacturing and forming machine and manufacturing and forming process

InactiveCN111775491AAchieve fixationRealize the clamping effectBox making operationsPaper-makingCartonIndustrial engineering

The invention relates to a corrugated packaging carton manufacturing and forming machine and a manufacturing and forming process. The corrugated packaging carton manufacturing and forming machine comprises a fixed base, a mounting plate, a clamping device, a gluing device and a pressure maintaining plate. The mounting plate is fixed to the right side of the upper end of the fixed base, and the clamping device is mounted in the middle of the mounting plate through a bearing. The gluing device is arranged on the left side of the clamping device, and the pressure maintaining plate is arranged onthe left side of the gluing device and arranged above the fixed base. The manufacturing and forming process can solve the following problems that in a traditional round corrugated carton manufacturingmethod, a cylinder and a bottom support of a corrugated carton need to be manually fixed in position firstly and then glued and connected, the manual fixing effect is poor, defects often occur at thebutt joint position of the cylinder and the bottom support of the round carton, and automatic production is inconvenient; and in the process of producing and preparing the round carton, pressure maintaining treatment is often lacked, so that the stability of the gluing connection position is poor, and the using effect of the round carton can be affected to a certain extent.

Owner:闫西英

Steel structure butt jointing device for building construction

ActiveCN111424994AConvenient docking and positioningGuaranteed docking accuracyBuilding material handlingButt jointArchitectural engineering

The invention discloses a steel structure butt jointing device for building construction. The steel structure butt jointing device comprises a limiting mechanism, a fixing mechanism and a supporting plate. One end of the supporting plate is mounted on the limiting mechanism, the other end of the supporting plate is mounted on the fixing mechanism, a fixing groove is formed in one side of the fixing mechanism, and the lifting mechanism is mounted in the fixing groove. A clamping mechanism and a fastening device can clamp steel structures with different sizes, the steel structures with differentsizes can be butted, and the practicability of the device is guaranteed. The lifting mechanism can lift the steel structure needing butt jointing, the steel structure can be conveniently positioned and butted in the air, the labor intensity is reduced, and the butt joint efficiency is guaranteed. The limiting mechanism can limit the steel structure needing butt jointing, the butt jointing precision of the steel structure is guaranteed, and the butt jointing quality of the steel structure is guaranteed.

Owner:BEIJING TIANHENG CONSTR

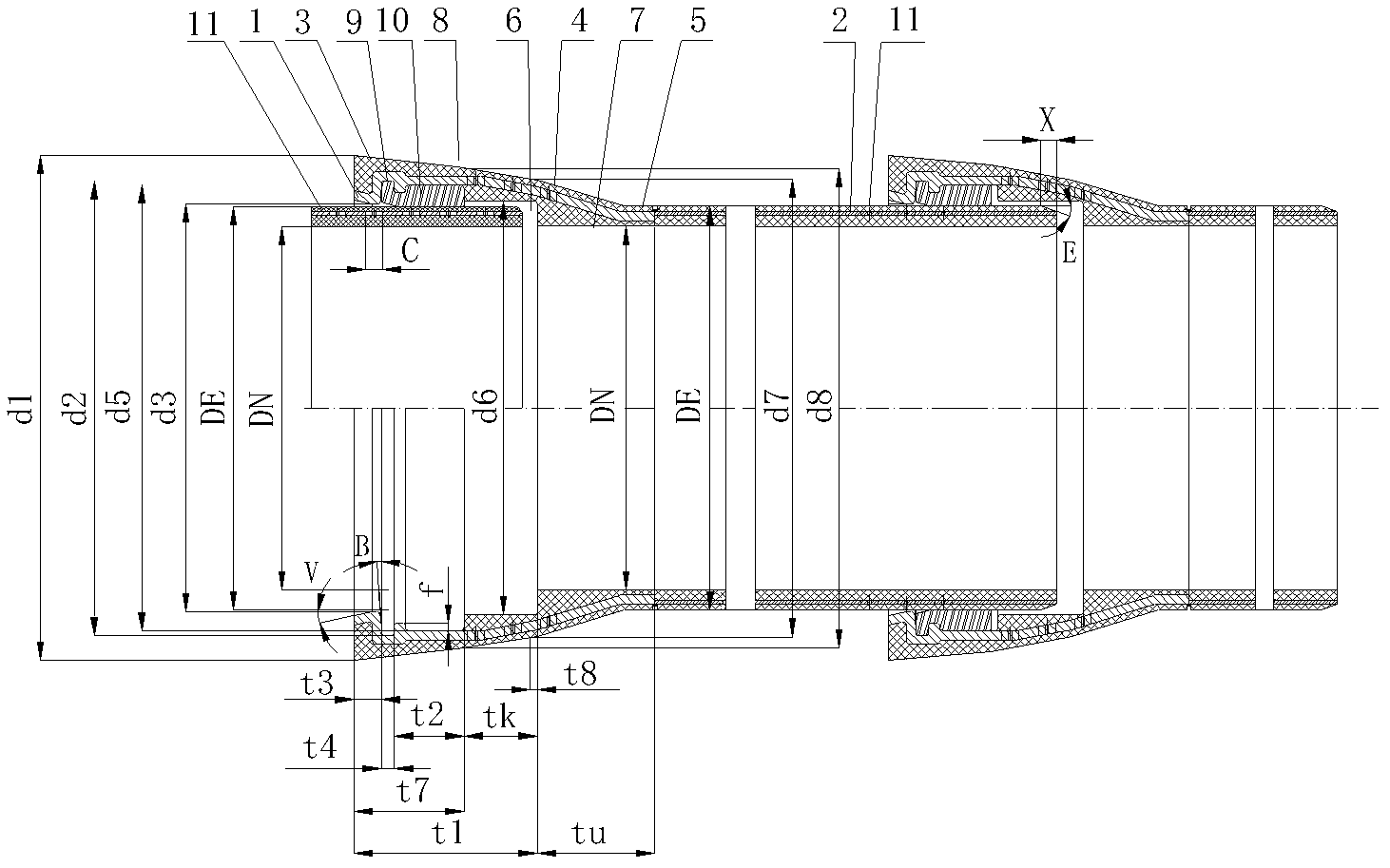

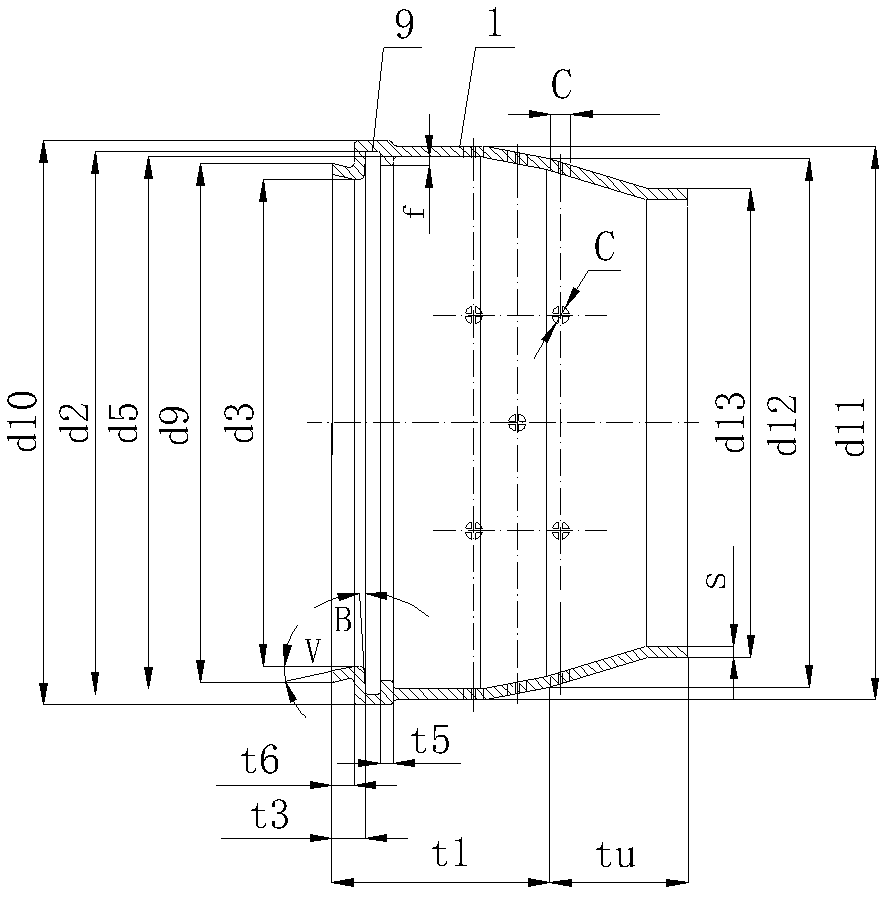

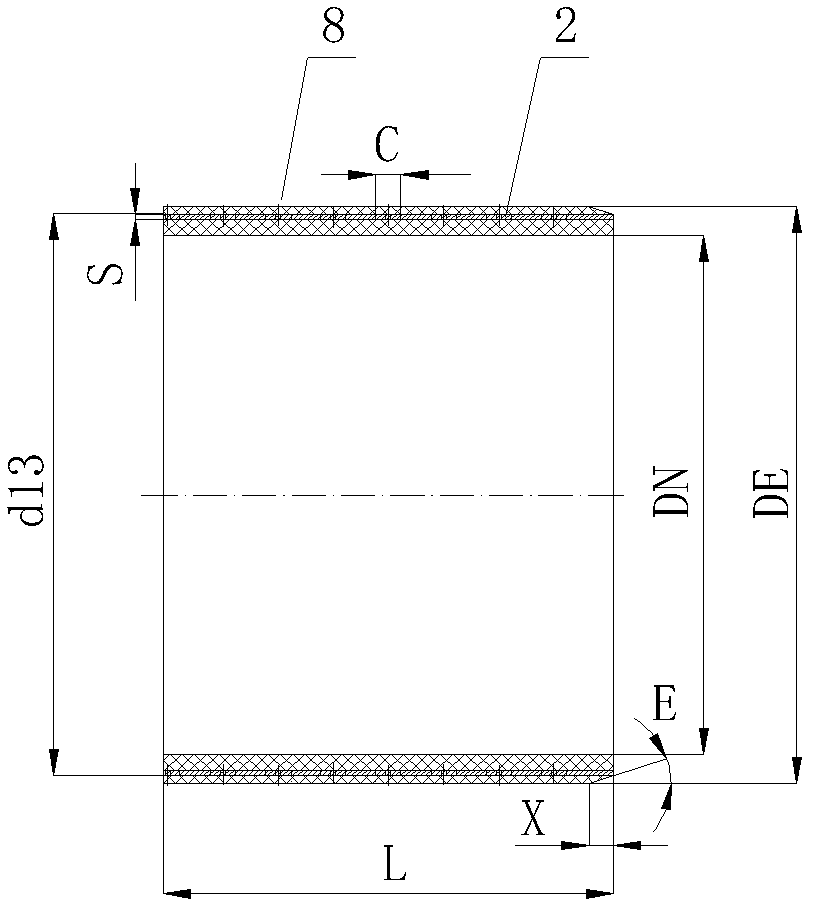

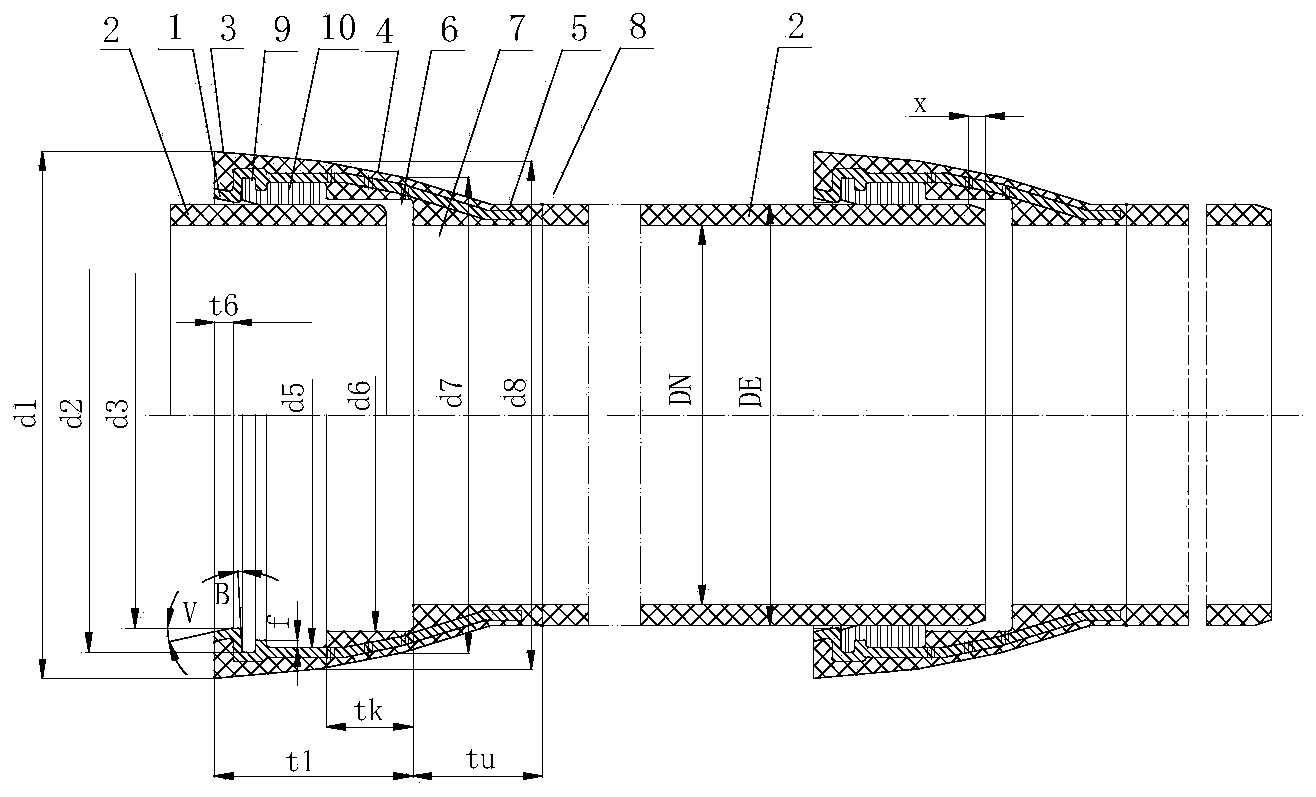

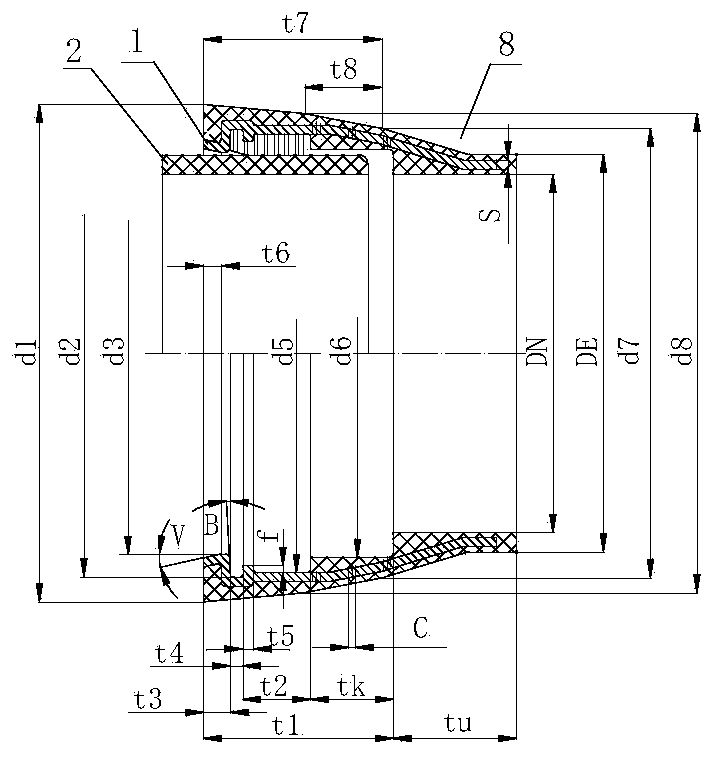

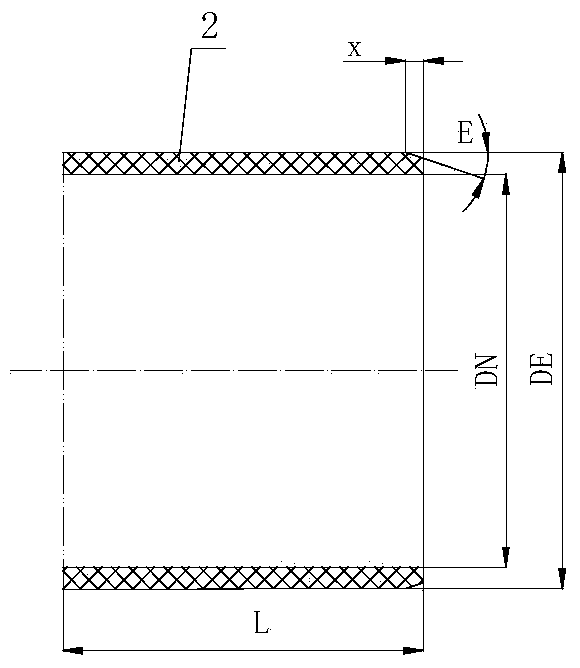

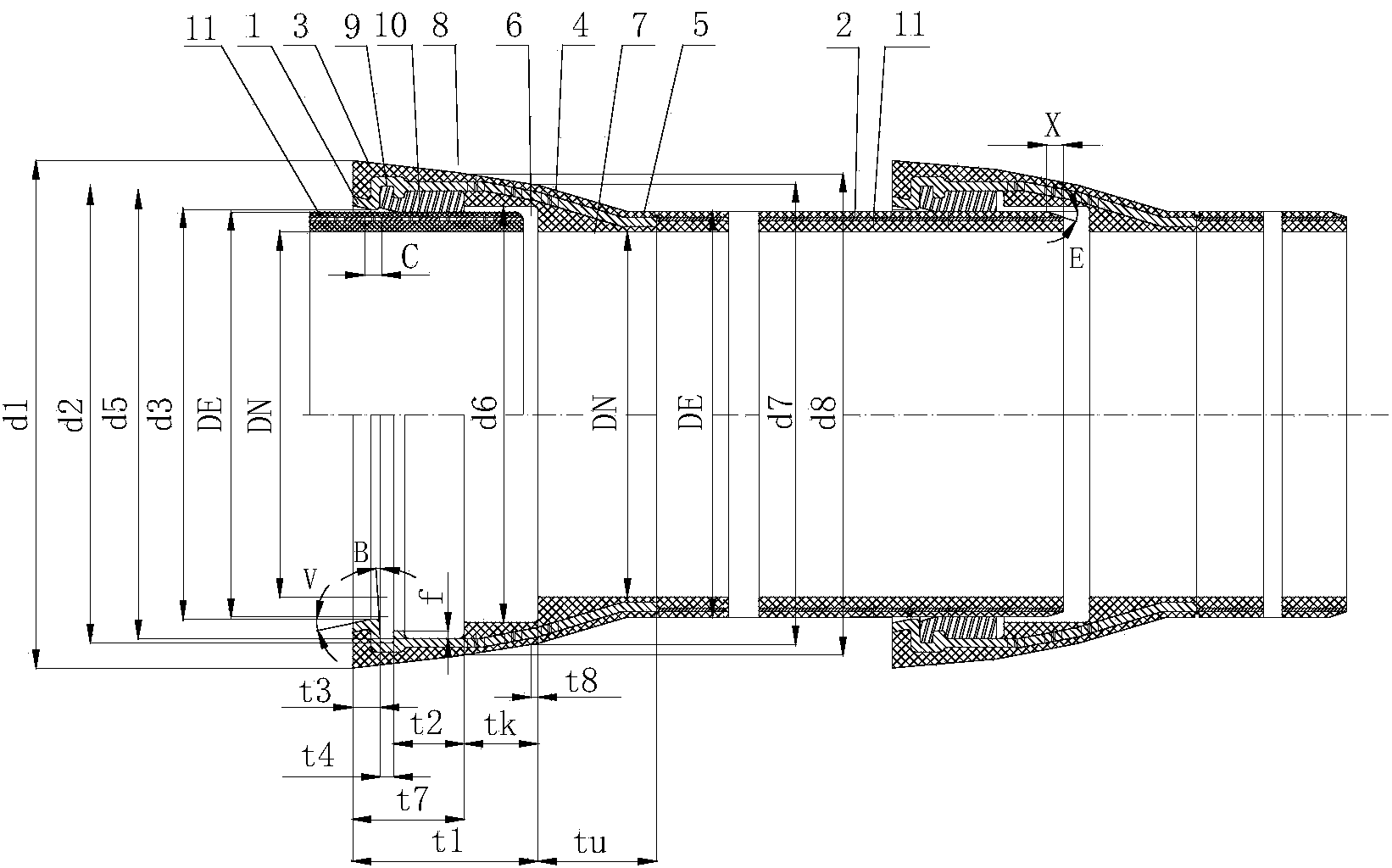

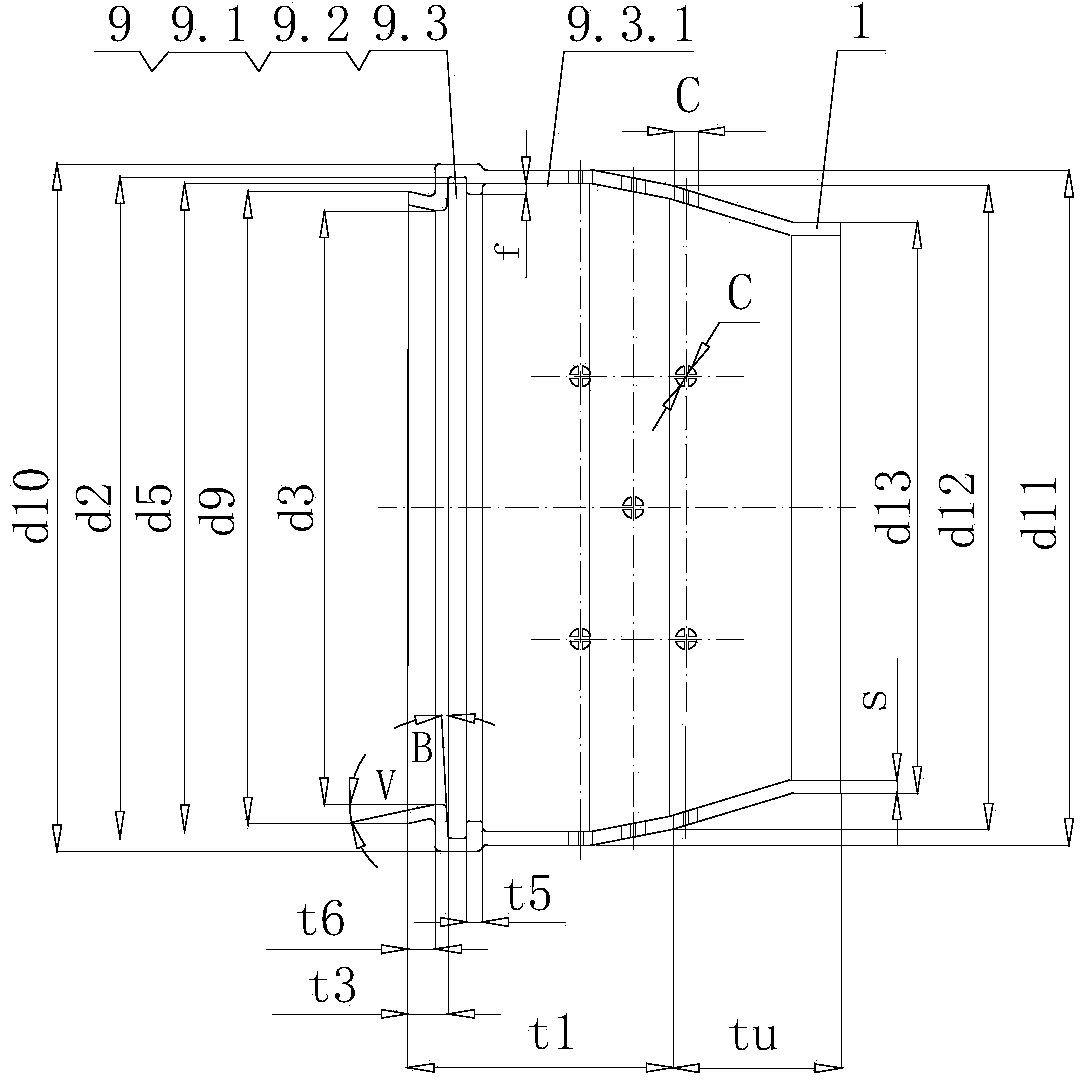

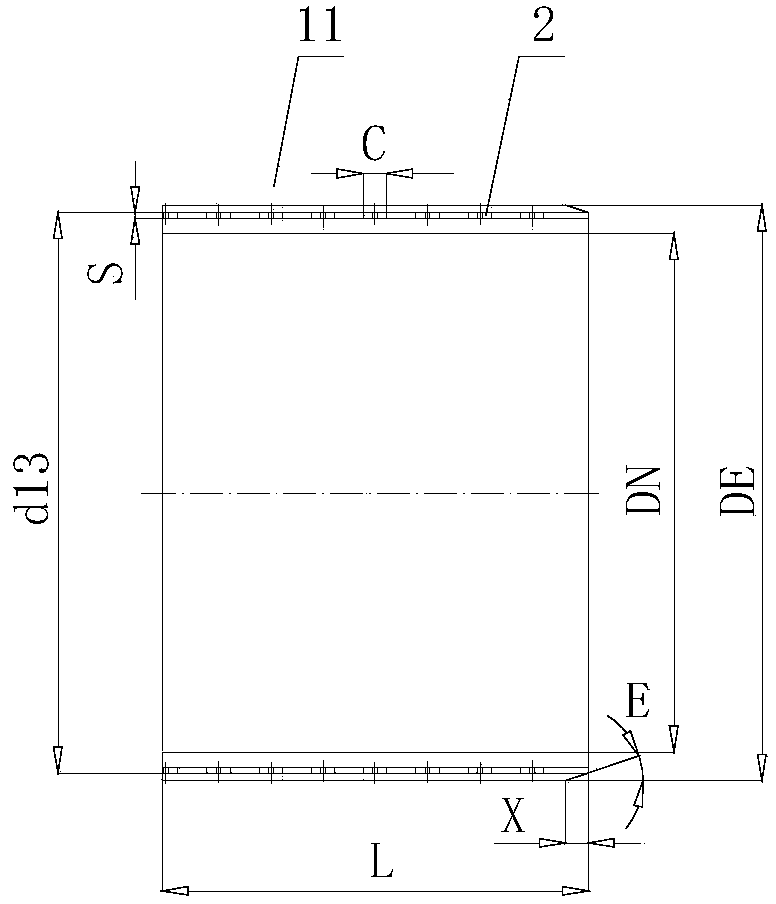

Full steel framework enhanced plug type composite pipe and manufacture technology thereof

ActiveCN102620064ASimple manufacturing processIncrease productivityPipe-jointsRigid pipesManufacturing technologyWater leakage

The invention provides a full steel framework enhanced plug type composite pipe and a manufacture technology thereof. The composite pipe comprises a main framework semi-product and an auxiliary framework semi-product which are respectively manufactured through a casting or stamping process, an injection molding process and a plastic spraying process, wherein the end parts of the semi-products are connected with each other, so as to form a product; the outer layer of the main framework is a plug main pipe outer wall formed by combining a front large tapered wall and a rear cylindrical wall with a middle small tapered wall; the plug main pipe inner wall comprises a plug cavity and a flow cavity; and a group of grooves are formed in the inner cavity of the main framework. Through the adoption of the technical scheme, the composite pipe has the advantages that the separation caused during the connection of conventional composite pipes due to different thermal expansion coefficients is avoided, so as not to enlarge the non roundness of the joints; fast stress crack, which is caused easily during welding, is reduced; the butting quality is guaranteed; defects such as water leakage, gas leakage, liquid leakage and the like caused by the connection of crack parts, which is longer than the length of a pipe plugging device, are overcome; and the composite pipe is suitable to serve as a connection pipe for various water conveying projects and gas conveying projects, and is particularly suitable for serving as an interchangeable connection plug for a plastic pipe made of PE, PVC-U, PVC-M or the like and a ductile cast iron pipe.

Owner:HUNAN ZHENHUI PIPE IND

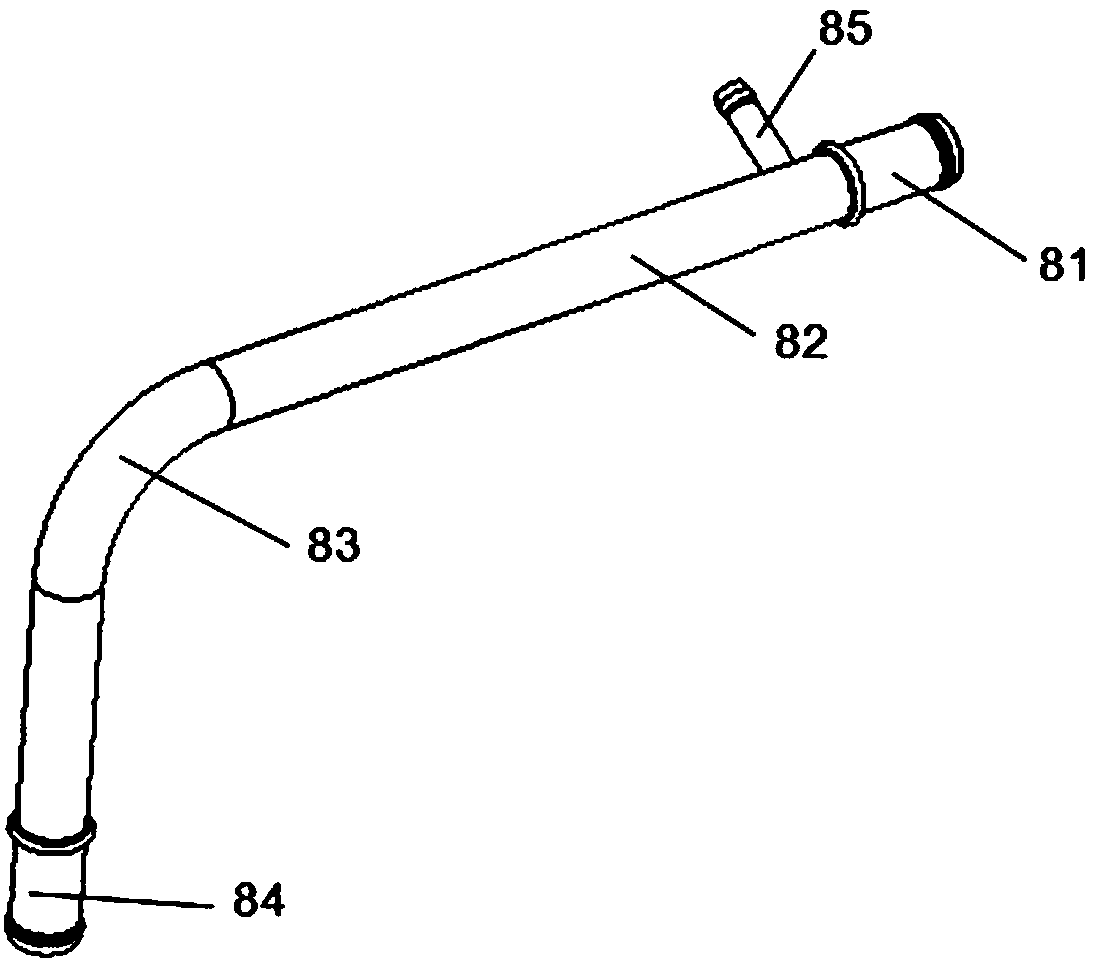

An elbow welding positioning and locking device

ActiveCN107617847BImprove efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention provides an elbow welding positioning and locking device, comprising: a base; a first support base, a second support base and an elbow positioning mechanism installed in parallel on the base from right to left; and the branch pipe positioning mechanism between the second support base; the first locking fixture installed on the second support base; the elbow positioning mechanism is installed on the left side of the second support base; fixed on the side wall of the elbow positioning mechanism and located Position the second locking clamp below the locking block. The elbow welding positioning and locking device can realize the rapid positioning and docking of pipe fittings of different shapes through the preset first support seat, second support seat, first locking fixture, elbow positioning mechanism, and second locking fixture, and ensure Butt joint quality, the branch pipe positioning mechanism can ensure that the welding angle between the branch pipe and the first tube and the second tube meets the requirements, and the straight pipe and the second tube can be realized through the first locking fixture and the second locking fixture quick lock.

Owner:GUANGDONG JUNCHI TECH HLDG

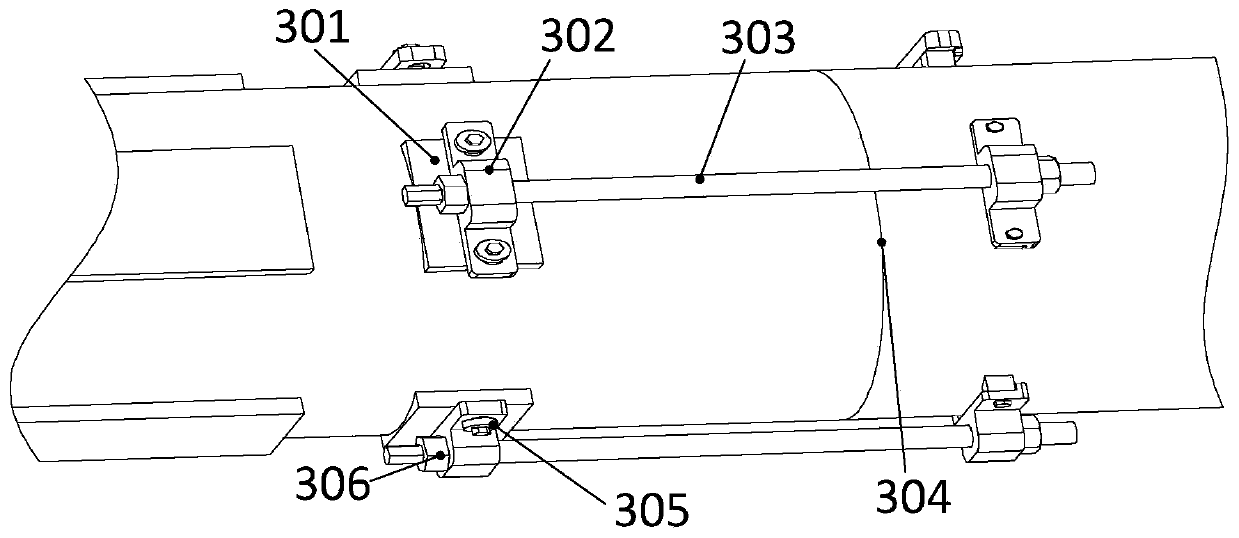

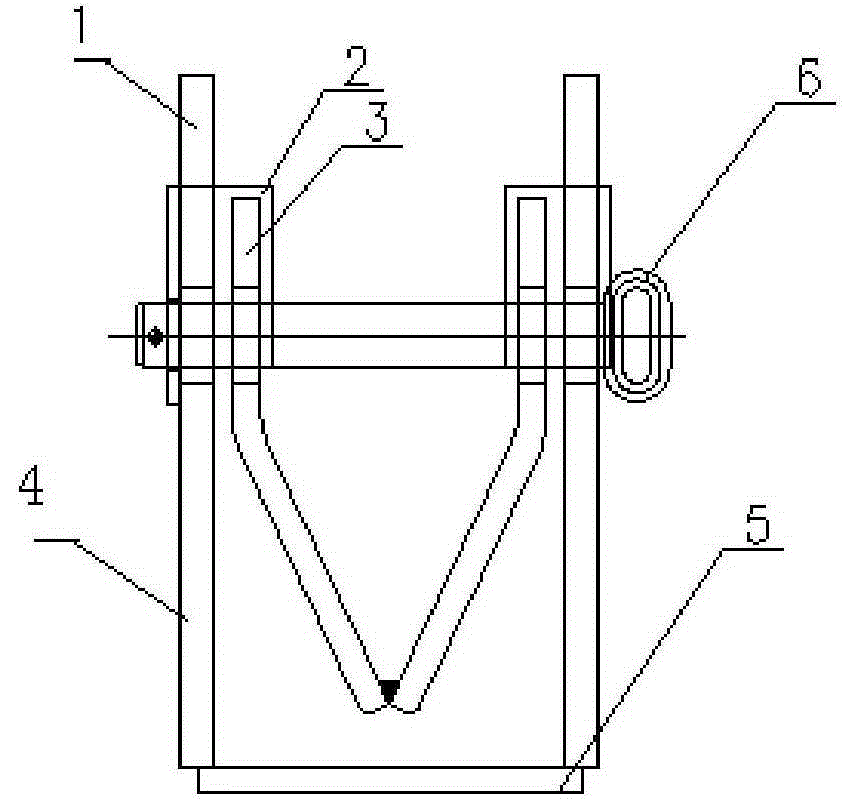

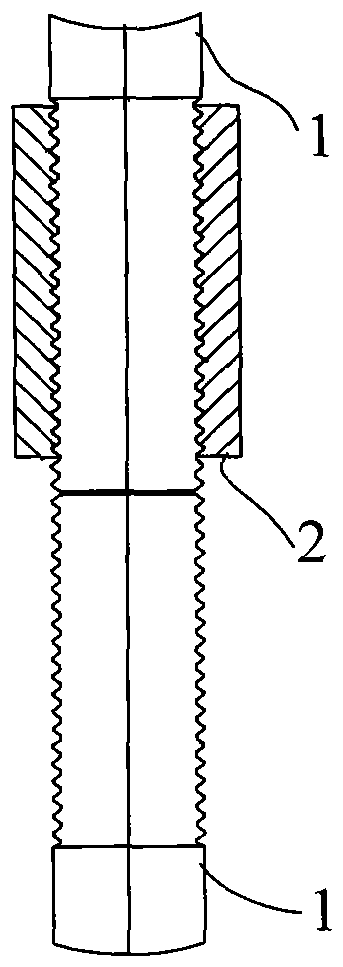

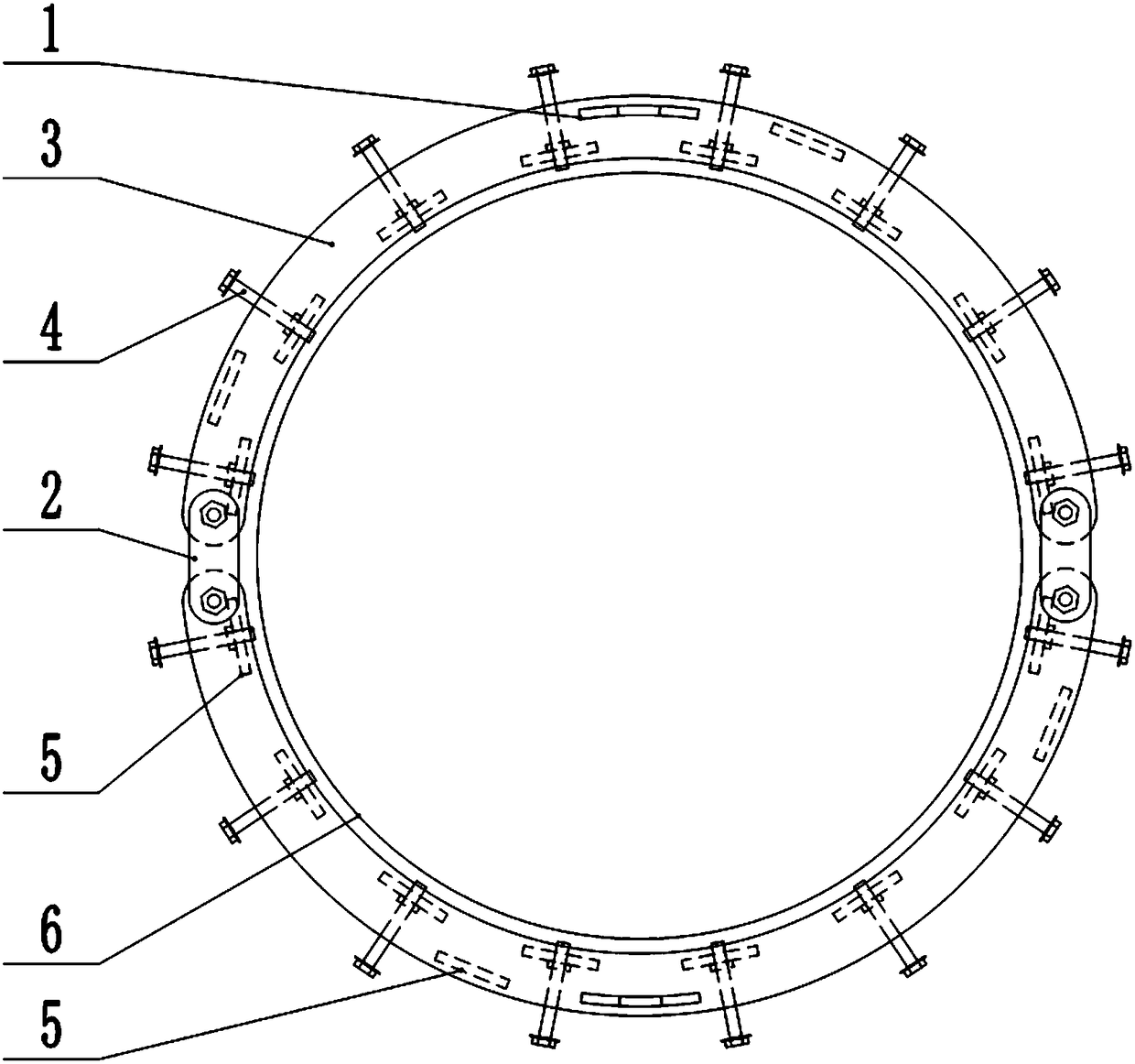

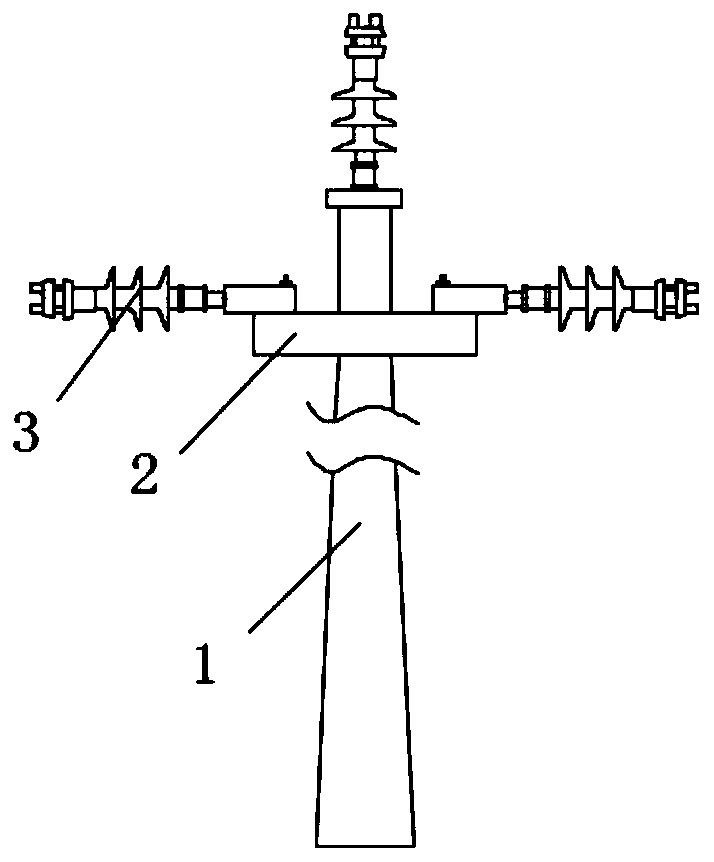

Pile leg segmented butt-joint guide device

InactiveCN105297697AGuaranteed to be correctGuarantee docking qualityArtificial islandsUnderwater structuresButt jointEngineering

The invention belongs to the manufacturing field of pile legs of a self-elevating drilling platform, and particularly relates to a pile leg segmented butt-joint guide device. The pile leg segmented butt-joint guide device comprises an upper wedge block and a lower wedge block, wherein the upper wedge block comprises two upper wedge block fixed plates, two upper wedge block connecting plates and two upper wedge block guide plates which are symmetrically arranged; the outer sides of the upper wedge block fixed plates are in welded connection with a rack plate; the lower parts of the upper wedge block guide plates which are symmetrically arranged form a V shape and form a guide structure with the lower wedge block; the upper wedge block fixed plates and the upper wedge block guide plates are fixed by the upper wedge block connecting plates in a welding manner to form the upper wedge block of the guide device; and the lower wedge block comprises lower wedge block fixed plates, a lower wedge block baseplate and a pin. The pile leg segmented butt-joint guide device solves the problem of complex working process of pile leg segmented closure in the prior art and greatly facilitates the segmented closure working of pile legs.

Owner:TIANJIN HOIDI OFFSHORE ENG

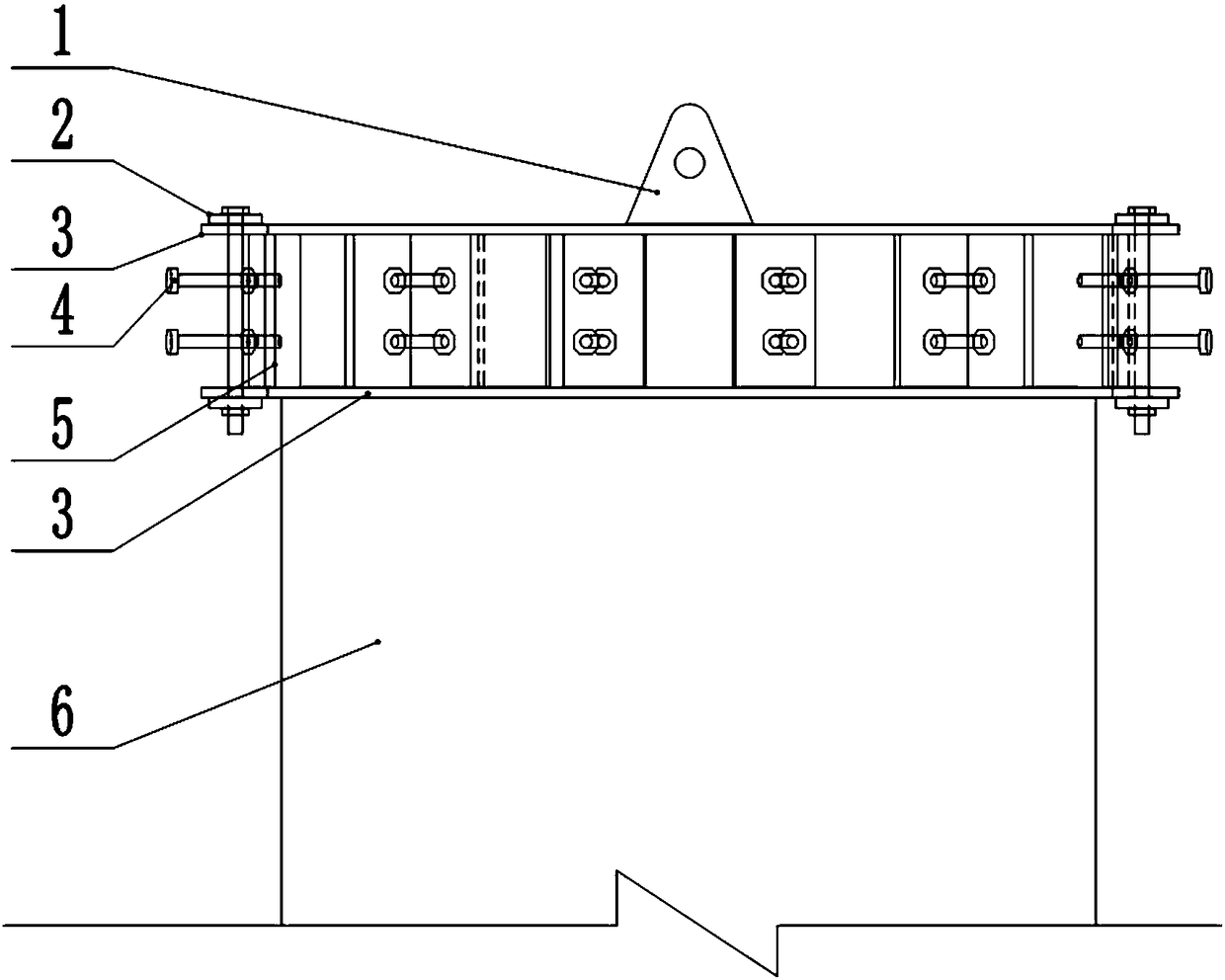

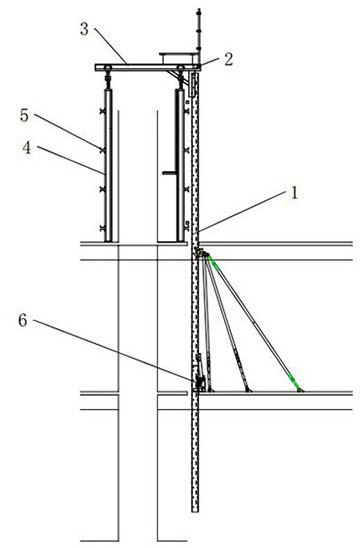

Major diameter steel bar integral vertical hoisting apparatus in high pier construction

InactiveCN104671057AImprove installation efficiencyGuarantee docking qualityLoad-engaging elementsInterference fitArchitectural engineering

A major diameter steel bar integral vertical hoisting apparatus in high pier construction is characterized in that the contact flange of two section steel clamps arranged in parallel is provided with a plurality of jaw grooves forming interference fit together with steel bars, two ends of the two section steel clamps are respectively provided with a left pin hole plate and a right pin hole plate, a latch bolt traverses through the left pin hole plate and the right pin hole plate to connect the two section steel clamps, and two ends of each of the section steel clamps are respectively provided with a hanger. The section steel clamps with the jaw grooves are arranged, so the major diameter steel bar integral vertical hoisting apparatus in high pier construction can realize one-shot vertical hoisting of a plurality of steel bars, ensures the quality of reinforced bars, and reduces the risk and cost of construction. The apparatus can guarantee the fastness and the safety of hoisting of major diameter steel bars, and greatly improves the installation efficiency of high pier construction steel bars.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Pool wall prefabricated block splicing structure suitable for static pressure assembled pool and construction method thereof

InactiveCN110725595AImprove anti-seepage performanceGuaranteed stiffnessBulk storage containerArchitectural engineeringRebar

The invention discloses a pool wall prefabricated block splicing structure suitable for a static pressure assembled pool and a construction method thereof. The splicing structure comprises a prefabricated block which is spliced along the circumferential direction to form a pool wall, a steel bar which penetrates through the prefabricated block and extends out from the circumferential end part of the prefabricated block, a splicing block which is positioned at the circumferential end part of the prefabricated block to form the outer wall of the pool and a soil retaining block which is positioned at the bottom of the prefabricated block, and the splicing block and the soil retaining block are enclosed to form a connecting groove for circumferential splicing, when the prefabricated blocks are assembled along the circumferential direction, two opposite steel bars in the connecting grooves of the adjacent prefabricated blocks are fixedly connected with each other, and concrete is filled inthe connecting grooves to form cast-in-place blocks. The construction method comprises the following steps of determining the size and the quantity of the prefabricated blocks according to the size of the water pool; manufacturing the prefabricated block, pressing the prefabricated block into a soil body, and butting the steel bars; pouring concrete to form the cast-in-place blocks. According tothe splicing structure and the construction method, the prefabricated block and the cast-in-place block are assembled to form the pool wall, and the prefabricated structure and the cast-in-place structure are combined, so that the anti-seepage performance of the pool wall is improved, and the integral rigidity of the structure is guaranteed.

Owner:HOHAI UNIV

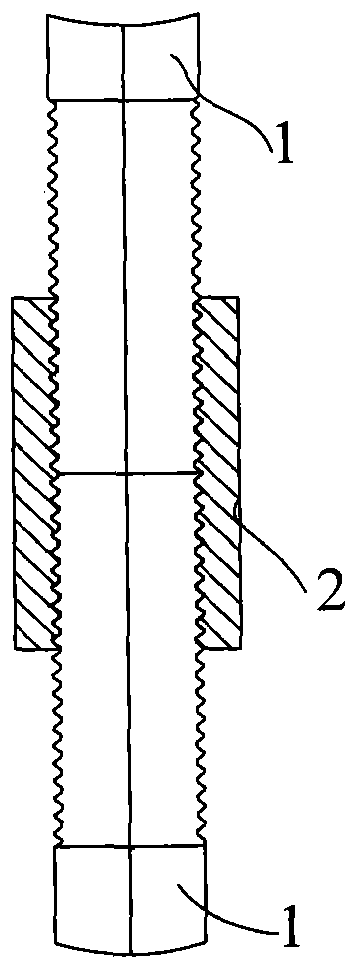

A butt joint for steel bars

ActiveCN105082058BImprove work efficiencyEasy to openMetal-working hand toolsElastic componentEngineering

The invention provides an abutting apparatus for reinforcing steel bars. On the basis of guaranteeing the abutting quality of the reinforcing steel bars and not increasing labor force, the construction speed of a sleeve joint of the reinforcing steel bars can be improved. The abutting apparatus for the reinforcing steel bars comprises a sleeve clamping fixture and a sleeve rotating clamp, wherein the sleeve clamping fixture comprises a clamping tube, a clamping handle and a gear; the sleeve rotating clamp comprises a rotating handle and a retainer ring; a ratchet matched with the gear and a first elastic component are arranged at a hinged part of the retainer ring; the first elastic part drives the ratchet to have a tendency of rotating towards one direction by taking a hinge point as a pivot. According to the abutting apparatus for the reinforcing steel bars, disclosed by the invention, the sleeve clamping fixture is used for fastening a sleeve; the sleeve rotating clamp is used for enabling the sleeve clamping fixture and the sleeve to jointly rotate so as to realize the abutting of two thread reinforcing steel bars; the sleeve clamping fixture and the retainer ring of the sleeve rotating clamp are of two split structures, so that the opening or closing can be conveniently realized; the abutting apparatus is particularly suitable for abutting the thread reinforcing steel bars of a filling pile in a deep pile hole, and is beneficial for safe production and improvement on the working efficiency of abutting of the reinforcing steel bars.

Owner:CHINA STATE CONSTR PORT ENG GRP

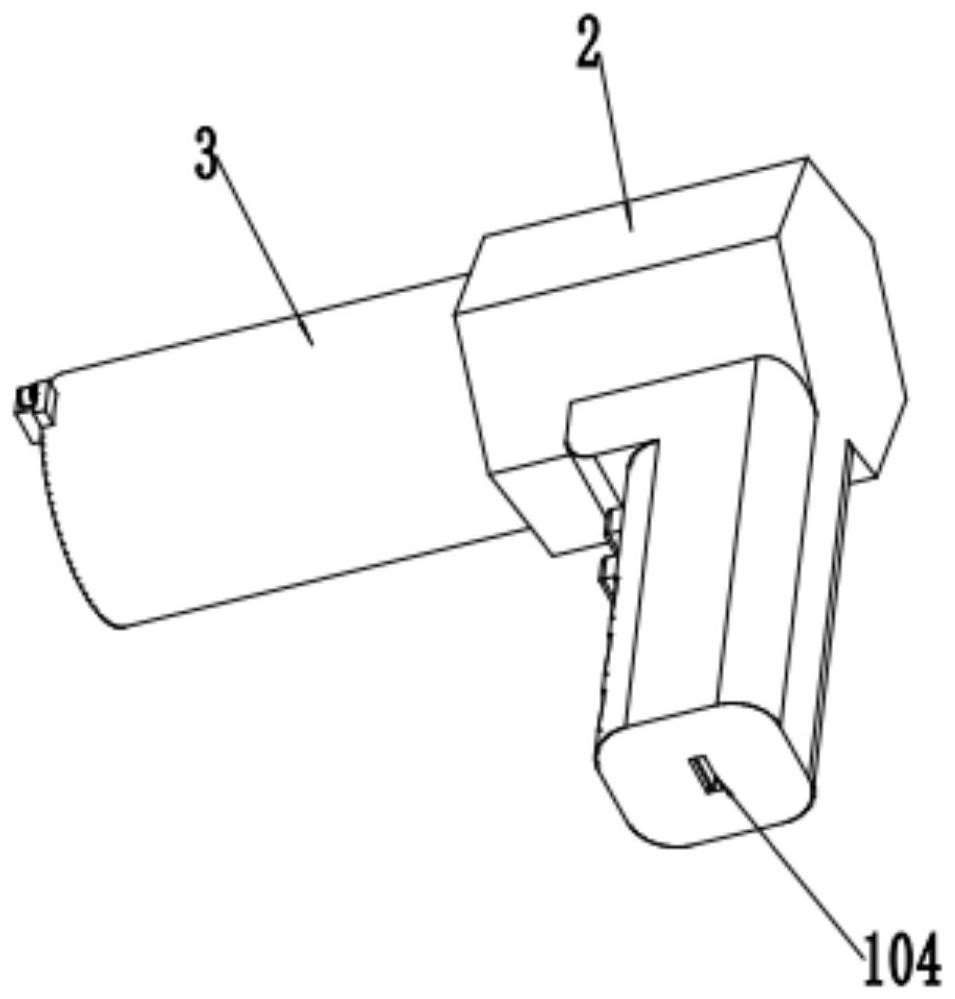

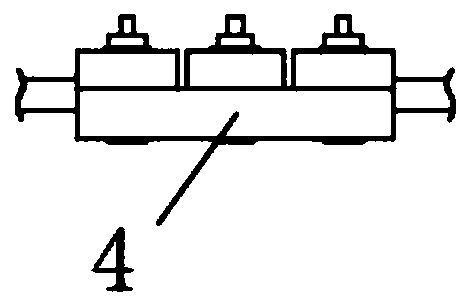

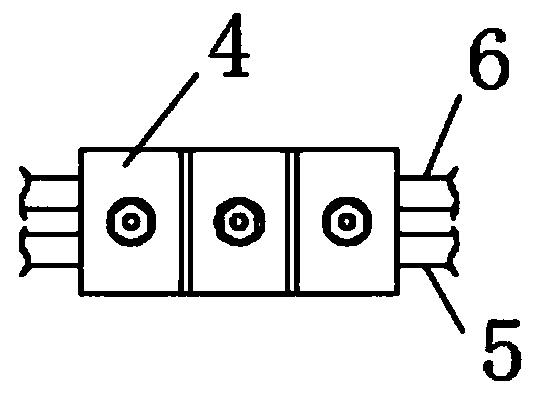

Ear-bent tube bundle device

PendingCN114151780AGuarantee docking qualityEliminates bloatBoiler drums/headersSteam superheatersStructural engineeringMechanical engineering

The invention discloses a tube bundle device of a lug bend, and aims to provide the tube bundle device of the lug bend capable of effectively preventing tube cracks, the tube bundle device of the lug bend is characterized by comprising a collecting box, a through tube is arranged at the top end of the collecting box, and a bending device is further arranged between the collecting box and the through tube; the bending device comprises an outlet formed in the top end of the collecting box and a bent pipe arranged at the outlet, the bent pipe comprises a first pipeline connected with the outlet and a second pipeline connected with the through pipe, and inward grooves are further formed in the two sides of the first pipeline.

Owner:JIANGSU TAIHU BOILER

A cabin rapid pose adjustment and tensioning device based on a six-axis platform

The invention discloses a cabin section rapid posture adjustment and tensioning device based on a six-axis platform, which belongs to the field of missile cabin section docking. In order to solve the problems of coaxiality adjustment and tensioning force application of the docking cabin section, the device includes a slewing card The ring module, the tensioning module, and the rotating snap ring module are used to fix the docking section and adjust the posture; the tensioning module applies the tensioning force evenly in the circumferential direction of the cabin to complete the precise and efficient docking of the cabin. Suitable for fast and safe docking between socket-connected missile compartments.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

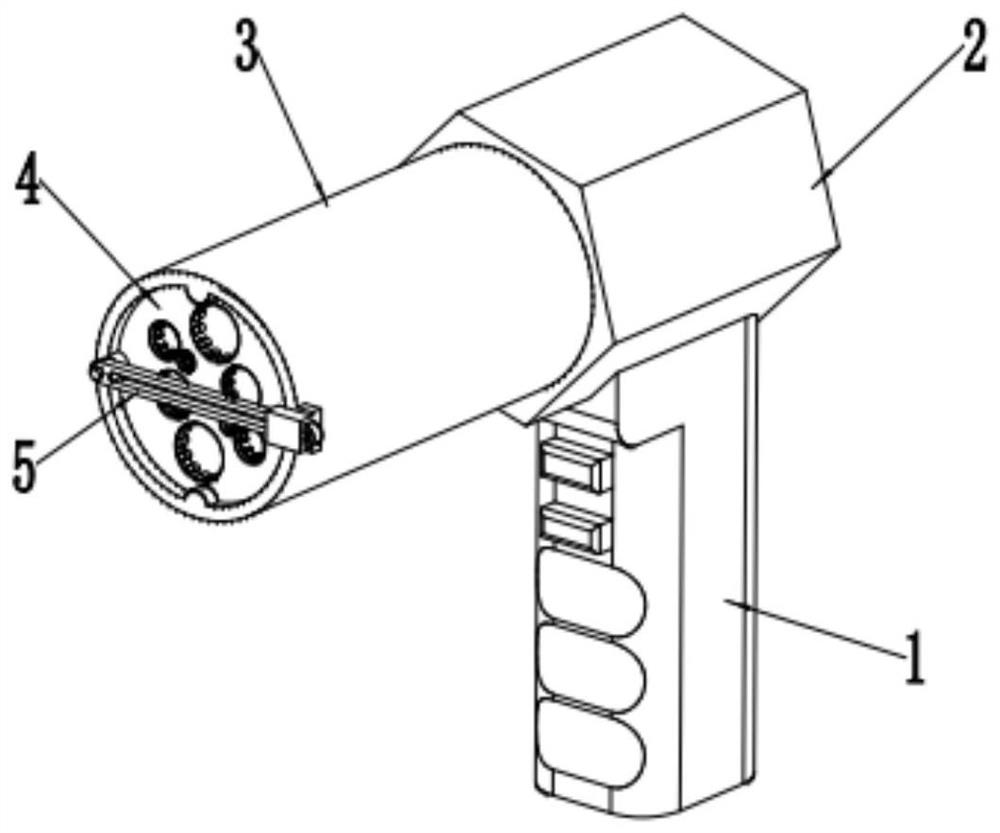

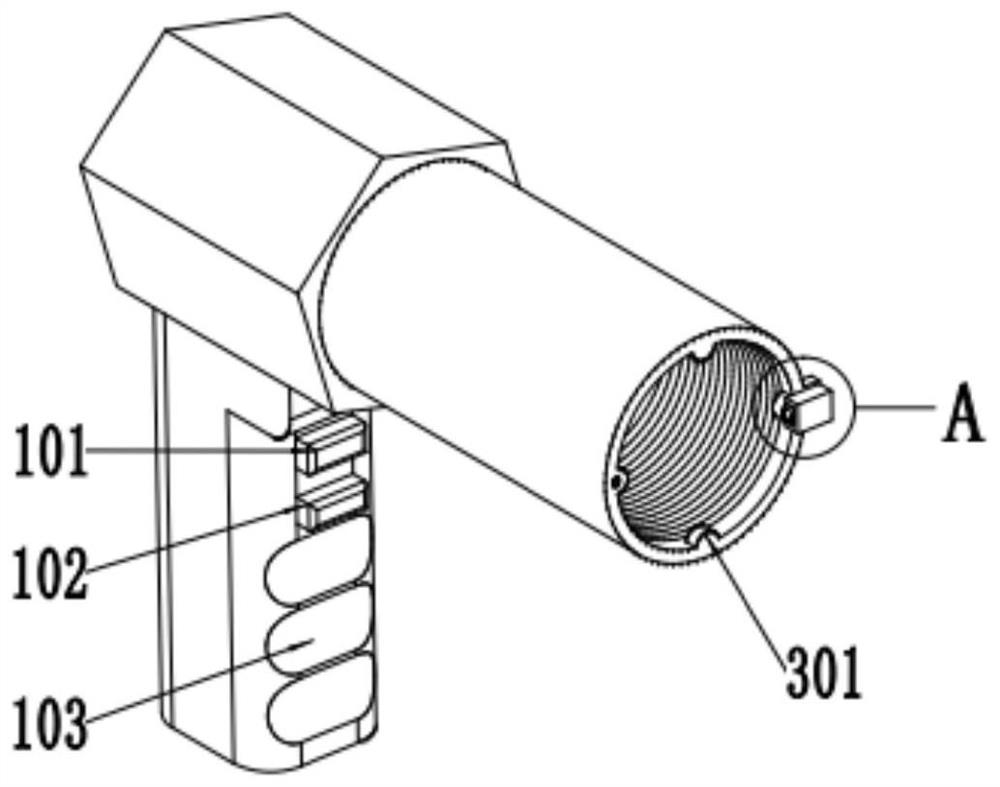

Wire butt joint device

PendingCN113991558AAchieve high efficiencyAchieve securityFilament handlingApparatus for joining/termination cablesElectric machineElectrical battery

The invention discloses a wire butt joint device which comprises a gun body and a wire spool, wherein the gun body comprises a handle, a motor and a winding reel, the end, provided with a rotating shaft, of the motor is connected with the winding reel, the lower end of the motor is connected with the handle, a battery for supplying power to the motor is arranged in the handle, and the handle is provided with a winding switch for controlling the motor to rotate forwards and backwards and a reset switch. A wire spool is rotatably connected in the winding reel, the wire spool is connected with a rotating shaft of the motor, wire holes with different diameters are formed in the wire spool, and the number of the wire holes with the same diameter is at least two. Manpower is saved, and the operation safety and the working efficiency are improved. Through the cooperation of the wire spool and the winding reel, the uniformity of wire winding is ensured, the butt joint quality of wires each time is ensured, the aesthetic property and firmness of wire butt joint are ensured, the complexity of wire connection by hands or by using pliers at present is solved, and the high efficiency and safety of electric power wire connection are realized.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

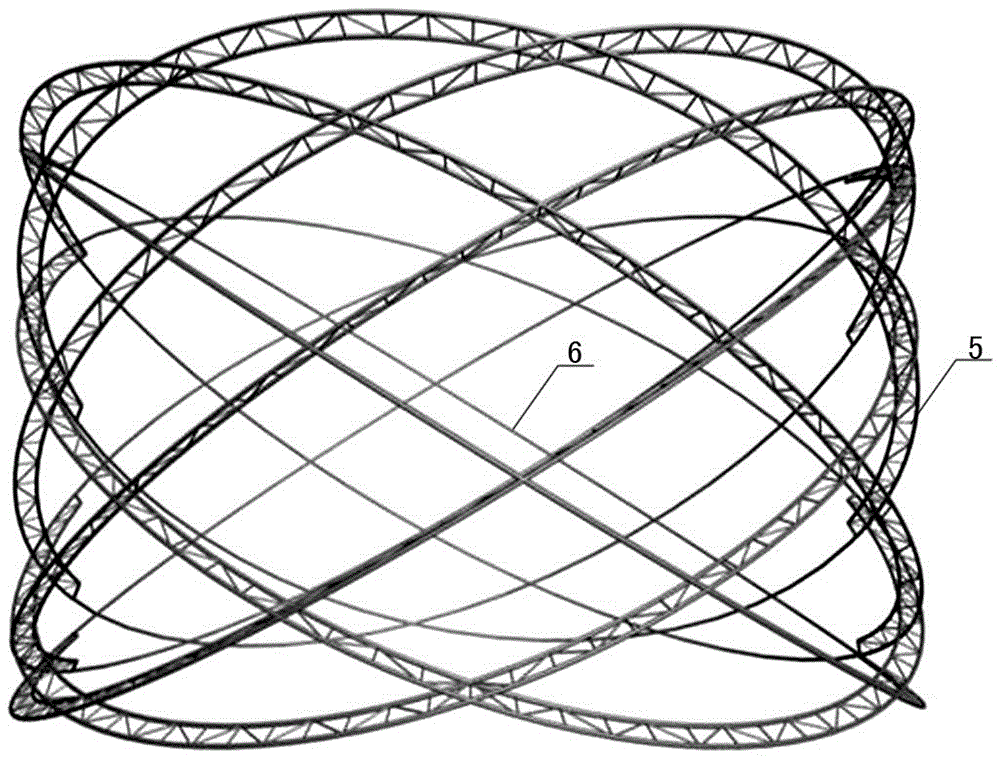

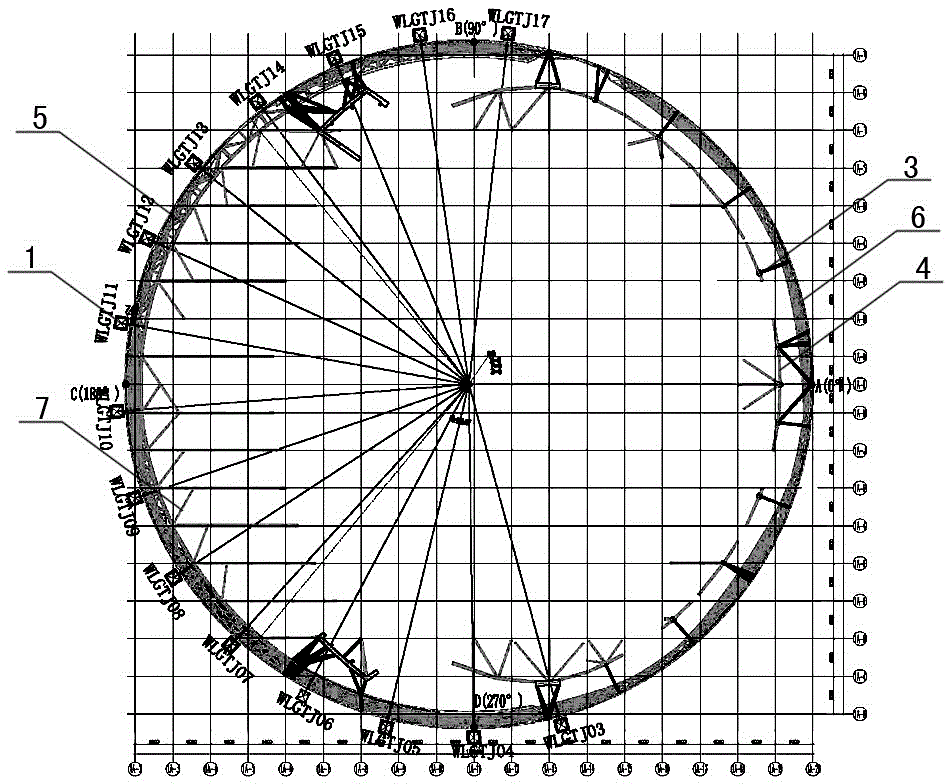

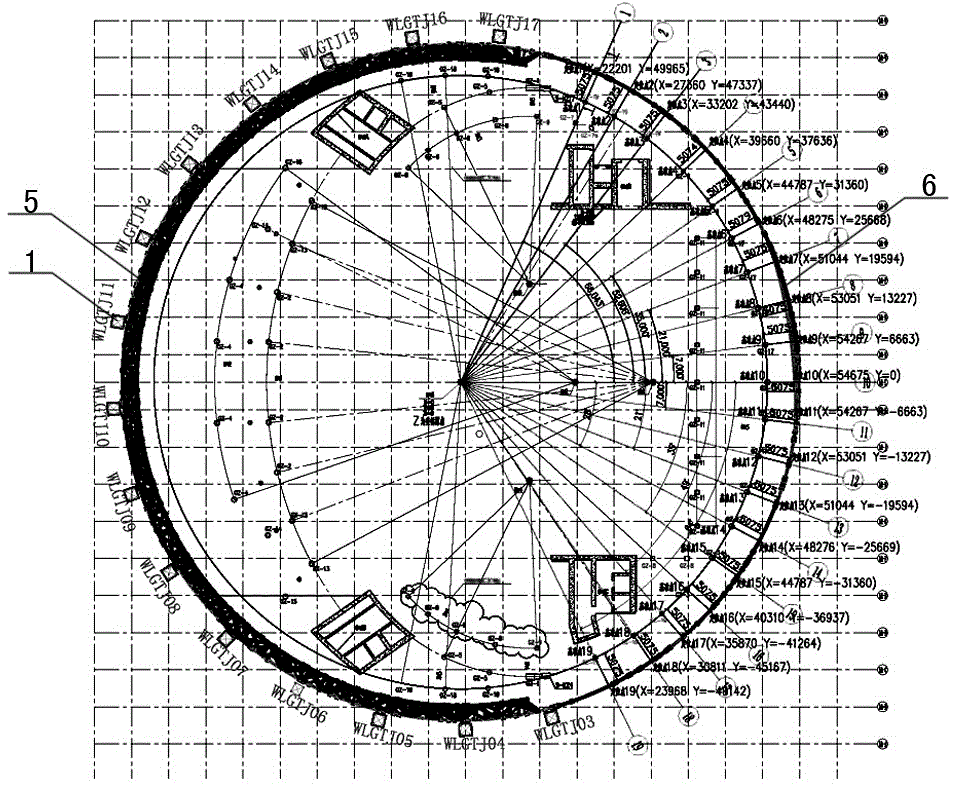

Reticulated Cylindrical Steel Structure Reticulated Shell and Its Construction Method

InactiveCN104264781BSolve technical problems in constructionOvercome the shortcomings that the construction and installation accuracy is difficult to guaranteeBuilding material handlingSurface mountingMaterials science

The invention provides a grid-shaped, cylindrical-surface and steel structured latticed shell and a construction method thereof. The grid-shaped, cylindrical-surface and steel structured latticed shell comprises eight elliptical frameworks which are mutually and slantly crossed and connected in a sleeving manner; the cross section of the grid-shaped, cylindrical-surface and steel structured latticed shell is circular and is divided into a front arc surface and a back arc surface; each elliptical framework is a closed structure constituted by a double-pipe truss and a single-pipe structure frame; the double-pipe trusses of the eight elliptical frameworks are positioned on the front arc surface; the single-pipe structure frames of the eight elliptical frameworks are positioned on the back arc surface. According to the invention, the elliptical frameworks are split into a plurality of arc-shaped components; the manner of segmental hoisting and piecewise installation is adopted to perform construction; the three-point hoisting manner is adopted to lift the arc-shaped components to a assigned position; adjusting steel wire ropes and adjusting chain blocks are utilized, so as to adjust the spatial position and rotation angle of the arc-shaped components; multiple safeguard measures are adopted, so as to realize accurate butting of the component connectors; the plane surface mounting position and height mounting position of the arc-shaped components are ensured; accurate installation of the rotation angle of the connector is ensured; the grid-shaped, cylindrical-surface and steel structured latticed shell and the construction method thereof can be extensively applied to the construction of large-scale space three-dimensional arc-shaped structures.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

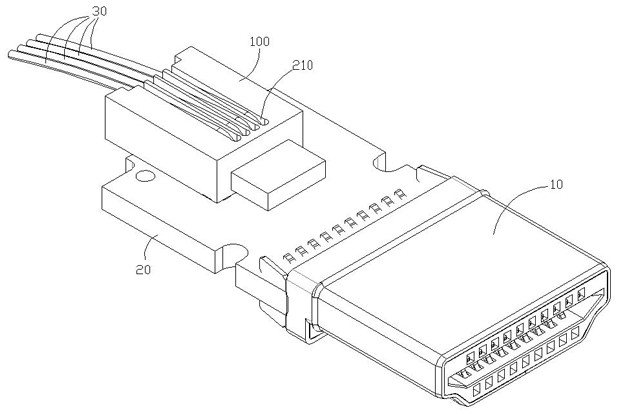

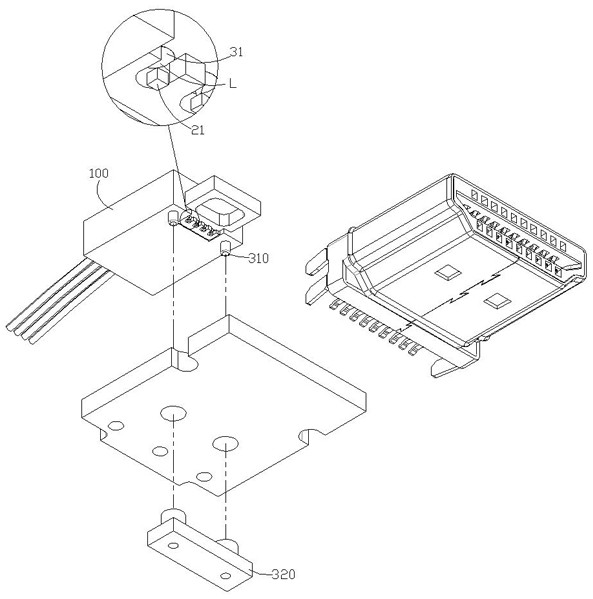

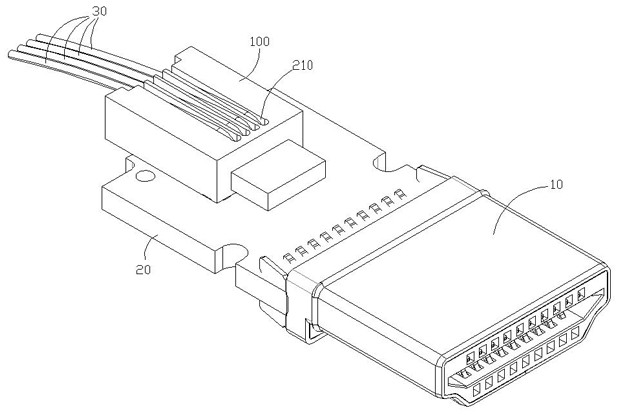

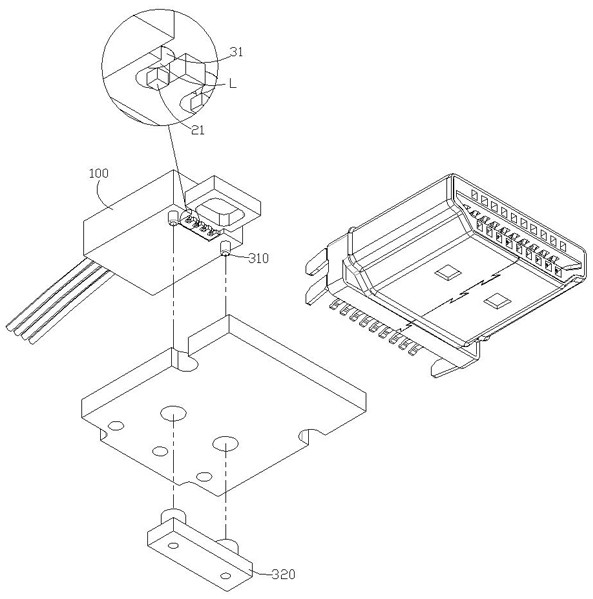

Optical module capable of being quickly aligned and assembled

ActiveCN114415298ASimplify the assembly processEasy to operateCoupling light guidesOptical ModulePlastic optical fiber

The invention relates to an optical module capable of being quickly aligned and assembled, which comprises an optical module and an optical fiber connector, and is characterized in that the optical module comprises a connector, a control circuit board and a plastic optical fiber, the control circuit board is connected to the connector, a functional optical module is arranged on the control circuit board, and the plastic optical fiber is provided with an optical fiber end surface; the optical fiber end face corresponds to the functional optical module, the optical fiber connector is connected between the plastic optical fiber and the control circuit board, and the optical fiber connector is used for fixing the plastic optical fiber on the control circuit board, so that the optical fiber end face of the plastic optical fiber corresponds to the functional optical module on the control circuit board.

Owner:SHENZHEN AFALIGHT CO LTD

A method of manufacturing a large-diameter pile foundation reinforcement cage

The invention discloses a large-diameter pile foundation reinforcement cage manufacturing method. The method includes the steps that firstly, a large-diameter pile foundation reinforcement cage manufacturing region is arranged; secondly, longitudinal main ribs are machined; thirdly, the first joint of a reinforcement cage is manufactured; fourthly, a standard joint of the reinforcement cage is manufactured; fifthly, the first joint of the reinforcement cage is pushed to a track vehicle, the first joint of the reinforcement cage is conveyed to the reinforcement cage storage region through the track vehicle, and outer hoops and spacer bars of the first joint of the reinforcement cage are welded; sixthly, the second joint of the reinforcement cage is conveyed to a first manufacturing platform center through the track vehicle to serve as the locating rebar cage for manufacturing of the next joint of the reinforcement cage, and the fourth step is repeated to finish manufacturing of other standard joints; and seventhly, a tail joint of the reinforcement cage is manufactured. By the adoption of the method, the butt joint accuracy of the joints of the reinforcement cage is guaranteed, and the error is very small.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

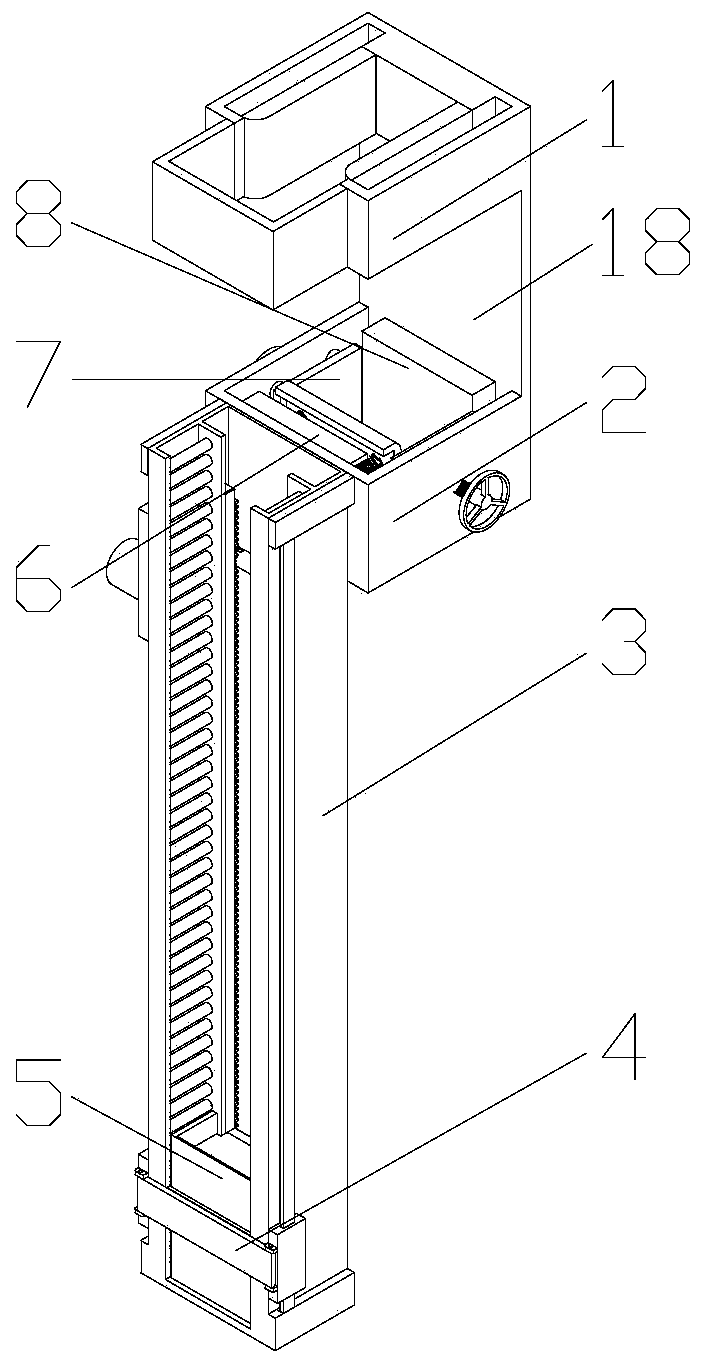

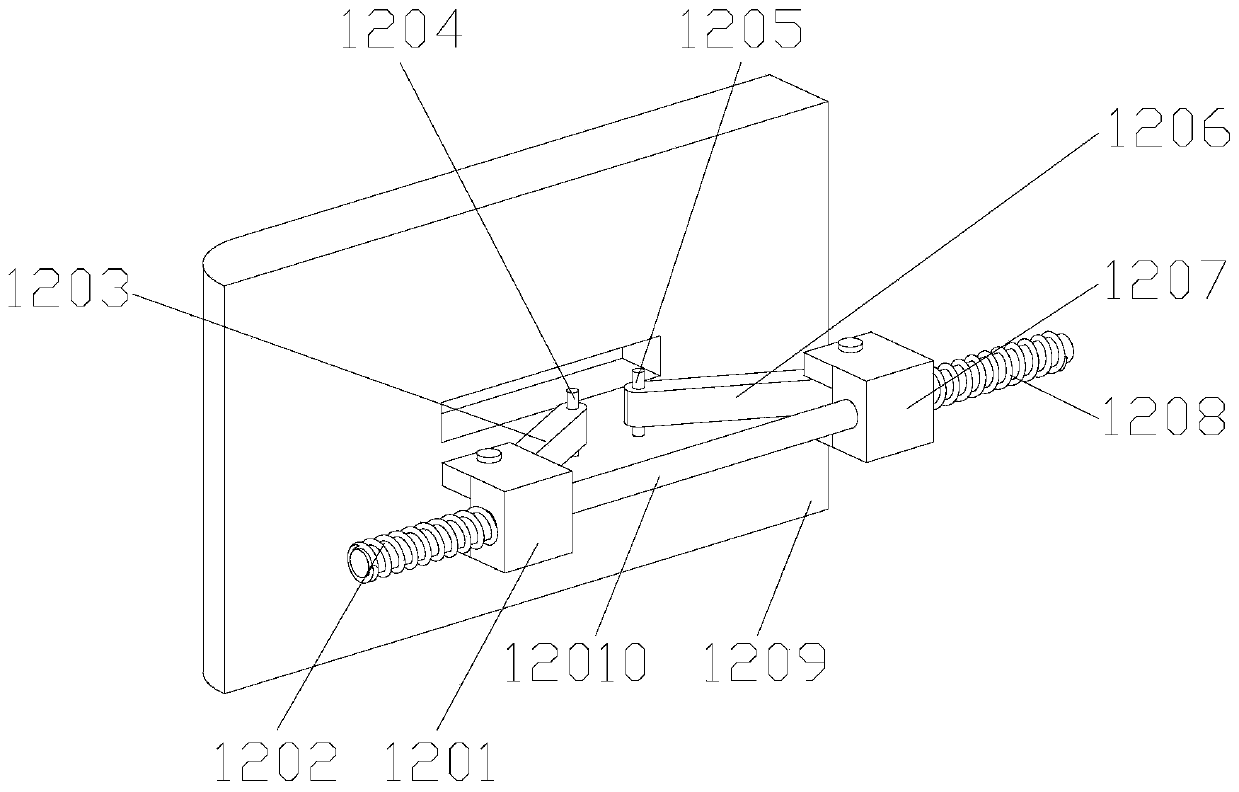

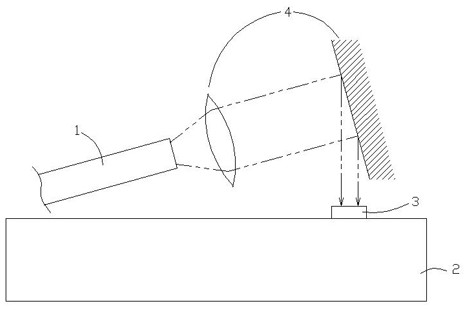

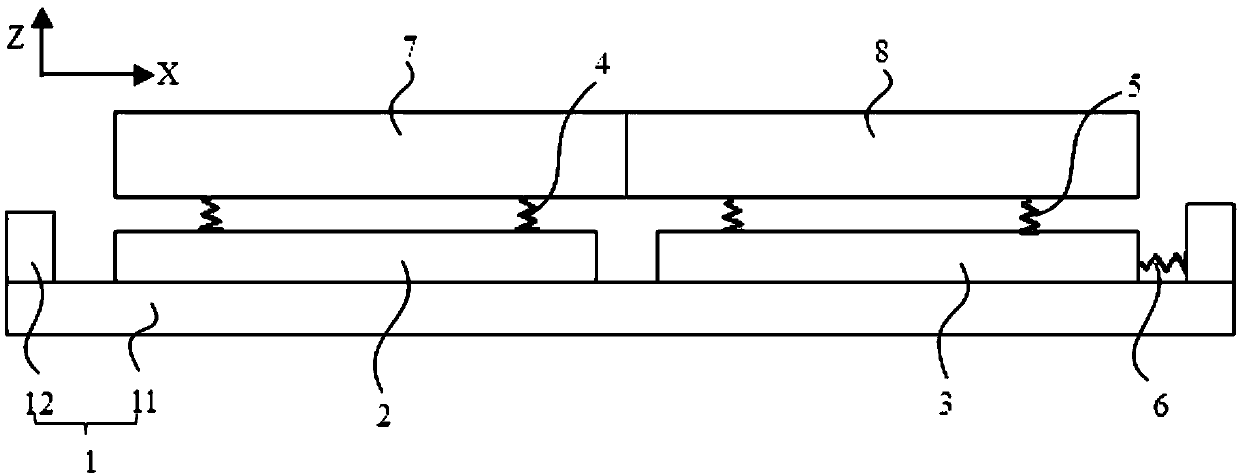

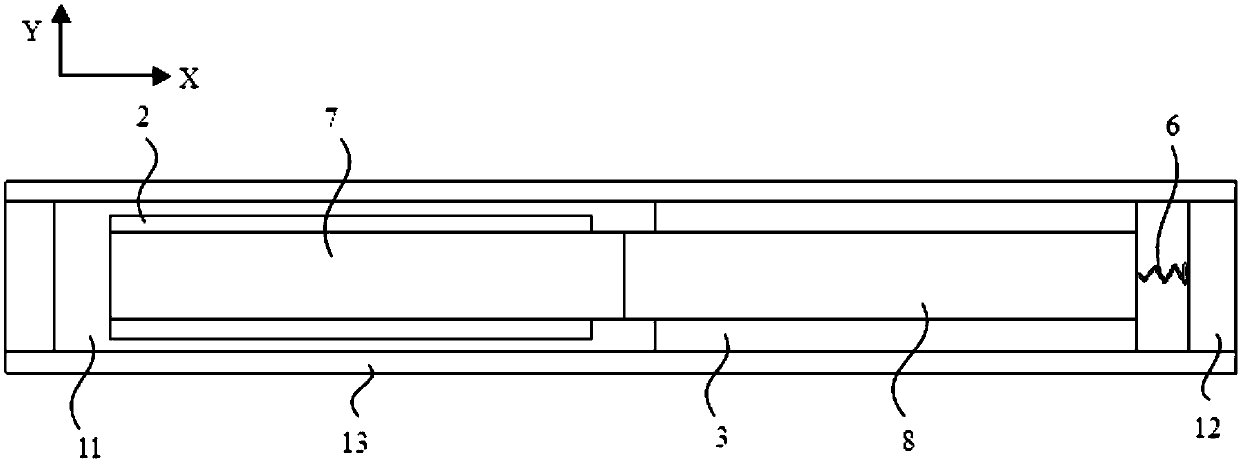

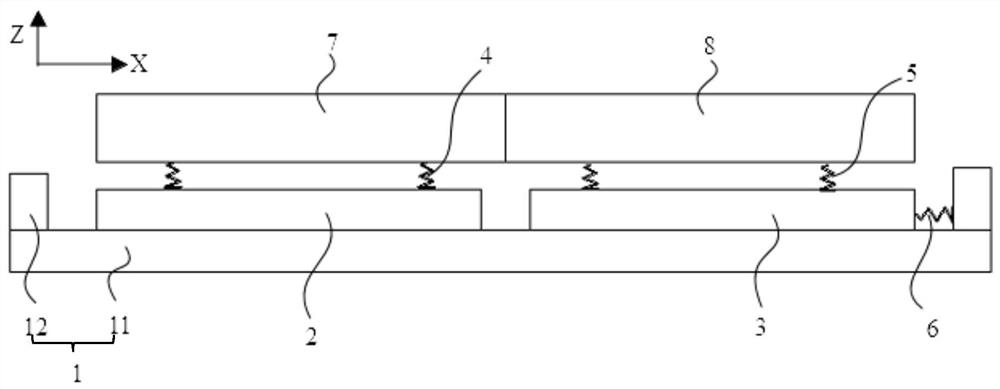

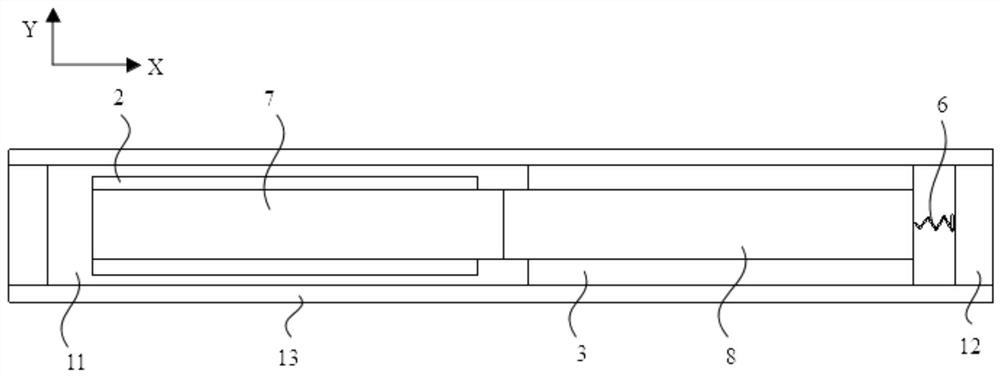

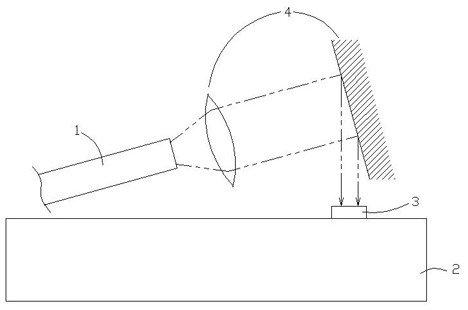

Quartz rod butt joint table

ActiveCN110941147AReduce chipping rateGuarantee docking qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusButt jointPhysics

The invention relates to a quartz rod butt joint table which comprises a base.. The table comprises a first mounting table, wherein the lower surface of the first mounting table is connected with thebase and first mounting table can slide in the first horizontal direction relative to the base, the upper surface of the first mounting table is connected with the lower end of a first elastic element, and the upper end of the first elastic element is used for being connected with a first quartz rod; a second mounting table, wherein the lower surface of the table is connected with the base; the upper surface of the second mounting table is connected with the lower end of a second elastic element, the upper end of the second elastic element is used for being connected with a second quartz rod,the second mounting table and the first mounting table are adjacently arranged in the first horizontal direction, and one end of the first quartz rod faces the second quartz rod. Edge breakage probability in the quartz rod butt joint process can be reduced, and the butt joint quality of the quartz rods and the light homogenizing effect of the quartz rods are guaranteed.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

A docking station for quartz rods

ActiveCN110941147BReduce chipping rateGuarantee docking qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusDocking stationClassical mechanics

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

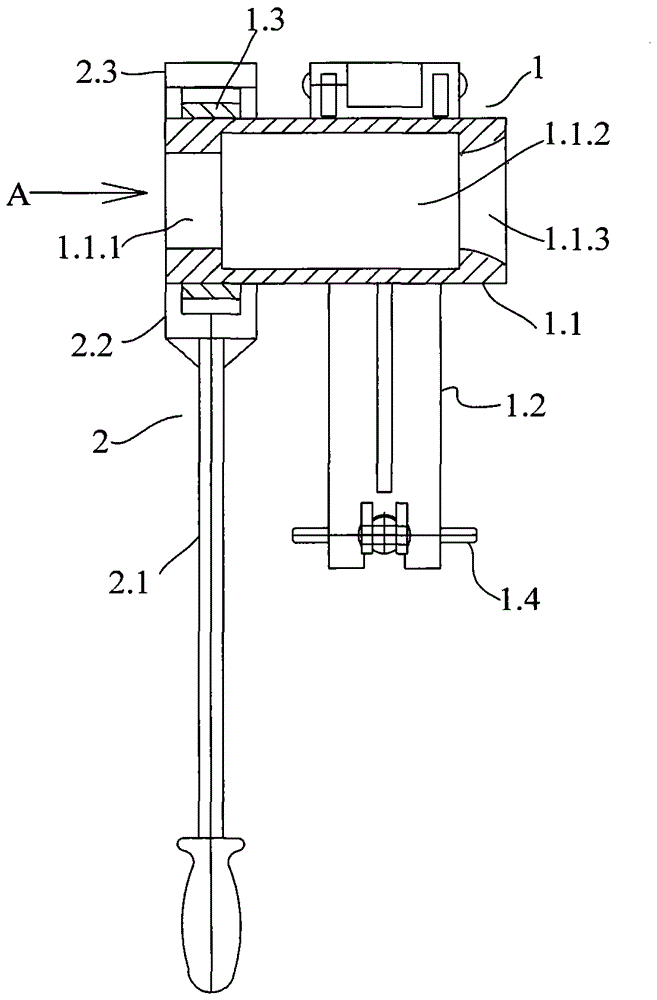

Steel pile afloat joining limiter and use method thereof

PendingCN108457268AGuarantee docking qualityGuaranteed verticalityBulkheads/pilesSheet steelArchitectural engineering

The invention provides a steel pile afloat joining limiter and a use method thereof. The limiter comprises flange plates, vertical connecting plates and a puller bolt; each flange plate comprises twosemi-circular-ring steel plates, the connecting ends of the two semi-circular-ring steel plates are connected through an arc connecting plate, the two ends of the arc connecting plate are in bolt connection with the two semi-circular-ring steel plates correspondingly, the flange plates are arranged in an upper and lower layer manner, the vertical connecting plates are located between the flange plates on the two layers, the vertical connecting plates are divided into an inner ring and an outer ring, the inner ring of the vertical connecting plates comprises multiple vertical connecting platesevenly distributed around the circumference of the inner circle of the flange plates, the outer ring of the vertical connecting plates comprises multiple vertical connecting plates evenly distributedaround the circumference of the outer circle of the flange plates, an upper nut and a lower nut are welded to each vertical connecting plate of the inner ring, and the puller bolt is screwed with thenuts and penetrates the vertical connecting plates. The construction need that other components are not welded to the outer surface of a steel pile is met, the good effect on adjusting of the ovalityof the steel pile deforming due to clamping of a vibratory hammer is achieved, and the steel pile abut-joint quality is ensured.

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

Half steel frame reinforcing type socket-and-spigot composite pipe and manufacture process thereof

Provided are a half steel frame reinforcing type adapting type composite pipe and a manufacture process thereof. The manufacture process includes manufacturing a frame by adopting casting or stamping process, and respectively manufacturing a socket-and-spigot main pipe and a socket-and-spigot auxiliary pipe in injection molding and spraying mode and assembling the pipes. A frame outer layer is characterized in that an outer wall of the socket-and-spigot main pipe is formed by a large conical wall on the front portion, a cylindrical wall on the back portion and a middle small conical wall, the inner wall of the socket-and-spigot main pipe is composed of a socket-and-spigot cavity and an overflow cavity, a socket-and-spigot composite pipe is composed of the adapting main pipe and the adapting auxiliary pipe in adaptive fit mode, a group of grooves are arranged on a front end opening of the frame, and a sealing ring is arranged in the grooves respectively in fit mode. The half steel frame reinforcing type adapting type composite pipe overcomes the shortcoming that a polyethylene resin plastic composite pipe / polyethylene (PE) pipe is easy to separate due to the fact that expansion coefficient is different in connection installation, non-roundness at the abutting connection position is increased, the welding position generates quick stress cracking and causes the fact that the connection system of the cracking portion leaks water, gas and liquid, a cast-iron pipe and the PE pipe cannot be interchanged, old project modification is affected and the like. The composite type and the manufacture process are suitable for connection pipes of various water delivery and gas delivery projects and are especially suitable for interchangeable connection of plastic pipes such as PE, PVC-U and PVC-M and nodular cast iron pipes.

Owner:HUNAN ZHENHUI PIPE IND

A butt-type wire fixing frame for eliminating heat defects of cable heads with electricity

Owner:QIXIA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

Full steel framework enhanced plug type composite pipe

ActiveCN102620064BSimple structureCompact structurePipe-jointsRigid pipesWater leakageThermal expansion

The invention provides a steel framework enhanced plug type composite pipe, which comprises a main framework semi-product and an auxiliary framework semi-product which are respectively manufactured through a casting or stamping process, and a socket welding main pipe semi-product and a socket welding auxiliary pipe semi-product are respectively manufactured through an injection molding process and a plastic spraying process and are connected to form the product at the end of the two frameworks. In the main framework, the socket welding main pipe outer wall is formed by a large tapered wall, a small tapered wall and a cylinder wall, an inner layer front part of the main framework is the framework body and forms the front inner wall of the socket welding main pipe, and the socket welding cavity wall and an overflow cavity wall form the socket welding main pipe rear inner wall. A front end of the main framework is an inner cone V trumpet shape, and the rear end of the main framework forms a groove and a sealing ring adapted to the groove. The steel framework enhanced plug type composite pipe overcomes the defects such as polyethylene resin composite pipes and cast iron pipes, cast steel pipes, steel pipes, PE pipes, PVC pipes, PPR pipes and plastic pipes can not be exchanged, separation is caused by thermal expansion difference during connection, non-roundness increases at a joint position, it is easy to crack during welding and water leakage, gas leakage and pollution to the environment due to the breakage connection beyond the half section length.

Owner:HUNAN ZHENHUI PIPE IND

Pipe flanging device and method applicable to fiber composite pipeline

The invention discloses a pipe flanging device and method applicable to a fiber composite pipeline. The device comprises two movable frames which are symmetrically arranged; shaping molds are arrangedon the two movable frames respectively and are symmetrically arranged; the shaping molds comprise pressing molds and pressing plates which are all in a semi-annular shape; the pressing molds are fixed on the movable frames on the corresponding sides; the pressing plates are connected with axial ends of the pressing molds and are driven by squeezing driving members to make squeezing motion; the shaping molds on the two movable frames are closed and sleeve on a pipe to be flanged; the two pressing plates are combined into a complete annular shape; and the two pressing molds are combined into acomplete annular shape and a flanging cavity which is in a complete annular shape is formed between the two pressing molds. According to the device and method, the split shaping molds form flanging atthe opening of the pipe, feeding and discharging of the pipe are convenient, and effective positioning and flanging operation of the pipe can be realized; and the flanging shaping quality of the pipeis excellent, so the butt-joint cost of pipes can be effectively lowered, the construction difficulty is lowered and the butt-joint quality of the pipes is guaranteed.

Owner:福建益峰科技有限公司

Self control type multi- degree of freedom buttjunction platform

InactiveCN100448629CSo as not to damageWith adaptive functionWork benchesAdaptive controlButt jointControl system

The present invention discloses one kind of butt-jointing platform with several freedom degrees, and the butt-jointing platform is one self-regulating mechanical butt-jointing platform with adaptive control system. The self-regulating mechanical butt-jointing platform includes one support platform, one work platform and three planar regulating mechanisms in the same structure. It features that three planar regulating mechanisms and one servo mechanism set between the support platform and the work platform are distributed to form one square, and that three vertical regulating mechanisms in the same structure on the support platform are distributed to form one triangle. The present invention features the self adapting function including measuring the butt-jointing position and angle between the butt-jointed body and the butt-jointed cavity and regulating the position and angle automatically to ensure high butt-jointing quality and effect.

Owner:CHONGQING UNIV

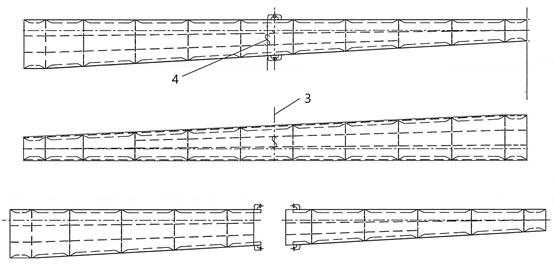

Sectional transportation and on-site butt joint process for portal frame of tire crane

InactiveCN112605544ASmooth alignment stitchingFacilitate subsequent processingWelding apparatusButt jointArchitectural engineering

The invention relates to a sectional transportation and on-site butt joint process for a portal frame of a tire crane. The sectional transportation and on-site butt joint process structurally comprises a main beam and support legs, and is characterized by comprising a tire crane portal frame sectional transportation process and a sectional tire crane portal frame on-site butt joint process. The main beam and the support legs are cut into sections at reasonable positions and then transported and ensured to reach a container yard of a user, cutting lines of panels and webs are staggered by 120-260 mm, and welding flange plates are assembled at the sectional lines of the panels, so that rapid and smooth alignment and splicing in the later period are facilitated; reasonable internal and external welding and up and down welding methods are adopted during on-site splicing, so that the butt joint quality is ensured, the problem of deformation easily generated in sectional butt joint is prevented, and the butt joint construction progress is promoted.

Owner:SHANGHAI ZHENHUA HEAVY IND

A New Method for Butt-connection of 10kv Large-capacity Overhead Line Leads

ActiveCN110011164BReduce power consumptionDock stableCoupling device engaging/disengagingElectrical resistance and conductanceButt joint

The invention discloses a new method for lead butt joint of a 10KV high-capacity overhead line, which comprises the steps of S1, preparation before the butt joint; S2, pretreatment of a conductor anda parallel groove clamp; and S3, butt joint of a lead, wherein the lead passes through the parallel groove clamp, and a transition lead and a down lead are transitionally connected to the main conductor by adopting the parallel groove clamp and do not bound with the return of an insulator; the binding methods include a binding joint method, a fork joint method and a crimping method. According to the new method for strictly controlling the lead butt joint of the 10KV high-capacity overhead line, pretreatment is carried out on the conductor surface and the parallel groove clamp, an oxide film and burrs on the butt-joint contact surface are removed, the contact resistance can be reduced during the butt joint, the electric energy loss of the overhead line is saved, the conductor adopts three binding methods which can be selected according to different types and specifications of the conductor, and the butt joint is convenient in use. In addition, the lead butt joint is stable, there is nobroken strands, twisted strands or dead bends, and the butt joint quality is guaranteed.

Owner:江西远大科技有限公司

An optical module that can be quickly aligned and assembled

ActiveCN114415298BSimplify the assembly processEasy to operateCoupling light guidesOptical ModuleEngineering

The invention relates to an optical module that can be quickly aligned and assembled, which includes an optical module and an optical fiber connector, wherein the optical module includes a connector, a control circuit board and a plastic optical fiber, and the control circuit board is connected to the connector. The control circuit board is provided with a functional optical module, the plastic optical fiber has an optical fiber end face corresponding to the functional optical module, and the optical fiber connector is connected between the plastic optical fiber and the control circuit board. The plastic optical fiber is fixed on the control circuit board, so that the optical fiber end face of the plastic optical fiber corresponds to the functional optical module on the control circuit board.

Owner:SHENZHEN AFALIGHT CO LTD

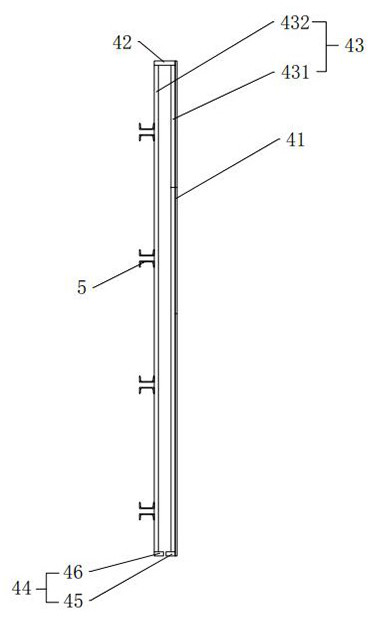

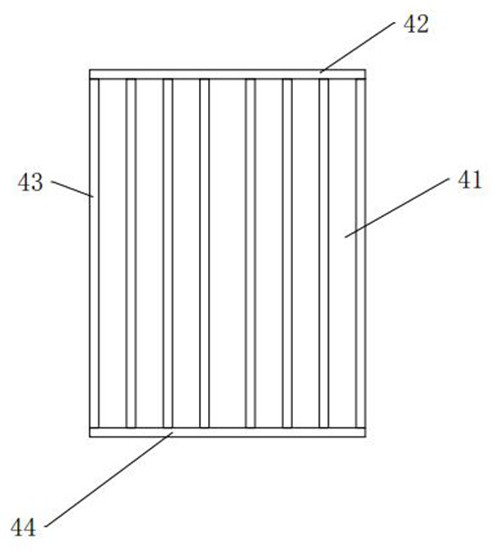

Wood formwork lower opening protection structure of hydraulic plate-penetrating creeping formwork and construction method of wood formwork lower opening protection structure

PendingCN114753618AImprove structural strengthQuality assuranceForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringBatten

The invention discloses a wooden formwork lower opening protection structure of a hydraulic plate-penetrating creeping formwork and a construction method thereof.The wooden formwork comprises a rectangular panel, batten transverse edges, batten longitudinal edges, square steel and back edges, the batten longitudinal edges comprise the first row of batten longitudinal edges and the second row of batten longitudinal edges, the first row of batten longitudinal edges are fixed to the rectangular panel in an attached mode, and the top ends of the first row of batten longitudinal edges are fixed to the batten transverse edges; the second row of batten longitudinal ridges are fixed to the bottoms of the ends, away from the panel, of the batten transverse ridges, back ridge structures are arranged on the sides, away from the rectangular panel, of the second row of batten longitudinal ridges, the square steel comprises first square steel and second square steel, and the first square steel is fixed to the bottom ends of the first row of batten longitudinal ridges and attached to the rectangular panel; the second square steel is fixed to the bottom ends of the second row of batten longitudinal edges. The combination of the double rows of batten longitudinal edges and the square steel ensures the overall strength of the wood formwork and the enhancement of the quality of the lower opening, avoids the damage of the lower opening after long-time use, ensures the quality of the lower opening, and ensures the quality of the joint.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com