Reticulated Cylindrical Steel Structure Reticulated Shell and Its Construction Method

A construction method and technology for steel structures, which are applied in the construction of buildings, construction, and the processing of building materials, can solve the problems of difficulty in ensuring the accuracy of installation of arc-shaped components, so as to ensure construction efficiency, simplify operation procedures, and achieve installation accuracy. and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

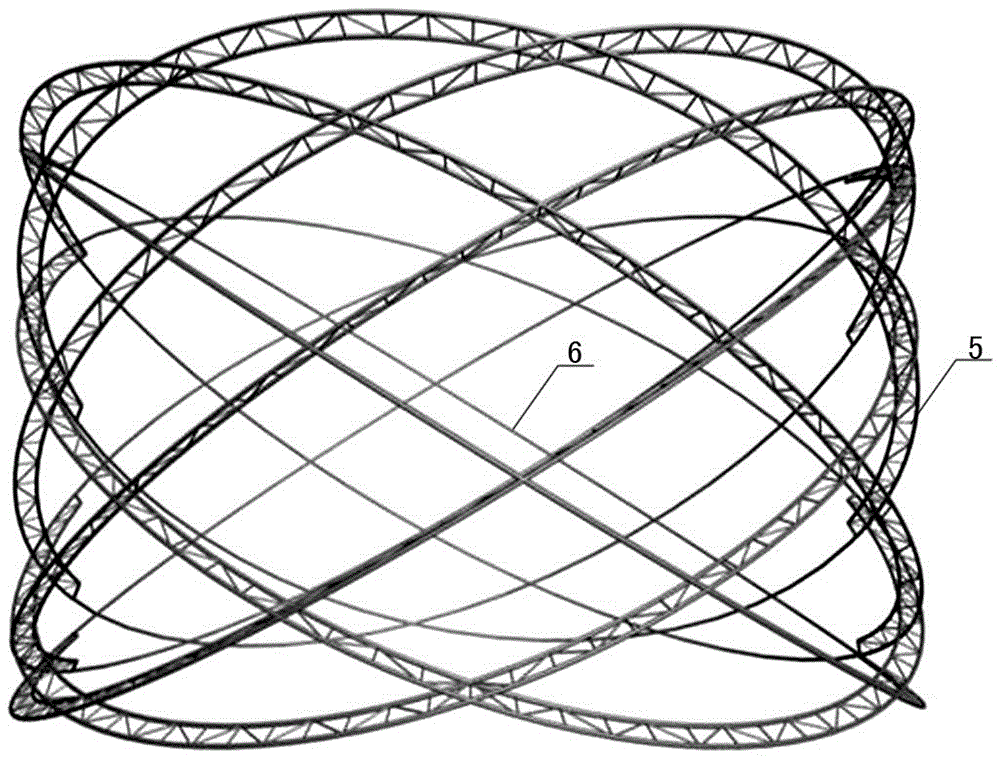

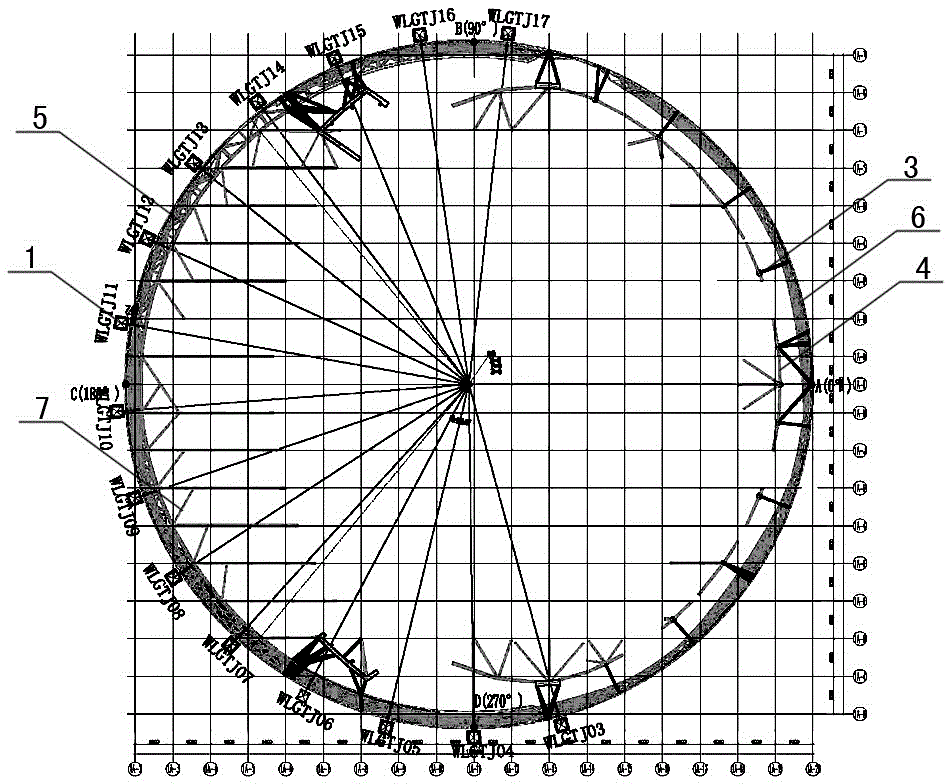

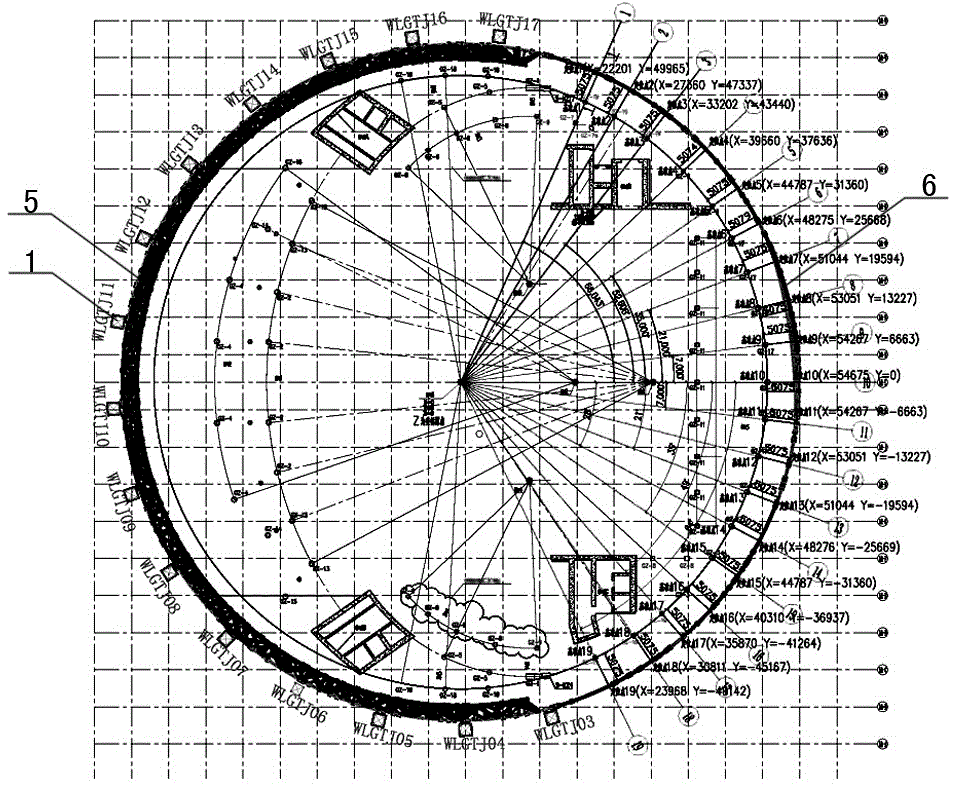

[0063] Examples see figure 1 As shown, this grid-shaped cylindrical steel reticulated shell is connected to the main structure in the reticulated shell through the support structure 7, and the supporting structure connected to the main structure of the grid-shaped cylindrical steel reticulated shell includes a grid connected to the The cantilever support between the top of the front arc of the shell and the roof of the main structure, the bottom support connected between the bottom end of the front arc of the reticulated shell and the podium of the main structure, and the middle part connected to the back arc of the reticulated shell The umbrella-shaped support between the main structure and the bottom support is welded on the beams of the podium; the main structure in the grid-like cylindrical steel structure reticulated shell includes a reinforced concrete core tube and a steel frame floor structure. The grid-like cylindrical steel structure reticulated shell is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com