Ear-bent tube bundle device

A bending device and ear technology, which is applied to steam boiler components, lighting and heating equipment, steam boiler accessories, etc., can solve problems such as thermal expansion and contraction, cracking of welded joints of connecting tube bundles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] The technical scheme adopted in the present invention is:

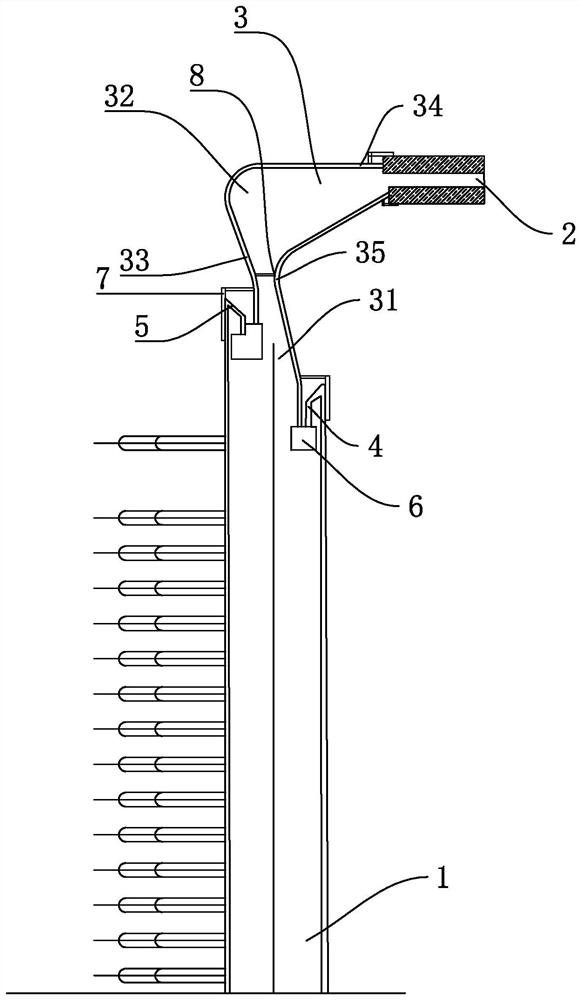

[0019] A tube bundle device for ear bends, such as figure 1 As shown, the header 1 is included, the top of the header 1 is provided with a through pipe 2, and a bending device 3 is also provided between the header 1 and the through pipe 2. The bending device 3 includes an outlet 31 located at the top of the header 1. An elbow 32 is provided at the outlet 31, and the elbow 32 includes a first pipe 33 connected to the outlet 31 and a second pipe 34 connected to the through pipe 2, and inward grooves 35 are also provided on both sides of the first pipe 33. , the bottom of the first pipeline 33 is also provided with a welding device 4, and the welding device 4 includes a folding plate 5 provided at the bottom of the first pipeline 33, a welding plate 6 is provided on the folding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com